Fann Rheovadr User Manual

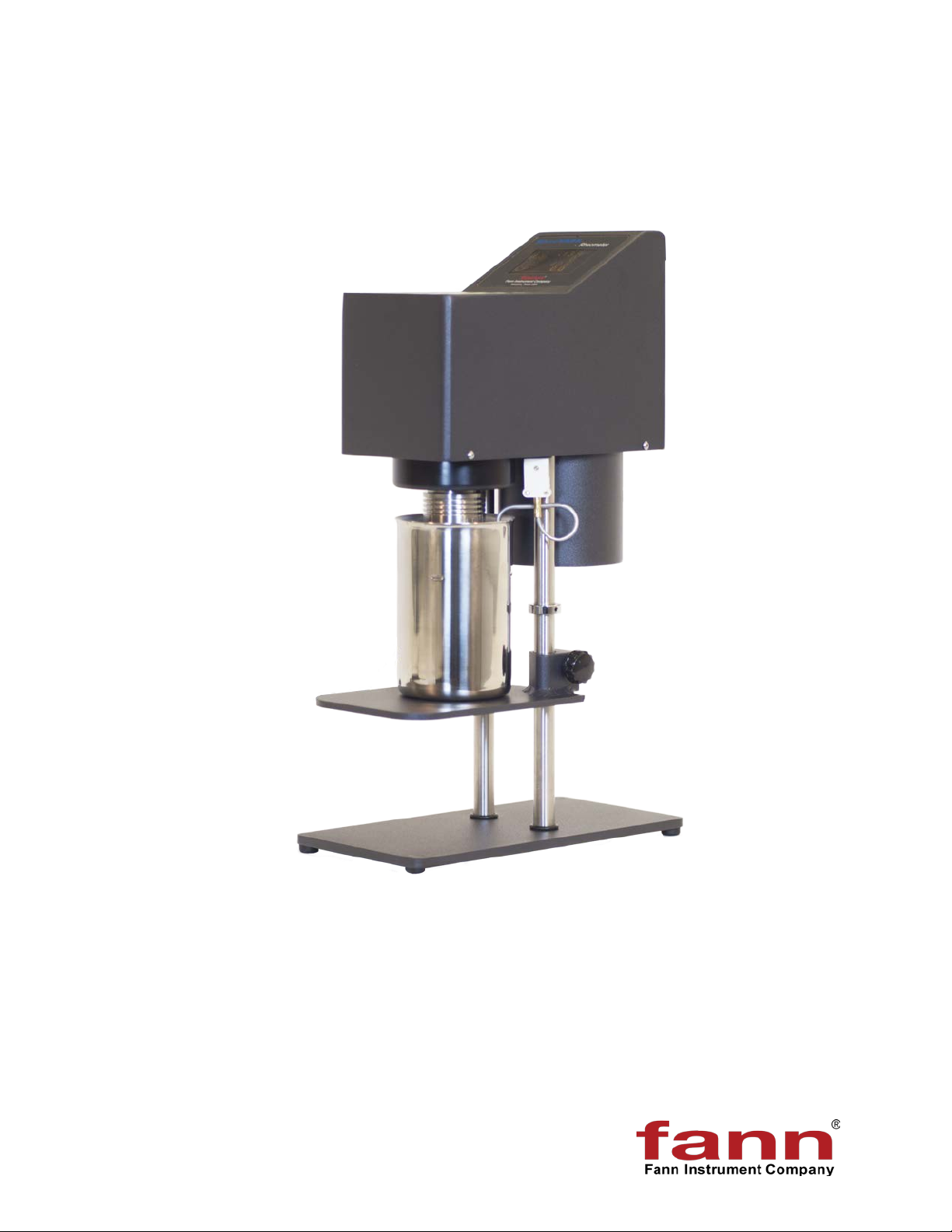

RheoVADR™ Rheometer

Instruction Manual

Manual No. D00845847, Revision A

Instrument No. 102267855

RheoVADR™ Rheometer Instruction Manual

©2014 Fann Instrument Company

Houston, Texas, USA

All rights reserved. No part of this work covered by the copyright hereon may be reproduced or

copied in any form or by any means (graphic, electronic, or mechanical) without first receiving the

written permission of Fann Instrument Company, Houston, Texas, USA.

Printed in USA.

The information contained in this document includes concepts, methods, and apparatus which may be

covered by U.S. Patents. Fann Instrument Company reserves the right to make improvements in

design, construction, and appearance of our products without prior notice.

®

FANN

States and/or other countries. All other trademarks mentioned in the operating instructions are the

exclusive property of the respective manufacturers.

and the FANN logo are registered trademarks of Fann Instrument Company in the United

Contact FANN

Phone

TELEPHONE: 281-871-4482

TOLL FREE: 800-347-0450

FAX: 281-871-4358

Mail

Fann Instrument Company

P.O. Box 4350

Houston, Texas, 77210 USA

Location

Fann Instrument Company

14851 Milner Road, Gate 5

Houston, Texas, 77032, USA

Online

www.fann.com

fannmail@fann.com

D00845847 Revision A, January 2014 2

RheoVADR™ Rheometer Instruction Manual

Table of Contents

1 Introduction .............................................................................................................. 5

1.1 Document Conventions .................................................................................... 5

2 Safety ....................................................................................................................... 7

2.1 Safe Electrical Operation .................................................................................. 7

2.2 Heated Sample Cup ......................................................................................... 7

3 Features and Specifications ..................................................................................... 8

4 Installation .............................................................................................................. 11

5 Operation ............................................................................................................... 12

5.1 Instrument Start-up ........................................................................................ 14

5.2 Manual Operating Instructions ........................................................................ 16

5.3 API Test Profile .............................................................................................. 18

5.4 Set-up Mode .................................................................................................. 22

6 Troubleshooting and Maintenance ......................................................................... 26

7 Accessories ............................................................................................................ 27

8 Parts List ................................................................................................................ 28

9 Warranty and Returns ............................................................................................ 31

9.1 Warranty ........................................................................................................ 31

9.2 Returns .......................................................................................................... 31

D00845847 Revision A, January 2014 3

RheoVADR

™

Rheometer Instruction Manual

List of Figures

Figure 3-1 RheoVADR™ Rheometer (front and back) ...................................................... 8

Figure 5-1 RheoVADR

Figure 5-2 Start Up Message ........................................................................................ 14

Figure 5-3 System Information ...................................................................................... 14

Figure 5-4 Data Display ................................................................................................ 15

Figure 5-5 API Test Profiles (pages 1 and 2) ................................................................ 18

Figure 5-6 Data Display in API Test Mode .................................................................... 19

Figure 5-7 SETUP Mode (page 1) ................................................................................ 22

Figure 5-8 SETUP Mode (page 2) ................................................................................ 22

Figure 5-9 Select Calibration......................................................................................... 24

Figure 5-10 Fluid Calibration ......................................................................................... 24

Figure 8-1 RheoVADR

™

Rheometer Keypad ................................................................ 12

™

Rheometer Assembly ............................................................. 30

List of Tables

Table 3-1 RheoVADR

Table 3-2 Rotor and Bob Dimensions .......................................................................... 10

Table 3-3 Rotor-Bob Specifications............................................................................... 10

Table 3-4 Range of Environmental Conditions .............................................................. 10

Table 5-1 RheoVADR

Table 5-2 API Six Speed & Gel .................................................................................... 19

Table 5-3 API PV/YP & Gel......................................................................................... 20

Table 5-4 API Gel ........................................................................................................ 20

Table 5-5 API Cement .................................................................................................. 21

Table 7-1 Accessories for RheoVADR

Table 8-1 RheoVADR

™

Rheometer, P/N 102267855 Specifications ............................... 9

™

Keypad Functions .................................................................... 13

™

Rheometer ..................................................... 27

™

Rheometer, P/N 102267855, Revision B ................................. 28

D00845847 Revision A, January 2014 4

RheoVADR

1 Introduction

The RheoVADR™ Variable Automated Digital Rheometer is the latest addition to

the Fann viscometer family. RheoVADR™ is a direct-reading instrument for

evaluating the rheological properties of fluids, Newtonian and non-Newtonian. The

advantages of the RheoVADR™ are its digital display, pre-programmed API tests,

data recording feature, and speed range — 12 preset and variable speeds from 0.01

rpm to 999 rpm.

This design includes a R1 Rotor Sleeve, B1 Bob, F1 Torsion Spring, and a stainless

steel sample cup for testing according to American Petroleum Institute

Recommended Practice for Field Testing Water Based Drilling Fluids, API RP

13B-1/ISO 10414-1 Specification. This instrument is also fitted for universal power

supply.

1.1 Document Conventions

™

Rheometer Instruction Manual

The following icons are used as necessary in this instruction manual.

NOTE. Notes emphasize additional information that may be

useful to the reader.

CAUTION. Describes a situation or practice that requires operator

awareness or action in order to avoid undesirable consequences.

MAN D AT O R Y AC TION . Gives directions that, if not observed,

could result in loss of data or in damage to equipment.

WARNING! Describes an unsafe condition or practice that if not

corrected, could result in personal injury or threat to health.

D00845847 Revision A, January 2014 5

RheoVADR

ELECTRICITY WARNING! Alert s t he operator that there is risk of

electric shock.

™

Rheometer Instruction Manual

HOT SURFACE! Alerts the operator that there is a hot surface and

that there is risk of getting burned if the surface is touched.

EXPLOSION RISK! Alerts the operator that there is risk of

explosion.

D00845847 Revision A, January 2014 6

RheoVADR™ Rheometer Instruction Manual

2 Safety

Safe laboratory practices and procedures should be observed while operating and

maintaining the RheoVADR™ Rheometer. This section lists some precautions to

follow.

2.1 Safe Electrical Operat i on

This instrument is driven by 100V to 240V, 50/60 Hz electrical power. Heated

sample cups and recirculating sample cups (optional) are electrically heated.

Make sure the power and other wiring associated with this rheometer and

electrically heated sample cups are in good condition and properly grounded.

Make sure the rheometer’s power switch is in the OFF position and

unplugged from the source before cleaning, repairing or performing

maintenance.

Keep hands, clothes and other objects away from the rotating parts of the machine.

2.2 Heated Sample Cup

When using the heated sample cups, wear the proper hand

protection to avoid getting burned.

When using heated sample cups, do NOT exceed 200oF (93oF).

D00845847 Revision A, January 2014 7

RheoVADR

3 Features and Specifications

RheoVADR™ Rheometer comes with the standard R1 rotor sleeve, B1 bob, F1

torsion spring, and a stainless steel sample cup. Its features include the following:

• Preprogrammed API tests— API drilling fluid and API cement

• Data recording at 100, 200, 500 milliseconds, and at 1, 5, 10 sec for observing

trends and analyzing, sharing, printing, or downloading data

• USB port for connecting a flash drive to save test data (CSV) that can be read

in a spreadsheet program

• Resistance Temperature Detector (RTD) for 0.5°F accuracy and repeatability

• Secure fit, left-hand turn for rotor and right-hand turn for bob to help prevent

disconnection when measuring high viscosity fluids

• LED display for high-contrast , making it easier to read

• LED-lighted sample cup for dimly lit locations

™

Rheometer Instruction Manual

• Pushbutton design for easier operation

• RS485 serial connector for connecting to a computer and instantaneous

control software (optional)

Figure 3-1 RheoVADR™ Rheometer (front and back)

D00845847 Revision A, January 2014 8

RheoVADR

™

Rheometer Instruction Manual

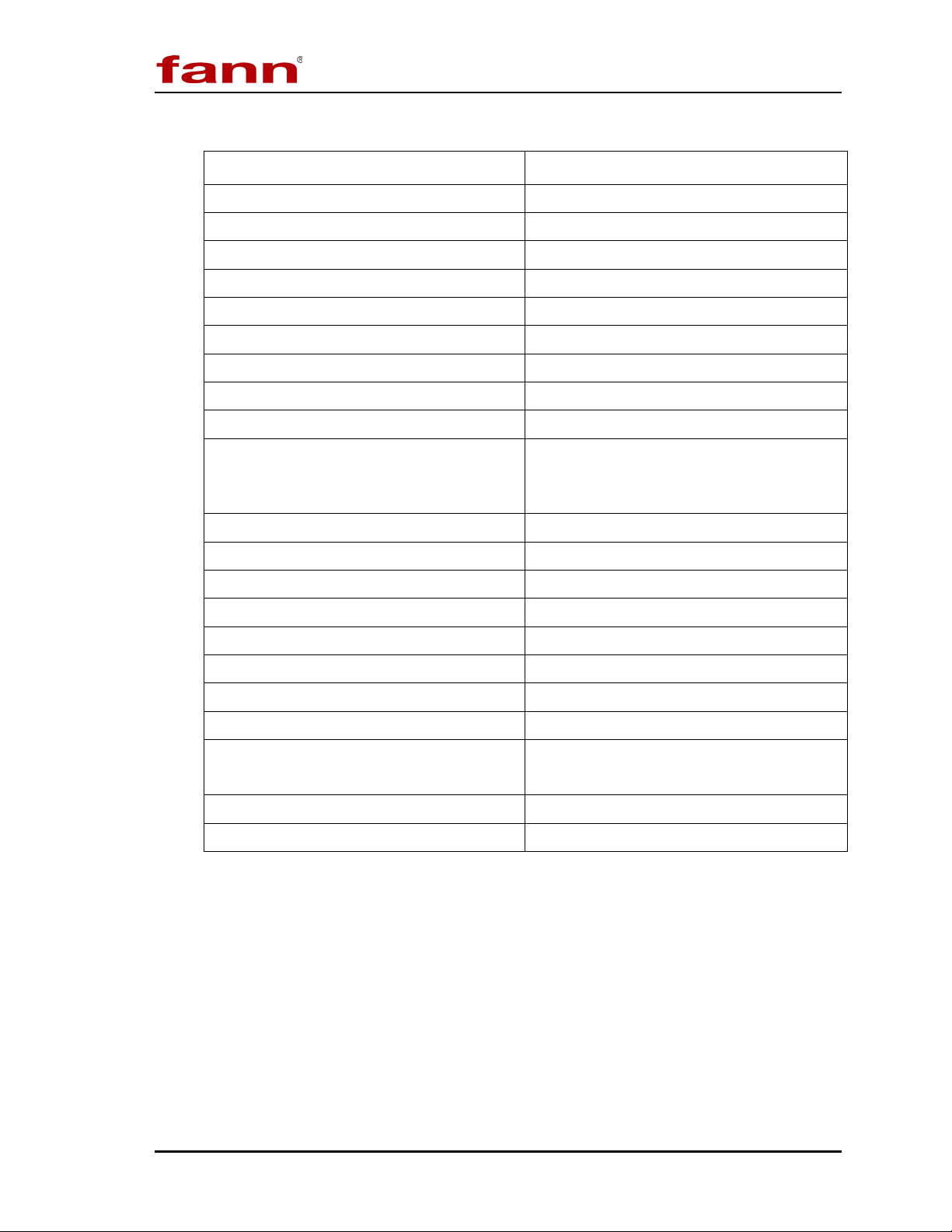

Table 3-1 RheoVADR™ Rheometer, P/N 102267855 Specifications

Category Specification

Torsion Spring F1

Rotor - Bob R1, B1

Operating Temperature Range 40°F to 125°F (4.44°C to 51.7°C)

Automatic Tests 4 Pre-programmed API tests

Multiple units on 1 computer Up to 8 units

Sample Cup Volume 350 ml

Sample Temperature 200°F (93°C)

Temperature Measurements RTD

Tempe rature Accuracy 0.5°F

Variable 0.01 to 999 rpm

Speed Range

12 Preset: 600, 300, 200, 100, 60, 30,

20, 10, 6, 3, 2, 1

Speed Accuracy 0.001 rpm

Shear Rate 0.01 sec

-1

to 1700 sec-1

Dial Resolution 0.1

Dial Accuracy 0.5

cP Range (R1-B1-F1) 0.1 to 9M (displays 9999 cP max)

Ports Power, RS485 Serial, USB

Data Port USB Flash Drive

Data Recording Speeds (intervals) 100, 200 & 500 ms; 1, 5, & 10 sec

16 x 5 x 9.5 inches

Dimensions

40.6 x 12.7 x 24 centimeters

Weight 15 lb (6.8 kg)

Power Requirement 100V to 250V, AC, 50/60 Hz , 75W

D00845847 Revision A, January 2014 9

RheoVADR

(cm)

(cm)

n/a

80% RH at 87.8oF (31oC) or less

50% RH at 104oF (40oC)

™

Rheometer Instruction Manual

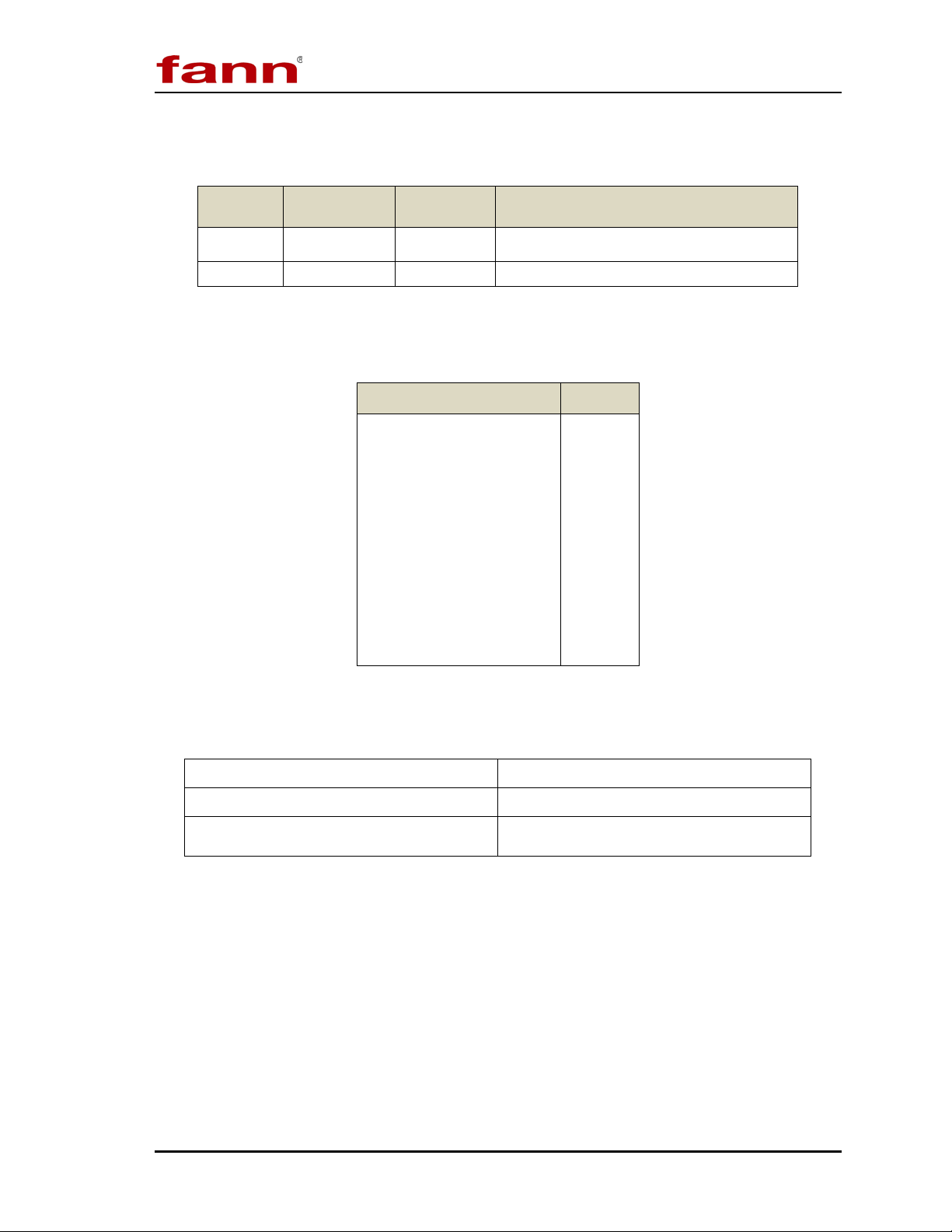

Table 3-2 Rotor and Bob Dimensions

Unit

Radius

B1 1.7245

R1 1.8415

Length

3.8

Cylinder Area (cm2) x Radius (cm)

71.005

Table 3-3 Rotor-Bob Specifications

ROTOR-BOB R1 B1

Rotor Radius, R0 (cm) 1.8415

Bob Radius, Ri (cm) 1.7245

Bob Height, L (cm) 3.8

Shear Gap in Annulus

(cm)

0.117

Radii Ratio, Ri /R0 0.9365

Maximum Use

Tempe rature (

Minimum Use

Tempe rature (

o

o

C)

C)

93

0

n/a

Table 3-4 Range of Environmental Conditions

Maximum Altitude

Temperature Range

6562 ft (2000 m)

o

F to 104oF (5oC to 40oC)

41

Maximum Relative Humidity (RH)

D00845847 Revision A, January 2014 10

Loading...

Loading...