FasTest FasMate FN Series User Manual

WARNING

CONNECTOR

O-RING

OPERATING INSTRUCTIONS

GENERAL INFORMATION:

The FasCal/FasMate is designed to provide a safe, reliable leak-tight

seal and connection when properly maintained and used. A flat, smooth,

sealing surface perpendicular to the connector axis is required around the

female test port. Verify the connector seal mates well with the sealing

surface. Improper mating with a test piece can result in poor sealing,

leakage and risk of connector failure resulting in damage or injury.

MAINTENANCE:

User must establish a regular interval for maintenance as determined by the

user media and operational environment.

Periodically inspect the FasCal and its seal for wear, damage and proper

operation. Inspect also for lubrication needs or corrosion. Repair or replace

as required to assure proper sealing, function, and safety.

Difficulty of operation indicates a need for inspection, lubrication, repair or

other maintenance.

Use only factory authorized replacement seals and parts. Use

of unauthorized parts/seals can cause failure resulting in

damage or injury.

Parts and instructions available through FasTest or your FasTest

distributor.

NOTE: Any field modification of FasTest connectors voids Factory

warranty.

FasTest, Inc. Product Warranty

FasTest, Inc. warrants its products against defects of workmanship and/or material for 12 months from the date of the

sale by FasTest, Inc. This warranty is void if the product is misused, tampered with or used in a manner that is not in

accordance with FasTest, Inc. recommendations and/or instructions. FasTest, Inc. is not liable for consequential or

other damages including, but not limited to, loss, damage, personal injury, or any other expense directly or indirectly

arising from the use of or inability to use its products either separately or in combination with other products. ALL

OTHER WARRANTIES EXPRESSED OR IMPLIED, WHETHER ORAL OR WRITTEN, INCLUDING BUT NOT

LIMITED TO

WARRANTIES OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY

EXCLUDED.

Remedy under this warranty is limited to replacement of the product or an account credit in the amount of the original

selling price, at the option on FasTest, Inc. All allegedly defective products must be returned prepaid transportation to

FasTest, Inc. along with information describing the products performance, unless disposition in the field is authorized

in writing by FasTest, Inc.

WP101 Rev C 9/4/2012

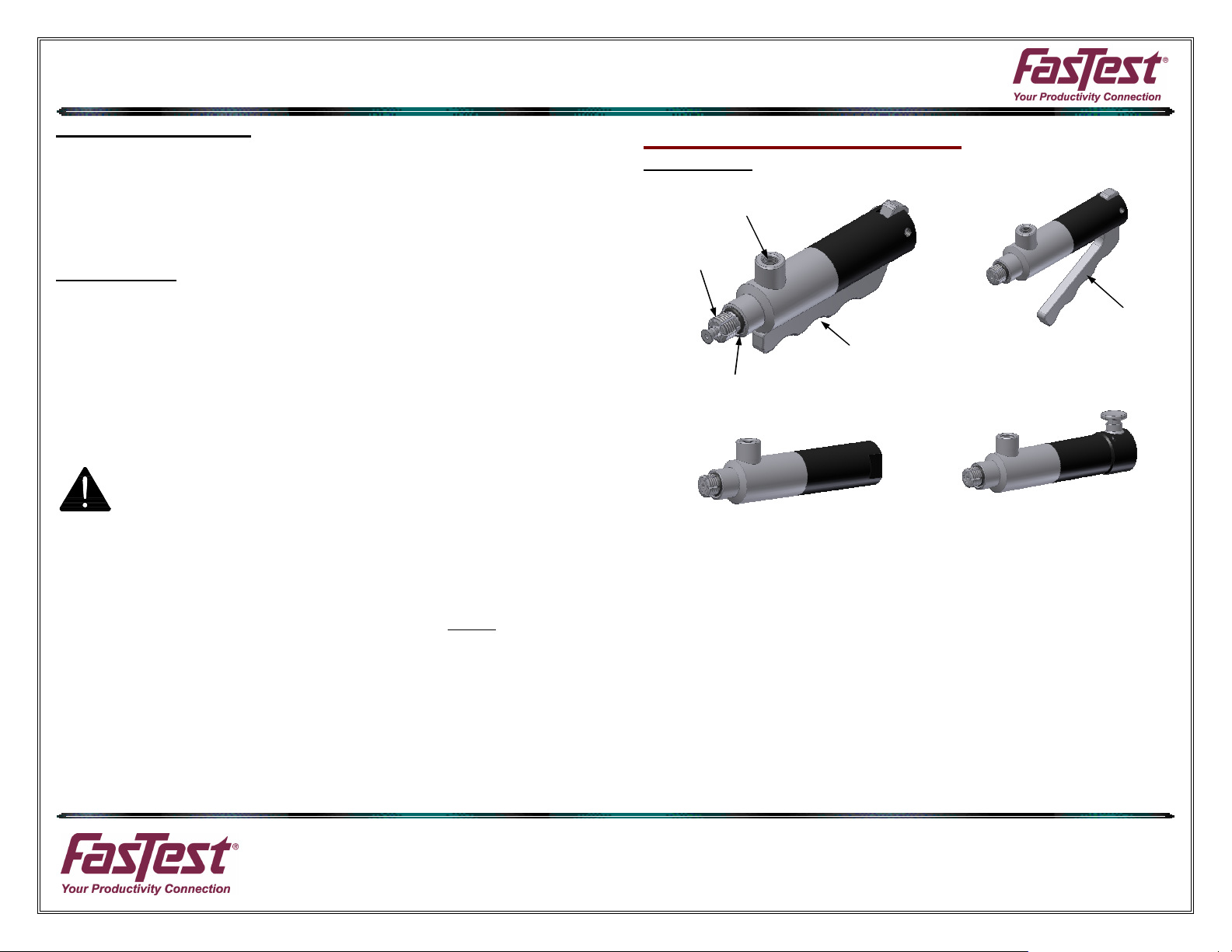

FasCal/FasMate Series

Description: Lever, Pneumatic & Thumb Valve operated

Connectors for Female Threads.

THREADED

GRIP COLLETS

FasCal/FasMate Connector provides a reliable leak-tight connection that

grips and seals into female threads.

Please thoroughly read and understand these operating instructions prior to

operating connector. The use of pressurized media for sealing and testing

requires a thorough understanding of the FasTest FasCal/FasMate

Operating Instructions.

• Operation

• General Information

• Maintenance

• Warranty

MEDIA PORT

MAIN SEAL

PNEUMATIC

SQUEEZE

HANDLE (INSERT

AND REMOVE

POSITION)

SQUEEZE HANDLE

(RELEASED

POSITION COLLETS

ENGAGED)

THUMB VALVE

CONNECTOR

Roseville, MN

Ph: 1-800-444-2373

Fax: 651-645-7390

www.fastestinc.com

MEDIA PORT

REMOVAL

PILOT

PORT

OPERATING INSTRUCTIONS

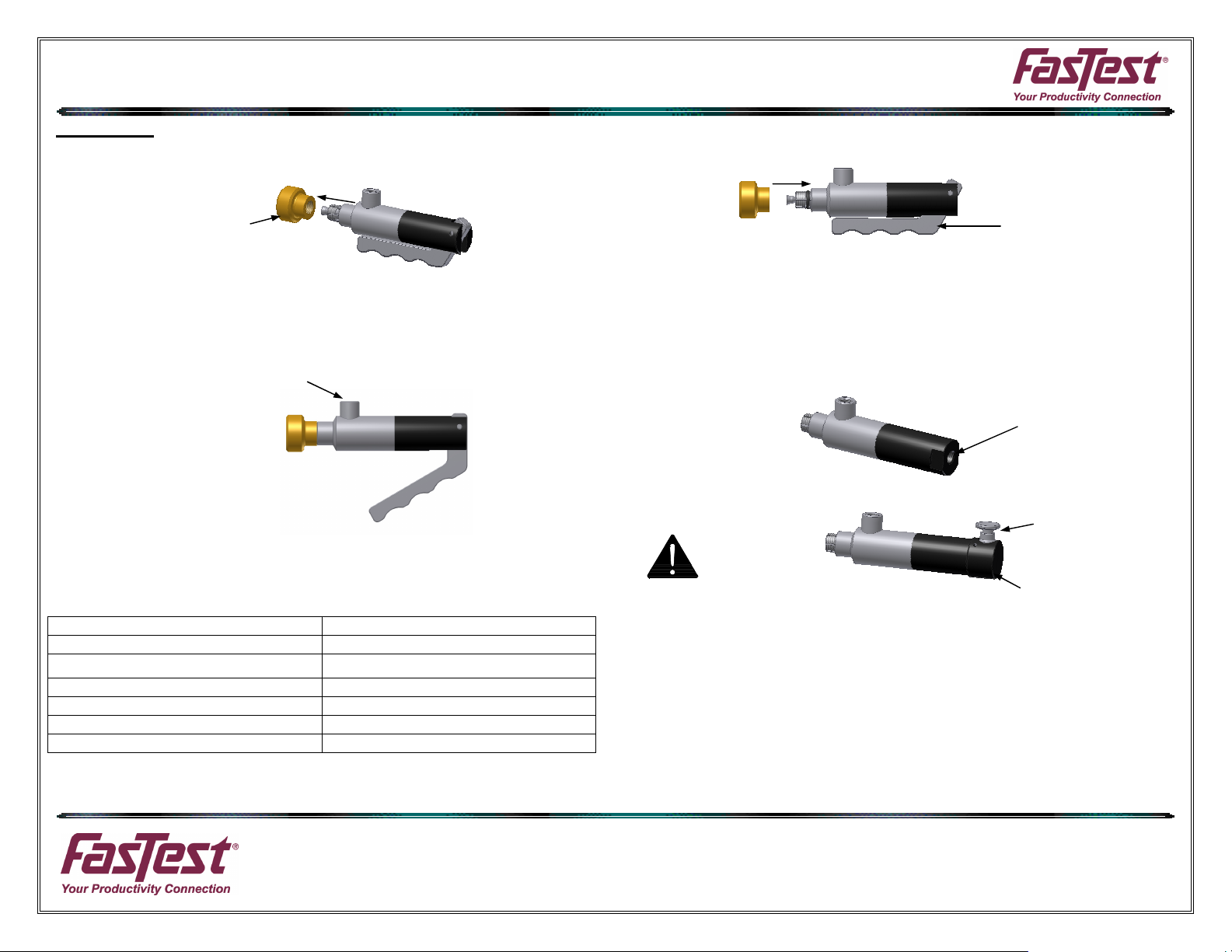

OPERATION:

1. Squeeze the handle and insert the gripping collets of the FasCal into the

female test port threads until the main seal o-ring contacts the component

to be tested.

TEST PIECE

INSERTION

2. Release the handle of the FasCal, expanding the collets to grip the test

port threads.

• Threaded collets lock into female threaded port, drawing in the sealing oring creating a leak tight seal for pressure testing, evacuation, charging or

filling operations.

3. Introduce test media through media port for the duration of test.

See chart below for media port, fitting, torque specifications. Thread sealant must be used..

Note: The torque limit is typically achieved 2-3 turns past finger tight of the

fitting.

Media Port Size (NPT/BSPP) Media Port Torque Limit (lbf-ft)

1/8 12

1/4 21

3/8 28

1/2 35

3/4 46

1 90

WP101 Rev C 9/4/2012

4. When test is complete relieve test pressure and squeeze the handle to

disengage threaded grip collets from test piece.

SQUEEZED HANDLE

POSITION

5. The previous four steps of connecting also apply to the operation of the

Pneumatic and Thumb Valve operated connectors.

6. Both the Pneumatic and Thumb Valve connector require 60-120 psi. Both

operators have 1/8” NPT pilot ports.

7. Pneumatic Valve Connector: This requires external control provided by

the user to engage and disengage the collets pneumatically.

PILOT PORT

8. The Thumb Valve connector controls collet engagement by pressing the

Thumb Valve on connector.

THUMB VALVE

WARNING:

FasTest Connectors are designed ONLY for the threads meeting the

specifications listed in the FasTest literature. DO NOT use in other

threads.

Connectors are NOT designed for permanent connections and are for

temporary connections only.

DO NOT EXCEED pressure rating as marked on connector.

Verify proper connection BEFORE pressurizing. Use only in a safe

environment. Safety chains and guards are recommended for all

applications.

DO NOT move connector while under pressure. Damage or injury may

result.

Roseville, MN

Ph: 1-800-444-2373

Fax: 651-645-7390

www.fastestinc.com

Loading...

Loading...