Page 1

fantech

VHR150

Heat Recovery Ventilator

Item #: 422474

Rev Date: 2015-05-13

Installation Manual

United States

10048 Industrial Blvd., Lenexa, KS, 66215

Tel.: 800.747.1762 • Fax: 800.487.9915

Canada

50 Kanalflakt Way, Bouctouche, NB, E4S 3M5

Tel.: 800.565.3548 • Fax: 877.747.8116

Fantech reserves the right to modify, at any time and without notice, any or all of its products’ features, designs,

components and specifications to maintain their technological leadership position.

Please visit our website www.fantech.net for more detailed technical information.

Page 2

2

Note Warning/

Important

note

Information Technical

information

Practical tip

PLEASE READ THIS MANUAL BEFORE INSTALLING UNIT

For residential use only

Before installation careful consideration must be given to how this system will operate if connected to

any other piece of mechanical equipment, i.e. a forced air furnace or air handler operating at a higher

static pressure. After installation, the compatibility of the two pieces of equipment must be conrmed by

measuring the airow of the Heat Recovery Ventilator using the balancing procedure found in this manual.

It is always important to assess how the operation of any HRV may interact with vented combustion equipment (i.e.

Gas Furnaces, Oil Furnaces, Wood Stoves, etc.)

Products are designed and manufactured to provide reliable performance, but they are not guaranteed to be 100%

free of defects. Even reliable products will experience occasional failures, and this possibility should be recognized

by the user. If these products are used in a life support ventilation system where failure could result in loss or injury,

the user should provide adequate back-up ventilation, supplementary natural ventilation or failure alarm system, or

acknowledge willingness to accept the risk of such loss or injury.

Your ventilation system should be installed in accordance with the local building code that is in effect, in absence

of such requirements, it is recommenced to check with local authorities having jurisdiction in your area prior to

installing this product.

fantech

Page 3

TABLE OF CONTENTS

DETERMINING YOUR AIRFLOW REQUIREMENT ..................................................... 4

INSTALLATION EXAMPLES

Fully dedicated system ................................................................ 5

Partially dedicated system .............................................................. 6

Simplified Installation

Option 1 ...................................................................... 7

Option 2 .......................................................................8

EXTERIOR DUCTING INSTALLATION

Weatherhood Location ................................................................. 9

Installing the ducting to the weatherhood ................................................... 9

INTERIOR DUCTING INSTALLATION

General Tips ....................................................................... 10

Installing duct to HRV ................................................................ 10

Supply & Exhaust Air Grilles Location...................................................... 10

3

DUCTING INSTALLATION EXAMPLES..............................................................11

HRV INSTALLATION ........................................................................ 12

AIRFLOW ADJUSTMENT & BALANCING

General preparation ................................................................. 13

Adjusting airflow using integrated balancing system ........................................... 13

Balancing steps .................................................................... 14

LOW VOLTAGE CONTROL SYSTEMS ............................................................. 15

WIRING DIAGRAM ......................................................................... 16

TROUBLESHOOTING .........................................................................18

HRV MAINTENANCE CHART ...................................................................19

fantech

Page 4

4

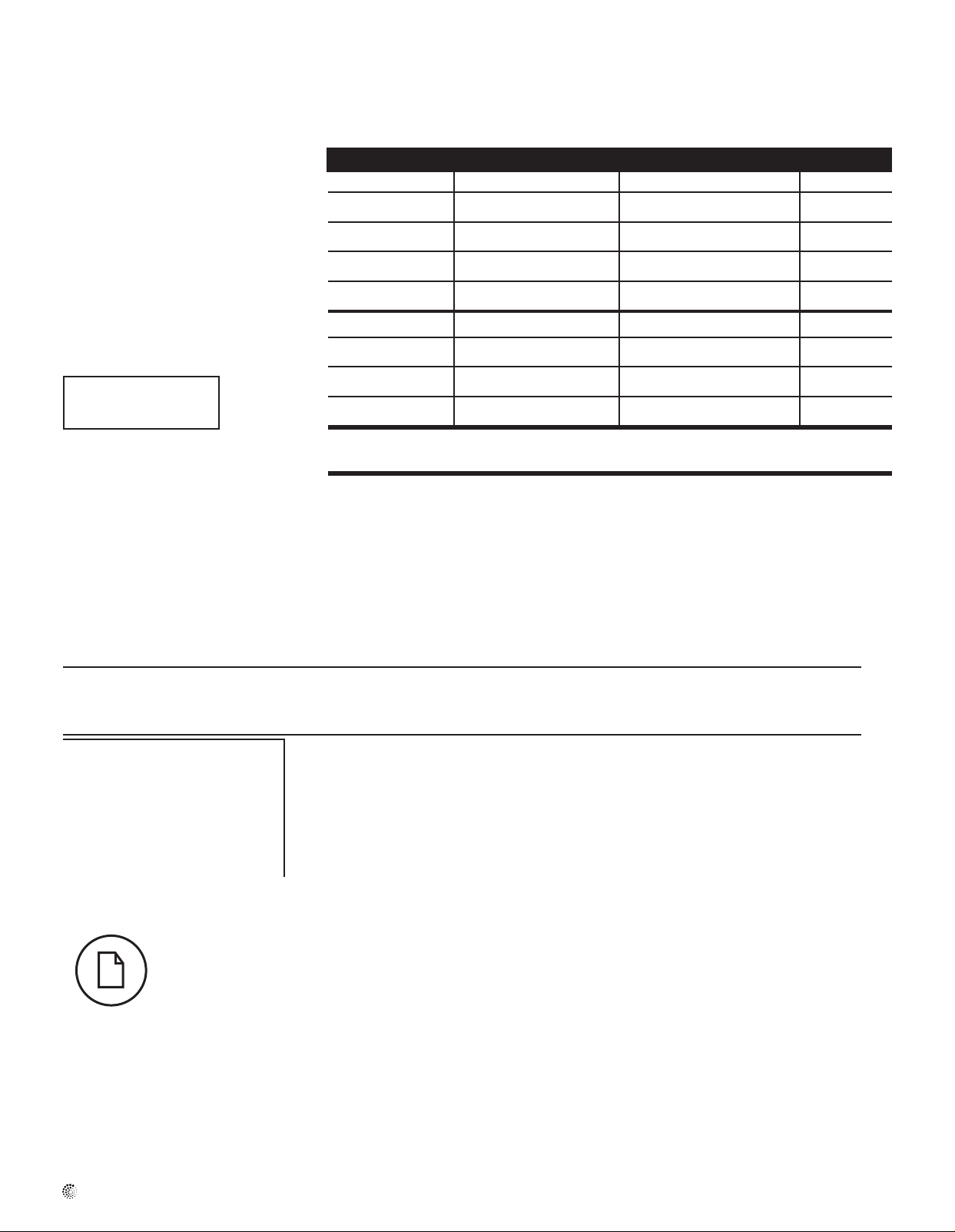

DETERMINING YOUR AIRFLOW REQUIREMENT

Room Count Method

1 CFM = 0.47 L/s

1 L/s = 2.13 CFM

ASHRAE method

Room classification Number of rooms CFM (L/s)

Master bedroom x 10 L/s (20 CFM) =

Basement yes or no =

Bedrooms x 5 L/s (10 CFM) =

Living room x 5 L/s (10 CFM) =

Others x 5 L/s (10 CFM) =

Kitchen x 5 L/s (10 CFM) =

Bathroom x 5 L/s (10 CFM) =

Laundry room x 5 L/s (10 CFM) =

Utility room x 5 L/s (10 CFM) =

Total Ventilation Requirements (add last column ) =

if yes add 10 L/s (20 CFM)

if no = 0

CFM Required

Ventilation Air requirements

Floor area Bedrooms

0-1 2-3 4-5 6-7 >7

2

Ft

< 1500 <139 30 14 45 21 60 28 75 35 90 42

1501-3000 139.1-279 45 21 60 28 75 35 90 42 105 50

3001-4500 279.1-418 60 28 75 35 90 45 105 50 120 57

4501-6000 418.1-557 75 35 90 42 105 50 120 57 135 64

6001-7500 557.1-697 90 42 105 50 120 57 135 64 150 71

>7500 >697 105 50 120 57 135 64 150 71 165 78

* ASHRAE 62.2-2010 Table 4.1, Ventilation and Acceptable Indoor Air Quality in Low-Rise Residential Buildings.

2

m

CFM L/s CFM L/s CFM L/s CFM L/s CFM L/s

Bathroom: If the HRV is going to provide the required local exhaust ventilation for each bathroom with each a continuous 20 CFM

(10 L/s), this ventilation rate can be considered as part of the whole-building ventilation rate.

fantech

Page 5

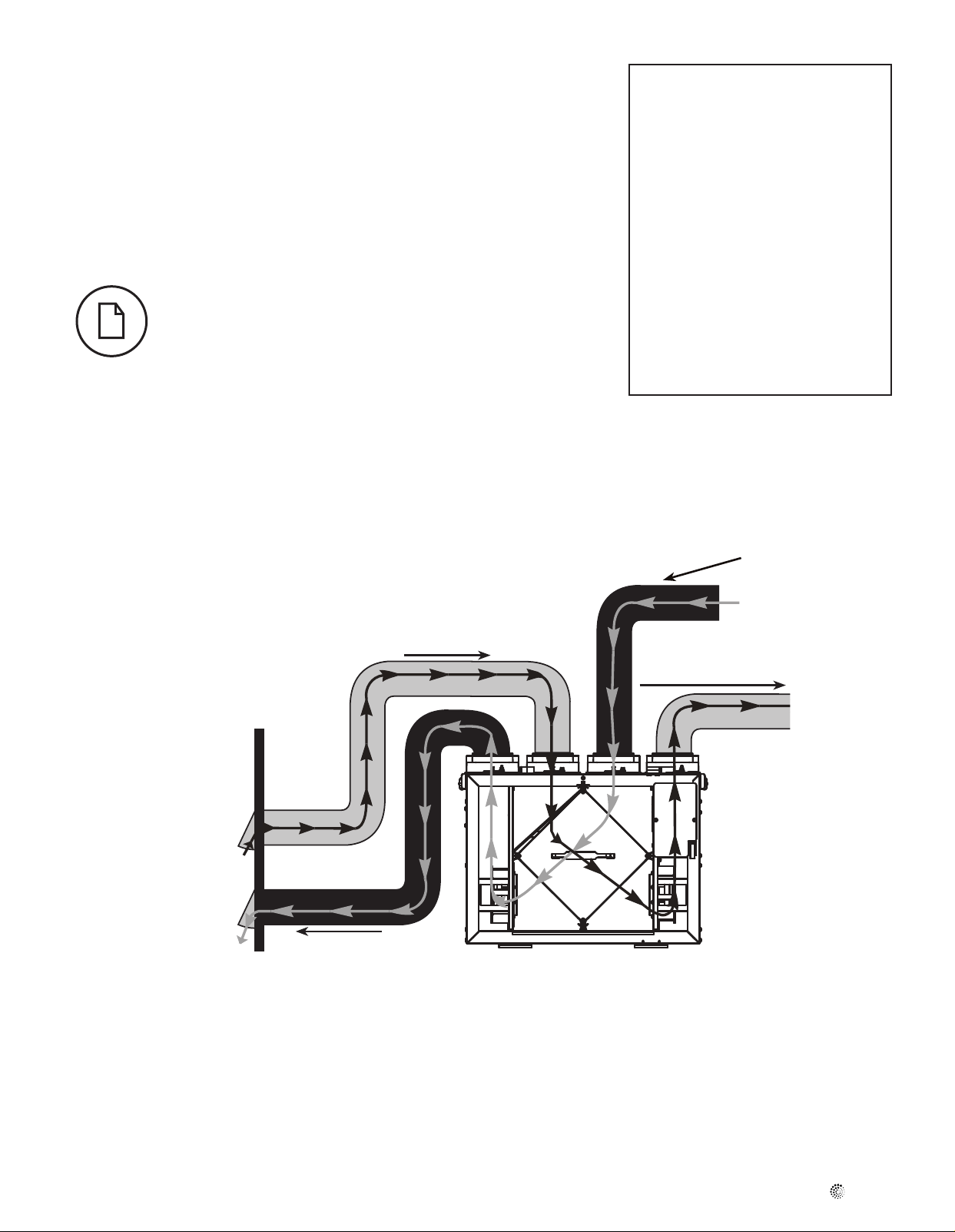

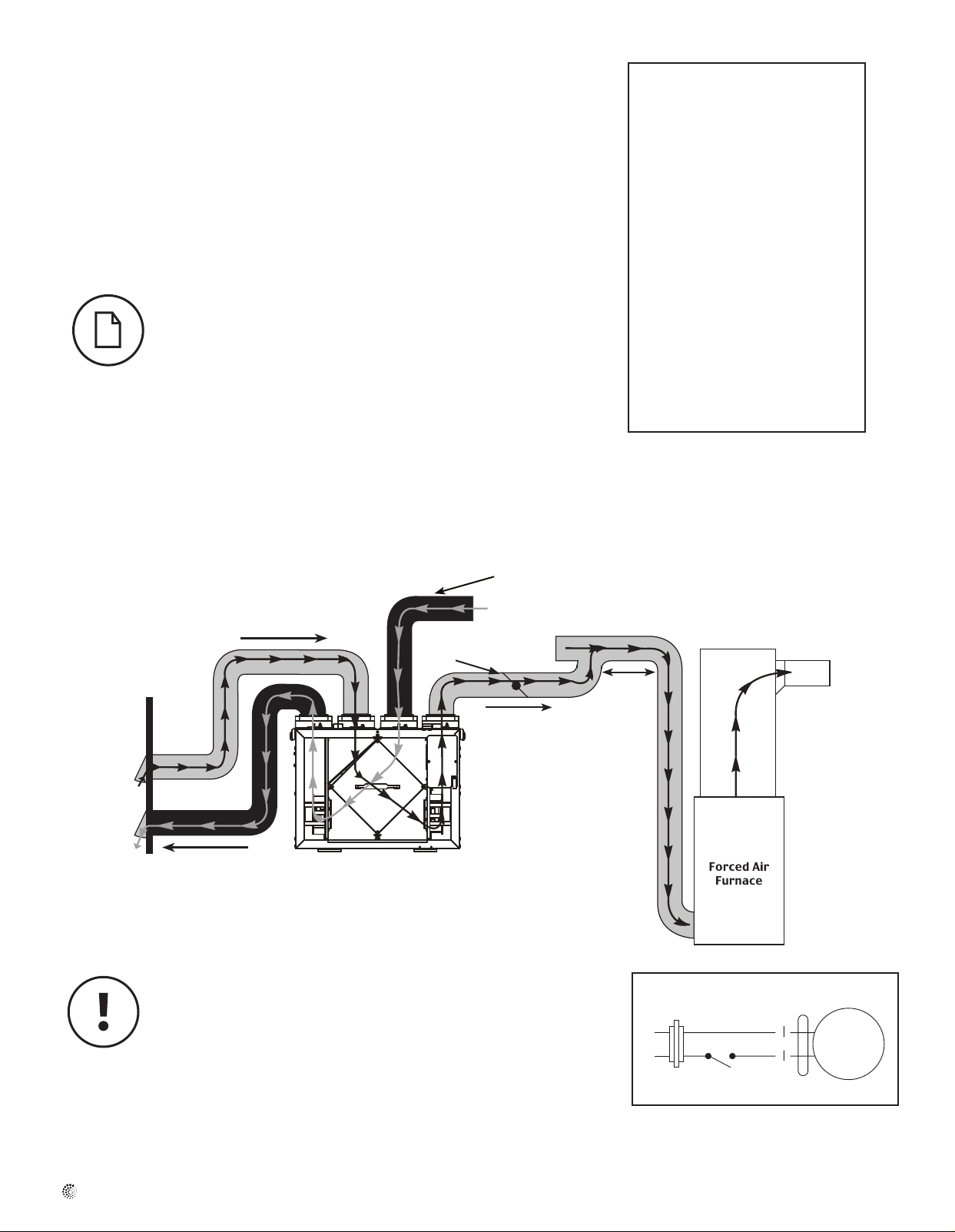

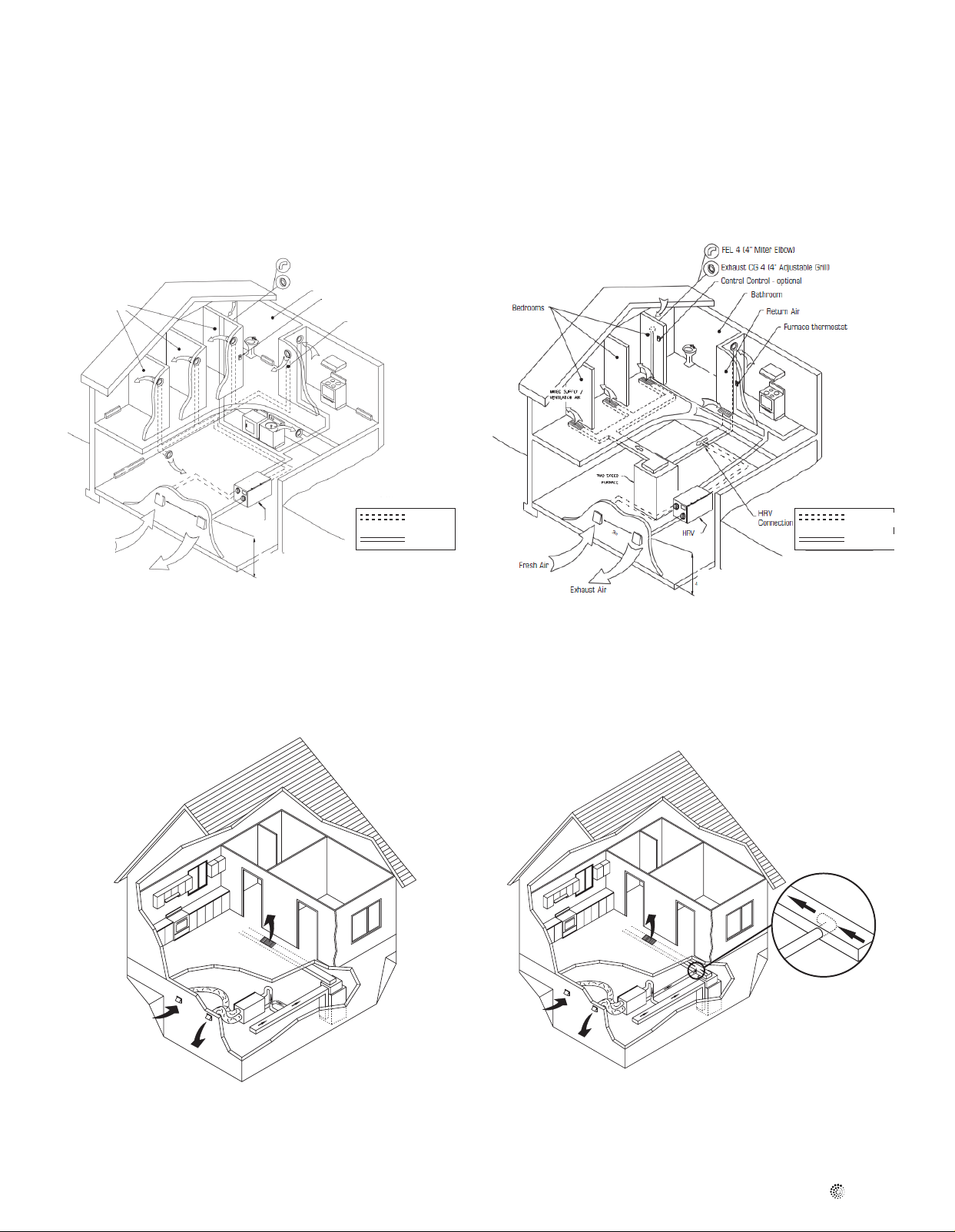

INSTALLATION EXAMPLES

5

Example only – duct configuration may differ depending on the model.

FULLY DEDICATED SYSTEM

BEST FOR NEW CONSTRUCTION

1. Stale air is drawn from key areas of the home requiring local exhaust

(bathroom, kitchen, laundry room).

2. Fresh air is distributed directly to habitable rooms in the house

(bedrooms, living room)

3. The HRV’s airflow must be balanced after installation using the procedure

found in the section “AIRFLOW BALANCING”

HRV ducting for fully Dedicated System

Suggested installation for:

• Hydronic baseboard

• Inoor heating

• Electric baseboard

• Mini split heat pump

Benets: Provides the best

fresh air distribution in the

house; lowest operation cost

since the furnace/air handler

unit is not needed.

Stale air from inside

Outside

Fresh air from

outside

Fresh air to living areas

Stale air to

outside

fantech

Page 6

6

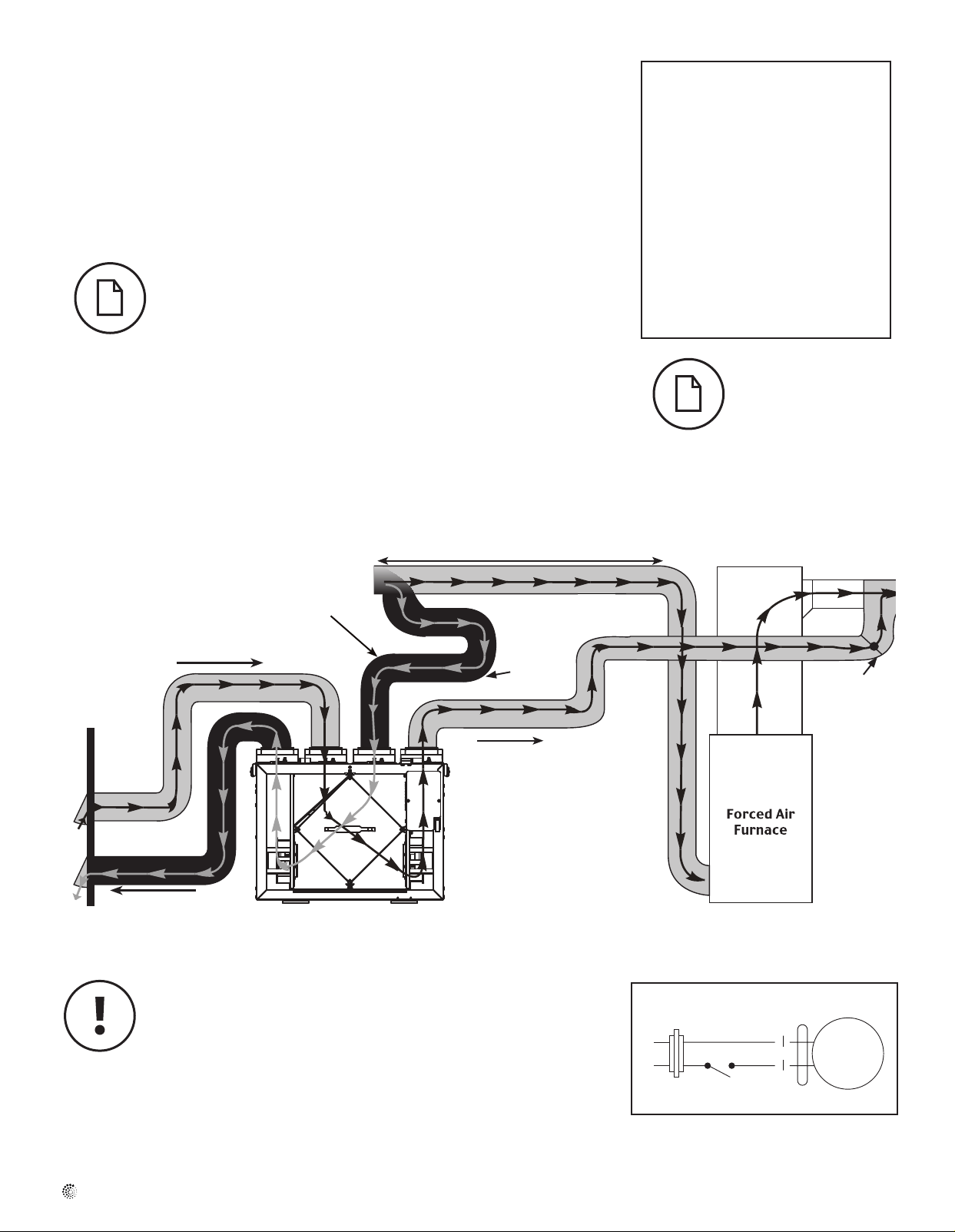

INSTALLATION EXAMPLES (CONT'D)

DIRECT CONNECTION of the FRESH air to living area to the RETURN PLENUM

of the AIR HANDLER (Stale air drawn from key areas of home)

PARTIALLY DEDICATED SYSTEM (BETTER)

1. Furnace blower must operate when ventilation from HRV is required. The

furnace should be set to run continuously or interlocked with HRV

2. Stale air is drawn from key areas of the home (bathroom, kitchen, laundry

room).

3. Fresh air is supplied to the return air plenum of the furnace.

4. Due to the difference in pressure between the HRV and the equipment it

is being connected to the HRV’s airflow must be balanced on site, using

the procedure found in the section “AIRFLOW BALANCING”

HRV/ Furnace ducting for Partially Dedicated System

Suggested installation for:

• Central furnace (air

handling unit or central

air conditioners)

• When ducting fresh

air to living area is not

possible or practical,

i.e. expensive or when

the central AHU will

operate year-round.

Benets: Conditions the

fresh air prior to

distributing it throughout

the house

Outside

Stale air from inside

Fresh air from

outside

Motorized Damper

Fresh air

to living

areas

Stale air to

outside

Fantech heat recovery ventilators (HRV) that use a supply fan shutdown for frost prevention do not include an outdoor air motorized damper. If you are using a simplied installation, i.e. connecting the HRV supply air duct to a furnace's return air duct, the HRV must

operate continuously. When the HRV is turned off, no warm exhaust air will ow through

the HRV but the furnace's fan will continue to draw in outdoor air directly into the furnace.

If it's cold outside, cold air will be introduced, without re-heating, directly into the furnace.

If the HRV is installed such that the homeowner may turn off the HRV during the winter, we

recommend installing a motorized damper between the HRV's supply air and the furnace's

return air duct that closes when the HRV is not operating. See wiring diagram (gure 1).

You may also choose to use a Fantech HRV that uses a recirculation defrost that incorporates an outdoor air damper.

* Unit airflow should be balanced while HRV is on

“Normal” speed and furnace blower is running.

recommended

1 m (3' 3")

min.

Cold air

return

24 VAC Transformer

24V

120V

COM

HRV Furnace interlock

See page 16.

Figure 1

*Transformer and Damper motor not included

NO

Damper

Motor

fantech

Page 7

INSTALLATION EXAMPLES (CONT'D)

7

DIRECT CONNECTION of both the HRV SUPPLY AIR STREAM and EXHAUST AIR STREAM

to the FURNACE COLD AIR RETURN

SIMPLIFIED INSTALLATION (GOOD)

(RETURN/RETURN METHOD) - OPTION 1

1. Furnace blower must operate when ventilation from HRV is required. The

furnace should be set to run continuously or interlocked with HRV.

2. A minimum separation of 1m (3`3’’) is recommended between the two

direct connections.

3. In order to prevent exhausting any fresh air, the HRV’s exhaust air connection

should be upstream of the HRV’s supply air connection when ducting to the

furnace’s cold air return.

4. Due to the difference in pressure between the HRV and the equipment it is

being connected to the HRV’s airflow must be balanced on site, using the

procedure found in the section “AIRFLOW BALANCING”

HRV/ furnace for Simplified Installation – Option 1

Suggested installation for:

• When bathroom and kitchen

already have local exhaust

system

• May be suitable for

retrotting

Benets: Least expensive

installation type

1 m (3' 3") min. recommended

Stale air from inside

Fresh air from

outside

Outside

Fresh air to

living areas

Stale air to

outside

Fantech heat recovery ventilators (HRV) that use a supply fan shutdown for frost prevention do not include an outdoor air motorized damper. If you are using a simplied installation, i.e. connecting the HRV supply air duct to a furnace's return air duct, the HRV must

operate continuously. When the HRV is turned off, no warm exhaust air will ow through

the HRV but the furnace's fan will continue to draw in outdoor air directly into the furnace.

If it's cold outside, cold air will be introduced, without re-heating, directly into the furnace.

If the HRV is installed such that the homeowner may turn off the HRV during the winter, we

recommend installing a motorized damper between the HRV's supply air and the furnace's

return air duct that closes when the HRV is not operating. See wiring diagram (gure 1).

You may also choose to use a Fantech HRV that uses a recirculation defrost that incorporates an outdoor air damper.

* Unit airflow should be balanced while HRV is on

“Normal” speed and furnace blower is running.

Motorized

Damper

1 m (3' 3")

min.

recom-

mended

Cold air

return

24 VAC Transformer

24V

120V

COM

HRV Furnace interlock

See page 16.

Figure 1

*Transformer and Damper motor not included

NO

Damper

Motor

fantech

Page 8

8

Installation examples (Cont'd)

DIRECT CONNECTION of the HRV SUPPLY AIR STREAM to the SUPPLY AIR SIDE on the

FURNACE & EXHAUST AIR STREAM to the FURNACE COLD AIR RETURN

SIMPLIFIED INSTALLATION (GOOD)

OPTION 2

1. Furnace blower must operate when ventilation from HRV is required. The

furnace should be set to run continuously or interlocked with HRV.

2. Due to the differences in pressure between the HRV and the equipment it is

being connected to, the HRV‘s airflow must be balanced on site, using the

procedure found section "AIRFLOW BALANCING".

HRV/Furnace ducting for Simplified Installation - Option 2

1 m (3' 3") min. recommended

* Ductwork layout may differ depending on model

Suggested installation for:

• When bathroom and

kitchen already have local

exhaust system

• May be suitable for

retrotting

Benets: Least expensive

installation type

In the case of a simplified

installation, Option 1 is

recommended.

Outside

fantech

Air from inside

Fresh air from

outside

Fresh air to living areas

Stale air to

outside

Fantech heat recovery ventilators (HRV) that use a supply fan shutdown for frost prevention do not include an outdoor air motorized damper. If you are using a simplied installation, i.e. connecting the HRV supply air duct to a furnace's return air duct, the HRV must

operate continuously. When the HRV is turned off, no warm exhaust air will ow through

the HRV but the furnace's fan will continue to draw in outdoor air directly into the furnace.

If it's cold outside, cold air will be introduced, without re-heating, directly into the furnace.

If the HRV is installed such that the homeowner may turn off the HRV during the winter, we

recommend installing a motorized damper between the HRV's supply air and the furnace's

return air duct that closes when the HRV is not operating. See wiring diagram (gure 1).

You may also choose to use a Fantech HRV that uses a recirculation defrost that incorporates an outdoor air damper.

* Unit air flow should be balanced while HRV is on "Normal" speed and

furnace blower is running.

Motorized

Damper

Cold air

return

24 VAC Transformer

24V

120V

COM

HRV Furnace interlock

See page 16.

Figure 1

*Transformer and Damper motor not included

NO

Motorized

Damper

Damper

Motor

Page 9

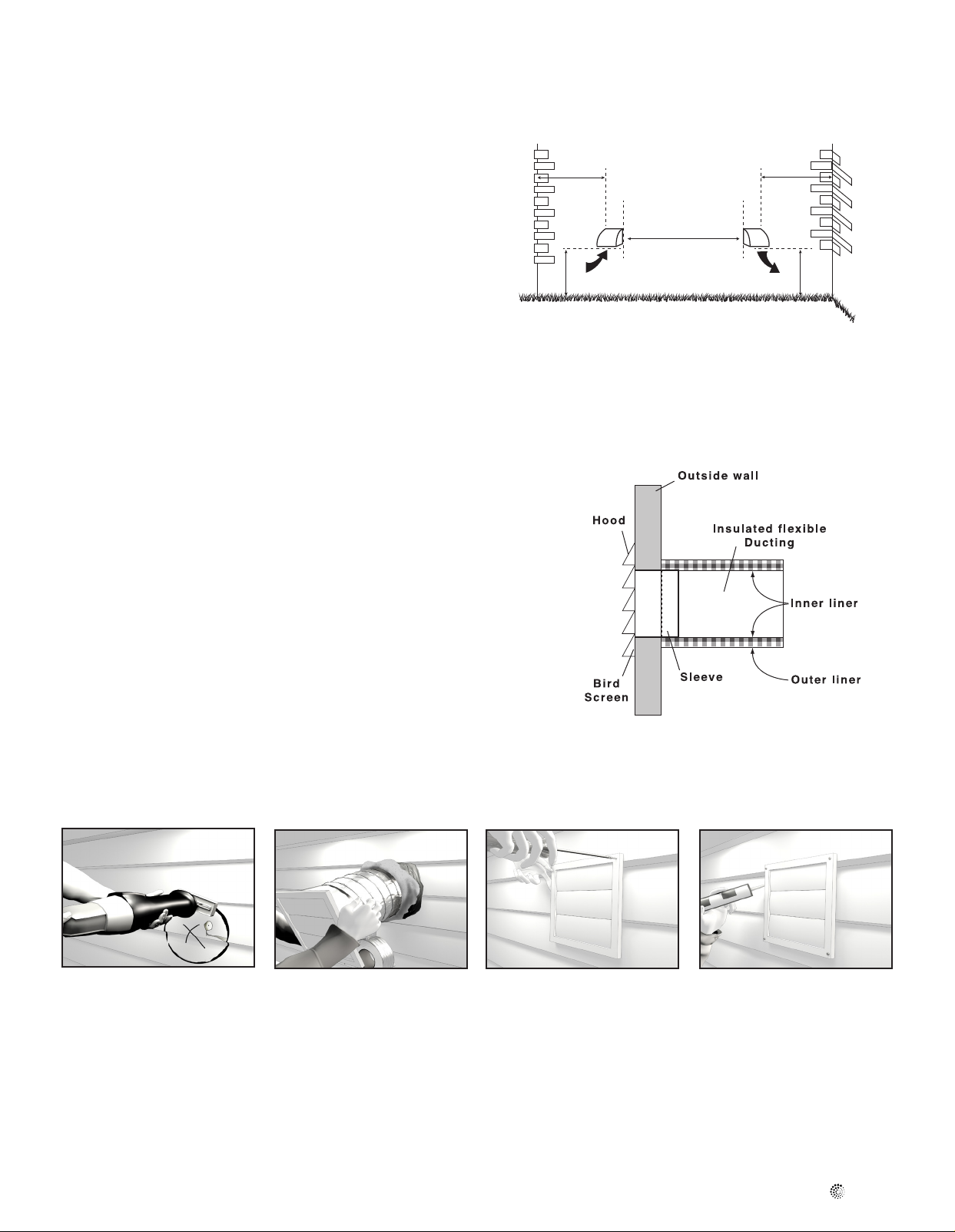

EXTERIOR DUCTING INSTALLATION

9

WEATHERHOOD LOCATION

OUTSIDE CORNER INSIDE CORNER

• Decide where your intake and exhaust hoods will be located.

Locating the Intake Weatherhood

• Should be located upstream (if there are prevailing winds) from the

exhaust outlet.

• At a minimum of 2m (6’) away from dryer vents and furnace exhaust

(medium or high efficiency furnaces), driveways, oil fill pipes, gas meters,

or garbage containers.

• At a minimum height of 460mm (18’’) above the ground, or above the level

of expected snow accumulation.

• At a minimum distance of 1m (3’) from the corner of the building.

• Do not locate in the garage, attic, crawl space, or underneath deck.

Locating the Exhaust Weatherhood

• At least 460mm (18") above ground or above the depth of expected snow accumulation

• At least 1m (3’) away from the corner of the building

• Not near a gas meter, electric meter or a walkway where fog or ice could create a hazard

• Do not locate in a garage, workshop or other unheated space

INSTALLING THE DUCTING TO THE WEATHERHOODS

A well designed and installed ducting system will allow the HRV to operate at its

maximum efficiency. The inner liner of the flexible insulated duct must be secured to the

sleeve of the weatherhood (as close to the outside as possible) and to the appropriate duct

connection on the HRV. The insulation should remain full and not crushed. The outer liner,

which acts as a vapor barrier, must be completely sealed to the outer wall and the HRV

using tape and/or caulking. A good bead of high quality caulking (preferably acoustical

sealant) will seal the inner flexible duct to both the HRV duct connection and the

weatherhood prior to securing them.

To minimize airflow restriction, the flexible insulated duct that connects the two outside

weatherhoods to the HRV should be stretched tightly and be as short as possible.

Twisting or folding the duct will severely restrict airflow.

See “Installation Diagram Examples” for installation examples.

36" (1m)

min.

INTAKE

18" (460mm) min.

6' (2m)

min.

36” (1m)

min.

EXHAUST

18" (460mm) min.

STEPS FOR HOOD INSTALLATION:

1 Using the duct connection of

the outside hood, outline the

intake & exhaust holes to be

cut. The holes should be slightly

larger than the duct connection

to allow for the thickness of the

insulated flexible duct. Cut a

hole for both the intake and

exhaust hoods.

2 Pull the insulated flexible duct

through the opening until it is

well extended and straight.

Slide the duct’s inner vinyl sleeve

over the hood duct connection

and secure. Pull the insulation

over the duct and pull the vapor

barrier over the sleeve. Secure

with appropriate tape or

sealant.

3 Push the hood into the opening

and then attach the hood to the

outside wall with mounting

screws.

Repeat the installation

procedure for both the supply

and exhaust hoods.

4 Using a caulking gun, seal

around both hoods to prevent

any leaks.

fantech

Page 10

10

INTERIOR DUCTING INSTALLATION

• To maximize airflow through the ductwork system, all ducts should be kept short

and have as few bends or elbows as possible.

• 45º elbows are preferable to 90º.

• Use “Y“ ducts instead of “T” ducts whenever possible.

• All duct joints must be fastened with screws or duct sealant and wrapped with

aluminum foil duct tape to prevent leakage.

• Galvanized ducting from the HRV to the living areas in the house is recommended

whenever possible, although flexible ducting can be used in moderation when

necessary.

• To avoid possible noise transfer through the ductwork system, a short length

(approximately 300mm, 12’’) of nonmetallic flexible insulated duct should be

connected between the HRV and the supply/exhaust ductwork system.

• The main supply and return line to/from the HRV must have the same diameter as the

duct connection or larger.

• Branch lines to the individual rooms may be as small as 100mm (4’’).

INSTALLING DUCT TO HRV

For flexible duct installation, slide flexible ducting onto duct connection. Then install a cable tie over flexible duct to prevent leakage between the ducting and

the duct connection.

In the case of solid ducting, slide duct over duct connection, screw in place and seal.

SUPPLY AIR GRILLES LOCATION

In homes without a forced air furnace, fresh air should be supplied to all habitable rooms, including bedrooms and living areas. It should be supplied

from high wall or ceiling locations. Grilles that diffuse the air comfortably are recommended. In homes with a forced air furnace, you may want to connect

the HRV to the furnace ductwork (see information below).

EXHAUST AIR GRILLES LOCATION

The stale air exhaust system is used to draw air from the points in the house where the worst air quality problems occur. It is recommended that return

air ducts be installed in the bathroom, kitchen, and laundry room. Additional return air ducts from strategic locations may be installed. The furnace

return duct may also be used to exhaust from. In this method, the exhaust air is not ducted back from bathrooms, kitchens, etc to the HRV with

“dedicated lines”.

As per building codes and installation requirements for combustion appliances:

Air return ducts, or openings for air return, should not be placed in enclosed spaces containing combustion

appliances that are subject to spillage.

fantech

Page 11

DUCTING INSTALLATION EXAMPLES

Fully dedicated system Partially dedicated system

FEL 4 (4” Miter Elbow)

Bedrooms

Exhaust CG 4 (4” Adjustable Grill)

Bathroom

Central Control - optional

Fresh air to living room

11

3m

Fresh Air

Exhaust Air

HRV

460 mm

Simplified installation - Option 1

Supply

Exhaust

Supply

Exhaust

460 mm

Simplified installation - Option 2

fantech

Page 12

12

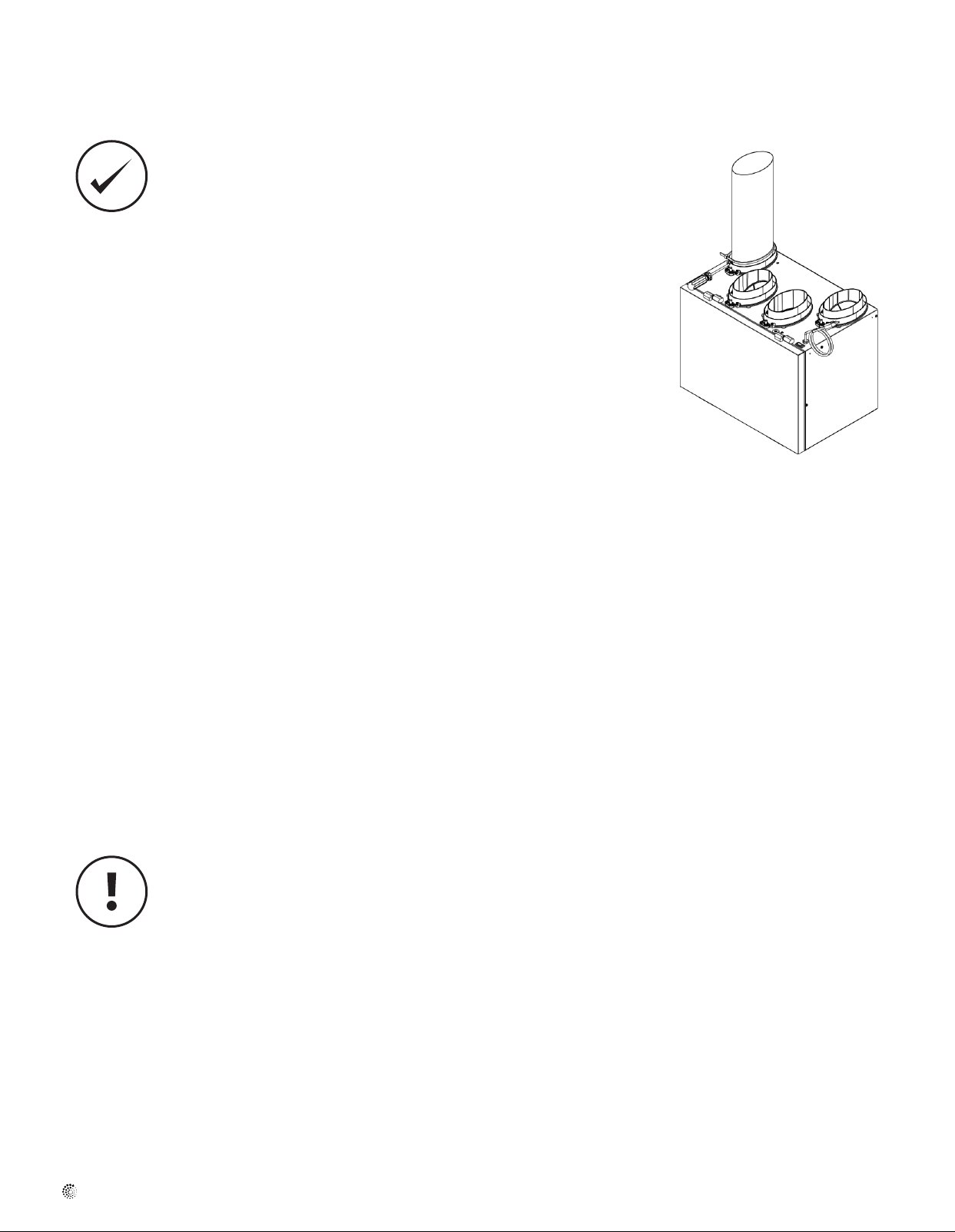

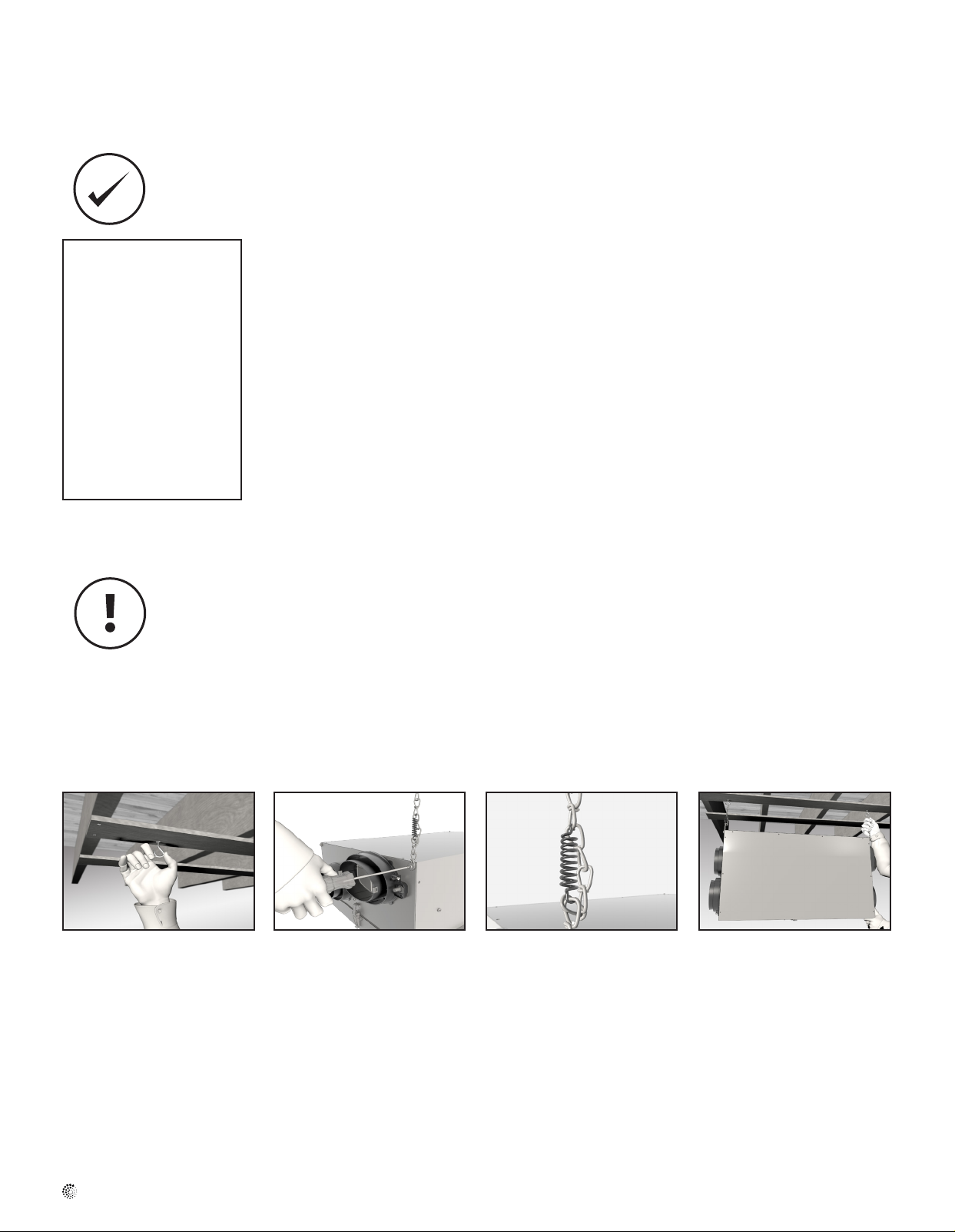

HRV INSTALLATION

LOCATION

The HRV must be located in a conditioned space where it will be possible to conveniently service the unit. Typically

the HRV would be located in the mechanical room or an area close to the outside wall where the weatherhoods will

be mounted. If a basement area is not convenient or does not exist, a utility room may be used.

Attic installations are not normally recommended due to:

• Have a nearby power supply

(120 volts, 60Hz)

• Choose a location which

allows the possibility

of mounting the unit to

supporting beams.

• The unit should be level

in order to allow proper

condensate drainage

• To minimize noise, do not

install unit in living area

• Ensure proper drainage

• The complexity of the installation

• Freezing conditions in the attic

• Difficulty of access for service and cleaning

• No drain access

• Clothes dryer

• Range top

• Stovetop fan

• Central vacuum system

• Bathroom exhaust fans unless they are specifically designed for this purpose

These appliances may cause lint, dust or grease to collect in the HRV, damaging the unit.

Connecting appliances to the HRV is not recommended. These include:

Connecting any of

these types of

appliances to the

HRV will void your

warranty.

Mounting- Chain mount

1 Place fastening hooks on

the strapping board or

the oor joists.

2 Attach a hanging chain

(provided) to each 19 mm

(3/4") bolt (provided) in the

top 4 corners of the unit

and tighten.

3 Install a spring on each

chan. Hook the spring

in the links so a loop is

created in the chain. The

spring will then support the

unit's weight and absorb

vibrations.

4 Hang the unit by slipping

a link onto the hanging

hooks, making sure the

unit is level.

fantech

Page 13

13

INSTALLING DRAIN LINE

Through normal operation and during its defrost mode, the HRV may produce some condensation. This water should flow into a nearby drain, or be taken

away by a condensate pump. The HRV and all condensate lines must be installed in a space where the temperature is maintained above the freezing point.

A “P” trap should be made in the drain line. This will prevent odors from being drawn back up into the unit.

1 Install the drain nipple.

2 Install the drain hose,

making a “P” trap

Secure the condensate

line to the drain connection using a tie wrap

or other appropriate

method.

AIRFLOW ADJUSTMENT & BALANCING

BALANCING THE AIRFLOWS IS CRUCIAL TO ENSURE OPTIMAL OPERATION OF THE UNIT. IF THE AIRFLOW IS NOT PROPERLY BALANCED, THE

FOLLOWING ISSUES MAY OCCUR:

• SIGNIFICANT POSITIVE OR NEGATIVE PRESSURE INSIDE THE HOUSE

• UNIT’S EFFICIENCY MAY BE NEGATIVELY AFFECTED

• UNIT’S DEFROST MAY NOT WORK EFFECTIVELY

• CAN LEAD TO AIR LEAKS OR BACKDRAFTING OF ANY COMBUSTION APPLIANCES.

The airflow adjustment and balancing procedure consists of adjusting the fresh airflow to make sure it meets the requirements for the building and then

balance the system to make sure there is an equal amount of stale air being exhausted. In the case that the airflow is not exactly the same, it is

recommended to have a higher stale airflow of up to 10% in colder climates to ensure that the temperature of the fresh airflow coming from the outside

is as close to the room temperature as possible.

GENERAL PREPARATION:

Before performing the adjustment and balancing for unit, make sure to check the following:

• Seal all the ductwork

• Fully open all dampers (if present)

• Turn off all other exhaust appliances such as range hood, dryers, bathroom fans, etc.

• If performing balancing during cold weather, make sure the unit is not operating in defrost mode.

• If the installation type is Simplified or Partially Dedicated, make sure that the furnace/air handler blower is operating at normal speed during

the balancing sequence.

• When reading with a mechanical type manometer (Magnehelic), make sure the manometer is placed on a level surface

For optimal performance, HRV unit should be re-balanced after a major renovation or after the installation of extra grilles or registers.

• In cold climates, continuous excessive positive pressure inside the house may drive moisture inside the external walls of the

house. Moisture present inside the external wall may condense if the outside temperature is cold enough and can cause damage

to structural components. A symptom of excessive positive pressure inside a house is frozen door locks.

• Continuous excessive negative pressure can have undesirable effects. In some geographic locations, negative pressure can

increase the infiltration of soil gases such as methane and radon. Negative pressure is also undesirable where combustion

equipment is present and may cause back drafting of the combustion gases.

ADJUSTING AIRFLOWS USING INTEGRATED BALANCING SYSTEM

Adjustable dampers are integrated into the Fresh Air to Building and the Stale Air to Outside duct connections. Those dampers replace the installation of

separate back draft and balancing dampers in the duct line.

The integrated dampers are preset at the fully opened position. In order to reduce the amount of airflow, turn the adjustable lever using a flat screw driver

by turning it counter clock wise. Turning the lever clockwise may damage the plastic screw head. Follow the balancing steps to properly adjust the airflow.

fantech

Page 14

14

BALANCING STEPS

Use balancing chart located on the

door of the HRV

Airow Normal Speed Reduced Speed

STEP #1: Identify the desired airflow using the provided chart. From

the desired airflow (left column) identify the pressure reading

needed by simply following the line. Make sure to set the unit at

the Normal speed before performing the next step.

STEP #2: Measure the pressure reading by connecting a manometer

on the LOW and HIGH pressure ports located on the duct

connection. Refer to Illustration #1. If the pressure reading is

LOWER than the desired value, adjust the balancing dampers by

turning the adjustable arm counter clockwise until the correct

corresponding pressure value is reached. Refer to Illustration #2

Do the same for both the SUPPLY and EXHAUST airflows. If the

pressure reading is HIGHER than desired when the damper is fully

opened, please check the distribution system for any anomalies

that could increase the resistance in the distribution system.

• If the house is tightly sealed, adjusting one airflow

may affect the other airflow as well. It is recommended to check each airflow

again to make sure the value did not change dramatically during the

balancing procedure. Make adjustments as necessary.

• The pressure reading from the duct connection refers to the total pressure

loss from the distribution system. A well designed distribution system should

have a total pressure loss between 0.4” (100Pa) and 0.6” (150Pa). The

pressure reading can therefore be used to troubleshoot distribution system.

If the pressure reading is higher than 0.6” (150Pa), we recommend that you

inspect the system and check for closed grilles, blocked exterior hoods or

twisted flexible duct.

STEP #3: Secure the adjustable arm by tightening the set screw as shown in Illustration #3.

CFM L/s

110 52 0.36 91

100 47 0.46 114

90 42 0.55 137

80 38 0.64 161

70 33 0.74 184 0.13 32

65 31 0.78 195 0.16 40

60 28 0.83 207 0.19 48

55 26 0.87 219 0.22 55

50 24 0.92 230 0.25 63

Pressure reading

BALANCING CHART (example only)

In W.G.

Pa

HIGH LOW LOW HIGH

Pressure reading

EXHAUST

In W.G.

SUPPLY

Pa

fantech

Adjustment lever (in front)

Illustration #1

Set screw (on top)

Illustration #3Illustration #2

Page 15

Low Voltage Control Systems

* Please see instruction manuals for individual controls for proper wiring and set up of control systems.

CENTRAL CONTROLS

These control options can only be used individually

CONTROLS FEATURES CONNECT TO

DIR-TS • Our most complete, yet easy to use control system

• Sleek design with backlight touchscreen LCD

• ECO mode selects the best operating mode and speed for the

season, minimizing energy use associated with ventilation

• Set preferred indoor relative humidity range and ventilation

mode for day and night conditions

• No battery to replace, all programmed settings are retained

during power outage

• Maintenance reminder indicator

• Error code messages reduce troubleshooting time

DIR-DG

EDF1 • Press button once for continuous Reduced speed

• MODE button provides 3 modes of operations: Ventilation ,

Recirculation and Standby

• User selected fan speed: Reduced, Medium, Normal and

20 minutes per hour

• AUTO setting allows the homeowner to deactivate the

dehumidistat

• When the humidity exceeds the desired setpoint, the ventilation system operates at Normal speed.

• Once the desired humidity level is achieved, your ventilation

system resumes to its previous mode of operation

• Press button twice and the unit will cycle 20 minutes ON/

40 minutes OFF and repeat

• EDF1 – Press button a third time and the system will run

continuously on HIGH speed

W

W

W

W

W

W

15

1. Ensure that unit is not

plugged when connecting

the control

2. Recirculation mode is only

available with the “R” sufx

at the end of the model

number.

The wiring connectors

can be removed for

easier connection.

AUXILIARY CONTROL

These controls can be paired

RTS2*

RTS5

MDEH1

• 20- minute timer with LED light

• Boosts system to high speed with the touch of a button

• Up to 5 can be used in one system

• Use in bathroom, kitchen, laundry room

• 20/40/60 minute timer with LED light

• Boosts system to high speed with the touch of a button

• Up to 5 can be used in one system

• Use in bathroom, kitchen, laundry room

• Rotary dial Dehumidistat

• Multiple units can be used

• We recommend setting the relative humidity above 80%

during the summer

+T

-T

+T

-T

*Maintain polarity

between control

and HRV

(+ → + ; - → -)

D

D

fantech

Page 16

16

WIRING DIAGRAM

Observe polarity on all accessory controls where

applicable.

fantech

* Wiring diagram of complete unit inside of access panel

Page 17

WIRING DIAGRAM (CONT'D)

17

WIRING DIAGRAM TO

FURNACE

FOR A FURNACE

CONNECTION TO

A COOLING SYSTEM:

On some newer furnaces and older

thermostats, energizing the R and

G terminal at the furnace has the

effect of energizing the Y at the

thermostat and thereby turning on

the cooling system. If you identify this

type of thermostat, you must use the

“Alternate Furnace Interlock Wiring”

FURNACE

24-VOLT

TERMINAL BLOCK

FOUR

WIRE

TWO WIRE

heating only

W

R

G

C

Y

Standard Accessory Control Contact

Standard Furnace Interlock Wiring

THERMOSTAT

TERMINALS

R G

W

Alternative Accessory Control Contact

Alternate Furnace Interlock Wiring

THERMOSTAT

TERMINALS

Y

TWO

WIRE

COOLING SYSTEM

R G

TWO WIRE

heating only

FURNACE

24-VOLT

TERMINAL BLOCK

FOUR

WIRE

W

W

R

G

C

Y

WIRE JOINT

Y

TWO

WIRE

COOLING SYSTEM

As per building codes and installation requirements for combustion appliances:

Air return ducts, or openings for air return, should not be placed in enclosed spaces containing combustion

appliances that are subject to spillage.

fantech

Page 18

18

TROUBLESHOOTING

Problem Causes Solutions

Air is too dry Dehumidistat control is set too low Increase the desired level of humidity. Change ventilation mode from

HRV out of balance Have contractor balance HRV airows

Air is too humid Dehumidistat control is set too high Reduce the desired level of humidity. Combine this with the use of continuous

Sudden change in temperature Wait until outside temperature stabilizes (winter). Heating will also improve

Storing too much wood for heating Store a majority of your wood outside. Even dried, a cord of wood contains

Dryer vent exhaust is inside home Make sure the dryer vent is exhausting outside.

Poor air circulation near windows Open curtains or blinds.

HRV out of balance Have contractor balance HRV airows

Well sealed basement door is closed Open the door or install a grill on the door.

Persistent condensation

on window

Poor Air Flows 1/4" (6mm) mesh on the outside hoods is plugged Clean exterior hoods or vents

Supply air feels cold Poor location of supply grilles, the airow may irritate

Improper adjustment of dehumidistat control Reduce the desired level of humidity. Combine this step with use of continuous

HRV out of balance Have contractor balance HRV

Poor air circulation near windows Open curtains or blinds.

Filters plugged Remove and clean lter

Core obstructed Remove and clean core

Indoor grilles closed or blocked Check and open grilles

Inadequate power supply at site Have electrician check supply voltage

Ductwork is restricting airow Check duct installation

Improper speed control setting Increase the speed of the HRV (i.e. change unit control from REDUCED to NORMAL

HRV airow improperly balanced Have contractor balance HRV airows

Ducting has fallen down or been disconnected from HRV Have contractor reconnect ducting

the occupant

Outdoor temperature extremely cold If supply air is ducted into furnace return, the furnace fan may need to run

continuous mode to standby.

exchange mode.

situation.

more than 20 gallons of water.

exchange mode.

speed)

Locate the grilles high on the walls or under the baseboards, install ceiling

mounted diffuser or grilles so as not to directly spill the supply air on the

occupant (eg. Over a sofa)

Turn down the HRV supply speed. A small duct heater (1kw) could be used to

temper the supply air

Placement of furniture or closed doors is restricting the movement of air in

the home

continuously to distribute ventilation air comfortably

HRV and/or Ducts frosting up HRV air ows are improperly balanced Have HVAC contractor balance the HRV airows

Malfunction of the HRV defrost system Note: minimal frost build-up is expected on the core before unit initiates

Condensation or Ice Build Up in

Insulated Duct to the Outside

Note: It is best to get the unit checked by a certied HVAC Contractor/Technician.

Incomplete vapor barrier around insulated duct Tape and seal all joints

A hole or tear in outer duct covering Tape any holes or tears made in the outer duct covering

defrost cycle functions

Ensure that the vapor barrier is completely sealed.

fantech

Page 19

HRV MAINTENANCE CHART

Maintenance Required Recommended Frequency Date Maintenance Performed

Check and Clean Filters Every 3 months or if

dirty

Check Heat Recovery

Core

Check Drain Pan and

Lines

Vacuum the Inside of the

Unit

Clean and Un-block

Outside

Hoods

Clean and Inspect Duct

Work

General Servicing by a

Qualied Contractor

Every 6 months

Every 3 months

Annually

Annually

Annually

Annually

19

The Best

Limited Warranty

in the Business

• The heat recovery aluminum core

has a limited lifetime warranty.

• The motors found in all Fantech

HRV’s require no lubrication, and

are factory balanced to prevent

vibration and promote silent

operation.

• The limited warranty covers normal

use. It does not apply to any

defects, malfunctions or failures as

a result of improper installation,

abuse, mishandling,

misapplication, fortuitous

occurrence or any other

circumstances outside Fantech’s

control.

• Inappropriate installation or

maintenance may result in the

cancellation of the warranty.

* Schedule may be altered to meet your own needs. More frequent servicing may be required depending on the

severity of your home's indoor and outdoor environments.

Contractor Telephone Number Date Serviced

• Any unauthorized work will result in

the cancellation of the warranty.

• Fantech is not responsible for any

incidental or consequential

damages incurred in the use of the

ventilation system.

• Fantech is not responsible for

providing an authorized service

centre near the purchaser or in the

general area.

• Fantech reserves the right to

supply refurbished parts as

replacements.

• Transportation, removal and

installation fees are the

responsibility of the purchaser.

• The purchaser is responsible to

adhering to all codes in effect in his

area.

• The warranty is limited to 5 years

on parts and 7 years on the motor

from the date of purchase,

including parts replaced during this

time period. If there is no proof of

purchase available, the date

associated with the serial number

will be used for the beginning of

the warranty period.

* This warranty is the exclusive and

only warranty in effect relative to the

ventilation system and all other

warranties either expressed or

implied are invalid.

fantech

Page 20

20

NOTES

fantech

Page 21

fantech

Manuel d'installation

VHR150

Ventilateur récupérateur de chaleur

No. d'article #: 422474

Date de révision: 2015-05-13

Votre système de ventilation doit être installé conformément aux exigences de la province où vous habitez ou, à défaut de

telles exigences, conformément à l’édition actuelle du Code national du bâtiment du Canada ou aux « méthodes d’ingénierie

appropriées » de l’ASHRAE.

United States

10048 Industrial Blvd., Lenexa, KS, 66215

Tél.: 800.747.1762 • Fax: 800.487.9915

Canada

50 Kanalflakt Way, Bouctouche, NB, E4S 3M5

Tél.: 800.565.3548 • Fax: 877.747.8116

Fantech se réserve le droit de modifier partiellement ou entièrement, en tout moment et sans préavis, les

caractéristiques, la conception, les composants et les spécifications de ses produits, afin de conserver sa

position de leader de technologie.

S'il vous plaît visitez notre site siteweb www.fantech.net pour des informations techiques plus détaillées.

Page 22

22

Note Avertissement/

Note importante

Information Information

technique

Conseil

pratique

VEUILLEZ LIRE LE MANUEL AVANT D’INSTALLER L’APPAREIL

À n d’installation résidentielle seulement

Avant de procéder à l’installation, examinez avec soin la façon dont le système fonctionnera s’il est relié à tout

autre appareil mécanique, notamment une fournaise à air pulsé ou un appareil de traitement d’air dont la pression

statique est plus élevée. Une fois l’installation terminée, la compatibilité des deux appareils doit être conrmée en

mesurant le débit d’air du ventilateur récupérateur de chaleur (VRC) au moyen de la procédure d’équilibrage du

présent manuel. Il importe de toujours évaluer l’interaction du VRC avec les appareils de chauffage à évacuation

(fournaise à gaz, fournaise à mazout, poêle à bois, etc.)

Les produits sont conçus et fabriqués pour fournir une performance able, mais ils ne sont pas garantis à 100%

sans défaut. Même les produits ont des pannes occasionnelles et cette possibilité devrait être reconnue par

l'utilisateur. Si ces produits sont utilisés dans un système de ventilation qui maintien des fonctions vitales où une

défaillance pourrait entraîner des pertes ou des blessures, l'utilisateur doit fournir une ventilation de secours

adéquate, une ventilation supplémentaire naturelle, un système d'alarme de défaillance ou d'accepter les risques

de pertes ou de blessures.

Votre système de ventilation doit être installé en conformité avec le code du bâtiment local qui est en vigueur, en

l’absence de telles exigences, il est recommandé de vérier auprès des autorités locales ayant juridiction dans

votre région avant d’installer ce produit.

fantech

Page 23

TABLE DES MATIÈRES

DÉTERMINER VOS BESOINS DE VENTILATION ..................................................... 24

EXEMPLES D'INSTALLATION

Système entièrement spécialisé ......................................................... 25

Système partiellement spécialisé ........................................................ 26

Installation simplifiée

Option 1 ..................................................................... 27

Option 2 ......................................................................28

INSTALLATION DES CONDUITS EXTÉRIEURS

Emplacement des hottes .................................................................. 29

Installation de l'ensemble des conduits avec hottes ............................................... 29

INSTALLATION DES CONDUITS INTÉRIEURS

Conseils pratiques ....................................................................... 30

Installation des conduits sur le VRC .......................................................... 30

Emplacement des grilles d'approvisionnement et d'évacuation ........................................ 30

23

EXEMPLES D'INSTALLATIONS DE CONDUIT.........................................................31

INSTALLATION DU VRC ...................................................................... 32

ÉQUILIBRAGE DU DÉBIT D'AIR

Préparation générale ..................................................................... 33

Ajustement des débits d'air ................................................................ 33

Étapes de balancement ................................................................... 34

SYSTÈMES DE CONTRÔLE À BASSE TENSION...................................................... 35

SHÉMAS ÉLECTRIQUES ...................................................................... 38

DÉPANNAGE...............................................................................34

TABLEAU D'ENTRETIEN DU VRC.................................................................39

fantech

Page 24

24

DÉTERMINER VOS BESOINS DE VENTILATION

Méthode compte de pièces

3

1 pi

/min = 0.47 L/s

1 L/s = 2.13 pi3/min

Méthode ASHRAE

Liste des pièces Nombre de pièces Pi

Chambre principale x 10 L/s (20 pi3/min) =

Sous-sol oui ou no =

Chambre à coucher x 5 L/s (10 pi3/min) =

Salon x 5 L/s (10 pi3/min) =

Autres x 5 L/s (10 pi3/min) =

Cuisine x 5 L/s (10 pi3/min) =

Salle de bain x 5 L/s (10 pi3/min) =

Buanderies x 5 L/s (10 pi3/min) =

Lingerie x 5 L/s (10 pi3/min) =

Ventilation total nécessaire (La somme des chiffres de la dernière colonne ) =

Si oui, ajoutez 10 L/s (20

Sinon = 0

3

/min (L/s)

pi3/min

PCM Required

)

Débit d'air recommandé

Supercie Chambre à coucher

0-1 2-3 4-5 6-7 >7

2

Ft

< 1500 <139 30 14 45 21 60 28 75 35 90 42

1501-3000 139.1-279 45 21 60 28 75 35 90 42 105 50

3001-4500 279.1-418 60 28 75 35 90 45 105 50 120 57

4501-6000 418.1-557 75 35 90 42 105 50 120 57 135 64

6001-7500 557.1-697 90 42 105 50 120 57 135 64 150 71

>7500 >697 105 50 120 57 135 64 150 71 165 78

* ASHRAE 62.2-2010 Table 4.1, Ventilation and Acceptable Indoor Air Quality in Low-Rise Residential Buildings.

2

m

Pi3/min L/s Pi3/min L/s Pi3/min L/s Pi3/min L/s Pi3/min L/s

Salle de bain: Si le VRC fournit la ventilation d’échappement locale requise pour chaque salle de bain avec chacun un 20 PCM

continue (10L/s), ce taux de ventilation peut être considéré comme faisant partie du débit de ventilation de tout le bâtiment.

fantech

Page 25

EXEMPLES D'INSTALLATION

Exemple seulement – la configuration des conduits peut être différente selon le modèle.

SYSTÈME ENTIÈREMENT SPÉCIALISÉ

(NOUVELLE CONSTRUCTION)

1. L’air vicié est aspiré à partir des endroits clés de la maison (salle de

bains, cuisine, buanderie).

2. L’air frais est distribué parmi les pièces habitables (chambres à coucher,

salon).

3. Le débit d’air du VRC doit être confirmé sur place au moyen de la

procédure d’équilibrage du présent manuel d’installation.

25

Installation suggérée pour:

• Plinthe à eau chaude

• Plancher chauffant

• Plinthe électriques

• Thermopompe mural bibloc

Avantages: Fourni la meilleure

répartition de l’air frais dans

la maison; les coûts de

fonctionnement plus faibles,

puisque l’unité de traitement

d’air/ fournaise n’est pas

nécessaire

Conduit VRC/Fournaise de Système entièrement spécialisé

Air frais provenant

de l'extérieur

Extérieur

Air vicié évacué

à l'extérieur

Air vicié provenant de l'intérieur

Air frais distribué à l'intérieur

fantech

Page 26

26

EXEMPLES D'INSTALLATION (SUITE)

RACCORDEMENT DIRECT du FLUX D’AIR D’APPROVISIONNEMENT à la BOUCHE DE REPRISE

D’AIR DE LA FOURNAISE

(L’air vicié est aspiré à partir des endroits clés de la maison.)

SYSTÈME PARTIELLEMENT SPÉCIALISÉ

1. Si la ventilation du VRC doit être assurée, il peut être nécessaire de faire

fonctionner le ventilateur de la fournaise. La fournaise devrait être réglée

pour fonctionner continuellement ou en synchronisme avec le VRC.

2. Air vicié est aspiré à des endroits clés de la maison (salle de bain,

cuisine, buanderie).

3. L’air frais est fourni au plénum de retour d’air de la fournaise.

4. En raison de l’écart de pression entre le VRC et l’équipement auquel il est

raccordé, le débit d’air du VRC doit être équilibré sur place au moyen de

la procédure dans la section "équilibrage du débit d’air".

Conduits VRC/Fournaise pour Système partiellement spécialisé

Installation suggérée pour:

• Fournaise centrale (unité

de traitement d’air, air

climatisé central)

• Lorsque l’installation des

endroits habitable n’est

pas possible ou pratique,

dispendieux ou lorsque

l’unité de traitement d’air

fonctionnera toute l’année.

Avantages: Conditionne l’air

frais avant de la distribuer

dans la maison

Extérieur

fantech

Air vicié provenant de l'intérieur

Air frais provenant

de l'extérieur

Volet motorisé

1 m (3pi)

Air frais

distribué à

l'intérieur

Air vicié

évacué à

l'extérieur

Les ventilateurs récupérateurs de chaleur (VRC) de Fantech qui utilisent un arrêt du

ventilateur d'alimentation pour la prévention de gel ne comprennent pas un volet motorisé

pour l'air extérieur. Si vous utilisez une installation simpliée, c'est à dire relier de

conduit d'alimentation d'air du VRC à l'aire du conduit de retour d'une fournaise, le VRC

doit fonctionner en continu. Lorsque le VRC est éteint, pas d'air d'évacuation chaud circule

à travers le VRC mais le ventilateur da fournaise continuera à aspirer l'air extérieur directement dans la fournaise. S'il fait froid dehors, l'air froid sera introduit, sans réchauffage,

directement dans la fournaise.

Si le VRC est installé de telle sorte que le propriétaire peut désactiver le VRC au cours de

l'hiver, nous vous recommandons d'installer un volet motorisé entre l'apport d'air du VRC

et le retour d'air du conduit de la fournaise qui se ferme lorsque le VRC ne fonctionne pas.

Voir le schéma de câblage (gure 1). Vous pouvez aussi choisir d'utiliser une VRC Fantech

qui utilise un dégivrage de recirculation qui intègre un volet d'air extérieur.

*L’appareil est équilibré à vitesse normale et pendant

que le ventilateur de la fournaise est en marche.

.

recommendeé

Retour

d'air frais

min.

Fournaise à

air pulsé

24 VAC Transformer

24V

120V

COM

VRC Furnace interlock

Voir page 36.

Figure 1

* Le transformeur et le moteur du volet ne sont pas inclus.

NO

Damper

Motor

Page 27

EXEMPLES D'INSTALLATION (SUITE)

27

RACCORDEMENT DIRECT du FLUX D’AIR D’APPROVISIONNEMENT et du FLUX D’AIR ÉVACUÉ

DU VRC à la BOUCHE D’AIR DE LA FOURNAISE

INSTALLATION SIMPLIFIÉE (BONNE)

OPTION 1

1. Si la ventilation du VRC doit être assurée, il peut être nécessaire de faire

fonctionner le ventilateur de la fournaise. La fournaise devrait être réglée

pour fonctionner continuellement ou en synchronisme avec le VRC.

2. Une séparation minimum de 1m (3pi 3po) est recommandée entre les

deux connexions directes.

3. Afin d’éviter l’évacuation d’air frais, la connexion d’évacuation du VRC devrait

être située en amont de la connexion d’approvisionnement du VRC lorsqu’on

les branche à la bouche de reprise d’air de la fournaise.

4. En raison de l’écart de pression entre le VRC et l’équipement auquel il est

raccordé, le débit d’air du VRC doit être équilibré sur place au moyen de la

procédure détaillée dans la section " Équilibrage du débit d’air".

Conduits VRC/Fournaise pour Installation simplifiée

Installation suggérée pour:

• Lorsque la salle de bain

et la cuisine ont déjà un

système d’échappement

• Peut convenir pour la

modernisation

Avantages: Type d’installation

le moins dispendieux à mettre

en place

Extérieur

1 m (3pi 3po) min. recommandé

Air vicié provenant de l'intérieur

Air frais provenant

de l'extérieur

Volet

motorisé

Air frais distribué à

l'intérieur

Retour d'air

Air vicié évacué

à l'extérieur

Les ventilateurs récupérateurs de chaleur (VRC) de Fantech qui utilisent un arrêt du

ventilateur d'alimentation pour la prévention de gel ne comprennent pas un volet motorisé

pour l'air extérieur. Si vous utilisez une installation simpliée, c'est à dire relier de

conduit d'alimentation d'air du VRC à l'aire du conduit de retour d'une fournaise, le VRC

doit fonctionner en continu. Lorsque le VRC est éteint, pas d'air d'évacuation chaud circule

à travers le VRC mais le ventilateur da fournaise continuera à aspirer l'air extérieur directement dans la fournaise. S'il fait froid dehors, l'air froid sera introduit, sans réchauffage,

directement dans la fournaise.

Si le VRC est installé de telle sorte que le propriétaire peut désactiver le VRC au cours de

l'hiver, nous vous recommandons d'installer un volet motorisé entre l'apport d'air du VRC

et le retour d'air du conduit de la fournaise qui se ferme lorsque le VRC ne fonctionne pas.

Voir le schéma de câblage (gure 1). Vous pouvez aussi choisir d'utiliser une VRC Fantech

qui utilise un dégivrage de recirculation qui intègre un volet d'air extérieur.

*L’appareil est équilibré à vitesse normale et pendant que le

ventilateur de la fournaise est en marche.

frais

1 m (3pi

3po) min.

recommandé

Fournaise à

air pulsé

24 VAC Transformer

24V

120V

COM

VRC Furnace interlock

Voir page 36.

Figure 1

* Le transformeur et le moteur du volet ne sont pas inclus.

NO

Damper

Motor

fantech

Page 28

28

Exemple d'installation (suite)

RACCORDEMENT DIRECT du FLUX D’AIR D’APPROVISIONNEMENT du VRC à la BOUCHE DE

REPRISE D’AIR DE LA FOURNAISE

INSTALLATION SIMPLIFIÉE (BONNE)

OPTION 2

1. Si la ventilation du VRC doit être assurée, il peut être nécessaire de faire

fonctionner le ventilateur de la fournaise. La fournaise devrait être réglée

pour fonctionner continuellement ou en synchronisme avec le VRC.

2. Pour fins d'acceptation, vérifiez auprès des autorités locales au sujet des

codes du bâtiment propres à votre région.

Conduits VRC/Fournaise pour Installation simplifiée - Option 2

* Les raccords de conduit

peuvent être différents

selon le modèle.

Air vicié provenant de l'intérieur

Air frais distribué à l'intérieur

Installation suggérée pour:

• Lorsque la salle de bain

et la cuisine ont déjà un

système d’échappement

• Peut convenir pour la

modernisation

Avantages: Type d’installation

le moins dispendieux à mettre

en place

Dans le cas d’une installation

simplifiée, il est recommandé

d’utiliser l’option 1.

Extérieur

Air frais provenant

de l'extérieur

Air vicié évacué

à l'extérieur

Les ventilateurs récupérateurs de chaleur (VRC) de Fantech qui utilisent un arrêt du

ventilateur d'alimentation pour la prévention de gel ne comprennent pas un volet motorisé

pour l'air extérieur. Si vous utilisez une installation simpliée, c'est à dire relier de

conduit d'alimentation d'air du VRC à l'aire du conduit de retour d'une fournaise, le VRC

doit fonctionner en continu. Lorsque le VRC est éteint, pas d'air d'évacuation chaud circule

à travers le VRC mais le ventilateur da fournaise continuera à aspirer l'air extérieur directement dans la fournaise. S'il fait froid dehors, l'air froid sera introduit, sans réchauffage,

directement dans la fournaise.

Si le VRC est installé de telle sorte que le propriétaire peut désactiver le VRC au cours de

l'hiver, nous vous recommandons d'installer un volet motorisé entre l'apport d'air du VRC

et le retour d'air du conduit de la fournaise qui se ferme lorsque le VRC ne fonctionne pas.

Voir le schéma de câblage (gure 1). Vous pouvez aussi choisir d'utiliser une VRC Fantech

qui utilise un dégivrage de recirculation qui intègre un volet d'air extérieur.

* L’appareil est généralement équilibré à Normale vitesse et pendant

que le ventilateur de la fournaise est en marche.

1 m (3pi 3po) min. recommandé

Volet

motorisé

Volet motorisé

retrour

d'air

frais

Fournaise à

air pulsé

24 VAC Transformer

24V

120V

COM

VRC Furnace interlock

Voir page 36.

Figure 1

* Le transformeur et le moteur du volet ne sont pas inclus.

NO

Damper

Motor

fantech

Page 29

INSTALLATION DES CONDUITS EXTÉRIEURS

Coin extéreur Coin intérieur

EMPLACEMENT DES HOTTES

• Décidez de l’emplacement des hottes d’aspiration et d’évacuation.

Emplacement de la hotte d’aspiration

• Doit être située en amont de la sortie d’évacuation (en présence de vents

dominants).

• Doit être située à au moins 2m (6 pi) de la hotte d’évacuation, des évents

de la sécheuse et de l’évacuation de la fournaise à air pulsé (fournaise à

moyen ou à haut rendement).

• Doit être montée à au moins 460 mm (18 po) au-dessus du sol ou

au-dessus de la couche de neige prévue.

• Doit être située à au moins 1m (3 pi) d’un coin du bâtiment.

• Ne doit jamais être située dans un garage, un grenier ou un vide sanitaire.

Emplacement de la hotte d’évacuation

• Doit être située à au moins 2m (6 pi) de la prise d’air de ventilation.

• Doit être montée à au moins 460 mm (18 po) au-dessus du sol ou au-dessus de la couche de neige prévue.

• Doit être située à au moins 1m (3 pi) d’un coin du bâtiment.

• Ne doit pas être située à proximité d’un compteur de gaz, d’un compteur d’électricité ou d’une allée où le brouillard et la glace peuvent

constituer un danger

• Ne doit jamais être située dans un garage, un atelier ou un espace non chauffé.

OUTSIDE CORNER INSIDE CORNER

36po (1m)

36" (1m)

min.

min

Apport

d'air

INTAKE

18" (460mm) min.

18po (460mm) min.

6 pi (2m)

6' (2m)

min.

min.

18po (460mm) min.

36po (1m)

36” (1m)

min.

min

Évacuation

d'air

EXHAUST

18" (460mm) min.

29

INSTALLATION DE L’ENSEMBLE DE CONDUITS AVEC LES HOTTES

Le rendement maximum du VRC est assuré par un ensemble de conduits d’évacuation de haute

qualité technique qui est bien installé. Le revêtement intérieur des conduits flexibles isolés doit être

encastré dans un manchon des hottes de protection contre les intempéries (aussi près que possible

de l’extérieur) et dans l’orifice approprié du VRC. Assurez-vous que l’isolation demeure entièrement

et qu’elle n’est pas écrasée. Le revêtement extérieur, qui joue le rôle de parevapeur, doit être

complètement scellé sur le mur extérieur et le VRC à l’aide de ruban ou de produit de calfeutrage.

Déposez un cordon de produit de calfeutrage de première qualité (du mastic d’isolation acoustique

de préférence) pour sceller le conduit flexible intérieur à l’orifice du VRC et à la hotte de protection

avant de procéder à l’encastrement. Pour réduire au minimum la restriction de débit d’air, le conduit

flexible isolé qui relie les deux hottes de protection extérieures du VRC doit être bien tendu et le

plus court possible. Des conduits tordus ou pliés réduisent fortement le débit d'air.

Reportez-vous aux exemples illustrés dans la section "Exemples d’installation"

ÉTAPES DE L’INSTALLATION DE LA HOTTE:

Hotte

Grillage à

oiseaux

Mur extérieur

Conduit exible isolé

Manche

Chemise

intérieur

Chemise

extérieur

1 Tracez le contour du collet de la

hotte externe pour découper les

trous d’aspiration et

d’évacuation. Le diamètre des

trous doit être un peu plus

grand que celui du collet, pour

tenir compte de l’épaisseur du

conduit flexible isolé. Percez un

trou pour la hotte d’aspiration

et un trou pour la hotte

d'échappement

2 Faites passer le conduit flexible

isolé dans l’ouverture jusqu’à ce

qu’il soit bien tendu et droit.

Faites glisser le manchon en

vinyle interne du conduit sur le

collet avec l’isolation et placez le

parevapeur sur le manchon.

Fixez à l’aide de ruban adhésif

en toile.

3 Enfoncez la hotte dans

l’ouverture. Fixez la hotte sur le

mur extérieur en utilisant des

vis de montage. Répétez la

procédure d’installation pour la

hotte d’aspiration et la hotte

d’évacuation.

4 À l’aide d’un pistolet à

calfeutrer, calfeutrez les deux

hottes pour empêcher les

fuites.

fantech

Page 30

30

INSTALLATION DES CONDUITS INTÉRIEURS

• Pour maximiser le débit d’air dans le réseau de conduits, assurez-vous que tous les

conduits sont le plus court et le plus droit possible.

• Il est préférable d’utiliser des coudes de 45 degrés plutôt que des coudes de 90

degrés.

• Dans la mesure du possible, utilisez des raccords en Y plutôt que des raccords en T.

• Pour éviter les fuites, fixez tous les joints des conduits en utilisant des vis ou un

produit d’étanchéité pour conduits puis recouvrez-les d’un ruban adhésif en toile de

qualité.

• Dans la mesure du possible, utilisez un ensemble de conduits galvanisés entre le VRC

et les pièces d’habitation de la maison; il est également possible d’utiliser des conduits

flexibles en modération.

• Pour éviter que le bruit ne se propage dans le réseau de conduits, reliez le VRC au

réseau de conduits d’aspiration/d’évacuation par un court conduit flexible isolé non

métallique (environ 300 mm [12 po]).

• Les conduits principales d'alimentation et de retour de VRC doivent avoir le même

diamètre ou plus grand que les connections.

• Les branchements qui aboutissent dans chaque pièce peuvent mesurer aussi peu que

100 mm (4 po).

INSTALLATION DES CONDUITS SUR LE VRC

Le collet est muni de crochets afin d’éviter le glissement du conduit flexible. Pour installer le conduit flexible, faites le glisser sur le collet et au-dessus

des crochets. Ensuite, installez un attache câble par-dessus le conduit flexible afin de prévenir des fuites entre le conduit et le collet.

Dans le cas d’un conduit galvanisé, faites le glisser sur le collet, vissez en place et scellez le.

EMPLACEMENT DES GRILLES D'APPROVISIONNEMENT

Dans les maisons non munies d’une fournaise à air pulsé, il faut distribuer de l’air frais dans toutes les pièces d’habitation, y compris les chambres à

coucher. L’air devrait provenir de la partie supérieure d’un mur ou du plafond. Il est recommandé d’utiliser des grilles qui distribuent l’air confortablement.

Dans les maisons pourvues d’une fournaise à air pulsé, il est possible de relier le VRC au réseau de conduits de la fournaise.

EMPLACEMENT DES GRILLES D'ÉVACUATION

Le système d’évacuation de l’air vicié sert à aspirer l’air des endroits de la maison où la qualité d’air est la moins bonne. Il est recommandé d’installer

les conduits de retour d’air dans la salle de bains, la cuisine et la buanderie. Il est également possible d’installer des conduits supplémentaires de retour

d’air dans des endroits stratégiques. Le conduit de retour de la fournaise peut également servir de conduit d’évacuation. Ainsi, l’air évacué des salles

de bain, cuisine, etc. ne retourne pas au VRC par des «conduits spécialisées».

Selon les codes du bâtiment et les codes d'installation des appareils de combustion, il est interdit de poser des

grilles de reprise d'air ou de percer une ouverture pour une prise d'air dans une piêce close où se trouvent des

appareils à combustion sujet à des déversements.

fantech

Page 31

EXEMPLES D'INSTALLATION DES CONDUITS

Système entièrement spécialisé Système partiellement spécialisé

31

Chambres

Air frais

Air évacué

FEL 4 (Coude 4 po)

Grille d'évacuation CG4 (Grille ajustable 4 po)

Salle de bains

Commande centrale (en option)

Air frais acheminé au

salon

3m

HRV

460 mm

Approvisionnement

Évacuation

Chambres

Air frais

Air évacué

FEL 4 (Coude 4 po)

Grille d'évacuation CG4 (Grille ajustable 4 po)

Commande centrale (en option)

Salle de bains

Air frais acheminé au salon

Thermostat de la fournaise

460 mm

Approvisionnement

Évacuation

Installation spécialisée - Option 1 Installation spécialisée - Option 2

fantech

Page 32

32

INSTALLATION

• Assurez-vous d'avoir une

source d'alimentation près.

(120 volts, 60Hz)

• Choisissez un emplacement

où il y a possibilité de

montage à des poutres de

support.

• L'unité doit être au niveau

an d'assurer un drainage

approprié.

• An de minimiser le bruit, ne

pas installer l'appareil à un

endroit habitable.

• Assurez un drainage

approprié

EMPLACEMENT

Le VRC doit être situé dans un endroit chauffé où il sera possible d’en effectuer l'entretient convenablement.

Généralement, le VRC doit être situé dans la chambre des appareils mécaniques ou à proximité. S’il n’y a pas de

sous-sol ou si le sous-sol ne convient pas, il est possible d’installer l’appareil dans la lingerie ou dans la buanderie.

Il n’est généralement pas recommander d’installer l’appareil au grenier pour les raisons suivantes:

• La complexité de l’installation;

• Le gel possible au grenier;

• La difficulté d’accès pour fins d’entretien et de nettoyage;

• Aucun accès pour drainage.

Il n’est pas recommander de raccorder des appareils électroménagers au VRC, notamment:

• Sécheuse de linge;

• Table de cuisson;

• Ventilateur de cuisinière;

• Système d’aspirateur central.

Ces électroménagers peuvent entraîner l’accumulation de charpie, de poussière ou de graisse dans le VRC et

l’endommager.

Le raccordement de n’importe

quel type d’appareils

électroménagers au VRC

annule la garanti

MONTAGE- CHAINE

1 Installez les crochets de

xation sur la fourrure ou

les solives de plancher.

2 Suspendez la chaîne

(fournie) à chaque boulon

de 19 mm (3/4 po)

(fournis) situés aux quatre

coins supérieurs du VRC et

serrez.

3 Installez un ressort sur

chaque chaîne. Accrochez

le ressort de sorte qu'une

boucle est créée dans

la chaîne. Le ressort

supportera le poids du

VRC et absorbera les

vibrations.

4 Suspendez le VRC en

faisant glisser un maillon

de la chaîne dans les

crochets de suspension

et assurez vous que

l’appareil est de niveau.

fantech

Page 33

33

INSTALLATION DU TUYAU D'ÉCOULEMENT

En mode normal ainsi qu’au cours du cycle de dégivrage, le VRC peut produire de la condensation. L’eau de condensation doit d’écouler vers le drain

avoisinant ou être aspirée par une pompe à condensat. Le VRC et toutes les canalisations de condensats doivent être installés dans un endroit où la

température ambiante est maintenue au-dessus du point de congélation. Faires un siphon en P dans un tuyau d’écoulement. Ce siphon empêche le retour

des odeurs vers l’appareil.

1 Posez l'embout de drain

2 Installer le tuyau

d'écoulement et faite une

boucle (siphon en P).

Fixer la conduite de

condensat à la connexion de drainage à

l'aide d'une attache

ou d'une autre méthode appropriée.

ÉQUILIBRAGE DU DÉBIT D’AIR

SI LES FLUX D’AIR DE L’APPAREIL NE SONT PAS CORRECTEMENT ÉQUILIBRÉS…

• L’EFFICACITÉ DE L’APPAREIL PEUT ÊTRE RÉDUITE.

• DES DOMMAGES AU NOYAU DE RÉTABLISSEMENT DE LA CHALEUR PEUVENT SURVENIR.

• UN REFOULEMENT DE L’AIR DANS VOS APPAREILS DE CHAUFFAGE À COMBUSTION

• LE DÉGIVRAGE DE L’APPAREIL PEUT NE PAS FONCTIONNER.

Le procédé d’équilibrage consiste de mesurer l’air d’échappement partant du système et l’air d’approvisionnement entrant dans le système et d’assurer

que ces deux sont égaux. Dans ces cas où il y a une déviation, on recommande d’avoir une plus grande quantité d’air d’échappement soit jusqu’à 10% pour

s’assurer que la température de l’air introduite dans la maison est la plus près possible de celle qui est déjà présente.

PRÉPARATION GÉNÉRALE:

Avant d’équilibrer l’appareil, assurez-vous de vérifier les points suivants:

• Scellez tous les conduits

• Ouvrez complètement les registres d’équilibrage (si présents)

• Éteignez tous les appareils d’évacuation tels que hotte de cuisinière, sécheuse, ventilateur de salle de bain, etc.

• Si vous effectuez l’équilibrage pendant une saison froide, assurez-vous que l’appareil ne fonctionne pas en mode de dégivrage

• Si le type d’installation est Simplifié ou partiellement Simplifié, assurez-vous que le ventilateur de la fournaise opère durant la procédure de

balancement

• Lors de la lecture avec un manomètre analogique (Magnehelic), assurez-vous que le manomètre est placé sur une surface plane.

Afin d’assurer une performance optimal, le VRC devrait être rééquilibré après toute rénovation majeure ou après l’ajout de nouveaux conduits.

• Dans les endroits froids, la continuelle pression positive excessive à l’intérieur de la maison peut chasser l’humidité à l’intérieur

des murs extérieurs de la maison. L’humidité présente à l’intérieur de la paroi externe peut se condenser si la température

extérieure est assez froide et peut causer des dommages aux composants structuraux. Un symptôme de la pression positive

excessive à l’intérieur d’une maison est des serrures gelées.

• La continuelle pression négative excessive peut avoir des effets indésirables. Dans certaines régions, la pression négative peut

augmenter l’infiltration de gaz à effet de sol tels que le méthane et de radon. Une pression négative est également indésirable

où l’équipement de combustion est présent et peut causer des refoulements de la réaction des gaz de combustion.

AJUSTEMENT DES DÉBITS D’AIR

Un registre est intégré dans le collet d’air frais distribué à l’intérieur. Ce registre remplace l’installation d’un registre dans les conduits de distribution d’air

frais à l’intérieur.

Les registres sont préréglés en position entièrement ouverte. Afin de réduire le débit d’air, tournez le levier réglable à l’aide d’un tournevis plat en tournant

dans le sens antihoraire. Tournant dans le sens horaire peut endommager l'appareil. Suivez les étapes d’équilibrage afin de régler correctement le débit

d’air.

fantech

Page 34

34

ÉTAPES DE BALANCEMENT

Utilisez la charte de balancement

localisée sur la porte du VHC

Débit d'air Vitesse normale Vitesse réduite

Étape 1: Identifiez le débit d’air désiré en vous référent à la charte

fournie. Du débit d’air désiré (colonne de gauche) identifiez la

lecture de pression nécessaire en suivant tout simplement la ligne.

Assurez-vous de régler l’appareil à la vitesse normale avant

d’effectuer l’étape suivante.

Étape 2: Mesurez la lecture de la pression en branchant un

manomètre sur les ports de basse et haute pression situés sur le

conduit de raccordement. Reportez-vous à l'illustration n1. Si la

lecture de pression est inférieure à la valeur désirée, ajuster les

registres de réglage en tournant le bras réglable dans le sens

antihoraire jusqu’à la valeur de pression désirable est atteinte.

Reportez-vous à l'illustration n2. Faites de même pour le débit

d’air d’APPROVISIONNEMENT et d’ÉCHAPPEMENT. Si la lecture

de la pression est plus élevée que souhaité lorsque le registre est

complètement ouvert, s’il vous plait vérifier le système de

distribution pour toutes anomalies qui pourraient accroître la

résistance dans le système de distribution.

• Parce que la maison est bien scellée, le réglage d’un débit d’air peut affecter le

débit d’autres aussi. Il est donc recommandé de vérifier chaque débit d’air à

nouveau pour s’assurer que la valeur n’a pas changer considérablement. Faites

les ajustements nécessaires.

• La lecture de pression de la connexion du conduit se réfère à la perte totale du

système de distribution. Un système de distribution bien conçu doit avoir une

perte de pression entre 0.4po (100Pa) et 0.6po (150Pa). La lecture de pression

peut être donc utilisée comme dépannage du système de distribution. Si la

lecture de pression est supérieure à 0.6po (150Pa), nous vous recommandons

d’inspecter le système et vérifier pour des grilles fermées, hottes extérieures

bloquées ou des conduits flexibles torsadés.

Étape 3: Fixez le bras de réglage en serrant la vis de fixation comme indiqué dans l'illustration n3.

pi3/min L/s

110 52 0.36 91

100 47 0.46 114

90 42 0.55 137

80 38 0.64 161

70 33 0.74 184 0.13 32

65 31 0.78 195 0.16 40

60 28 0.83 207 0.19 48

55 26 0.87 219 0.22 55

50 24 0.92 230 0.25 63

CHARTE DE BALANCEMENT (exemple seulement)

In W.G.

Lecture de pression

In W.G.

Pa

Lecture de pression

HAUTE HAUTEBASSE BASSE

HIGH LOW LOW HIGH

Apport d'air

SUPPLY

Échappement

EXHAUST

Illustration n° 1

Pa

fantech

Bras de réglage (à l'avant)

Vis de fixation (au dessus)

Illustration n° 3Illustration n° 2

Page 35

SYSTÈME DE CONTRÔLE À BASSE TENSION

* Veuillez voir les instructions individuelles des contrôles pour le câblage et la mise en pièce appropriée.

CONTRÔLES CENTRALS – Ces options de contrôle peuvent seulement être utilisé individuellement

CONTRÔLE CARACTÉRISTIQUES CONNEXION À

ECO-Touch • Notre système de contrôle le plus complet, mais facile à

utiliser

• Conception élégante avec un écran tactile rétro-éclairé

• Mode ECO sélectionne le meilleur mode de fonctionnement

pour la saison, en réduisant les coûts d’énergie grâce au

mode de ventilation

• Gamme d’humidité relative réglable et le mode de ventilation

pour les conditions de jour et de nuit

• Indicateur rappel d’entretient

• Messages d’erreur de code réduit le temps de dépannage

EDF7

EDF1 • Appuyez le bouton pour une vitesse réduite continuelle

• Le bouton MODE fournit trois mode de fonctionnement: Ventilation,

Recirculation et en attente

• Sélection de la vitesse du ventilateur par l'utilisateur : Vitesse

Réduite, vitesse moyenne, vitesse normal et 20 min/h

• Réglage AUTO permet auu propriétaire de désactiver le

déhumidistat

• Lorsque que le d'humidité relative désiré excèfe le point désiré, le

système de ventilation fonctionne à vitesse normale.

• Une fois le niveau d'humidité désiré est atteint, votre système de

ventilation retourne à son mode de fonctionnement précédent

• Appuyez le bouton une seconde fois, l’appareil fera un cycle de 20

minutes ON/ 40 minutes OFF et répéter

• EDF1 – Appuyez le bouton une troisième fois et le système

fonctionnera en haute vitesse continuellement

W

W

W

W

W

W

35

1. Assurez-vous que l'appareil

n'est pas branché lors de

la connexion des contrôles.

2. Le mode de recirculation

est seulement disponible

lorsqu'il y a le sufxe R à la

n du numéro de modèle

Le connecteurs de câblage

peuvent être enlevé pour

faciliter la connexion

CONTÔLES AUXILIAIRES – Ces contrôles peuvent être combinés

RTS2*

RTS5

MDEH1

• Minuterie de 20 minutes avec lumière DEL

• Stimule le système à haute vitesse avec le toucher d’un bouton

• Jusqu’à cinq peuvent être utilisés dans un système

• Utilisation pour salle de bain, cuisine, buanderie

• Minuterie de 20/40/60 minutes avec lumière DEL

• Stimule le système à haute vitesse avec le toucher d'un bouton

• Jusqu'à 5 peuvent être utilisés dans un système

• Utilisation pour salle de bain, cuisine, buanderie

• Déshumidistat cadran rotatif

• Multiple appareil peuvent être utilisés

• Nous vous recommandons de régler l’humidité relative au-dessus

de 80% au cours de l’été

+T

+T

-T

-T

*maintenir la polarité

entre le contrôle et le VRC

(+ → + ; - → -)

D

D

fantech

Page 36

36

SCHÉMAS ÉLECTRONIQUES

fantech

* Schéma électrique de l'appareil au complet situé à l'intérieur du paneau

d'accès

Page 37

SCHÉMAS ÉLECTRONIQUES (SUITE)

37

CONNEXION ÉLECTRIQUE

À UNE FOURNAISE

DANS LE CAS D'UNE

FOURNAISE RACCORDÉE À

UN SYSTÈME DE

REFROIDISSEMENT

Sur certaines nouvelles fournaises, et

certains thermostats plus anciens,

l’excitation des bornes R et G de

la fournaise provoque l’excitation

de la borne Y du thermostat et

conséquemment la mise sous tension

du système de refroidissement. Si