FasTest ST Series User Manual

OPERATING INSTRUCTIONS

top.

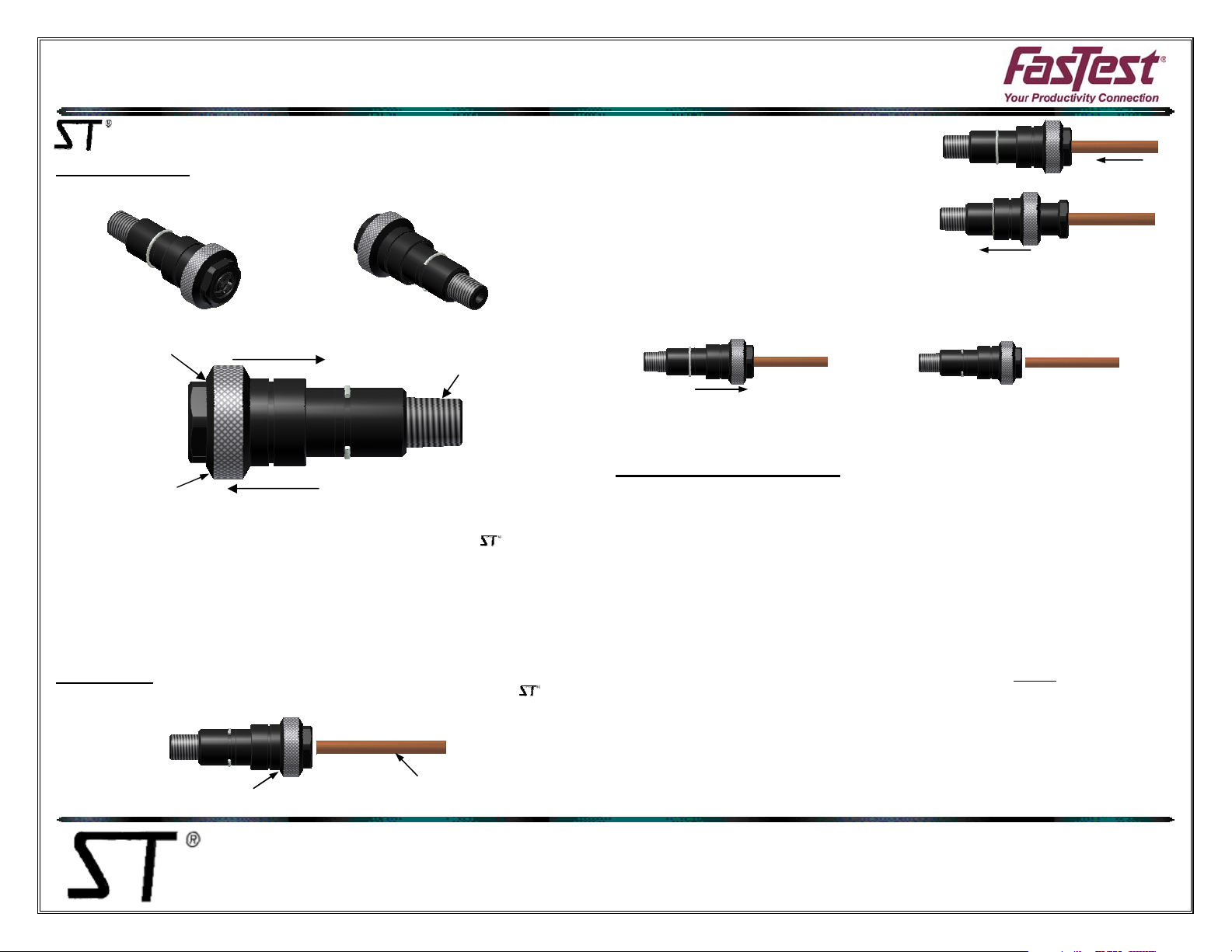

SLEEVE DIRECTION TO CONNECT

TUBE REMOVED

FROM CONNECTOR

TUBE

Series Connectors

DESCRIPTION:

Instant Sleeve-Action Connections for Tubes to 1000 psi

HEX STOP

SLEEVE

Please thoroughly read the instructions prior to operating the connector. The is designed to

provide a safe, reliable leak-tight seal and connection when properly maintained and operated.

• The connector is designed to mate with a specific application. Verify the application prior to the

introduction of pressure or processing. Use only in a safe environment. Safety chains and

guards are recommended for all applications.

• Connectors are NOT designed for permanent connections and are for temporary connections

only.

DO NOT EXCEED pressure rating as marked on connector or corresponding literature.

OPERATION:

1. TO CONNECT TO TUBE: Before inserting the smooth or swaged tube into the

Connector, make sure the external locking sleeve is (pushed forward against hex stop).

SLEEVE FORWARD

SLEEVE CONNECT

SLEEVE

DISCONNECT

¼” MALE NPTF

TERMINATION STD.

TUBE

2. Insert tube until it rests against the internal s

3. Move the sleeve toward the threaded end, away

from the hex stop, to lock connector. Tube gripping

position.

WARNING: Tug on the connector to assure proper

engagement and gripping of the tube before

introduction of pressurized media.

4. TO DISCONNECT FROM TUBE: Deactivate test

pressure and reverse the connecting procedure. The sleeve must be moved to the extreme

position evidenced by a snap to provide ease of removal.

WARNING: Media and pressure will be vented during the disconnect operation. Do not attempt

to disconnect unless safe conditions are met.

SLEEVE FORWARD

CONNECTOR MAINTENANCE:

• A daily, weekly and periodic inspection of the connector by competent person is

recommended.

o User must establish a regular interval for maintenance as determined by the user

media and operational environment.

o Periodically inspect connector and seal for wear, damage and proper operation.

• Use only original FasTest spare parts that are designed for the application and are subject

to strict quality control. See warranty.

• Difficulty of operation after continual use indicates need for lubrication or other

maintenance.

• Lubricate on regular intervals under normal operating conditions. Lubrication should be

compatible with user application.

FasTest, Inc. Product Warranty

FasTest, Inc. warrants its products against defects of workmanship and/or material for 12 months from the date of the sale by

FasTest, Inc. This warranty is void if the product is misused, tampered with or used in a manner that is not in accordance with

FasTest, Inc. recommendations and/or instructions. FasTest, Inc. is not liable for consequential or other damages including, but not

limited to, loss, damage, personal injury, or any other expense directly or indirectly arising from the use of or inability to use its

products either separately or in combination with other products. ALL OTHER WARRANTIES EXPRESSED OR IMPLIED,

WHETHER ORAL OR WRITTEN, INCLUDING BUT NOT LIMITED TO WARRANTIES OR MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

Remedy under this warranty is limited to replacement of the product or an account credit in the amount of the original selling price,

at the option on FasTest, Inc. All allegedly defective products must be returned prepaid transportation to FasTest, Inc. along with

information describing the products performance, unless disposition in the field is authorized in writing by FasTest, Inc.

www.fastestinc.com

Roseville, MN

Ph: 1-800-444-2373

Fax: 651-645-7390

WP024 10/6/2010

Loading...

Loading...