FasTest FE01, FE6 User Manual

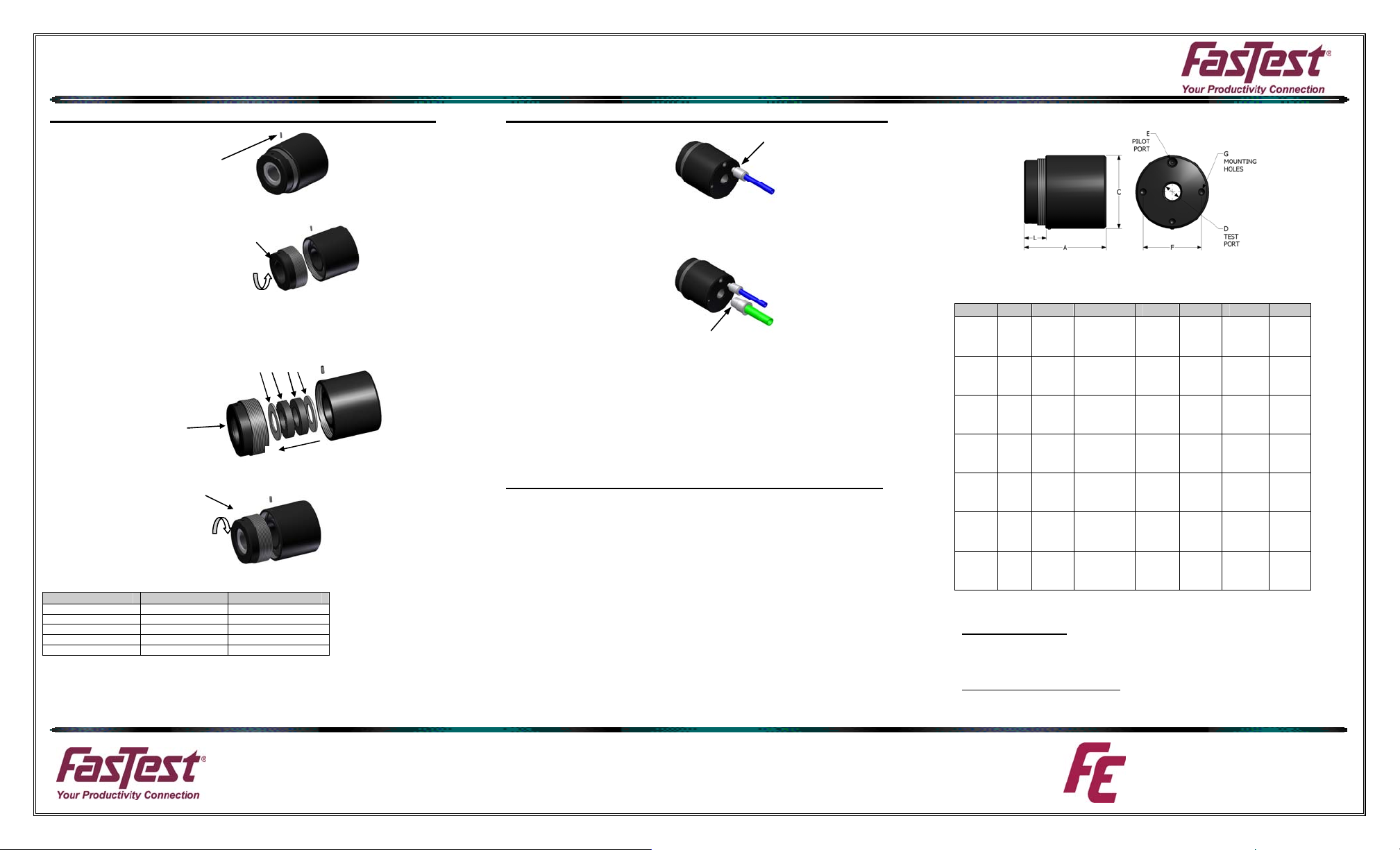

SPANNER

CCW

FE SEAL SET

SEE CHART 1

ASSEMBLY

DIRECTION

OF SEALS

& WASHERS

SEAL

CASING

CW

SEAL CASING

DIAGRAM 2

OPERATING INSTRUCTIONS

Installation of Seals:

• For seal install or replacement

loosen set screw on side of housing.

SET SCREW

• Unscrew (counterclockwise) and

remove seal casing. NOTE: A spanner

wrench hole is provided for breaking

the seal casing loose if required.

WRENCH

HOLE

• Seal sets contain elastomer seals and backup washers per Chart 1. For complete

listing of seal set size ranges see catalog.

• Verify that seals and washers are the same size.

• Assemble seal set into seal casing.

See Chart 1.

• Reassemble and tighten seal casing w/seal set to housing.

• Retighten set screw.

*Seal Set Parts Required CHART 1

Connector Number of Seals Number of Washers

FE01, FE01M 1 2

FE1, FE1M 1 2

FE2, FE2M 2 2

FE3, FE4, FE3M, FE4M 3 2

FE5, FE6, FE5M, FE6M 3 2

• Use of less than the listed number of seals (for less insertion depth) requires a spacer. See FasT-

est catalog. Seal Installation Instructions included with seal sets.

• WARNING: Seals and washers must have the same size outside and inside diameters. Use of the

incorrect size seals or washers will result in loss of seal ability.

WITH SEAL SET

Attachment of Pilot Pressure and Test Media Supply Line:

FE MODEL CONNECTOR

• Attach pilot pressure line

to pilot port “E” from Diagram 2.

• A pneumatic regulated source is required to maximize seal life and assure optimum

seal ability for the application. The pilot pressure should be minimized to maintain

sealing on the test piece without excessive compression of the seal.

• Attach test media line to

test port “D” from Diagram 2.

FITTING/TUBING

TO TEST PORT “D”

• Provide a means whererby test pressure will not be introduced until the pilot pressure required to seal is reached. The means should also provide quick exhaust of

test pressure in the event pilot pressure falls below the minimum required to seal.

Mounting of Connector:

The FE Connector must be SECURED to the test piece by a mechanical device

before proceeding.

• The test connector must be secured with a mechanical or other device to assure the

connector is not uncoupled from the test piece. The test itself will provide an uncoupling force. The securing or holding device may be a fixture, clamp, cylinder or

other appropriate means that prevents ejection of the test piece from the connector.

Uncoupling force example:

If the test piece has a ½” O.D. and is tested at 400 psi maximum. The uncoupling force = area(πr²) x

pressure) = π x .25² x 400 = 79 lbs.

• Secured device should be designed to withstand this force and include an adequate margin for

safety.

• Do not activate the connector without an adequate and safe securing mechanism.

• Mount the FasTest FE connector to the fixture or appropriate device using either threaded

mounting holes on the rear of the connector body, (“G” Diagram 2), or appropriate adapter.

FITTING/TUBING

TO PILOT PORT “E”

FE Connector Dimensions

Maximum test pressure: Vacuum to 500 psi

Flow capability: Limited by “D” below

CHART 2

FE A C D E F G* L**

FE01

FE01M

FE1

FE1M

FE2

FE2M

FE3

FE3M

FE4

FE4M

FE5

FE5M

FE6

FE6M

* FE4, FE4M, FE5, FE5M, FE6, FE6M have 3 mounting holes.

**L = Minimum insertion length of test piece.

Material Specifications

Body, Housing, Piston: Aluminum

Main Seal Washers: Steel QPQ treated or Stainless Steel

Main Seal: Neoprene

O-rings: Buna-N

Other materials available on request.

NOTE: All specifications subject to change without notice.

2.05 1.49 1/8

2.72 2.22 ¼

3.50 3.11 ½

4.48 4.23 1 NPTF

4.60 5.48 1-1/2

4.60 6.98 2 NPTF

4.97 7.48 2-1/2

NPTF

1/8

BSPP

NPTF

¼

BSPP

NPTF

½

BSPP

1 BSPP

NPTF

1-1/2

BSPP

2 BSPP

NPTF

2-1/2

BSPP

10-32

UNF

M5x.8

1/8

NPTF

1/8

BSPP

1/8

NPTF

1/8

BSPP

1/8

NPTF

1/8

BSPP

1/8

NPTF

1/8

BSPP

1/8

NPTF

1/8

BSPP

1/8

NPTF

1/8

BSPP

1.10 10-32

1.62 ¼-28

2.50 ¼-28

3.25 ¼-28

4.25 ¼-28

5.50 3/8-24

6.12 3/8-24

UNF

M5x.8

UNF

M6x1

UNF

M6x1

UNF

M6x1

UNF

M6x1

UNF

M11x1.5

UNF

M11x1.5

.58

1.06

1.06

1.64

1.64

1.64

1.64

www.fastestinc.com

Roseville, MN

Ph 1-800-444-2373

Fax 651-645-7390

WP007 03/2009

Loading...

Loading...