FasTest TwistMate Series Seal Replacement User Manual

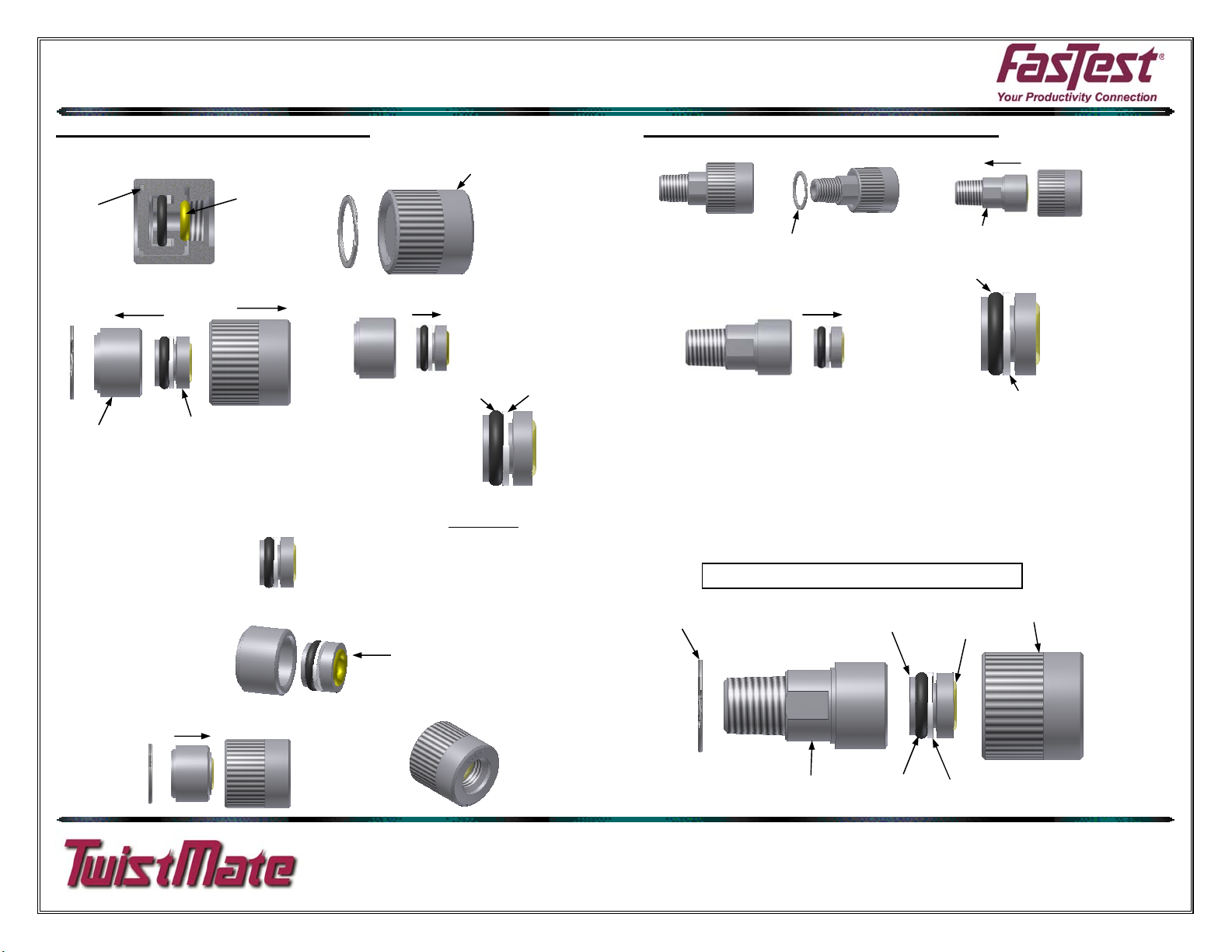

RING (A

)

REPLACMENT INSTRUCTIONS

1. Cap Body Connector Seal Replacement:

1. Using a sharp stiff pick remove ret. ring (A) from connector and discard.

NOTE: WHEN THE END OF THE RING IS FREE ‘WALK’ RING OUT OF GROVE WITH PICK.

RET.

FACE

SEAL

SLEEVE (B)

2. Push body (C) and piston (D) out of sleeve (B). Then remove piston from body.

CAP BODY (C)

3. Remove o-ring (F) and back-up ring (E) from piston and discard.

. Before Installing new back-up ring and o-ring make sure piston and inside of body are clean and free of

4

dust and dirt.

5. Install new back-up ring as shown on piston. Then lubricate new o-ring with petroleum jelly and install as

shown.

6. Install piston with new o-ring and back-up ring into body with a slight twist as you push into body.

7. Slide body/piston assembly into sleeve and install new ret. ring, making sure it is completely seated in its

roove.

g

PISTON (D)

SLEEVE

O-RING (F)

PISTON INSTALL

WITH SLIGHT TWIST

TEFLON

BACK-UP RING (E)

FINISHED

ASSEMBLY

2. Threaded Body Connector Seal Replacement:

1. Follow the steps to the left for this style connector as well.

RET. RING

EXPLODED VIEW OF THREADED BODYCONNECTOR

THREADED BODY

O-RING

TEFLON BACK-UP RING

RET. RING

PISTON

FACE SEAL

THREADED BODY

O-RING

BACK-UP RING

SLEEVE

Roseville, MN

Ph: 1-800-444-2373

Fax: 651-645-7390

www.fastestinc.com

WP111 10/7/2010

REPLACMENT INSTRUCTIONS

CONNECTOR MAINTENANCE:

daily, weekly and periodic inspection of the connector by competent

• A

person is recommended.

• User must establish a regular interval for maintenanc

e as determined by

the user media and operational environment.

• Inspection should include damage to the body missing or loose

components, leak tightness, ease of operation, sufficient lubrication,

wear, dirt accumulation and damage.

• Inspect threads for wear.

• Use only original FasTest spare parts that are designed for the

application and are subject to strict quality control. See Warranty.

• Lubricate on regular intervals under normal operating conditions.

Lubrication should be compatible with user application.

FasTest, Inc. Product Warranty

FasTest, Inc. warrants its products against defects of workmanship and/or material for 12 months

the date of the sale by FasTest, Inc. This warranty is void if the product is misused, tampered with or

used in a manner that is not in accordance with FasTest, Inc. recommendations and/or instructions.

FasTest, Inc. is not liable for consequential or other damages including, but not limited to, loss, damage,

personal injury, or any other expense directly or indirectly arising from the use of or inability to use its

products either separately or in combination with other products. ALL OTHER WARRANTIES

EXPRESSED OR IMPLIED, WHETHER ORAL OR WRITTEN, INCLUDING BUT NOT LIMITED TO

WARRANTIES OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE

EXPRESSLY EXCLUDED.

Remedy under this warranty is limited to replacement of the product or an account credit in the amount

of the original selling price, at the option on FasTest, Inc. All allegedly defective products must be

returned prepaid transportation to FasTest, Inc. along with information describing the products

performance, unless disposition in the field is authorized in writing by FasTest, Inc.

from

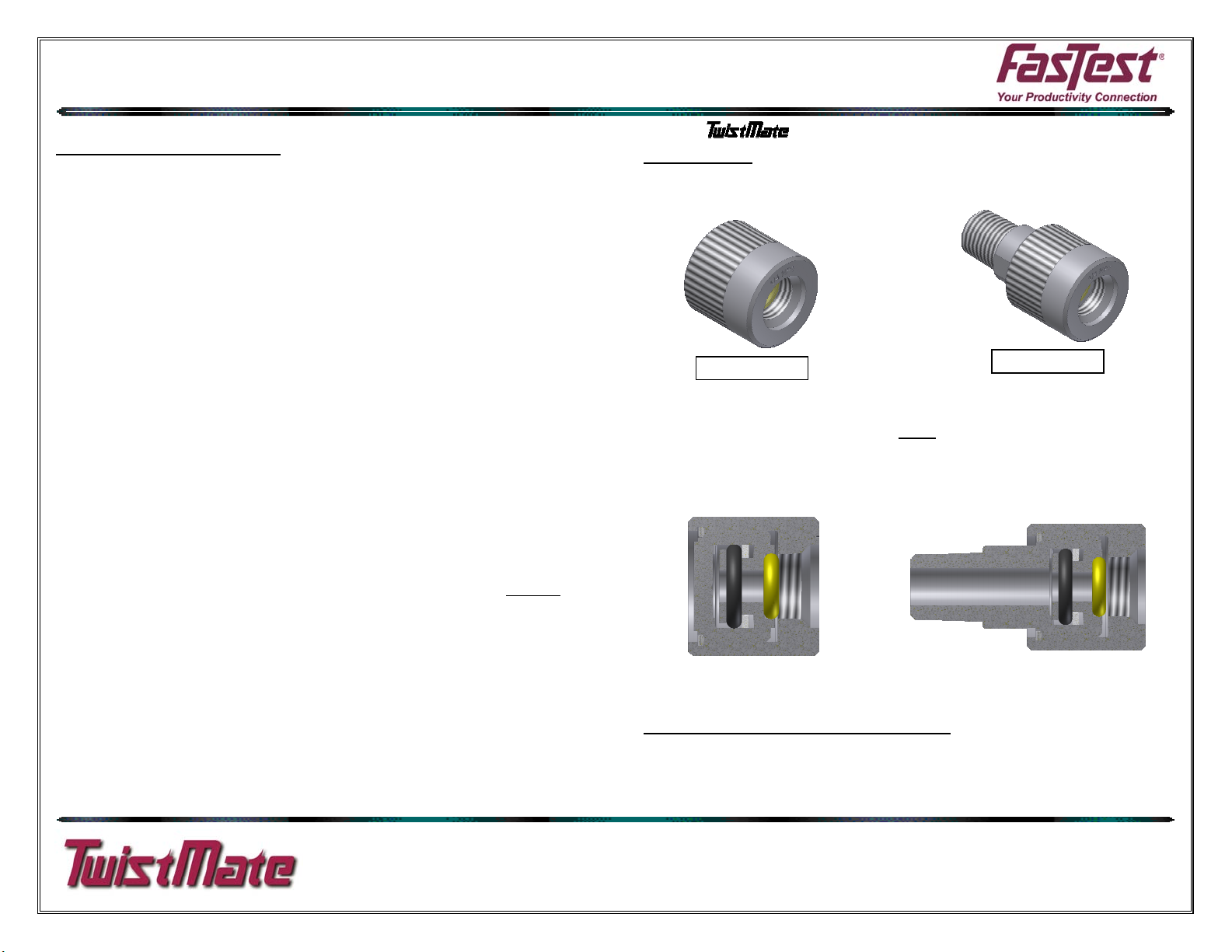

METR Internal Seal Replacement Instru

Description:

Internal Seal and Back-Up Ring Replacement

ctions.

Instructions for NPT, JIC and SAE O-Ring Boss Connectors.

Please thoroughly read the following steps

CAP CONNECTOR

on properly replacing seals and

back-up rings on MET Connectors.

1. MET Cap Connector Internal Seal Replacement.

2. MET Connector Internal Seal Replacement.

CAP CROSS-SECTION

CONNECTOR CROSS-SECTION

NOTE: FACE SEALS SOLD SEPARATELY

WARNING: If instructions are not clear or components are missing, contact

factory before using connector.

CONNECTOR

Roseville, MN

Ph: 1-800-444-2373

Fax: 651-645-7390

www.fastestinc.com

WP111 10/7/2010

Loading...

Loading...