Fein ASb 110, ASb 110 K Operating Instruction

ASb

110

To

be

handed

to

the

workshop!

Operating

instruction

for

the

Impact

Wrench

type

ASb 110

(three

phase

A.

C.)

and

ASb 110 K

(42

Volts)

1.

Technical

Data

Type

of

current:

3 ~ (A.C.

three

phase)

50

cycles

for

screws

up

to

Max.

Torque

I

Type

mm

I

in

.

kpm

llbs.

ft

I

ASb

110

}

1

3

/t6

30

50

360

ASb

110 K (42 V)

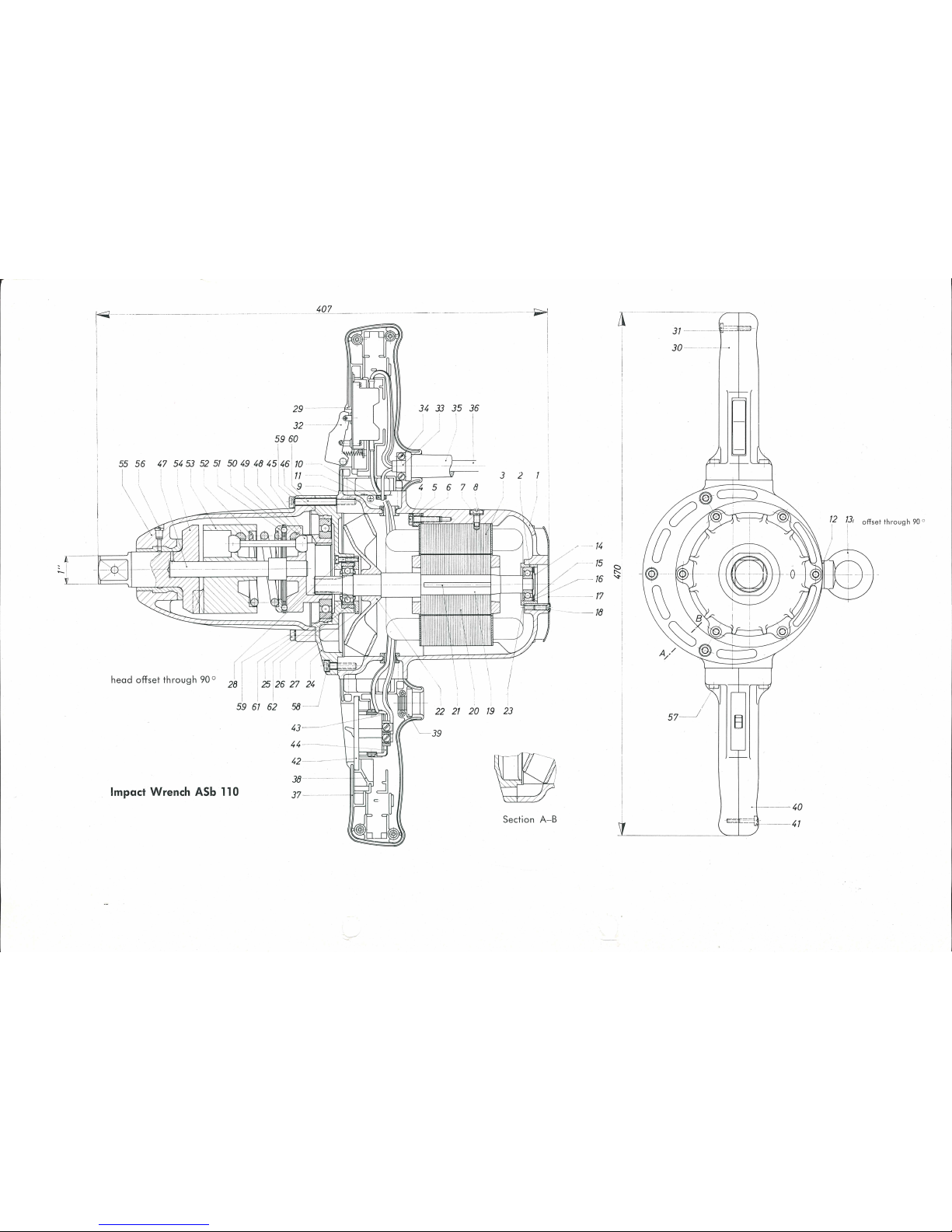

2.

Construction

The

percussion

mechanism

of

the

Impact

Wrench ASb

110

is

driven

by a robust,

fan-cooled

AC-motor.

All

housing

parts

are

made

of

light

alloy,

the

two

side

handles

of

high

quality shock-

proof

plastic

material.

Gearings

and

percussion

mechanism

are

mounted

in

the

tool-head.

The

construction

is

well-balanced

and

clear.

The

tool

holder

complies

with

international

standards

and

has

a 1" (25,4 mm)

square

drive.

The

impact

wrench

can

be

adjusted for

clockwise

and

anticlock-

wise

rotation.

The

reversing

switch

is

mounted

in

the

left-hand

handle

and

must

only

be

operated

at

standstill

of

the

machine

.

3.

Mode

of

Operation

The

motor

drives

the

tool

holder

with

tool

attached

via

gearing

and

percussion

mechanism.

The

direct

drive

is

cut

out

as

soon

as

the

screw

or

nut

has

been

roughly

run

down.

Once

the

motor

reaches

its

rated

load,

the

percussion

mechanism

comes

into

operation

and

converts

the

drive

force

of

the

motor -which

continues

to

run

at

uniform

speed -into

an

intermittent

torque

with

two

strokes

for

each

revolut

ion

of

the

dri

ve

assembly.

Screws

and

nuts are

slackened

in

reverse

order:

first

percussion

strokes,

followed

by

direct

drive.

The

tool

is

easy

to han

dle,

as

the

operator

needs

not

exert

any

restraining

torqu

e.

As the

clutch will always

disengage

as

soon

as the

rat

ed l

oad

is

attain

ed,

the

motor

cannot

be

overloaded.

4.

Application

The

full

tightening

or

slackening

action

provided

depends

on

the

time

during

which

the

percussion

mechanism

is

allowed

to

run.

Max.

tightening

torque

is

the

sum

of

the

torques

applied

by

each

stroke.

According

to

the

type of

screwed

connection the

max

.

torq

ue

will

generally represent

between

60

and

120 single

torqu

e

strokes,

which

are

appli

ed

in 3 to 5 seconds.

Ava

ilable max.

torque

in

normal

service is 360

lbs.ft

(50

kpm) (see

diagramm

p.

4).

There

is

no

point

in

applying

the

tool

for

long

er

than

5

BE 163

/e

X 8.

66

Printed

in

Germany

I

Speed

R.P.M.

Taps

Input

Output

Net

weight

full

load

per

min.

Watts

Watts

lbs

I

kg

I

! I

780

1560

1100 740 27.8

12.5

seconds

since

the

torque will

not

increase

any

further,

while

the

tool

head

will

appreciably heat. Overheating

will

lead

to

incr

eased

wear

of

all

percussion

componen

ts

and

excessive

lubricant

consumption

.

It

is

not

advisable

to use

attachments

exceeding

8.9

lbs

in

weight,

since

the

tool

hold

er

seating

is

not designed

for

such

loads.

Attention!

Alwa

ys

secure

attachments

with

securing

pin

and

rubber

supporting

ring, otherwise

the

square-dri

ve

is

liable

to

break

.

5.

Maintenance

and

Lubrication

This will

depend

on

the

dut

y. The

following

instructions

are

for

continuous use

in

8-hour day

with

actual

tool

running

time

representing

40

Ofo

of

total

c!.uty

period.

The

tool

holder (54)

should

be

lubricat

ed

every other day

by

means

of the

oiler

(56)

at

the

outer

bearing

(55). (Use

machine

oil

or

thin-flowing

grease

.)

The

percussion

mechanism

should

be

completely

cleaned

of

old

grease

at

least

every

300

hours

(approx. 6 weeks).

For

this

pur-

pose

remove

the 6 screws

(60, 61).

then

take

off

theouterbearing

(55)

and

lift

the

percussion

mechanism

out

of th e

intermediate

bearing

without

taking

it

apart.

Then

apply

grease

FK 3 liberall

y

to

the

impact

fac

es

of

par

ts

(53)

and

(54).

Ball

pivots

(48) and

planetary

gearings

(45)

should

also

be

greased

w ith

FK

3. The

total

quantity

of

grease

in the

percu

ssion

mechanism

should

be

ap

prox.

150 g (5 oz.).

FK 3 is a high-grade

quali

ty

grease

and

is

suitable

for

all

percussion

mechanism

parts

because

of

its

good

heat

resistance.

Ball

bearing

grease

packings should

also

be

replenish

ed

with

FK

3.

If,

after

long

duty,

the

impact

dogs

of

percussion

piston

(53)

and

tool

holder

(54)

are

worn

they

must

be

reground

so

that

the

machine

reaches

its

full

tightening

torque.

Damaged

percussion

me

chanisms

should

be

dismantled

according

to

the

instru

ctions

of

page

4.

We rec

ommend

our

Fein

Service Stations

to

carr

y

out all

repair

work

of

this

kind

quickly

and

expe

rtly

.

lJJ~

ll);Niversat

Grease

type

Sst

1

llhetead

ot

oto-,er

types

o.t

grease

I

r-

,

I

I

I

I

55

56

he

ad

offset

through

90°

40_7

___

_

32

---

-

(>

r'(?

I I ! : I

28 1 'i

2s

1

.

26

2

~

24

\ I

59

61

62 58--

38- -

·.

Impact Wrench

ASb

110

37-

--

--

--jj.lr=flr

34

33

35

36

I I I

I

3

-

~

I

I

22

21

20

19

23

39

\19

7:

S

ect

ion A-B

11

-·-

/ -

14

/ ·

15

<:::>

"'

'-7-

~

18

I

1

31

t:=

30

-

12

1J,

offset

through

90 °

··

---

40

=t:.=-~

~----

41

Loading...

Loading...