FasTest JNL User Manual

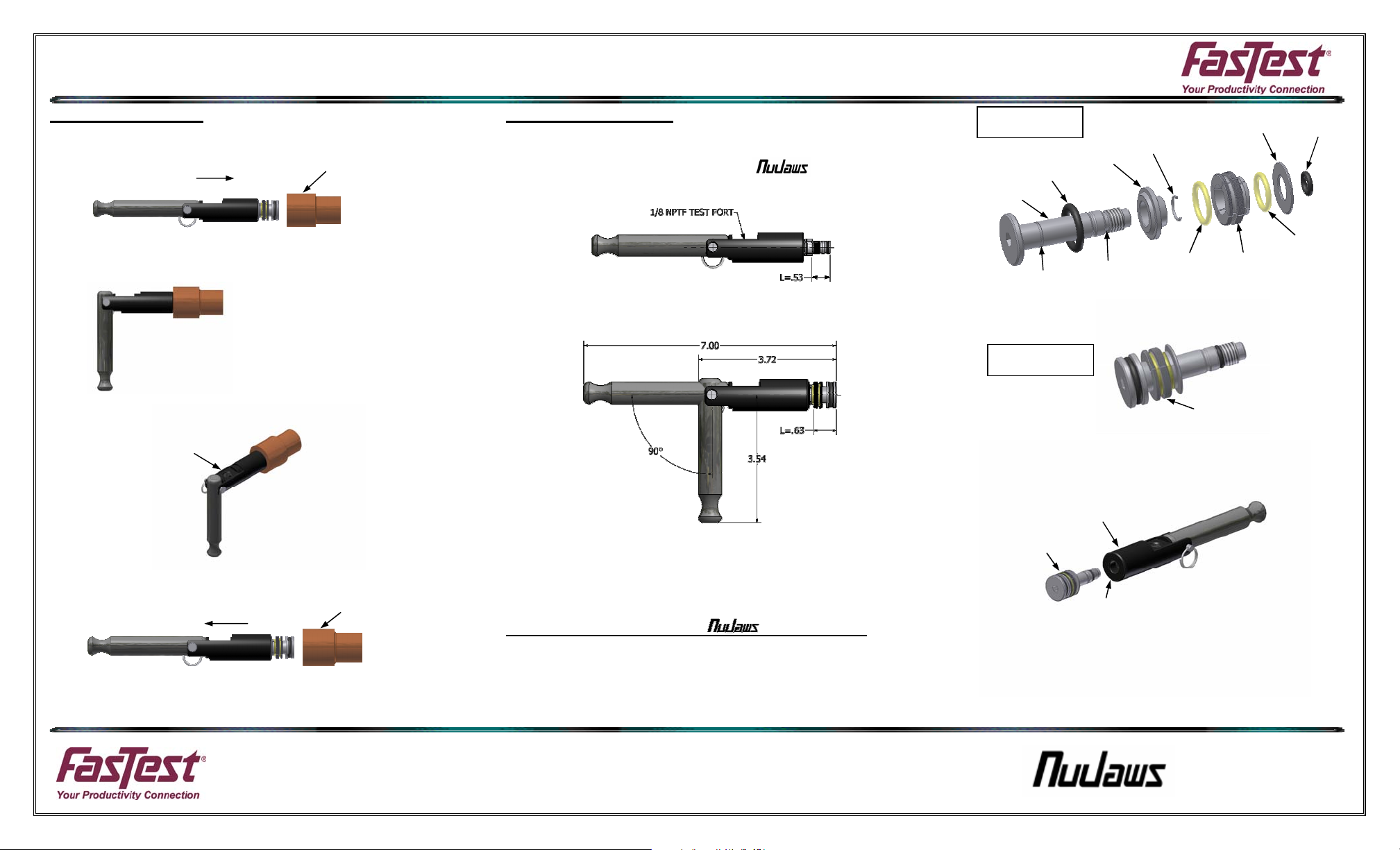

JNL

0H Series

DIAMETER .11”

JNL1

Series

DIAMETER .17”

SEAL

O-RING

(H) WASHER

LOC

ATION

ASSEMBLY

OPERATING INSTRUCTIONS

Operating Instructions:

CONNECTING ACTION:

1. Insert connector into test piece. Make sure test piece is inserted to the required

minimum insertion length. This will assure proper location relative to the seals.

2. Rotate lever to the 90 degree position for grip and seal action. After connecting,

always tug on the connector to assure proper engagement and gripping of the collet

before introduction of pressurized test media.

Note: Lever is designed to rotate down when connector test port is on top.

3. Introduce test media through test port.

DISCONNECTING ACTION:

1. Vent test media pressure.

2. Rotate lever to in-line position.

3. Remove connector.

Note: Connector should be pulled straight back. If connector catches, push forward

and pull back. Do not attempt to force out a connector that is catching. This will

cause it to jam in the test piece port.

GRIP & SEAL POSITION

TEST MEDIA PORT

INSERT CONNECTOR

REMOVE CONNECTOR

TEST PIECE

TEST PIECE

WP011 04/2009

Dimensional Information:

All DIMENSIONS APPLY TO BOTH SIZES EXCEPT “L” (Minimum insertion length of test

piece for standard application).

Lever in-line for connector insertion and disconnect

Lever at 90 degree position to grip and seal

Collet and Seal Installation for JNL Connector:

ASSEMBLY OF COLLET AND SEAL SET:

1. Set connector shaft (A) on table so that the threaded end is pointed upward. Place

main seal (B) onto shaft as shown.

2. Install sleeve ramp (C) onto shaft so that smooth flat area is against main seal.

3. Place small C-Ring (D) into groove shown. Most easily installed from side. Sleeve

ramp may need to be squeezed close to flat end of shaft to expose c-ring groove.

LEVER ACTION

MAX. FLOW

MAX. FLOW

EXPLODED VIEW OF

COLLET SET

(C) SLEEVE

(B) MAIN

(A) SHAFT

C-RING

LOCATION

4. Assemble the collet segments (F) and retaining o-ring(s) (E) & (G). Arrange the four

pieces of collet (F) into a circle with the raised area facing upward. Place the

retaining o-ring(s) into the groove(s) on the raised area.

ASSEMBLY VIEW OF

COLLET SET

5. Install complete collet and retaining o-ring assembly onto shaft (A) as shown in

diagram. Note that the I.D. of the collet assembly is tapered. Larger end of this

tapered I.D. goes on the shaft (A) first.

6. Place washer (H) on shaft (A).

7. Place shaft o-ring (I) onto shaft (A) and into groove immediately in front of thread.

8. The shaft assembly is now ready to attach to the connector body. Apply a drop of

Loctite® to the threads to avoid loosening during use.

COLLET &

SEAL SET

RAMP

SHAFT

O-RING

(J) BODY

9. Holding body (J) with shaft hole pointed downward, insert threaded end of shaft (A)

into hole in body (J). A hex hole at front of shaft is provided to tighten shaft into body

until snug. Collet set should be threaded in so that edge of collet (F) overlaps edge

of sleeve ramp (C) by approximately .02”.

10. Rotate the lever to actuate connector. Visually verify that the connector is gripping

and sealing action is correct before introduction of pressurized test media.

CAUTION: Keep fingers away from collet assembly. Pinching can occur.

THREAD INTO SHAFT HOLE IN BODY

(D) C-RING

(E) LARGE

RETAINING

ASSEMBLY

TAPERED END FIRST

www.fastestinc.com

® Roseville, MN

Ph 1-800-444-2373

Fax 651-645-7390

(F) COLLET

SEGMENTS

QTY. (4)

COLLET

(I) SHAFT

O-RING

(G) SMALL

RETAINING

O-RING

(LARGE

COLLET

SIZES ONLY)

OPERATING INSTRUCTIONS

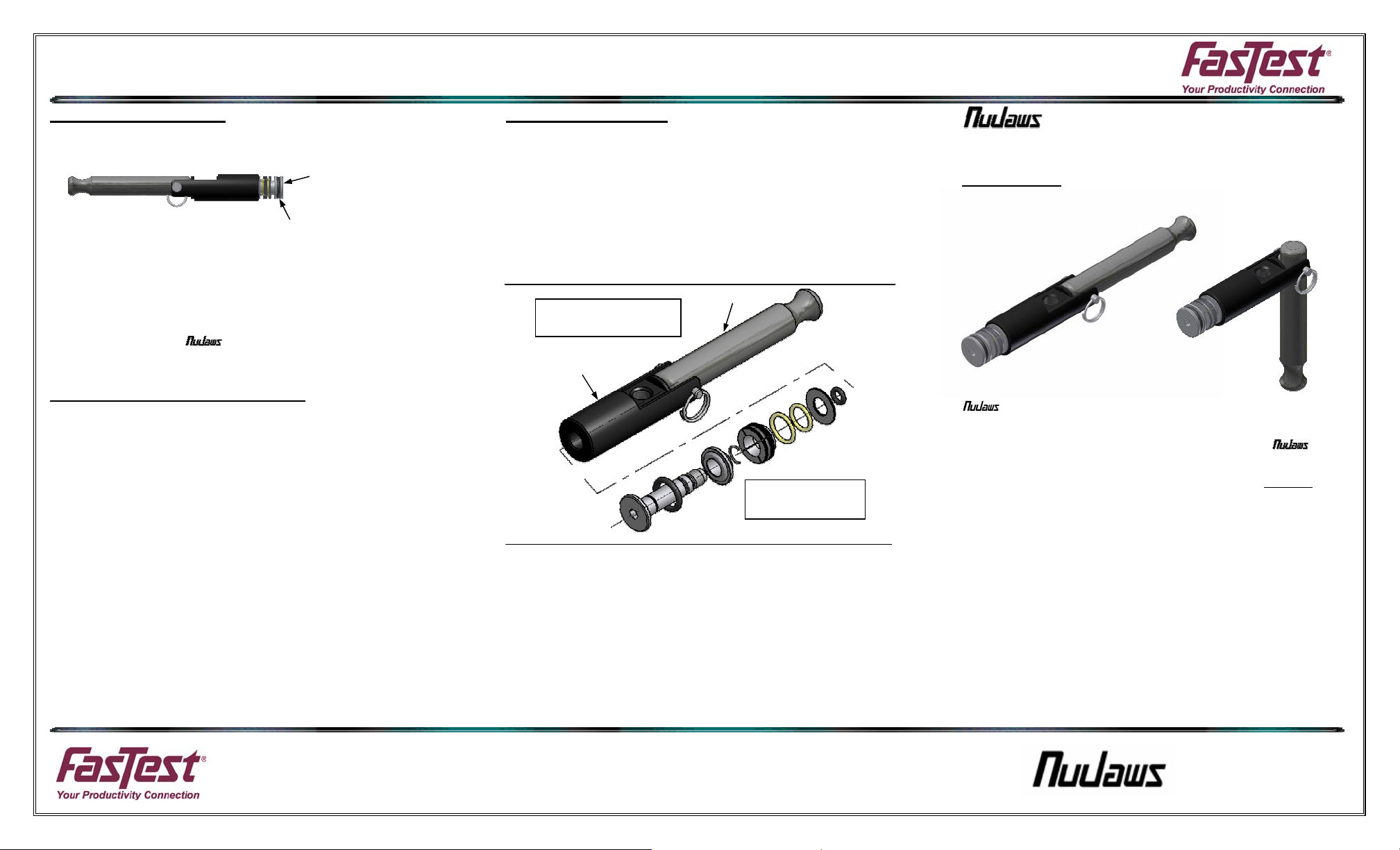

Replacement of Main Seal:

1. Place lever in the in-line position so that seal/collet assembly is in the relaxed

position. Using a pointed repair tool to get behind the main seal (B) and roll this seal

over the front of shaft.

FRONT END OF SHAFT

2. Verify correct size and material of replacement main seal.

3. Install the replacement main seal (B) by rolling it over the front end of shaft into the

space between the shaft and sleeve ramp (C). Be sure seal is seated in groove.

4. Lube collet assembly with a liquid or spray that is compatible with the main seal

material and your specific application.

5. Rotate lever to actuate connector. Visually verify that the connector gripping and

sealing action is correct.

CAUTION: Attach assembled connector to a test piece and tug on the

connector to assure proper engagement and gripping of collet before introduction

of pressurized test media.

ROLL MAIN SEAL OVER

FRONT END OF SHAFT

Safety Warnings – General Guidelines:

1. If instructions are not completely understood by operator or components

are missing, contact FasTest before attempting use of the connector.

2. All operating parameters should be considered when connector selection

is made. Parameters include, but are not limited to: dimensional

tolerance, hardness and surface finish of test piece, pressure or vacuum

requirements of application, fluid compatibility, temperature, environment

and mechanical load or vibration affecting the connector.

3. FasTest JNL Connectors must only be used with test pieces of a specific

size as indicated by the part number. Improper use could cause

separation of the connector from the test piece resulting in physical harm

or damage. The connector part number and maximum pressure rating is

marked clearly on the label.

4. FasTest JNL Connectors are to be used only on materials that meet the

following specifications: The test piece has to have a surface finish

greater than 16rms and a hardness of no more than 95Rb, to grip and

seal at the rated pressure. A surface finish of 8rms may be acceptable if

the test piece has a hardness greater than 40Rb. If the application is out

of this range, or there is a question concerning this requirement, contact

FasTest.

5. CAUTION REMINDER: Keep fingers or other objects away from

gripping collets when actuating connector. Pinching or crushing

can occur.

6. FasTest JNL Connectors are not internally valved, and will not

prevent loss of media when disconnected. Do not attempt to

disconnect unless safe conditions are met.

WP011 04/2009

Connector Maintenance:

• A daily, weekly and periodic inspection of the connector by competent person is

recommended. User must establish a regular interval for maintenance as determined

by the user media and operational environment.

• Lubricate connector on regular intervals. Petroleum jelly is recommended but care

should be taken to verify the lubricant is compatible with the application.

• Inspection should include visual checks of the collet sealing area, housing, missing

or loose components, leak tightness, ease of operation, sufficient lubrication, wear, dirt

accumulation and damage.

• Use only original FasTest spare parts that are designed for the application and are

subject to strict quality control. See warranty.

“JNL” EXPLODED VIEW

FOR REFERENCE

BODY

LEVER

EXPLODED VIEW

OF COLLET SET

FasTest, Inc. Product Warranty

FasTest, Inc. warrants its products against defects of workmanship and/or material for 12 months from the

date of the sale by FasTest, Inc. This warranty is void if the product is misused, tampered with or used in a

manner that is not in accordance with FasTest, Inc. recommendations and/or instructions. FasTest, Inc. is not

liable for consequential or other damages including, but not limited to, loss, damage, personal injury, or any

other expense directly or indirectly arising from the use of or inability to use its products either separately or in

combination with other products. ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, WHETHER ORAL

OR WRITTEN, INCLUDING BUT NOT LIMITED TO WARRANTIES OR MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

Remedy under this warranty is limited to replacement of the product or an account credit in the amount of the

original selling price, at the option on FasTest, Inc. All allegedly defective products must be returned prepaid

transportation to FasTest, Inc. along with information describing the products performance, unless disposition

in the field is authorized in writing by FasTest, Inc.

JNL Lever Action Grip and

Seal Connectors.

DESCRIPTION: JNL Series Connectors seal on the inside

diameter of holes and tubes. Instant internal connections to

1,000 psi.

CONNECT/

DISCONNECT

JNL Connectors provide a reliable leak-tight connection that grips and

seals in holes and ports. Simply place the JNL connector into a port, activate

the mechanical gripping and sealing action, then introduce the test media. For

vacuum to 1000 psi applications with air, gas or liquid, Fastest JNL

Connectors provide secure, leak tight sealing for manual connections.

Please thoroughly read and understand each of the following four steps before

operating the connector. The use of pressurized media for sealing, testing and

filling requires a thorough understanding of the FasTest JNL Installation and

Operating Instructions.

1. Operating Instructions

2. Dimensional Information

3. Collet and Seal Installations

4. Safety-General Guidelines

• The connector is designed to mate with a specific application. Verify the

application prior to the introduction of pressure or processing.

• Use only in a safe environment.

• Connectors are NOT designed for permanent connections and are for

temporary connections only.

• Maximum rated test pressure for standard JNL models is 1000 psi. DO NOT

EXCEED pressure rating as marked on connector or corresponding

literature. Consult your FasTest representative with other requirements.

GRIP & SEAL

www.fastestinc.com

® Roseville, MN

Ph 1-800-444-2373

Fax 651-645-7390

Loading...

Loading...