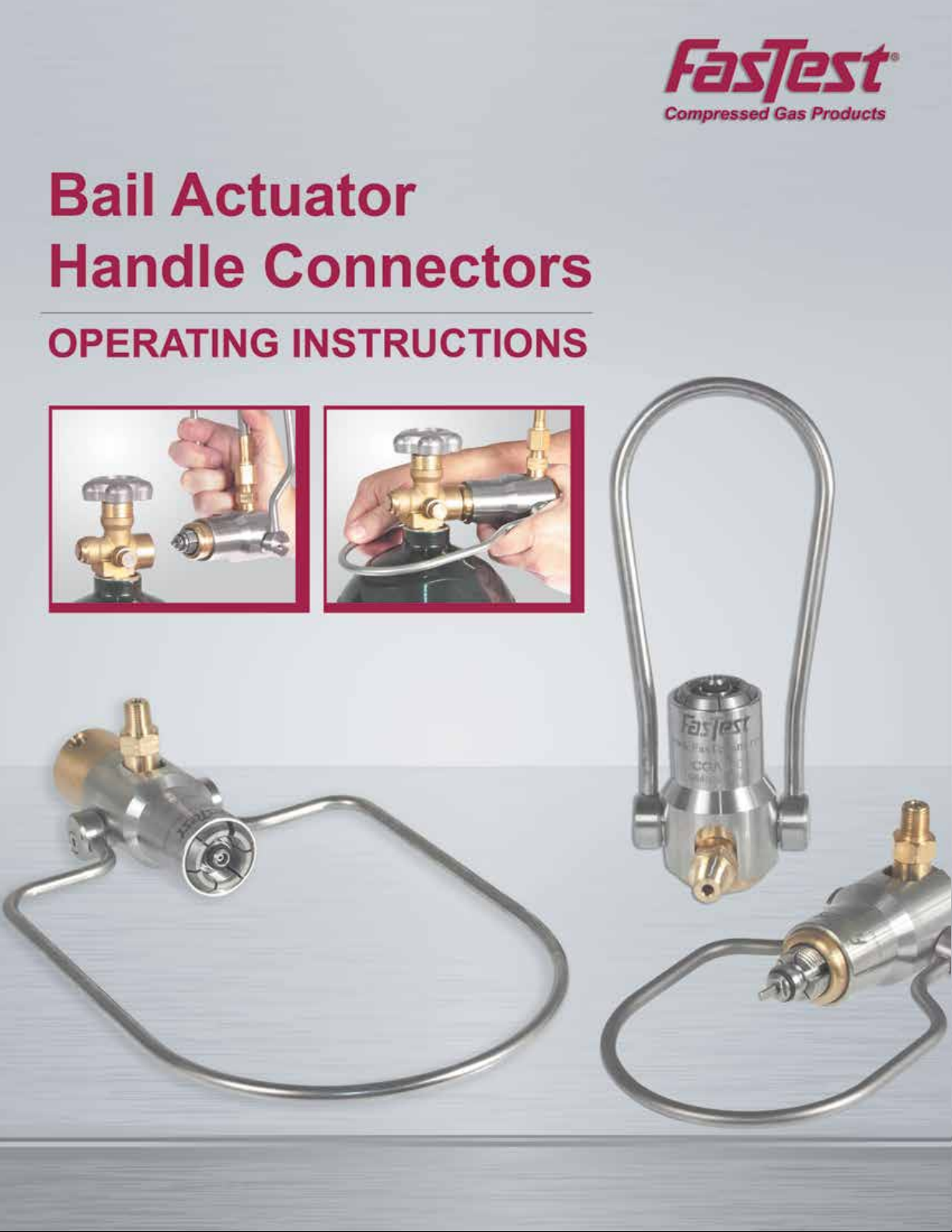

FasTest Bail Handle Gas Connectors User Manual

Bail Handle Compressed Gas Connectors

INTRODUCTION TO FASTEST

Why Choose FasTest? ...

FasTest is a dedicated manufacturer of advanced connection

tools for pressure and vacuum testing applications. Our

connection tools are easy, safe, and reliable and can dramatically

lower your operating costs and increase operational throughput.

FasTest customers have switched from inefcient plugging

or sealing methods for their testing or lling needs. Our

connectors are used in the compressed gas, manufacturing,

calibration, processing with refrigerant and medical industries,

as well as major automotive manufacturers and leading

appliance companies internationally.

Our connection products and extensive experience since 1985

will help you specify the right connector for your application.

At FasTest, we regularly modify standard products to t your

specic application and testing requirements.

Thank You ...

We thank you for deciding to use FasTest series gas

connectors. The following pages include operating and

maintenance instructions. Read these instructions carefully

and follow them before using any gas connectors.

FasTest Connection Tools Offer:

• A unique and proprietary pressure-assisted gripping

and sealing technology that increases gripping

pressure as the pressure increases, virtually

eliminating accidental removal under pressure

• A oating split collet design that eliminates operator

adjustment

• Dynamic Seals that minimize seal stress to increase

seal life, reliability and sealing pressure

• Seals that provide a wide range of options to meet

your application demands

• Minimal maintenance, easy seal replacement, long life

and ergonomically friendly designs

FasTest connectors may be used for a variety of applications.

However, the customer should check with FasTest to see

whether the connector is appropriate for their application.

The information corresponds with product knowledge at the

time of printing. Failure to observe these instructions may

result in loss of warranty.

Table of Contents

Application Guidelines . . . . . . . . . . . . . . . . . . .1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Operation (Connect & Disconnect) . . . . . . .3-5

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Standard Replacement Parts List . . . . . . . . . .9

Troubleshooting . . . . . . . . . . . . . . . . . . . .10-11

Warranty . . . . . . . . . . . . . . . . . . . . .Back Cover

FasTest, Inc. 1646 Terrace Drive Roseville, MN 55113 Support: (800) 444-2373 Fax: (651) 645-7390 www.fastestinc.com

Bail Handle Compressed Gas Connectors

APPLICATION GUIDELINES

z FasTest gas series connectors are designed to connect to specic CGA gas valves

z Do not connect to a damaged cylinder valve

z Contact FasTest if the product is damaged, or if you have inquiries on the proper function of the connector

z Do not use the connector until clarication is sought

z Connectors may only be dismantled by FasTest or trained personnel

z Do not use excessive force when connecting. See Operating Instructions outlined in this manual

z Filling gas cylinders is potentially dangerous. Appropriate safety measures must be taken. FasTest is not liable or

injuries to persons or property arising from incorrect use

z Connectors for respiratory air/oxygen must be kept free from oil and grease

z Connectors without an operating loop require additional security by means of safety wire, safety cage, etc

z When using a quick connector with lling hose, please ensure that the cylinders to be lled are secure

FasTest, Inc. 1646 Terrace Drive Roseville, MN 55113 Support: (800) 444-2373 Fax: (651) 645-7390 www.fastestinc.com

1

Bail Handle Compressed Gas Connectors

INSTALLATION

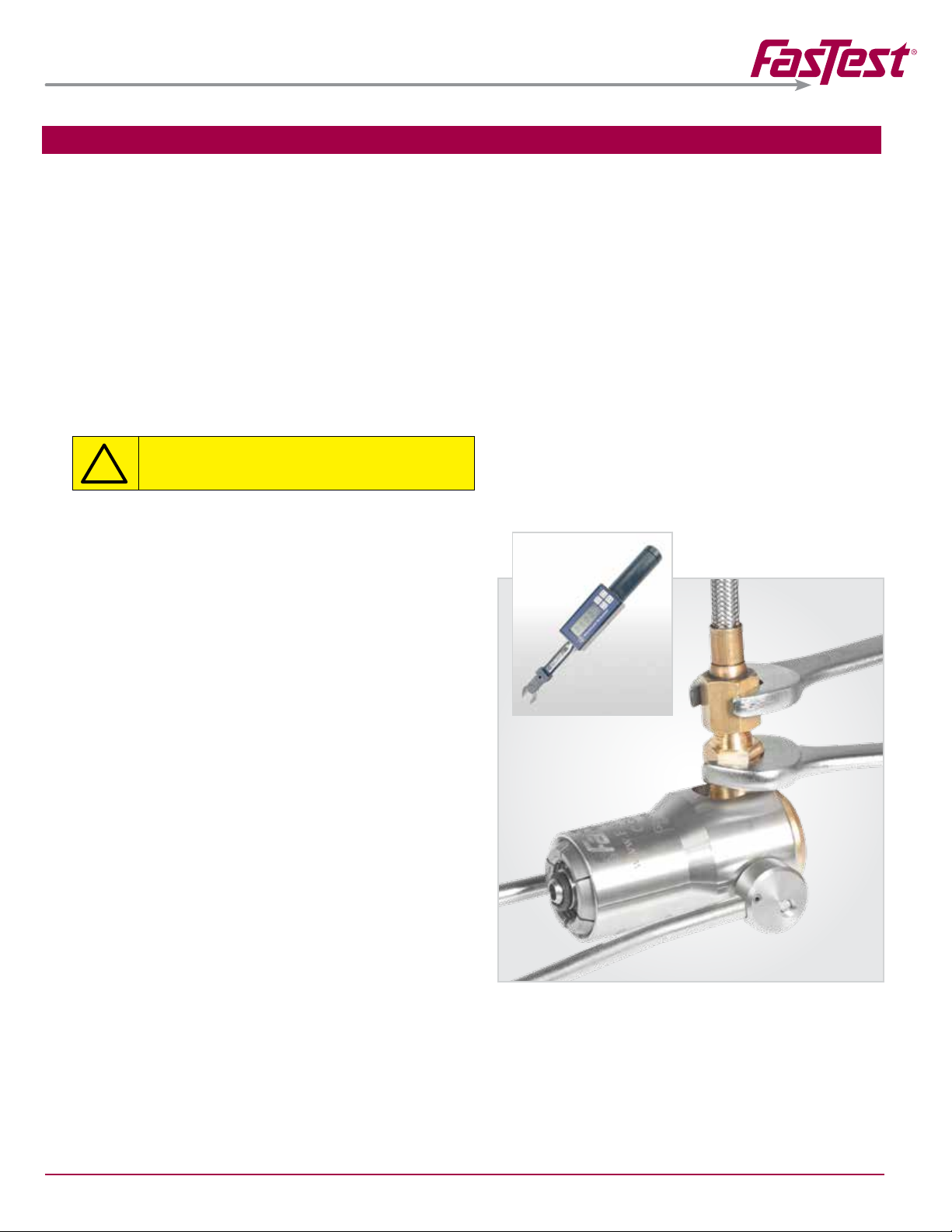

Step 1

Protect the connector from damage and dirt by keeping it in the original packaging until you are ready to use it.

Step 2

Check that the connector part number and delivery notes (if applicable) comply with the application.

Step 3

Connect the hose securely and leak-tight to inlet B (Figure 1). Tighten to a max torque of 15 ft-lbs.

A higher torque can result in damage causing leaks when the system is pressurized.

Ensure that the connectors cannot be damaged when loading and removing the cylinder.

CAUTION:

!

Do not over tighten.

Over tightening could break

connector and cause injury to operator.

Step 4

Review total function:

• Check leak-tight seal

• Check if collets open and close properly by actuating

the connector several times

• Check if connector marking complies with the

application

• The FasTest connector is ready to operate

Note

Avoid lateral forces like short connecting hoses because

this could cause leakage.

Figure 1. Torque to maximum 15 ft-lb

2

FasTest, Inc. 1646 Terrace Drive Roseville, MN 55113 Support: (800) 444-2373 Fax: (651) 645-7390 www.fastestinc.com

Bail Handle Compressed Gas Connectors

OPERATION

Step 1

At the start of each shift

• Check all connectors for main seal condition

• Check for smooth operation of the actuating loop before the rst ll

Incoming Line

Termination

Bail

Handle

Collet

Main Seal

Figure 2. CGA 346, CGA 540 Figure 3. CGA 580, CGA 590

Sleeve

Main Seal

Step 2

When making a connection:

• Ensure that the connector is in the fully open position

and in direct contact with the front of the valve before

moving the actuator

• Align the connector to the thread to prevent damage

to the front seal from sharp edges of the valve

• Place the connector onto/into the valve until it stops.

DO NOT USE FORCE!

• Rotate the bail to engage the connector. Do

not actuate the loop with excessive force. If the

connection is made correctly, it will connect with

relative ease

• Ensure that the actuating loop has traveled to a

position below parallel to the connector body. Check

to make sure the collets are fully engaged.

(See good vs. bad connection photos, pages 4-5)

Figure 4a - 4b. Correct CGA 346/540 alignment and connection

Incoming Line

Termination

Bail

Handle

Sleeve

Collet

Figure 4c - 4d. Align CGA 580/590 connector tight and

square against valve with no visible gap to avoid damage to

the sealing surface

FasTest, Inc. 1646 Terrace Drive Roseville, MN 55113 Support: (800) 444-2373 Fax: (651) 645-7390 www.fastestinc.com

3

Loading...

Loading...