Page 1

Installation, Operation and Maintenance

CATEGORY I NATURAL GAS AND LP GAS

HIGH EFFICIENCY

TWO STAGE VARIABLE SPEED

WARM AIR FURNACE

MODEL 77

For future reference write down the model, serial

number, and date of purchase. Use these numbers in

any correspondence or service calls concerning your

furnace.

Model

Serial Number

Date of Purchase

Keep these instructions for future reference.

Please read the operating instructions and safety

precautions carefully and thoroughly before installing

and operating your furnace. Keep this manual in a

safe place for future reference.

FV95A054 FV95A072 <

FV95A090<

FV95A108

USER’S INSTRUCTION GUIDE

LOCATED AFTER PAGE 43 OF THIS

INSTALLATION, OPERATION AND

MAINTENANCE MANUAL

23-23-0508N-003

Page 2

Table of Contents

INTRODUCTION ....................................................................... 1

S

AFETY ..................................................................................... 1

S

afety Rules ................................................................... 1

C

ODES....................................................................................... 3

FURNACE SIZING ..................................................................... 4

AIR CONDITIONING

INSPECTION/ACCESS PANEL

LOCATION OF UNIT ................................................................. 5

General ......................................................................... 5

Other Considerations:................................................... 5

CLEARANCES ........................................................................... 6

UNIT DIMENSIONS ................................................................... 6

DUCTWORK ............................................................................. 7

Guide: ........................................................................... 7

Ductwork Steps: ........................................................... 7

INSTALLATION POSITIONS....................................................... 8

Inducer Blower Rotation ............................................. 9

Inducer Rotation Steps ............................................... 9

Non-Suspended Installation ......................................... 9

Suspended Installation ................................................. 9

Upflow Installation ...................................................... 10

Downflow Installation ................................................ 11

Horizontal Installation ................................................ 12

AIR FOR COMBUSTION .......................................................... 13

Case 1: Furnace Located In An

Case 2: Furnace Located In A

Case 3: Furnace Located In A Confined Space,

Case 4: Furnace Located In A Confined Space,

FURNACE VENTING ................................................................ 14

Direct Venting Pipe Connection.................................. 14

Combustion Air Inlet Piping........................................ 14

Air Filters....................................................................... 15

Exhaust Vent Piping...................................................... 15

Guidelines...................................................................... 16

Joining Pipe And Fittings.............................................. 16

Direct Vent Piping Termination................................... 17

Calculating Piping Length............................................ 18

Termination of Combustion Air and Ventilation

Pipe Using A Concentric Venting Kit.......................... 19

Horizontal Termination of Combustion Air and

Exhaust Vent................................................................. 20

Vertical Termination of Combustion Air and

Exhaust Vent................................................................. 21

Non Direct Vent Furnace Installations......................... 22

CONDENSATE DRAINS............................................................. 25

Drain Hose Installation.................................................. 25

Condensate Drain Installation....................................... 27

................................................................. 4

................................................... 4

Unconfined Space .......................................... 13

Confined Space .............................................. 13

Outdoor Air From Attic Or Crawl Space ...... 13

Outdoor Air Ducted Horizontally.................. 13

GAS SUPPLY ............................................................................. 28

Gas Piping ..................................................................... 28

Leak Testing ................................................................. 28

High Altitude ................................................................ 29

CONVERSIONS ......................................................................... 29

Natural to L.P. Gas ....................................................... 29

. to Natural Gas ........................................................ 29

L.P

Conversion Steps .......................................................... 29

HIGH ALTITUDE & AIRFLOW SPECIFICATION TABLES ........... 30

ELECTRICAL SPECIFICATIONS................................................... 32

Furnace Connection ..................................................... 32

Low Voltage Wiring ..................................................... 32

Thermostat ................................................................... 33

Thermostat Location..................................................... 33

Thermostat Heat Anticipator Setting ......................... 33

START UP PROCEDURES ......................................................... 34

To Start The Furnace: ................................................... 34

To Shut Down The Furnace:......................................... 34

Sequence of Operation ............................................... 34

Sequence of Operation if the Furnace

Does Not Light or Detect Flame ................................. 34

Setting The Manifold Gas Pressure ............................. 34

Checking Furnace Input ............................................... 34

Circulating Air Blower and

Temperature Rise Check............................................... 35

Temperature Rise Check............................................... 35

AIR FLOW ................................................................................. 35

Calculating Airflow....................................................... 35

Adjusting Dip Switches................................................. 36

ADJUSTING BLOWER SPEEDS ................................................. 37

Cooling Mode ............................................................... 37

Heating Mode ............................................................... 37

How To Remove The Blower ....................................... 37

How To Install The Blower........................................... 37

MAINTENANCE ....................................................................... 38

Air Filter......................................................................... 38

Lubrication ................................................................... 38

Vent Connector............................................................. 38

Operating Tips ............................................................. 38

ANNUAL INSPECTION/SERVICE ............................................... 38

Heat Exchanger............................................................. 38

Burners ......................................................................... 38

Induced Blower ............................................................. 38

Circulating Fan ............................................................. 38

Electrical ....................................................................... 39

Furnace Operation ....................................................... 39

FIELD SUPPLIED AND INSTALLED

OPTIONAL ACCESSORIES......................................................... 39

Electronic Air Cleaner................................................... 39

Humidifier/ Electronic Air Cleaners ............................. 39

TROUBLESHOOTING ............................................................... 39

WIRING DIAGRAM .................................................................. 43

Page 3

INTRODUCTION

This 95% efficient gas fired furnace series is CGA / AGA

esign certified as a Category I (condensing with positive

d

vent pressure) non-direct or direct vent central forced air furnace. It is an upflow, downflow, horizontal left and right furnace suitable for residential and light commercial heating

applications from 54,000 to 108,000 BTU/Hr. When installed

as a direct vent furnace, all combustion air is supplied directly to the furnace burners through a special air intake system.

(See Section “Ventilation and Combustion Air.”)

ll models may be fired by natural gas or field convertible to

A

LP gas (propane). The furnace is shipped completely assembled except for the drain trap assembly and the venting.

Please inspect for damage when the furnace is unpacked.

SAFETY

Throughout the manual, symbols and words are used to draw

attention to potentially hazardous conditions.

DANGER

THIS INDICATES AN IMMINENTLY HAZARDOUS

SITUATION WHICH, IF NOT AVOIDED, WILL RESULT IN

DEATH OR SERIOUS INJURY.

WARNING

THIS INDICATES A POTENTIALLY HAZARDOUS

SITUATION WHICH, IF NOT AVOIDED, COULD RESULT IN

DEATH OR SERIOUS INJURY.

CAUTION

THIS INDICATES A POTENTIALLY HAZARDOUS

SITUATION, WHICH, IF NOT AVOIDED, MAY RESULT IN

MINOR OR MODERATE INJURY.

. Always install furnace to operate within the furnace’s

6

intended temperature rise range with a duct system

which has an external static pressure within the

allowable range, as specified in the Furnace Sizing

section on page 4, the Ductwork section on page 7, and

he Airflow section on page 35 of these instructions.

t

7. When a furnace is installed so that the supply ducts carry

air circulated by the furnace to areas outside the space

ontaining the furnace, the return air shall also be

c

handled by duct(s) sealed to the furnace casing and

terminating outside the space containing the furnace.

(Furnace for heating the home located in the attached

arage, for example).

g

8. A gas fired furnace for installation in a residential

garage must be installed so that the burners and ignitor

are no less than 18 inches above the floor. The furnace

must be located, or protected to avoid physical damage

by vehicles.

9.

THIS FURNACE IS NOT TO BE USED FOR TEMPORARY

HEATING FOR BUILDINGS UNDER CONSTRUCTION.

DANGER

DO NOT INSTALL THIS FURNACE IN A MOBILE HOME!

THIS FURNACE IS NOT APPROVED FOR INSTALLATION IN

A MOBILE HOME. DOING SO COULD CAUSE FIRE,

PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF

LIFE.

WARNING

THE FURNACE CONTAINS FOIL COVERED FIBERGLASS

INSULATION. INHALATION OF FIBERGLASS PARTICLES IS

ASSOCIATED WITH RESPIRATORY DISEASE INCLUDING

CANCER.

Safety Rules:

1. Use this furnace only with type of gas approved for this

furnace. Refer to the furnace rating plate.

2. Install this furnace only in dry indoor locations

(protected from weather).

3. Provide adequate combustion and ventilation air to the

furnace space as specified in the Determining

Combustion Air section on page 13 of these instructions.

4. Combustion products must be discharged outdoors.

Connect this furnace to an approved vent system only, as

specified in the Furnace Venting section on page 14 of

these instructions.

5. Never test for gas leaks with an open flame. Use a

commercially available soap solution made specifically

for the detection of leaks to check all connections as

specified in the Gas Supply section on page 28 of these

instructions.

WARNING

THE FUEL SUPPLIER NORMALLY ODORIZES NATURAL

GAS AND PROPANE. IN SOME CASES, THE ODORANT

MAY NOT BE PERCEIVABLE. INSTALLATION OF UL AND

CUL RECOGNIZED FUEL GAS DETECTORS INSTALLED IN

ACCORDANCE WITH THEIR MANUFACTURER’S

INSTRUCTIONS IS RECOMMENDED AS AN ADDITIONAL

MARGIN OF SAFETY.

DANGER

FIRE OR EXPLOSION HAZARD

IF THE INFORMATION IN THESE INSTRUCTIONS IS NOT

, A FIRE OR EXPLOSION MA

FOLLOWED EXACTL

RESULT, CAUSING PROPERTY DAMAGE, PERSONAL

INJURY OR LOSS OF LIFE.

Y

CAUTION

MAKE SURE TO REMOVE FOAM BLOWER HOUSING

SHIPPING SUPPORTS BEFORE OPERATING FURNACE.

SHIPPING SUPPORTS ARE LOCATED ON THE BOTTOM

RIGHT AND BOTTOM LEFT SIDES OF BLOWER HOUSING.

Y

1

Page 4

DANGER

WHAT TO DO IF YOU SMELL GAS:

• DO NOT TRY TO LIGHT ANY APPLIANCE

• DO NOT TOUCH ANY ELECTRICAL SWITCH; DO NOT

USE ANY PHONE IN YOUR BUILDING

IMMEDIATELY CALL YOUR GAS SUPPLIER FROM A

•

EIGHBOR’S PHONE, OR A CELLULAR PHONE FROM A

N

LOCATION WELL AWAY FROM THE BUILDING.

FOLLOW THE GAS SUPPLIER’S INSTRUCTIONS.

IF YOU CANNOT REACH YOUR GAS SUPPLIER, CALL

•

THE FIRE DEPARTMENT

• DO NOT ENTER THE BUILDING UNTIL AUTHORIZED TO

DO SO BY THE GAS SUPPLIER OR THE FIRE

DEPARTMENT

IMPROPER INSTALLATION, OPERATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

INJURY, PROPERTY DAMAGE OR LOSS OF LIFE. REFER TO

THIS MANUAL FOR PROPER INSTALLATION, OPERATION,

VICE, AND MAINTENANCE INSTRUCTIONS.

SER

A QUALIFIED INSTALLER, SERVICE AGENCY OR

THE GAS SUPPLIER MUST PERFORM

INSTALLATION AND SERVICE.

DO NOT DESTROY THIS MANUAL

PLEASE READ CAREFULLY AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE BY A SERVICE TECHNICIAN.

DANGER

HEN THIS FURNACE IS INSTALLED IN A RESIDENTIAL

W

GARAGE, IT MUST BE INSTALLED SO THE BURNERS AND

IGNITION SOURCE ARE LOCATED NO LESS THAN 18

INCHES ABOVE THE FLOOR TO PREVENT THE RISK OF

IGNITING FLAMMABLE VAPORS WHICH MAY BE

RESENT IN THE GARAGE.

P

THE FURNACE MUST BE LOCATED OR PROTECTED TO

AVOID PHYSICAL DAMAGE BY VEHICLES.

FAILURE TO HEED THESE WARNINGS CAN CAUSE A FIRE

OR EXPLOSION, RESULTING IN PROPERTY DAMAGE,

PERSONAL INJURY OR LOSS OF LIFE.

WARNING

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO

QUALIFIED SERVICE PERSONNEL FOR PROPER

INSTALLATION, ADJUSTMENT AND OPERATION OF THIS

FURNACE. READ THESE INSTRUCTIONS THOROUGHLY

BEFORE ATTEMPTING INSTALLATION OR OPERATION.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT

IN IMPROPER INSTALLATION, ADJUSTMENT, SERVICE OR

MAINTENANCE, POSSIBLY RESULTING IN FIRE,

ELECTRICAL SHOCK, CARBON MONOXIDE POISONING,

EXPLOSION, PROPERTY DAMAGE, PERSONAL INJURY OR

DEATH.

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS AND LIQUIDS, OR OTHER

COMBUSTIBLE MATERIALS IN THE VICINITY OF THIS OR

ANY OTHER APPLIANCE.

WARNING

THE EXHAUST GASES FROM THIS FURNACE CONTAIN

CHEMICALS, WHICH ON SOME OCCASIONS MAY

INCLUDE CARBON MONOXIDE (CO). CARBON

MONOXIDE IS AN ODORLESS, TASTELESS, CLEAR

COLORLESS GAS, WHICH IS HIGHL

CONCENTRA

DEFECTS AND OTHER REPRODUCTIVE HARM.

UL AND CUL RECOGNIZED CO DETECTORS ARE

RECOMMENDED FOR ALL BUILDINGS EQUIPPED WITH

FOSSIL FUEL BURNING APPLIANCES. ALL CO DETECTORS

SHOULD BE INST

MANUFACTURER’S INSTRUCTIONS AND APPLICABLE

LOCAL BUILDING CODES.

TIONS ARE SUSPECTED OF CAUSING BIR

ALLED IN ACCORDANCE WITH THEIR

Y TOXIC. EVEN LOW

TH

2

Page 5

CODES:

This furnace must be installed:

In accordance with all local codes, bylaws and

•

regulations by those authorities having jurisdiction

• In the United States, this furnace must be installed in

ccordance with the current ANSI Z223.1 (NFPA 54)

a

National Fuel Gas Code

• In Canada, this furnace must be installed in

ccordance with the current CAN/CGA -B149

a

Installation Code for Fuel Burning Appliances

Electrical connections must be made

in accordance with:

• Any applicable local codes, bylaws and regulations

• Canada: current edition of CAN/CSA C22.1, Canadian

Electrical Code (Part 1)

• United States: current edition of ANSI/NFPA 70,

National Electrical Code

Codes and additional information may

be obtained from:

• American Gas Association

1515 Wilson Boulevard

Arlington, VA, 22209

703-841-8400

•

National Fire Protection Association

1 Batterymarch Park

Quincy, MA, 02269-9101

617-770-3000

•

Canadian Gas Association

Suite 1, 243 Consumers Road

North York, ON, M2J 5E3

416-498-1994

INSTALLATION REQUIREMENTS SPECIFIC

TO THE STATE OF MASSACHUSETTS FOR

DIRECT VENT APPLIANCES.

FOR ALL SIDE WALL HORIZONTALLY VENTED GAS FUELED

EQUIPMENT INSTALLED IN EVERY DWELLING, BUILDING OR

STRUCTURE USED IN WHOLE OR IN PAR

PURPOSES, INCLUDING THOSE OWNED OR OPERATED BY

THE COMMONWEALTH AND WHERE THE SIDE WALL

EXHAUST VENT TERMINATION IS LESS THAN SEVEN (7)

FEET ABOVE FINISHED GRADE IN THE AREA OF THE VENTING, INCLUDING BUT NOT LIMITED TO DECKS AND PORCHES, THE FOLLOWING REQUIREMENTS SHALL BE SA

INSTALLA

1.

At the time of installation of the side wall horizontal

vented gas fueled equipment, the installing plumber

or gas fitter shall observe that a hard wired carbon

monoxide detector with an alarm and battery back-up

is installed on the floor level where the gas equipment is to be installed. In addition, the installing

plumber or gas fitter shall observe that a battery

operated or hard wired carbon monoxide detector

TION OF CARBON MONOXIDE DETECTORS:

T FOR RESIDENTIAL

TISFIED:

with an alarm is installed on each additional level of

the dwelling, building or structure served by the side

wall horizontal vented gas fueled equipment. It shall

be the responsibility of the property owner to secure

the services of qualified licensed professionals for the

installation of hard wired carbon monoxide detectors.

a. In the event that the side wall horizontally vented

gas fueled equipment is installed in a crawl space or

an attic, the hard wired carbon monoxide detector

ith alarm and battery backup may be installed on

w

he next adjacent floor level.

t

b. In the event that the requirements of this subdivi-

sion can not be met at the time of completion of

installation, the owner shall have a period of thirty

(30) days to comply with the above requirements;

provided, however that during said thirty (30) day

period, a battery operated carbon monoxide detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS:

Each carbon monoxide detector as required in accor-

dance with the above revisions shall comply with NFPA

720 and be ANS/UL 2034 listed and IAS certified.

3. SIGNAGE:

A metal or plastic identification plate shall be perma-

nently mounted to the exterior of the building at a

minimum height of eight (8) feet above grade directly

in line with the exhaust vent terminal for the horizontally vented gas fueled heating appliance or equipment. The sign shall read, in print size no less than

one-half (1/2) inch in size, “GAS VENT DIRECTLY

BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS”.

4. INSPECTION:

The state or local gas inspector of the side wall hori-

zontally vented gas fueled equipment shall not

approve the installation unless, upon inspection, the

inspector observes carbon monoxide detectors and signage installed in accordance with the provisions of 248

CMR 5.0(2)(a)1 through 4.

5. PRODUCT-APPROVED VENT/AIR-INTAKE:

A product-approved vent terminal must be used and, if

applicable, a product-approved air intake must be

used. Installation shall be in strict compliance with the

manufacturer’s instructions.

6. INST

ALLATION INSTRUCTIONS:

A copy of all installation instructions for all product

approved side wall horizontally vented gas fueled

equipment, all venting instructions, all parts lists for

venting instructions, and/or all venting design instructions shall remain with the appliance or equipment at

the completion of the installation.

3

Page 6

FURNACE SIZING

The maximum hourly heat loss for each heated space shall

be calculated in accordance with the procedures described

n Manual J titled, "Load Calculation" published by the Air

i

Conditioning Contractors of America, or by any other

method which is suitable for local conditions, provided the

results obtained are in substantial agreement with, and not

less than those obtained using the procedure described in

heir manual.

t

In Canada, the maximum hourly heat loss for each heated

space shall be calculated in accordance with the procedures

escribed in the manuals of the Heating, Refrigeration and

d

Air Conditioning Institute of Canada (HRAI), or by any other

method which is suitable for local conditions, provided the

results obtained are in substantial agreement with, and not

less than those obtained using the procedure described in

their manuals.

If the installation is a retrofit application, do not rely on the

capacity of the existing heating equipment as a method to

size the new fur

listed in earlier versions of load calculation manuals were

much higher than those listed in more recent editions. It is

possible that energy saving measures have been completed

since the installation of the existing furnace. This might

include additional insulation in the attic or walls, the

application of sprayed foam insulation, the addition of

storm windows and doors, weather stripping, caulking, etc.

Many of the older furnaces were equipped with large belt

drive blower systems, operating at low RPMs. If replacing an

existing furnace, be sure that the existing ductwork can

handle the amount of airflow necessary for a reasonable

temperature rise. Most older gas furnaces operated with a

system temperature rise of 70 - 100°F. This series furnace has

been designed for operation with a system temperature rise

(

∆T) of 35 - 65°F. If the furnace selected has an identical

output capacity as the original furnace, a substantial

increase in system airflow will be required.

nace. Many of the heat transfer multiples

Existing ductwork should be assessed for its air handling

capabilities. For residential applications, the recommended

air velocity of a supply air trunk duct is 700 feet per minute

(fpm), and should not exceed 900 fpm. The recommended

air velocity of a supply air branch run is 600 fpm, and should

not exceed 900 fpm. These values are slightly lower for

lexible ducting. The recommended air velocity of a return

f

ir trunk duct is 600 fpm, and should not exceed 700 fpm.

a

The recommended and maximum air velocity of a return air

branch is 600 fpm.

The equal friction chart, as published by ASHRAE and HRAI,

is the basis for the various air duct calculators available

through heating supply companies.

IMPORTANT

The return air system is equally as important as the

supply air system. An undersized return air system will

prevent sufficient quantities of air from reaching the

supply air system, properly sized or otherwise, and will

consequently reduce the service life of the furnace and

its components.

AIR CONDITIONING

This furnace may be used as part of an air conditioning

system. The furnace wiring and control system are “air

conditioning ready”. There are the following factors to

consider:

• The air conditioning evaporator coil must be

downstream of the heat exchanger. The cooled air

passing over the warm ambient air inside the heat

exchanger tubes can cause condensation inside the

tubes, resulting in corrosion and premature failure.

• A parallel duct system can be installed to direct the air

from the furnace through the evaporator coil only. Use

dampers or other means to bypass the heat exchanger.

If [summer/winter] dampers are used, they should be

interlocked to prevent system operation unless the

dampers are in the full open or full closed position.

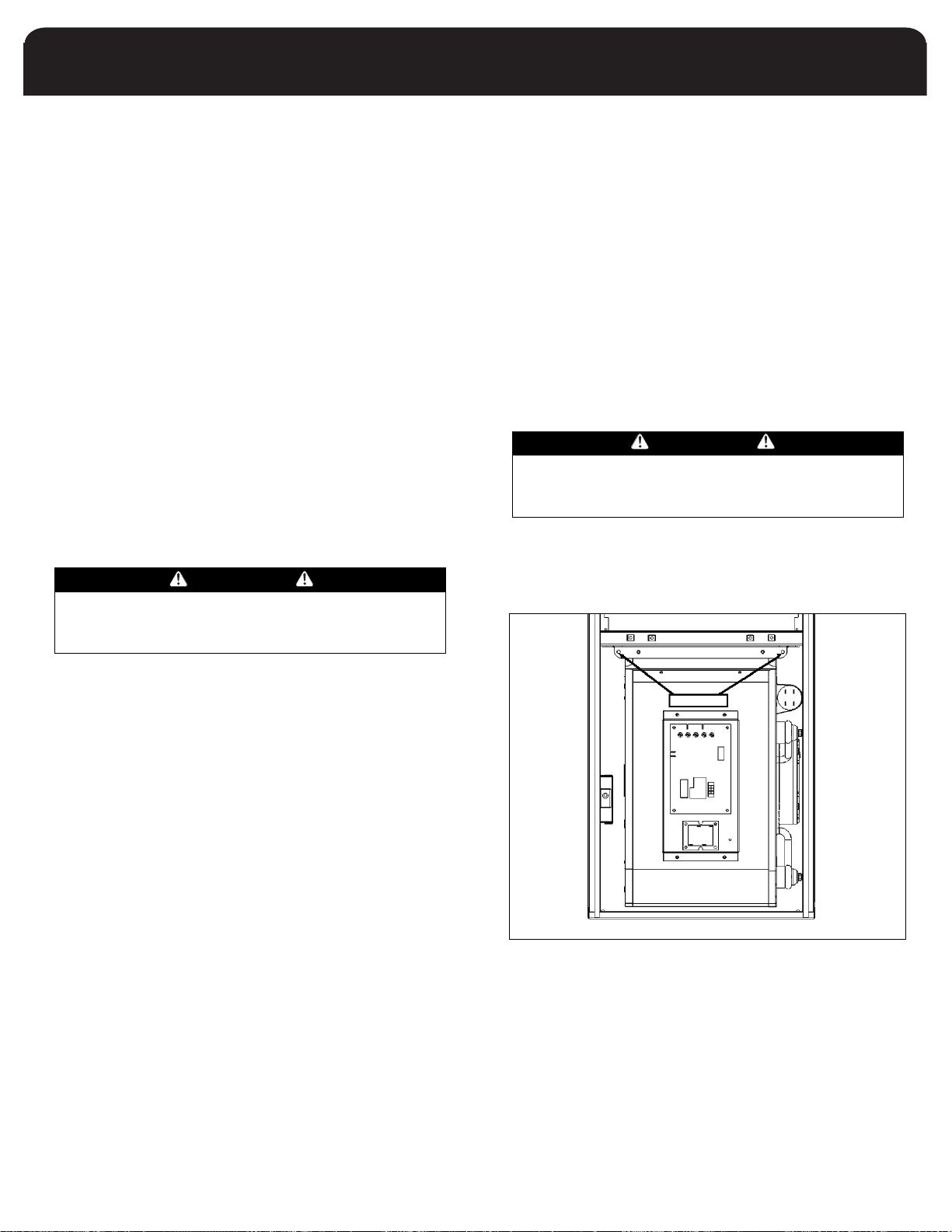

INSPECTION / ACCESS PANEL

If an air conditioning coil is not to be used in the supply air

plenum, it is recommended that the outlet duct be provided

with a removable access panel, which is accessible when

installed so the heat exchanger may be viewed for possible

openings using light assistance or a probe that can be

inserted for sampling the air stream. The access cover must

be fabricated in such a manner as to prevent leaks.

4

Page 7

LOCATION of UNIT

General

1. The furnace is not weatherized. Select a dry indoor

location.

2. Select a location where the exhaust and combustion air

iping can be routed between the furnace and their

p

terminations with a minimum of lengths and fittings.

Be sure to check that the proposed termination location

will meet code requirements with respect to location

and minimum clearances. (See venting section for

inimum and maximum limits.)

m

. Select a location as near as possible to the existing or

3

proposed duct system.

4. The furnace location must permit access for servicing,

and be within the clearance to combustibles guidelines

as marked on the appliance rating plate.

5. The furnace should be installed on a firm base when

installed in the upflow position. This is typically a

concrete floor if installing the furnace in a basement.

6. If the furnace is being installed so that the return air

will enter through the bottom, the perimeter of the

furnace must be properly supported.

7. When installed in the horizontal position, the furnace

may be supported from the bottom, or suspended.

8. When installed in the down flow position on a

combustible floor, subbase kit #30476 is required

(contact manufacturer for availability).

9. The furnace location must have provisions for

condensate drainage. If a suitable drain is unavailable

near the furnace, a condensate pump must be used. The

condensate pump drain tubing must not terminate

outdoors; similar to some air conditioning condensate

installations. Be sure to select a condensate pump that

has been approved for furnace condensate

applications.

10. The furnace must be installed level, or tilted slightly

down in the front, to allow for the proper drainage of

condensate. The furnace may shut down during

operation if the condensate does not drain freely away

from the furnace.

11. If the furnace is installed in an area where freezing may

occur, a garage, an attic, a crawl space or any

unconditioned space, steps must be taken to protect

the condensate trap and drain line from freezing. One

possible measure could be to use a self-regulating 5 or

6 watt per foot heat tape covered with a jacket of

insulation. Heat tapes are available in plumbing supply

houses.

Other Considerations:

1. This furnace is not to be used for temporary heating of

buildings or structures under construction.

2. If this furnace is to be used with air conditioning and is

o be installed in an area over a finished ceiling or

t

living area, install a field fabricated auxiliary drain pan

under the furnace to protect that area from accidental

condensate spills. The auxiliary pan should be large

enough to collect accidentally spilled condensate from

he air conditioning evaporator coil assembly if

t

applicable. Follow local codes.

3. These furnaces are approved for installation in attics,

alcoves, utility rooms, closets and crawlspaces. If this

furnace is to be installed in a utility room, be sure that

it is located in such a way as to allow access for

servicing or the removal of any other appliance, (hot

water heater, for example).

4. If the furnace is to be installed in a residential garage,

the burners must be a minimum of 18 inches (460 mm)

above the floor

5. If the furnace is to be installed in a commercial (repair)

garage, the burners must be a minimum of 4.5 feet

(1375 mm) above the floor.

6. The furnace must be protected from physical damage

by metal barriers or other acceptable means.

7. If the furnace is to be located in an area where the

combustion air is laden with chemical compounds such

as bromine, chlorine or fluorine, as may be found in

swimming pool chemicals, laundry detergents, etc., use

outdoor air for combustion. These compounds when

exposed to flame, form acids, which attack the heat

exchanger and other components.

A partial list of these contaminants includes:

• Aerosols, particularly CFC based aerosols

• Air fresheners

• “Airplane” glue and similar cements

• Ammonia, as is commonly found in permanent wave

solutions used in women’

• Anti-static fabric softeners used in clothes dryers

• Carbon tetrachloride

• Chlorinated cleaners and waxes

• Chlorine and bromine based swimming pool

chemicals and treatments

• De-icing salts or chemicals, rock salt, etc.

• Dry cleaning solutions such as perchloroethylene

• Halogen based refrigerants including R-12 and R-22

• Hydrochloric acid, muriatic acid, or other acid based

masonry washing compounds

• Polyurethane and similar derivatives fumes

• Printer’s inks, paint removers, furniture strippers,

varnishes, varsol, toluene, etc.

• Water softener salts and chemicals

.

s hair dressing salons

5

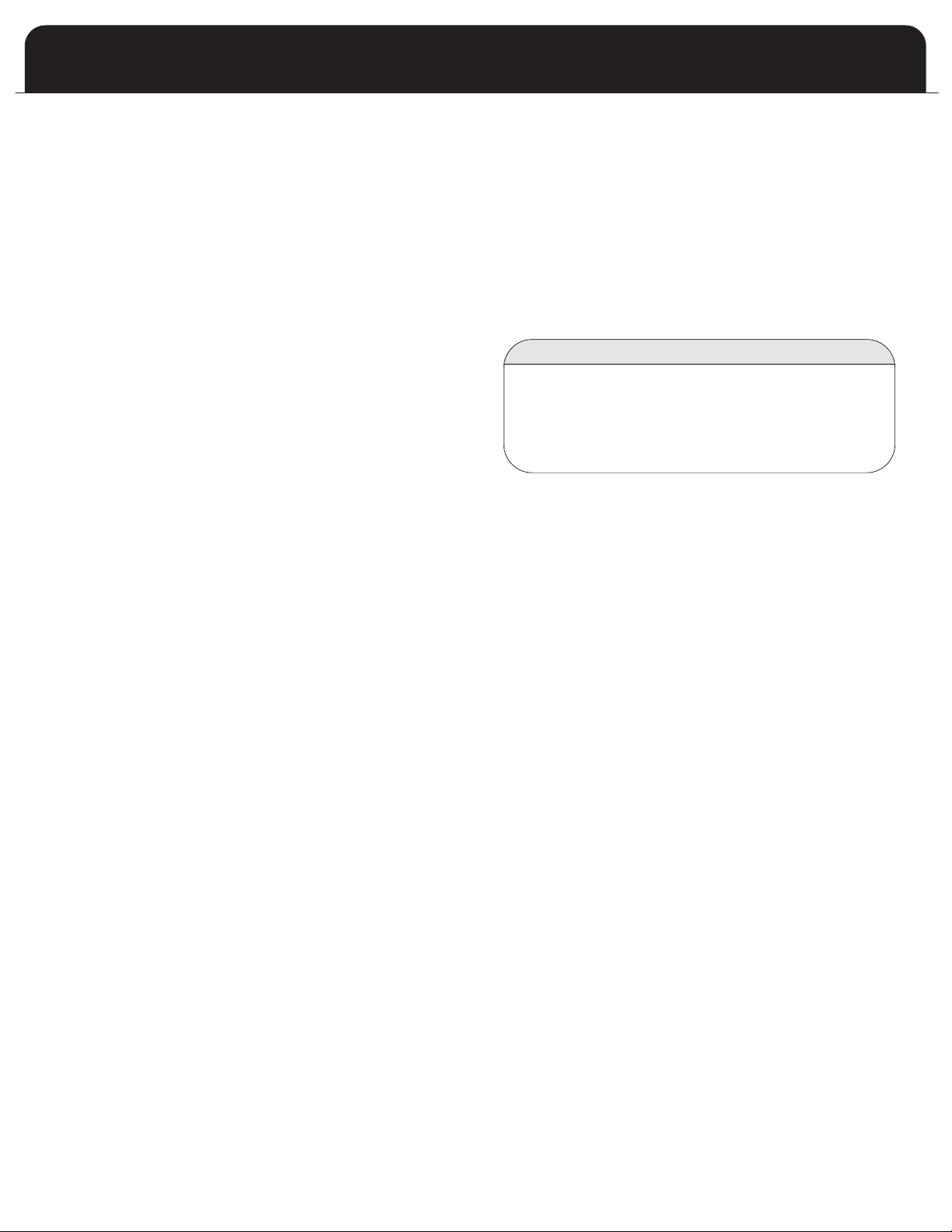

Page 8

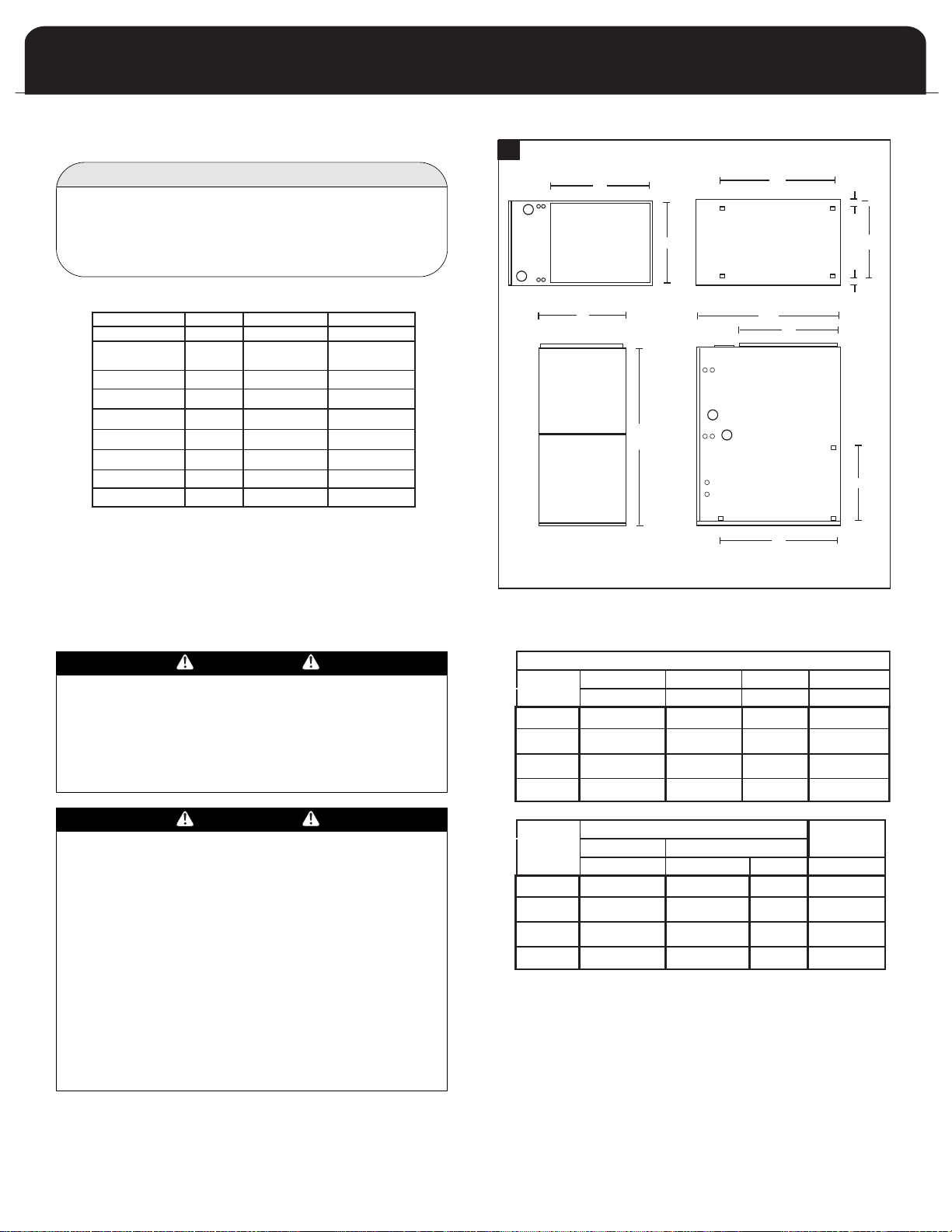

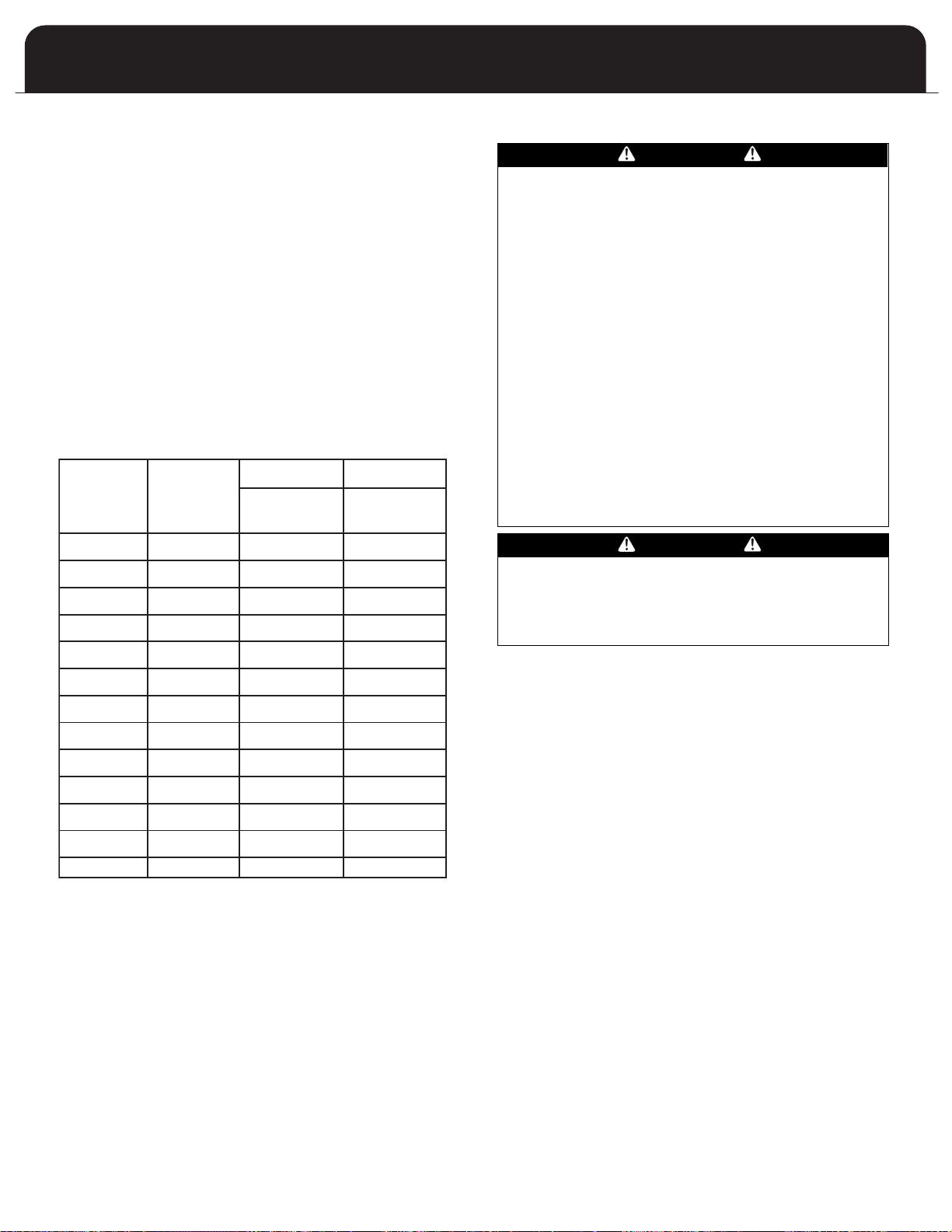

G

A

C

G

B

F

E

D

J

L

L

K

1

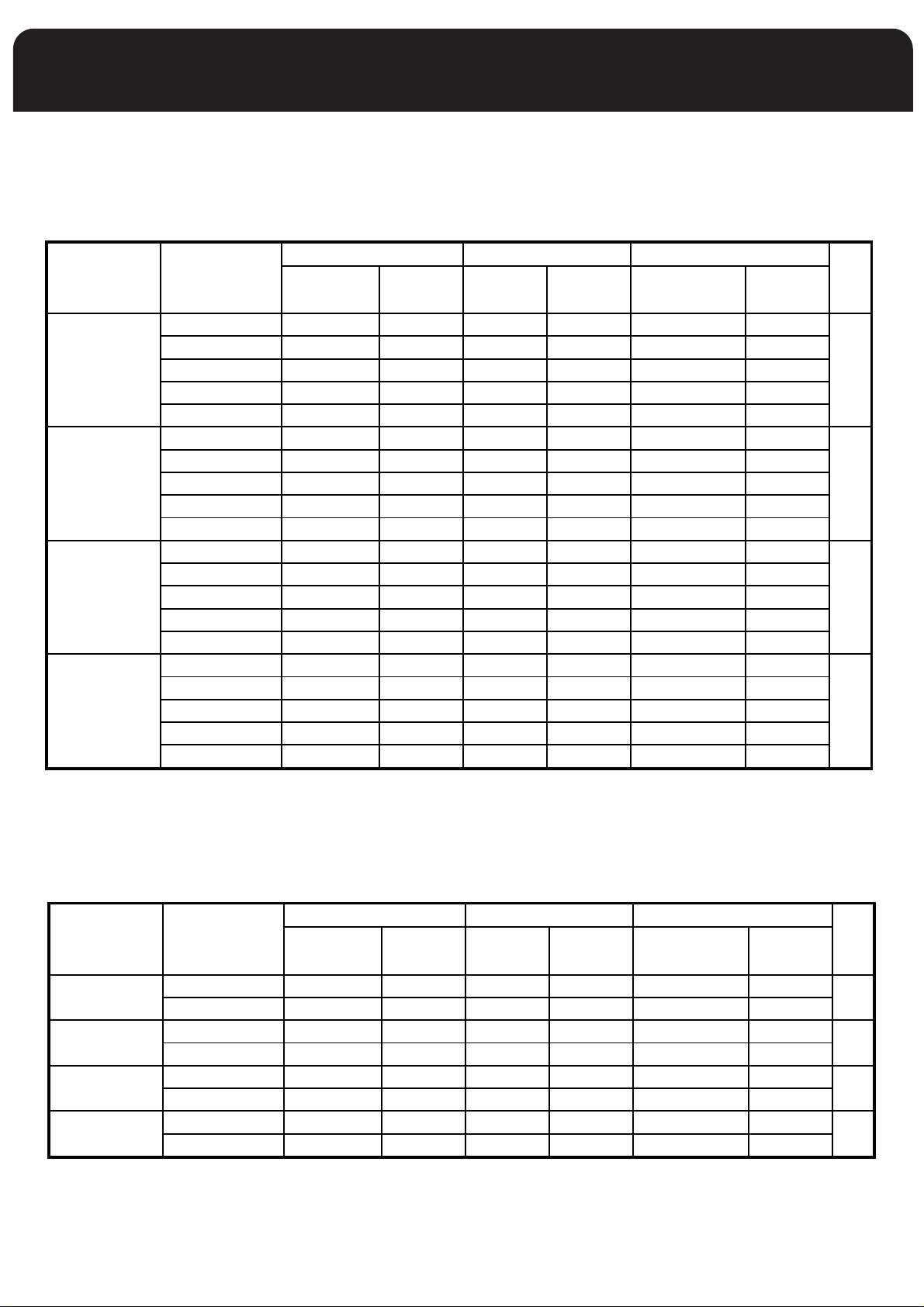

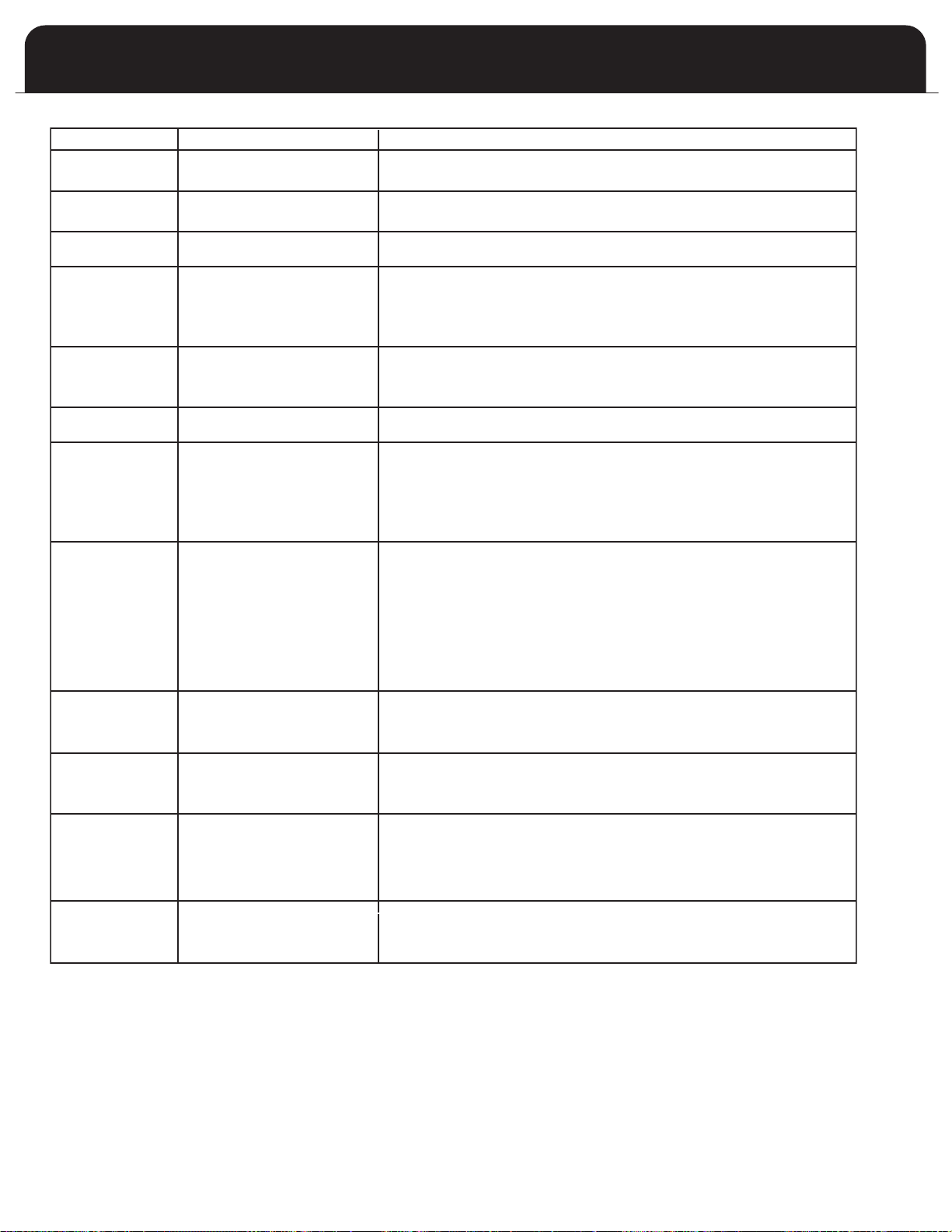

DIMENSIONS (Inches)

MODEL

INPUT

WIDTH DEPTH HEIGHT SUPPLY

ABCFx G

RETURN

SIDE BOTTOM

D x E J x K L H

54,000

72,000

90,000

108,000

54,000

72,000

90,000

108,000

17.5

20.5

20.5

24.5

14 x 22 16 x 19 3/4 2

2

2

2

14 x 22 19 x 19 3/4

14 x 22 19 x 19 3/4

14 x 22 23 x 19 3/4

VENT

29

29

29

29

40

40

40

40

16.5 x 19

19.5 x 19

19.5 x 19

24 x 19

CLEARANCES

0" 0" 0"

LOOKING AT UNIT AS INSTALLED

Table 2 provides the certified clearances to combustibles.

IMPORTANT

This furnace requires a minimum of 24-inches of front

clearance for service purposes. For this purpose, service

learance takes precedence over clearance to

c

combustibles.

TABLE 2: CLEARANCES TO COMBUSTIBLES

TOP

PLENUM

TOP/BOTTOM

PLENUM SIDES

UNIT FRONT

UNIT BACK

UNIT SIDES

UNIT BASE

UNIT FLUE PIPE

ENCLOSURE

* 24" REQUIRED FOR SERVICE

** SUPPLY AIR END / RETURN AIR END

*** CERTIFIED FOR CLOSET INSTALLATION ON COMBUSTIBLE FLOORING

**** CERTIFIED FOR INSTALLATION ON COMBUSTIBLE FLOORING ONLY WHEN INSTALLED

ON SPECIAL BASE PART #30476

UPFLOW

CLOSET

COUNTERFLOW

1"

1" 1"

0.5"

0" *

0" 0"

0" ***

0"

0"

0.5" 0.5"

0" *

0" ****

0"

CLOSET

See the appliance rating plate affixed to the

furnace for specific model number, serial

number and clearance to combustibles

information.

HORIZONTAL

2"

2.5"

0" *

1" **

0"

0"

CLOSET

ALL DIMENSIONS IN INCHES

IGURE 2: DIMENSIONS

F

TABLE 3: DIMENSIONS

COMBUSTIBLE MATERIAL MUST NOT BE PLACED ON OR

AGAINST THE FURNACE JACKET.

PLACEMENT OF COMBUSTIBLE MATERIALS ON, AGAINST

OR AROUND THE FURNACE JACKET CAN CAUSE AN

EXPLOSION OR FIRE RESULTING IN PROPERTY DAMAGE,

PERSONAL INJURY OR LOSS OF LIFE.

THE AREA AROUND THE FURNACE MUST BE KEPT CLEAR

AND FREE OF ALL COMBUSTIBLE MATERIALS INCLUDING

GASOLINE AND OTHER FLAMMABLE VAPORS AND

LIQUIDS.

THE HOMEOWNER SHOULD BE CAUTIONED THA

FURNACE AREA MUST NOT BE USED AS A BROOM

CLOSET OR FOR ANY OTHER STORAGE PURPOSE.

UPFLOW FURNACES ARE DESIGN CER

INSTALLATION ON COMBUSTIBLE FLOORS. THIS SHALL

BE INTERPRETED AS A WOOD FLOOR ONLY.

THE FURNACE MUST NOT BE INSTALLED DIRECTLY ON

CARPETING, VINYL TILE, OR OTHER COMBUSTIBLE

MATERIAL EXCEPT WOOD. INSTALLATION ON

COMBUSTIBLE MATERIAL CAN RESULT IN FIRE, CAUSING

PROPER

DANGER

DANGER

TY DAMAGE, PERSONAL INJUR

T THE

TIFIED FOR

Y OR DEA

TH.

6

Page 9

DUCTWORK

Proper airflow is required for the correct operation of this

furnace. Insufficient airflow may cause erratic operation,

ould cause the furnace to cycle on the high temperature

c

limit, and may damage the heat exchanger. Excessive

airflow may result in an excessively noisy duct system and

may result in undesirable consequences such as creating

uncomfortable drafts and causing drapes or curtains to

low around.

b

If air conditioning is to be used with the furnace, the duct

system must be capable of delivering the correct amount of

irflow for each system.

a

The ductwork should be sized and constructed in

accordance with accepted industry standards. Duct sizing

and construction information may be obtained from:

• A.C.C.A. (Air Conditioning Contractors of America)

• A.S.H.R.A.E. (American Society of Heating,

Refrigeration and Air Conditioning Engineers)

• H.R.A.I. (Heating, Refrigerating and Air Conditioning

Institute (Canada)

• S.M.A.C.N.A. (Sheet Metal and Air Conditioning

Contractors’ National Association (United States)

All of the above professional organizations have duct sizing

manuals available.

The total static pressure drop of the air distribution system

should not exceed 0.5 inches water column.

Guide:

Filter free area (in2) = 144 x (CFM / desired velocity (fpm))

IMPORTANT

Some high efficiency filters have a greater than normal resistance to airflow. This can adversely affect furnace operation. Pressure check the static differential

from before the filter to the supply.

NOTE

When calculating an air filter size use the free air not

the advertised size.

NOTE

UNITS FOR 4 AND 5 TON CF AIR CONDITIONING MUST

HAVE DUAL RETURN AIR INLETS FOR OPTIMAL

AIRFLOW AND AIR FIL

STATED BY THE FILTER MANUFACTURER, FOR

EFFECTIVE AIR FILTRATION, ASSUME A MAXIMUM

VELOCITY OF 300 FPM FOR DISPOSABLE TYPE FIL

OR 600 FPM FOR PERMANENT TYPE FILTERS.

TION. IF NOT SPECIFICALLY

TRA

TERS,

WARNING

DO NOT, UNDER ANY CIRCUMSTANCES, CONNECT

RETURN OR SUPPLY AIR DUCTWORK TO OR FROM ANY

THER HEAT-PRODUCING DEVICE SUCH AS A FIREPLACE

O

INSERT, STOVE, ETC. DOING SO MAY RESULT IN FIRE,

CARBON MONOXIDE POISONING, EXPLOSION,

PERSONAL INJURY, LOSS OF LIFE, OR PROPERTY

AMAGE.

D

Ductwork Steps:

1. Position the furnace to minimize ductwork length and

fittings.

2. Cut open a return air inlet. The choices are:

a) either side

b) furnace bottom

c) any combination, i.e. two sides or a side and the

bottom.

In all cases, cut the inlet air opening the full width of

NOTE

When two return air inlets are used, both must be

equipped with filters.

CAUTION

DO NOT USE THE REAR PANEL AS A RETURN AIR INLET.

THERE IS INSUFFICIENT AREA TO PERMIT ADEQUATE

AIRFLOW.

3. Install the filter rack(s) (field supplied).

4. Connect the return air duct or fitting to the furnace. The

connection should be as air tight as possible to prevent

entraining combustion gases from an adjacent fuel

burning appliance, or entraining combustion air for this

furnace .

5. Ensure that there is adequate space and accessibility for

the air filter

6. If an air conditioning evaporator coil is required,

position it on the top of the furnace. Ensure that no air

can bypass the evaporator coil.

7. Connect the supply air plenum to the supply air outlet.

Flexible duct connectors are an effective device to

prevent the telegraphing of mechanical noise from the

furnace to other parts of the home via the ductwork. If

using flexible connectors, ensure that the adjoining

duct is independently supported.

Adequate provisions for combustion and ventilation air

must be in accordance with ANSI Z223.1 (NFP

5.3 "Air for Combustion and Ventilation" in the United

States, and CAN/CGA B149 in Canada. Check with local

authorities for any additional building codes, bylaws or

regulations.

.

A 54), section

7

Page 10

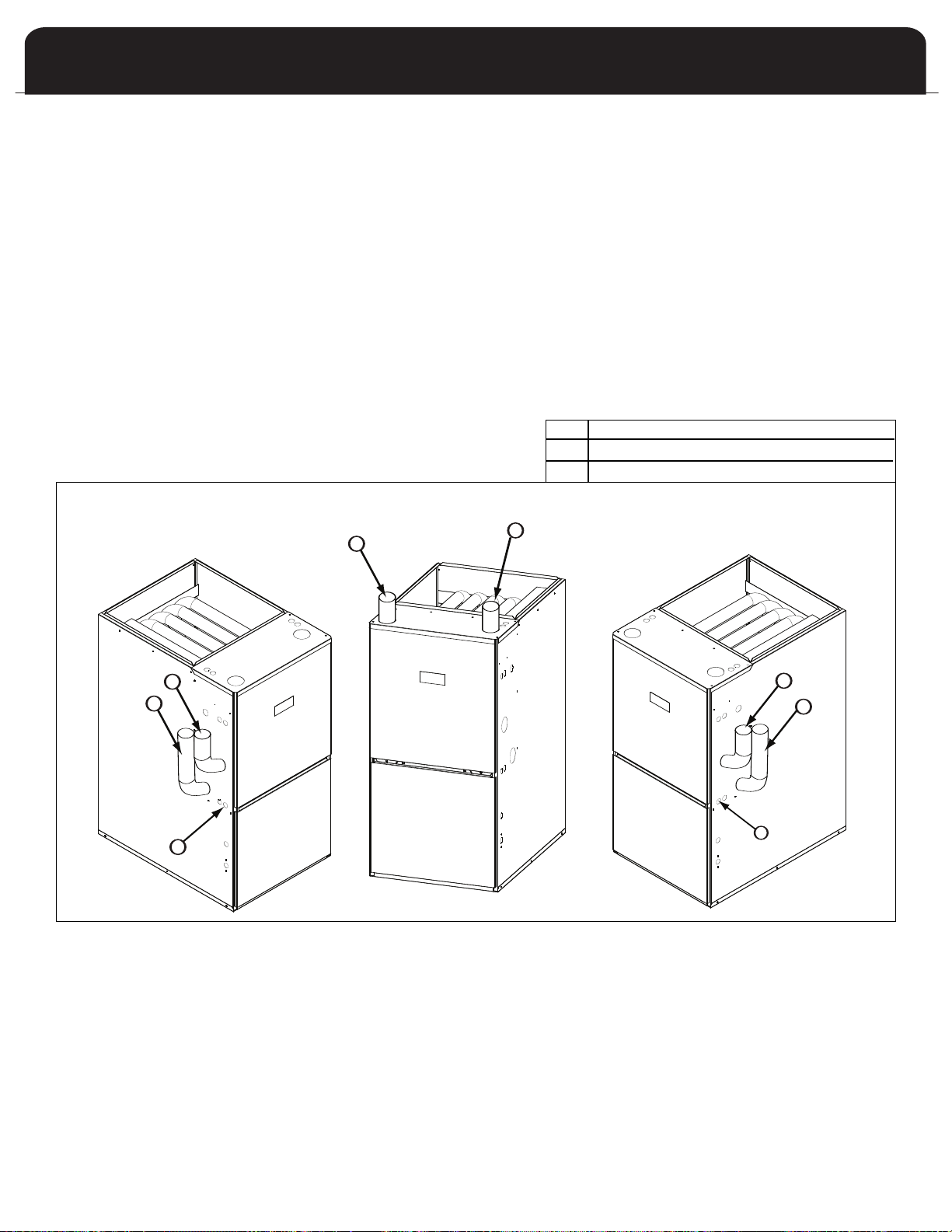

INSTALLATION POSITIONS

he furnace can be installed in any of four positions:

T

• Upflow

• Downflow

• Horizontal left

• Horizontal right

aintain clearances to combustibles as outlined in Table 2.

M

Support the furnace cabinet to prevent twisting or

sagging.

General Considerations

When choosing an installation position the installer must

consider the following connections:

• Combustion air intake

• Exhaust vent

• Gas pipe

• Electrical wiring

• Condensate drain trap

Also consider the air conditioning connections, a/c drain,

access to filter(s) and access to furnace and a/c for repair.

The blower compartment should be completely isolated

from the burner compartment. In tight rooms with other

combustion devices, the blower compartment must be

completely isolated from the room. The combustion

compartment must also be completely isolated from the

room (unless non-direct vent). Sometimes the knockout

tool will punch too deep and open holes. Use caulking on

the inside of the cabinet to seal any holes. Insure that the

combustion door gasket is in good condition.

IMPORTANT

Always secure or support the exhaust vent and

combustion air inlet piping to the floor joists or rafters

to avoid sagging and possible fatigue of venting

materials. This ensures proper drainage and

preventing spilling of the products of combustion into

the building.

IMPORTANT

If the pipe and fittings are to be other than PVC, use

the proper cleaner, primer and cement for the

dissimilar materials.

IMPORTANT

Drains and traps of furnaces installed in spaces

subjected to freezing temperature must also be

protected against freezing.

IMPORTANT

lean and de-burr all pipe cuts. The shavings must not

C

be allowed to block the exhaust, combustion air inlet

r condensate drain lines.

o

Combustion Air Inlet Connection

The combustion air inlet fitting is a 2” PVC Socket to Pipe

Thread adapter. Chose the intake location and open the

appropriate knock out. Install the adapter to the exterior

anel using the gasket on the outside of the panel and the

p

locknut on the inside of the panel.

IMPORTANT

If the pipe is increased in size with a reducer it must

be on a vertical section of the pipe to facilitate draining the vent. Reducing the size of pipe to exit the

house (as shown on page 19, Figures 4 and 6), the

reducer can be on the horizontal.

WARNING

THERE MUST NOT BE ANY OPENINGS BETWEEN THE

BLOWER DIVISION PANEL AND THE COMBUSTION

COMPARTMENT. THE BLOWER COMPARTMENT IS UNDER

GREATER SUCTION THEN THE COMBUSTION

COMPARTMENT AND CAN PULL COMBUSTION AIR FROM

THE BURNERS AND CAUSE INCOMPLETE COMBUSTION

AND ERRATIC FURNACE OPERATION.

IMPORTANT

Keep pressure switch hose above heat exchanger drain

and exhaust port.

Exhaust V

The exhaust vent must be clamped to the exterior panel(s)

with the clamp provided. Place the gasket between the

clamp and the side panel. Tighten clamp and fasten in

place using the three screws provided.

The clamp should secure the vent pipe to prevent internal

damage if the vent pipe is tampered with.

THE VENT MUST BE CLAMPED TO THE FURNACE PANEL

USING THE GASKET AND CLAMP PROVIDED.

THE INTAKE MUST USE THE THREADED PVC

CONNECTOR WITH THE GASKET AND LOCK NUT.

ent Connection

W

ARNING

8

Page 11

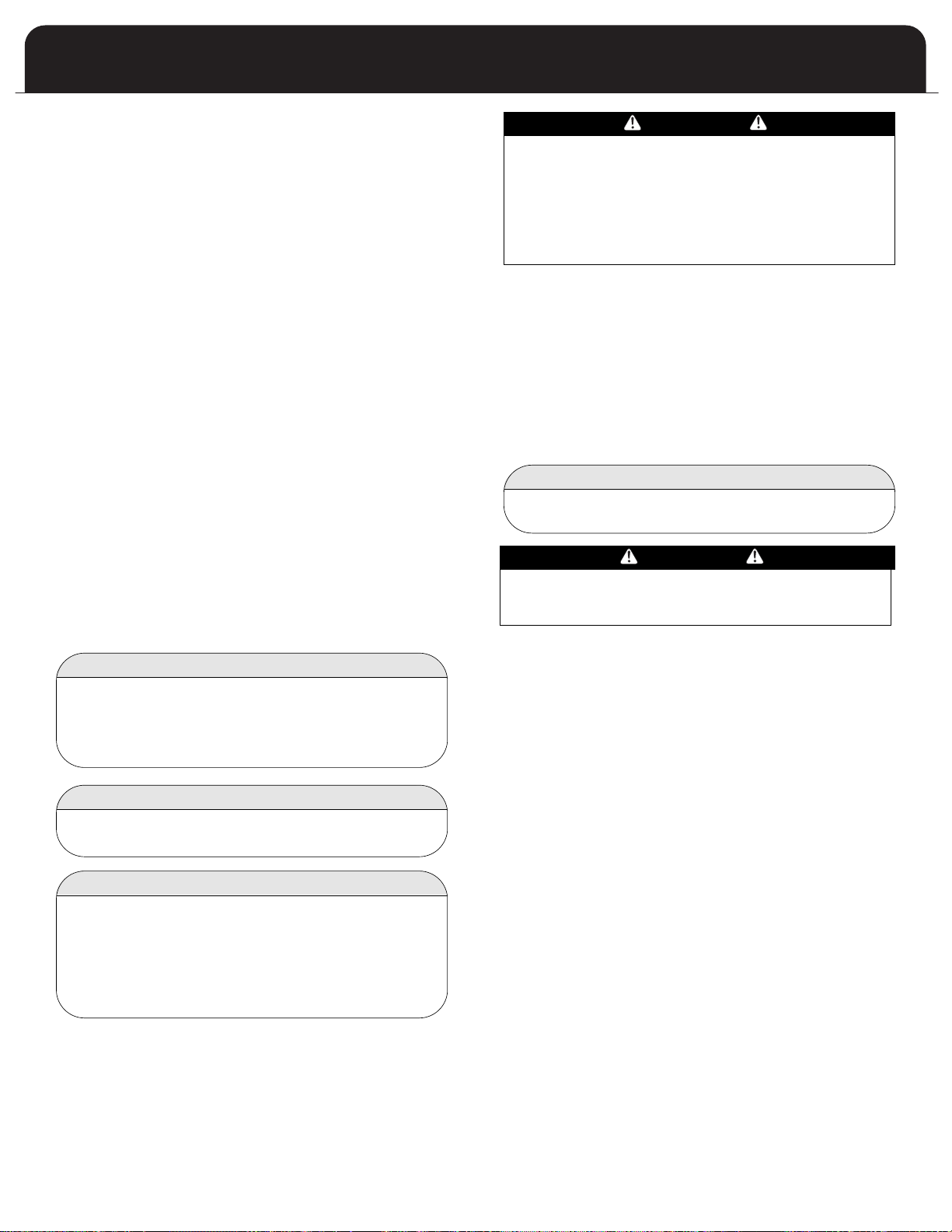

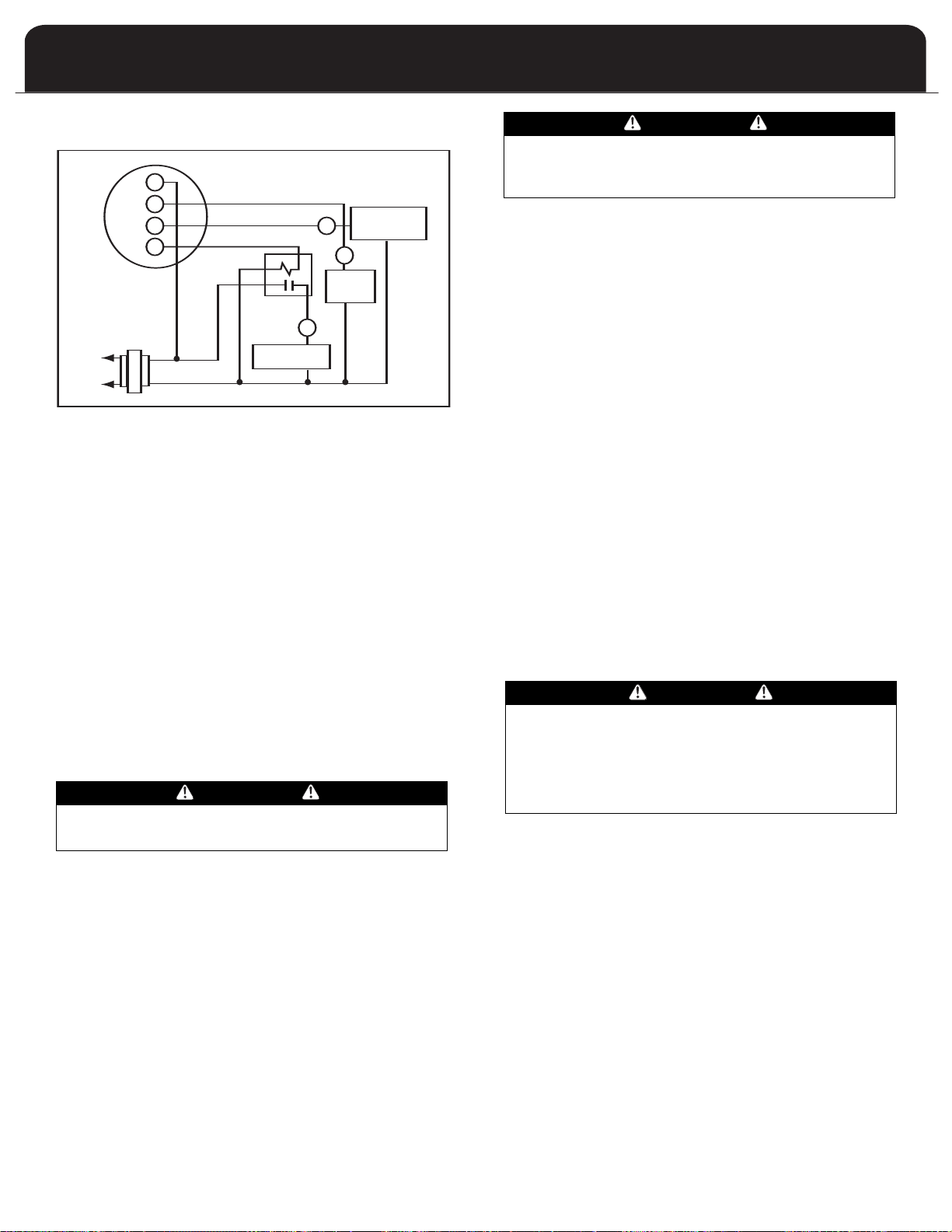

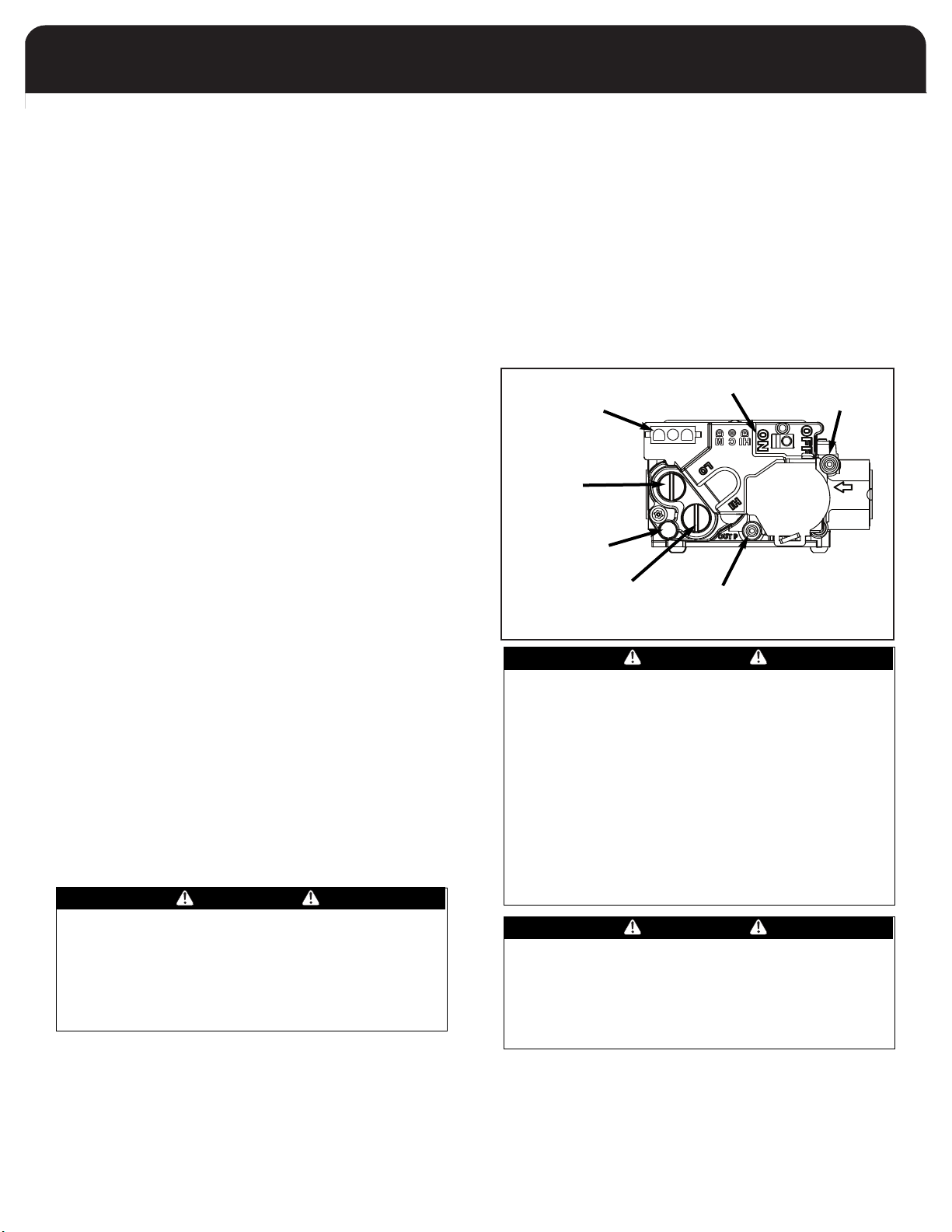

Instructions for Re-orienting Air Inducer

FIGURE A : RIGHT INDUCER POSITION

FIGURE B : LEFT INDUCER POSITION

SUGGESTED METHOD FOR

SUSPENDING HORIZONTAL FURNACE

ALLOW ENOUGH ANGLE

IRON OVERHANG TO

PERMIT OPENING THE

BLOWER DOOR

3/8 INCH THREADED ROD

2 INCH ANGLE IRON

JAM NUTS

LOCK WASHER

FLAT WASHER

SUPPLY AIR PLENUM

RETURN AIR PLENUM

SUSPENDED INSTALLATION

This furnace comes assembled ready for left side or vertical

venting. Rotate the inducer 180 degrees to exit the right

hand side.

1. Disconnect inducer wire connections.

2. Remove pressure switch hoses.

3. Remove pressure switches.

4. Remove 4 inducer screws

5. Remove inducer.

6. Reverse the bands on the rubber drain coupling so the

screws are accessible if necessary. (Do not reverse the

drain coupling.) Confirm that directional arrows on

drain coupling point away from inducer.

7. Remove the appropriate knock out.

8. Reinstall the inducer in the correct orientation with 4

screws removed in step 1.

9. Reinstall the pressure switches so that the switches and

hose is above the heat exchanger drain.

10. Complete the external venting as installation requires.

11. Rotate the drain coupling so the drain holes are angled

downward and tighten coupling bands.

12. Tighten the vent clamp and secure in place using the

screws provided.

INSTALLATION POSITIONS

Non-Suspended Installation

Maintain clearances to combustibles as outlined in Table 2

on page 6. The furnace must be supported in such a way

as to not allow twisting or sagging of the cabinet.

Horizontal Suspended Installation

The furnace may be suspended in either the horizontal right

or left position by field fabricated a cradle of angle iron and

threaded rod. Secure the furnace with 2 inch minimum

slotted angle or equivalent, as shown in figure below. The

furnace must be supported in such a way as not to allow

twisting or sagging of the cabinet. Position the supports so

as not to interfere with accessing the burner and blower

compartments.

9

Page 12

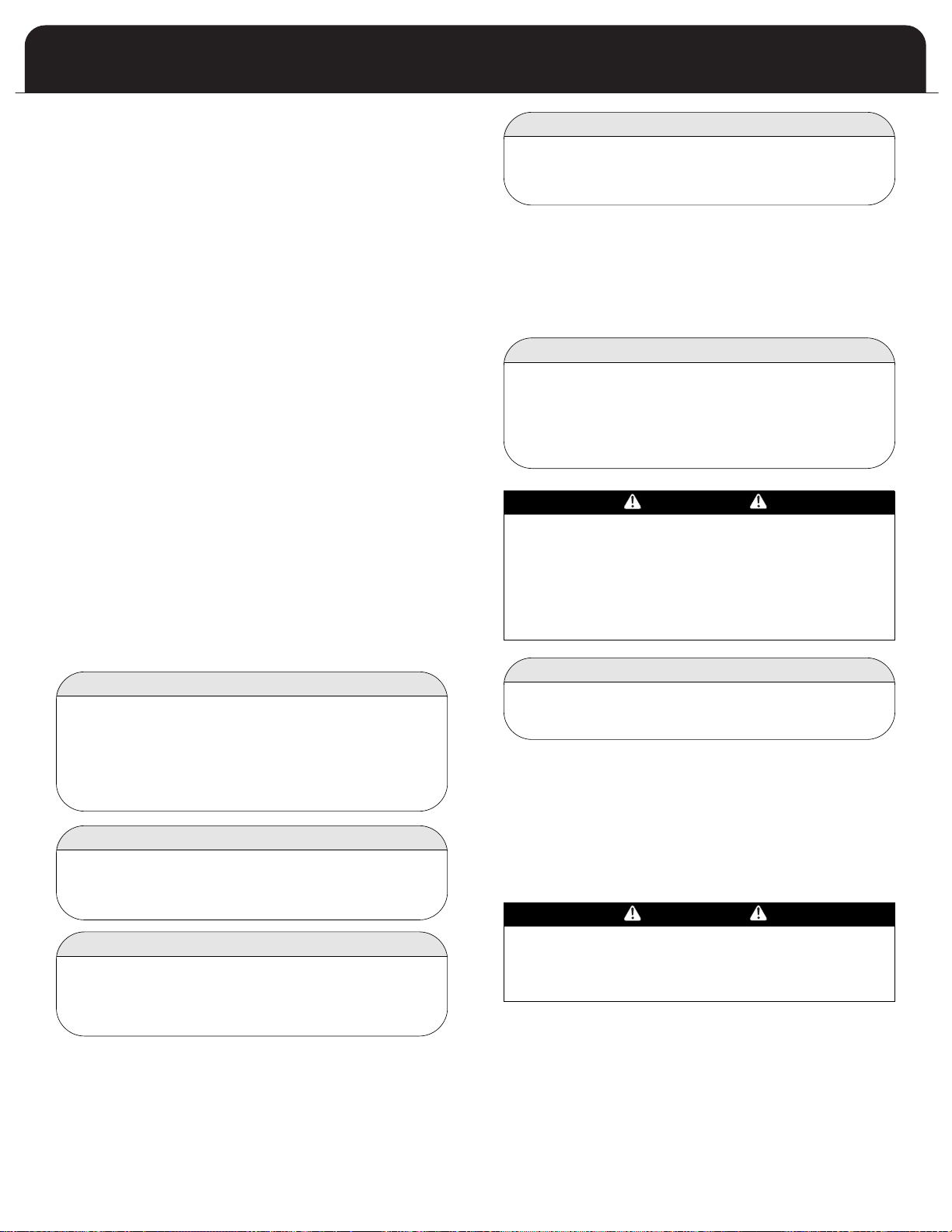

C

C

A

B

A

B

A

B

Upflow Installation

The combustion air and exhaust vent may exit through

the top, left or right side of the cabinet when viewed in

the upflow position. The inducer is installed so that the

exhaust vent may exit the top and left sides without

requiring rotation.

f exhaust vent exits the top panel, use the two street

I

elbows to route the vent. One elbow secured to the

inducer drain connector, will angle toward the front of

cabinet with the second nested inside directed towards

the top panel. (The 108,000 BTUH will require an

extension between the inducer and the first elbow that

is not provided.)

If exhaust vent exits the left-side panel the pipe can be

routed straight outside the cabinet.

exists the right-side panel the inducer requires

rotation.

The exhaust vent pipe exiting the cabinet in any

installation should be long enough to install the vent

clamp on the outside of the cabinet.

If exhaust vent

A

COMBUSTION AIR

B

EXHAUST VENT

C

CONDENSATE DRAIN

10

Page 13

Downflow Installation

When the furnace is installed in the downflow position

the combustion air and exhaust vent may exit through

the left or right side of the cabinet (when viewed in the

upflow position.). The inducer is installed so that the left

side exits require no rotation.

If exhaust vent exits the left-side panel the pipe can be

routed straight outside the cabinet.

If exhaust vent exists the right-side panel the

inducer requires rotation.

The pipe exiting the cabinet in any installation should be

long enough to install the vent clamp on the outside of

the cabinet.

WARNING

WHEN INSTALLED IN THE DOWNFLOW POSITION ON A

COMBUSTIBLE FLOOR, SUBBASE KIT #30476 IS

REQUIRED. FAILURE TO INSTALL SUBBASE KIT COULD

RESULT IN FIRE, DEATH OR SERIOUS INJURY.

The opening in the floor must provide adequate clearances

to the combustible material.

A half-inch of clearance will be required between the

plenum and the combustible material. If installed on a

non-combustible material, zero clearance is required.

In the downflow installation, this furnace can only vent

through the left or right side of the furnace.

The condensate drain trap can be mounted on the right or

left side.

B

B

A

D

C

C

A

COMBUSTION AIR

B

EXHAUST VENT

C

CONDENSATE DRAIN

D

SUBBASE KIT - REQUIRED WHEN

A

D

INSTALLED IN THE DOWNFLOW POSITION

ON A COMBUSTIBLE FLOOR

11

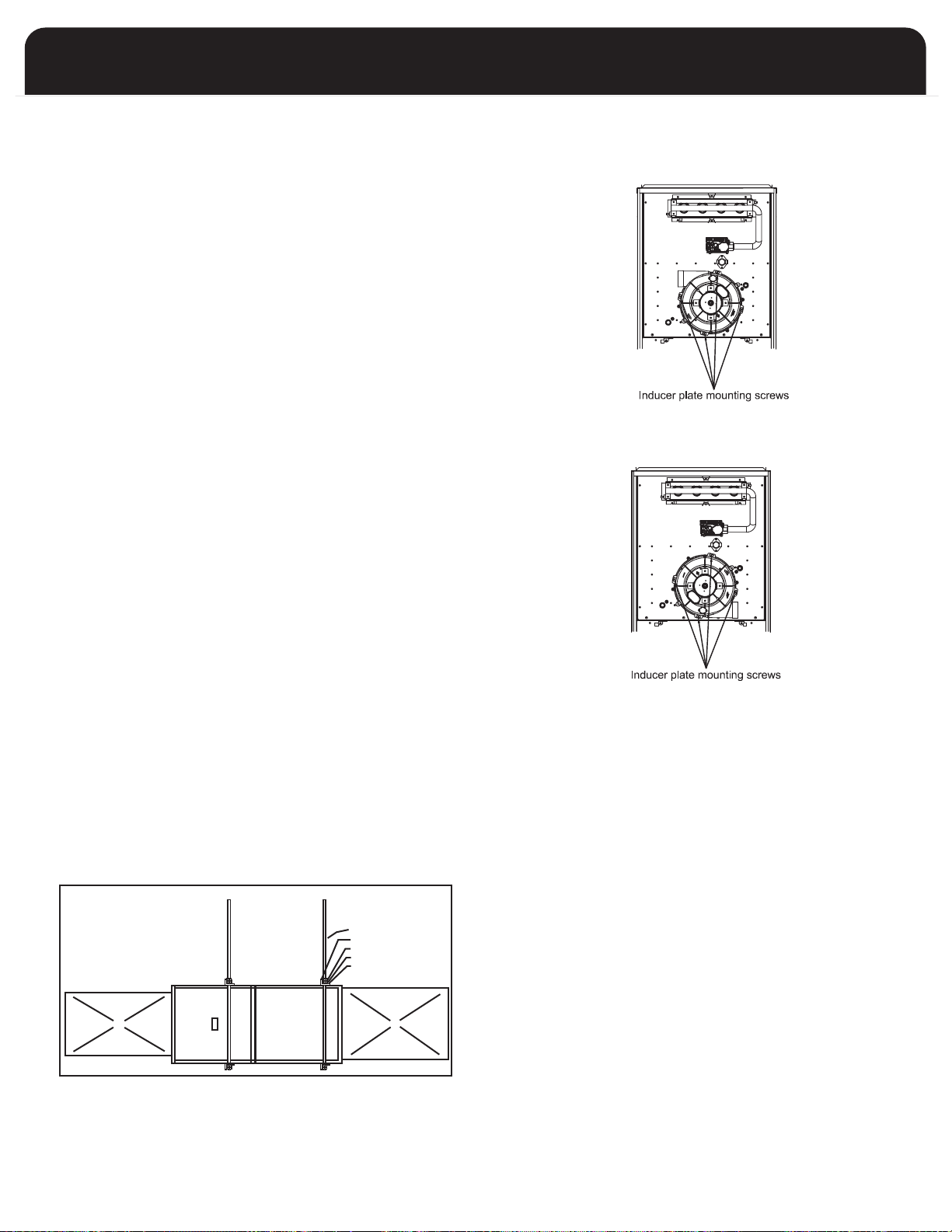

Page 14

C

A

B

A

A

B

B

B

A

C

C

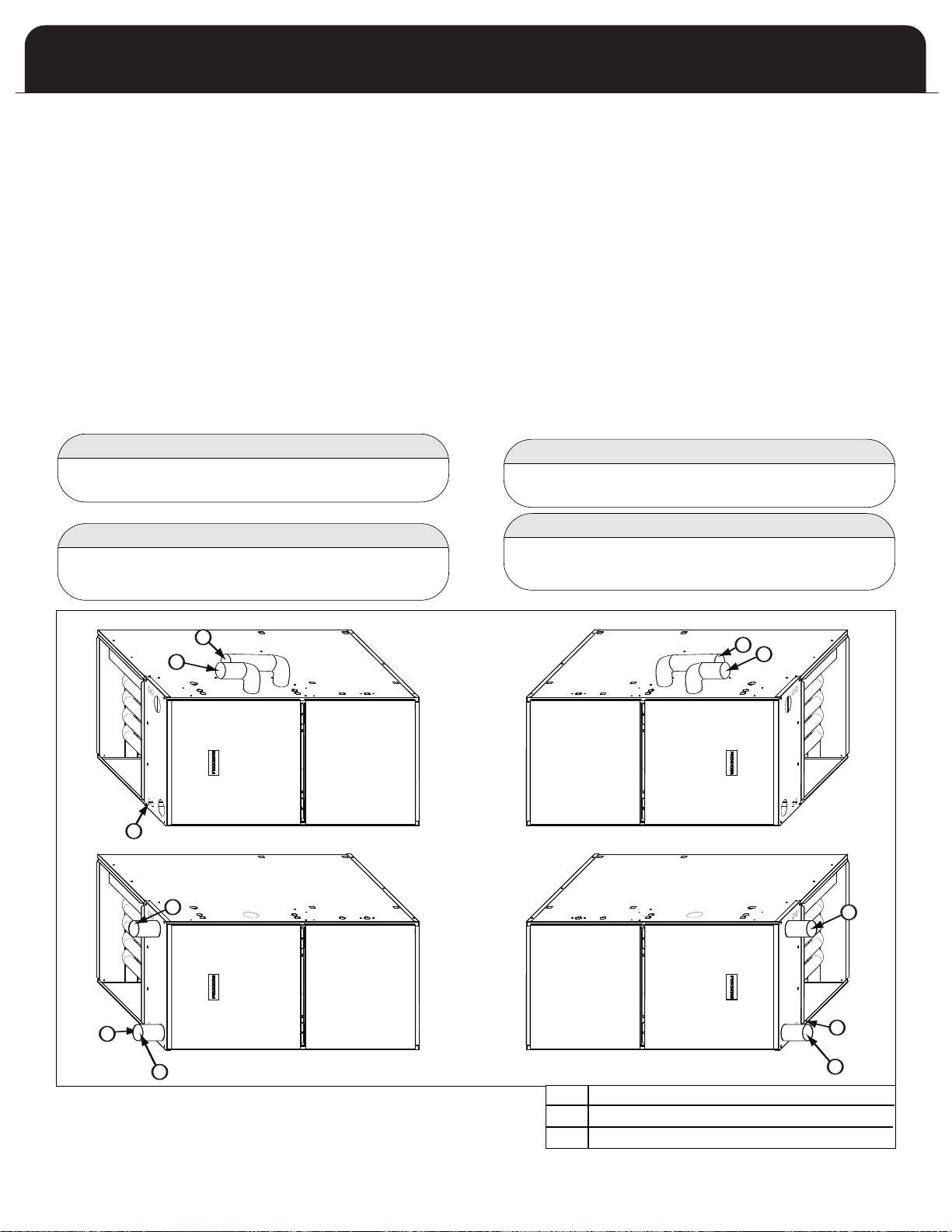

Horizontal Left Installation

In the horizontal left installation the combustion air and

exhaust vent may exit through the top or left side of the

cabinet (when viewed in the upflow position). It is not

permissible to vent downwards. The inducer is installed

so that the top and left side exits require no rotation.

f exhaust vent exits the top panel, use the two street

I

elbows to route the vent. One elbow secured to the

inducer drain connector, will angle toward the front of

cabinet with the second nested inside directed towards

the top panel. (The 108,000 BTUH will require an

extension between the inducer and the first elbow that

is not provided.)

If exhaust vent exits the left-side panel the pipe can be

routed straight outside the cabinet.

The pipe exiting the cabinet in any installation should be

long enough to install the vent clamp on the outside of

the cabinet.

Horizontal Right Installation

In the horizontal right installation the combustion air

and exhaust vent may exit through the top or right side

of the cabinet (when viewed in the upflow position). In

the horizontal right installation, it is not permissible to

vent downwards.

he right side exit is used.

t

If exiting the top panel, use the two street elbows to

route the vent. One elbow secured to the inducer drain

connector, will angle toward the front of cabinet with

the second nested inside directed towards the top panel.

(The 108,000 BTUH will require an extension between

the inducer and the first elbow that is not provided.)

If exiting the right-side the pipe can be routed straight

outside the cabinet after the inducer has been rotated.

The pipe exiting the cabinet in any installation should be

long enough to install the vent clamp on the outside of

the cabinet.

The inducer will require rotation if

NOTE

It is not permissible to use a rear of the

furnace as a return.

IMPORTANT

The furnace must be installed level or sloping towards

the front to facilitate proper drainage.

NOTE

It is not permissible to use a rear of the

furnace as a return.

IMPORTANT

The furnace must be installed level or sloping towards

the front to facilitate proper drainage.

A

COMBUSTION AIR

B

EXHAUST VENT

C

CONDENSA

12

TE DRAIN

Page 15

CASE 1:

FURNACE LOCATED IN AN UNCONFINED SPACE

nconfined space does not necessarily mean that combus-

U

tion and ventilation will not have to be introduced from

the outdoors, particularly in airtight homes. Refer to the

appropriate installation code requirements regarding the

minimum combustion air required for all fuel burning

appliances located within the unconfined area.

f the amount of combustion and ventilation air is insuffi-

I

ient to properly operate the furnace and other fuel burn-

c

ing appliances within the unconfined area, it will be necessary to supply it from the outdoors based on the criteria

used when calculating the air supply for a confined space.

NOTE

If planning to use the inside air of an unconfined

space, remember to test for proper furnace operation

(as well as other fuel burning appliances located

within the unconfined space) with respect to adequate

combustion and ventilation air with fireplace dampers

open, clothes dryer running, bathroom exhaust fans

on, kitchen range hood on, etc.

CASE 2:

FURNACE LOCATED IN A CONFINED SPACE

A confined space, (any space smaller than the minimums

discussed in CASE 1), must have two air openings one within 12 inches of the ceiling and the other within 12 inches of

the floor. The air openings must be sized based on whether

the combustion and ventilation air is being taken from

indoors or outdoors, the method outdoor air (if used) is

introduced, and taking into account any other fuel burning

appliances in the confined space.

If sufficient indoor combustion and ventilation air is available for the furnace and all other fuel burning appliances,

even when clothes dryers, bathroom fans, range hoods, etc.

are running, size each opening according to the appropriate installation codes.

NOTE

If using grilles to cover the two openings, factor in the

free area of the grille. Typically, a grille will have a

free area approximately 50% of its nominal size.

Consequently, if the required opening is 10 inches x 10

inches , it will have to be doubled if using a sidewall

grille with 50% free area.

IMPORTANT

CASE 3:

FURNACE LOCATED IN A CONFINED SPACE, OUT-

DOOR

AIR FROM ATTIC OR CRAWL SPACE

In this circumstance, refer to the appropriate installation code for the free area of the combustion and

ventilation air openings. If other fuel burning appli-

nces are present, their combustion air and ventilation

a

ir requirements must be added to those of the fur-

a

ace. If the attic has an exhaust fan (power vent), it

n

may create a negative pressure sufficiently large

enough to prevent the attic from being an effective

source of combustion and ventilation air.

Powered attic fans do not customarily run during the

heating season; however, some are controlled by a

humidistat as well as a thermostat, which may allow

some operation during the heating season.

The choices are (a) use the direct vent option; (b) obtain

outdoor air from elsewhere; or (c) interlock the attic

exhaust fan with the furnace such that the two cannot

operate simultaneously.

CASE 4:

FURNACE LOCATED IN A CONFINED SPACE, OUTDOOR

AIR DUCTED HORIZONTALLY

Similar to CASE 3, outdoor air for combustion and ventilation may be drawn through horizontal ducting.

Consult the appropriate installation code for the free area

for openings. If other fuel burning appliances are present,

their combustion air and ventilation air requirements must

be added to those of the furnace.

IMPORTANT

The outdoor grilles must be installed in a location

where they will not be obstructed in any manner.

If grilles are used on the outside wall, they must be

sized properly. Most sidewall grilles have only 50%

free area, so the grill size opening must be twice the

size of the free air opening requirement.

WARNING

DO NOT ALLOW GAS PIPING TO BE ROUTED THROUGH

JOIST SP

POSES. DO NOT USE JOIST SPACES FOR RETURN AIR

PURPOSES IF THE JOIST SPACE ALREADY CONTAINS

PLUMBING STACKS, CHIMNEY COMPONENTS, ETC.

UNLESS THE PORTION USED FOR RETURN AIR PURPOSES CAN BE COMPLETEL

WITH OTHER USAGES.

ACES THA

T ARE USED FOR RETURN AIR PUR

Y ISOLATED FROM PORTIONS

-

If an exhaust fan, fireplace, clothes dryer or any similar device is present in the indoor area from which the

combustion and ventilation air will be drawn, negative

pressure could be a problem if natural infiltration

from the outdoors does not match the rate at which

air is exhausted.

13

Page 16

FIGURE 1

FURNACE VENTING

Direct Venting Pipe Connections

(USING OUTDOOR COMBUSTION AIR)

The direct vent configuration is the preferred installation method. The primary advantages are:

• Dedicated combustion air and vent piping eliminates the need to use already heated air for

combustion purposes

• The probability of corrosive contaminants being

present in the combustion air is greatly reduced

• The direct vent configuration is unaffected by

any other appliances, exhaust fans, or other

devices that tend to create negative pressure

conditions while operating

• No vents for combustion and ventilation air are

required in confined spaces

DANGER

DANGER

READ, UNDERSTAND AND FOLLOW ALL INSTRUCTIONS

IN THIS SECTION. FAILURE TO PROPERLY VENT OR

SUPPLY COMBUSTION AIR TO THIS FURNACE CAN

CAUSE CARBON MONOXIDE POISONING, OR AN

EXPLOSION OR FIRE, RESULTING IN PROPERTY DAMAGE,

PERSONAL INJURY OR LOSS OF LIFE.

DANGER

DANGER

THIS FURNACE AND ANY OTHER FUEL BURNING

APPLIANCE MUST BE PROVIDED WITH ENOUGH FRESH

AIR FOR PROPER COMBUSTION AND VENTILATION OF

THE FLUE GASES. MOST HOMES WILL REQUIRE THA

OUTSIDE AIR BE BROUGHT TO THE FURNACE AREA.

FAILURE TO DO SO CAN CAUSE PERSONAL INJURY OR

DEATH FROM CARBON MONOXIDE POISONING.

Combustion Air Inlet Piping

This furnace is certified as a Category I Type FSP Non-

Direct and Direct Vent Furnace. When installed as a direct

vent furnace, all combustion air is supplied from the outdoors via the plastic piping system. All components are

field supplied except for the adapter used to connect the

piping to the furnace.

DANGER

The following types of installation sites (but not limited

to the following) will require OUTDOOR AIR for

combustion because of chemical exposures: commercial

buildings, buildings with indoor swimming pools,

furnaces installed in laundry rooms, furnaces in hobby

r craft rooms, furnaces installed near chemical storage

o

areas.

The combustion air piping, like the exhaust piping, must be

ir tight throughout the system. The adapter joining the

a

ombustion air to the furnace is supplied with a gasket to

c

aintain the seal.

m

IMPORTANT

The supplied adapter is made of PVC. If planning to

use ABS pipe, use an all-purpose cleaner and ABS to

PVC transition cement. If planning to use CPVC pipe,

use an all-purpose cleaner, a clear or purple primer

and all-purpose cement approved for the purpose.

Additional information about cleaners, primers, solvents and cements may be obtained from their manufacturers.

CAUTION

Combustion air must be free of acid forming chemicals

such as sulphur, fluorine and chlorine. These elements

are found in aerosol sprays, detergents, bleaches,

cleaning solvents, air fresheners, paint and varnish

removers, refrigerants, and many other commercial and

household products.

When burned in a gas flame, vapors from these products

form acid compounds. Acid compounds increase the dew

point temperature of the flue products and are highly

corrosive after they condense.

Any furnace failure caused by corrosive elements is

excluded from warranty coverage.

Exposure to the following substances in the combustion

air supply (but not limited to the following) will also

require OUTDOOR AIR for combustion:

•

Aerosols, particularly CFC based or propelled aerosols

• Air fresheners

• Airplane Glue and similar adhesives and cements

• Ammonia, as commonly found in permanent wave

solutions used in hair dressing salons

• Antistatic fabric softeners used in clothes dryers

Carbon tetrachloride

•

Chlorinated cleaners and waxes

•

• Chlorine and bromine based swimming pool chemicals

• Deicing salts or chemicals, e.g. rock salt, etc.

• Dry cleaning fluids such as perchloroethylene

• Fumes from curing polyurethane and similar

substances

• Halogen based refrigerants including R-12 and R-22

• Hydrochloric acid, muriatic acid and other acid based

masonry washing and curing materials

• Printer’s inks, paint removers, varnishes, varsol,

toluene, etc.

Water softener salt and chemicals

•

14

Page 17

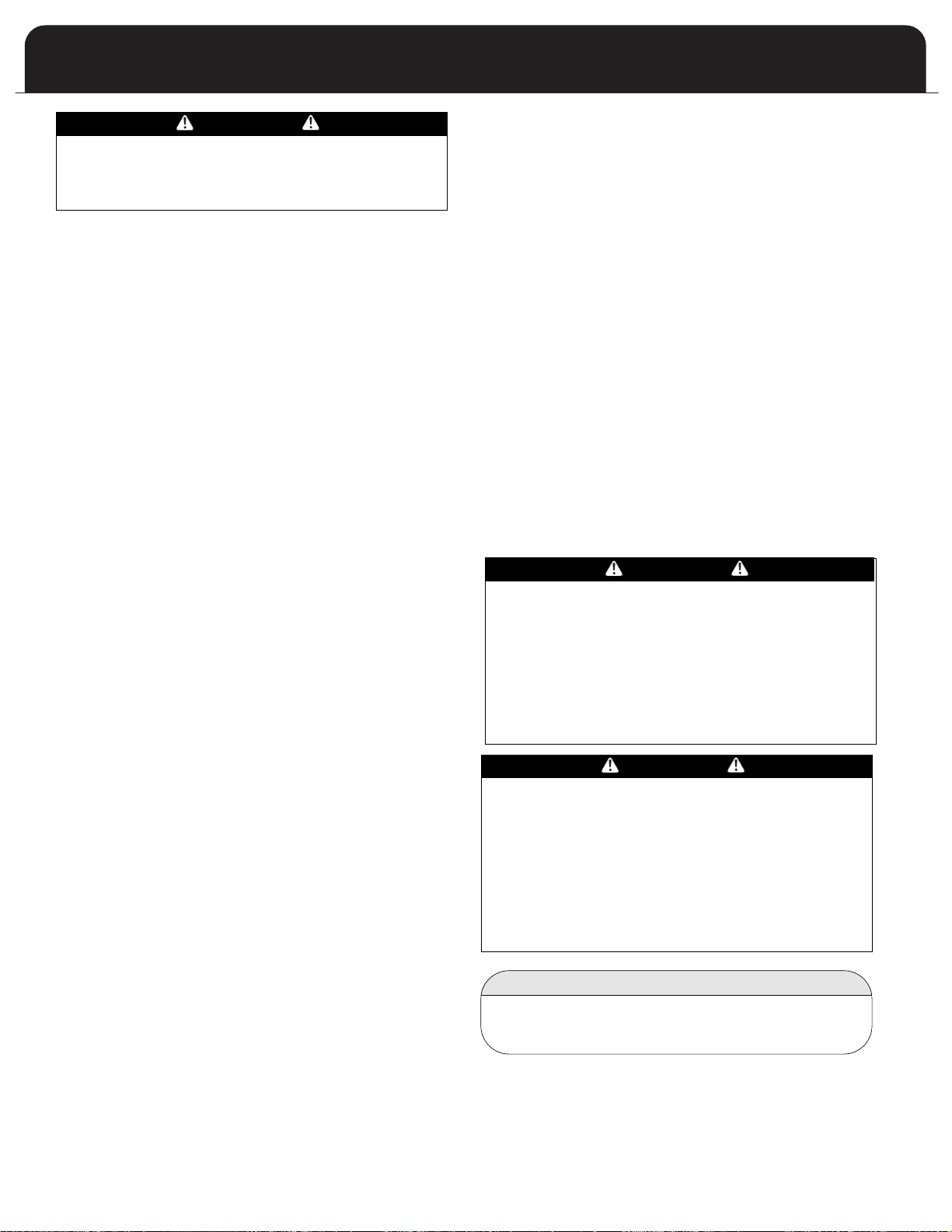

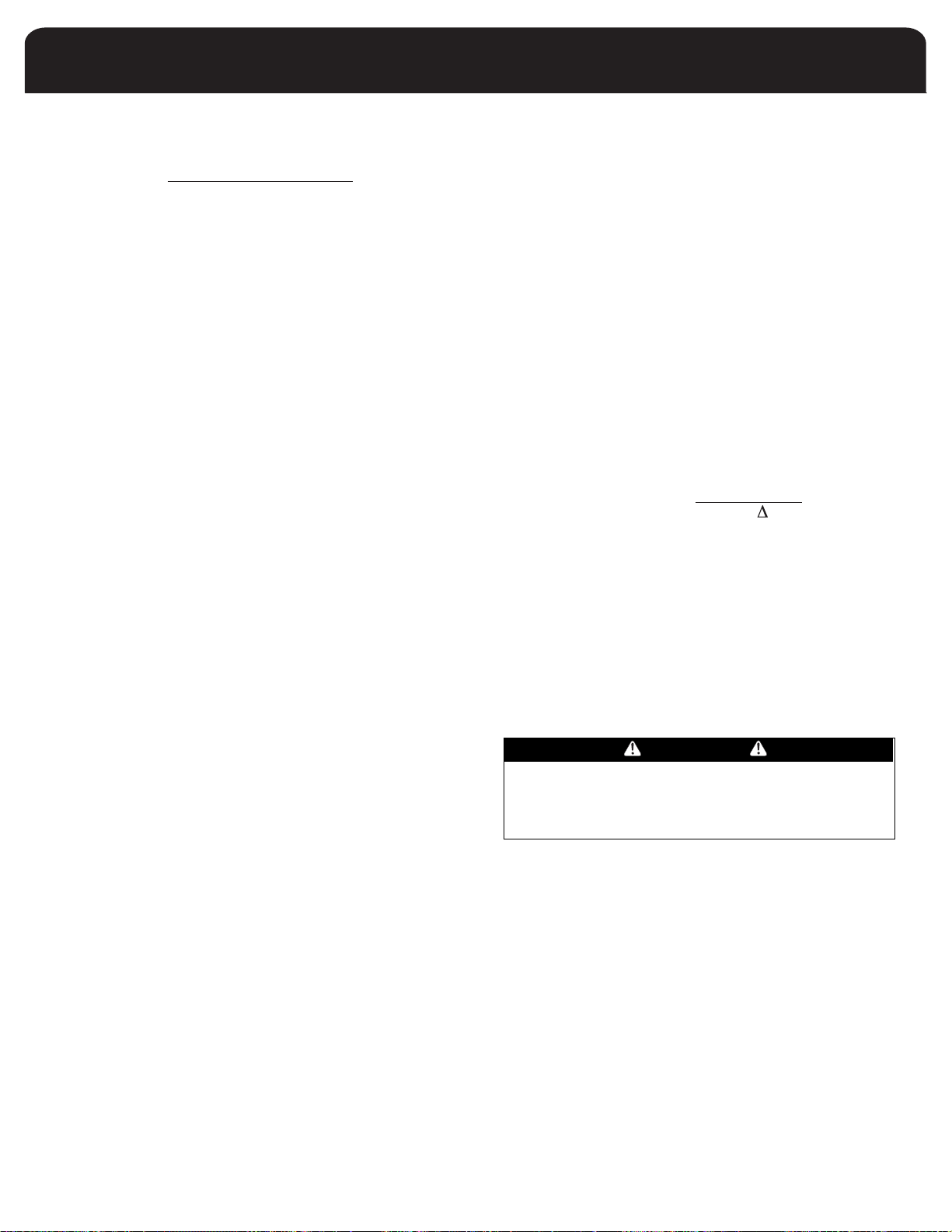

TABLE F

RECOMMENDED AIR FILTER AREA (SQUARE INCHES),

FOR DISPOSABLE AND PERMANENT TYPE FILTERS

COOL

(TONS)

AIR FLOW

(SCFM)

AREA

(INCH2)

AREA

(INCH2)

1.5

2

2.5

3

3.5

4

5

650

810

1000

1150

1350

1550

1750

312

389

480

552

648

744

840

156

194

240

276

324

372

420

919

1226

1532

1839

441

588

735

883

221

294

368

441

HEAT INPUT

(BTU/HR)

54,000

72,000

90,000

108,000

Air Filters

IAQ types of air filters may cause higher static, higher

temperature rise and erratic furnace operation and, with an

ECM drive, can cause blower over speed more noise. Also

he consumer may at some time want to add UV treatment,

t

nd electrostatic air cleaners or HEPA filters. Thus the return

a

duct should be sized larger than traditionally and also more

clearance space allow around the return duct for future

quipment.

e

Angling the air filter is one method of installing a larger

area air filter. Table below shows the recommended air

filter sizes. By examining the table one can see that many

existing installations have undersized air filters, resulting

in poorer air quality.

RECOMMENDED AIR FILTER AREA (SQUARE

INCHES), FOR DISPOSABLE AND PERMANENT

TYPE FILTERS

DISPOSABLE PERMANENT

Exhaust Vent Piping

WARNING

NEVER ALLOW THE PRODUCTS OF COMBUSTION FROM

THE FLUE TO ENTER THE RETURN AIR OR SUPPLY AIR

UCTWORK.

D

ALL RETURN AIR DUCTWORK MUST BE ADEQUATELY

SEALED AND SECURED TO THE FURNACE WITH SHEET

ETAL SCREWS. TAPE THE SHEET METAL SEAMS IN THE

M

VICINITY OF THE FURNACE WITH DUCT TAPE OR

SIMILAR MATERIAL.

WHEN THE FURNACE IS MOUNTED ON A PLATFORM

WITH RETURN AIR THROUGH THE BOTTOM, IT MUST BE

SEALED AIR TIGHT BETWEEN THE FURNACE AND THE

RETURN AIR PLENUM. THE FLOOR OR PLATFORM MUST

PROVIDE SOUND PHYSICAL SUPPORT OF THE FURNACE

WITHOUT SAGGING, CRACKS OR GAPS AROUND THE

BASE, PROVIDING A SEAL BETWEEN THE SUPPORT AND

THE BASE.

FAILURE TO PREVENT PRODUCTS OF COMBUSTION

FROM BEING CIRCULATED INTO THE LIVING SPACE CAN

CREATE POTENTIALLY HAZARDOUS CONDITIONS,

INCLUDING CARBON MONOXIDE POISONING THAT

COULD RESULT IN PERSONAL INJURY OR DEATH.

WARNING

READ AND FOLLOW ALL INSTRUCTIONS IN THIS SECTION. FAILURE TO PROPERLY VENT THIS FURNACE CAN

CAUSE CARBON MONOXIDE POISONING OR AN EXPLOSION OR FIRE RESULTING IN PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE.

Definitions

"Vent" and "Chimney" refer to open passageways that

convey vent gases from the furnace, or its vent connector, to

the outside. Vents and chimneys usually run vertically or

nearly vertically. When they serve only one gas appliance,

they are called "dedicated" vents or chimneys. When they

serve multiple gas appliances, they are called "common"

vents or chimneys.

"Vent Connector" refers to a pipe or duct that connects the

furnace to a vent or chimney. Vent connectors usually run

from the furnace’s vent collar to the vent or chimney. Vent

connectors may have vertical and horizontal runs.

"Venting System" refers to a continuous open passageway

from the vent collar to the outside. Venting systems usually

have a vent connector(s) and a vent or chimney

systems commonly serve a single furnace, or a single

furnace and a hot water heater

venting systems are less common.

"Fan Assisted Combustion System" refers to an appliance

equipped with an integral mechanical means to either draw

or force products of combustion through the combustion

chamber and/or heat exchanger. This series furnace uses a

draft inducer to draw combustion products through the

heat exchanger and is considered to have a fan assisted

combustion system. Category I furnaces with fan assisted

combustion systems must not be vented into single wall

metal vents.

. Other multiple appliance

. V

enting

15

Page 18

CAUTION

FAILURE TO FOLLOW ALL VENTING GUIDELINES MAY

RESULT IN ERRATIC FURNACE OPERATION, FREEZE-UP

OF THE VENTILATION AIR PIPING, OR SOOTING OF THE

FURNACE.

Guidelines

• Venting may be vertical or horizontal.

Minimum vent length - 25 total equivalent feet.

•

(See page 18, Table 4 - Venting Table)

• Horizontal piping must slope back towards the furnace

at a minimum rate of 1/4” to the foot, so that

condensate drains towards the furnace.

• Horizontal runs must be supported at least every 3

feet. Horizontal sections must not dip or sag

• All vent runs through unconditioned space where

freezing might occur should be insulated with 1”

thick, medium density, foil-faced Fiberglass insulation.

An equivalent “arm-aflex” or “rub-a-tex” may also be

used as long as there is no heat tape applied to the

vent pipe. For horizontal runs where water may

collect, wrap the vent pipe with self regulating 3 or 5

watt heat tape. The heat tape must be CSA, UL, or ULC

listed and installed per the manufacturer’s instructions.

• DO NOT COMMON VENT WITH ANY OTHER

APPLIANCE.

• If venting vertically, do not vent up a chimney serving

another appliance or install in a chase with a metal or

high temperature plastic pipe from another gas or fuel

burning appliance unless the required clearances to

combustibles can be maintained between the PVC pipe

and other pipes.

• All exhaust piping must be installed in accordance

with CAN/CGA-B149.in Canada; the latest edition of

National Fuel Gas Code, NFPA 54 / ANSI Z223.1 in the

United States, as well as in accordance with local

codes.

• Take the building orientation and the presence of

other buildings or other nearby structures into

consideration when planning the venting system

location. Certain external structures could create air

turbulence around the vent termination leading to

downdrafts and similar venting problems. In windy

and hill locations, roof venting may improve

operations. Maximum venting length is based on 30

mph winds, areas where higher gusts are dominant it

is suggest to shorten the horizontal vent length,

increase the diameter of the vent, or vent vertically.

The exhaust vent and combustion air intake shall be

•

installed so that both are located in the same wind

pressure zone.

JOINING PIPE AND FITTINGS

Acceptable Materials for Combustion Air and

Exhaust Vent Pipe

The furnace products of combustion include both flue

gases and condensate. All venting and drain materials are

lastic.

p

The combustion air and vent piping and fittings may be

comprised of:

• Schedule 40 PVC, ASTM D1785 or CSA B137.3

• PVC-DWV, ASTM D2665 or CSA B181.2

• ABS-DWV, ASTM D2661 or CSA B181.1

• Schedule 40 CPVC, ASTM F441 or CSA B137.6

In Canada, construct all combustion-air and vent pipes for

this unit of CSA or ULC S636 listed schedule-40 PVC, PVCDWV or ABS-DWV pipe and pipe cement. SDR pipe is not

approved in Canada. In addition, the first three feet of the

exhaust must be accessible for visual inspection.

Procedure for Cementing Joints (ASTM D2855):

It is preferable to use a single type of plastic throughout

the venting and combustion air piping; however, if

dissimilar piping or fitting materials are used, they must be

joined with an appropriate transition cement. Dissimilar

pipe segments may be joined together by mechanical

means (i.e., 2” rubber coupling).

DANGER

SOLVENT CEMENTS AND PRIMERS ARE HIGHLY FLAMMABLE. PROVIDE ADEQUATE VENTILATION AND DO

NOT ASSEMBLE NEAR HEAT SOURCE OR OPEN FLAME.

DO NOT SMOKE. AVOID SKIN OR EYE CONTACT.

OBSERVE ALL CAUTIONS AND WARNINGS PRINTED ON

MATERIAL CONTAINERS. FAILURE TO FOLLOW THESE

GUIDELINES MAY RESULT IN FIRE, EXPLOSION OR ASPHYXIATION CAUSING PERSONAL INJURY OR LOSS OF

LIFE.

WARNING

All pipe, fittings, solvent cement, primers and

procedures must conform to American National

Standards Institute and American Society for Testing

Materials (ANSI / ASTM) standards.

PIPE AND FITTINGS: ASTM D1785, D2466 and D2564

PVC PRIMER AND SOLVENT CEMENT: ASTM D2564

ABS PIPE AND FITTINGS: Use ABS Primer and Solvent

Cement D2235

CPVC SOL

VENT CEMENT

: F493

IMPORTANT

16

For proper installation, DO NOT thin or use solvent

cement that has become curdled, lumpy or thickened.

Page 19

PROCEDURE:

This guide is intended specifically for PVC pipe; however,

the general procedure applies to all plastic piping systems.

MATERIALS: PVC Cleaner / Primer and PVC Solvent Cement.

IMPORTANT

After cutting pipe, remove all ragged edges and burrs.

This will reduce restriction (pressure drop) throughout

the venting and combustion air system.

Direct Vent Piping Termination

CAUTION

Moisture in the flue gases condenses as it leaves the

terminal. This moisture can freeze on exterior walls, on

soffits, and other nearby objects. Some discoloration is

to be expected; however, improper location or installa-

ion can cause structural or exterior finish damage to

t

he building. Caulk all cracks, seams or joints within a 6

t

foot radius of the termination.

1. Cut the pipe end square. Chamfer edge of pipe. Clean

the fitting socket and pipe joint area of all dirt, grease

and moisture.

2. After checking the pipe and socket for proper fit, wipe

socket and pipe with cleaner / primer. Apply a liberal

coat of primer to inside surface of socket and outside

surface of pipe. DO NOT ALLOW THE PRIMER TO DRY

BEFORE APPLYING THE CEMENT.

NOTE

If alignment is critical, make an alignment mark with a

lead pencil on the outside of the socket to the portion

of pipe beyond the joint. This will allow proper alignment as the joint is processed.

3.

Apply a thin coat of solvent cement to the inside surface of the fitting socket. Quickly apply a heavy coat

of solvent cement to the pipe end and insert it into

the socket with a slight twisting motion until it bottoms out. If alignment is critical, match up the pencil

marks made prior to this step.

NOTE

Cement must be fluid; if not, re-coat.

4. Hold the pipe in the fitting for 30 seconds to prevent

the tapered socket from pushing the pipe out of the

fitting. Failure to do this may result in a weak or leaky

joint.

5. Wipe all excess cement from the joint with a rag.

Allow 15 minutes before handling. Cure time varies

according to fit, temperature and humidity.

NOTE

Stir the solvent cement frequently while using. Use a

natural bristle brush or the dauber supplied with the

container. If a dauber was not supplied, a 1 inch brush

is ideal.

Observe shelf precautions printed on containers. Minimize

the exposure of the container’s contents to air.

For applications below 32°F (0°C), use only low

temperature-type solvent cement.

CAUTION

Improper location or installation can result in structural

damage to the building, damage to the exterior finish

of the building, or may allow recirculation or freezing

of the flue gases onto or into the combustion air

intake. Moisture in the flue gases condenses as it leaves

the terminals. This moisture can freeze on exterior

walls, soffits, and other nearby objects. Some discoloration is to be expected.

General Guidelines

The external portion of the piping in all cases is to consist

of 2” pipe. If 3” pipe is used between the furnace and

terminal, transition to 2” within 18” or less of the exterior

wall.

When 3” pipe is used, exit the cabinet with 2” pipe.

Reduce or increase immediately after exiting the cabinet in

a vertical run making provisions to secure the vent bracket

between cabinet and fitting.

Avoid locating the terminals where the flue gas could

become stagnant and allow recirculation into the

combustion air intake.

Avoid locating the terminal in locations where dripping

condensate may cause problems such as sidewalks, patios,

above planters, near windows where exhaust gases may

cause fogging, etc.

void locating the termination too close to shrubs and

A

other vegetation. The condensate may stunt or kill them.

Caulk all cracks, seams or joints within a 6 foot radius of

the termination.

Do not terminate under a deck unless there is adequate

clearance to prevent damage from the flue gases. A

termination may be located at the end of a patio deck.

Piping running beneath the deck must be suitably

insulated and suspended in a manner to prevent

condensate from collecting and freezing.

Do not locate the terminal on the side of the building

facing the prevailing winter winds.

Avoid locating the terminal in locations where dripping

condensate may cause problems such as side walks, patios,

above planters, near windows where exhaust gases may

cause fogging, etc. Avoid locating the termination too

close to shrubs and other vegetation. The condensate may

stunt or kill them.

The vent terminal should be located no fewer than 6 feet

from an inside corner formed by two exterior walls. A 10

foot distance is recommended.

17

Page 20

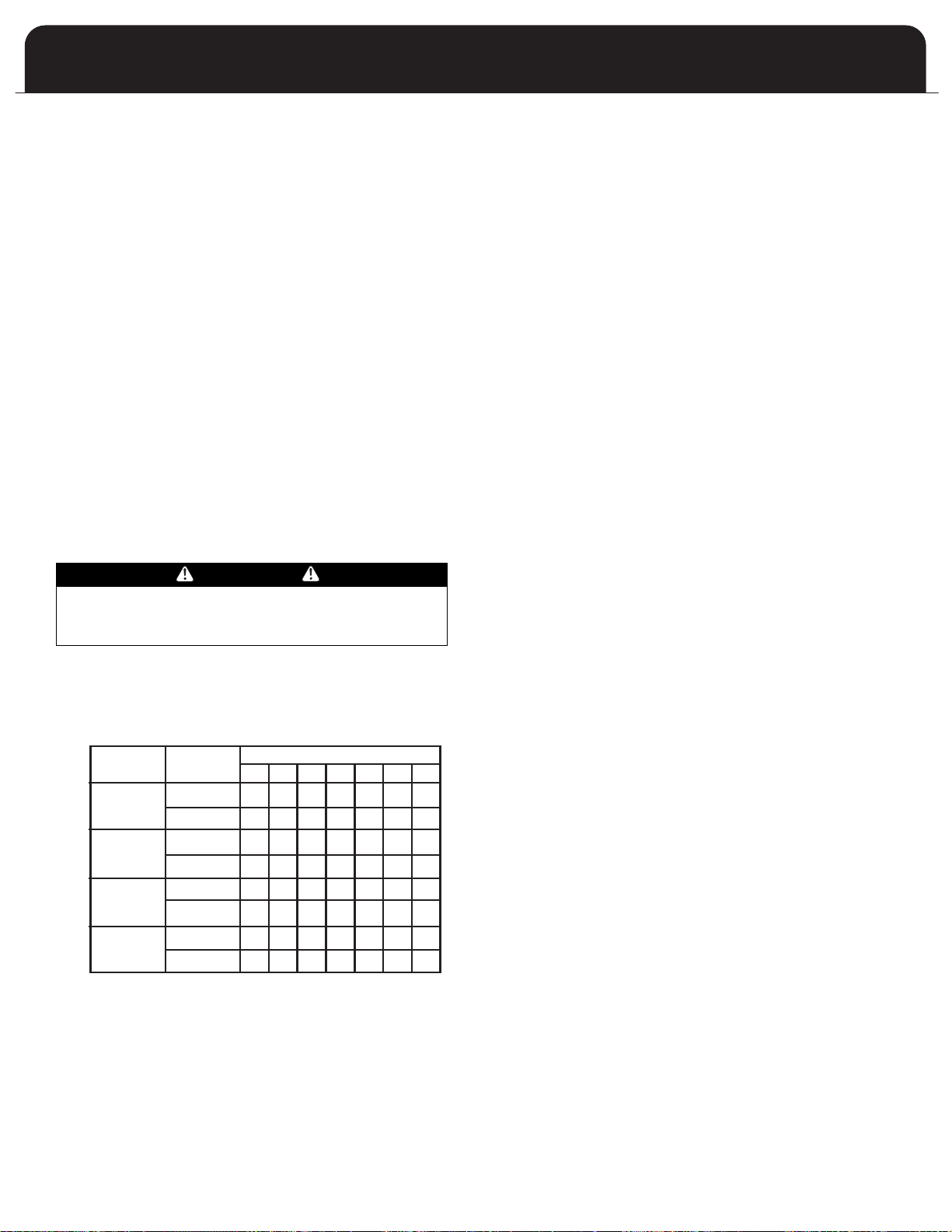

PIPE SIZE

NUMBER OF 90° ELBOWS

MAXIMUM ALLOWABLE

STRAIGHT LENGTH OF EXHAUST OR INTAKE

2

3

2

3

2

3

2

3

0123456

MODEL

054

072

090

108

70

15065140601305512050110451004090

65

140601305512050110451004090

65

140601305512050110451004090

65

140601305512050110451004090

70

150

70

150

70

150

Recommended clearance for overhangs is a minimum of 1

foot vertically for each foot horizontally up to 6 feet.

As a protection against freezing, do not expose a 3 x 2

reducing coupling to outdoor ambient temperatures.

Any adjacent painted surfaces should be in good condition;

no cracks, peeling paint, etc. If wooden surfaces that may

be periodically exposed to flue gases are present, consider

treating with a sealer.

Calculating Piping Length

When calculating allowable vent lengths, be sure to count

all termination fittings in addition to counting the

concentric vent as a straight pipe. The ventilation pipe

extending through the roof must extend 18” above the

highest point where it extends through the roof, surface

and above any obstruction within an 18” horizontal

distance. The ventilation pipe must extend a minimum of

12” above the anticipated snow level.

Exterior vent pipe greater than 24” should be insulated

with 1/2” insulation to prevent moisture from freezing

within the pipe and accumulating.

Size the ventilation pipe as specified in Table 4 - Direct and

Non-Direct Vent Lengths. This table lists the maximum

allowable length of pipe with respect to the number of 90°

elbows used. For the purposes of this calculation, one 90°

elbow is equivalent to two 45° elbows.

WARNING

DO NOT CONNECT FURNACE TO A CHIMNEY OR FLUE

SERVING OTHER APPLIANCES OR A SOLID FUEL BURNING APPLIANCE.

TABLE 4:

VENT LENGTHS- DIRECT/NON-DIRECT VENT LENGTHS

• Count concentric vent fitting as straight pipe.

Use medium or long sweep elbows where possible.

•

One 90

•

• For direct vent, the above is the length allowed for

each vent (intake and exhaust)

• For non-direct vent, the above is length allowed

for exhaust. The intake should have a two inch

upside down “U” intake installed on the cabinet

intake fitting.

elbow is equivalent to two 45

°

elbows.

°

18

Page 21

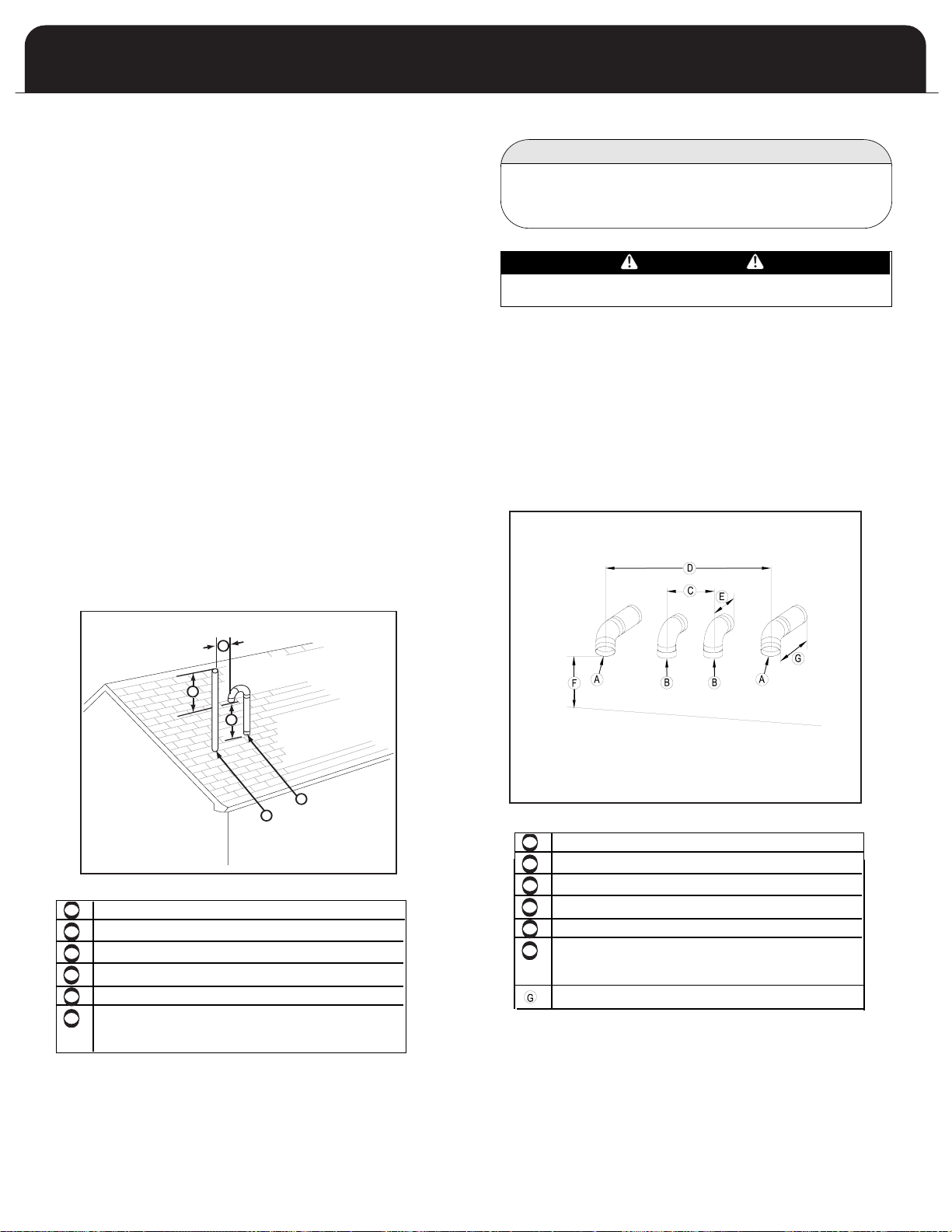

A

B

C

D

E

A

B

D

F

A

A

B

B

G

E

E

D

A

A

B

B

G

TERMINATION OF COMBUSTION AIR

AND VENTILATION PIPE USING A

CONCENTRIC VENTING KIT

oncentric venting terminal kits may be used for this series

C

urnace. They provide a means of obtaining combustion air

f

nd exhausting products of combustion utilizing a single

a

penetration through the exterior wall. This can be useful

when there is limited wall space available. Kits are available

in 2” and 3” sizes. Read the instructions supplied with the kit

for additional installation instructions and details.

he concentric venting terminal has the combustion air intake

T

uilt into the assembly. If using the concentric vent terminal,

b

here must be a minimum of 12” clearance to grade or antici-

t

pated snow level. There are no means available to raise the

terminal externally. If planning to use this terminal kit, see

Figures 5 and 6.

The concentric vent termination kits may also be used in the

vertical position.

Figure 3

A

B

C

D

VENT

COMBUSTION AIR

AIN 12” CLEARANCE

MAINT

(18” FOR CANADA) ABOVE HIGHEST

ANTICIP

A

TED SNOW LEVEL.

MAINTAIN 12” CLEARANCE

(18” FOR CANADA) ABOVE HIGHEST

Figure 4

E

F

G

STRAP (FIELD SUPPLIED)