Page 1

Ferm b.v. • P.O. Box 134 • 8280 AC Genemuiden NL Web: www.ferm.nl 0103/19.1

USERS MANUAL

Orbital palm sander 02

BEDIENUNGSANLEITUNG

Faustschwingschleifer 05

GEBRUIKSAANWIJZING

Handpalmschuurmachine 09

MODE D’EMPLOI

Ponçeuse orbitale 13

BRUKSANVISNING

Planslipmaskin 17

KÄYTTÖOHJE

Tasohiomakone 20

BRUKSANVISNING

Plansliper 23

BRUGER VEJLEDNING

Planslibemaskine 26

Art.nr. 326220

GB

D

NL

F

SV

SU

NO

DK

FPS-135

Page 2

Ferm 31

FPS-135 Orbital palm sander

The following pictograms are used in these instructions for

use:

Denotes risk of personal injury, loss of life or damage to the tool in case of non-observance of

the instructions in this manual.

Denotes risk of electric shock.

Carefully read this manual before using the machine.

Make sure that you know how the machine functions and

how to operate it. Maintain the machine in accordance

with the instructions to make sure it functions properly.

Keep this manual and the enclosed documentation with

the machine.

SAFETY INSTRUCTIONS

When using electric machines always observe the

safety regulations applicable in your country to reduce the risk of fire, electric shock and personal injury.

Read the following safety instructions and also the

enclosed safety instructions.

Keep these instructions in a safe place!

• If you are working with the sanding machine, wear always ear protectors and dust mask.

• The sanding machine is not suitable for wet sanding.

• Check if the switch is not in position “ON”, before you

connect the mains plug to the mains voltage.

• Keep the mains lead always away from moving parts

of the tools.

• Use safety glasses, especially when you sand above

your head.

• Do not bring pressure to your machine, this will only

delay the sanding.

IMMEDIATELY SWITCH OFF THE MACHINE WHEN:

• Excessive sparking of the carbon brushes and verticiliosis in the collector.

• Interruption in the mains plug, mains lead or mains

lead damage.

• Defect switch.

• Smoke or stench of scorched isolation.

TECHNICAL SPECIFICATIONS

Voltage 230 V

Frequency 50 Hz

Power input 135 W

No load speed 10.000/min.

Sand paper dimensions 155 x 100 mm

Sand sole dimensions 110 x 100 mm

Weight 1,3 kg

Lpa(sound pressure) 72,9 dB(A)

Vibration value 4 m/s

2

Electrical safety

Always check that the power supply corresponds to the

voltage on the rating plate.

Your machine is double insulated in accordance

with EN 50144; therefore no earthwire is required.

Replacing cables or plugs

Immediately throw away old cables or plugs when they have been replaced by new ones. It is dangerous to insert the

plug of a loose cable in the wall outlet.

Using extension cables

Only use an approved extension cable suitable for the power input of the machine. The minimum conductor size is

1.5 mm

2

. When using a cable reel always unwind the reel

completely.

GB

English

2 Ferm

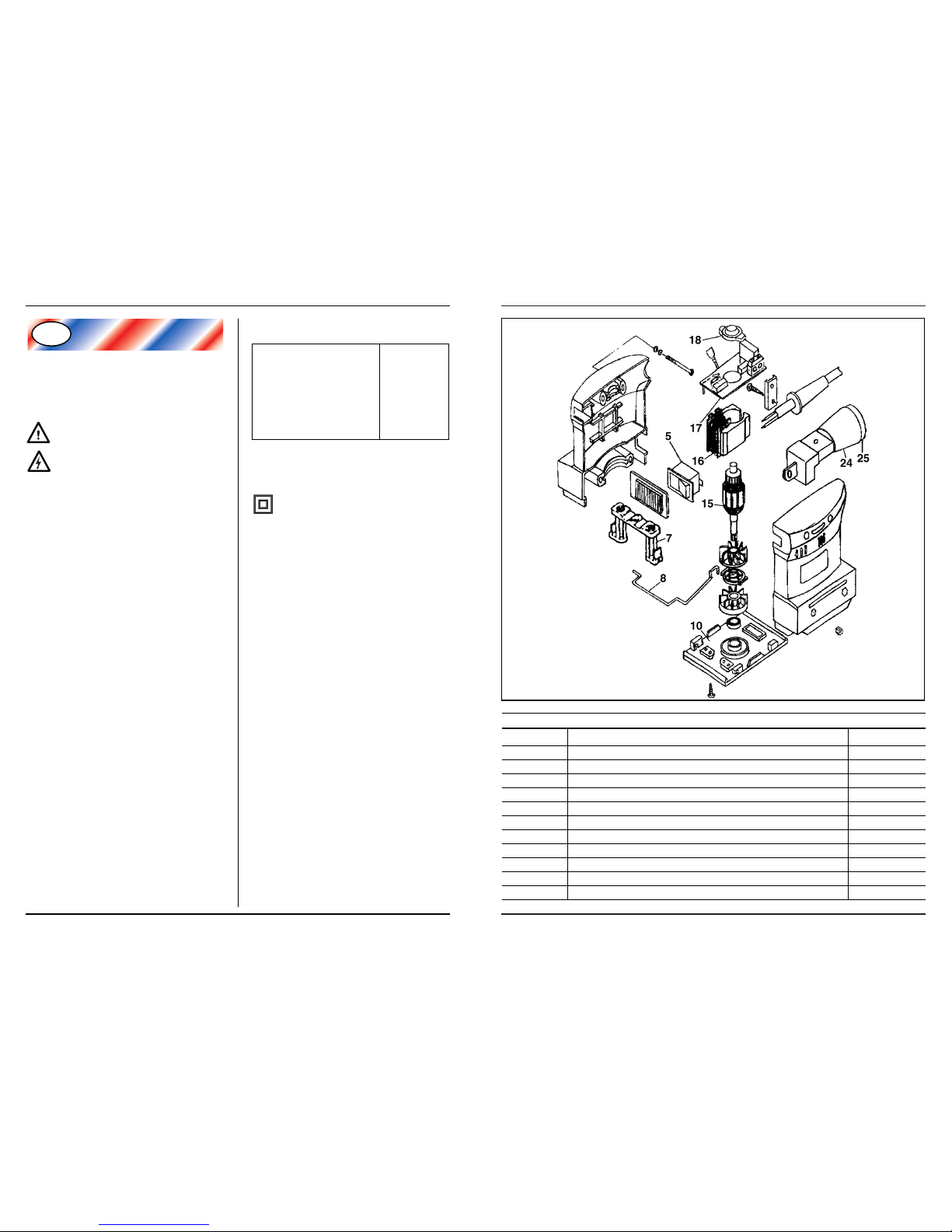

SPARE PARTS FPS-135

REF.NR. DESCRIPTION FERM NR.

5 SWITCH 408230

7 FOOT 408231

8 LEVER 408232

10 BASE PLATE 408233

15 ROTOR 408234

16 STATOR 408235

17 PRINT CIRCUIT BOARD 408236

18 SMALL SELFOILING BEARING 408237

24 CONNECTION SLEEVE (OUTER) 408238

25 CONNECTION SLEEVE (INNER) 408239

- CARBON BRUSH SET 408240

EXPLODED VIEW

Page 3

30 Ferm

PRODUCT INFORMATION

Fig. A.

1. On/off switch

2. Dust exhauster adaptor

3. Paper clamp

4. Sand sole

OPERATION

Choice of the sand-paper.

Coarse sand-paper (grain 50) removes in general the bigger part of the material and fine sand-paper is used for the

finishing. If the surface is not even, then start with rough

sand-paper. Further you use middlecoarse sand-paper

(grain 80) to remove the scratches left behind by the coarse sand-paper and finally you take fine sand-paper (grain

120) for the finishing.

Installing sand-paper.

The sanding machine is provided with a rectangle sand

sole. By tightening the sand-paper it does not wear out that

fast and so it will wear well longer.

• Pull the mains plug out of the power-point;

• Open the hindmost clamp by pressing up the interlocking;

• Install the sand-paper under the clamp, see to the paper being in the middle and look after the perforations

in the paper. They have to correspond with those on

the sand sole, so that the dust can be exhausted.

• Put the clamping spring back into the original position.

• Repeat the operation to fix the sand-paper on the front

side.

• Check all the time if the exhaust gaps are not stopped

up when you place the sand-paper, and check if the

perforations in the sand-paper correspond with the exhaust gaps.

• Fix the sand-paper as tight as possible.

Before assembly sanding paper always remove

the plug from the mains.

1

3

2

4

Ferm 3

Page 4

DUST COLLECTION FEATURE

For a better dust extraction of the working surface your

sanding machine can be connected to the ordinary vacuum cleaner for house-use. You can use the adaptor.

The adaptor has to be installed on the back side of the machine, in the opening.

OPERATION

- Slide the switch to position “1” to make your sanding

machine work.

- If you want to disconnect the machine, you have to slide the switch to position “0”.

APPLICATIONS.

(Only useful for subjoined applications)

1. Sanding wooden surfaces.

2. Removing rust and sanding metal surfaces.

3. Polishing.

TROUBLESHOOTING

In case the sanding machine does not work well, we give

you some possible causes and solutions.

1. The electromotor gets hot.

The cool ventilation slots in the motor are stopped up

with dirt

- clean the cool ventilation slots

The motor is defect.

- Have your sanding machine repaired or checked

by your local Ferm dealer.

2. The connected machine does not work.

Interruption in the mains connection.

- Check mains connection for fracture;

- Have your sanding machine repaired/checked by

your local Ferm dealer.

3. The dust is not absorbed:

This can be caused by a stopped up dust extraction.

- Clean your dust collection opening.

Repairing of electric appliances may be carried

out only by experts.

MAINTENANCE

Make sure that the machine is not live when carrying out maintenance work on the motor.

The Ferm machines have been designed to operate over

a long period of time with a minimum of maintenance. Continuous satisfactory operation depends upon proper machine care and regular cleaning.

Cleaning

Keep the ventilation slots of the machine clean to prevent

overheating of the engine.

Regularly clean the machine housing with a soft cloth, preferably after each use. Keep the ventilation slots free from

dust and dirt.

If the dirt does not come off use a soft cloth moistened with

soapy water. Never use solvents such as petrol, alcohol,

ammonia water, etc. These solvents may damage the

plastic parts.

Lubrication

The machine requires no additional lubrication.

Faults

Should a fault occur, e.g. after wear of a part, please contact your local Ferm dealer.

In the back of this manual you find an exploded view

showing the parts that can be ordered.

ENVIRONMENT

In order to prevent the machine from damage during transport, it is delivered in a sturdy packaging. Most of the pack-

4 Ferm

DRIFTSFEJL

Hvis slibemaskinen ikke funktionerer tilfredsstillende, gives nedenfor eventuelle årsager og afhjælpning.

1. Udsædvanlig mange gnister.

Dette tyder næsten altid på tilstedeværelse af smuds i

motoren eller på opslidte kulbørster.

- Få slibemaskinen kontrolleret hos Deres Fermforhandler.

2. Slibemaskinen bliver for varm.

Slibemaskinen belastes for meget.

- Brug maskinen til det, den er beregnet til.

Motoren er defekt.

- Indlever slibemaskinen til reparation hos Deres

Ferm forhandler.

6. Støvet suges ikke op:

Dette kan eventuelt skyldes, at støvudsugningen er tilstoppet.

- Rens åbningen til udsugning af støv.

Indlever slibemaskinen til reparation altid hos

Deres Ferm forhandler.

VEDLIGEHOLDELSE

Sørg for at maskinen ikke står under strøm, når

der udføres vedligeholdelsesarbejder på mekanikken.

Maskinerne fra Ferm er udviklet til at fungere længe uden

problemer med et minimum af vedligeholdelse. Ved at

rengøre maskinen regelmæssigt og behandle den korrekt, bidrager De til en længere levetid for maskinen.

Rengøring

Rengør regelmæssigt maskinkappen med en blød klud,

helst efter hvert brug. Sørg for at ventilationshullerne er fri

for støv og snavs. Brug en blød klud, der er vædet i sæbevand til at fjerne hårdnakket snavs. Brug ingen opløsningsmidler, så som benzin, alkohol, ammoniak, osv. Den

slags stoffer beskadiger kunststofdelene.

Smøring

Maskinen behøver ingen ekstra smøring.

Fejl

Kontakt Deres Ferm-forhandler, hvis der opstår fejl som

følge af slitage af en del.

Bagerst i denne brugsanvisning finder De en reservedelstegning med de reservedele, der kan bestilles.

MILJØ

For at undgå transportbeskadigelse leveres maskinen i

en solid emballage. Emballagen er så vidt muligt lavet af

genbrugsmateriale. Genbrug derfor emballagen.

Når de udskifter Deres maskinen bør De tage den gamle

maskine med til Deres lokale Ferm-forhandler. Der vil

maskinen blive bearbejdet på miljøvenlig vis.

GARANTI

Læs det separat vedlagte garantikort for garantibetingelserne.

ClEl

■

KONFORMITETSERKLÆRING

(DK)

Vi erklærer at under almindeligt ansvar, at dette

produkt er i overenstemmelse med følgende

normer eller normative dokumenter

EN50144-2-4, EN50144-1, EN55014-1,

EN55014-2, EN61000-3-2, EN61000-3-3

i henhold til bestemmelserne i direktiverne:

98/37/EØF, 73/23/EØF

89/336/EØF

01-12-2000

GENEMUIDEN NL

G.M. Ensing

Quality department

Ferm 29

Page 5

BRUG

VÆLG SANDPAPIR.

Groft sandpapir (korn 50) fjerner almideligvis de fleste materialer, og fint sandpapir bruges til efterbehandling. Hvis

overfladen er ujævn, skal man begynde med groft sandpapir. Derefter bruges mellemgroft sandpapir (korn 80) for

at fjerne ridserne fra det grove sandpapir. Til sidst bruges

fint (korn 120) sandpapir til efterbehandling.

SANDPAPIR SÆTTES PÅ.

Slibemaskinen har en firkantet sål. Hvis sandpapiret sættes stramt på, slides det ikke så hurtigt og holder længere.

1. Tag stikket ud af stikkontakten;

2. Åben den bageste klemme ved at trykke klemfjederen

opad og ud af blokeringen.

3. Sæt sandpapiret under klemmen og sørg for, at papiret sidder i midten, og at hullerne i papiret sidder over

hullerne i sålen, så støvet kan suges væk.

4. Sæt klemmefjederen tilbage i blokeringen.

5. Gør det samme for at fastgøre sandpapiret i den anden ende.

6. Kontroller altid, om hullerne er tilstoppet, når der sættes papir i, og at hullerne i sandpapiret er over hullerne i

sålen.

7. Sæt sandpapiret så stramt som muligt.

Ved vedlikehold og rengjøring må alltid nettspenningen koples bort fra apparatet. Bruk aldri

vann eller lett antennelige væsker til rengjøring

av maskinen. Børst maskinen ren ved hjelp av ei

børste.

STØVUDSUGNING

Hvis man vil opnå en bedre bortsugning af støv, kan man

tilslutte en almindelig støvsuger til slibemaskinen. Hertil

bruges en af adapterne (se illustration). Adapteren skal

sættes i åbningen bag på slibemaskinen.

FORMÅL.

(Må kun bruges til nedenstående formål)

1. Slibning af træoverflader.

2. Bortslibning af rust og slibning af metaloverflader.

3. Polering.

IBRUGTAGNING

• Tænd sliberen ved at anbringe kontakten i positionen

'1'.

• Afbryd sliberen ved at anbringe kontakten i positionen

'0'.

28 Ferm

aging materials can be recycled. Take these materials to

the appropriate recycling locations.

Take your unwanted machines to your local Ferm-dealer.

Here they will be disposed of in an environmentally safe

way.

GUARANTEE

The guarantee conditions can be found on the separately

enclosed guarantee card.

ClEl

■

DECLARATION OF CONFORMITY

(GB)

We declare under our sole responsibility that this

product is in conformity with the following

standards or standardized documents

EN50144-2-4, EN50144-1, EN55014-1,

EN55014-2, EN61000-3-2, EN61000-3-3

in accordance with the regulations.

98/37/EEC,

73/23/EEC,

89/336/EEC

from 01-12-2000

GENEMUIDEN NL

G.M. Ensing

Quality department

FPS-135 FAUSTSCHWINGSCHLEIFER

In dieser Betriebsanleitung erscheinen folgende Piktogramme:

Verweist auf Verletzungsgefahr, Gefahr für Leben und mögliche Beschädigung der Maschine,

falls die Anweisungen in dieser Betriebsanleitung nicht befolgt werden.

Deutet das Vorhandensein elektrischer Spannung an.

Lesen Sie diese Betriebsanleitung aufmerksam, bevor

Sie die Maschine in Betrieb nehmen. Machen Sie sich vertraut mit der Funktionsweise und der Bedienung. Warten

Sie die Maschine entsprechend den Anweisungen, damit

sie immer einwandfrei funktioniert. Die Betriebsanleitung

und die dazugehörende Dokumentation müssen in der

Nähe der Maschine aufbewahrt werden.

SICHERHEITSVORSCHRIFTEN

Beachten beim Benutzen von Elek tromaschinen immer die örtlichen Sicherheitsvorschriften bezüglich

Feuerrisiko, Elektroschock und Verletzung. Lesen

Sie außer den folgenden Hinweisen ebenfalls die Sicherheitsvorschriften im einschlägigen Sonderteil.

Die Hinweise müssen sicher aufbewahrt werden!

• Tragen Sie immer Gehörschutz und Staubmaske

beim Arbeiten mit dem Schwingschleifer.

• Der Schwingschleifer ist nicht geeigenet für Naßschleifen.

• Kontrolliere ob der Schalter nicht in ‘AN’-position ist

geschaltet, bevor Sie den Netzstecker in der Wandsteckdose stecken.

• Halten Sie immer das Schnur weg von bewegende

Teile des Gerätes.

Benützen Sie immer eine Sicherheitsbrille.

DAS GERÄT SOFORT AUSSCHALTEN BEI:

• Übermäßigen Funken der Kohlebürsten und Ringfeuer im Kollektor.

• Störung im Netzstecker, dem Netzkabel oder Schnurbeschädigung.

• Defektem Schalter.

• Rauch oder Gestank verschmorter Isolation.

Deutsch

D

Ferm 5

Page 6

TEKNISKE SPECIFIKATIONER

Spænding 230 V

Frekvens 50 Hz

Optaget effekt 135 W

Omdrejninger, ubelastet 10.000/min

Sandpapir kapacitet 155 x 100 mm

Slibesål kapacitet 110 x 100 mm

Vægt 1,3 kg

Lpa(lydtryk) 72,9 dB(A)

Vibrationsværdi 4 m/s

2

Elektrisk sikkerhed

Kontroller altid om netspændingen svarer til værdien på

typeskiltet.

Maskinen er dobbeltisoleret i henhold til EN

50144; det er derfor ikke nødvendigt med en

jordledning.

Ved udskiftning af ledninger og stik

Kasser gamle ledninger og stik, så snart de er skiftet ud

med nye. Det er farligt at sætte et stik fra en løs ledning i en

stikkontakt.

Ved brug af forlængerledninger

Brug udelukkende godkendte forlæn gerledninger, der er

beregnede til maskinens effekt. Lederne skal have et gennemsnit på mindst 1,5 mm

2

. Hvis forlængerledningen sid-

der på en tromle, rulles ledningen helt af.

BESKRIVELSE

Fig. A.

1. Tænd/sluk kontakt

2. Støvsugeradapter

3. Papirklemme

4. Slibesål

1

3

2

4

Ferm 27

TECHNISCHE DATEN

Spannung 230 V

Frequenz 50 Hz

Aufgenommene Leistung 135 W

Drehzahl unbelastet/min 10.000

Abbmessung Schleifpapier 155 x 100 mm

Abmessung Schleifschuh 110 x 100 mm

Gewicht 1,3 kg

Lpa(Schalldruck) 72,9 dB(A)

Vibrationswert 4 m/s

2

Elektrische Sicherheit

Überprüfen Sie immer, ob Ihre Netzspannung der des Typenschilds entspricht.

Die Maschine ist nach EN 50144 doppelisoliert;

daher ist Erdung nicht erforderlich.

Austauschen von Kabeln oder Steckern

Entsorgen Sie alte Kabel oder Stecker, unmittelbar nachdem Sie durch neue ersetzt sind. Das Anschließen eines

Steckers eines losen Kabels an eine Steckdose ist gefährlich.

Verwendung von Verlängerungskabeln

Benutzen Sie nur ein genehmigtes Verlängerungskabel,

das der Maschinenleistung entspricht. Die Ader müssen

einen Mindestquerschnitt von 1,5 mm

2

haben. Befindet

das Kabel sich auf einem Haspel. muß es völlig abgerollt

werden.

KENZEICHNEN

Abb. A.

1. An/Aus Schalter

2. Staubsaugeradapter

3. Papierklemme

4. Schleifschuh

1

3

2

4

6 Ferm

Page 7

Lever gamle maskiner som blir byttet ut til den lokale

Ferm-forhandleren. Maskinen blir da behandlet på en

miljøvennlig måte.

GARANTI

Garantibetingelsene er å finne på det vedlagte garantikortet.

ClEl

■➊

ERKLÆRING AV ANSVARSFORHOLD

(N)

Vi erklærer at det er under várt ansvar at

dette produkt er i overenstemmelse med følgende

standarder eller standard-dokumenter

EN50144-2-4, EN50144-1, EN55014-1,

EN55014-2, EN61000-3-2, EN61000-3-3

i samsvar med reguleringer:

98/37/EEC, 73/23/EEC

89/336/EEC

frà 01-12-2000

GENEMUIDEN NL

G.M. Ensing

Quality department

FPS-135 PLANSLIBEMASKINE

I denne brugsanvisning anvendes de følgende piktogrammer :

Angiver risiko for legemensbe skadigelse, livsfare eller maskinskade, hvis instruktionerne i

denne brugsanvisning tilsidesættes.

Angiver elektrisk spænding.

Læs denne brugsanvisning godt igennem før maskinen

tages i brug. Sørg for at De kender maskinens funktion og

betjening. Vedligehold maskinen i følge instruktionerne,

for at maskinen altid kan fungere optimalt. Bevar denne

brugsanvisning og den vedlagte dokumentation til maskinen.

SIKKERHEDSFORSKRIFTER

Ved anvendelse af elektriske mas kiner skal man altid

følge de lokalt gældende sikkerhedsforskrifter i forbindelse med brandfare, fare for elektrisk stød og legemensbeskadigelse. Læs udover de nedenstående

instruktioner også sikkerhedsforskrifterne i den separat vedlagte sikkerhedsfolder.

Bevar instruktionerne godt!

• Når der arbejdes med planslibemaskinen, skal der altid bæres høreværn og støvmaske.

• Planslibemaskinen er ikke beregnet til våd slibning.

• Kontroller, at maskinen ikke er blokeret i TÆNDT-position, før stikket sættes i stikkontakten.

• Hold altid ledningen borte fra maskinens bevægelige

dele.

• Brug beskyttelsesbriller, især hvis der arbejdes over

hovedhøjde.

• Udøv ikke tryk på maskinen, det gør kun arbejdet sværere.

MASKINEN SKAL ØJEBLIKKELIGT SLUKKES I TIL

FÆLDE AF:

• defekt netstik, netledning eller beskadigelse af ledning;

• defekt kontakt;

• gnistdannelse i kullene eller ringild i kollektoren;

• røg eller lugt fra sveden isolering.

!

DK

Dansk

26 Ferm

BEDIENUNG

AUSWAHL DES SANDPAPIERS

General gesprochen, wird mit einem grobkörnigen Papier

viel Material abgetragen und mit einem feinkörnigen Papier die Endbearbeitung vorgenommen. Ein ungeleichmäßige Oberfläche wird zunächst mit grobkörnigen

Papier abgeschliffen, bis sie nicht mehr rauh ist. Anschließend werden mit einem mittelkörnigen Papier die Kratzer entfernt und dann mit einem feinkörnigen Papier fertiggeschliffen. Schleifen Sie ab, bis die Oberfläche ganz

glatt ist.

SCHLEIFPAPIER ANBRINGEN

Der Schwingschleifer ist versehen mit ein rechteckige

Schleifschuh. Für ein optimales Ergebnis ist es wichtig

daß, das Papier richtig aufgespannt wird. Festgespanntes Papier nutzt weniger schnell ab und hält länger.

• Ziehen Sie den Stecker aus der Steckdose.

• Öffnen Sie die Hinterklemmfeder (Feder nach oben

aus der Vergrendlung drücken).

• Legen Sie das Schleifpapier unter die Klemme. Achten Sie darauf, daß das Papier in der Mitte liegt und das

die Löcher genau mit der des Schleifschuhes übereinstimmt, damit der Staub abgesaugt werden kann.

• Die Klemmfeder wieder einrasten.

• Wiederholen Sie diesen Vorgang zur Befestigung des

Schleifpapieres auf der anderen Seite.

• Kontrollieren Sie ob die Absauglöcher nicht verstopft

sind wenn Sie das Schleifpapier anbringen. Achten

Sie darauf, daß die Löcher übereinstimmen.

• Befestigen Sie das Papier so fest wie möglich.

Ziehen Sie den Netzstecker aus der Steckdose,

beim Wechseln von Schleifpapier

STAUBSAUGANLAGE

Für die Staubabsaugung der Arbeitsoberfläche ist es

möglich ein normaler Staubsauger an zu schließen, benutzen Sie dazu einem Adapter.

Der Adapter muß angebracht werden an der Hinterseite

der Maschine.

ANWENDUNGEN

(Nur für die unten aufgefürten Anwendungen einsetzen).

1. Schleifen Holzoberflächen.

2. Rostentfernung und Schleifen von Metalloberflächen.

3. Polieren.

INBETRIEBNAHME

• Zum Einschalten der Maschine schieben Sie den

Schalter in Postion '1'.

• Zum Ausschalten der Maschine schieben Sie den

Schalter in Postion '0'.

Ferm 7

Page 8

STØVAVSUGET

For å oppnå et bedre støvavsug fra arbeidsoverflaten, er

det mulig å kople plansliperen din til en vanlig husholdnings-støvsuger. Til dette brukes en av adapterne (se illustrasjon). Adapteren må plasseres i åpningen i bakkant av

maskinen.

NÅR MASKINEN SLÅS PÅ

• Skyv bryteren til posisjon '1' for å få slipemaskinen til å

virke.

• Skyv bryteren til posisjon '0' for å slå av maskinen.

BRUKSOMRÅDER

(Maskinen skal kun anvendes til oppgavene som er

nevnt nedenfor)

1. Sliping av overflater av tre.

2. Fjerning av rust og sliping av metalloverflater.

3. Polering.

FEIL

I tilfelle plansliperen ikke virker som den skal, gjengir vi nedenfor noen mulige årsaker og tilhørende løsninger:

1. Den elektriske motoren blir varm.

Motorens kjøleriller er tilstoppet av skitt.

- Rengjør kjølerillene.

Motoren er defekt.

- Lever maskinen til kontroll og/eller reparasjon hos

din Ferm-forhandler.

2. Maskinen virker ikke etter at den er slått på.

Brudd i strømtilførselen

- Kontroller nett-tilkoplingen for brudd.

- Lever maskinen til kontroll og/eller reparasjon hos

din Ferm-forhandler.

3. Støvet suges ikke opp.

Det kan skyldes at støvavsuget er tilstoppet.

- Rens åpningen til støvavsuget.

La alltid reparasjoner utføres av en anerkjent installatør eller service-bedrift!

VEDLIKEHOLD

Sørg for at maskinen er spenningsløs når det

skal utføres vedlikeholdsarbeid på de mekaniske delene.

Maskinene fra Ferm er konstruert slik at de kan fungere

uten problemer med et minimum av vedlikehold.

Hvis maskinen rengjøres regelmessig og behandles på

riktig måte, bidrar dette til å gi maskinen en lang levetid.

Rengjøring

Rengjør maskinhuset regelmessig med en myk klut, helst

etter hver bruk. Sørg for at ventilasjonsåpningene er fri for

støv og skitt.

Hardnakket skitt fjernes med en myk klut som er fuktet

med såpevann. Bruk ikke løsemidler som bensin, alkohol,

ammoniakk o.kl. Slike stoffer skader kunststoffdelene.

Smøring

Maskinen trenger ikke ekstra smøring.

Feil

Hvis det skulle opptre en feil som følge av f.eks. slitasje på

en del, må man ta kontakt med den lokale Ferm-forhandleren.

Bakerst i denne bruksanvisningen finnes det en deltegning med de deler som kan bestilles.

MILJØ

For å unngå transportskader leveres maskinen i solid emballasje. Emballasjen er i den grad dette er mulig fremstilt

av resirkulerbart materiale. Benytt derfor anledningen til å

resirkulere emballasjen.

!

Ferm 25

STÖRUNGEN

Im Fall das das Gerät nicht gut funktioniert, geben wir jetzt

einige mögliche Ursachen und Lösungen:

1. Erhitzen des Motors.

Die Entlüftungsschlitze sind verstopft mit Schmutz.

- Saubern Sie die Entlüftungsschlitze

Der Motor ist defekt.

- Bieten Sie das Gerät zur Reperation an bei Ihren

Ferm-Händler.

2. Das eingeschaltete Gerät funktioniert nicht.

Bruch im Netzanschluß.

- Kontollieren Sie die Netzanschluß

- Bieten Sie das Gerät zur Reparation an bei Ihren

Ferm-Händler.

3. Das Staub wird nicht weggesogen.

Die Staubsauganlage ist verstopft.

- Saubern Sie die Öfnung der Sauganlage.

Reparaturen dürfen nur von einer Elektrofachmann ausgeführt werden.

WARTUNG

Trennen Sie die Maschine vom Netz, wenn Sie

am Mechanismus Wartungsarbeiten ausführen

müssen.

Die Maschinen von Ferm sind entworfen, um während einer langen Zeit problemlos und mit minimaler Wartung zu

funktionieren. Sie Verlängern die Lebensdauer, indem

Sie die Maschine regelmäßig reinigen und fachgerecht

behandeln.

Reinigen

Reinigen Sie das Maschinengehäuse regelmäßig mit einem weichen Tuch, vorzugsweise nach jedem Einsatz.

Halten Sie die Lüfterschlitze frei von Staub und Schmutz

Entfernen Sie hartnäckigen Schmutz mit einem weichen

Tuch, angefeuchtet mit Seifenwasser. Verwenden Sie

keine Lösungsmittel wie Benzin, Alkohol, Ammonia, usw.

Derartige Stoffe beschädigen die Kunststoffteile.

Schmieren

Die Maschine braucht keine zusätzliche Schmierung.

Störungen

Wenden Sie sich in Störungsfällen, z.B. durch Verschleiß

eines Teils, an Ihren örtlichen Ferm-Vertragshändler.

Am Ende dieser Betriebsanleitung finden Sie eine Zeichnung der erhältlichen Ersatzteile.

UMWELT

Um Transportschäden zu verhinderen, wird die Maschine

in einer soliden Verpackung geliefert. Die Verpackung

besteht weitgehend aus verwertbarem Material. Benutzen Sie also die Möglichkeit zum Recyclen der Verpackung.

Bringen Sie bei Ersatz die alten Maschinen zu Ihren örtlichen Ferm-Vertagshändler. Er wird sich um eine umweltfreundliche Verarbeitung ïhrer alten Maschine bemühen.

GARANTIE

Lesen Sie die Garantiebedingungen auf der separat beigefügten Garantiekarte.

ClEl

■

KONFORMITÄTSERKLÄRUNG

(D)

Wir erklären in alleiniger Verantwortung, daß

dieses Produkt mit den folgenden Normen oder

normativen Dokumenten übereinstimmt:

EN50144-2-4, EN50144-1, EN55014-1,

EN55014-2, EN61000-3-2, EN61000-3-3

gemäß den Bestimmungen der Richtlinien:

98/37/EWG

73/23/EWG

89/336/EWG

ab 01-12-2000

GENEMUIDEN NL

G.M. Ensing

Quality department

8 Ferm

Page 9

MONTERING AV TILBEHØR

Fig. A.

1. På/Av - bryter

2. Støvsugeradapter

3. Papirklemme

4. Slipesåle

BRUKS

VALG AV SLIPEPAPIR

Grovt slipepapir (50 korn) fjerner vanligvis mesteparten av

materialet, mens fint slipepapir brukes til finpussing. Dersom overflaten er ujevn, lønner det seg å begynne med

grovt slipepapir. Deretter kan du bruke middels grovt slipepapir (80 korn) for å fjerne de ripene som det grove papiret etterlater seg. Til slutt kan du finslipe med fint papir (120

korn).

PÅSETTING AV SLIPEPAPIR

Slipemaskinen er utstyrt med en rettvinklet slipesåle. Ved

å stramme slipepapiret godt til slites sålen langsommere

og holder lenger.

• Fjern støpselet fra stikk-kontakten.

• Åpne den bakre klemma ved å trykke klemmefjæra

opp og ut av låsemekanismen.

• Plasser slipepapiret under klemma. Sørg for at papiret

er midtstilt og at perforeringen i slipepapiret stemmer

overens med slipesålens huller slik at slipestøvet kan

suges bort.

• Sett klemmefjæra tilbake i sin opprinnelige posisjon.

• Gjenta prosedyren for å feste slipepapiret i forkant.

• Kontroller stadig at støvavsuget ikke tettes til når du

setter på slipepapiret, og at perforeringen i slipepapiret hele tiden stemmer overens med avs-hullene i slipesålen.

• Stram til slipepapiret så godt som mulig.

Trekk alltid ut støpselet av stikk-kontakten ved

vedlikeholdsarbeid eller rengjøring. Vann eller

andre væsker må aldri brukes ved rengjøring av

slipemaskinens elektriske deler.

1

3

2

4

24 Ferm

FPS-135 HANDPALMSCHUURMACHINE

In deze gebruiksaanwijzing worden de volgende pictogrammen gebruikt:

Duidt op mogelijk lichamelijk letsel, levensgevaar of kans op beschadiging van de machine

indien de instructies in deze gebruiksaanwijzing

worden genegeerd.

Geeft elektrische spanning aan.

Lees deze gebruiksaanwijzing aandachtig door voor u de

machine in gebruik neemt. Zorg dat u kennis heeft van de

werking van de machine en op de hoogte bent van de bediening. Onderhoud de machine volgens de instructies

opdat deze altijd goed functioneert. Bewaar deze gebruiksaanwijzing en de bijgevoegde documentatie bij de

machine.

VEILIGHEIDSVOORSCHRIFTEN

Neem bij het gebruik van elektrische machines altijd

de plaatselijk geldende veiligheidsvoorschriften in

acht in verband met brandgevaar, gevaar voor elektrische schokken en lichamelijk letsel. Lees behalve onderstaande instructies ook de veiligheidsvoorschriften in het apart bijgevoegde veiligheidskatern door.

Bewaar de instructies zorgvuldig!

• Draag tijdens het werken met de handpalmschuurmachine altijd gehoorbeschermers en stofmasker.

• De handpalmschuurmachine is niet geschikt voor natschuren.

• Controleer dat de schakelaar niet in de AAN-stand

staat vergrendeld voordat u de netstekker op de netspanning aansluit.

• Houd het netsnoer altijd uit de buurt van bewegende

delen van het gereedschap.

• Gebruik een veiligheidsbril, zeker als u boven het

hoofd schuurt.

• Oefen geen druk uit op uw machine, dit vertraagd het

schuren alleen maar.

HET APPARAAT ONMIDDELLIJK UITZETTEN BIJ:

• Overmatig vonken van de koolborstels en ringvuur in

de collector.

• Storing in de netstekker, netsnoer of snoerbeschadiging.

• Defecte schakelaar.

• Rook of stank van verschroeide isolatie.

TECHNISCHE SPECIFICATIES

Spanning 230 V

Frequentie 50 Hz

Opgenomen vermogen 135 W

Toerental, onbelast 10.000/min

Afmeting schuurpapier 155 x 100 mm

Afmeting schuurzool 110 x 100 mm

Gewicht 1,3 kg

Lpa(geluidsdruk) 72,9 dB(A)

Vibratiewaarde 4 m/s

2

Elektrische veiligheid

Controleer altijd of uw netspanning overeenkomt met de

waarde op het typeplaatje.

De machine is dubbel geïsoleerd overeenkomstig EN 50144; een aardedraad is daarom niet

nodig.

Bij vervanging van snoeren of stekkers

Gooi oude snoeren of stekkers direct weg zodra ze door

nieuwe exemplaren zijn vervangen. Het is gevaarlijk om

de stekker van een los snoer in het stopcontact te steken.

Bij gebruik van verlengsnoeren

Gebruik uitsluitend een goedgekeurd verlengsnoer, dat

geschikt is voor het vermogen van de machine. De aders

moeten een doorsnede hebben van minimaal 1,5 mm

2

.

Wanneer het verlengsnoer op een haspel zit, rol het snoer

dan helemaal af.

Nederlands

NL

Ferm 9

Page 10

FPS-135 PLANSLIPER

I denne bruksanvisningen benyttes følgende symboler:

Henviser til mulig personskade, livsfare eller fare for skader på maskinen hvis instruksene i

denne bruksanvisningen ikke overholdes.

Viser til elektrisk spenning.

Les denne bruksanvisningen nøye før maskinen tas i

bruk. Sørg for å vite hvordan maskinen virker og hvordan

den skal betjenes. Vedlikehold maskinen i henhold til instruksene, slik at den alltid virker som den skal. Oppbevar

denne bruksanvisningen og den vedlagte dokumentasjonen ved maskinen.

SIKKERHETSFORSKRIFTER

Overhold ved bruk av elektriske maskiner alltid de lokale sikkerhetsforskriftene. Dette for å unngå brannfare, fare for elektrisk støt og personskade. Les i tillegg til nedenstående instrukser også sikkerhetsforskriftene i det vedlagte separate sikkerhetsheftet.

Ta godt vare på instruksene!

• Bruk alltid hørselsvern og støvmaske under arbeid

med maskinen.

• Plansliperen er ikke egnet til våtsliping.

• Kontroller at bryteren ikke står låst i stilling "PÅ" før du

setter støpselet i stikk-kontakten.

• Hold alltid nettkabelen borte fra redskapets bevegelige deler.

• Bruk vernebriller, særlig hvis du skal arbeide over hodehøyde.

• Ikke press maskinen mot underlaget; det fører til at slipingen tar lenger tid.

SLÅ ØYEBLIKKELIG AV MASKINEN VED:

• Uvanlig gnistring fra kullbørstene og flammer i kollektorringen.

• Feil på støpselet, nettkabelen eller ødelagte ledninger.

• Defekt bryter.

• Røyk eller lukt av svidd isoleringsmateriell.

TEKNISKE SPESIFIKASJONER

Spenning 230 V

Frekvens 50 Hz

Opptatt effekt 135 W

Turtall, ubelastet 10.000/min

Kapasitet slipepaper 155 x 100 mm

Kapasitet slipesåle 110 x 100 mm

Vekt 1,3 kg

Lpa(lydtrykk) 72,9 dB(A)

Värähtelyarvo 4 m/s

2

Elektrisk sikkerhet

Kontroller alltid om nettspenningen er i overensstemmelse med verdien på typeskiltet.

Maskinen er dobbelt isolert i henhold til EN

50144; det er derfor ikke nødvendig med jordledning.

Utskifting av ledninger og støpsler

Kast gamle ledninger og støpsler så snart de har blitt erstattet av nye. Det er farlig å stikke støpselet på en løs ledning i stikkontakter.

Bruk av skjøteledninger

Bruk utelukkende en godkjent skjøteledning som er egnet

til maskinens effekt. Ledningene må ha et tverrsnitt på

minst 1,5 mm

2

. Hvis skjøteledningen sitter på en rull, må

den rulles helt ut.

Norsk

N

Ferm 23

PRODUCTINFORMATIE

Fig. A.

1. Aan/Uit-schaklaar

2. Stofzuigeradapter

3. Papierklem

4. Schuurzool

BEDIENING

Keuze van het schuurpapier.

Grof schuurpapier (korrel 50) verwijdert over het algemeen het meeste materiaal en fijn schuurpapier wordt gebruikt voor de afwerking. Als het oppervlak oneffen is, begint u met grof schuurpapier. Vervolgens gebruikt u middelgrof schuurpapier (korrel 80) om de krassen die het

eerste papier heeft achtergelaten te verwijderen en tenslotte neemt u fijn schuurpapier (korrel 120) voor de afwerking.

Schuurpapier aanbrengen.

De schuurmachine is voorzien van een rechthoekige

schuurzool. Door het schuurpapier strak te spannen verslijt het minder snel en gaat het langer mee.

• Verwijder de netstekker uit het stopcontact;

• Open de achterste klem door de klemveer omhoog uit

de vergrendeling te drukken.

• Plaats het schuurpapier onder de klem, zorg ervoor

dat het papier in het midden zit en dat de perforaties in

het papier overeenkomen met die op de schuurzool

zodat het stof afgezogen kan worden.

• Breng de klemveer terug in haar oorspronkelijke positie.

• Herhaal de bewerking om het schuurpapier aan de

voorkant te bevestigen.

• Controleer steeds of de afzuiggaten niet verstopt zijn

wanneer u het schuurpapier aanbrengt, en dat de perforaties in het schuurpapier steeds overeenkomen

met de afzuiggaten.

• Zet het schuurpapier zo strak mogelijk vast.

Voor het verwisselen van het schuurpapier, de

stekker uit het stopcontact nemen.

1

3

2

4

10 Ferm

Page 11

HÄIRIÖT

Tasohiomakoneen toimintahäiriöt ja niiden mahdolliset

syyt sekä korjaukset.

1. Sähkömoottori kuumenee liikaa.

Moottorin jäähdytysilmanottoaukot ovat tukossa.

- Puhdista aukot.

Moottori on viallinen.

- Vie kone Ferm-jälleenmyyjälle tarkistettavaksi tai

korjattavaksi.

2. Kone ei toimi, vaikka se on päällä.

Virransyöttö on keskeytynyt.

- Tarkista johto ja pistoke.

- Vie moottori Ferm-jälleenmyyjälle tarkistettavaksi

tai korjattavaksi.

3. Pölynimurointi ei toimi.

Imuaukko on mahdollisesti tukossa.

- Puhdista imuaukko.

Korjaukset on aina teetettävä valtuutetussa

huoltoliikkeessä.

HUOLTO

Irrota aina kone virtalähteestä ennen huollon

aloittamista.

Ferm-koneet on suunniteltu toimimaan pitkään ja mahdollisimman pienellä huoltotarpeella.

Puhdistamalla ja käyttämällä sitä oikealla tavalla voit itsekin vaikuttaa koneen käyttöikään.

Puhdistaminen

Puhdista koneen ulkopinta säännöllisesti pehmeällä kankaalla. Parasta olisi puhdistaa se jokaisen käyttökerran

jälkeen. Pidä koneen jäähdytysaukot puhtaina.

Jos lika on pinttynyt, voit käyttää saippuavedellä kostutettua kangaspalaa. Älä kuitenkaan käytä liuottimia kuten

bensiiniä, alkoholia, ammoniakkia jne, koska ne vahingoittavat koneen muoviosia.

Voitelu

Konetta ei tarvitse voidella.

Häiriöt

Jos koneen toiminnassa ilmenee häiriö esim. jonkin osan

kulumisen johdosta, ota yhteyttä lähimpään Ferm-jälleenmyyjään.

Näiden käyttöohjeiden lopusta löydät kokoonpanopiirustuksen ja varaosalistan.

YMPÄRISTÖ

Kuljetusvaurioiden välttämiseksi kone on pakattu tukevaan laatikkoon. Tämä pakkaus on mahdollisimman

ympäristöystävällinen. Kierrätä se.

Jos vaihdat koneen uuteen, voit viedä vanhan koneen

Ferm-jälleenmyyjällesi, joka huolehtii ympäristöystävällisestä jätehuollosta.

TAKUU

Lue takuuehdot koneen mukaan liitetystä takuukortista.

ClEl

n

TODISTUS STANDARDINMUKAISUUDESTA

(SF)

Todistamme täten ja vastaamme yksin siitä,

että tämä tuote on allalueteitujen standardien ja

standardoimisasiakirjojen vaatimusten mukainen:

EN50144-2-4, EN50144-1, EN55014-1,

EN55014-2, EN61000-3-2, EN61000-3-3

seruaavien sääntöjen mukaisesti:

98/37/EEC, 73/23/EEC

89/336/EEC

01-12-2000

GENEMUIDEN NL

G.M. Ensing

Quality department

!

22 Ferm

STOFAFZUIGING

Voor een verbeterde stofafzuiging van het werkoppervlak

kan uw handpalmschuurmachine worden aangesloten op

een gewone stofzuiger voor huis-gebruik, waarbij gebruik

wordt gemaakt van de adapter. De adapter moet op de

aansluiting aan de achterkant van de machine worden

aangesloten.

INSCHAKELEN

• U schakelt de machine in door de schuifschakelaar

naar de '1'-positie te schuiven. Omgekeerd schakelt u

de machine uit, door de schuifschakelaar naar de '0'positie te schuiven.

TOEPASSINGEN

(Uitsluitend te gebruiken voor onderstaande toepassingen)

1. Houten oppervlakken schuren.

2. Roest verwijderen en metalen oppervlakken schuren.

3. Polijsten.

STORINGEN

In het geval de schuurmachine niet naar behoren functioneert, geven wij onderstaand een aantal mogelijke oorzaken en de bijbehorende oplossingen.

1. De elektromotor wordt heet.

De koelluchtsleuven in de motor zijn verstopt met vuil.

- Reinig de koelluchtsleuven.

De motor is defect

- Bied de machine aan bij uw Ferm-dealer voor controle en/of reparatie.

2. De ingeschakelde machine werkt niet.

Onderbreking in de netaansluiting.

- Netaansluiting controleren op breuk

- Bied de machine aan bij uw Ferm-dealer voor controle en/of reparatie.

3. Het stof word niet opgezogen:

Dit is mogelijk te wijten aan een verstopte stofafzuiging.

- Reinig de stofafzuig-opening.

Laat reparaties altijd uitvoeren door een erkend

installateur of reparatiebedrijf.

ONDERHOUD

Zorg dat de machine niet onder spanning staat

wanneer onderhoudswerkzaamheden aan het

mechaniek worden uitgevoerd.

De machines van Ferm zijn ontworpen om gedurende lange tijd probleemloos te functioneren met een minimum

aan onderhoud. Door de machine regelmatig te reinigen

en op de juiste wijze te behandelen, draagt u bij aan een

hoge levensduur van uw machine.

Reinigen

Reinig de machine-behuizing regelmatig met een zachte

doek, bij voorkeur iedere keer na gebruik. Zorg dat de ventilatiesleuven vrij van stof en vuil zijn.

Gebruik bij hardnekkig vuil een zachte doek bevochtigd

met zeepwater. Gebruik geen oplosmiddelen als benzine,

alcohol, ammonia, etc. Dergelijke stoffen beschadigen de

kunststof onderdelen.

Smeren

De machine heeft geen extra smering nodig.

Storingen

Indien zich een storing voordoet als gevolg van bijvoorbeeld slijtage van een onderdeel, neem dan contact op

met uw plaatselijke Ferm-dealer.

Achterin deze gebruiksaanwijzing vindt u een onderdelentekening met de na te bestellen onderdelen.

!

Ferm 11

Page 12

BRUGER

HIOMAPAPERIN VALINTA

Karkeaa hiomapaperia (50) käytetään poistamaan suurin

osa materiaalista ja hienoa hiomapaperia viimeistelyyn.

Jos pinta on epätasainen, aloita karkealla hiomapaperilla.

Hio tämän jälkeen vähemmän karkealla hiomapaperilla

(80), joka poistaa juuri äsken syntyneet naarmut. Käytä

hienoa hiomapaperia (120) viimeistelyyn.

HIOMAPAPERIN ASETTAMINEN

Hiomakoneeseen kuuluu suorakaiteen muotoinen hiomataso. Kun kiristät kunnolla hiomapaperin, se kuluu vähemmän ja kestää kauemmin käytössä.

• Vedä pistoke pistorasiasta.

• Avaa takimmainen pidike työntämällä puristusjousi

ylös lukituksestaan.

• Aseta hiomapaperi pidikkeen alle. Tarkista, että paperi on tason keskellä ja että paperissa olevat reiät asettuvat hiomatasossa oleviin reikiin, jotta pölynimurointi

toimii.

• Kiinnitä pidike takaisin.

• Kiinnitä hiomapaperi etupidikkeeseen edellä kuvatulla tavalla.

• Tarkista aina hiomapaperia asettaessasi, että imureiät eivät ole tukossa ja että hiomapaperin reiät asettuvat hiomatason reikiin.

• Kiinnitä hiomapaperi mahdollisimman tiukasti.

PÖLYNIMUROINTI

Tehokkaan pölynimuroinnin saamiseksi kone voidaan liittää tavalliseen pölynimuriin. Tällöin tarvitaan adapteria.

Adapteri on kiinnitettävä koneen takaosassa olevaan liitäntään.

KÄYTTÖALUEET

(Käytä tasohiomakonetta vain alla mainittuihin käyttötarkoituksiin.)

1. Puupintojen hiominen.

2. Ruosteen poisto ja metallipintojen hiominen.

3. Kiillottaminen.

KÄYTTÖ

• Käynnistä laite liu'uttamalla kytkin asentoon 1.

• Jos haluat kytkeä laitteen pois päältä, liu'uta kytkin

asentoon 0.

Ferm 21

MILIEU

Om transportbeschadiging te voorkomen, wordt de machine in een stevige verpakking geleverd. De verpakking

is zo veel mogelijk gemaakt van recyclebaar materiaal.

Maak daarom gebruik van de mogelijkheid om de verpakking te recyclen.

Breng oude machines wanneer u ze vervangt naar uw

plaatselijke Ferm-dealer. Daar zal de machine op milieuvriendelijke wijze worden verwerkt.

GARANTIE

Lees voor de garantievoorwaarden de apart bijgevoegde

garantiekaart.

ClEl

■

CONFORMITEITSVERKLARING

(NL)

Wij verklaren dat dit product

voldoet aan de volgende

normen of normatieve documenten

EN50144-2-4, EN50144-1, EN55014-1,

EN55014-2, EN61000-3-2, EN61000-3-3

overeenkomstig de bepalingen in de richtlijnen

98/37/EEG

73/23/EEG

89/336/EEG

vanaf 01-12-2000

GENEMUIDEN NL

G.M. Ensing

Quality department

FPS-135 PONCEUSE ORBITALE

Dans ce mode d’emploi, il est fait usage des pictogrammes suivants :

Indique un éventuel risque de lésion corporelle,

un danger de mort ou un risque d’endommagement de la machine si les instructions de ce mode d’emploi ne sont pas respectées.

Indique la présence de tension électrique.

Lisez attentivement ce mode d’emploi avant d’utiliser la

machine. Assurez-vous d’avoir bien pris connaissance du

fonctionnement de la machine et de son utilisation. Entretenez la machine conformément aux instructions afin

qu’elle fonctionne toujours correctement. Conservez ce

mode d’emploi et la documentation jointe à proximité de la

machine.

CONSIGNES DE SÉCURITÉ

Lors d’utilisation de machines électriques, observez

les consignes de sécurité locales en vigueur en matière de risque d’incendie, de chocs électriques et de

lésion corporelle. En plus des instructions ci-dessous, lisez entièrement les consignes de sécurité

contenues dans le cahier de sécurité fourni à part.

Conservez soigneusement ces instructions!

• Portez toujours des protecteurs pour l’ouïe si vous travaillez avec la Ponceuse orbital.

• La Ponceuse orbital n’est pas facile pour poncer sous

liquide.

• Contrôlez si l’interrupteur n’est pas dans la postion

“MARCHE” avant de brancher la fiche-secteur sur la

tension du réseau.

• Tenez le fil d’alimentation toujours loin de parties mouvantes des outils.

• Utilisez des lunettes de sécurité, surtout si vous poncez au-dessus de la tête.

• N’exercez pas de la pression sur votre machine, ceci

seulement retard le poncer.

ARRÊTER IMMÉDIATEMENT L’APPAREIL EN CAS

DE :

• Étinceler démesurément des balais et feu annulaire

dans le collecteur.

• Court-circuit de la fiche-secteur ou du fil d’alimentation

ou endommagement du fil d’alimentation.

• Interrupteur défectueux.

• Fumée ou odeur d’isolant brûlé.

F

Français

12 Ferm

Page 13

SPECIFICATIONS TECHNIQUES

Tension 230 V

Fréquence 50 Hz

Puissance consommée 135 W

Vitesse à vide/min 10.000

Dimension du papier abrasive 155 x 100 mm

Dimension du semelle à poncer 110 x 100 mm

Poids 1,3 kg

Lpa(pression sonore) 72,9 dB(A)

Valeur vibratoire 4 m/s

2

Sécurité électrique

Vérifiez toujours si la tension de votre réseau correspond

à la valeur mentionnée sur la plaque signalétique.

La machine est doublement isolée conformément à la norme EN 50144 ; un fil de mise à la terre n’est pas donc pas nécessaire.

En cas de changement de câbles ou de fiches

Jetez immédiatement les câbles ou fiches usagés dès

qu’ils sont remplacés par de nouveaux exemplaires. Il est

dangereux de brancher la fiche d’un câble défait dans une

prise de courant.

En cas d’emploi de câbles prolongateurs

Employez exclusivement un câble pro longateur homologué, dont l’usage est approprié pour la puissance de la

machine. Les fils conducteurs doivent avoir une section

minimale de 1,5 mm

2

. Si le câble prolongateur se trouve

dans un dévidoir, déroulez entièrement le câble.

DESCRIPTION

Fig. A.

1. Marche/arret interrupteur

2. Aspirateur adaptation

3. Trombone

4. Semelle de décapage

1

3

2

4

Ferm 13

TEKNISET TIEDOT

Jännite 230 V

Taajuus 50 Hz

Kulutettu teho 135 W

Kierrosnopeus, kuormittamaton 10.000/min

Hioma paparin kapasiteetti 155 x 100 mm

Hiomataso kapasiteetti 110 x 100 mm

Paino 1,3 kg

Lpa(äänenpaine) 72,9 dB(A)

Värähtelyarvo 4 m/s

2

Sähköturvallisuus

Tarkista aina, ovatko verkkojännite ja koneen tyyppikilvessä ilmoitettu jännite yhteen sopivia.

Koneessa on kaksinkertainen eristys EN

50144:n mukaan; maadoitusjohto ei ole tarpeellinen.

Johdon tai pistokkeen vaihtaminen

Heitä käytöstä poistetut johdot ja pistokkeet heti pois. On

vaarallista työntää irrotetun johdon pistoke pistorasiaan.

Jatkojohtojen käyttö

Käytä vain virallisesti hyväksyttyjä jatkojohtoja koneen teho huomioon ottaen. Johdon ytimien on oltava vähintään

1,5 mm

2

. Käytettäessä johtokelaa koko jatkojohto on ve-

dettävä kelalta.

VARUSTEIDEN ASENNUS

Kuva A

1. Päällä/Pois päältä -kytkin

2. Imurin adapteri

3. Paperipidike

4. Hiomataso

1

3

2

4

20 Ferm

Page 14

så stadig förpackning som möjligt. Förpackningen har så

långt det är möjligt tillverkats av återvinningsbart material.

Ta därför tillvara möjligheten att återvinna förpackningen.

Återlämna gamla maskiner till din lokala Ferm-återförsäljare när du byter ut dem. Där kommer maskinen att tas om

hand på ett miljövänligt sätt.

GARANTI

Garantivillkoren framgår av det separat bifogade garantikortet.

ClEl

■

FÖRSÄKRAN

(S)

Vi intygar och ansvarar för, att denna

produkt överensstammer med följande

norm och dokument

EN50144-2-4, EN50144-1, EN55014-1,

EN55014-2, EN61000-3-2, EN61000-3-3

enl. bestämmelser och riktlinjema:

98/37/EEC, 73/23/EEC

89/336/EEC

fràn 01-12-2000

GENEMUIDEN NL

G.M. Ensing

Quality department

FPS-135 TASOHIOMAKONE

Näissä ohjeissa käytetään seuraavia symboleja:

Käytetään, kun on olemassa loukkaantumisvaara, hengenvaara tai koneen rikkoutumisvaara, mikäli annettuja ohjeita ei noudateta.

Sähköjännite.

Lue nämä ohjeet huolellisesti ennen laitteen käyttöönottoa. Tutustu laitteen toimintaan ja käyttöön liittyviin tietoihin. Laitteen moitteettoman toiminnan varmistamiseksi

laite on huollettava näiden ohjeiden mukaisesti. Säilytä

nämä ohjeet ja muut tiedot myöhempää käyttöä varten.

TURVAOHJEET

Sähkölaitteita käytettäessä on aina noudatettava paikallisia turvamääräyksiä tulipalon, sähköiskujen ja

loukkaantumisten välttämiseksi. Lue alla olevat ohjeet ja erilliset turvaohjeet huolellisesti.

Säilytä nämä ohjeet!

• Käytä aina kuulon- ja hengityksensuojaimia.

• Tasohiomakone ei sovellu märkähiontaan.

• Tarkista, että laitteen kytkin ei ole lukittu PÄÄLLÄasentoon, ennen kuin työnnät pistokkeen pistorasiaan.

• Pidä verkkojohto aina poissa laitteen liikkuvista osista.

• Käytä suojalaseja, varsinkin jos käytät laitetta pään

yläpuolella.

• Älä paina laitetta tarpeettomasti hiottavaa pintaa vasten. Tämä vain hidastaa hiomista.

PYSÄYTÄ KONE VÄLITTÖMÄSTI, JOS:

• Hiiliharjat kipinöivät liikaa tai kollektori on tulessa.

• Pistoke tai johto on viallinen.

• Kytkin on viallinen.

• Savua tai käryä erittyy.

!

FIN

Suomi

Ferm 19

OPERATION

CHOIX DU PAPIER ABRASIF

Du papier abrasif gros (grain 50) éloigne généralement le

plus matérial et papier abrasif fin est utilisé pour le finissage. Si la surface est inégale, vous commencez avec du papier abrasif gros. Ensuite vous utilisez du papier abrasif

gros à demi (grain 80) pour éloigner les rayures par le premier papier et finalement vous prenez du papier abrasif fin

( grain 120) pour le finissage.

METTRE PAPIER ABRASIF

La ponceuse est pourvue d’un semelle à poncer rectangle. En attelant le papier abrasif il consomme moins rapidement et il est utile plus long.

• Poussez la fiche-secteur de la prise (prise femelle

fixe);

• Ouvrez la dernière borne en poussant le ressort de la

borne en haut du blocage.

• Placez le papier abrasif sous la borne, prenez soin que

le papier soit dans la centre et que les perforations

dans le papier correspondent avec celles à la semelle

de décapage, de sorte que la poussière peut être aspirée.

• Remettez le ressort de la borne en sa place originèle.

• Refaites le façonnage pour fixer le papier abrasif au

devant.

• Contrôlez toujours si les ouvertures d’aspiration ne

sont pas bouchés si vous mettez le papier abrasif, et

que les perforations dans le papier abrasif toujours

correspondent aux ouvertures d’aspiration.

• Fixez le papier abrasif si raide que possible.

Débranchez l’appareil quand il n’est pas en service, pendant l’entretien ou pendant le remplacement d’accessoires ou d’outils de la machine.

SATISFACTION DE DÉPOUSSIÉRAGE

Pour une meilleure aspiration dépoussière de la surface

de travail votre Ponceuse orbital peut être branchée sur

un aspirateur normal pour l’usage dans votre maison, près

de adaptation est utilisée. L’adaptation doît être mis à l’arrière-côté de la machine, dans l’ouverture pourvue.

OPERATION

• Poussez l'interrupteur en position '1' pour utiliser la

ponceuse.

• Pour arrêter l'appareil, poussez l'interrupteur en position '0'

APPLICATIONS

(seulement utile pour applications ci-après)

1. Poncer des surfaces de bois.

2. Éloigner rouille et poncer des surfaces métalliques.

3. Polir.

14 Ferm

Page 15

PANNES

Si la ponceuse ne fonctionne pas bon, nous indiquons cidessous quelques possibles raisons et solutions assortis.

1. Le moteur électrique est chaud.

Les encoches d’air frais dans le moteur sont bouchés

avec du sale.

- Nettoyez les encoches d’air frais

Le moteur est défectueux.

- Donnez la ponceuse à réparer à votre distributeur

Ferm.

2. La machine branchée ne fonctionne pas.

Interruption dans le raccordement du réseau.

- Contrôlez si le raccordement du réseau a une rupture.

- Donnez la ponceuse à réparer ou à contrôler à votre distributeur Ferm.

3. La poussière n’est pas aspirée:

Cela peut àtre dû à une aspiration dépoussière.

- Nettoyez l’ouverture de l’aspiration dépoussière.

Toute réparation doit être faite par un spécialiste

et uniquement avec des pièces d’origine!

ENTRETIEN

Assurez-vous que la machine n’est pas sous

tension si vous allez procéder à des travaux

d’entretien dans son système mécanique.

Les machines de Ferm ont été conçues pour fonctionner

longtemps sans problème avec un minimum d’entretien.

En nettoyant régulièrement et correctement la machine,

vous contribuerez à une longue durée de vie de votre machine.

Nettoyage

Nettoyez régulièrement le carter au moyen d’un chiffon

doux, de préférence à l’issue de chaque utilisation. Veillez

à ce que les fentes d’aération soient indemnes de poussière et de saletés.

En présence de saleté tenace, employez un chiffon doux

humecté d’eau savonneuse. Proscrivez l’emploi de solvants comme l’essence, l’alcool, l’ammoniaque etc. car

ces substances attaquent les pièces en plastique.

Graissage

Cette machine ne nécessite pas de graissage supplémentaire.

Pannes

En cas de panne survenue par exemple à la suite de l’usure d’une pièce, contactez votre distributeur Ferm local.

Au dos de ce mode d’emploi, vous trouverez un dessin

des pièces avec les pièces dont vous pouvez renouveler

la commande.

ENVIRONNEMENT

Pour éviter les dommages liés au transport, la machine est

livré dans un emballage robuste. L’emballage est autant

que possible constitué de matériau recyclable. Veuillez

par conséquent destiner cet emballage au recyclage.

Si vous allez changer de machines, apportez les machines usagées à votre distributeur Ferm local qui se chargera de les traiter de la manière la plus écologique possible.

GARANTIE

Pour les conditions de garantie, lisez le certificat de garantie joint à part.

ClE l

■

DÉCLARATION DE CONFORMITÉ

(F)

Nous declarons sous notre propre responsabilité

que ce produit est en conformité avec les normes

ou documents normalisés suivants

EN50144-2-4, EN50144-1, EN55014-1,

EN55014-2, EN61000-3-2, EN61000-3-3

conforme aux réglementations:

98/37/CEE

73/23/CEE

89/336/CEE

le 01-12-2000

GENEMUIDEN NL

G.M. Ensing

Quality department

Ferm 15

DAMMUPPSAMLING

För att hålla arbetsplatsen ren kan slipmaskinen anslutas

till er vanliga hushållsdammsugare. Maskinen levereras

tillsammans med två olika muffar, som kopplas mellan

dammsugaren och öppningen baktill på maskinen.

APPLIKATIONER

Planslipmaskinen är avsedd för slipning av träytor, borttagning av rost och slipning av metallytor samt polishing.

FUNKTION

• Sätt knappen i läge "1" för att starta slipmaskinen.

• När du vill stänga av maskinen, sätt knappen i läge "0".

FELSÖKNING

Nedan anges några problem som kan uppstå samt troliga

orsaker respektive lämpliga åtgärder.

1. Motorn överhettas.

Ventilationshålen är igentäppta.

- Rengör ventilationshålen.

Motorn är defekt;

- Låt er återförsäljare se över verktyget och åtgärda

felet.

2. Verktyget startar inte.

Skadad kabel eller kontakt;

- kontrollera och låt vid behov er återförsäljare åtgärda felet.

Defekt strömställare;

- Låt er återförsäljare se över verktyget och åtgärda

felet.

3. Dammet sugs inte upp.

Sugöppningen är igentäppt;

- rengör sugöppningen.

Reparation för endast utföras av behörig servicetekniker.

UNDERHÅLL

Tillse att maskinen inte är spänningsförande när

underhållsarbeten utförs på de mekaniska delarna.

Ferms maskiner har konstruerats för att under lång tid fungera problemfritt med ett minimalt underhåll. Genom att

regelbundet rengöra maskinen och hantera den på rätt

sätt bidrar du till en lång livslängd för din maskin.

Rengöring

Rengör maskinhöljet regelbundet med en mjuk duk, företrädesvis efter varje användning. Tillse att ventilationsspringorna är fria från damm och smuts.

Använd en mjuk duk fuktad med tvålvatten vid svår smuts.

Använd inga lösningsmedel som bensin, alkohol, ammoniak etc. Sådana ämnen skadar plastdelarna.

Smörjning

Maskinen behöver ingen extra smörjning.

Driftstörningar

Om en driftstörning uppträder till exempel till följd av att en

del har blivit sliten, kontakta då din lokala Ferm-återförsäljare.

Längst bak i denna bruksanvisning finns en ritning med de

delar som kan efterbeställas.

MILJÖ

För att undvika transportskador levereras maskinen i en

18 Ferm

Page 16

BESKRIVNING

Fig. A.

1. Strömställare av/på

2. Adapter för dammutsugning

3. Sandpappershållare.

4. Sandpappersdyna.

FÖRBEREDELSER

VALAV SANDPAPPER

Grovt sandpapper används för att slipa ner det mesta av

ytmaterialet medan fint sandpapper används till putsning

och finish. Är ytan ojämn slipas ytan först jämn med ett

grovt sandpapper och därefter slipas repor och andra spår

efter det grova sandpapperet bort med ett mediumgrovt

sandpapper. Den slutliga finishen erhålls sedan med ett

fint sandpapper.

MONTERING AV SANDPAPPER

Slipmaskinen är försedd med en rektangulär slipdyna.

Korrekt aptering av sandpapperet förlänger dynans

livslängd:

• Koppla loss maskinen från elnätet.

• Öppna den bakre klämman genom att trycka upp spärren.

• Aptera sandpapperet på dynan. Kontrollera att papperet är väl centrerat samt att papperets perforering möter dynans perforering så att damm kan ventileras ut.

• Spänn åt klämman genom att trycka tillbaka spärren.

• Upprepa anvisningarna ovan för det främre sandpapperet.

• Observera betydelsen av att sandpapperets perforering möter slipdynans perforering.

• Aptera sandpapperet så tätt mot slipdynan som möjligt.

Koppla alltid loss verktyget från elnätet när det

byte av delar och sandpapper.

1

3

2

4

Ferm 17

FPS-135 PLANSLIPMASKIN

I denna bruksanvisning används följande symboler:

Anger att det föreligger risk för kroppsskada,

livsfara eller risk för skador på maskinen om instruktionerna i denna bruksanvisning inte efterlevs.

Anger elektrisk spänning.

Läs igenom denna bruksanvisning noggrant innan maskinen tas i bruk. Se till att du känner till hur maskinen fungerar och är insatt i hur den skall användas. Följ underhållsinstruktionerna för att maskinen alltid skall fungera på bästa

sätt. Förvara denna bruksanvisning och den bifogade dokumentationen vid maskinen.

SÄKERHETSFÖRESKRIFTER

Vid användning av elektriska maski ner, iaktta alltid

de säkerhetsföreskrifter som gäller lokalt i samband

med brandfara, fara för elektriska stötar och kroppsskada. Läs förutom nedanstående instruktioner även

igenom bladet med säkerhetsföreskrifter som bifogas separat.

Förvara instruktionerna omsorgsfullt!

• Använd alltid hörselskydd och ansiktsmask vid arbete

med putsmaskinen.

• Observera att maskinen inte är avsedd för våtslipning.

• Kontrollera före anslutning till elnätet att verktygets

strömbrytare är frånslagen.

• Se noga till att elsladden inte kommer nära verktygets

rörliga delar.

• Använd skyddsglasögon. Detta är särskilt viktigt vid

slipning ovanför ert ansikte.

• Anbringa inte för stort tryck på maskinen, detta fördröjer enbart slutresultatet.

STAN NA OMEDELBART MASKINEN NÄR:

• Kollektorns borstar och kransar uppvisar onormal

gnistbildning.

• Elkabel eller kontakter uppvisar någon som helst defekt, t ex skadad isolering.

• Strömbrytaren inte fungerar som den ska.

• Rökig eller dålig lukt indikerar bränd isolering.

TEKNISKA SPECIFIKATIONER

Spänning 230 V

Frekvens 50 Hz

Effektförbrukning 135 W

Varvtal, obelastad/min 10.000

Sandpapper mått 155 x 100 mm

Slipdyna mått 110 x 100 mm

Vikt 1,3 kg

Lpa(bullernivå) 72,9 dB(A)

Vibrationsvärde 4 m/s

2

Elektrisk säkerhet

Kontrollera alltid om din nätspänning överensstämmer

med värdet på typplattan.

Maskinen är dubbelt isolerad i överensstämmelse med EN 50144, vilket innebär att det inte

behövs någon jordledare.

Vid utbyte av kablar eller stickkontakter

Släng omedelbart bort gamla kablar eller stickkontakter

så fort de har ersatts av nya exemplar. Det är farligt att sticka in stickkontakten till en lös kabel i vägguttaget.

Vid användning av förlängnings kablar

Använd uteslutande en godkänd förlängningskabel som

är lämplig för maskinens effekt. Ledarna måste ha en diameter på minst 1,5 mm

2

. Om förlängningskabeln sitter på

en haspel, rulla då ut den helt och hållet.

S

Svenska

16 Ferm

Loading...

Loading...