FasTest XT Series Rebuild User Manual

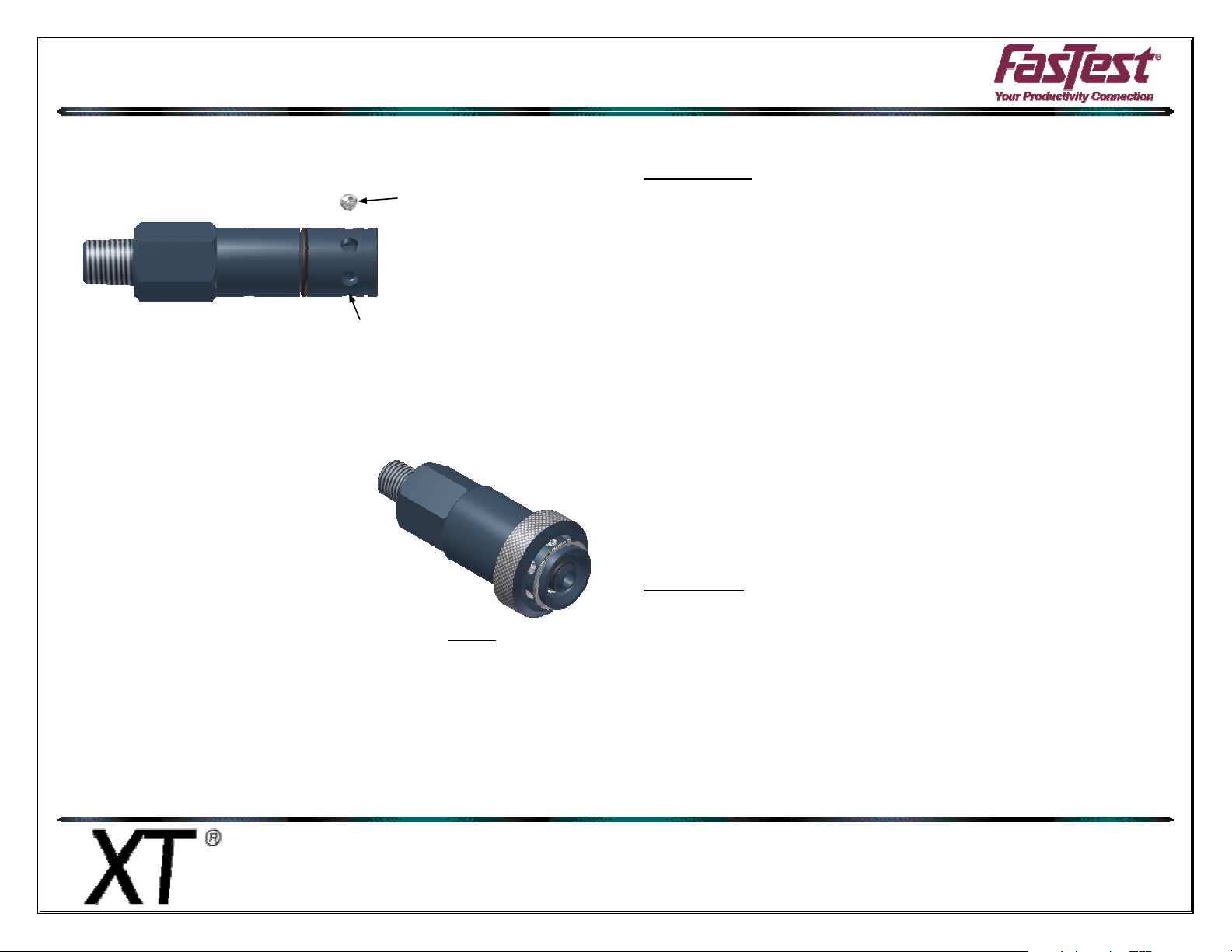

XT Connector Exploded

View

REBUILD INSTRUCTIONS

9. Place a small amount of petroleum jelly into the latching ball holes in the

body. This will help retain the balls while assembling the connector. Insert

the larger latching balls(3) into the latching ball holes in the body.

10. Lubricate the inside of sleeve(7) and slide it over the body(1) until it

bottoms. Make sure the small outside diameter of the sleeve is towards

the termination end.

11. Install the retaining ring(9) into the front groove in body.

12. Check connector operation and leak test.

13. Discard all used components.

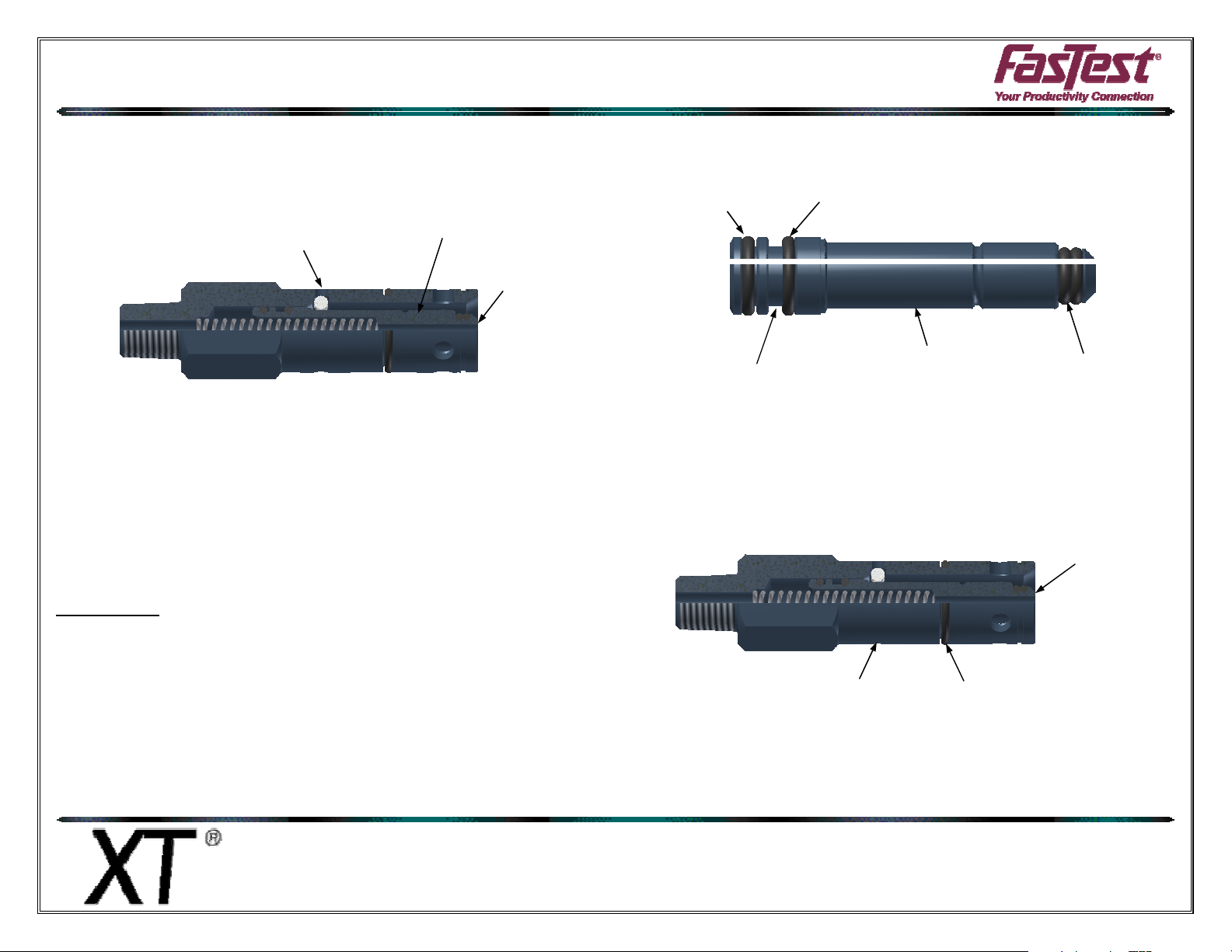

LATCHING BALL HOLES

LATCHING BALL (3)

FasTest, Inc. Product Warranty

FasTest, Inc. warrants its products against defects of workmanship and/or material for 12 months from the date of the

sale by FasTest, Inc. This warranty is void if the product is misused, tampered with or used in a manner that is not in

accordance with FasTest, Inc. recommendations and/or instructions. FasTest, Inc. is not liable for consequential or

other damages including, but not limited to, loss, damage, personal injury, or any other expense directly or indirectly

arising from the use of or inability to use its products either separately or in combination with other products. ALL

OTHER WARRANTIES EXPRESSED OR IMPLIED, WHETHER ORAL OR WRITTEN, INCLUDING BUT NOT

LIMITED TO WARRANTIES OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE

EXPRESSLY EXCLUDED.

Remedy under this warranty is limited to replacement of the product or an account credit in the amount of the original

selling price, at the option on FasTest, Inc. All allegedly defective products must be returned prepaid transportation to

FasTest, Inc. along with information describing the products performance, unless disposition in the field is authorized

in writing by FasTest, Inc.

XTR Rebuild Instructions

Description:

Please thoroughly read the instructions prior to

rebuilding the XT Connector. If you do not understand

instructions, or if components are missing, call FasTest

before rebuilding connector.

Disassembly:

1. Open the rebuild kit and remove instructions from bag. Slide the

sleeve(7) back toward the termination end to expose the retaining ring(9).

Using a pick (or like tool), remove the retaining ring. Note: the retaining

ring will be replaced.

2. Slide the sleeve(7) off the end of the connector opposite the termination

end.

3. The latching balls(3) can now be removed. They will either fall out or can

be pushed from the inside. Note: the balls will be replaced.

XT Connector rebuild instructions

Roseville, MN

Ph: 1-800-444-2373

Fax: 651-645-7390

www.fastestinc.com

WP070 10/6/2010

REBUILD INSTRUCTIONS

4. Depress the piston(6) flush with body(1), then use compressed air and

blow air into the smaller retaining ball hole in the body(1). The retaining

balls(2) should be forced out the other, larger ball hole in the body. If they

do not come out, the connector may need to be cleaned, so the balls

move freely. Note: the balls will be replaced.

SMALL RETAINING

BALL HOLE

PISTON (6)

FLUSH

5. The piston(6) should now be free. Simply pull and remove the piston(6).

The internal spring(4) will be loose and can be removed.

6. Remove o-rings(5, 10 & 11) from the piston. Note: the o-rings will be

replaced.

7. Remove the o-ring(8) from the outside of the body. Note: the o-ring will be

replaced.

Re-Assembly:

1. Make sure all components have been cleaned and are ready for

assembly. Open the rebuild kit and identify the components.

2. Install the smallest o-rings(11) onto the piston(6).

3. Install the Teflon coated o-ring(5) into the large wider groove in the

piston(6). Make sure the o-ring is located towards the front end of the

piston. (As shown below).

4. Install o-ring(10) into the large narrower groove on piston.

5. Lubricate the two o-rings(5 & 10) on the large end of the piston(6) with

White Petroleum Jelly. Apply lubricate so as to fill the void between the orings. (As shown below). Note: Do not lubricate the small o-rings(11).

O-RING (10)

TEFLON O-RING (5) TO THIS SIDE OF GROOVE

FILL THIS AREA WITH LUBE

PISTON (6)

DO NOT LUBE THESE

TWO O-RINGS

6. Place the spring(4) into the piston(6) and install the assembly into the

body(1).

7. Compress the piston(6) into the body(1) until it stops. Install the small

balls(2) through the larger retaining ball hole in the body(1).

COMPRESS

PISTON

LARGE RETAINING

BALL HOLE

O-RING (8)

8. Install the sleeve friction o-ring(8) into groove on outside of the body(1).

Roseville, MN

Ph: 1-800-444-2373

Fax: 651-645-7390

www.fastestinc.com

WP070 10/6/2010

Loading...

Loading...