Page 1

Ferm BV • P.O.Box 134 • 8280 AC Genemuiden • NL • www.ferm.com 0304-28

UK Subject to change

Document Ref:

FRTD-13/350

Copyright ©

These instructions are the sole property of Ferm-Omega Tools and may not

be reproduced

Ferm Radial Table Drill

FRTD-13/350

USER’S MANUAL

Art.nr.733504

Screwfix Art.nr.

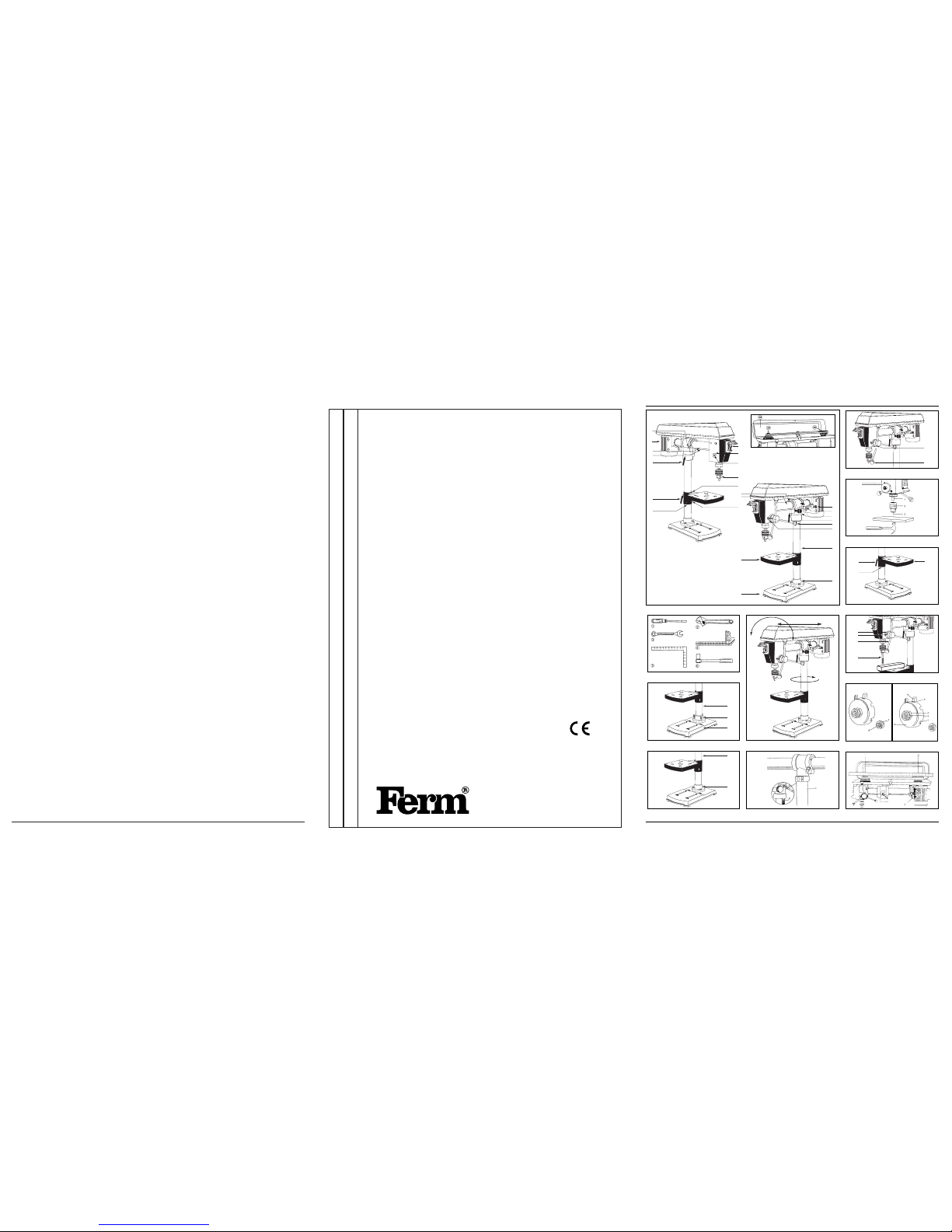

Fig.A

Fig.B

Fig.C

Fig.D

Fig.E

Fig.F

Fig.G

Fig.H

Fig.I

Fig.J

Fig.K Fig.L

Fig.M

1

2

3

4

2

3

1

1

2

360°

45°90°

12-1/4"

763

2

1

2 Ferm

20

22

16

14

23

24

21

27

15

17

18

19

1

9

5

2

3

6

7

8

12

11

13

4

10

Page 2

Fig.N

Fig.O

Fig.P

Fig.Q

Fig.R

Fig.S

Fig.T

Fig.U

Fig.V

Fig.W

Fig.X

Fig.Y

Fig.Z

Fig.AA

Fig.BB

5

4

3

2

1

Spindle Motor

1 - 469 2 - 946

3 - 1576 4 - 2259

5 - 3028

1

2

Ferm 3

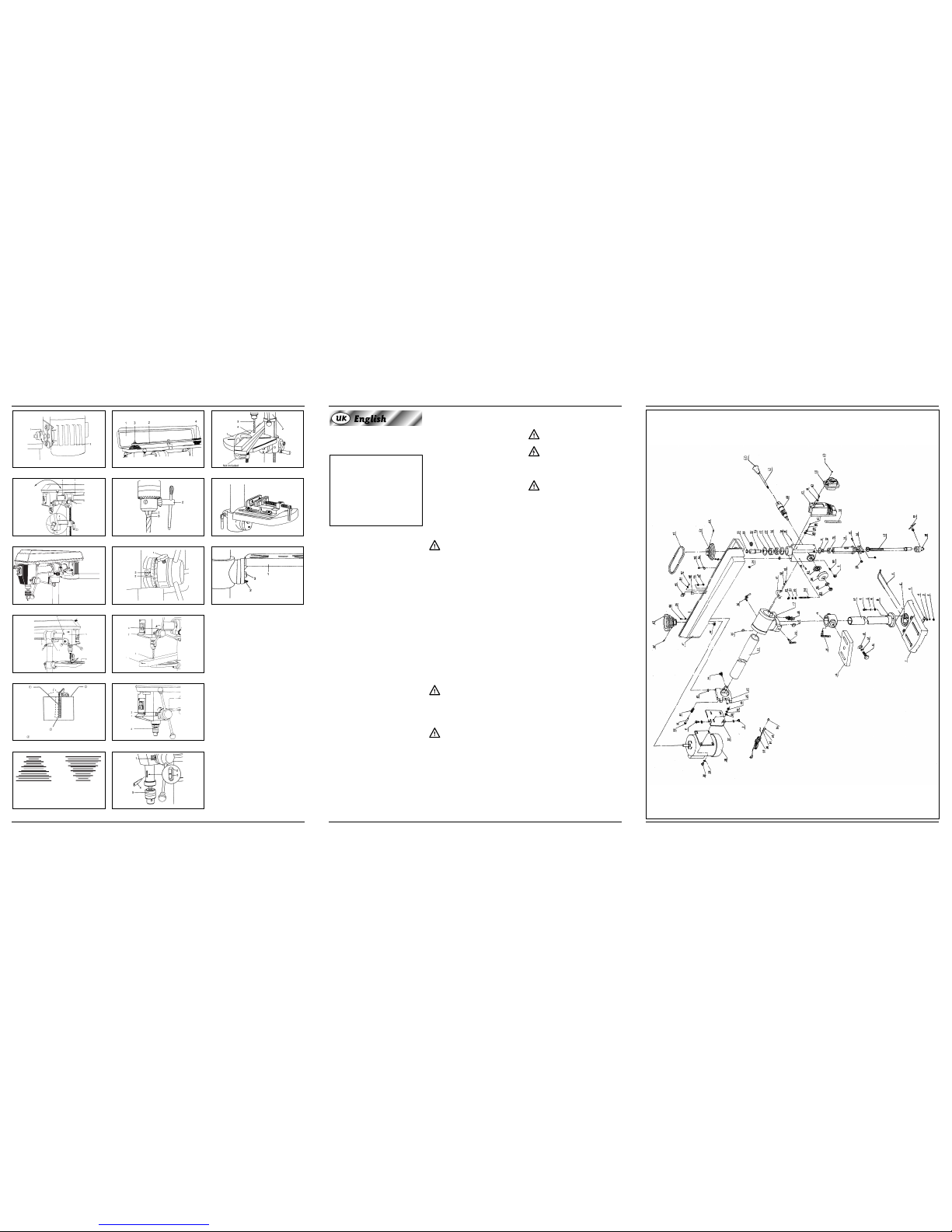

RADIAL ARM DRILL PRESS

THE NUMBERS IN THE FOLLOWING TEXT CORRESPOND WITH THE PICTURES AT PAGE 2-3.

TECHNICAL DATA

PRODUCT INFORMATION

Fig.A

1 Motor

2 Mill-cut groove

3 Horizontal toothed rack

4 Rotation locking clamp

5Table support lock

6Table support

7 Conical locking screw

8 Conical scale

9Vertical locking button

10 Chuck

11 Spring cover

12 Return spring

13 On / off switch

14 Base

15 Stand

16 Table

17 Drilling grips

18 Depth scale locking knob

19 Depth scale indicator

20 Protractor

21 Horizontal drill button

22 V-groove

23 Belt tension locking button

24 Tilt locking clamp

27 Mill-cut groove

28 Drive belt guard0}

29 Spindle pulley block

30 Motor pulley block

GENERAL GUIDELINES

• Inspect all parts after unpacking,for possible damage

during transport.In the event of transport damage,

the carrier should be immediately notified.

• Complaints made later will not be accepted.

• Inspect the delivery for completeness.

• Become familiar with the machine by reading the

operator’s guide thoroughly prior to first use.

• When fitting/replacing accessories,wear- and

reserve parts,use exclusively original Ferm parts.

Spare parts are available from your supplier.

• When ordering,please specify our article number

and the machine type.

Remark:According to the applicable product liability

law,the manufacturer of this appliance is not liable for

damage caused to or by this appliance,arising from:

• Negligent operation.

• Failure to follow the instructions in the operator’s

guide.

• Repairs carried out by third parties,and unqualified

workmen.

• The fitting of,or replacement with,other than

original Ferm spare parts.

• Usage other than that for which the machine is

designed,failure of the electrical installation,by not

observing the electrical regulations and the VDE

provisions 0100,DIN 57113 1 VDE 0113.

We strongly recommend:

Before assembling and using the machine,read

the complete text of the operator’s guide.

This operator's guide is designed to make it easier for

you to get to know your machine,and to learn how to

make use of it’s many functions.

The operator's guide includes important directions as

to how you can safely,expertly and economically employ

the machine,and how you can avert hazards,save on

repair costs,reduce unavailability,and increase the

reliability and useful life of the machine.

Besides following the safety guidelines in this operator's

guide,you should give your fullest attention to the

regulations applicable in your country for the use of this

machine.

Keep the operator's guide close to the machine,packed

inside a plastic sleeve to protect it from dirt and

moisture.It should be carefully read and strictly followed

by every operator of the machine.Only persons who

have received instruction in the operation of the

machine and who are aware of the potential hazards

should be allowed to operate the machine.The

minimum age should be heeded.

Besides the safety guidelines in this operator's guide and

the specific regulations applicable in your country,the

generally recognised technical rules for the use of

woodworking machines should also be heeded.

UNPACK THE CONTENTS OF THE BOX AND

INSPECT THEM CLOSELY.

Should any part be missing or damaged,do not

connect the machine to the power supply until the

machine is complete and in order.

Unpack the machine and parts carefully,and compare

them to the drawing.

To protect the drill from moisture,the surfaces have

been coated with a protective layer which you can

remove using a soft cloth and WD-40.

To prevent danger of fire or poisonous fumes,never

use petrol,naphtha,acetone,thinners or similar

volatile solutions for cleaning the machine.

SAFETY INSTRUCTIONS

The following pictograms are used in these instructions

for use:

Indicates potential for bodily injury,fatality or risk

of damaging the machine,in the event that the

instructions in this operator's guide are ignored.

Indicates electrical current.

GENERAL SAFETY INSTRUCTIONS

Safety is a combination of common sense,continual

alertness and a good knowledge of the machine’s

operations.

Only insert the plug in the wall socket,once you

have read and understood the following directions,

to avoid faults that could cause injury.

1. Read the entire operator's guide and become

familiar with its contents.Learn how you should use

the tools and what the limitations and potential

hazards are.

2. Be absolutely certain that all safety precautions are

operational,and that they are in a good state.

3. Remove adjustment tools and spanners.Get

accustomed to checking,before switching on the

machine,whether adjustment tools and spanners

have been removed.

4. Keep the work surface clean.Untidy and fouled work

surfaces cause accidents.

5. Never use the machine in an unsafe environment.

Never use electrical equipment in damp or wet

places,and protect them from rainwater.Ensure

good lighting of the work area.

6. Keep children at a distance.Persons,who are not

working with the machine,should maintain a safe

distance from the work area.

7. Use locks if necessary,to ensure that children cannot

enter the work area.

8. Never apply brute force on or about the machine.

The machine functions better and more safely at the

speed it was designed for.

9. Use appropriate tools.Do not try to use force to

apply the machine to operations it was not designed

for.

10.Use a regulation extension cable certain that it is in a

good state.The extension cable must be strong

enough to carry the current drawn by the tool for

your workpiece.A cable that is too weak will

dissipate the current,which leads to power loss and

overheating.

11.Work with the right equipment.Do not wear loose

clothes,gloves,ties,rings,armbands or other

accessories that could come in contact with moving

parts.Wear anti-slip shoes.Protect long hair by using

a hairnet.

12.Wear safety glasses.Your eyes are your most valuable

possession.Always wear safety glasses.Every drill can

throw foreign objects into the eyes,which can cause

irreparable harm.Always wear safety glasses that

conform to the safety guidelines (not a normal pair

of glasses.) Normal optical glasses offer no

protection against objects flying around.They have

no safety glass in the lenses.If these lenses break,this

can cause serious injury.

13.Wear a face- or dust mask.Drills create dust.

14.Work safely.Make as much use as possible of a clamp

or vice.This is safer than using your hands,and leaves

both hands free to operate the machine.

15.Remove the plug from the power socket when

performing maintenance,and when changing

accessories such as cutter,drill,routing bit,etc.

16.Reduce the risk of unintended activation of power.

Verify that the power switch is OFF,before you

connect mains power.

17.Only use recommended accessories.These

accessories can be found in the operator's guide.

Poorly fitting accessories create a substantial risk of

personal injury.

18.Never stand on the machine.This can cause serious

injury,should the machine tilt,or if you accidentally

come into contact with the cutting tools.

19.Inspect the machine for damaged parts. Before you

make further use of the machine,any damaged safety

features as well as any other damaged part must be

carefully inspected,as to whether they still function

without problem and can still perform their specific

task.Inspect all moving parts for alignment,position,

and correct couplings;furthermore check for

breakages,correct assembly and any other

conditions that could have an influence on the

machine’s functioning.Any damaged safety features

Power| 230 V

Frequency | 50 Hz

Unloaded speed | 469-3028 RPM

Number of speeds | 5

Power drawn | 350 W

Max.drilling depth | 110 mm

Table rotation | 0˚ to 45˚ (L/R)

Table dimensions | 220 x 195 mm

Clearance | 110 - 335 mm

Dimensions base | 345 x 225 mm

Height | 725 mm

Chuck opening | 13 mm

Lpa (sound pressure level) | 65.5 dB(A)

Lwa (sound power level) | 78.5 dB(A)

Vibration value | 0.853 m/s

2

4 Ferm Ferm 13

EXPLODED VIEW

Loading...

Loading...