Page 1

INSTALLATION INSTRUCTIONS

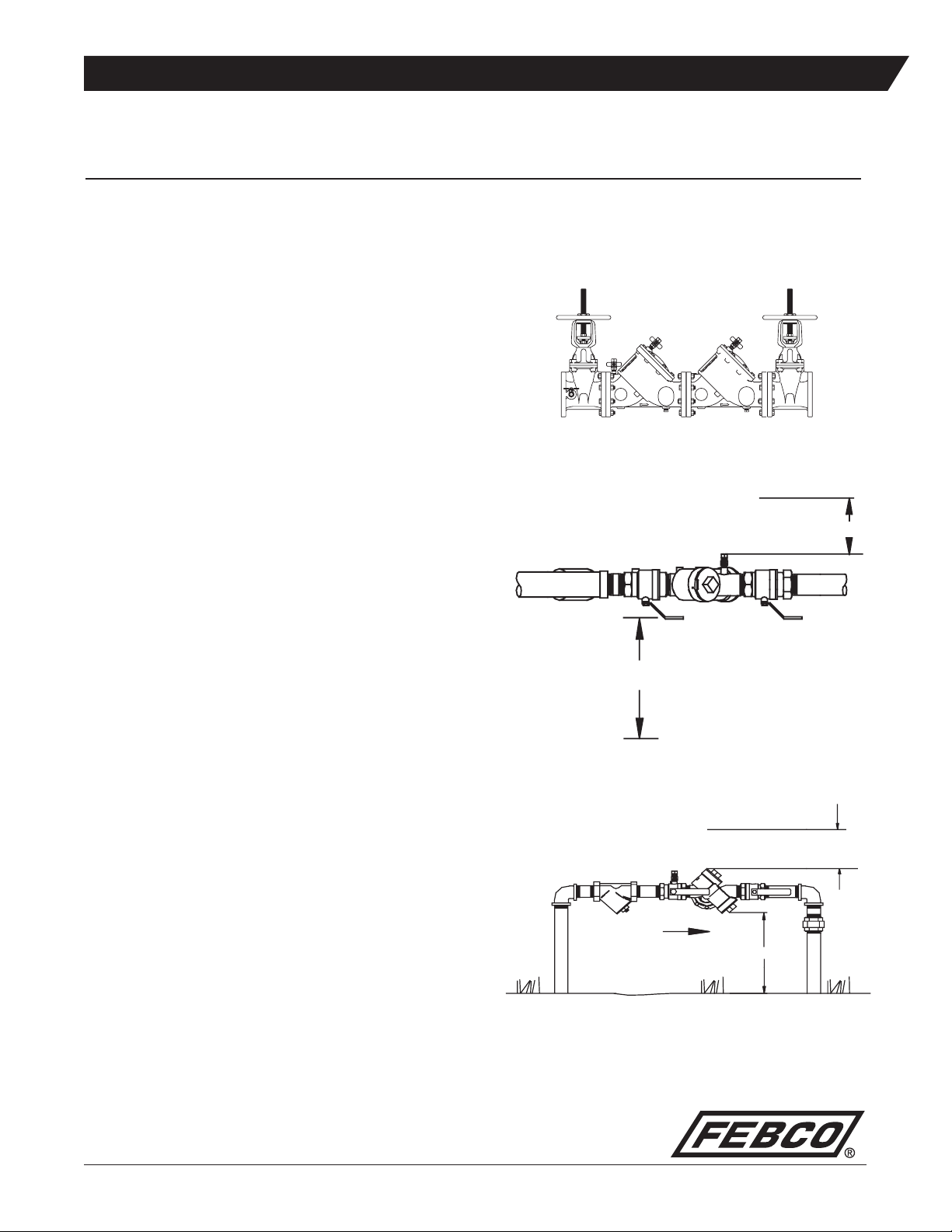

Series 805Y, 805YD, 806YD

Double Check Detector Assemblies

Installation Instructions

1. Consult local codes for specific installation requirements and restrictions

applicable to your area. It is recommended that system supply pressure

be at least 20psi (138 kPa).

2. These instructions apply only to Series 805Y sizes 3⁄4" – 2" (20 – 50mm),

805YD sizes 21⁄2" – 10" (65 – 250mm), and 806YD sizes 3" – 10"

(80 – 250mm). The valves may be installed only in the orientation/flow

directions as shown. The gate valves may be rotated, as permitted by

the flange bolt pattern, on vertical installations only.

3. The valve assembly must be installed where it is accessible for periodic

testing and maintenance. Clearances shown in the installation views

apply to exterior, interior and pit/vault installations and are only recommendations. These minimums do not apply to removable protective

enclosures. Refer to local codes for actual requirements in your area.

4. PRIOR TO INSTALLING THE VALVE INTO THE LINE, FLUSH THE

SUPPLY LINE OF ALL FOREIGN MATERIAL. Failure to flush the

supply line may cause the check valves to become fouled and require

disassembly and cleaning.

5. Lift the assembly by the valve body. DO NOT LIFT THE ASSEMBLY

BY CONNECTING TO THE VALVE HANDLES, STEMS, OR

BYPASS PIPING. On 21⁄2" – 10" (65 – 250mm) units lift eyes are bolted

to the check covers.

6. After installation SLOWLY fill the assembly with water and bleed air

from the body using the # 2, # 3 and # 4 test cocks. Test the valve

assembly to ensure correct operation.

NOTE: All assemblies are tested at the factory for proper operation and

leakage. If the valve does not pass the field test, it is most likely due to

a fouled check valve. This is not covered by the factory warranty. The

valve cover(s) must be removed and the check seats inspected and

cleaned. Any damage or improper operation caused by pipeline debris

or improper installation/start-up is not included in the factory warranty.

In case of a possible warranty claim, contact your local supplier or

FEBCO Representative. DO NOT REMOVE THE VALVE ASSEMBLY

FROM THE PIPELINE.

7. The assembly must be protected from freezing and excessive pressure

increases. Pressure increases can be caused by thermal expansion or

water hammer. These excessive pressure situations must be eliminated to protect the valve and system from possible damage.

8. Plastic testcock plugs and tethers are provided for the Series 805Y

(loose in box) for areas that require them.

Figure 1

Figure 2

IS-F-805Y/805YD/806YD

Sizes: 3⁄4" – 10" (20 – 250mm)

6" (150mm) Min

Horizontal Installation for the DC Series 805YD

(Top View, Shown with Strainer)

12" (300mm) Min

Flow

Horizontal Installation for the Series 805YD

(Top View, Shown with Strainer)

12" (300mm) Min

18" (450mm) Min

Page 2

MAINTENANCE MANUAL

FRT

175

RWWP

4

Service and Maintenance

General

1. Detailed maintenance manuals are available from your local FEBCO representative.

2. Rinse all parts with clean water prior to reassembly.

3. DO NOT USE ANY PIPE DOPE, OIL, GREASE, OR SOLVENT ON

ANY PARTS unless instructed to do so.

4. Do not force parts. Parts should fit together freely. Excess force may

cause damage and render the assembly inoperable.

5. Carefully inspect seals and seating surfaces for debris or damage.

6. After servicing, repressurize the assembly and test to ensure proper

operation.

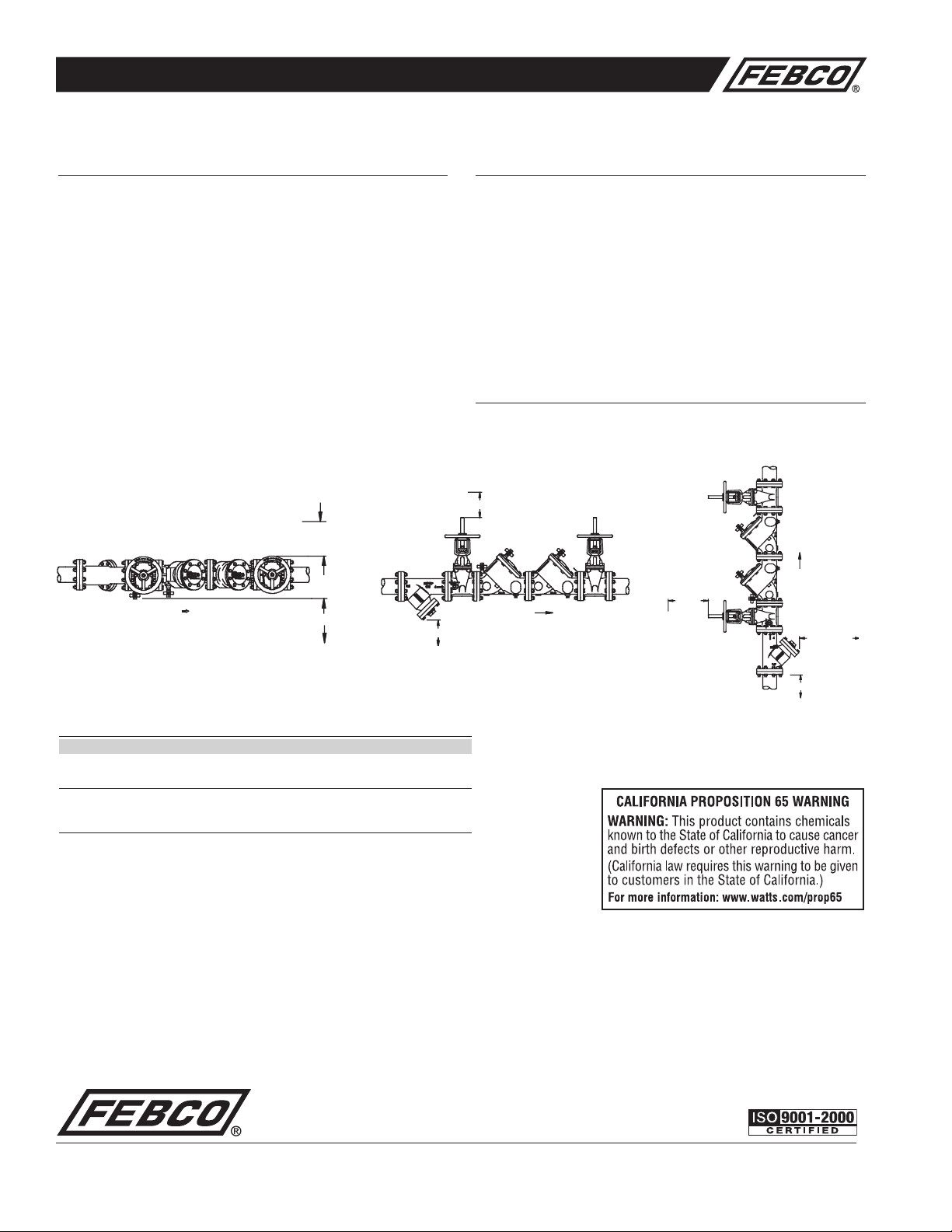

12" (300mm) Min.

6" (150mm) Min.

Refer to Local Codes

Flow

Horizontal Installation of the DC Series 805YD

(Top View, Shown with Stainer)

18" (450mm) Min.

Refer To Local Codes

Horizontal Installation of the DC Series 805YD

(Front View, Shown with Stainer)

Troubleshooting

PROBLEM CAUSE SOLUTION

1. Check valve leaking a. Debris on check seating surfaces Disassemble/clean

b. Leaking shutoff valve Disassemble/clean

2. Low flows passing a. Mainline check fouled Disassemble/clean

through mainline valve b. Bypass line plugged Disassemble/clean

(DCDA)

Check Valve Disassembly

1. Close the outlet shutoff valve, then close the inlet shutoff valve. Bleed

residual pressure from the assembly by opening the #4, #3 and #2 tests

cocks in this sequence.

2. Unscrew/Unbolt the cover and remove the spring and disc holder

assembly. NOTE: Unbolt covers on valves 4" (100mm) and larger have

their springs retained and the covers should push away from the body

approximately 1⁄4" (8mm) as the bolts are loosened. CAUTION: The covers on valves 3" (80mm) and smaller are spring loaded.

3. Inspect/clean debris from the disc and seat area. Replace worn/damaged parts as required.

4. Reassemble the valve in the reverse order of disassembly.

Test Procedure

FEBCO recommends the use of the appropriate test method presented in

the ASSE Series 5000 manual that is consistent with your local codes.

Flow

Flow

12"

(300mm)

Min.

Vertical Installation of the DC Series 805YD

(Shown with Stainer)

(Approved vertically only through ASSE)

Refer To

Local

Codes

Refer To

Local Codes

Limited Warranty: FEBCO warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of original shipment. In the event

of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER

WARRANTIES, EXPRESS OR IMPLIED. THE COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of warranty, and the Company shall not be responsible for any incidental, special

or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting

from labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any other circumstances over which the Company has no

control. This warranty shall be invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above

limitations may not apply to you. This Limited Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state laws to

determine your rights. SO FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL SHIPMENT.

A Division of Watts Water Technologies, Inc.

IS-F-805Y/805YD/806YD 0845 EDP# 980003 © FEBCO, 2008

USA: 4381 N. Brawley • Ste. 102 • Fresno, CA • 93722 • Tel. (559) 441-5300 • Fax: (559) 441-5301 • www.FEBCOonline.com

Canada: 5435 North Service Rd. • Burlington, ONT. • L7L 5H7 • Tel. (905) 332-4090 • Fax: (905) 332-7068 • www.FEBCOonline.ca

Loading...

Loading...