Page 1

INSTALLATION, OPERATION, MAINTENANCE

Relief Valve Assembly Instructions

Series 825YD, 826YD, 860, 880V

Repair Kits: 905102, 905316, 905192, 905187, 905188,

905189, 905190, 905191, 905227, 905228, 905229

IOM-F -RV

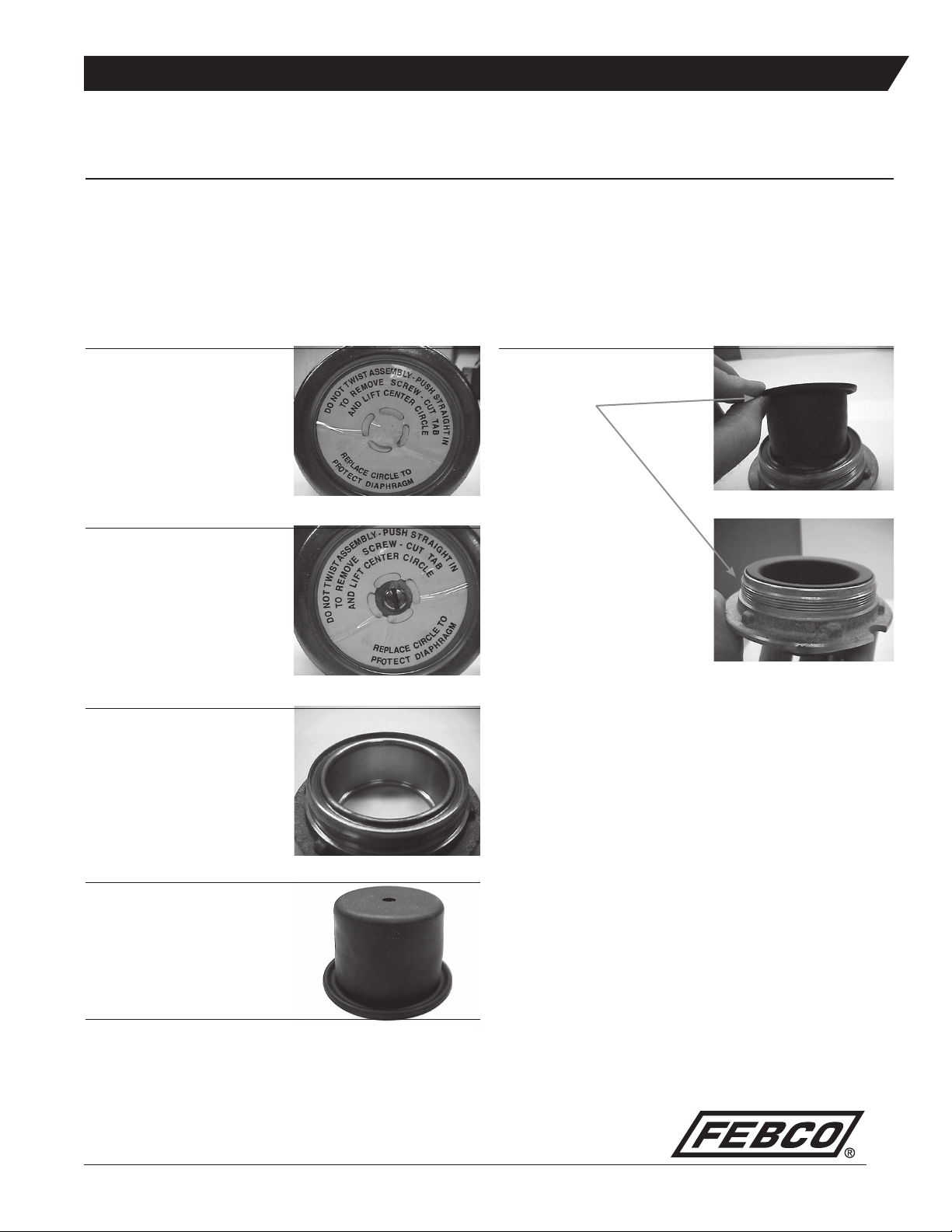

STEP #1:

When cleaning relief valve, remove

module assembly from relief valve

body by pulling, not twisting.

STEP #2:

If module repair is necessary,

remove plastic label from around

pan head retaining screw.

STEP 3:

Remove retaining screw and completely disassemble relief valve

module. Thoroughly clean main

guide.

STEP 5:

Position inner diaphragm over the

main guide and drop into place with

beaded flange fully engaging groove

on main guide.

STEP 4:

New inner diaphragm will come in

kit with fabric side out and the beaded flange positioned up, as shown.

Page 2

MAINTENANCE MANUAL SERIES 825YD, 826YD, 860, 880V

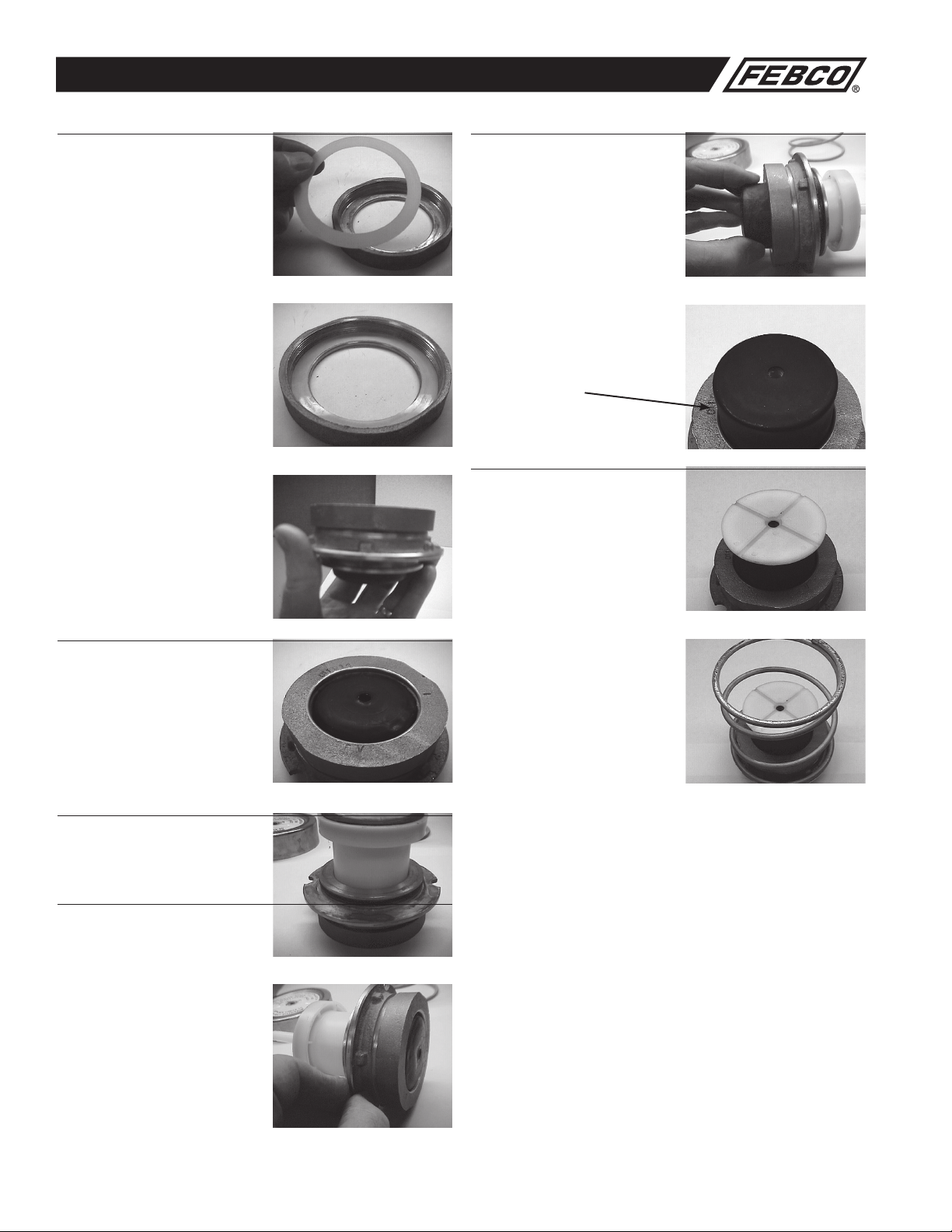

STEP 6:

Clean or replace plastic slip ring.

Clean the brass diaphragm retainer.

Lightly lubricate retainer threads

with a food grade petroleum jelly or

equal. Place slip ring into retainer.

Screw retainer with slip ring onto

main guide, securing inner diaphragm. Make sure the retainer is

secure.

STEP 9:

Push the disc holder through the

guide while holding the diaphragm

flush against the end of the holder.

Continue until the holder stops on

the guide. Place the assembly on

a flat surface with the diaphragm

facing up.

This will ensure that excess rubber

will roll to the inside of the main

guide when the holder assembly

strokes, otherwise the diaphragm

will crack and leak.

STEP 10:

Place flow washer on top of the

diaphragm with cross channels facing upward (Series 860 and 880V

ONLY). Line up the center holes,

then place the spring into the guide.

STEP 7:

Push inner diaphragm back through

main guide until top of the diaphragm is flush with the top of the

retainer.

STEP 8:

Turn guide/diaphragm assembly upside down and work disc

holder into guide until flush with

diaphragm.

2

Page 3

MAINTENANCE MANUAL SERIES 825YD, 826YD, 860, 880V

STEP 11:

Place the spring button over the

spring. While pressing the button

firmly against the inner diaphragm,

insert the pan head retaining screw.

860 and 880V require a drilled flow

screw.

Flow screw must have two drilled

holes intersecting each other and

unobstructed. Place the previously

removed decal or tape over the

screw head to protect the outer

diaphragm.

STEP 13:

Place new outer diaphragm upside

down on a flat service and insert the

module as shown.

STEP 14:

Push the flange section of the

diaphragm down around the base

of the module until it is partially

inverted as shown.

STEP 12:

Reassemble disc and lower the

guide to the disc holder. DO NOT

ALLOW THE DISC HOLDER TO

TURN OR TWIST DURING THIS

OPERATION. Clean, lubricate and

install main guide O-ring.

Models 825YD and 826 YD use a

Stainless Steel Lower Guide and a

Disc Washer in place of the Plastic

Lower Guide as shown.

3

Page 4

For additional information, visit our web site at: www.FEBCOonline.com

STEP 15:

Clean inside surfaces of the relief

valve and push in the module

assembly, being careful not to pinch

the guide's O-ring.

Note: The lower guide must align

itself properly with the seat ring

once all of the parts are assembled

in the body for the relief valve to

function properly.

STEP 16:

Take the partially inverted diaphragm and place it over the spring

button of the module. Take a blunt

tool and carefully work the diaphragm in and around the button.

Line up diaphragm bolt holes with

body flange bolt holes.

STEP 17:

Replace the cover and check for

proper positioning.

Limited Warranty: FEBCO warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of original shipment. In the event

of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER

WARRANTIES, EXPRESS OR IMPLIED. THE COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of warranty, and the Company shall not be responsible for any incidental, special

or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting

from labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any other circumstances over which the Company has no

control. This warranty shall be invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above

limitations may not apply to you. This Limited Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state laws to

determine your rights. SO FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL SHIPMENT.

A Division of Watts Water Technologies, Inc.

USA: 4381 N. Brawley • Ste. 102 • Fresno, CA • 93722 • Tel. (559) 441-5300 • Fax: (559) 441-5301 • www.FEBCOonline.com

Canada: 5435 North Service Rd. • Burlington, ONT. • L7L 5H7 • Tel. (905) 332-4090 • Fax: (905) 332-7068 • www.FEBCOonline.ca

IOM-F-RV 0845 EDP# 1915982 © FEBCO, 2008

Loading...

Loading...