Page 1

IS-F-850/856-DC/DCDA

Installation Instructions • Instrucciones de instalación • Instructions d’installation

Series 850, LF850, 856, LF856 and 856ST

Serie 850, LF850, 856, LF856 y 856ST

Séries 850, LF850, 856, LF856 et 856ST

Double Check Valve Assemblies

Double Check Detector Assemblies

Montajes con válvula de retención doble

Montajes de detección de retención doble

Dispositif à double clapet

Détecteur à double clapet

1

Size: 2

Tamaño: 65 a 250 mm (21⁄ 2 a 10 pulg.)

Dimensions : 65 mm à 250 mm (2,5 po à 10 po)

⁄2" - 10" (65-250mm)

Series 850 / Serie 850 / Série 850

Page 2

ENGLISH INSTRUCTIONS

!

WARNING

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information can

result in death, serious personal injury, property damage, or

damage to the equipment.

Keep this Manual for future reference.

Local building or plumbing codes may require modifications to the information provided.

You are required to consult the local building and plumbing codes prior to installation. If

this information is not consistent with local building or plumbing codes, the local codes

should be followed.

Need for Periodic Inspection/Maintenance: This product must be tested periodically in

compliance with local codes, but at least once per year or more as service conditions warrant. Corrosive water conditions, and/or unauthorized adjustments or repair could render

the product ineffective for the service intended. Regular checking and cleaning of the

product’s internal components helps assure maximum life and proper product function.

Installation Instructions

1. Consult local codes for specific installation requirements and restrictions applicable to your area. It is recommended

that system supply pressure be at least

20psi (133kPa).

2. These instructions apply to Series 850,

LF850 (DC), 856, LF856 and 856ST

(DCDA), sizes 2

250mm). The valves may be installed

only in the orientation/flow direction as

shown. The gate valves may be rotated

as permitted by the flange bolt pattern

on vertical installations only.

3. The valve assembly must be installed

where it is accessible for periodic

testing and maintenance. Clearances

shown in the installation views apply

to exterior, interior and pit/vault installations and are only recommendations.

These minimums do not apply to

removable protective enclosures. Refer

to local codes for actual requirements in

your area.

4. PRIOR TO INSTALLING THE VALVE

INTO THE LINE, FLUSH THE SUPPLY

LINE OF ALL FOREIGN MATERIAL.

Failure to flush the supply line may

cause the check valves to become

fouled and require disassembly and

cleaning.

5. Lift the assembly by connecting lift

hooks to the lift rings cast into

1

⁄2" to 10" only (65 –

the valve body. DO NOT LIFT THE

ASSEMBLY BY CONNECTING TO

THE GATE VALVE HANDWHEELS OR

STEMS.

6. After installation SLOWLY fill the

assembly with water and bleed air

from the body using the # 3 and # 4

test cocks. Test the valve assembly to

ensure correct operation.

NOTICE

All assemblies are tested at the factory for

proper operation and leakage. If the valve

does not pass the field test, it is most likely due to a fouled check valve. This is not

covered by the factory warranty. The valve

cover(s) must be removed and the check

seats inspected and cleaned. Any damage

or improper operation caused by pipeline

debris or improper installation/start-up is

not included in the factory warranty.

In case of a possible warranty claim,

contact your local supplier or FEBCO

Representative. DO NOT REMOVE THE

VALVE ASSEMBLY FROM THE PIPELINE.

7. The assembly must be protected

from freezing and excessive pressure

increases. Thermal expansion or water

hammer can cause pressure increases.

These excessive pressure situations

must be eliminated to protect the valve

and system from possible damage.

2

Page 3

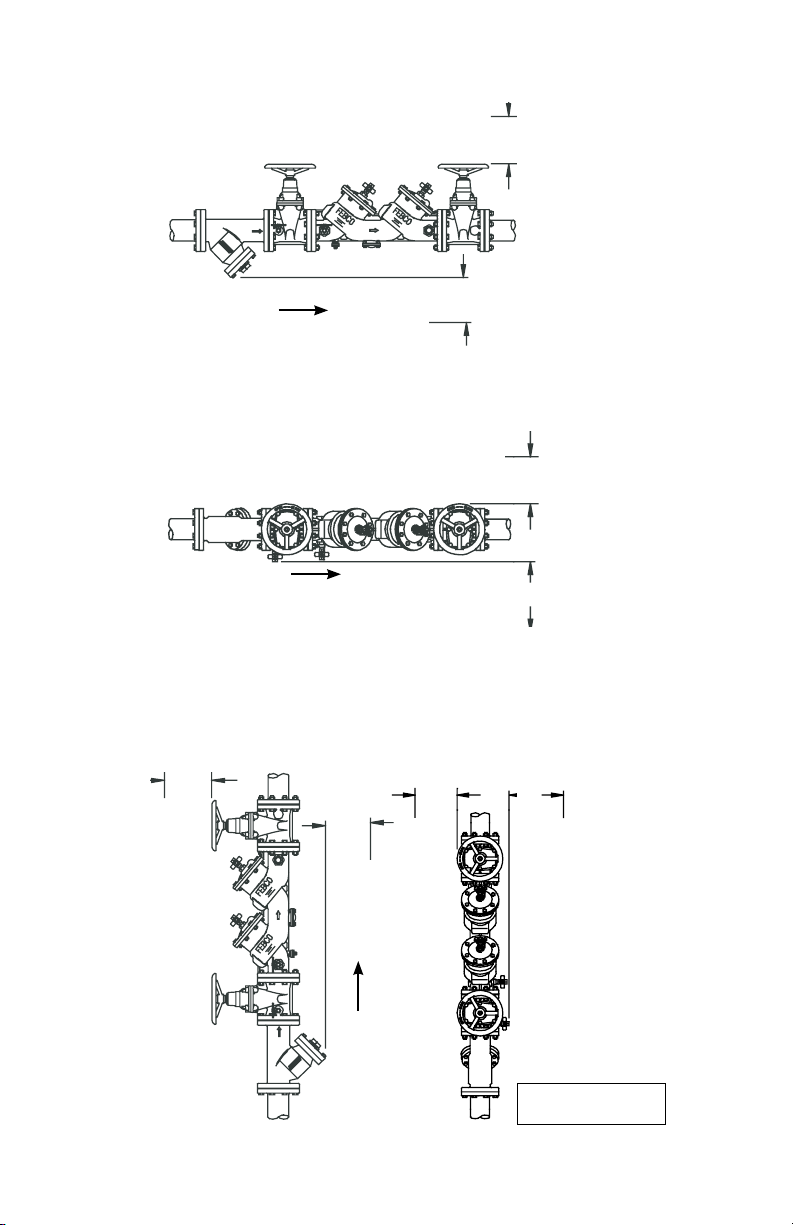

Typical Installation

RWWP

FRT

4175

Flow

Flow

HORIZONTAL INSTALLATION OF THE DC SERIES 850

(FRONT VIEW, SHOWN WITH STRAINER)

HORIZONTAL INSTALLATION OF THE DC SERIES 850

(TOP VIEW, SHOWN WITH STRAINER)

12" min. (300mm)

Refer To Local Codes

6" min. (150mm)

Refer To Local Codes

6" min. (150mm)

Refer To Local Codes

18" min. (45mm)

Figure 1

FRT

HORIZONTAL INSTALLATION OF THE DC SERIES 850, LF850

& DCDA SERIES 856, LF856, 856ST

(Front View, Shown With Strainer)

RWWP

4175

Flow

12" Min (300mm)

Refer to Local Codes

6" Min (150mm)

Refer to Local Codes

Figure 2

Flow

HORIZONTAL INSTALLATION OF THE DC SERIES 850, LF850

& DCDA SERIES 856, LF856, 856ST

(Top View, Shown With Strainer)

Figure 3

12" Min (300mm)

Refer to Local Codes

6" Min (150mm)

Refer to Local Codes

VERTICAL

INSTALLATION

OF THE DC

SERIES 850,

LF850 & DCDA

SERIES 856,

LF856, 856ST

(Front View,

Shown With

Strainer)

4175

RWWP

FRT

Flow

6" Min (150mm)

Refer to Local Codes

18" Min (450mm)

Figure 4

6" Min (150mm)

Refer to Local Codes

18" Min (450mm)

12" (300mm) minimum

above all downstream

piping and use

VERTICAL

INSTALLATION OF THE

DC SERIES 850, LF850

& DCDA SERIES 856,

LF856, 856ST

(Top View, Shown

With Strainer)

CHECK WITH LOCAL

CODE REQUIREMENTS

3

Page 4

Servicing Check Valve Assemblies

General

FEBCO recommends yearly maintenance. Consult your local codes for requirements in

your area.

1. Detailed maintenance manuals

are available from your local Febco

representative.

2. Rinse all parts with clean water prior to

reassembly.

3. DO NOT USE ANY PIPE DOPE, OIL,

GREASE OR SOLVENT ON ANY PARTS

unless instructed to do so.

4. Do not force parts. Parts should fit

together freely. Excess force may

cause damage and render the assembly

inoperable.

5. Carefully inspect seals and seating

surfaces for debris or damage.

6. After servicing, repressurize the

assembly and test to ensure proper

operation.

Disassembling the Check Valve

1. Close the outlet shutoff valve, then

close the inlet shutoff valve. Bleed

residual pressure from the assembly by

opening the #4, #3, and # 2 test cocks

in this sequence.

2. Remove the cover bolts/nuts and lift

the cover from the body. The springs

are retained and the cover should be

pushed away from the body approxi-

1

mately

⁄4 inch.

3. Inspect/clean debris from the disc and

seat ring. Replace worn or damaged

parts as required.

4. Replace the cover, ensure the spring

assembly is positioned in the pivot socket. If necessary, apply FDA approved

grease to the O-ring groove in the body

to keep the O-ring in position while

installing the cover.

5. Install the bolts and nuts and tighten.

Test Procedure

FEBCO recommends the use of

the appropriate annual test method

presented in the ASSE Series 5000

manual that is consistent with your

localcodes.

Troubleshooting for Double Check Assemblies

PROBLEM CAUSE SOLUTION

1. Check valve leaking a. Debris on seating surface Disassemble and clean

b. Leaking shutoff valve. Disassemble and clean

2. Low flows passing through a. Mainline check fouled Disassemble and clean

b. Bypass line plugged Disassemble and clean

4

Page 5

INSTRUCCIONES EN ESPAÑOL

!

ADVERTENCIA

PIENSE

SEGURIDAD

ANTE

TODO

Es posible que los códigos locales de edificación y plomería exijan modificaciones con respecto

a la información provista. Deberá consultar los códigos locales de edificación y plomería antes

de instalar este producto. Si la presente información no coincide con los códigos locales de

edificación o plomería, siga las pautas establecidas en dichos códigos.

Necesidad de inspección o mantenimiento periódicos: Este producto debe ser probado

periódicamente para verificar que cumpla con los códigos locales, al menos una vez por

año o más, según lo requieran las condiciones de uso. El agua con alto contenido corrosivo

o cualquier ajuste o reparación no autorizados podrían inutilizar el producto para el uso

pretendido. Verificar y limpiar periódicamente los componentes internos del producto ayuda a

garantizar su máxima vida útil y correcto funcionamiento.

Lea este manual ANTES de utilizar este equipo.

El no leer y seguir todas las medidas de seguridad y usar la información

puede causar la muerte, lesiones personales graves, daños materiales o

daños en el equipo.

Guarde este manual para referencia futura.

Instrucciones de instalación

1. Consulte los códigos locales para ver los

requisitos y restricciones de instalación

específicos correspondientes a su

área. Se recomienda que la presión de

suministro del sistema sea de al menos

133 kPa (20psi).

2. Estas instrucciones corresponden

únicamente a las Series 850, LF850

(MONTAJE DE RETENCIÓN DOBLE),

856, LF856 y 856ST (MDRD), de 65 a 250

mm (21⁄2 a 10 pulg.). Las válvulas pueden

instalarse solamente en la orientación/

dirección de flujo como se muestra. Las

válvulas de paso pueden girarse según

lo permita el patrón del perno con bridas

únicamente en las instalaciones verticales.

3. El montaje de la válvula debe instalarse

en un lugar accesible para la realización

periódica de pruebas y mantenimiento.

Los espacios de separación mostrados

en las ilustraciones de instalación

corresponden a instalaciones exteriores,

interiores y en pozos/sótanos y son

solamente sugerencias. Estos valores

mínimos no corresponden a cajas

protectoras extraíbles. Consulte los

códigos locales para ver los requisitos

reales de su área.

4. ANTES DE INSTALAR LA VÁLVULA A

LA LÍNEA, ENJUAGUE LA LÍNEA DE

SUMINISTRO QUITANDO TODA MATERIA

EXTRAÑA. No enjuagar la línea de

suministro puede provocar el bloqueo de

las válvulas de retención y requerir su

desarmado y limpieza.

5. Levante el montaje conectando los

ganchos de elevación a los anillos de

elevación fundidos en el cuerpo de la

válvula. NO LEVANTE EL MONTAJE

CONECTÁNDOLO A LOS VOLANTES

DE MANO O LOS VÁSTAGOS DE LA

VÁLVULA DE PASO.

6. Después de la instalación llene

LENTAMENTE el montaje con agua y

purgue el aire del cuerpo usando los grifos

de prueba N.º 3 y N.º 4. Pruebe el montaje

de la válvula para asegurar su correcto

funcionamiento.

AVISO

todos los montajes son probados

en la fábrica para evaluar su correcto

funcionamiento y la ausencia de fugas. Si la

válvula no pasa la prueba de campo, lo más

probable es que se deba a una válvula de

retención bloqueada. Esto no está cubierto

por la garantía de fábrica. La(s) cubierta(s)

de la válvula debe(n) extraerse y los asientos

de la válvula de retención deben revisarse

y limpiarse. Todo daño o funcionamiento

incorrecto provocado por residuos de la

tubería o la instalación/arranque incorrectos no

se incluye en la garantía de fábrica.

En caso de un posible reclamo cubierto por

la garantía, póngase en contacto con su

proveedor o representante de FEBCO local.

NO QUITE EL MONTAJE DE LA VÁLVULA DE

LA TUBERÍA.

7. El montaje debe protegerse del congelamiento y de los aumentos de presión excesivos. La expansión térmica o los golpes

de ariete pueden provocar aumentos de

presión. Estas situaciones de presión excesiva deben ser eliminadas para proteger a

la válvula y al sistema de posibles daños.

5

Page 6

Instalación típica

Flow

Flow

12" min. (300mm)

Refer To Local Codes

6" min. (150mm)

Refer To Local Codes

6" min. (150mm)

Refer To Local Codes

18" min. (45mm)

Figura 1

Mínimo 300 mm (12 pulg.)

Consulte los códigos locales

RWWP

FRT

4175

Mínimo 150 mm (6 pulg.)

Consulte los códigos locales

Flujo

INSTALACIÓN HORIZONTAL DEL MONTAJE DE RETENCIÓN DOBLE SERIES

850, LF850 Y DEL MDRD SERIES 856, LF856, 856ST

(vista frontal, se muestra con filtro)

Figura 2

Mínimo 150 mm (6 pulg.)

Consulte los códigos locales

Flujo

Mínimo 450 mm (18 pulg.)

INSTALACIÓN HORIZONTAL DEL MONTAJE DE RETENCIÓN DOBLE SERIES

850, LF850 Y DEL MDRD SERIES 856, LF856, 856ST

(vista superior, se muestra con filtro)

Figura 3

INSTALACIÓN

VERTICAL DEL

MONTAJE DE

RETENCIÓN

DOBLE SERIES

850, LF850 Y

DEL MDRD

SERIES 856,

LF856, 856ST

(vista frontal,

se muestra con

filtro)

Mínimo 300 mm (12 pulg.)

Consulte los códigos locales

Figura 4

Mínimo 300 mm (12

pulg.) sobre todo uso y

tuberías descendentes

Mínimo 150 mm (6 pulg.)

Mínimo 150 mm (6 pulg.)

Consulte los códigos locales

4175

RWWP

FRT

Flujo

Consulte los códigos locales

Mínimo 450 mm (18 pulg.)

INSTALACIÓN

VERTICAL DEL

MONTAJE DE

RETENCIÓN DOBLE

SERIES 850, LF850 Y

DEL MDRD SERIES

856, LF856, 856ST

(vista superior, se

muestra con filtro)

VERIFIQUE LOS REQUISITOS

DEL CÓDIGO LOCAL

6

Page 7

Montajes con válvula de retención de servicio

Información general

FEBCO recomienda efectuar un mantenimiento anual. Consulte los códigos locales para

conocer los requisitos del área donde se encuentra.

1. Su representante local de FEBCO dispone

de manuales de mantenimiento detallados.

2. Enjuague todas las piezas con agua limpia

antes de reensamblarlas.

3. NO USE LACA PARA TUBERÍAS, ACEITE,

GRASA O SOLVENTE SOBRE NINGUNA

PIEZA a menos que se le indique hacerlo.

4. No fuerce las piezas. Las piezas deben

calzar con facilidad. El exceso de fuerza

puede provocar daños y dejar el montaje

fuera de funcionamiento.

5. Inspeccione los sellos y superficies de

apoyo en busca de residuos o daños.

6. Después de realizar el servicio, vuelva

a presurizar el montaje y pruébelo para

asegurar su correcto funcionamiento.

Desarmado de la válvula de retención

1. Cierre la válvula de retención de salida,

luego cierre la válvula de retención de

entrada. Purgue la presión residual del

montaje abriendo los grifos de prueba

N.º4, N.º 3 y N.º 2, en este orden.

2. Quite los pernos/tuercas de la cubierta y

levante la cubierta del cuerpo. Los resortes

son retenidos y la cubierta debe alejarse

del cuerpo aproximadamente 6 mm

(1/4depulg.).

3. Inspeccione/limpie residuos del disco y

del anillo de asiento. Reemplace piezas

gastadas o dañadas según sea necesario.

4. Vuelva a colocar la cubierta; asegúrese

de que el montaje de resortes esté

colocado en el receptáculo del pivote. Si

es necesario, aplique grasa aprobada por

la FDA a la ranura de la junta tórica en el

cuerpo para mantener la junta tórica en

posición mientras instala la cubierta.

5. Coloque los pernos y tuercas y ajústelos.

Procedimiento de prueba

FEBCO recomienda el uso del método de

prueba anual adecuado presentado en el

manual del ASSE Serie 5000 que concuerda

con sus códigos locales.

Resolución de problemas para montajes de retención doble

PROBLEMA CAUSA SOLUCIÓN

1. Fuga en la válvula de retención a. Residuos en la superficie de apoyo

b. Fugas en la válvula de cierre

2. Pasaje de bajo flujo a. Retención de la línea principal bloqueada

b. Línea de derivación obstruida

7

Desarme y limpie

Desarme y limpie

Desarme y limpie

Desarme y limpie

Page 8

INSTRUCTIONS EN FRANÇAIS

!

AVERTISSEMENT

PEN SEZ

SÉCURITÉ

AVANT

TOUT

Les codes du bâtiment ou de plomberie locaux peuvent nécessiter des modifications à

l’information fournie. Vous êtes tenu de consulter les codes du bâtiment ou de plomberie locaux

avant l’installation. Si cette information n’est pas compatible avec les codes du bâtiment ou de

plomberie locaux, les codes locaux doivent être suivis.

Nécessité d’une inspection ou d’un entretien périodique : Ce produit doit être testé

périodiquement et en conformité avec les codes locaux, mais au moins une fois par an ou

plus selon les conditions de service. Des conditions d’eau corrosive et/ou des ajustements ou

des réparations non autorisées pourraient rendre le produit inefficace pour le service prévu. La

vérification et le nettoyage régulier des composants internes du produit contribuent à assurer

une durée de vie maximale et un fonctionnement correct du produit.

Lisez attentivement ce manuel avant d'utiliser cet équipement.

Négliger de lire et de suivre toutes les consignes de sécurité et

d'utilisation de l'information peut entraîner la mort, des blessures graves

ou des dégâts matériels, ou endommager l'équipement.

Veuillez conserver ce manuel pour toute référence ultérieure.

Instructions d’installation

1. Se documenter sur la règlementation

locale en vigueur, concernant l’installation

ainsi que ses exigences et restrictions

particulières. La pression d’alimentation

recommandée du circuit doit être d’au

moins 133 kPa (20 psi).

2. Ces instructions s'appliquent uniquement

aux soupapes de mise à l'air libre des

séries 850, LF850 (DC), 856, LF856 et

856ST (DCDA), de diamètre de 65 mm

à 250mm (2,5 po à 10 po). L’orientation

de la soupape par rapport à la direction

du débit doit être exactement la même

que sur l’illustration. Les robinets-vannes

peuvent être tournés dans la mesure où

le motif des boulons de la bride le permet

sur les installations verticales uniquement.

3. L’accès à l’ensemble de vannes doit

faciliter leur révision et leur entretien

périodiques. Les dégagements minimums

sur les illustrations sont donnés à titre

indicatif pour une installation intérieure,

extérieure ou dans une fosse/voûte. Ils

ne s’appliquent pas aux soupapes logées

dans un boîtier protecteur amovible.

Se conformer aux exigences de la

règlementation locale en vigueur.

4. PURGER LA CONDUITE D’ALIMENTATION

AVANT L’INSTALLATION. La conduite

sera ainsi débarrassée de toute impureté

risquant d’obstruer les clapets de nonretour, ce qui exigerait un démontage et

un nettoyage.

5. Soulever l’ensemble en accrochant les

crochets de levage aux anneaux de

levage moulés dans le corps de la vanne.

NE PAS SOULEVER L’ENSEMBLE EN

L’ACCROCHANT AUX DISQUES OU AUX

TIGES DU ROBINET-VANNE.

6. Après l’installation, remplir LENTEMENT

le dispositif avec de l’eau et purger l’air

du corps à l’aide des robinets de test

no 3 et no 4. Vérifier ensuite son bon

fonctionnement.

AVIS

L’étanchéité et le bon fonctionnement des

soupapes ont été vérifiés en usine. En

conséquence, le dysfonctionnement d’une

soupape chez le client sera fort probablement

dû à un clapet de non-retour obstrué par des

impuretés. Cette anomalie n’est pas couverte

par la garantie. Le couvercle des soupapes

devra alors être enlevé et les sièges du clapet

vérifiés et nettoyés. La garantie d’usine ne

couvre pas les dysfonctionnements causés

par des impuretés dans la conduite ou une

mauvaise installation/mise en service.

Par ailleurs, si la réclamation est couverte

par la garantie, contacter votre fournisseur

local ou le représentant FEBCO. NE

PAS DÉPOSER LA SOUPAPE DE LA

CANALISATION.

7. La soupape doit être protégée contre le

gel et une montée de pression excessive.

Une dilatation thermique ou un coup de

bélier peuvent occasionner une pression

excessive. Ces occurrences de surpression

doivent être éliminées pour prévenir tout

dommage à la soupape et au circuit.

8

Page 9

Installation type

Flow

12" min. (300mm)

Refer To Local Codes

6" min. (150mm)

Refer To Local Codes

6" min. (150mm)

Refer To Local Codes

18" min. (45mm)

Figure 1

INSTALLATION HORIZONTALE DU DISPOSITIF À DOUBLE CLAPET DES

SÉRIES 850 ET LF850 ET DU DÉTECTEUR À DOUBLE CLAPET DE SÉRIE 856,

LF856 ET 856ST (Vue de face, illustrée avec une crépine)

Figure 2

INSTALLATION HORIZONTALE DU DISPOSITIF À DOUBLE CLAPET DES

SÉRIES 850 ET LF850 ET DU DÉTECTEUR À DOUBLE CLAPET DE SÉRIE

856, LF856 ET 856ST (Vue de dessus, illustrée avec une crépine)

300 mm (12 po) min.

Se conformer aux codes locaux

RWWP

FRT

4175

Débit

150 mm (6 po) min.

Se conformer aux codes locaux

150 mm (6 po) min.

Se conformer aux codes locaux

Débit

450 mm (18 po) min.

Figure 3

300 mm (12 po) min.

INSTALLATION

VERTICALE DU

DISPOSITIF À

DOUBLE CLAPET DES

SÉRIES 850 ET LF850

ET DU DÉTECTEUR À

DOUBLE CLAPET DE

SÉRIES 856 ET 856ST

(Vue de face, illustrée

avec une crépine)

Se conformer aux codes locaux

Figure 4

450 mm (18 po) min.

300 mm (12 po) min.

150 mm (6 po) min.

au-dessus de tous tuyaux

150 mm (6 po) min.

et usages en aval

Se conformer aux codes locaux

INSTALLATION VERTICALE

DU DISPOSITIF À DOUBLE

CLAPET DES SÉRIES 850 ET

4175

RWWP

FRT

Débit

LF850 ET DU DÉTECTEUR

À DOUBLE CLAPET DE

SÉRIES 856 ET 856ST (Vue

de dessus, illustrée avec

une crépine)

VÉRIFIER LES EXIGENCES

DU CODE LOCAL

Se conformer aux codes locaux

9

Page 10

Entretien des dispositifs à double clapet

Généralités

FEBCO recommande d’effectuer un entretien annuel. Consultez les codes locaux pour

connaître les exigences dans votre région.

1. Contacter au besoin son représentant local

Febco pour obtenir un manuel d’entretien.

2. Rincer toutes les pièces à l’eau propre

avant de les remonter.

3. NE PAS APPLIQUER DE PÂTE À JOINT,

D’HUILE, DE GRAISSE, NI DE SOLVANT

SUR LES PIÈCES, sauf indication contraire.

4. Ne pas forcer sur les pièces : elles doivent

s’assembler avec aisance. Une force

excessive pourrait les endommager et

rendre la soupape inutilisable.

5. Vérifier avec soin les surfaces de portée et

les joints (dommages ou impuretés).

6. Après avoir terminé l’entretien, pressuriser

puis contrôler à nouveau la soupape.

Démontage du clapet de non-retour

1. Fermer le robinet de sortie, puis le robinet

d’arrivée d’eau. Ouvrir d’abord le robinet

de contrôle no 4, puis le no 3 et le no 2,

dans cet ordre, afin d’éliminer la pression

résiduelle.

2. Déposer les boulons et les écrous du

couvercle et soulever le couvercle du corps

du dispositif. La charge des ressorts est

conservée et le couvercle doit être éloigné

du corps du dispositif d’environ 6 mm

(0,25po).

3. Inspecter et nettoyer les débris du disque

et du siège de la bague. Remplacer les

pièces usées ou endommagées au besoin.

4. Remettre en place le couvercle en

s’assurant que le dispositif à ressorts est

placé sur l’emboîtement du pivot. Appliquer

au besoin de la graisse approuvée par la

FDA dans la rainure du joint torique du

corps afin de garder le joint torique en

position pendant l’installation du couvercle.

5. Installer les boulons et les écrous et les

resserrer.

Procédé d’essai

FEBCO recommande de choisir l’un des tests

annuels présentés dans le manuel ASSE de

série 5000, en fonction de sa conformité à la

règlementation locale en vigueur.

Dépannage des dispositifs à double clapet

ANOMALIE CAUSE PROBABLE CORRECTIF

1. Le clapet de

non-retour fuit

2. Débit trop faible a. Le clapet de non-retour de la conduite principale est obstrué

a. Des débris se sont logés sur la surface du siège

b. Le robinet d’arrêt fuit

b. La conduite de dérivation est obstruée

Démonter et nettoyer

Démonter et nettoyer

Démonter et nettoyer

Démonter et nettoyer

10

Page 11

ENGLISH

WARNING: This product contains chemicals known to the

State of California to cause cancer and birth defects or

other reproductive harm.

For more information: www.watts.com/prop65

Limited Warranty: FEBCO (the “Company”) warrants each product to be free from defects in material and workmanship under

normal usage for a period of one year from the date of original shipment. In the event of such defects within the warranty period,

the Company will, at its option, replace or recondition the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH

RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED. THE COMPANY

HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of warranty,

and the Company shall not be responsible for any incidental, special or consequential damages, including without limitation, lost

profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs

resulting from labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water

conditions, chemical, or any other circumstances over which the Company has no control. This warranty shall be invalidated by

any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or

limitation of incidental or consequential damages. Therefore the above limitations may not apply to you. This Limited Warranty

gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state

laws to determine your rights. SO FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT

MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL SHIPMENT.

SPANISH

ADVERTENCIA: Este producto contiene sustancias químicas

que en el Estado de California se conocen como causantes de

cáncer y malformaciones u otros daños reproductivos.

Para más información: www.watts.com/prop65

Garantía limitada: FEBCO (en adelante, “la Compañía”) garantiza, por un período de un año a partir de la fecha de embarque original, que

sus productos están libres de defectos en materiales y mano de obra bajo condiciones de uso normal. En caso de que se encuentren tales

defectos dentro del período de garantía, la Compañía reemplazará o reacondicionará, a su elección, el producto sin costo alguno.

LA GARANTÍA AQUÍ ESTIPULADA SE OTORGA EN FORMA EXPRESA Y ES LA ÚNICA GARANTÍA OTORGADA POR LA COMPAÑÍA

EN RELACIÓN CON EL PRODUCTO. LA COMPAÑÍA NO OTORGA NINGUNA OTRA GARANTÍA, YA SEA EXPRESA O IMPLÍCITA. LA

COMPAÑÍA POR LA PRESENTE RENUNCIA ESPECÍFICAMENTE A TODAS LAS DEMÁS GARANTÍAS, EXPRESAS O IMPLÍCITAS,

INCLUYENDO SIN LIMITACIÓN, LAS GARANTÍAS IMPLÍCITAS DE APTITUD PARA LA COMERCIALIZACIÓN E IDONEIDAD PARA UN

PROPÓSITO EN PARTICULAR.

La solución descrita en el primer párrafo de esta garantía constituirá la única y exclusiva solución por incumplimiento de garantía, y la

Compañía no se hará responsable por daños accidentales, especiales o indirectos, incluyendo sin limitación, la pérdida de ganancias o el

costo de reparación o reemplazo de otra propiedad que resulte dañada por el mal funcionamiento de este producto, otros costos resultantes

por mano de obra, retardos, vandalismo, negligencia, obstrucciones ocasionadas por materiales extraños, daños debidos a condiciones

adversas del agua, químicos o cualquier otra circunstancia sobre la cual la Compañía no tenga control. Esta garantía no tendrá validez en

cualquier caso de abuso, uso indebido, aplicación incorrecta, instalación inadecuada, o mantenimiento adecuado o alteración del producto.

Algunos Estados no permiten limitaciones en la duración de una garantía implícita y algunos Estados no permiten la exclusión o limitación

de daños accidentales o indirectos. Por lo tanto, es posible que las limitaciones anteriores no sean aplicables en su caso. Esta garantía

limitada le da derechos legales específicos; usted podría tener también otros derechos que varían según el Estado. Usted debe consultar

las leyes estatales aplicables para determinar sus derechos. EN LA MEDIDA EN QUE SEA CONGRUENTE CON LAS LEYES ESTATALES

APLICABLES, CUALQUIER GARANTÍA IMPLÍCITA QUE NO SEA RECHAZADA, INCLUYENDO LAS GARANTÍAS IMPLÍCITAS DE APTITUD

PARA LA COMERCIALIZACIÓN E IDONEIDAD PARA UN PROPÓSITO EN PARTICULAR, SE LIMITA EN SU DURACIÓN A UN AÑO A PARTIR

DE LA FECHA DEL EMBARQUE ORIGINAL.

11

Page 12

FRENCH

AVERTISSEMENT: Ce produit contient des produits chimiques

reconnus par l’État de Californie comme étant cancérigènes et

pouvant provoquer des anomalies congénitales ou affecter la

capacité de reproduction.

Pour plus d'informations : www.watts.com/prop65

Garantie limitée: FEBCO (la « Société ») garantit que chacun de ses produits est exempt de vice de matériau et de fabrication dans

des conditions normales d’utilisation pour une période d’un an à compter de la date d’expédition d’origine. Dans l’éventualité où de tels

vices se manifesteraient pendant la période de garantie, la Société, à sa discrétion, remplacera ou reconditionnera le produit sans frais.

LA PRÉSENTE GARANTIE EST EXPRESSE ET REPRÉSENTE LA SEULE GARANTIE OFFERTE PAR LA SOCIÉTÉ POUR CE PRODUIT. LA

SOCIÉTÉ N’OFFRE AUCUNE AUTRE GARANTIE, EXPRESSE OU TACITE. PAR LA PRÉSENTE, LA SOCIÉTÉ REJETTE SPÉCIFIQUEMENT

TOUTE AUTRE GARANTIE, EXPRESSE OU TACITE, NOTAMMENT TOUTE GARANTIE TACITE DE QUALITÉ MARCHANDE OU

D’ADAPTATION À UN BUT PARTICULIER.

Le recours décrit dans le premier paragraphe de cette garantie constitue le seul recours à toute violation de la présente garantie. La

Société ne saurait être tenue responsable de tout dommage accessoire, spécial ou indirect, y compris, de façon non limitative : la perte

de profits ou le coût afférent à la réparation ou au remplacement d’autres biens qui seraient endommagés par suite du fonctionnement

incorrect dudit produit ; d’autres coûts résultant de frais de main-d’œuvre, de retards, de vandalisme, de négligence, d’une obstruction

causée par des matériaux étrangers, de dommages causés par une eau impropre, des produits chimiques ou par tout autre événement échappant au contrôle de la Société. La présente garantie est déclarée nulle et non avenue en cas d’usage abusif ou incorrect,

d’application, d’installation ou d’entretien incorrects ou de modification du produit.

Certains États n’autorisent pas les limitations de durée d’une garantie tacite ou l’exclusion ou la limitation des dommages accessoires ou

indirects. Les limitations susmentionnées peuvent donc ne pas s’appliquer à vous. Cette garantie limitée vous donne des droits spécifiques et il se peut que vous ayez aussi d’autres droits qui varient d’un État à l’autre. Veuillez vous référer aux lois applicables de l’État

pour déterminer vos droits en la matière. DANS LA MESURE PERMISE PAR LA LOI APPLICABLE DE L’ÉTAT, TOUTES LES GARANTIES

TACITES NE POUVANT PAS ÊTRE REJETÉES, Y COMPRIS LES GARANTIES TACITES DE QUALITÉ MARCHANDE ET D’ADAPTATION

À UN BUT PARTICULIER, SONT LIMITÉES QUANT À LEUR DURÉE À UN AN À COMPTER DE LA DATE D’EXPÉDITION D’ORIGINE.

A Watts Water Technologies Company

Una compañía de Watts Water Technologies

Une entreprise de Watts Water Technologies

USA: Tel: (800) 767-1234 • Fax: (800) 788-4491 • FEBCOonline.com

Latin America: (52) 81-1001-8600 • Fax: (52) 81-8000-7091 • FEBCOonline.com

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068 • FEBCOonline.ca

IS-F-850/856-DC/DCDA 1452 EDP# 980048 © 2014 FEBCO

Loading...

Loading...