Fein ASb 53-2, ASb 53-2K Operating Instruction

(

ASb

53-2

To

be

handed

to

the

workshop!

Operating

instruction

for

the

Impact

Wrench

type

ASb

53-2

(D.C.

and

A.

C.

single phase)

and

ASb

53-2K

(42

Volts)

Technical

data

Type

of

current

:

~;,....,

(D.C.

and

A.C.

single

phase)

For

screws

Square

Sp

eed

R.P.M. Ta

ps

Input

I

Ou

t-

Net weigh

t

Ty

pe

standard

I

high

ten

sile

dri

ve

full I no

p. M.

put

up

to

up

to

AS

b 53-2

M 22

(1

/s") M 18 (

3

/4'')

A

Sb

53-2 K (42

Volts)

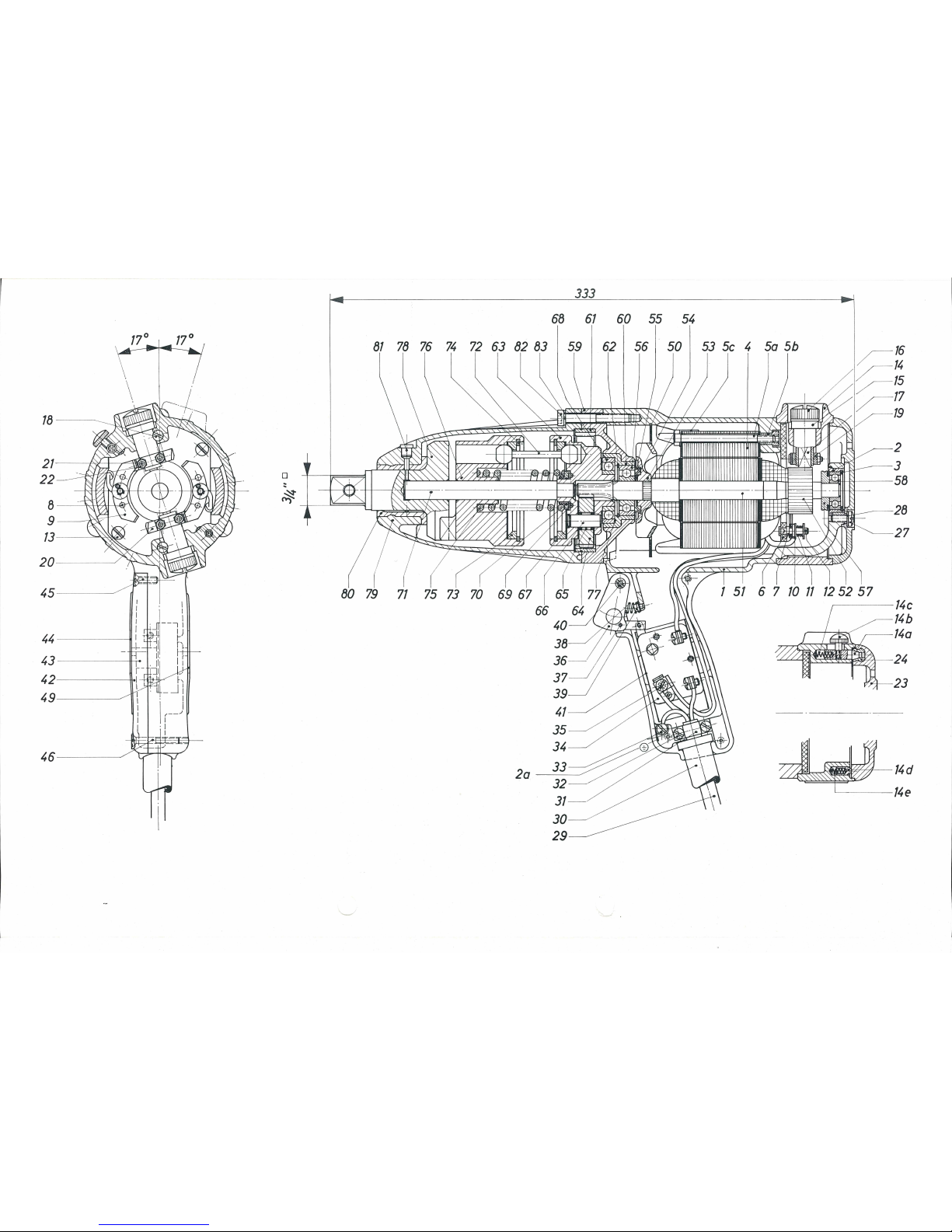

1. Construction

Th

e tool

is

driven

by

a ro

bus

t,

fan-cooled

AC/DC

motor mount

ed

in

an e

xtra-r

igid

light

alloy

housing. The compact

planetary

reduction

gearing

is

robust

and

silent

in

operation. The well-

balanced

percussion

mechanism

is

totally

enclosed

in

the

tool-

head

casing

and

is

easily

removed. The

tool hold

er co

mpli

es

w

ith

international standards

and

has a

3

/

4"

(19

mm)

square

drive.

2.

Rev

ersing

the

drive

is

done by means of the

reversing ring (14) mounted on the

motor

housing.

Turn

reversing

ring

only

when

tool

is

switched

off,

otherwise commutator

and

windings

will

be

damaged.

3.

Mode

of

operation

Th

e m ot

or

dri

ves the tool

hold

er w

ith tool attac

hed via ge

arin

g,

d

rive spindl

e a

nd percussion mechanism.

The direct

dri

ve

of

a

pprox. 1,100 r.p.m. is

cut out

as soon

as the

screw

or nut has

be

en

roughly

run

down.

Once

the

motor

reaches

its rat

ed load,

the

percussion mec

hanism

comes

into

operation

and

converts

the

drive forc

e of

the

motor -which

continues

to

run

at

uniform

speed -into an

intermittent

torque applied

at

the

rat

e of 1,500

r.p

.m., i. e. two

str

okes

for

each

revolut

ion

of the dr

ive spindl

e.

Screws and

nuts are slacke

ne d

in reverse ord

er:

fir

st percussi

on

st

rokes, followed by d

irect drive. The tool is very easy to

h

andle,

as the opera

tor needs

not exert any restraining

torque.

As

the

clutch will

always

disengage as

soon

as

the rated load

is

attain

ed, the mo

tor

cannot

be overloaded.

4.

Application

The full

tightening

or

slackening

action

provided

depends

on

the time during

which the p e

rcussion

mechani

sm

is

allowed

to

run.

Max.

tig

hte

ning torque i s the s

um

of

th e to

rque ap

pli

ed by

each

stroke.

According

to

the

type

of

screwed

connection

the

max.

torque

will

generally

represent

between

80

and

150

single

torque strokes, whi

ch are

appli

ed

in 3 to 5 second

s. Availabl

e

m

ax.

torqu e

in

norm

al serv i

ce

is

185

lbs.

ft. (26

kpm)

(see dia-

gr

am

m p. 4).

Th

ere

is no point

in

applying the tool for longer th

an 5

sec

ond

s

sin

ce

th e

torq

ue will

not increase

any

furth

er, whil

e the

tool

BE 176/e BX

11.

64 Print

ed

in

German

y

i

n.

3f,,

load

lo

ad

in Watt

s

lbs

I

kg

- -

I

I I

750

1400

I

1500 I 480 280

I

11.1 5.0

I

I

I

head

will

appreciably

heat. Ove

rheating will

lead

to

increased

wear of

all

percussion

compone

nts

an d

excessive

lubri

cant con

-

s

ump

tio

n. Mor

eover,

such

overheating w

ill

make the

tool too

hot

to

handle

.

It

is not adv

isable

to u

se

attachments exceedi

ng 4.5

lbs

in

w

eigh

t, since tqe teel

holder

se

ati

ng

is

not

design

ed

for such

loads.

I

Use

U n iversa

l

Gre~se

typ

13

Sst

1

! l

ns•..,a

o r;f

o~

""r

t'/.C::

'

-·.f

,•r ,5 1

5.

Maintenance

and· lubrication

··

-

8

This w

ill

depe

nd

on the duty. The fo

llowing

ins

tru

ctio

ns

are

for conti

nuous

use

in 8-hour

day

with

actual tool

running

time

representing 20°

/o

of

total

duty

period

. The tool

hold

er (78)

should

be

lubricat

ed every ot

her

day

by mean s

of

the

oil

er

(81

)

at

the hea

d (79). U

se

machine oil

or

thin-flowing

grease

. T

he

pe

rcu

ssion mecha

nism

sho

uld

be

completely clea

ned

of

old

grea

se

at l

east

eve

ry 300 h

ours (ap

prox. 6

weeks). For this pur-

pose r

emove the

thr

ee scr

ews

(82), then

take

off

th e outer

bea

r-

ing (79) and li.f

t the percussion mechanism out of the inter

-

media

te

bearing

without

taking

it

apart.

Then

app

ly

grease

liberally to

th e

impact

fac

es of

parts (76) a

nd

(78) (30

to

40 g

or

about 1 to

P/2 oz.).

Ball pivo

ts a

nd

planetar

y

ge

arin

gs should

also

be gre

ase

d w

ith

FK

3.

FK

3 is a

high-gr

ade

quality grease and

is suitable

for a

ll

percu

ssio

n mech

anism

parts

beca

use

of

its good he

at resi

stan

ce

and adhe

rence. Ba

ll

beari

ng grea

se packin

gs shou

ld

also

be replenished with FK

3.

Should

th e

percussion mechanism

jam

or

run irregul

arly in

spite

of adequate

lubrication

and regul

ar

maint

enance

, th e

combin

ed

dri

ve

asse

mbly sho

uld

be tak

en

out

as described

und

er

par

a-

graph

7, a

nd the

individu

al parts

should

be t

ested. Frequentl

y,

ho

wev

er, uneven runni

ng

is cau

sed

by

wear

, i.e.

imp

act

dogs

which h

ave beco

me radi

use

d, or rel

axatio

n of

spring (75).

so

that sp

ring pressure

weake

ns. Worn d

ogs

can

be

regro

und.

Max.

tightening

or

slackening

torque

can

only be

obtained with

a

tool

applying

uniform strokes

along

the

axis

.

Carb

on

brushes

(17)

shoul

d b e che

cked

at

interva

ls

of abo

ut

6

w

eeks

and replaced if

appr

eci

ably wo

rn dow

n (wh en compl

e-

tely

worn dow

n th

ey will

be 7 mm

[1

/4"

]

long).

In ord

er

to re-

pl

ac

e th

em

take

off carb

on h old

er

caps (16). Replace

brushes

in

ti

me

to

avo

id

dam

age

to the commutator

.

78

21

22-~lr/1£\

'~~~

-

~

333

68

61

60 55

54

81

78

76

74

72

63 82 83 I 59 I 62 1 56 1

50

I 53 5c 4

Sa

5b

8~~-

-,-

.

($!

28

9-~.

. -

13

. "

~

27

20

45

--

--

--

--

--

14c

74b

44

U 1

~

f-'

II

/ I

'

~

\Y

..&

6.\\\n\l:'t.. \ f I

'"""

,----

14a

43

42

\Jffr ii

i/

:~

~/

/\

\\~V\\\\\

,.. '

~

23

49

46

--------

30

__/

29

~

~

:::

Loading...

Loading...