FasTest HPB User Manual

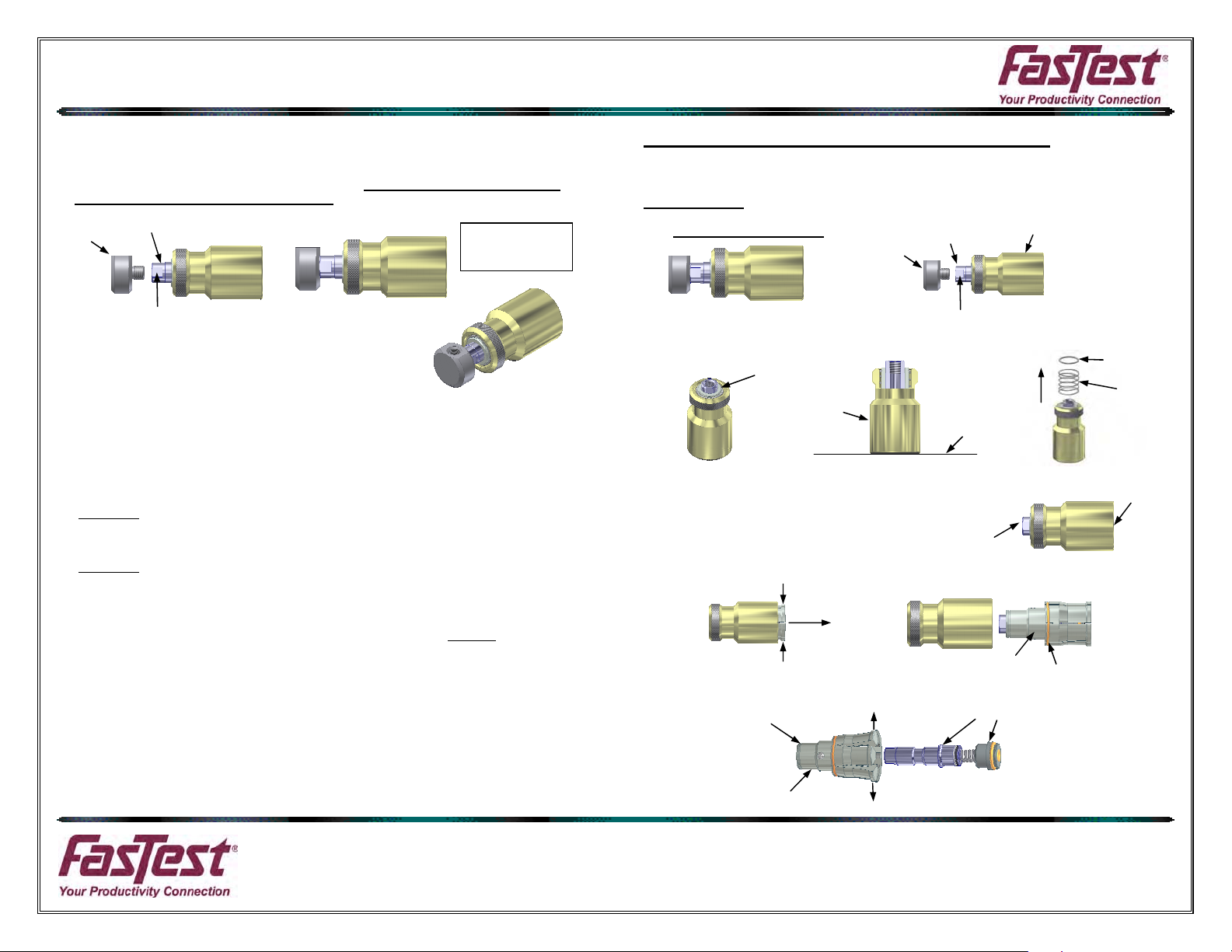

REPAIR KIT INSTRUCTIONS

. Re-install Handle Knob. Clamp knob in vise and apply a drop of LocTite 569 onto threads of

9

knob.

10. Thread the Handle Knob into the shaft of connector. Tighten using a 13mm Open End

Wrench. Knob should be tightened to 18 ft-lbs.

Knob

Shaft

Assembled

Connector

Wrench Flats

• CAUTION: The maximum rated pressure is stamped on the connector

body. Before using, verify that this pressure rating is within your working

pressures.

• WARNING: Connect test piece and tug on the connector to assure proper

engagement and gripping before introduction of pressurized media.

• DO NOT force connector onto test part when connecting. The split collet

design should easily mate with test piece. Forcing the connector will result

in poor sealing and possible leakage.

• DO NOT turn or rotate connector after the collets have gripped the test

piece. Damage to test piece and the connector’s internal parts may result.

FasTest, Inc. Product Warranty

FasTest, Inc. warrants its products against defects of workmanship and/or material for 12 months from the date of the

sale by FasTest, Inc. This warranty is void if the product is misused, tampered with or used in a manner that is not in

accordance with FasTest, Inc. recommendations and/or instructions. FasTest, Inc. is not liable for consequential or

other damages including, but not limited to, loss, damage, personal injury, or any other expense directly or indirectly

arising from the use of or inability to use its products either separately or in combination with other products. ALL

OTHER WARRANTIES EXPRESSED OR IMPLIED, WHETHER ORAL OR WRITTEN, INCLUDING BUT NOT

LIMITED TO WARRANTIES OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE

EXPRESSLY EXCLUDED.

Remedy under this warranty is limited to replacement of the product or an account credit in the amount of the original

selling price, at the option on FasTest, Inc. All allegedly defective products must be returned prepaid transportation to

FasTest, Inc. along with information describing the products performance, unless disposition in the field is authorized

in writing by FasTest, Inc.

HPB C

onnector Repair/Rebuild Kit

“**” Denotes items included in the kit.

Disassembly:

1. Remove Handle Knob from Connector. Place knob in vise and loosen shaft from knob using

a 13mm Open End Wrench.

Knob

2. Place connector on flat surface and remove ret. ring (A) using small screwdriver/sharp tool.

3. Save spring (B), discard ret. ring (A).

** Ret. Ring (A)

Shaft

Wrench Flats

Sleeve

Table

Surface

Sleeve

** Ret. Ring (A)

Spring (B)

4. After (A) & (B) are removed, slide connector to edge of table. Make sure collets remain

inside sleeve and flush with end of sleeve.

5. Push on shaft with left thumb and squeeze collets as they

expose themselves from sleeve with right hand.

6. Continue to squeeze collets as you pull the

entire assembly from sleeve.

7. After (ZZ) Assy is removed from sleeve grab body with either hand allowing collets to open.

ull Shaft & Piston Assy from collets.

P

Squeeze

Squeeze

Ret. Ring Groove

Body

Pull

Collets Opened

Collets Opened

Shaft

Body

Shaft & Piston

Assy.

Shaft,Collet,Body,

Piston Assy. (ZZ)

** Collet O-Ring (C)

Roseville, MN

Ph: 1-800-444-2373

Fax: 651-645-7390

www.fastestinc.com

WP102 RevB 11/16/2012

Collets Flush

with Sleeve

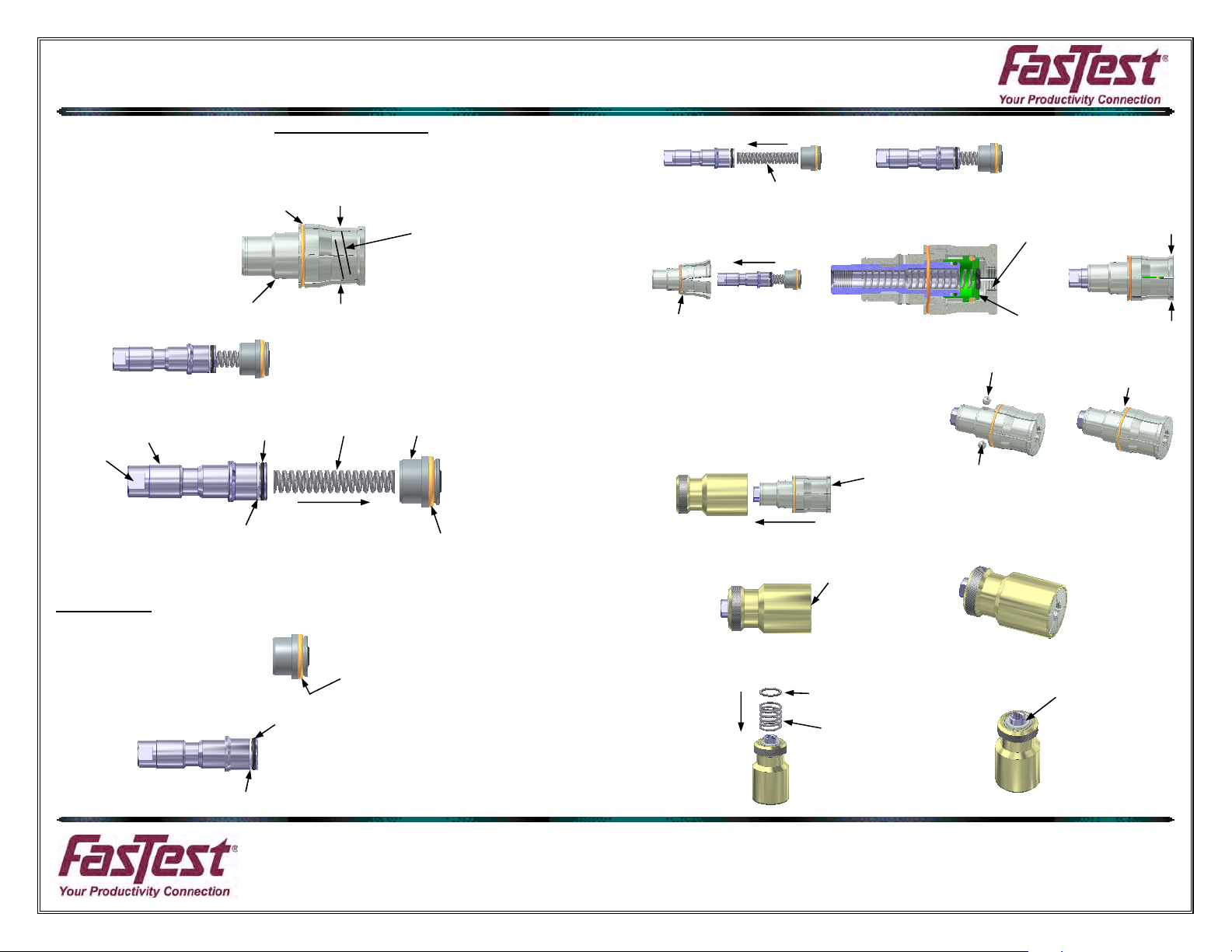

REPAIR KIT INSTRUCTIONS

8. Collet O-Ring or Garter Spring(C) removal and replacement. Squeeze tightly around col-

lets with either hand. Using a repair pick, or similar tool remove o-ring (C). Replace with new

o-ring (C) to keep collets together on body.

Note: Collets are a matched set. If collet(s) fall off body they must be assembled

correctly. There is a spiral groove on the outside of collets that must be aligned as they

are assembled.

** Collet O-Ring (C)

Squeeze

Spiral

Groove

9. Spring force will push piston off of shaft. This will expose (D) & (F) on shaft.

Body

Squeeze

10. Remove and discard the following items: (D), (E), (F) & (G). Use a sharp tool to remove

o

-rings.

Wrench

Flats

Shaft

** Shaft O-Ring

(D)

** Piston Spring

(E)

Piston

** Back-Up Ring

(F)

** Piston Outer O-Ring

(G)

Reassemble:

Use all the new seals provided and lubricate lightly with silicone.

1. Install new piston outer o-ring (G).

2. Install the following two new items onto shaft (D) & (F).

** Shaft O-Ring (D)

** Back-Up Ring

(F)

** Piston Outer O-Ring

(G)

3. Install new piston spring (E) into shaft. Then place piston onto spring as shown.

** Piston Spring

(E)

4. Using an arbor press or best set-up push shaft assembly into jaw/body assembly until piston

face is in past jaw threads. Squeeze collets with hand.

Jaw Threads

Jaw/Body Assy

Piston Face

5

. Maintain squeeze on collets and make sure balls are in holes on body.

Assembly (ZZ) is now ready to be inserted into sleeve.

6. Maintain squeeze on collets and

insert assembly (ZZ) into sleeve.

Collet Face

7. Insert assembly (ZZ) until collet faces are flush with end of sleeve.

8. Place connector on a flat surface and install spring (B) and new ret. ring (A).

Collets Flush

with Sleeve

** Ret. Ring (A)

Spring (B)

** Ret. Ring (A)

Roseville, MN

Ph: 1-800-444-2373

Fax: 651-645-7390

www.fastestinc.com

WP102 RevB 11/16/2012

Shaft,Collet,Body,

Piston Assy. (ZZ)

Squeeze

Squeeze

Loading...

Loading...