Page 1

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

PBW Series

PREMIUM BATH FANS

Single Grille Units

4" Duct

PBW100

SEVEN-YEAR

WARRANTY

PBW100F

PBW100H

IMPORTANT: PLEASE READ THIS MANUAL BEFORE INSTALLING UNIT

WARNINGS:

WARNING! TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS –

a. Use this unit only in the manner intended by the manufacturer. If you have any questions, contact your

manufacturer's representative.

b. CAUTION: Before installation, servicing or cleaning unit, switch power off at service panel and lock the service

disconnecting means to prevent power from being switched on accidentally. When the service disconnecting

means cannot be locked, securely fasten a prominent warning device, such as tag, to the service panel.

c. Installation work and electrical wiring must be done by qualified person(s) in accordance with all applicable

codes and standards. This unit is only for use in non-fire-rated installations.

d. When cutting or drilling into wall and ceiling, do not damage electrical wiring and other hidden utilities.

e. NEVER place a switch where it can be reached from a tub or shower.

f. If this unit is installed over a tub or shower, it must be connected to a GFCI (Ground Fault Circuit Interrupter) –

protected branch circuit.

g. The combustion airflow needed for safe operation of fuel burning equipment may be affected by this unit’s

operation. Follow the heating equipment manufacturer’s guidelines and safety standards such as those

published by the National Fire Protection association (NFPA), the American Society of Heating, Refrigeration,

and Air Conditioning Engineers (ASHRAE) and the local code authorities.

h. Exhaust fans must always be vented to the outdoors.

CAUTION: "For General Ventilation Use Only. Do Not Use To Exhaust Hazardous Or Explosive Material and Vapors."

CAUTION: BULB USED IN FLUORESCENT MODELS NOT DIMMABLE

CAUTION: USE ONLY FANTECH (MODEL PBB14) FLUORESCENT BULBS AND

PAR16/MR16 GU10 50W MAX. HALOGEN BULBS (FANTECH MODEL PBB50).

DO NOT CONNECT POWER SUPPLY until unit is completely installed.

Make sure electrical service to the fan and light is locked in“OFF” position.

OBSERVE THE FOLLOWING:

Page 2

Planning Your Fan Location

As with any exhaust system, your exhaust fan should be located a

minimum of 6 feet horizontally and 8 feet vertically from any fresh air

intakes to prevent re-entrainment of exhaust air streams. For example

HVAC systems, heat recovery systems, and windows would all be

considered fresh air intakes.

When planning your fan placement keep in mind that you will need to

be able to run your duct work from the exterior fan to the bathroom

inlet. Considering access for the duct run before hand will make

installation easier.

Installing Exterior Wall Fan

1. Once you have chosen the location where you wish to mount the fan,

cut a 4 ³⁄₈" diameter hole in the exterior of the wall. Prepare a piece

of rigid duct (purchase separately) approximately 2" longer than the

wall thickness. This will be used as a collar extension placed through

the wall.

2.

T

ake off the fan discharge cover by removing the four screws. Center

the fan in the hole that was cut into the wall. Mark the locations of

the mounting holes and electrical knockout. Drill a hole for the

electrical that is ¹⁄₈" larger than the conduit being used. A 1"

electrical service opening is provided on the fan backplate.

NOTE: When mounting the fan to a masonry wall, drill ⁷⁄₃₂" holes for

the four anchors and mounting screws (provided). Anchors should be

flush with the edge of the holes. For mounting to wood surfaces use

wood screws (purchased separately).

3. Bring your electrical supply through the wall. Attach the fan collar to

the extension collar using duct tape. Be sure this connection is as

airtight as possible to prevent leakage. Apply polyurethane caulk to

the exterior of fan housing backplate, leaving bottom uncaulked for

drainage. This will ensure an airtight/waterproof connection between

the fan and wall.

NOTE: If installing on lapped siding it may be necessary to use a

mounting frame made from 1x1 board to insure a flush fit.

4.

Mount the fan to the wall. Replace the discharge cover

ducting to the extension collar using plastic ties or duct tape

(purchased separately).

FINAL INSTALLATION NOTE: If fan location

is not protected by an eve, a standard

flashing should be installed. Seal against

the wall and upper edge of the fan

discharge cover to prevent rain water

from entering fan housing.

Fantech recommends insulated flexible

duct for all bathroom exhaust applications.

. Connect your

Electrical Connection

1. Remove the screws securing the terminal box cover located on the

fan motor mounting bracket. All fan motor and capacitor connections

are pre-wired to an electrical terminal strip. A

3

⁄8" romex type cable

restraint connector will be needed to secure the wiring through the

knockout on the side of the terminal box.

2. Bring incoming electrical service through the romex connector and the

fan electrical service opening. Be sure to place the connector nut over

the wiring coming into the terminal box. There are two open ports on

the terminal strip. Using a small regular screwdriver, tighten the neutral

(white) wire of the incoming supply under the open terminal strip port

labeled “N”. Tighten the line (black) wire of the incoming supply under

the open terminal strip port labeled “L” to the ground connection on the

terminal block.

3. Secure the romex connector. Secure the incoming supply with the

romex connector. Place the capacitor back into the terminal box.

Replace the fan terminal box cover.

All fan motor and capacitor connections have been pre-wired from

the factory. No additional fan wiring is necessary.

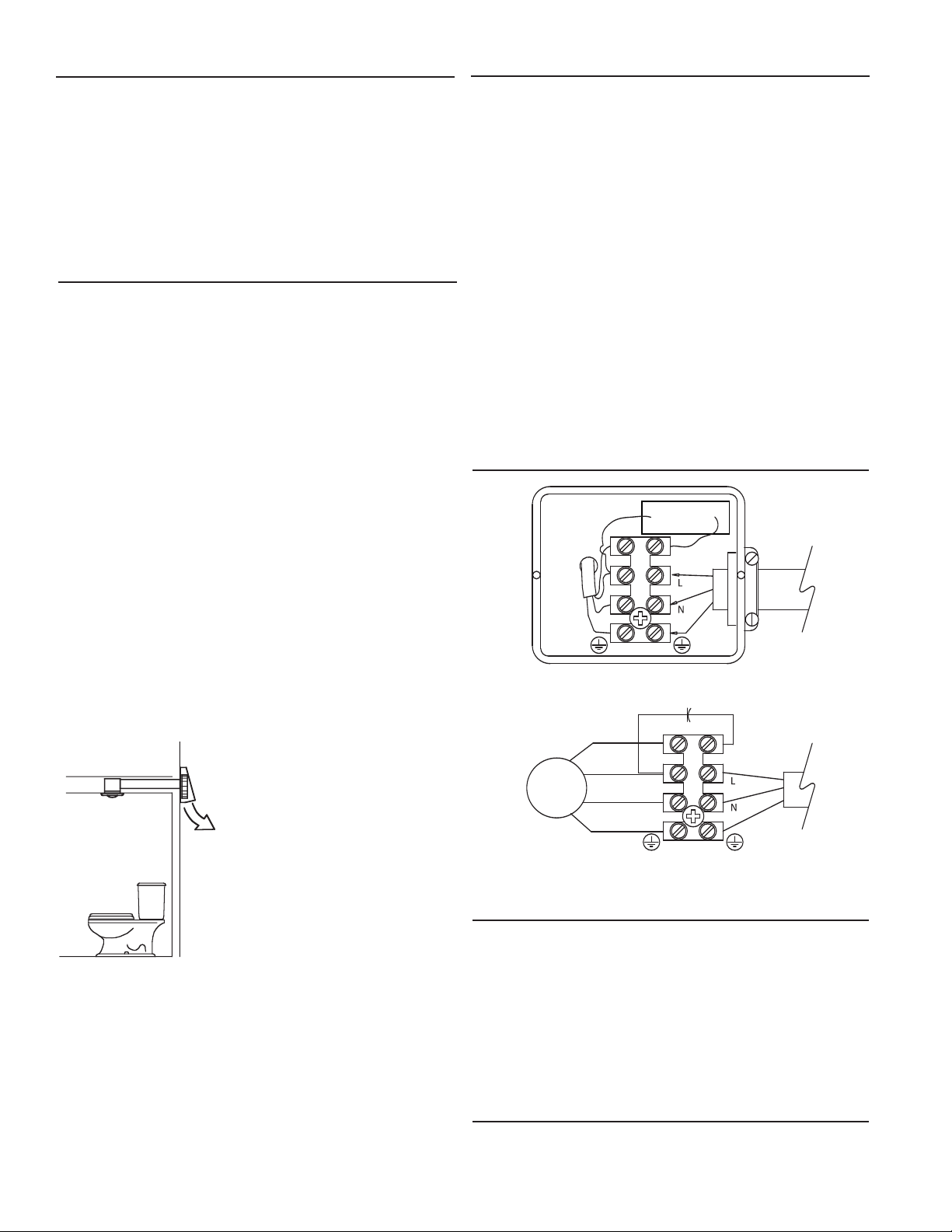

Wiring Diagrams

Capacitor

115V

Supply

Ground

Capacitor

Ground

115V

Supply

Motor

Leads

Brown

Black

Blue

Green/Yellow

Flexible Duct Installation Hints

Fantech strongly recommends the use of flexible insulated duct where

ducting passes through unconditioned space or where noise is a factor.

Check local code requirements before installing. Failure to use insulated

flexible duct could result in excessive condensation buildup within the

duct, and undesirable sound levels within the room.

A minimum of 8' of insulated flexible duct is recommended between

the fan and any inlet grille. Duct should be stretched as tight and straight

as possible. Failure to do so could result in dramatic loss of system

performance. Connect flex duct to the fan with plastic zip ties or duct tape.

Connections should be airtight as possible for maximize performance.

Troubleshooting

If fan fails to operate, please check the following:

1. Consult wiring diagrams (above) to ensure proper connection.

2. Check motor lead wiring, capacitor leads and incoming supply leads

to insure definite contact.

3. If possible, use a meter to test for continuity across the fan motor

leads. In order to do this, the capacitor must be disconnected (do

not test the capacitor - it will not meter continuity). If motor leads

show continuity, consult factory for a replacement capacitor.

Maintenance Instructions

Since fan bearings are sealed and provided with an internal lubricating

material, no additional lubrication is necessary.

Page 3

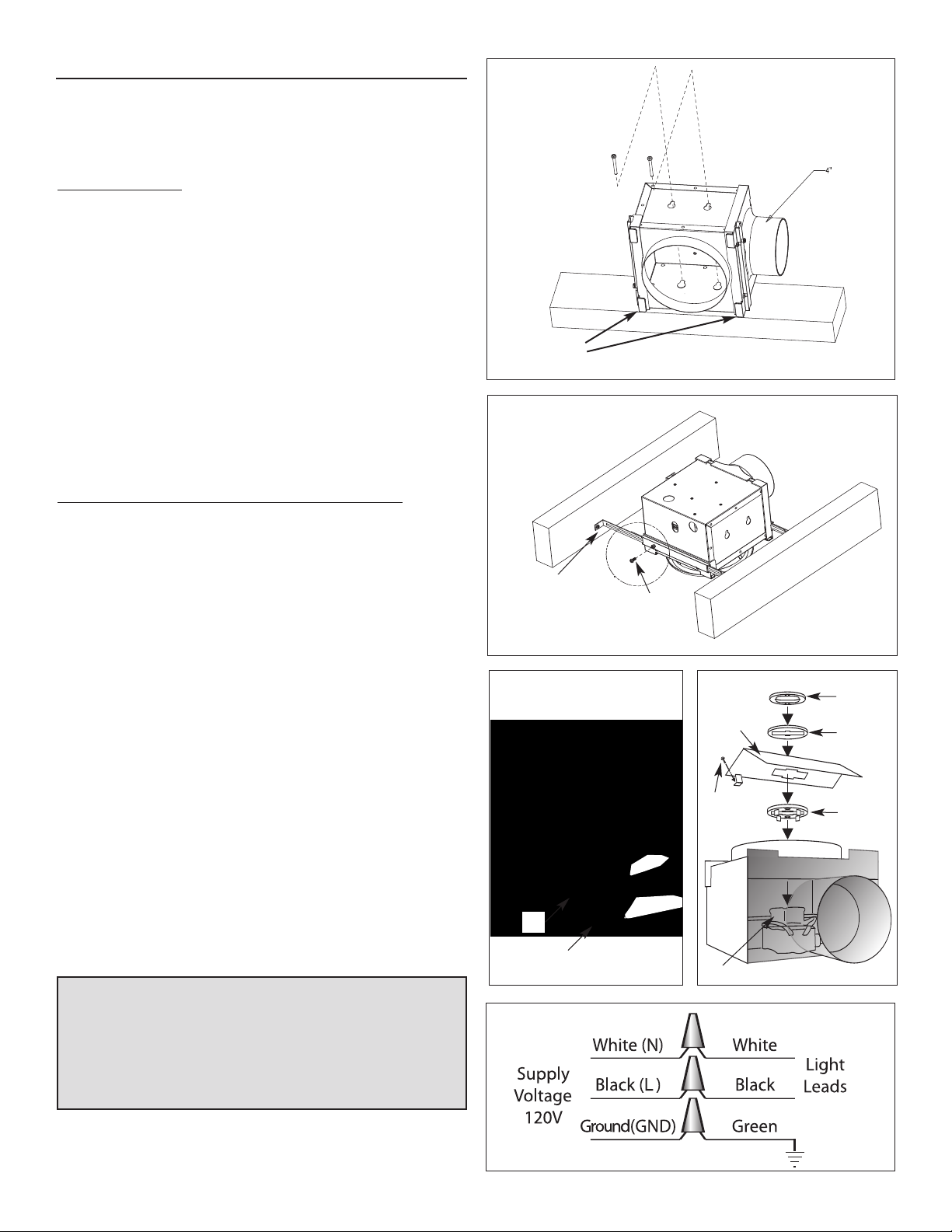

Installation of Ceiling Grille Housing With or Without Light

1. Plan Location of Inlet Grilles.

Based on the bathroom layout and fixtures, plan the location of the ceiling

grilles for the most effective ventilation.

2. Securing the Housing to the Ceiling Joists.

NEW CONSTRUCTION

Mount housing directly to the ceiling joist using screws and keyhole slots.

Locator tabs on housing should be flush with the bottom edge of the ceiling

joist for correct positioning of the unit once drywall is installed.

(Figure 1)

OR

Use the hanger bars to suspend the housing between ceiling joists. For

correct positioning, hanger bars should be positioned

bottom edge of the ceiling joist on models with 4" duct connection and 15⁄32"

up from bottom edge of joist on models with 6" duct connection. On

models with 4" duct, tighten anti-slide screws to keep hanger bars in

place. (Figure 2).

Note: Hanger bars on units with 4" duct connection can be used on ceiling

joists up to 24" on center. Hanger bars on units with 6" duct connection

span ceiling joists up to 16" on center.

Note: If drywall or ceiling material is thicker than

be removed to allow the grille collar to be flush with the finished ceiling

material. When ceiling drywall is being installed, cut hole for ceiling grille.

EXISTING CONSTRUCTION OR WHEN DR

YWALL IS IN PLACE.

Cut a 6" round hole for the ceiling grille only and install the housing from

the attic. (Figure 3)

Place the housing against the ceiling joist using the locator tabs to

determine the correct position (Figure 1) or align it using the hanger bars.

(Figure 2).

Punch out the keyhole knockouts (if using) and the electrical knockout if

needed.

To complete installation for Bath Fan models with lights, continue with

steps 3 through 5. For models without lights, skip to steps 4 and 5.

3

⁄16" up from the

5

⁄8" the locator tabs may

Figure 1

Postion Locator Tabs

flush with bottom

edge of joist

Figure 2

Housings with 4"

duct: 3⁄16" from

bottom edge of

joist.

Housings with 6"

15

⁄32"

duct:

Anti-slide

locking screw

on models with

4" duct.

3. Make Electrical Connections to the Ceiling Grille Housing.

Remove the electrical cover inside the steel housing using a screwdriver.

Connect power by following wiring diagram (Figure 5) and following local

or National Electrical Codes. Replace the electrical cover.

4. Connect the Fan to the Ceiling Grille Housing(s). Install appropriate

diameter duct from the fan to the ceiling grille housing. (Insulated flexible duct

is recommended for all Fantech bathroom exhaust applications for quieter

operation.) For dual grille models, install duct between fan and wye adapter*

(included). Then, attach duct to each leg of the wye and to each ceiling grille

housing. Secure duct in place and seal. If using insulated flexible duct, seal

the inner liner to the duct connector then seal the outer shell over the top of

the inner liner. Do not leave the insulation material exposed.

5. Installing the Bulb. Install the bulb by gently inserting it into the

socket in the grille housing. Install the grille by pushing it firmly into the

steel collar until it is shouldered by the ceiling drywall (Figure 3).

ADDITIONAL STEPS REQUIRED WHEN INSTALLING A FLUORESCENT

MODEL OVER A TUB OR SHOWER.

(Figure 4)

1. Place ring 1 on on socket legs first.

2. Screw metal shield in place over socket.

3. Add rubber gasket

4. Secure ring 2 to socket. Click indicates a secure installation.

Repeat steps 1 through 5 for each additional ceiling grille housing being installed.

Figure 3

Grille

Fluorescent

lamp

Figure 5

Figure 4

Shield

Screw

Socket

Ring 2

Gasket

Ring 1

Electrical

*For most efficient operation wye adapter should be positioned the equivalent of

three duct diameters away from the fan inlet.

3

Page 4

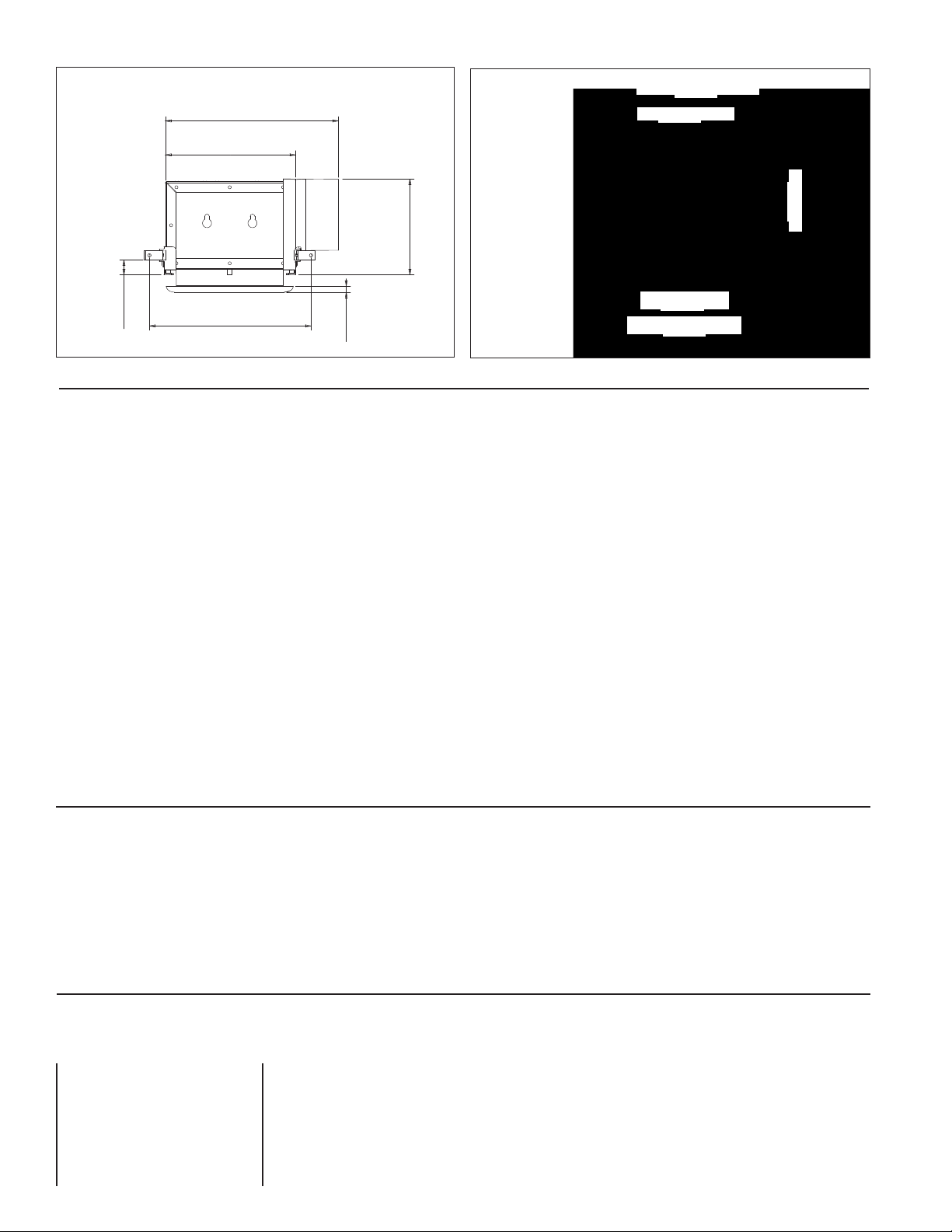

Housing Dimensions

of 4" duct models

99⁄16" (243mm)

73⁄16" (182.5mm)

⁄16" (134mm)

5

5

Housing Dimensions

of 6" duct models

9 ¹¹⁄₁₆" (246mm)

8" (205mm)

6" (150mm)

5 ¹³⁄₁₆" (148mm)

9" (230mm)

⁄16" (21mm)

13

815⁄16" (227mm)

⁄16" (8mm)

5

Seven (7) Year Warranty

DURING ENTIRE WARRANTY PERIOD:

FANTECH will repair or replace any part which has a factory defect in

workmanship or material. Product may need to be returned to the Fantech

factory, together with a copy of the bill of sale and identified with RMA number.

FOR FACTORY RETURN YOU MUST:

• Have a Return Materials Authorization (RMA) number. This may be obtained

by calling FANTECH either in the USA at 1.800.747.1762 or in CANADA at

1.800.565.3548. Please have bill of sale available.

• The RMA number must be clearly written on the outside of the carton, or the

carton will be refused.

• All parts and/or product will be repaired/replaced and shipped back to buyer;

no credit will be issued.

OR

The Distributor may place an order for the warranty part and/or product and is

invoiced. The Distributor will receive a credit equal to the invoice only after

product is returned prepaid and verified to be defective.

FANTECH WARRANTY TERMS DO NOT PROVIDE FOR REPLACEMENT WITHOUT

CHARGE PRIOR TO INSPECTION FOR A DEFECT. REPLACEMENTS ISSUED IN

ADVANCE OF DEFECT INSPECTION ARE INVOICED, AND CREDIT IS PENDING

INSPECTION OF RETURNED MATERIAL. DEFECTIVE MATERIAL RETURNED BY END

USERS SHOULD NOT BE REPLACED BY THE DISTRIBUTOR WITHOUT CHARGE TO

THE END USER, AS CREDIT TO DISTRIBUTOR’S ACCOUNT WILL BE PENDING

INSPECTION AND VERIFICATION OF ACTUAL DEFECT BY FANTECH.

THE FOLLOWING WARRANTIES DO NOT APPLY:

• Damages from shipping, either concealed or visible. Claim must be filed

with freight company.

• Damages resulting from improper wiring or installation.

• Damages or failure caused by acts of God, or resulting from improper

consumer procedures, such as:

1. Improper maintenance

2. Misuse, abuse, abnormal use, or accident, and

3. Incorrect electrical voltage or current.

• Removal or any alteration made on the FANTECH label control number

or date of manufacture.

• Any other warranty, expressed, implied or written, and to any consequential

or incidental damages, loss or property, revenues, or profit, or costs of

removal, installation or reinstallation, for any breach of warranty.

WARRANTY VALIDATION

• The user must keep a copy of the bill of sale to verify purchase date.

• These warranties give you specific legal rights, and are subject to an applicable

consumer protection legislation. You may have additional rights which vary from

state to state.

Limitation of Warranty and Liability

This warranty does not apply to any FANTECH INC. product or part which has failed as a result of faulty installation or abuse, incorrect electrical

connections or alterations made by others, or use under abnormal operating conditions or misapplication of the product or parts. We will not

approve for payment any repair not made by us or our authorized agent without prior written consent. The foregoing shall constitute our sole and

exclusive warranty and our sole exclusive liability, and is in lieu of any other warranties, whether written, oral, implied or statutory. There are no

warranties which extend beyond the description on the page hereof. In no event, whether as a result of breach of contract, or warranty or alleged

negligence, defect incorrect advice or other causes, shall FANTECH be liable for special or consequential damages, including, but not limited to,

loss of profits or revenue, loss of use of equipment or any other associated equipment, cost of capital, cost of substitute equipment, facilities or

services, downtime costs, or claims of customers of purchase for such damages. FANTECH neither assumes or authorizes any person to assume

for it any other liability in connection with the sale of product(s) or part(s). Some jurisdictions do not allow the exclusion or limitation of incidental

or consequential damages so the above limitations and exclusions may not apply to you.

Warning

FANTECH, INC. products are designed and manufactured to provide reliable performance, but they are not guaranteed to be 100% free from defects. Even reliable

products will experience occasional failures and this possibility should be recognized by the user. If these products are used in a life support ventilation system where

failure could result in loss or injury, the user should provide adequate backup ventilation, supplementary natural ventilation, failure alarm system, or acknowledge

willingness to accept the risk of such loss or injury.

United States

1712 Northgate Blvd.,

Sarasota, FL. 34234

Phone: 800.747.1762;

941.309.6000

Fax: 800.487.9915; 941.309.6099

www.fantech.net; info@fantech.net

Canada

50 Kanalflakt Way,

Bouctouche, NB E4S 3M5

Phone: 800.565.3548;

506.743.9500

Fax: 877.747.8116; 506.743.9600

www.fantech.ca; info@fantech.ca

Fantech, reserves the right to modify, at any time and without notice, any or all

of its products’ features, designs, components and specifications to maintain

their technological leadership position.

Item #: 801007

Rev Date: 0807

Page 5

MANUEL D’INSTALLATION, D’OPÉRATION ET D’ENTRETIEN

Série PBW

VENTILATEURS POUR SALLE DE BAINS PREMIUM

Grille simple

Conduit de 4 po

PBW100

GARANTIE

DE 7 ANS

PBW100F

PBW100H

IMPORTANT : VEUILLEZ LIRE CE MANUEL AVANT L’INSTALLATION

AVERTISSMENTS :

Assurez-vous que le courant électrique au ventilateur et lumière soit débranché « OFF ».

AVERTISSEMENT! POUR RÉDUIRE LE RISQUE D’INCENDIE, L’ÉLECTROCUTION OU LES BLESSURES

CORPORELLES – SUIVEZ LES INSTRUCTIONS SUIVANTES :

a. Utilisez cet appareil conformément aux spécifications du fabriquant. Si vous avez des questions, contactez votre représentant.

b. ATTENTION : Avant d’installer, d’entretenir ou de nettoyer l’appareil, coupez le courant au paneau électrique et vérouillez le service

électrique afin de prévenir que le courant soit branché accidentellement. S’il est impossible de vérouiller le courant électrique,

attachez un mécanisme d’avertissement au panneau électrique de façon visible. (Tel qu’un tag)

c. Les travaux d’installation et le raccordement électrique doivent être effectués par une personne qualifiée, conformément aux

codes et normes de construction. Cet appareil n’est pas conçu pour être exposé à de hautes températures.

d. Lorsque vous coupez ou perforez un mur ou un plafond, assurez-vous de ne pas endommager les fils électriques ou toute

autre installation.

e. NE JAMAIS placer un interrupteur pouvant être atteint de la baignoire ou de la douche.

f. Si l’appareil est installé au-dessus d’une baignoire ou d’une douche, il doit être branché dans une prise avec une mise à terre GFCI.

g. Le flux d'air à combustion requis pour l'opération sécuritaire de l'équipement à carburant peut être affecté par l'opération de cet appareil.

Suivez les directives de l’équipement de chauffage du fabriquant et les normes de sécurité dont celles publiées par le « National Fire

Protection Association (NFPA) », le « American Society of Heating, Refrigeration, and Air Conditioning Engineers (ASHRAE) » ainsi que les

codes de votre région.

h. Les ventilateurs à évacuation doivent toujours évacuer à l'extérieur de votre maison.

NE PAS BRANCHER LE COURANT ÉLECTRIQUE avant que l’appareil soit complètement installé.

ATTENTION : Pour usage de ventilation résidentielle seulement. Ne pas utiliser pour évacuer des matériaux et vapeurs dangereux ou explosifs.

ATTENTION : LES AMPOULES UTILISÉES DANS LES MODÈLES FLUORESCENTS NE SONT PAS RÉGLABLES.

ATTENTION : UTILISEZ SEULEMENT LES AMPOULES « TCP XR3014 B » POUR LES MODÈLES FLUORESCENTS ET LES AMPOULES « PAR 16 »

POUR LES MODÈLES HALOGÈNES.

5

Page 6

Planifier l’emplacement du ventilateur

Comme tout autre système d’évacuation, votre ventilateur devrait être situé à un

minimum de 6 pieds horizontalement et 8 pieds verticalement de toutes les

entrées d’air frais afin de prévenir la réintégration des courants d’air vicié. Par

exemple, les systèmes HVAC, les systèmes récupérateurs de chaleur et les

fenêtres sont tous considérés comme étant des entrées d’air frais.

Lorsque vous choisirez l’emplacement de votre ventilateur, assurez-vous qu’il soit

possible de passer les conduits du ventilateur extérieur à la grille de la salle de

bains. Une bonne planification facilitera l’installation.

Branchement électrique

1. Retirez les vis fixant le couvercle de la boîte de câblage sur le côté du ventilateur.

Tous les fils du moteur du ventilateur sont préalablement câblés à une bande de

branchement électrique. Un connecteur câble encastré de type « Romex »

15,8 mm sera nécessaire afin de fixer le fil d’alimentation à la boîte de câblage.

2. Passez les fils d’alimentation à travers le connecteur de câble encastré.

Assurez-vous de placer l’écrou du connecteur au-dessus des fils entrant dans

la boîte de câblage. Il y a deux emplacements libres sur la bande de

branchement. À l’aide d’un tournevis régulier, serrez le fil d’alimentation blanc

sous la vis indiquée « N ». Serrez le fil d’alimentation noir sous la vis indiquée

« L ». Puisque le moteur du ventilateur est isolé dans un boîtier en plastique, la

Installation du ventilateur au mur extérieur

1. Lorsque vous avez choisi l’emplacement désiré du ventilateur, percez un trou de

4³⁄₈ po de diamètre à l’extérieur du mur. Préparez un morceau de conduit rigide

(acheté séparément) d’environ 2 po plus long que l’épaisseur du mur qui sera

utililisé comme collier d’extension placé au travers du mur.

2.

Enlevez le couvercle de la sortie du ventilateur en enlevant les quatres vis.

Centrez le ventilateur dans le trou percé dans le mur. Marquez les endroits des

prise de terre n’est pas nécessaire.

3. Fixez le connecteur « Romex ». Fixez l’entrée de l’alimentation avec le connecteur

« Romex ». Replacez le couvercle de la boîte de câblage. Tous les fils du moteur

ayant été préalablement câblés à l’usine, aucun autre raccordement

est nécessaire.

Diagramme de branchement

trous de montages et trous pour les fils électriques. Percez un trou pour les fils

électriques d’un ¹⁄₈ pouce plus grand que le conduit utilisé. Une ouverture de

1 pouce existe sur la plaque arrière du ventilateur

.

NOTE : Lorsque vous montez le ventilateur sur un mur de maçonnerie, percez

des tr

ous de ⁷⁄₃₂ po pour les quatre ancres et vis (incluses). Les ancres

devraient être à l’égalité du mur

. Pour l’installation sur des sur

faces en bois,

utilisez des vis pour bois (achetées séparément).

3. Passez l’alimentation électrique au travers du mur. Attachez le collet du

ventilateur au collet d’extension en vous servant de ruban adhésif. Assurez-vous

que la connexion soit hermétique pour éviter tout échapement. Appliquez du

calfeutrage polyuréthane à l’extérieur du ventilateur de la plaque arrière du

boîtier du ventilateur, en laissant le dessous non calfeutré pour drainage. Ceci

assurera une installation hermétique entre le ventilateur et le mur.

NOTE : Si l’installation se fait sur une surface inégale, il sera peut être

nécessaire de fabriquer un cadre de montage fabriqué de piece de bois en

planche de 1 x 1 pour assurer une installation au niveau.

4. Installez le ventilateur au mur. Replacez le couvercle de sortie. Reliez les conduits

au collet d’extension en utilisant des attaches en

plastique ou du ruban adhésif (achétés

séparément).

NOTE FINALE D’INSTALLATION : Si l’endroit où se

trouve le ventilateur n’est pas protégé par la

toiture, un couvre-joint (solin) devrait être

installé. Scellez contre le mur et le bord

supérieur du couvercle de la sortie du ventilateur

afin de prévenir l’eau de pénétrer dans le boîtier.

Fantech recommande du conduit flexible isolant

pour toutes les applications d’évacuation pour

salle de bains.

Dépannage

Si le ventilateur ne fonctionne pas, vérifiez ce qui suit :

1. Consultez les diagrammes de câblage (voir ci-dessous) pour vous assurer que la

connexion est appropriée.

Conseils pour l’installation de tuyaux flexibles

Fantech recommande fortement l'utilisation de tuyaux flexibles isolants dans les

pièces à ventilation non contrôlée, ou pour minimiser le bruit. Consultez les codes

de votre région avant l'installation. Faute d’utiliser les conduits flexibles isolants

pourrait causer une accumulation excessive de condensation dans le conduit et un

niveau de bruit nuisible dans la pièce.

Un minimum de 8 pieds de tuyau flexible isolant est recommandé entre la grille et

le ventilateur. Il devrait être étiré à son maximum et être aussi droit que possible,

sans quoi la performance en serait grandement diminuée. Fixez le tuyau flexible au

ventilateur avec un collier de serrage ou un ruban adhésif en toile. Le branchement

doit être le plus étanche que possible afin de maximiser le rendement du système.

2. Contrôlez le fil de sortie du moteur, les fils de sortie du condensateur et

l’alimentation électrique pour vous assurer d’un bon contact.

3. Si possible, utilisez un appareil de mesure pour déterminer la continuité à

travers les fils de sortie du moteur du ventilateur. Pour faire ceci, le condensateur

doit être débranché (ne pas tester le condensateur - il ne montrera pas la

continuité). Si les fils de sortie du moteur montrent la continuité, consultez l’usine

pour un condensateur de rechange.

Instructions pour l'entretien

Puisque les roulements du ventilateur sont scellés et équipés d’un matériel lubrifiant

interne, aucune lubrification supplémentaire n’est nécessaire.

Fils de

moteur

Brun

Noir

Bleu

Vert/Jaune

Capacitor

Capacitor

Ground

Alimentation

115V

Alimentation

115V

Mise à terre

Page 7

Installation du boîtier avec ou sans éclairage

Figure 1

1. Planifiez l'endroit pour la grille

D'après votre salle de bain et ses installations, planifiez l'endroit où vous

installerez vos grilles de plafond pour une ventilation efficace.

2. Fixez le boîtier à la poutrelle du plafond.

NOUVELLE CONSTRUCTION

Fixez le boîtier directement sur la poutre du plafond avec les vis. Les languettes sur

le boîtier devraient être au même niveau que le côté inférieur de la poutrelle du plafond

(Figure 1).

OU

Utilisez les barres de suspension pour fixer le boîtier à la poutrelle du plafond. Pour

être exacte, les barr

es de suspensions doivent être à

inférieur de la poutrelle du plafond pour les modèles à collets de 4 po et

les modèles de 6 po. Sur les modèles à conduits de 4 po serrez les vis antidérapantes pour sécuriser les barres de suspension en place (Figure 2).

Note : Les barres de suspension des appareils à collets de 4 po peuvent être utilisées

sur les poutrelles de plafond jusqu'à 24 po du centre. Les barres de suspension pour

les appareils à conduits de 6 po peuvent aller jusqu'à 16 po du centre.

Si le gypse ou le matériel de plafond est plus épais que

Note :

de position peuvent être enlevées pour permettre au collier de la grille d’être au

même niveau que le plafond fini. Lorsque le gypse est posée au plafond, pratiquez

une ouverture pour accomoder la grille. Dégagez l’ouverture pour les fils

d’alimentation de la boîte de câblage.

3

⁄16 po au-dessus du côté

15

⁄32 po pour

5

⁄8 po, les languettes

à la poutrelle du plafond

Figure 2

Postionnez les

languettes de position

CONSTRUCTION

EXISTANTE OU GYPSE EN PLACE.

Percez un trou de 6 po pour la grille de plafond seulement et installer le boîtier

dans le grenier. Placez le boîtier sur la poutrelle de plafond en utilisant les locator

tabs pour déterminer l'emplacement exacte (Figure 1) ou enligner en utilisant les

barres de suspension (Figure 2). Percez un trou si nécessaire.

Pour compléter l'installation des ventilateurs pour salle de bains avec éclairage,

suivez les étapes 3 à 5. Pour les modèles sans éclairage, passez directement aux

étapes 4 et 5.

3. Faites la connexion électrique au boîtier de la grille au plafond. En utilisant un

tournevis, enlevez le couvercle électrique à l’intérieur du boîtier en métal. Connectez le

courant en suivant le diagramme de branchement (Figure 5) et en suivant les codes

électriques locaux ou les codes électriques nationaux. Remettez le couvercle électrique.

4. Raccordement du ventilateur du boîtier. Installez le conduit de 4 po ou de 6 po

du ventilateur au boîtier de la grille au plafond. (Les conduits flexibles isolants

recommandés par Fantech pour toutes applications d’évacuation pour salle de

bains vous donneront un rendement plus silencieux). Pour les modèles à grilles

jumelles, montez les conduits entre le ventilateur et l’adapteur « wye » (inclus),

puis reliez les conduits à chaque sortie du « wye » et à chaque boîtier des grilles.

Attachez les conduits en place, puis scellez. Si vous utilisez un tuyau flexible

isolant, scellez la couche intérieure au connecteur de conduit puis scellez la couche

extérieure couvrant la couche intérieure. Ne laissez pas le matériel isolant exposé.

5. Installation de l'ampoule. Procédez en insérant doucement l’ampoule dans la

douille située dans le boîtier de la grille. Posez la grille en la poussant fermement

le collier jusqu’à ce que la grillle soit en contact ferme avec le plafond. (Figure 3).

Étapes additionnelles lors de l’installation d’un modèle fluorescent

au-dessus d’une baignoire ou d’une douche. (Figure 4)

(Figure 4)

1. Placer l’anneau « 1 » sur la douille, en commençant par les pattes.

2. V

isser le panneau en métal sur la douille.

3. Ajouter le joint en caoutchouc.

4. Bien attacher l’anneau « 2 » sur la douille. Le clic indique une

installation sécurisée.

Figure 5

Boîtier avec un

conduit de 4 po :

3

⁄16 po du dessous

de la poutrelle.

Boîtiers avec 6 po :

15

⁄32 po

Figure 3

Grille

Ampoule

Fluorescente

Vis antidérapante

sur modèles à

conduits de

4 po.

Figure 4

Panneau

Vis

Douille

Anneau 2

Joint

Anneau 2

Électrique

Répétez les étapes 1 à 6 pour chaque boîtier de grille pour plafond additionnel à installer.

*Pour un fonctionnement plus efficace, l’adapteur « wye » devrait être positionné à une

distance égale à trois fois le diamètre du conduit de l'entrée du ventilateur.

7

Page 8

Dimension du boîtier des modèles

à conduit de 4 po

99⁄16 po (243mm)

73⁄16 po (182.5mm)

⁄16 po (134mm)

5

5

Dimension du boîtier

des modèles à

conduit de 6 po

9 ¹¹⁄₁₆ po (246mm)

8 po (205mm)

6 po (150mm)

⁄16 po (21mm)

13

815⁄16 po (227mm)

⁄16 po (8mm)

5

Garantie de sept (7) ans

PENDANT LA PÉRIODE DE LA GARANTIE :

FANTECH réparera ou remplacera toute composante ayant un défaut manufacturier. Il

est possible qu’il vous sera demandé de retourner le produit au manufacturier avec une

copie du bon d’achat identifié par le numéro RMA.

POUR UN ENVOI À L’USINE :

• Avoir obtenu un numéro d’autorisation de renvoi des produits (Return Materials

Authorization “RMA”). Ce numéro peut être obtenu en appelant FANTECH, INC. au

1-800-747-1762. A

yez votre facture en main lors de votre appel.

• Avoir le numéro RMA clairement indiqué sur l’extérieur de l’emballage de renvoi pour

éviter le refus de la livraison du colis.

• Les produits seront remplacés ou réparés, puis renvoyés à l’acheteur. Vous ne serez

pas remboursé.

OU

Le distributeur peut commander une pièce ou un appareil sous garanti mais il sera

facturé. Le distributeur recevra un crédit égal à la facture seulement après le retour du

produit prépayé et confirmé défectueux.

LES TERMES DE GARANTI FANTECH OFFRENT UN REMPLACEMENT SI L’INSPECTION

PROUVE UN DÉFAUT MANUFACTURIER. LES PIÈCES REMPLACÉES AVANT L’INSPECTION

SERONT FACTURÉES ET UN CRÉDIT SERA VERSÉ APRÈS L’INSPECTION. LES PIÈCES

DÉFECTUEUSES RETOURNÉES PAR L’UTILISATEUR NE DEVRAIENT PAS ÊTRE REMPLACÉES

PAR LE DISTRIBUTEUR GRATUITEMENT PUISQUE LE COMPTE DU DISTRIBUTEUR NE SERA

CRÉDITÉ QU’APRÈS LA VÉRIFICATION ET L’APPROBATION DE FANTECH.

LES CAS SUIVANTS NE S'APPLIQUENT PAS À LA GARANTIE :

• Endommagements causés lors du transport, cachés ou visibles. Les demandes de

garantie doivent être remplies auprès du transporteur.

• Endommagements causés par un mauvais raccordement électrique ou une

mauvaise installation.

• Dommages ou défaillances causés par calamités naturelles, ou résultant d’une

manipulation inadéquate de la part du consommateur

1. Mauvais entretien

2. Mauvaise utilisation, abus d’utilisation, ou accident

3. Application d’une mauvaise tension ou d’un mauvais courant électrique.

• Enlèvement du numéro de contrôle de l’étiquette FANTECH ou de la date de

fabrication, ou modification de ces derniers.

• Toute autre garantie exprimée, suggérée ou écrite ou tout dommage, incident ou

conséquent, perte de biens, revenus ou bénéfices ou coûts de démontage,

installation, remontage ou pour tout bris de garantie.

VALIDATION DE LA GARANTIE :

L’utilisateur doit garder une copie de la facture pour la vérification de la date d’achat.

• Ces garanties vous donnent des droits spécifiques dont la Loi sur la protection du

consommateur. Vous pouvez avoir des droits additionnels propres à votre région.

5 ¹³⁄₁₆ po (148mm)

9 po (230mm)

, tel que :

Limitation de la garantie et responsabilité

Cette garantie ne s'applique à aucun produit ou pièce FANTECH INC. qui aurait échoué en raison d’une mauvaise installation ou abus, un mauvais raccordement électrique ou toute

altération ou usage sous condition d’opérations normales ou utilisation non conforme du produit ou des pièces. Aucun remboursement ne sera fait pour toutes réparations effectuées

par autre que nous ou notre agent autorisé sans avoir été préalablement autorisé par écrit. Ci-dessus constituera notre garantie unique et exclusive, et notre seule et unique obligation,

rejettant toutes autre garanties écrites orales implécites ou statutaires. En aucun cas, que ce soit en raison de bris de contrat ou de garantie ou négligeance alléguée recommendations

erronées autres causes, Fantech sera responsable pour dommages spéciaux ou conséquents, incluant, mais non limité à, perte de profit ou revenus, la perte d'utilisation d'équipement

ou tout équipement relié, perte de valeur, coût de remplacement d’équipement, facilités ou services, perte de temps ou réclamations d'achat du client pour tels dommages. FANTECH

INC. n’assume ni autorise aucune personne à assumer pour elle aucune autre responsabilité en rapport avec la vente de produit(s) ou pièce(s). Certaines juridictions ne permettent pas

d’exclure ou de limiter des dommages incidents ou indirects, de sorte que les limites ou exclusions ci-dessus peuvent ne pas s'appliquer dans votre juridiction.

Avertissement

Les produits FANTECH INC. sont conçus et fabriqués pour fournir une performance fiable, mais ne sont pas garantis à 100% `a l’épreuve de défectuosités. Même les produits

fiables sont parfois succeptibles d’éprouver des vices occasionnels et le consommateur devrait en être conscient. Si ces produits sont utilisés dans un système de ventilation pour

soutien de la vie où l'échec pourrait avoir comme conséquence la perte la vie ou dommages, l'utilisateur devrait pouvoir procurer un système de remplacement adéquat, ventilation

naturelle supplémentaire, système d’alarme anti-défaillant, ou être prêt à envisager et accepter les risques de blessures ou de pertes possibles.

United States

1712 Northgate Blvd.,

Sarasota, FL. 34234

Phone: 800.747.1762; 941.309.6000

Fax: 800.487.9915; 941.309.6099

www.fantech.net; info@fantech.net

Canada

50, route Kanalflakt

Bouctouche, NB E4S 3M5

Téléphone : 800.565.3548;

506.743.9500

Téléc : 877.747.8116; 506.743.9600

www.fantech.ca; info@fantech.ca

Fantech se réserve le droit de modifier partiellement ou entièrement, en tout temps et sans

préavis, les caractéristiques, la conception, les composantes et les spécifications de ses produits

afin de conserver sa position de leader en matière de technologie.

Numéro d’article : 801008

8

Date de révision : 0807

Page 9

MANUAL DE INSTALACIÓN, FUNCIONAMIENTO Y MANTENIMIENTO

Serie PBW

VENTILADORES PARA BAÑO PREMIUM

Unidades de Reja

Solas 4" Conducto

PBW100

GARANTÍA

DE 7 AÑOS

PBW100F

PBW100H

IMPORTANTE: FAVOR DE LEER ESTE MANUAL ANTES DE INSTALAR LA UNIDAD

ADVERTENCIAS:

eléctrico del ventilador y la luz esté bloqueado en posición de “OFF” (apagado).

¡ADVERTENCIA! A FIN DE REDUCIR EL RIESGO DE INCENDIO, DESCARGA ELÉCTRICA, O LESIONES A

a. Use esta unidad únicamente de la manera prevista por el fabricante. Si tiene alguna duda, comuníquese con el representante del fabricante.

b. PRECAUCIÓN: Antes de la instalación, mantenimiento o limpieza de la unidad, desconecte la electricidad en el panel de servicio y bloquee el

medio de desconexión del servicio para impedir la conexión accidental de la corriente. Cuando no se pueda bloquear el medio de desconexión

del servicio, sujete en el panel de servicio, y de manera segura, un dispositivo de advertencia a la vista de todos.

c. El trabajo de instalación y el cableado eléctrico deben ser realizados por personal competente de conformidad con todos los códigos y

normas pertinentes. Esta unidad es para uso exclusivo en instalaciones no clasificadas para incendios.

d. Al hacer cortes o perforaciones en paredes o techos, no dañe los cables eléctricos ni otros dispositivos de servicios ocultos.

e. NUNCA instale un interruptor donde pueda ser alcanzado desde una tina o ducha.

f. Si esta unidad se instala sobre una tina o ducha, debe conectarse a un circuito de derivación protegido GFCI (interruptor accionado por

corriente de pérdida a tierra).

g. El caudal de aire de combustión necesario para el funcionamiento seguro de equipo de combustión podría ser afectado por el funcionamiento

de esta unidad. Siga las directrices del fabricante del equipo de calefacción y las normas de seguridad como las que publica la National Fire

Protection association - NFPA (Asociación Nacional de Protección contra Incendios), la American Society of Heating, Refrigeration, and Air

Conditioning Engineers – ASHRAE (Sociedad Estadounidense de Ingenieros de Calefacción, Refrigeración y Aire Acondicionado) y los códigos

de las autoridades locales.

h. La salida de los ventiladores de escape siempre debe estar orientada hacia el exterior.

PRECAUCIÓN:

PRECAUCIÓN:

PRECAUCIÓN: UTILICE SOLAMENTE FOCOS FLUORESCENTES FANTECH (MODELO PBB14) Y FOCOS DE HALÓGENO

NO CONECTE LA ALIMENTACIÓN ELÉCTRICA hasta que la unidad quede totalmente instalada. Asegúrese de que el servicio

PERSONAS – OBSERVE LO SIGUIENTE:

"Exclusivo para uso de ventilación general. No utilizar para el escape de materiales y vapores peligrosos o explosivos."

LA BOMBILLA UTILIZADA EN LOS MODELOS FLUORESCENTES NO ES ATENUABLE

PAR16/MR16 GU10 DE UN MÁXIMO DE 50 W (MODELO FANTECH PBB50).

Page 10

Planificación de la ubicación del extractor

Al igual que con todo sistema de extracción, el extractor de aire debe

Conexión eléctrica

1. Quite los tornillos de montaje de la tapa de la caja de conexiones en el

instalarse a una distancia mínima de 6 pies horizontalmente y 8 pies

verticalmente de toda entrada de aire fresco a fin de impedir el rearrastre

hacia el interior de corrientes del aire extraído. Por ejemplo, los sistemas

HVAC, los sistemas de recuperación de calor y las ventanas, todos ellos se

deben considerar como entradas de aire fresco.

2. Pase la alimentación eléctrica a través del conector romex y el agujero ciego

Al planificar la ubicación del extractor recuerde que será necesario tender los

conductos desde el ventilador exterior hasta la entrada del baño. La instalación

será más fácil si de antemano se tiene en cuenta el acceso para el tendido de

los conductos.

Instalación del extractor en la pared exterior

1. Una vez seleccionado el lugar de la instalación del extractor, corte un orificio

2. Retire la tapa de descarga del extractor quitando los cuatro tornillos.

3. Pase el suministro de electricidad por la pared. Sujete el collarín del

3

de 4

⁄8" de diámetro en el exterior de la pared exterior. Prepare una sección

de conducto rígido (adquirido por separado) de aproximadamente 2" más

grande que el grosor de la pared. Esta será la extensión del collarín colocado

a través de la pared.

Centre el extractor en el orificio que se perforó en la pared. Marque el sitio

de los orificios de montaje y el orificio ciego para el cable eléctrico. Perfore

un orificio para la conexión eléctrica que sea

1

⁄8" más grande que el conducto

que se esté utilizando. En la placa trasera del extractor se proporciona una

abertura de 1 pulgada para el mantenimiento eléctrico.

NOTA: Al instalar el extractor sobre un muro de mampostería, perfore

orificios de

7

⁄32" pulgadas para los cuatro anclajes y tornillos de montaje

(provistos). Los anclajes deben estar al ras del borde de los orificios. Para

el montaje sobre superficies de madera, utilice tornillos para madera (se

adquieren por separado).

extractor al collarín de extensión usando cinta para ductos. Para prevenir

fugas, verifique que esta conexión sea lo más hermética posible. Aplique

calafateo de poliuretano al exterior de la placa trasera de la caja del

extractor, dejando el fondo sin calafateo para el drenaje. De esta manera

se asegura una conexión hermética y a prueba de agua entre el extractor

y la pared.

NOTA: Si se instala sobre un recubrimiento sobrepuesto podría ser

necesario utilizar un marco de montaje de cartón de 1x1 para asegurar un

ajuste al ras.

4. Monte el extractor en la pared. V

uelva a

colocar la tapa de descarga. Conecte el

conducto al collarín de extensión usando

abrazaderas de plástico tipo CB o cinta para

conductos (se adquieren por separado).

NOTA FINAL SOBRE LA INST

ALACIÓN: Si la

ubicación del extractor no está protegida por

un alero, deberá instalarse una tapajuntas de

metal estándar. Séllela contra la pared y el

borde superior de la tapa de descarga del

extractor para impedir que entre agua en la

caja del extractor.

Fantech recomienda el uso de conductos

flexibles y aislados para todas las aplicaciones

de escape en el baño.

3. Asegure el conector romex. Asegure la alimentación entrante con el conector

Diagramas de cableado

Análisis de fallas

Si el ventilador deja de funcionar, revise lo siguiente:

1. Consulte los diagramas eléctricos (a la derecha) para asegurar que las

2. Revise el cableado del motor, del capacitor y de la alimentación eléctrica

Sugerencias para la instalación del conducto flexible

Fantech recomienda firmemente el uso de ducto aislado flexible cuando los ductos

atraviesan espacios no acondicionados o donde el ruido sea un factor a considerar.

Consulte los requerimientos del código local antes de la instalación. Para lograr la

instalación más silenciosa posible, Fantech recomienda un mínimo de 8 pies de

conducto flexible aislado entre cualquier rejilla de admisión y el ventilador. Al montar

un conducto de tipo flexible, el mismo se debe instalar lo más apretado y recto

posible. De lo contrario, el sistema podría sufrir una importante pérdida de

rendimiento. El conducto flexible se debe conectar al ventilador con abrazaderas de

plástico tipo CB o con cinta para conductos. T

odas las conexiones deben quedar lo

más herméticas posible para lograr un máximo rendimiento.

3. Si es posible, use un comprobador para verificar la continuidad entre los

Instrucciones de mantenimiento

Puesto que los rodamientos del ventilador están sellados y provistos de

lubricante interno, no es necesario aplicarles lubricante adicional.

costado del ventilador. Todas las conexiones del motor del ventilador están

precableadas a una regleta eléctrica. Se necesitará un conector de fijación de

cables tipo romex de

3

⁄8” para sujetar el cableado a través del agujero ciego

provisto en el costado de la caja de conexiones.

del ventilador. Tenga cuidado de colocar la tuerca del conector encima del

cableado que entra a la caja de conexiones. En la regleta de conexiones hay

dos lumbreras abiertas. Con un pequeño destornillador estándar, apriete el

cable neutro (color blanco) de la alimentación eléctrica debajo de la lumbrera

marcada “N” en la regleta. Apriete el hilo de línea (negro) de la alimentación

eléctrica debajo de la lumbrera marcada “L”. Dado que el motor del ventilador

está aislado por su carcasa de plástico, no es necesario conectarlo a tierra.

romex. Vuelva a colocar la tapa de la caja de conexiones del ventilador. Todas

las conexiones del motor del ventilador y del capacitor vienen precableadas

de fábrica. No hace falta ningún cableado adicional para el ventilador.

Capacitor

Alimentación

de 115V

Tierra

Capacitor

Alimentación de

115V

Tierra

Cables

del motor

Marrón

Negro

Azul

Verde/Amarillo

conexiones se hagan correctamente.

para asegurar el debido contacto.

hilos del motor del ventilador. Para ello, se debe desconectar el capacitor.

(No pruebe el capacitor, ya que no tiene continuidad.) Si los hilos del motor

muestran continuidad, solicite a la fábrica un capacitor de repuesto.

Page 11

Tierra

Instalación de la caja de rejilla de techo con o sin luz

1. Planee la ubicación de las rejillas de admisión.

Con base en el diseño y el mobiliario del baño, planee la ubicación de las

rejillas del techo para obtener la ventilación más efectiva.

2. Fije la caja a las viguetas del techo.

CONSTRUCCIÓN NUEVA

Fije la caja directamente en la vigueta del techo con tornillos y las ranuras

de alineación. Las pestañas de ubicación en la caja deben estar a nivel con

el borde inferior de la vigueta del techo para la correcta ubicación de la

unidad una vez instalada la tablarroca. (Figura 1)

O

Utilice las barras de soporte para sujetar la caja entr

Para su colocación correcta, las barras de soporte deben colocarse a

arriba del borde inferior de la vigueta del techo en los modelos con conexión

de ducto de 4" y

15

⁄32" arriba del borde inferior de la vigueta en los modelos con

conexión con ducto de 6". En los modelos con ducto de 4", apriete los tornillos

antideslizantes para mantener las barras de soporte en su sitio. (Figura 2).

Nota: Las barras de soporte en las unidades con conexión de ducto de 4"

pueden emplearse en viguetas de techo de hasta 24" en el centro. Las

barras de soporte en las unidades con conexión de ducto de 6" abarcan

las viguetas del techo hasta una distancia de 16" desde el centro.

Nota: Si el grosor del panel de yeso o del material del techo es de más de

5

⁄8" ahora puede retirar las pestañas guías. Durante la instalación de la

tablarroca, corte un hueco para la rejilla del techo.

CONSTRUCCIÓN EXISTENTE O CUANDO LA TABLARROCA ESTÁ EN SU SITIO

Corte una orificio redondo de 6” sólo para la rejilla e instale la caja desde

el altillo. (Figura 3)

Coloque la caja contra la vigueta del techo. Para completar la instalación en

los modelos de ventilador para baño con luz, continúe con los pasos del

3 al 5. Para los modelos sin luces, vaya a los pasos 4 y 5.

Perfore los agujeros ciegos (si se van a usar) y el que corresponda al cable

eléctrico si es necesario.

Siga con los pasos 3 a 5 para continuar con la instalación de los modelos

de ventiladores para baño Premium con luces. De lo contrario, siga a los

pasos 4 y 5 para completar la instalación de los modelos sin luces

3. Efectúe las conexiones eléctricas a la caja de la rejilla de techo.

Con un destornillador, retire la tapa eléctrica del interior del gabinete de

acero. Conecte la alimentación conforme a los diagramas de cableado

(Figura 5) y cumpliendo con los códigos locales o nacionales sobre

instalaciones eléctricas. Vuelva a colocar la tapa eléctrica.

4. Conecte el ventilador a la caja de la rejilla de techo. Instale el

conducto de 4" o 6" desde el ventilador hasta la caja de la rejilla. El uso

de conducto flexible con aislamiento (recomendado para todas las

aplicaciones de ventilación de baños de Fantech) producirá un

funcionamiento más silencioso. Sujete el conducto en su lugar y séllelo. Si

se usa conducto flexible con aislamiento, selle el forro interior al conector

del conducto, a continuación selle la carcasa exterior por sobre el forro

interior. No deje al descubierto el material aislante.

5. Instalación de la bombilla. Instale la bombilla introduciéndola con

cuidado en el portabombillas dentro del gabinete de acero. Para instalar

la rejilla empújela firmemente hacia el collarín de acero hasta quedar a ras

del panel de yeso del techo (Figura 3).

Pasos adicionales necesarios cuando se instala un modelo fluorescente

encima de una bañera o ducha.

(Figura 4)

1. Coloque el aro 1 sobre el casquillo, con las patas primero.

2. Atornille la placa protectora de metal sobre el casquillo.

3. Instale la guarnición de goma.

4. Fije el aro 2 en el casquillo. El chasquido indica la instalación segura.

e las viguetas del techo.

3

⁄16"

Figura 1

Coloque las pestañas

guías al ras con el borde

inferior de la vigueta.

Figura 2

Cajas con ducto de

4": A3⁄16"

desde la

base inferior de la

vigueta. Cajas con

15

ducto de 6”:

Figura 3

Grille

Bombilla

Fluorescente

Figura 4

Tornillo

antideslizante de

seguridad en

⁄32"

modelos con

ducto de 4

"

.

Figura 4

Planca

Tornillo

Casquillo

Aro 2

Guarnición

Aro 1

Eléctrico

Repita los pasos del 1 al 5 para cada caja de rejilla de techo que se instale.

* Para obtener una operación más eficiente el adaptador en “Y” debe colocarse a

una distancia equivalente a tres diámetros del ducto del ventilador de admisión.

11

Page 12

Dimensiones de la caja

de los modelos de

conductos de 4"

73⁄16" (182.5mm)

99⁄16" (243mm)

⁄16" (134mm)

5

5

Dimensiones de la caja

de los modelos de

conductos de 6"

9 ¹¹⁄₁₆" (246mm)

8" (205mm)

6" (150mm)

5 ¹³⁄₁₆" (148mm)

9" (230mm)

⁄16" (21mm)

13

815⁄16" (227mm)

⁄16" (8mm)

5

Garantía de siete (7) años

DURANTE TODO EL PERÍODO DE GARANTÍA:

FANTECH reparará o reemplazará cualquier pieza que presente defectos de fábrica, ya sea

de manufactura o del material. Puede que sea necesario devolver el producto a la fábrica de

Fantech, junto con una copia de la factura de compra e identificado con el número de RMA

(autorización de devolución de mercancía)

PARA DEVOLUCIONES A LA FÁBRICA USTED NECESITA:

•

El número de la Autorización de Devolución de Mercancía (RMA). Para obtener el número

deberá llamar a FANTECH, ya sea en los EE. UU. al teléfono 1.800.747.1762 o en

CANADÁ al teléfono 1.800.565.3548. Tenga a mano la factura de venta.

•

El número de RMA debe indicarse claramente en el exterior de la caja, o ésta no se aceptará.

•

Todas las piezas y/o productos se repararán/reemplazarán y se devolverán al comprador. No

se emiten saldos a favor.

El Distribuidor puede hacer un pedido para la pieza y/o el producto con garantía y se le expide la

factura correspondiente. El Distribuidor recibirá un saldo acreedor equivalente a la factura únicamente

después de devolver el producto prepagado y que se haya verificado que está defectuoso.

LAS CONDICIONES DE GARANTÍA DE FANTECH NO PREVÉN EL REEMPLAZO SIN COBRO ANTES

DE LA INSPECCIÓN PARA COMPROBAR EL DEFECTO. LOS REEMPLAZOS QUE SE ENVÍEN

ANTES DE LA INSPECCIÓN DE DEFECTOS VAN ACOMPAÑADOS DE LA FACTURA Y EL CRÉDITO

QUEDA PENDIENTE DE LA INSPECCIÓN DEL MATERIAL DEVUELTO. EL DISTRIBUIDOR NO DEBE

REEMPLAZAR EL MATERIAL DEVUELTO POR LOS USUARIOS FINALES SIN EL PAGO

CORRESPONDIENTE POR PARTE DE ESTOS YA QUE EL CRÉDITO DE LA CUENTA DEL

DISTRIBUIDOR QUEDA EN ESPERA DE LA INSPECCIÓN Y VERIFICACIÓN DEL EFECTO QUE

REALICE FANTECH.

O

LAS SIGUIENTES GARANTÍAS NO PROCEDEN:

• Daños de transporte, ya sean ocultos o visibles. El reclamo se deberá hacer

ante el transportista.

• Daños causados por mal cableado o instalación.

• Daños por situaciones de fuerza mayor o como consecuencia de

procedimientos indebidos por parte del consumidor, tales como:

1. Mantenimiento inadecuado

2. Mal uso, abuso, uso anormal, accidentes, y

3. Voltaje o corriente eléctrica incorrecta.

• Desprendimiento o alteración del número de control en la etiqueta de

FANTECH, o de la fecha de manufactura.

• Cualquier otra garantía, ya sea expresa, escrita o implícita, y cualquier daño

incidental o correlativo; pérdida de bienes, ingresos, utilidades; gastos

incurridos en el desmontaje, instalación o reinstalación o cualquier

incumplimiento de garantías.

VERIFICACIÓN DE GARANTÍA

• El usuario debe guardar una copia de la Factura de Venta para verificar la

fecha de compra.

• Estas garantías le otorgan derechos legales específicos, y están sujetas a una

legislación aplicable en materia de protección del consumidor. Es posible que

usted tenga derechos adicionales que varíen de un estado a otro.

Limitación de la garantía y de la responsabilidad

Esta garantía no se aplica a ningún producto, o pieza de un producto de FANTECH INC., que haya fallado como consecuencia de una instalación defectuosa o por mal uso,

conexiones eléctricas incorrectas o alteraciones realizadas por terceros, o por usarse en condiciones de funcionamiento anormales, o en aplicaciones indebidas. No

aprobaremos el pago de ninguna reparación que no hayamos efectuado nosotros o nuestros agentes autorizados sin consentimiento previo y por escrito. Lo anterior

constituirá nuestra única y exclusiva garantía y nuestra única y exclusiva responsabilidad, y se efectúa en lugar de cualquier otra garantía, ya sea escritas, verbales,

implícitas o establecidas por ley. No existen garantías que sobrepasen la descripción en esta página. Bajo ninguna circunstancia se responsabilizará a FANTECH por daños

especiales o correlativos, ya sea como resultado de incumplimiento de contrato o de garantía, o supuesta negligencia, defecto, consejo incorrecto u otras causas,

incluyendo los siguientes pero sin limitarse a ellos, la pérdida de utilidades o ingresos, pérdida de uso de equipo o de cualquier otro equipo relacionado, costo de capital,

costo de equipo de sustitución, instalaciones o servicios, costos por tiempo de inactividad, o reclamaciones de clientes de compras por tales daños. FANTECH no asume,

ni autoriza a ninguna persona a asumir en su nombre, ninguna otra responsabilidad en relación con la venta de productos o piezas. Algunas jurisdicciones no permiten la

exclusión o límites de daños incidentales o correlativos de modo que es posible que las anteriores limitaciones y exclusiones no se apliquen a usted.

Advertencia

Los productos de FANTECH, INC. están diseñados y fabricados para proporcionar un rendimiento fiable pero no se garantiza que estén 100% libres de defectos. Aun los productos fiables

experimentan fallas ocasionales y el usuario debe reconocer esta posibilidad. Si estos productos se utilizan en un sistema de ventilación de mantenimiento de las funciones vitales en el que una

falla podría derivar en pérdidas o lesiones, el usuario debe prever el uso de un sistema de ventilación de respaldo adecuado, ventilación natural adicional, sistema de notificación de fallas, o

reconocer la aceptación de los riesgos por tal pérdida o lesión.

United States

1712 Northgate Blvd.,

Sarasota, FL. 34234

Phone: 800.747.1762;

941.309.6000

Fax: 800.487.9915; 941.309.6099

www.fantech.net; info@fantech.net

Canada

50 Kanalflakt Way,

Bouctouche, NB E4S 3M5

Phone: 800.565.3548;

506.743.9500

Fax: 877.747.8116; 506.743.9600

www.fantech.ca; info@fantech.ca

12

Fantech se reserva el derecho de modificar, en cualquier momento y sin previo aviso, todas y cada

una de las características, diseños, componentes y especificaciones de sus productos a fin de

conservar su lugar de liderazgo tecnológico.

Item #: 801008

Rev Date: 0807

Loading...

Loading...