Fein ASb 648, ASb 748 Operating Instructions Manual

Operating instructions

for the

Impact Wrench type ASb

648

and ASb

748

(42

Volts)

1. Technical data

Current: ~ (single

phase

A.C.)

For

screws

Max

.

ASb

648

To be handed to the workshop

Net

weight

Type

torque

Square

drive

Speed

R.P.M.

Taps

Input

I

full

load

per

min. Watts

I

from

to

kpm

I

Lbs.

ft

ASb 648

M

12

(

1

/2")

M 22 ('/s")

40 289

ASb 748

2.

Connection

and

operation

Main

voltage

must

correspond

to

the

operating

voltage

marked

on

the

rating

plate.

To

prevent

the

overbridging

of

the

insulation

no

additional

marking

plates

and

signs

must

be

riveted

or

screwed

on

the

housing.

We

recommend

the

use

of

transfers

only.

The

machine

is

provided

with a reversing

switch

for

clockwise

and

anticlockwise

rotation.

It

must

not

be

operated

when

the

machine

is

running

.

The

full

tightening

or

slackening

action

provided

depends

on

the

time

during

which

the

percussion

mechanism

is

allowed

to

run

.

Max. tightening

torque

is

the

sum

of

the

torque

applied

by

each

stroke. According

to

the

type

of

screwed

connection

the

max

.

torque

will

be

generally

reached

in 3 or 5 seconds

.

The

running-down

torques

may

vary

considerably

with

thread

friction,

friction

between

bolt

head

and

rest

face,

flexibility

("spring")

in

the

parts

to

be

joined, wear

in

the

tool

drives

and

socket

squares.

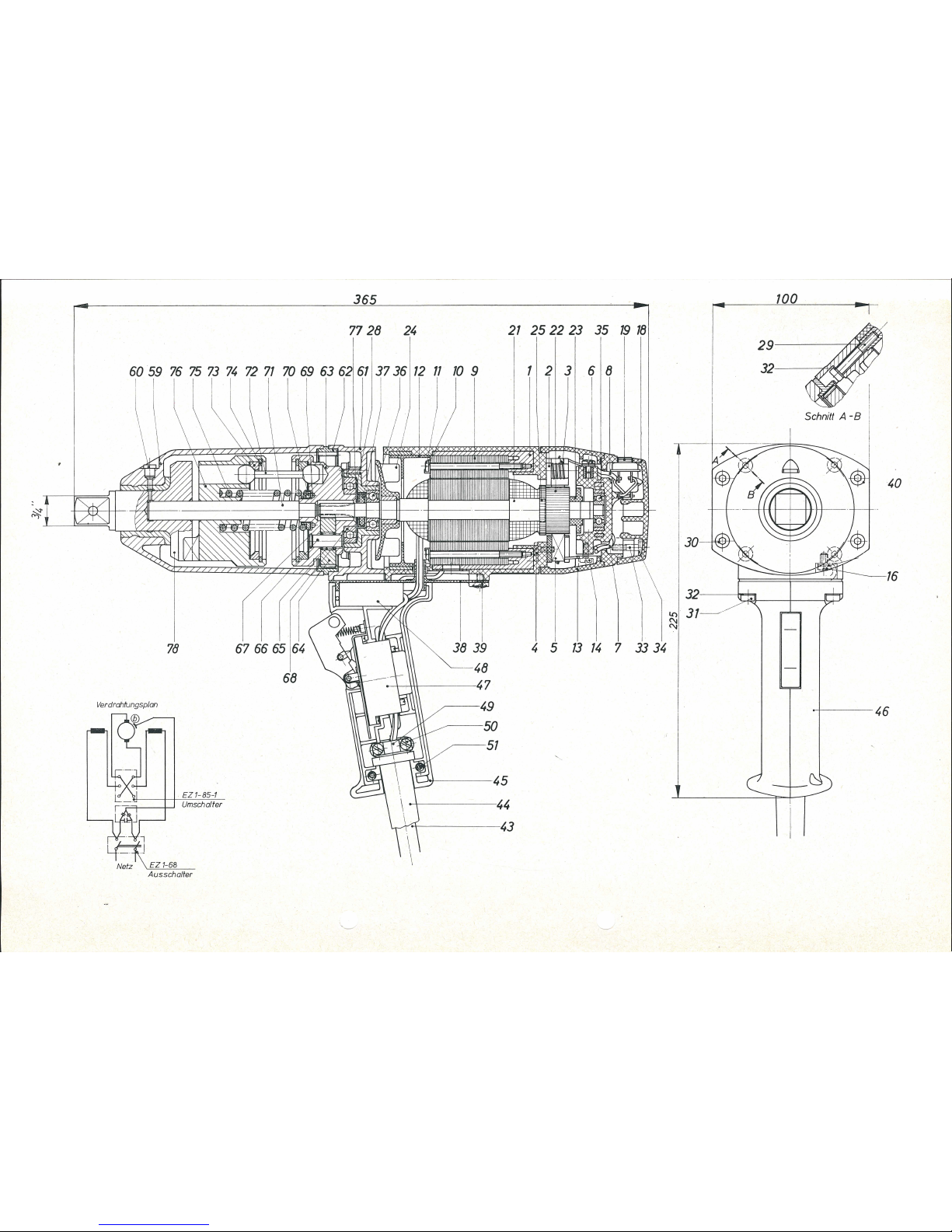

3.

Maintenance

and

lubrication

Pull

out

plug

before

carrying

out

any

maintenance

work.

Grease

once

per

week

at

the

lubricating

nipple

(60)

(when

needed

every

BE 349 e

EW

1. 73

Printed

in

German

y

lbs

.

kg

lf/'

1500 1500 450

10,5

5

two

days).

After

300

working

hours

clean

air

openings

of

the

motor

housing.

Blow

out

motor

with

dry

pneumatic

air.

Renew

the

gear

grease. Loosen

screws

(30)

and

take

off

gear head.

Only

use

special

gear

grease

Sst

1.

Quantity

of

grease

50

g.

Order

reference

for

the

tube

of

approx

. 90 g:

MZ

60-3/

Sst

1.

After

900

working

hours

clean

the

machine

thoroughly. Rinse

ball

bearings

and

gearing

in

clean

solvent

and

pack

with

fresh

grease

(Sst 1).

The

space

between

inner

and

outer

rings

is

to

be

one

third

filled

with

grease

in

order

to

prevent

overheating

of

the

bearing.

Clean

electric

parts

only

dry.

Replace

carbon

brushes

when

they

have

worn

down

to 7 mm

(0.28 in.).

To

replace

brushes

see

paragraph

4.

Only

use

Fein

carbon

brushes.

After

fitting

new

brushes

check

that

they

move

easily

in

their

holder. Run

tool

unloaded

for

about

15

min.

Check

connection

cable

(43)

at

regular

intervals.

To

replace

it,

unscrew

screws

(51, 31),

remove

the

handle

upper

part

(46),

loosen

the

screws

(50)

of

the

clamping

bridge

and

clamp

off

cable

from

switch

(47).

No

claims

can

be

entertained

for

damage

due

to

negligent

maintenance

and

inadequate

lubrication.

~

"1

60 59

76 75

73

74

72

71

70

69 63

I

78

Verdrohlungsplan

EZI-85-1

, -

--,

1 1 Umschal

ter

Ldl

1

Net

z1~

Au

ssc

ha/ter

68

-

3

77 28

24

17

TO

--------50

~

51

CJ

45

21

25

22

35

18

11213

1 6 18

4

13 14

33 34

1

--

1

I

i

!

1

3o~

I

TOO

29

A~

32

~

Schnitt A

-8

40

16

32

g;m

1.0

1

31

-

_/~

I

lctY

~

-+---

--

46

Loading...

Loading...