Fein ASb 658, ASb 758 Operating Instructions Manual

(

ASb

658

To be handed to the workshop

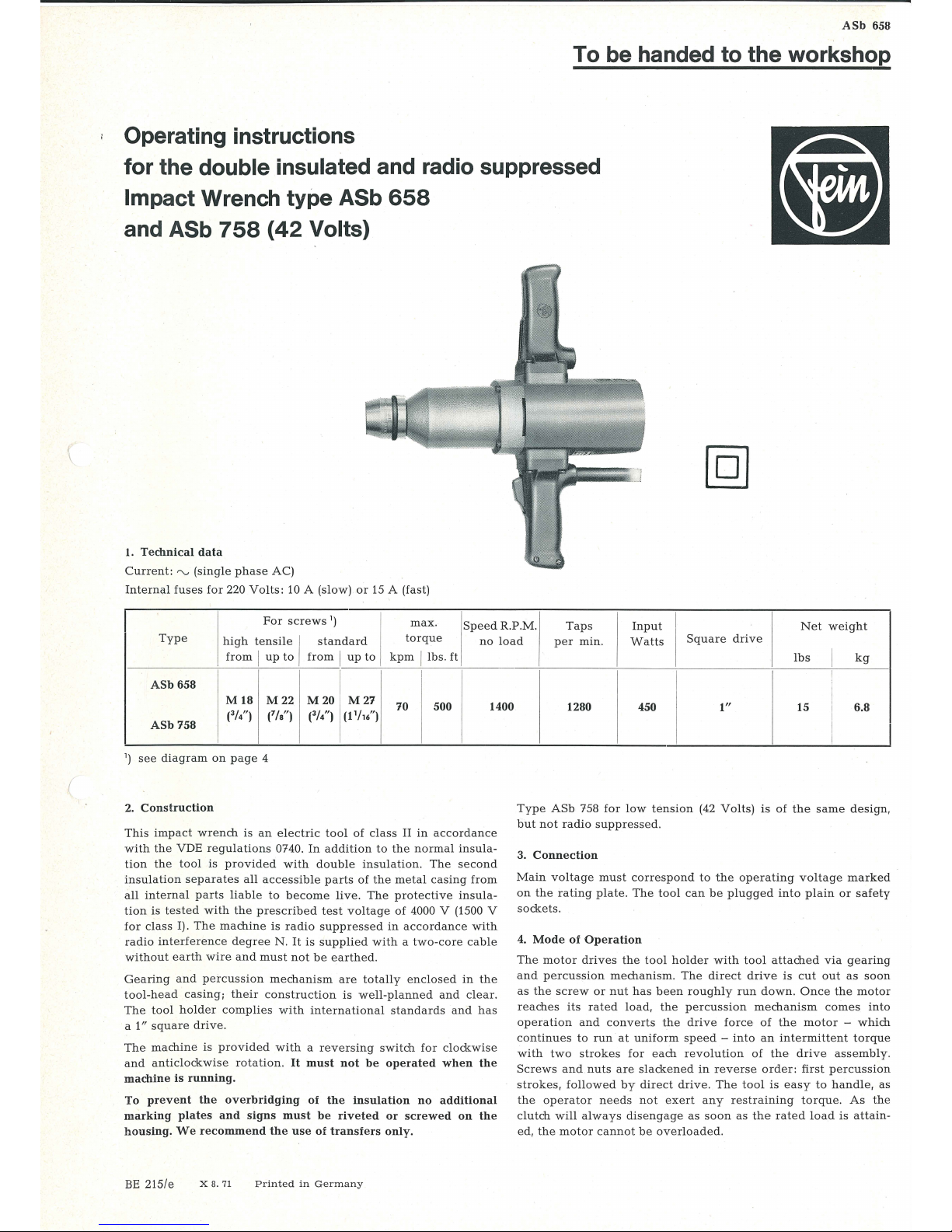

Operating instructions

for the double insulated and radio suppressed

Impact Wrench type ASb

658

and ASb

758

(42

Volts)

1.

Technical

data

Current:

"'-'

(single

phase

AC)

Internal

fuses

for

220

Volts:

10 A (slow)

or

15 A (fast)

For

scre

ws

1

)

m

ax.

Speed

R.P.M.

Taps

Inpu

t

I

Net weight

I

Type

high tens

il

e I s

tandar

d

torque

no loa

d

p

er

min

.

Watts

Sq

uare dri

ve

from j

up

to from j up

to

kpm

j ibs.

ft

ASb

658

M 18

M22

M20

M27

70 500 1400

ASb

758

(3/4")

f/s

")

(lf

[ )

(1

1

/,6")

I

I

1

)

see diag

ram

on p age 4

2.

Construction

This

impa

ct w rench is an

electri

c t

ool

of

class

II

in acco

rdanc

e

with the VDE re

gulations

0740.

In

addition

to the n ormal

insul

a-

ti

on the tool is provided with

doubl

e i

nsulati

on. The seco

nd

insulatio

n se

parat

es a

ll

access

ible part

s of t

he

metal casing from

all

intern

al

parts liable to become

liv

e. T

he

protecti

ve

insul

a-

tion

is

tested

with

the pre

scribed test

voltage

of

4000 V (1500 V

for

class I). The mac

hine

is

radio

suppressed

in

accordance

with

radio

interference

degr

ee

N.

It

is

suppli

ed

with a two-co

re c

abl

e

without earth wir

e a

nd must

not

be ea

rth

ed.

Gea

ring an

d pe

rcussi

on

mechani

sm are totally en

closed in the

tool-h

ead casing; the

ir

cons

truction

is

well-planned and clea

r.

Th

e tool holder c

ompli

es with

international

standar

ds a

nd has

a 1"

square

driv

e.

The

machine

is

provided

with

a reversing

switch

for

clockwise

and

anticlo

ckwi

se rotation.

It

must

not

be

operated

when

the

machine

is

running.

To p

reve

nt

the ove

rbridging

of

the

insulation

no

additional

ma

rking

plat

es

and

signs must

be

riveted

or

screwed

on the

housing.

We recommend the

use

of

transfers

onl

y.

BE 215/ e

X 8.

71

Printed

in

Germany

lb

s

I

kg

I

1280 450

1"

15

6.8

Ty

pe

ASb 758

for

low tension

(42

Volts

) is

of

the

same

design

,

but

not

radio

suppress

ed.

3.

Connection

Ma

in volt

age

must correspon

d to the op

erating voltag

e marked

on the

rating

plat

e. The tool can be

plugged into pla

in

or

safety

sock

ets.

4.

Mode

of

Operation

Th

e m

otor

driv

es the

too

l holder

with

tool

attac

hed

via gearing

a

nd perc

ussi

on mechan

ism. The direct

dri

ve

is

cu t

out

as soon

as

the screw or nut h

as been ro

ughly run down. On

ce the

mot

or

reach

es its rated load, the percussion

mechani

sm com

es into

operation

and

converts

the

drive

for

ce

of t

he

motor -which

continu

es

to

run

at

uniform speed -into

an inte

rmitte

nt

torque

w

ith two

strokes

for each rev

olution

of the

· driv e

assembl

y.

Screws and

nuts

are

sla

ckened

in

reverse o

rde

r:

fir

st

perc

ussi

on

s

trok

es, followed

by direct

drive. The tool is

easy to handl

e, as

the op

erat

or n

eeds not

exert

an y

restraining torq

ue.

As

the

cl

utch

will alw

ays

disengage

as

soon

as

the

rated loa

d is

atta

in-

ed

, t

he

motor cann

ot

be

overloaded.

r--~--

1

I

t

I

L

2

57

56

55

53

52

cam

eJ

ii###ii

o------

--

m

....,..

o

eJ

i@!e

0

51

46

54

49 48

47

l j . l

~~

i t

0

I

~

~~

~

~

,

I

I

I

~~·t

~

r

...

r I

e:~==-

64

.,

L®

O

OD~

9

1

-

~-

1--3

g-

3

!-

10

6t

- -

66

--

- -

11

5 4

I I

---@~

@~

~

-

11

1

t-.13

67- T

67

-U

!~

' '

I.

-

39

:_ ___

_ j

32-

---

29

I

///

~Oi;@

36

I .

34

lii;@--35

-

--

---

30

~

--?

··

·

·

----------

.

33

Loading...

Loading...