Fantech PBW100, PBW100F, PBW100H Installation, Operation And Maintenance Manual

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

PBW Series

PREMIUM BATH FANS

Single Grille Units

4" Duct

PBW100

SEVEN-YEAR

WARRANTY

PBW100F

PBW100H

IMPORTANT: PLEASE READ THIS MANUAL BEFORE INSTALLING UNIT

WARNINGS:

WARNING! TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS –

a. Use this unit only in the manner intended by the manufacturer. If you have any questions, contact your

manufacturer's representative.

b. CAUTION: Before installation, servicing or cleaning unit, switch power off at service panel and lock the service

disconnecting means to prevent power from being switched on accidentally. When the service disconnecting

means cannot be locked, securely fasten a prominent warning device, such as tag, to the service panel.

c. Installation work and electrical wiring must be done by qualified person(s) in accordance with all applicable

codes and standards. This unit is only for use in non-fire-rated installations.

d. When cutting or drilling into wall and ceiling, do not damage electrical wiring and other hidden utilities.

e. NEVER place a switch where it can be reached from a tub or shower.

f. If this unit is installed over a tub or shower, it must be connected to a GFCI (Ground Fault Circuit Interrupter) –

protected branch circuit.

g. The combustion airflow needed for safe operation of fuel burning equipment may be affected by this unit’s

operation. Follow the heating equipment manufacturer’s guidelines and safety standards such as those

published by the National Fire Protection association (NFPA), the American Society of Heating, Refrigeration,

and Air Conditioning Engineers (ASHRAE) and the local code authorities.

h. Exhaust fans must always be vented to the outdoors.

CAUTION: "For General Ventilation Use Only. Do Not Use To Exhaust Hazardous Or Explosive Material and Vapors."

CAUTION: BULB USED IN FLUORESCENT MODELS NOT DIMMABLE

CAUTION: USE ONLY FANTECH (MODEL PBB14) FLUORESCENT BULBS AND

PAR16/MR16 GU10 50W MAX. HALOGEN BULBS (FANTECH MODEL PBB50).

DO NOT CONNECT POWER SUPPLY until unit is completely installed.

Make sure electrical service to the fan and light is locked in“OFF” position.

OBSERVE THE FOLLOWING:

Planning Your Fan Location

As with any exhaust system, your exhaust fan should be located a

minimum of 6 feet horizontally and 8 feet vertically from any fresh air

intakes to prevent re-entrainment of exhaust air streams. For example

HVAC systems, heat recovery systems, and windows would all be

considered fresh air intakes.

When planning your fan placement keep in mind that you will need to

be able to run your duct work from the exterior fan to the bathroom

inlet. Considering access for the duct run before hand will make

installation easier.

Installing Exterior Wall Fan

1. Once you have chosen the location where you wish to mount the fan,

2. Take off the fan discharge cover by removing the four screws. Center

3. Bring your electrical supply through the wall. Attach the fan collar to

4. Mount the fan to the wall. Replace the discharge cover. Connect your

3

cut a 4

/8" diameter hole in the exterior of the wall. Prepare a piece

of rigid duct (purchase separately) approximately 2" longer than the

wall thickness. This will be used as a collar extension placed through

the wall.

the fan in the hole that was cut into the wall. Mark the locations of

the mounting holes and electrical knockout. Drill a hole for the

electrical that is

1

/8" larger than the conduit being used. A 1"

electrical service opening is provided on the fan backplate.

NOTE: When mounting the fan to a masonry wall, drill

7

/32" holes for

the four anchors and mounting screws (provided). Anchors should be

flush with the edge of the holes. For mounting to wood surfaces use

wood screws (purchased separately).

the extension collar using duct tape. Be sure this connection is as

airtight as possible to prevent leakage. Apply polyurethane caulk to

the exterior of fan housing backplate, leaving bottom uncaulked for

drainage. This will ensure an airtight/waterproof connection between

the fan and wall.

NOTE: If installing on lapped siding it may be necessary to use a

mounting frame made from 1x1 board to insure a flush fit.

ducting to the extension collar using plastic ties or duct tape

(purchased separately).

FINAL INSTALLATION NOTE: If fan location

is not protected by an eve, a standard

flashing should be installed. Seal against

the wall and upper edge of the fan

discharge cover to prevent rain water

from entering fan housing.

Fantech recommends insulated flexible

duct for all bathroom exhaust applications.

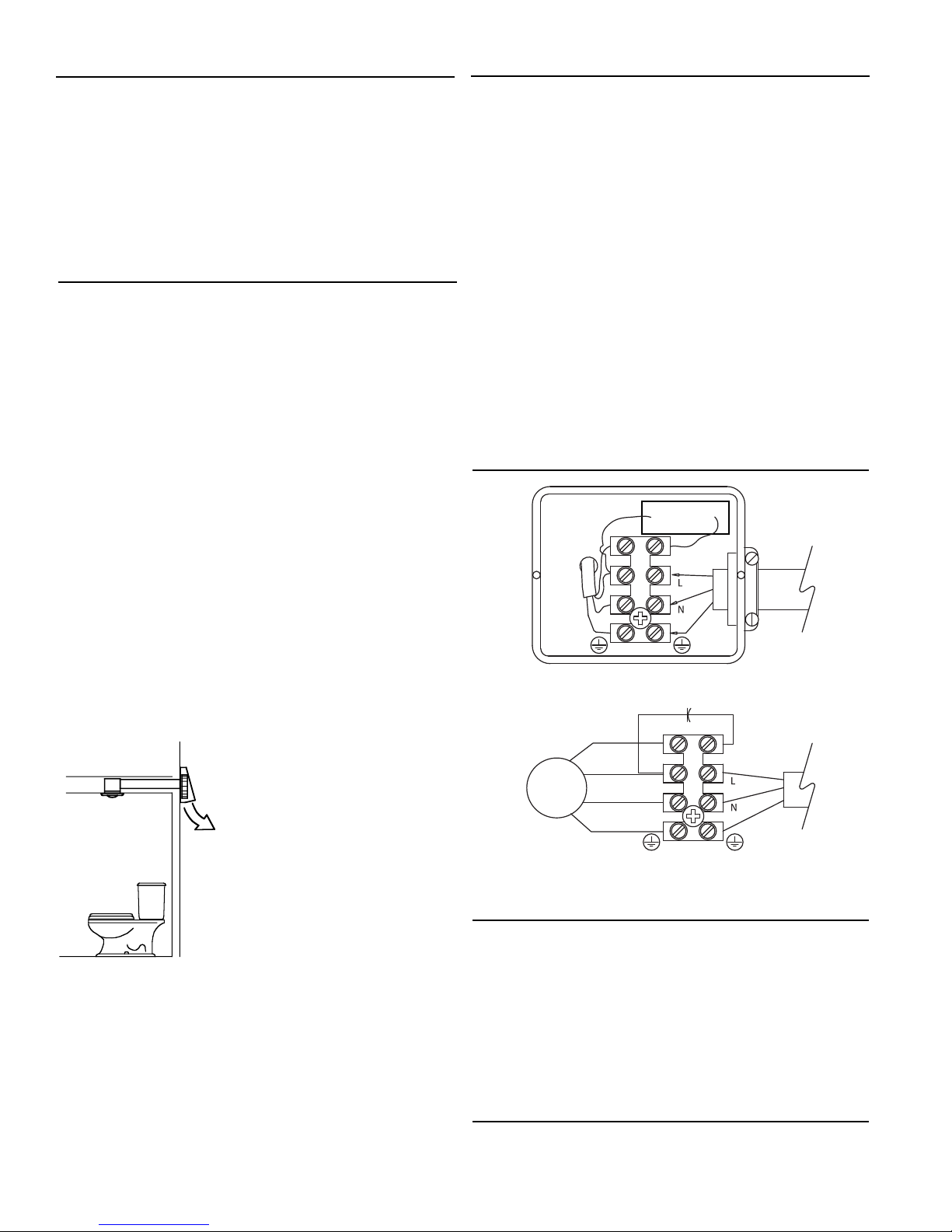

Electrical Connection

1. Remove the screws securing the terminal box cover located on the

fan motor mounting bracket. All fan motor and capacitor connections

are pre-wired to an electrical terminal strip. A

3

⁄8" romex type cable

restraint connector will be needed to secure the wiring through the

knockout on the side of the terminal box.

2. Bring incoming electrical service through the romex connector and the

fan electrical service opening. Be sure to place the connector nut over

the wiring coming into the terminal box. There are two open ports on

the terminal strip. Using a small regular screwdriver, tighten the neutral

(white) wire of the incoming supply under the open terminal strip port

labeled “N”. Tighten the line (black) wire of the incoming supply under

the open terminal strip port labeled “L” to the ground connection on the

terminal block.

3. Secure the romex connector. Secure the incoming supply with the

romex connector. Place the capacitor back into the terminal box.

Replace the fan terminal box cover.

All fan motor and capacitor connections have been pre-wired from

the factory. No additional fan wiring is necessary.

Wiring Diagrams

Capacitor

115V

Supply

Ground

Capacitor

Ground

115V

Supply

Motor

Leads

Brown

Black

Blue

Green/Yellow

Flexible Duct Installation Hints

Fantech strongly recommends the use of flexible insulated duct where

ducting passes through unconditioned space or where noise is a factor.

Check local code requirements before installing. Failure to use insulated

flexible duct could result in excessive condensation buildup within the

duct, and undesirable sound levels within the room.

A minimum of 8' of insulated flexible duct is recommended between

the fan and any inlet grille. Duct should be stretched as tight and straight

as possible. Failure to do so could result in dramatic loss of system

performance. Connect flex duct to the fan with plastic zip ties or duct tape.

Connections should be airtight as possible for maximize performance.

Troubleshooting

If fan fails to operate, please check the following:

1. Consult wiring diagrams (above) to ensure proper connection.

2. Check motor lead wiring, capacitor leads and incoming supply leads

to insure definite contact.

3. If possible, use a meter to test for continuity across the fan motor

leads. In order to do this, the capacitor must be disconnected (do

not test the capacitor - it will not meter continuity). If motor leads

show continuity, consult factory for a replacement capacitor.

Maintenance Instructions

Since fan bearings are sealed and provided with an internal lubricating

material, no additional lubrication is necessary.

Loading...

Loading...