FasTest ML Series User Manual

ccw

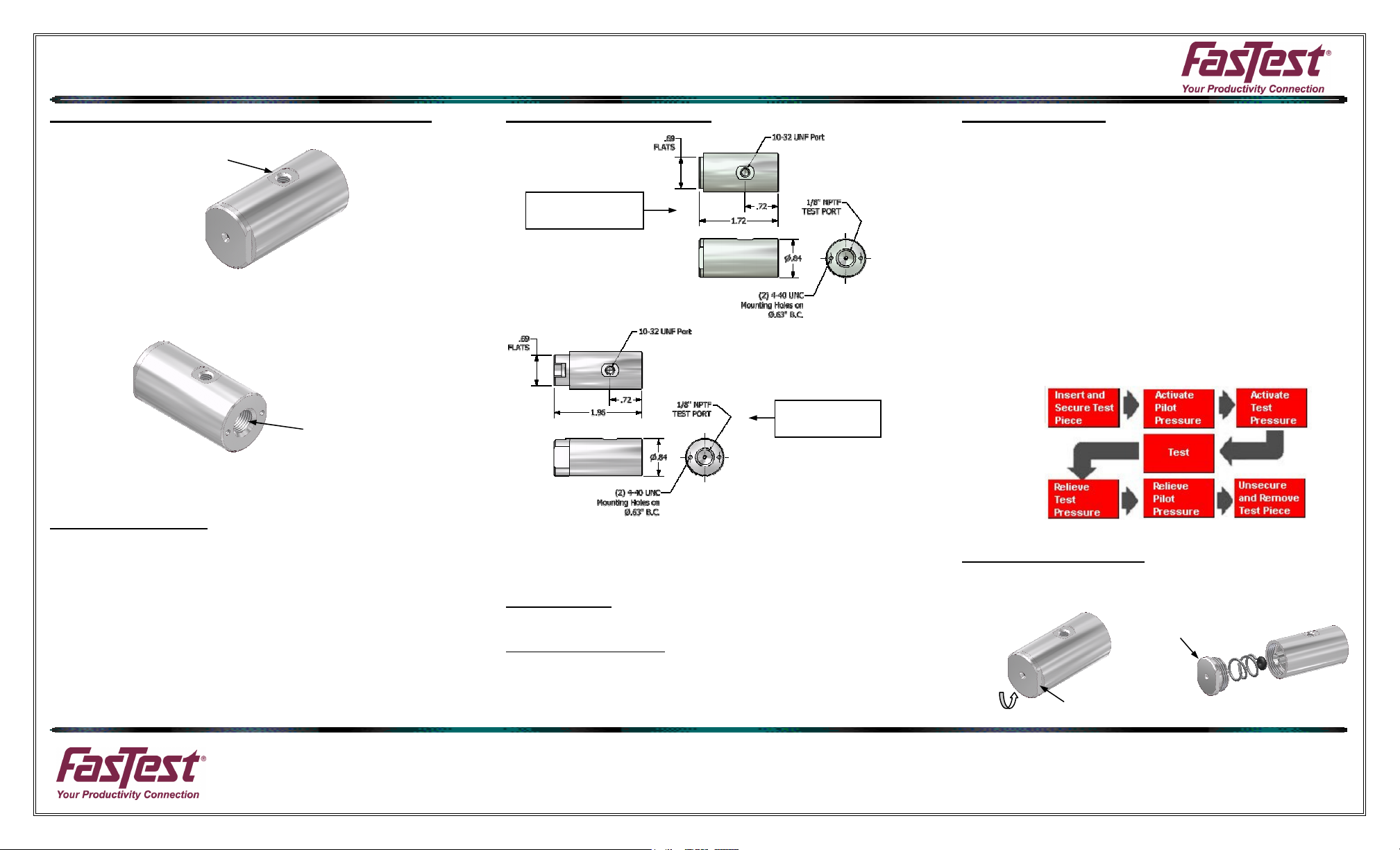

OPERATING INSTRUCTIONS

Attachment of Pilot Pressure and Test Media Supply Line:

1. Attach pilot pressure air line to pilot port.

2. A pneumatic regulated source is required to maximize seal life and assure

optimum seal ability for the application. The pilot pressure should be minimized to

maintain sealing on the test piece without excessive compression of the seal.

3. Attach test media line to the test port.

4. Provide a means whereby test pressure will not be introduced until the pilot

pressure required to seal is reached. The means should also provide quick exhaust

of test pressure in the event pilot pressure falls below the minimum required to seal.

PILOT PORT

ME & ML

TEST MEDIA PORT

ME & ML

Mounting of Connector:

The ME Connector must be SECURED to the test piece by a mechanical device

before proceeding.

• The test connector must be secured with a mechanical or other device to assure the

connector is not uncoupled from the test piece. The test itself will provide an uncoupling force. The securing or holding device may be a fixture, clamp, cylinder or

other appropriate means that prevents ejection of the test piece from the connector.

Uncoupling force example:

If the test piece has a ½” O.D. and is tested at 400 psi maximum. The uncoupling force = area(πr²) x

pressure) = π x .25² x 400 = 79 lbs.

• Secured device should be designed to withstand this force and include an adequate margin for

safety.

• Do not activate the connector without an adequate and safe securing mechanism.

• Mount the FasTest ME connector to the fixture or appropriate device using either threaded

mounting holes on the rear of the connector body, (“G” Diagram 2), or appropriate adapter.

WP090 9/30/2010

ME/ML Connector Dimensions:

ME001

CONNECTOR

Maximum test pressure: Vacuum to 500 psi

Material Specifications

Body, Housing, Piston: Aluminum

Standard Main Seal: FDA approved Viton

Standard O-Rings: FDA approved Viton

Other materials available on request.

NOTE: All specifications subject to change without notice.

ML001

CONNECTOR

Connector Operation:

1. Insert test piece into the end of the connector and secure.

2. Apply pilot pressure to seal against the part.

3. With pilot activated, introduce gas or liquid through the FasTest ME

4. Perform testing operation.

5. Relieve test pressure.

6. Relieve pilot pressure.

7. Remove test piece.

Make sure the test piece is inserted to the required minimum insertion

length. This will assure proper location relative to the seal. Make sure

the connector and test piece are secure

Generally, a 60 to 90 psi pneumatic pilot pressure source is required.

Additional pilot pressure may be required for contoured surfaces (i.e.,

threads etc…). See FasTest catalog for Pilot Pressure Booster.

CAUTION: Do not activate PILOT or TEST PRESSURE without test

piece in place.

connector until desired testing, filling or flushing is complete.

Provide a means whereby test pressure will not be introduced until the

pilot pressure required to seal is reached. The means should also

provide quick exhaust of test pressure in the event pilot pressure falls

below the minimum required to seal.

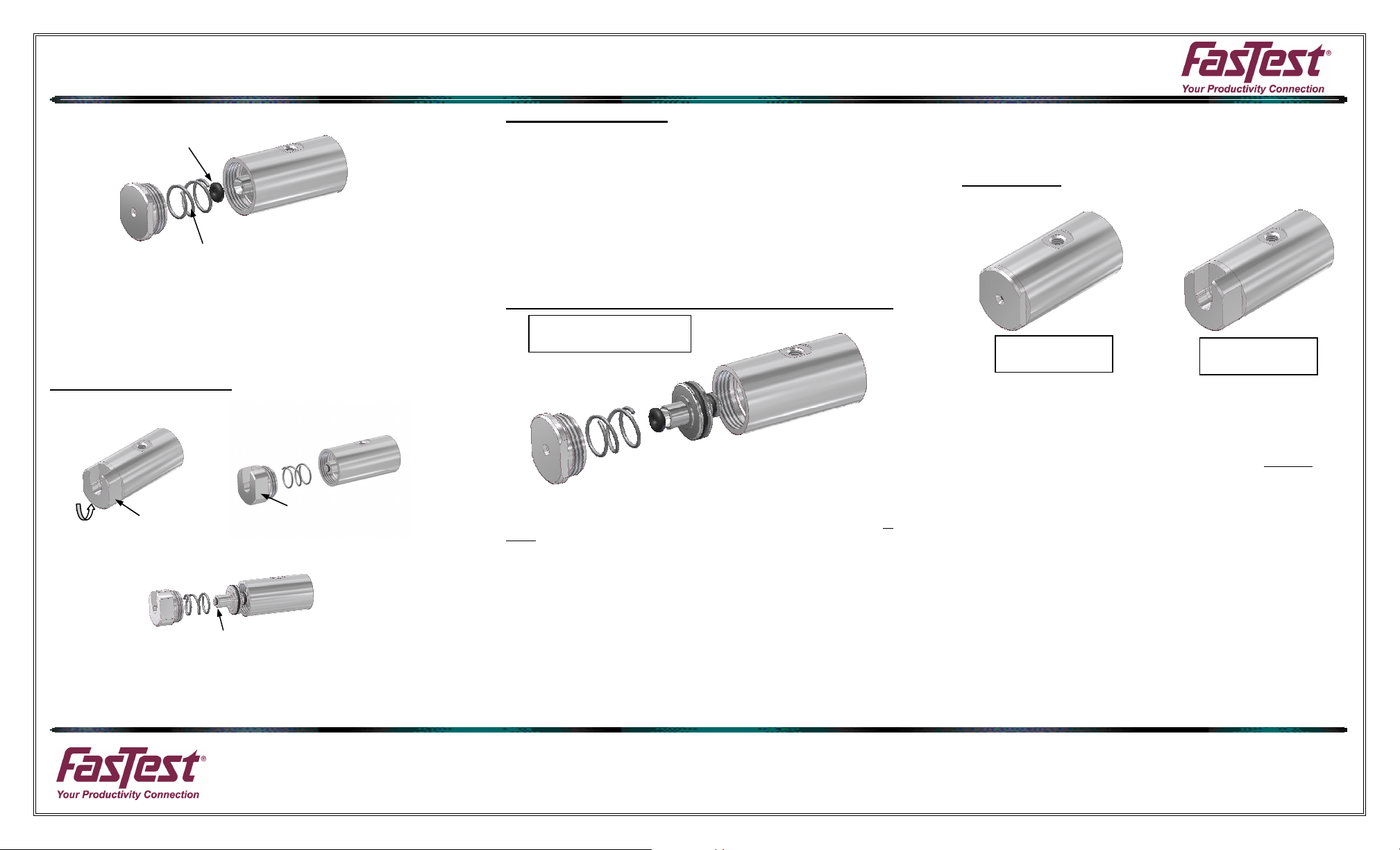

Installation of Seals ME001:

To Replace Seal

1. Unscrew and remove seal casing. W rench flats provide for easy removal.

NOTE: The internal spring is set loose inside the housing. Make sure that this spring is

not damaged or lost.

WRENCH

FLATS

SEAL

CASING

www.fastestinc.com

Roseville, MN

Ph 1-800-444-2373

Fax 651-645-7390

External Pneumatic Operated Connector.

ccw

CASING

OPERATING INSTRUCTIONS

2. Main seal o-ring is held in the seal casing by friction fit. Remove old o-ring and

replace with a new one.

ME001 Connector Seal Range

Changing the seal casing assembly allows the user to have one ME001 body seal the

entire .030” to .130” sealing range. The MES Replacement Seal Sets are list on the parts

list. Installation is similar to the replacement seal installation except that the entire seal

casing assembly (seal casing and Viton o-ring) is replaced.

MAIN SEAL O-RING

SPRING

3. Place spring into housing up against the piston.

4. Thread seal casing into housing. Wrench tighten to prevent loosening.

Installation of Seals ML001:

To Replace Seal

1. Unscrew and remove seal casing. W rench flats provide for easy removal.

2. Main seal o-ring is held in the piston by a recessed groove. Remove old o-ring by

sliding it over the end of the piston and replace with a new one.

3. Place spring into housing up against the piston.

4. Thread seal casing into housing. Wrench tighten to prevent loosening.

WRENCH

FLATS

MAIN SEAL O-RING

SEAL

WP090 9/30/2010

Connector Maintenance:

• A daily, weekly and periodic inspection of the connector by competent person is

recommended.

• Lubricate connector on regular intervals. Petroleum jelly is recommended but care

should be taken to verify the lubricant is compatible with the application.

• User must establish a regular interval for maintenance as determined by the user

media and operational environment.

• Inspection should include damage to the body missing or loose components, leak

tightness, ease of operation, sufficient lubrication, wear, dirt accumulation and

damage.

• Use only original FasTest spare parts that are designed for the application and are

subject to strict quality control. See warranty.

“ME001” EXPLODED VIEW

FOR REFERENCE

FasTest, Inc. Product Warranty

FasTest, Inc. warrants its products against defects of workmanship and/or material for 12

months from the date of the sale by FasTest, Inc. This warranty is void if the product is

misused, tampered with or used in a manner that is not in accordance with FasTest, Inc.

recommendations and/or instructions. FasTest, Inc. is not liable for consequential or other

damages including, but not limited to, loss, damage, personal injury, or any other expense

directly or indirectly arising from the use of or inability to use its products either separately or in

combination with other products. ALL OTHER WARRANTIES EXPRESSED OR IMPLIED,

WHETHER ORAL OR WRITTEN, INCLUDING BUT NOT LIMITED TO WARRANTIES OR

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY

EXCLUDED.

Remedy under this warranty is limited to replacement of the product or an account credit in the

amount of the original selling price, at the option on FasTest, Inc. All allegedly defective

products must be returned prepaid transportation to FasTest, Inc. along with information

describing the products performance, unless disposition in the field is authorized in writing by

FasTest, Inc.

ME001 & ML001 Mini Connector

DESCRIPTION: Operation and Seal Installation

Please thoroughly read and understand each of the following four steps before

operating the connector. The use of pressurized media for sealing, testing and

filling requires a thorough understanding of the FasTest ME/ML Operating

Instructions.

1. Attachment of Pilot Pressure and Test Media Supply Lines

2. Mounting Dimensions of Connector

3. Connector Operating Instructions

4. Installation of Seals

• The connector is designed to mate with a specific application. Verify the application

prior to the introduction of pressure or processing.

• Use only in a safe environment.

• Connectors are NOT designed for permanent connections and are for temporary

connections only.

• Maximum rated test pressure for standard ME models is 500 psi. DO NOT EXCEED

pressure rating as marked on connector or corresponding literature. Consult your

FasTest representative with other requirements.

FasTest ME & ML Pneumatic Operated Connectors are designed for use

in SECURED CONDITIONS ONLY.

ME001

CONNECTOR

ML001

CONNECTOR

www.fastestinc.com

Roseville, MN

Ph 1-800-444-2373

Fax 651-645-7390

Loading...

Loading...