FasTest Panel Mount User Manual

INSTALLATION INSTRUCTIONS

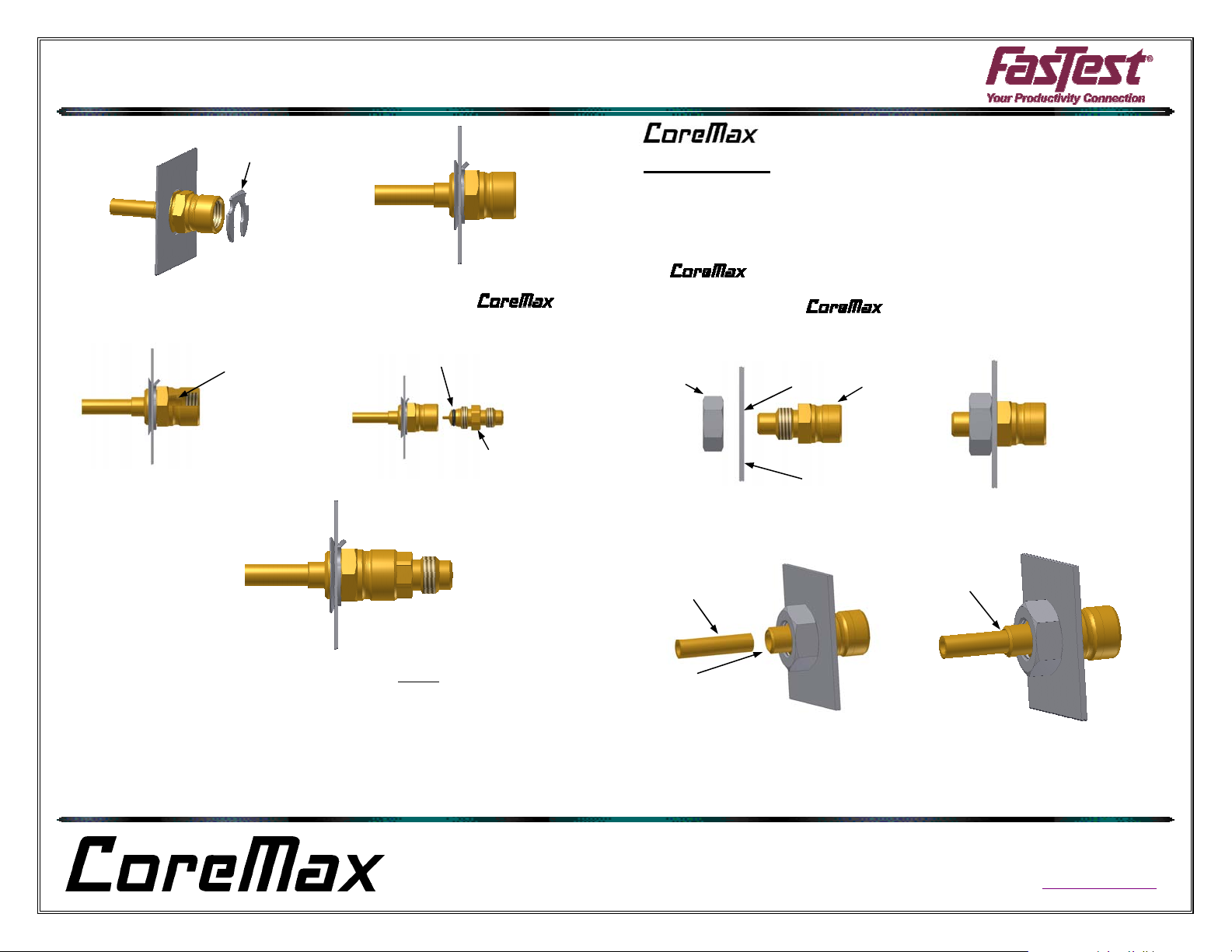

5. Install retaining ring into groove on the seat.

Retaining Ring

. Make sure the I.D. of seat is clean, and then inspect the

6

Core to ensure the o-rings is free of contamination and foreign

particulates. Lightly lubricate with compatible refrigerant oil.

Clean I.D.’s of Seat

Clean & Lube O-Ring

CoreMax Core

7. Thread Core into seat and torque clockwise to 8 ft-lb’s.

FasTest, Inc. Product Warranty

FasTest, Inc. warrants its products against defects

Inc. This warranty is void if the product is misused, tampered with or used in a manner that is not in accordance with FasTest, Inc.

recommendations and/or instructions. FasTest, Inc. is not liable for consequential or other damages including, but not limited to, loss,

damage, personal injury, or any other expense directly or indirectly arising from the use of or inability to use its products either

separately or in combination with other products. ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, WHETHER ORAL OR

WRITTEN, INCLUDING BUT NOT LIMITED TO

WARRANTIES OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

Remedy under this warranty is limited to replacement of the product or an account credit in the amount of the original selling price, at

the option on FasTest, Inc. All allegedly defective products must be returned prepaid transportation to FasTest, Inc. along with

information describing the products performance, unless disposition in the field is authorized in writing by FasTest, Inc.

of workmanship and/or material for 12 months from the date of the sale by FasTest,

Access Valve Installation

®

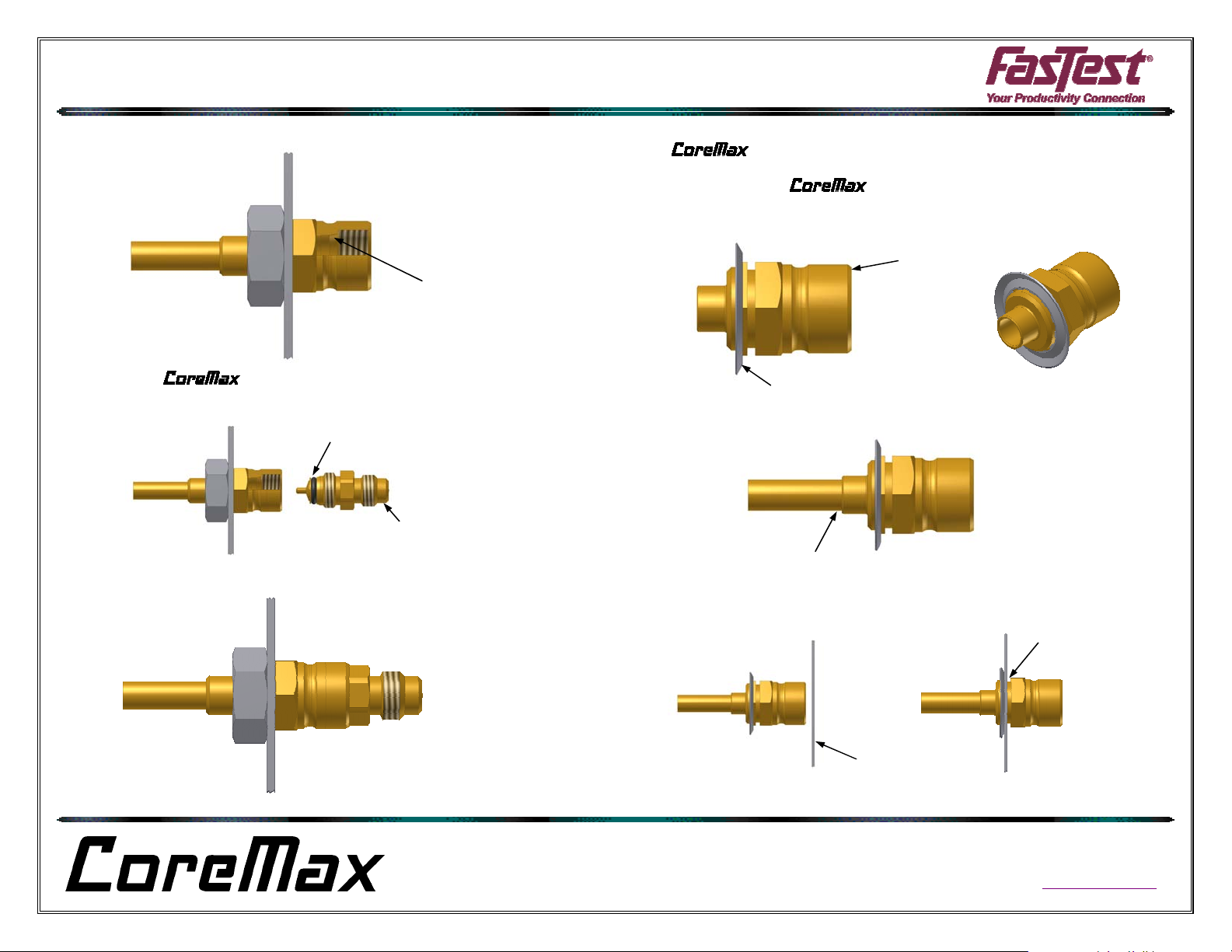

Description: Installation instructions of the Nut and

Clip Style Seat Panel Mounts.

Nut Style Panel Mount

1. Cores should remain in protective packaging until assembly

is required to ensure cleanliness and eliminate damage. Just prior to

assembly remove the Core from packaging tray.

2. Insert seat thru hole in panel and thread nut onto seat.

Nut

Panel

3. Braze SEAT ONLY onto tube or valve block before installing/threading

Core into seat.

Tube

Example: Tube brazed to Seat

Seat

Brazed

Area

Roseville, MN

Ph: 1-800-444-2373

Fax: 651-645-7390

www.fastestinc.com

WP035 10/6/2010

INSTALLATION INSTRUCTIONS

4. Make sure there is no contamination in the I.D. of seat, especially the

o-ring groove.

5. Inspect the Core to ensure the o-ring is free of contamination

and foreign particulates. Lightly lubricate with compatible refrigerant oil.

6. Thread Core into Seat and torque clockwise to 8 ft-lb’s.

Clean & Lube O-Ring

Clean I.D.’s of Seat

CoreMax Core

C

lip Style Panel Mount

1.

Cores should remain in protective packaging until assembly

is required to ensure cleanliness and eliminate damage. Just prior to assembly remove the Core from packaging tray.

2. Push the self-locking retaining ring (Backup Clip) onto seat as shown.

3. Braze SEAT ONLY onto tube or valve block before installing/threading

Core into seat.

4. Install seat thru hole in panel up to the Backup Clip. Hole in panel must

be larger then the hex corners.

Backup Clip

Example: Tube brazed to Seat

Seat

Retaining Ring

Groove

Panel

Roseville, MN

Ph: 1-800-444-2373

Fax: 651-645-7390

www.fastestinc.com

WP035 10/6/2010

Loading...

Loading...