Page 1

Instructions for DuraTech Series SRL’s

Warning!

THE USER OF THIS EQUIPMENT, AND THE USER’S EMPLOYER MUST READ AND

COMPLY WITH THESE INSTRUCTIONS. FURTHERMORE, THE USER AND THE

USER’S EMPOLYER MUST READ AND COMPLY WITH ALL INSTRUCTIONS, LABELS

WARNINGS AND MARKINGS INCLUDED WITH EACH COMPONENT OF THE FALL

ARREST SYSTEM OF WHICH THIS PRODUCT IS A PART. FAILURE TO

UNDERSTAND AND COMPLY WITH THESE INSTRUCTIONS CAN RESULT IN

SERIOUS INJURY OR DEATH.

IF THESE INSTRUCTIONS ARE UNCLEAR TO YOU, PLEASE CONSULT A

COMPETENT PERSON. SHOULD THESE INSTRUCTIONS BECOME LOST OR

DAMAGED, OR SHOULD AND LABELS, INSTRUCTIONS OR MARKINGS BECOME

ILLEGIBLE, PLEASE CONTACT FALLTECH FOR REPLACEMENTS. SHOULD YOU

NEED FURTHER ASSISTANCE WITH UNDERSTANDING THE PROPER

EMPLOYMENT OF THIS PRODUCT, PLEASE CONTACT FALLTECH FOR

ASSISTANCE:

Alexander Andrew, Inc. (dba FallTech)

1306 South Alameda Street

Compton, CA 90221, USA

1-800-719-4619

1-323-752-0066

www.falltech.com

FallTech DuraTech Series SRL’s

Model # Description Cable

Type

7226 15’ DuraTech SRL Galvanized Alloy Steel 310 lbs Y

7226HW 15’ Heavyweight SRL Galvanized Alloy Steel 400 lbs Y

7226S 15’ DuraTech SRL Stainless Alloy Steel 310 lbs Y

7226SS 15’ DuraTech SRL Stainless Stainless 310 lbs N

7227 20’ DuraTech SRL Galvanized Alloy Steel 310 lbs Y

7227HW 20’ Heavyweight SRL Galvanized Alloy Steel 400 lbs Y

7227S 20’ DuraTech SRL Stainless Alloy Steel 310 lbs Y

7227SS 20’ DuraTech SRL Galvanized Alloy Steel 310 lbs N

7229 25’ DuraTech SRL Galvanized Alloy Steel 310 lbs Y

7229S 25’ DuraTech SRL Stainless Alloy Steel 310 lbs Y

7232 30’ DuraTech SRL Galvanized Alloy Steel 310 lbs Y

7232HW 30’ Heavyweight SRL Galvanized Alloy Steel 400 lbs Y

7232S 30’ DuraTech SRL Stainless Alloy Steel 310 lbs Y

7232SS 30’ DuraTech SRL Stainless Stainless 310 lbs N

7232SSHW 30’ Heavyweight SRL Stainless Stainless 400 lbs N

7265 60’ DuraTech SRL Galvanized Alloy Steel 310 lbs Y

7265HW 60’ Heavyweight SRL Galvanized Alloy Steel 400 lbs Y

7267 40’ DuraTech SRL Galvanized Alloy Steel 310 lbs Y

7267S 40’ DuraTech SRL Stainless Alloy Steel 310 lbs Y

7268 60’ DuraTech SRL Galvanized Alloy Steel 310 lbs Y

7268HW 50’ Heavyweight SRL Galvanized Alloy Steel 400 lbs Y

7268S 50’ DuraTech SRL Stainless Alloy Steel 310 lbs Y

7268SS 50’ DuraTech SRL Stainless Stainless 310 lbs N

72687447 50’ DuraTech SRL Galvanized Alloy Steel 310 lbs Y

72688448 50’ DuraTech SRL Galvanized Alloy Steel 310 lbs Y

7266 60’ DuraTech SRL Galvanized Alloy Steel 310 lbs Y

7266SS 60’ DuraTech SRL Stainless Stainless 310 lbs N

726575 75’ DuraTech SRL Galvanized Alloy Steel 310 lbs Y

726575SS 75’ DuraTech SRL Stainless Stainless 310 lbs N

7211 98’ DuraTech SRL Galvanized Alloy Steel 310 lbs Y

7211S 98’ DuraTech SRL Stainless Alloy Steel 310 lbs Y

7212 138’ DuraTech SRL Galvanized Alloy Steel 310 lbs Y

7212S 138’ DuraTech SRL Galvanized Alloy Steel 310 lbs Y

7212145 145’ DuraTech SRL Galvanized Alloy Steel 310 lbs Y

7212195 195’ DuraTech SRL Galvanized Alloy Steel 310 lbs Y

7213S 195’ DuraTech SRL Stainless Alloy Steel 310 lbs Y

7279 10’ DuraTech SRL Galvanized Alloy Steel 310 lbs Y

7285 60’ DuraTech SRL Galvanized Alloy Steel 310 lbs Y

7285S 60’ DuraTech SRL Stainless Alloy Steel 310 lbs Y

7285SS 60’ DuraTech SRL Stainless Stainless 310 lbs N

7287 82’ DuraTech SRL Galvanized Alloy Steel 310 lbs Y

7287S 82’ DuraTech SRL Stainless Alloy Steel 310 lbs Y

7288 138’ DuraTech SRL Galvanized Alloy Steel 310 lbs Y

7285S 138’ DuraTech SRL Stainless Alloy Steel 310 lbs N

Connector

Type

Max.

Capacity

3,600 lb.

Gate

1

2

Page 2

Table of Contents

Section 1: Warnings and Advisories

Section 2: Fall Protection Basics – ABCD’s

2.1: Anchorage

2.2: Body wear

2.3: Connectors/Connecting devices

2.4: Deceleration devices

2.5: Fall Arrest

2.6: Fall Restraint

2.7: Work Positioning

2.8: Free-fall

2.9: Clear-fall

2.10: Swing-fall

Section 3: Use and Limitations

3.1: General Guidelines

3.2: Approved applications

3.3: Restricted Applications

3.4: Installation and use

Section 4: Product Selection

Section 5: Anchorage Considerations

Section 6: Employer and User Training

6.1: Special notes for the employer

6.2: User training

Section 7: Fall Protection Plan

7.1: The fall protection plan

7.2: Suspension trauma

7.3: Rescue plan

Section 8: Product Inspection

8.1: Issuing

8.2: Daily/Incidental use

8.3: Mandatory semi-annual inspection

Section 9: Maintenance and Storage

Section 10: Specifications

10.1: Mandatory disclosures

10.2: Performance specifications

10.3: Labels and markings

10.4: Standards and references

Section 1: Warnings and Advisories

This product is to be used as a part of a personal fall arrest system,

and should be used only with compatible components. Please see

Advisory #3 in this section for further details. Failure to use

compatible components can result in a failure of the system to

perform as intended, which may result in serious injury or death.

Throughout the OSHA regulations for safety and health, there are

references to Competent Persons and Qualified Persons. ANSI

Z359.0-2007 goes on to further define the roles and qualifications of

these individuals; as well as Authorized Persons and their

importance in the workplace. These terms are also used in these

instructions. Below is a brief description of the part these

individuals play in the employment of fall protection equipment:

Authorized Person - a person who is exposed to fall hazards during

the course of their work. This individual requires formal training in

the use of personal fall protection equipment and systems.

Competent Person – a trained and experienced person who is

designated to supervise, implement and monitor an employer’s

managed fall protection program. This individual is capable of

identifying and addressing fall hazards and is authorized to make

decisions and take corrective action in the workplace.

Qualified Person – a person possessing a degree or professional

certificate and having extensive training, knowledge and experience

with fall protection and who is capable of designing and specifying

fall protection equipment and systems to address fall hazards.

Please read these instructions and be sure that you understand

them prior to utilizing this equipment. Also be sure to read the

instructions included with other components which are being

utilized in your Personal Fall Arrest System (Harnesses,

connectors, anchorage connectors, etc.). Failure to understand and

comply with manufacturer’s instructions may result in serious

injury or death.

IF YOU DO NOT UNDERSTAND ANY PART OF THESE

INSTRUCTIONS, PLEASE HAVE THEM EXPLAINED TO YOU BY A

COMPETENT PERSON OR EXPERIENCED SUPERVISOR OR

FOREMAN.

3

4

Page 3

This product is to be used as part of a complete fall arrest system in

accordance with industry-recognized best-practices and your

employer’s fall protection plan, as required by the Occupational

Health and Safety Administration. Be aware of your employer’s fall

protection plan and rescue plan. Be aware of the specific fall

hazards on your jobsite and work deliberately to avoid these

hazards in the course of your work. Also be aware of hazards and

obstructions in your fall path, and work with your employer to

eliminate these hazards where possible. Failure to be aware of and

to address these hazards may result in serious injury or death.

Do’s and Don’ts

Do use this device only with compatible components of a

comprehensive fall arrest system.

Do use this device only in a system which limits free fall distance

to 5 ft or less.

Do use extreme caution when rigging this device.

Do rig this device to avoid the hazards of “swing fall” (see

Section 2.9)

Do inspect the entire lifeline of the SRL for cuts, abrasions,

kinks, wear, or other damage.

Do wear gloves when handling wire rope.

Do inspect the load indicating swivel snap hook for the red fall

indicator band.

Do use this device only when your clearance distance is a

minimum of 2 ft AFTER you have calculated the total fall

distance (see section 2.8 for details on clear fall distances).

Do check the brake mechanism by “hand locking” the device

before each use. Pull out 4 ft of line from the SRL and give a

swift pull to activate the brake. Then allow the line to retract

SLOWLY back into housing.

Do make compatible connections (see Advisory #3 at the end of

this Section).

Do use a tagline, if the SRL is remotely mounted, to access

cable and control the retraction speed of cable after use (see

Section 7)

Do call FallTech if the device is damaged, does not pass

inspection (see Section 6), or has arrested a fall.

Don’t use this device as a load arrestor when hoisting materials

or equipment.

5

Don’t use this device if it has been exposed to corrosion,

chemicals, excessive heat, flames, or electrical charge or shows

signs of any physical damage or deformation.

Don’t allow the lifeline to wrap around your body. Severe injury

or death could result.

Don’t loop the lifeline under an arm or leg, turn toward the SRL

and walk toward the SRL. If a fall should occur while the line is

under an arm or leg, severe injury may result.

Don’t move too quickly when using this device. The brake may

activate and cause the loss of footing or a fall.

Don’t leave lifeline exposed when the device is not in use.

Retract lifeline fully into the housing using a tagline when needed

Don’t use oil on the carabiner or any part of the device, except

the cable. If needed, use only 100% silicone lubricant for the

load indicating swivel snap hook.

Don’t use any type of cable in this device if you are working near

high voltage power lines or other energized electrical equipment.

Extreme caution must be taken when working under these

conditions, even when equipped with a FallTech approved hightech rope

Don’t use this device if you are pregnant, a minor, or have a

reduced tolerance to fall forces by reason of age, physical

medical condition, or other pre-existing disorders.

Don’t use this device if you weigh less than 75 lbs.

Don’t use this device if your total combined weight (body,

clothes, tools, etc) exceeds 310 lbs. Model #’s ending in HW

are approved for a maximum capacity of 400 lbs.

Don’t release the lifeline allowing it to “free wheel” (see Section

7) or retract back uncontrolled into the device.

Don’t attempt to open, repair or alter this device in any way

unless trained and certified to do so by FallTech.

Don’t knot, clamp, or rig lifeline in any fashion as to inhibit its

automatic retraction function.

Don’t use the device if it does not lock or retract automatically.

Don’t use this SRL with the cable fully extended. This product

has a red coating on the cable. If this red cover is exposed, then

your operating at the maximum allowable extension of the cable.

DO NOT ATTEMPT TO PULL ADDITIONAL CABLE OUT OF

THE UNIT!

Advisory #1: Further Reading

If you have access to the internet, please go to www.osha.gov.

This website is an exceptional resource, and has a great deal of

information which is easy to access. Use the search field to find

information on fall arrest, including standards, news,

6

Page 4

interpretations and other valuable tools. The more you know about

how this product works and how it is supposed to be used, the

safer you will be during the course of your work.

Advisory #2: Proper product selection

Product selection is an important element of fall protection. Fall

Arrest products are like any other tools that you may use in the

course of your work – there is a proper tool for every application.

You may find that while this product is suitable for some

applications, it may not be suitable for others. Please be sure to

pay close attention to sections 2, 3, and 4, for greater detail on this

point.

Advisory #3: Connector Compatibility

Making compatible connections may mean the difference

between life and death. Connectors (snap hooks, rebar hooks and

carabiners), must be of the locking type and require two distinct

actions to open the gate. Your connectors must be sized and

shaped so that the rings or structural members to which they are

attached will not pose a risk of forcing the gate open, and must fully

captivate the connector so that it cannot become disengaged, slide

or shift during use or in the event of a fall.

Certain connections are forbidden and should never be

attempted with this product or any other unless there is a specific

allowance in the manufacturer’s instructions. Forbidden

connections include, but are not limited to:

Two or more connectors to one d-ring are a forbidden

connection.

A connection that rests on or loads the gate is a forbidden

connection.

A connection that does not allow the gate to clos e and lock

is a forbidden connection.

Two or more connectors attached to one another are a

forbidden connection.

Connecting directly to webbing, rope, cable (wire rope) is a

forbidden connection.

Connecting directly to a horizontal lifeline is a forbidden

connection.

Tie-back with your FallTech DuraTech Series SRL is a

forbidden connection.

Connecting to any ring or structure that does not fully

captivate and completely restrict the movement your

connector is a forbidden connection.

Section 2: ABCD’s

Every Personal Fall Arrest System consists of four basic elements –

Anchorage, Body-wear, Connectors/Connecting Devices and

Deceleration Devices. Each of these four elements is discussed in

greater detail below. If, after reading though this section, you do not fully

understand these items and how they work together to form a compatible

fall arrest system, please be sure to have this explained to you by a

Competent Person.

It is absolutely critical that you be familiar with the proper wear and/or

use of each component of your Personal Fall Arrest System (PFAS).

Failure to read, understand and adhere to instructional materials and

warnings provided with each of these components could lead to

catastrophic failure of your PFAS, possibly resulting in serious injury or

death.

2.1: Anchorage

The selection of an anchor point and anchorage connector is critical

to the successful function of any Personal Fall Arrest System (PFAS).

OSHA 1926.502 (d) (15) states that:

“Anchorages used for attachment of personal fall arrest equipment shall

be independent of any anchorage being used to support or suspend

platforms and capable of supporting at least 5,000 pounds (22.2 kN) per

employee attached, or shall be designed, installed, and used as follows:

as part of a complete personal fall arrest system which maintains a

safety factor of at least two; and under the supervision of a qualified

person.”

Ensure that the structure to which you are attaching your anchorage

connector is capable of meeting the above requirements and that your

anchorage connector is installed in accordance with the manufacturer’s

instructions. Also be sure to check that the anchorage connector is

compatible with your FallTech DuraTech SRL and that it securely retains

the SRL without inhibiting its function. If you are unable to determine

whether your SRL and your anchorage are compatible, please

immediately consult with a competent person or your immediate

7

8

Page 5

supervisor. For more details on anchorages, please see section 5 of this

instruction manual.

2.2: Body-wear

Body wear for any application where this SRL is to be used will be

defined as a full body harness specifically manufactured for fall arrest.

This SRL should only be attached to the back d-ring of your full body

harness for fall arrest applications. The only allowable exception would

be in situations where the free fall is limited to an absolute maximum of

two feet – in this case, the attachment-end carabiner may be connected

to the front d-ring of a full body harness that is so equipped. Under no

circumstances should the SRL ever be attached to a side or hip d-ring:

Such a connection could cause serious injury or death. Be sure to read

and follow the manufacturer’s instructions included with your full body

harness at the time of purchase.

2.3: Connectors/Connecting Devices

Connectors and Connecting Devices are terms that are sometimes

used interchangeably. It is important to note the differences between

these two terms in order to help distinguish the parts that these

components play in the rigging of your PFAS. In both cases, these

products/components are required to have a minimum static strength of

5,000 lbs. For additional details on requirements for connectors and

connecting devices, see OSHA 1926.502 at www.osha.gov as

referenced in section 1, advisory #1.

A connector is any metallic, mechanical element such as a

carabiner, snap hook or rebar hook that physically links one or more

elements of a your PFAS together in a manner such that they will remain

engaged to one another unless they are intentionally disengaged.

A connecting device is an element that connects your full body

harness to the anchorage in an effort to ensure that you remain attached

or tethered to the structure upon which you are working. In other words,

the connecting device is that element which secures you to your

anchorage.

2.4: Deceleration Devices

A deceleration device is the element of a Personal Fall Arrest

System (PFAS) which is activated during a fall event and reduces the

forces exerted on the user’s body and on the anchorage during the arrest

of the fall. In the case of your FallTech DuraTech SRL, this product is

both a connecting device and a deceleration device as it will keep you

attached to your anchorage and will reduce the forces on your body in

the event of a fall. For more details on the capabilities and specifications

of your FallTech DuraTech SRL, please see section 10 of this instruction

manual.

2.5: Fall Arrest

Fall Arrest is an area of Fall Protection which focuses on stopping a

fall once it has occurred. Personal Fall Arrest Systems typically consist

of an anchorage, a full body harness and a self-retracting lifeline, shockabsorbing lanyard or other deceleration device designed to bring a falling

user to a stop in the shortest possible distance while limiting the force

imparted to the user’s body.

2.6: Fall Restraint

Fall Restraint is an area of Fall Protection devoted to restraining the

user of the system in a manner which restricts his or her access to the

fall hazard in a manner such that they cannot be subjected to a fall. A

typical Fall Restraint System consists of an anchorage, a full body

harness or a restraint belt and a restraint lanyard. An SRL should never

be utilized in a restraint application as it is not capable of restricting a

user’s access to fall hazards.

2.7: Work Positioning

Work Positioning is an area of Fall Protection devoted to allowing a

user to work on a vertical surface by means of a positioning assembly,

and restricting the user’s exposure to a fall of no more than two feet.

Typical positioning assemblies consist of a large rebar hook and a length

of chain, rope, wire rope or webbing with a double locking snap hook on

either end. These snap hooks are attached to d-rings on the hips or on

the waist of the user’s full body harness, with the rebar hook attached to

the structure upon which the user is working. An SRL should never be

used for work positioning, nor should it ever be attached to a side or hip

d-ring on a full body harness.

2.8: Free-Fall

Free-Fall is the distance that a worker will fall before the connecting

device or deceleration device elements of the PFAS will begin to engage

during a fall event. OSHA allows a maximum Free-Fall Distance of 6’ (6

feet) when rigging a Personal Fall Arrest System (PFAS). In some

cases, exceptions may be allowed when there is no practical way to limit

the Free-Fall Distance to 6’, such as a job-site where no overhead

9

10

Page 6

anchor-point is available. Tying off in a manner that would create a

Free-Fall greater than 6’ should always be a last resort. If you are

rigging a system that allows more than 6’ of Free-Fall, make sure your

Connecting Device/Deceleration Device is rated for this application.

FallTech DuraTech Series SRL’s ARE NOT rated for Free-Falls

greater than 5’!

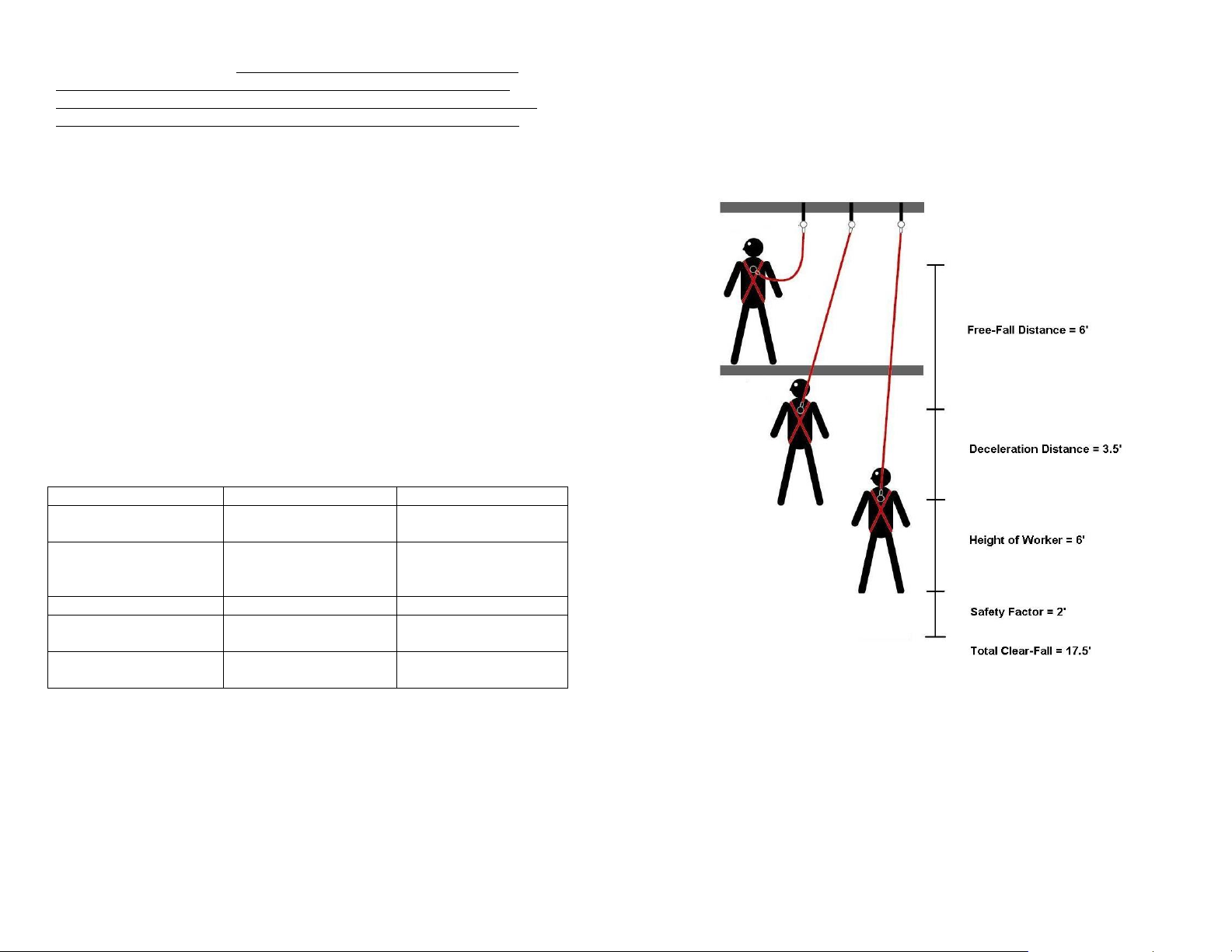

2.9: Clear-Fall

Clear-Fall or Clear-Fall Distance is the distance that is required to

safely arrest the fall of a user. When working at heights and using a

PFAS, it is important to consider the distance between the

walking/working level and the next lower level to ensure that the

components selected are capable of arresting the user’s fall before they

hit the next lower level. The required Clear-Fall Distance can easily be

calculated by adding together the Free-Fall Distance, the Deceleration

Distance, the height of the user plus a safety factor of 2 feet. The

formula for calculating Clear-Fall Distance is shown below:

Free-Fall Distance + Deceleration Distance + Height of Worker + Safety Factor = Clear-Fall

Distance

The matrix below can be used as a guide for calculating Clear-Fall

Distance on your job-site:

Free-Fall Distance

(OSHA allows up to 6’)

Deceleration

Distance

Example Values Actual Values

6’

3.5’

(Typically 3.5’ or less)

Height of Worker 6’

Safety Factor

(Minimum of 2’)

Total

(Sum of all values)

2’

17.5’

See figure 2.1 on the next page for a graphic illustration of Clear-Fall

Distance and the method for calculating. It is also necessary to consider

the fall path when determining the Clear-Fall limitations in your

application. Ensure the fall path is clear of obstructions, protrusions,

equipment or materials that may be a hazard in the event of a fall. Pay

special attention to those items which may present an impalement

hazard. Obstructions in the fall path may be just as hazardous as the fall

itself, and your PFAS may not be able to protect you from these hazards.

Failure to clear the fall path may result in serious injury or death. Rig

your PFAS with extreme caution, and be aware of all of the factors that

may come into play in the event of a fall.

Figure 2.1: Clear-Fall Diagram

2.10: Swing-Fall

Swing-Fall is the phenomenon that occurs when the user falls from a

location that is not directly adjacent to, or directly below the anchorage

connector. This is also referred to as the “pendulum effect”, and can

result in a situation where the user is not only falling vertically, but is also

swinging horizontally as well. This can bring additional hazards into play,

as you may swing into an obstruction or structural element, causing

11

12

Page 7

serious injuries (see figure 2.2). A significant Swing-Fall may also

require increased Clear-Fall distance. As a rule of thumb, you should

work in an area that does not exceed an angle greater than 15 degrees

in any direction from your anchorage.

Figure 2.2: Swing-Fall Diagram

Be sure to consider Swing-Fall when calculating your Clear-Fall

requirements and checking the fall path for hazards and instructions.

Failure to do so may result in serious injury or death. Should you have

any questions regarding Free-Fall, Clear-Fall, Swing-Fall or other

hazards in the fall path, be sure to contact FallTech or consult with a

competent person or your direct supervisor on your job-site.

Section 3: Use and Limitations

This section deals with the general use and limitations of the FallTech

DuraTech Series SRL’s. Please read this section and all sections of the

manual thoroughly. If your application is not addressed, or if you have

questions regarding your specific needs, please contact FallTech

immediately for additional guidance.

3.1: General Guidelines

When properly installed and utilized, this FallTech DuraTech SRL will

provide safety and mobility for a single user. As the user moves, the

SRL will pay out and retract automatically. In the event of a fall, a

centrifugal brake will arrest the fall in a very short distance while greatly

reducing the forces associated with the arrest.

Before using this product, the user should be trained in the use of fall

arrest products and should have completed a minimum course of

instruction (4-8 hours) for Authorized Person Training as outlined in ANSI

Z359.2-2007. The user must also read and be familiar with all of the

material contained in this instruction manual as well as all labels and

warnings affixed to the FallTech DuraTech SRL. If you have any

questions regarding the use or operation of this product, please contact

FallTech or your immediate supervisor before using.

This product must be inspected before each use. For details on

proper inspection procedures, please refer to section 8 of this manual.

Should this product fail to pass inspection, it must be immediately

removed from service and replaced.

This FallTech DuraTech Series SRL is intended to be used as part

of a Personal Fall Arrest System and will comprise the Connecting

Device/Deceleration Device elements of your PFAS (see section 2.3 and

2.4 of this manual for clarification of these terms). This product should

be attached to your anchorage connector using a properly dimensioned

connector (such as FallTech #7450 or #7447 carabiner).

Your anchorage should be overhead, or rigged in a manner such

that Free-Fall is restricted to no more than 2’ (2 feet). This product is not

designed to be used in applications where Free-Fall may exceed 5’. Be

sure to review the Clear-Fall diagram and worksheet in section 2.9 of this

manual.

This product meets the requirements of OSHA 1926.502 as well as

ANSI Z359.1-2007 and ANSI A10.32-2004. For further details on these

requirements, please go to www.osha.gov to review the OSHA

requirements. Copies of the ANSI standards are available at

www.asse.org in the e-standards store.

3.2: Approved Applications

13

14

Page 8

Below are applications for which the FallTech DuraTech SRL is

specifically suited. This list is not all-inclusive, but is intended to

anticipate the most common applications in which this product may be

used. If you have questions about whether this product is suitable for

your particular application, please consult a competent person or contact

FallTech for further advice.

Be sure to consult Section 5 of this instruction manual for details on

anchorage considerations, as the anchorage and its relationship to the

walking/working surface will be an important factor in determining

suitability and could contribute to the outcome of a fall event. Use of an

anchor point that is not properly rated could lead to a catastrophic failure

of your PFAS, possibly resulting in serious injury or death..

Direct Overhead Applications: This product is suitable for use in any

application where the properly rated anchorage is directly above the

walking/working surface, and allows for a maximum Free-Fall Distance of

2 feet.

Horizontal Lifelines: This product is suitable for use in any application

where a horizontal lifeline has been installed under the guidance of a

qualified person, and where the Free-Fall Distance does not exceed 5

feet.

Residential Construction: This product is suitable for use in residential

construction applications provided the anchorage meets the basic

requirements outlined in Section 5 of this instruction manual.

Residential Roofing: This product is suitable for use in residential roofing

applications provided that the anchorage meets the basic requirements

of Section 5 of this instruction manual, and provided it is used with a

compatible SRL roof anchor (i.e. “swivel-anchors”, “trees” and

“whirlybirds”), with Free-Fall limited to 5 feet or less.

General Construction: This product is suitable for use in general

construction applications provided the anchorage meets the basic

requirements outlined in Section 5 of this instruction manual, Free-Fall

does not exceed 5 feet, and there is no exposure to a sharp leading

edge.

Climbing/Fixed Ladders: This product is suitable for use on fixed ladders

or in conjunction with fixed ladder equipment, provided that the

anchorage meets the basic requirements outlined in Section 5 of this

instruction manual and provided that it is used in conjunction with a Full

Body Harness (FBH) containing a front or chest d-ring. Free-Fall must

not exceed 2 feet.

General Industrial Use: This product is suitable for use in general

industrial applications provided the anchorage meets the basic

requirements of Section 5 of this manual and provided that it is not

exposed to sharp edges, electrical hazards or prolonged exposure to

highly corrosive environments or substances.

If you have any questions regarding the suitability of this product for

your specific application, please consult with a competent person or

contact FallTech before using. Misuse of this product may result in

serious injury or death.

3.3: Restricted Applications

Leading-Edge Work: The DuraTech series of SRL’s may be used in

leading edge work, but extreme care must be taken to ensure that the

SRL cable does not engage or come in contact with any sharp, jagged or

abrasive edges in the course of working or in the projected fall path.

Offshore Oil Rigs: For offshore oil rigs and other similarly corrosiv e

environments, FallTech strongly recommends the use of a DuraTech

model containing the SS suffix (i.e. 7232SS), which contain stainless

cable, pressure plate and attachment end connector).

Harsh Chemical Environments: Acids and other caustic chemicals can

cause damage to this SRL and its components. Damage from chemical

exposure can be difficult to detect and FallTech recommends frequent

replacement and/or factory service.

Arborist Applications: This product should never be used in arborist

applications or tree-trimming applications.

Aerial Lifts: This product is not approved for use in aerial lifts, bucket

trucks or scissor lifts.

Extended Free-Falls: The maximum allowable Free-Fall for a DuraTech

SRL is 5’. Certain applications are restricted to a shorter Free-Fall. See

Section 3.2 for allowances by application. If you have questions about

your specific application, contact FallTech for advice.

Heavyweight: This product should not be used in applications where the

total weight of the user (including clothing, tools and equipment) exceeds

310 lbs. Model #’s ending in HW have a maximum capacity of 400

lbs.

15

16

Page 9

Power Transmission: Use of this product in areas where the lifeline may

come in contact with electrical hazards is prohibited. FallTech

recommends the use of Aramid webbing SRL’s (Kevlar®, Nomex® or

Dyneema®) for these applications.

Welding: Use of this product in areas where the lifeline may come in

contact with high heat or welding slag is not recommended. FallTech

recommends the use of Aramid webbing SRL’s (Kevlar®, Nomex® or

Dyneema®) for these applications.

3.4: Installation and Use

1. Select the appropriate FallTech DuraTech SRL based on the

work conditions and distance needed of unhindered vertical

travel. Be sure not to operate with the cable at full extension.

FallTech recommends operating at with a maximum of 90% of

the cable extended to ensure proper deceleration in the event of

a fall. DuraTech SRL’s are equipped with a red indicator sleeve

on the inner-most end of the cable. Should this begin to protrude

from the SRL housing, then you have reached the limit of the

cable’s working length. Do not attempt to force more cable to

pay out from the SRL and do not continue working if the red

indicator sleeve is visible outside of the SRL housing.

2. Read, understand and comply with manufacturer’s instructions

for each component of your Personal Fall Arrest System (FullBody Harness, Anchorage Connectors, etc.). Be sure to choose

components that are compatible with this SRL. If you have

questions about product or component compatibility, be sure to

contact FallTech for additional instructions.

3. Calculate possible swing fall hazards, total fall distance, and

required clearance distance. If you have a swing-fall hazard or

do not have the required clearance distance, STOP and

reevaluate your application and system. Your work location

should never exceed an angle of 15 degrees in any direction in

relation to your SRL’s anchorage location.

4. Attach the SRL by connecting a double-locking carabiner to top

end of the unit. Ensure that the carabiner is properly

dimensioned to join the SRL to the anchorage connector or

bracket. If either the SRL or the anchorage interferes with the

operation of the carabiner gate, use a larger carabiner. Hang the

unit from an approved anchorage capable of supporting a

minimum of 5,000 lbs (or 3,600 lbs with the certification of a

qualified person). This should be done without exposing anyone

to a fall hazard. The anchorage should be at a minimum height

so that the attachment connector of the SRL is even with, or

above, the back D-ring of your full body harness. Ensure that

the connector gate is closed and locked once the SRL has been

mounted to the anchorage.

5. If the SRL is to be remotely mounted, attach a tagline to the end

of the lifeline. This tagline allows access to the lifeline of a

remotely mounted FallTech SRL and allows the lifeline to be

retracted completely back into the housing in a controlled

manner without hazardous “Free Wheeling”.

6. Detach the tagline to avoid tangling. Do not leave the tagline

attached to the SRL while you are using it.

7. Before use, be sure to inspect in accordance with the

instructions in section 8-B of this manual. Test for proper

braking action by grasping the lifeline and pulling down hard,

ensuring that the unit locks.

8. Attach the load-indicating swivel carabiner on the attachment

end of the SRL to the back D-ring of your Full Body Harness.

Ensure that the load-indicating swivel carabiner’s gate is closed

and locked.

9. You are now attached and protected by the SRL. The preferred

orientation of the device is vertical with the lifeline exit at the

bottom; however, the device will perform either completely

horizontal or any other angle. To assure proper lifeline

retraction, keep lifeline path clear of obstructions. Beware of

swing fall hazards when working at extreme angles.

Once the above steps have been taken, the user will have access to

their work area while walking and moving at normal speeds. It is

important not to make sudden or dramatic movements, as the SRL is

designed to lock up when the line begins to move at a rate of 4.5 feet per

second. Sudden movements or acceleration can cause the SRL to lock

up, which may “jerk” the user and could result in the user losing his or

her balance. When using the equipment, care must be taken to be

aware of the work environment and any hazards, obstructions or

obstacles that may exist. Be careful of any and all fall hazards and also

be aware of slipping and tripping hazards as well.

Section 4: Product Selection

Product selection is as important as the proper use of the product

itself. Poor judgment in product selection can have catastrophic results –

therefore be sure to consult a competent person to ensure that the

product that is issued is appropriate for the application and the specific

location for which it is intended.

17

18

Page 10

ANSI Z359.1-2007, Section 7 describes in detail the steps that should

be taken with regard to the selection of fall arrest equipment. FallTech

strongly encourages the use of this guide by those who employ users of

fall arrest products. The ANSI standard recommends the following steps

be taken:

A workplace assessment by a competent person taking into

account the presence of sources of extreme heat, chemicals,

electrical hazards, environmental contaminants, sharp objects,

abrasive surfaces; moving equipment and materials, unstable,

uneven and slippery walking/working surfaces; unguarded

openings; climatic/weather factors and foreseeable changes to

these conditions. Care must be taken to ensure that the

equipment that is selected is suitable for use where any of these

conditions may exist.

The workplace assessment must identify all paths of movement

and the fall hazards along these paths. Care must be taken to

ensure that there are proper anchorages at appropriate intervals

along these paths to protect the users from these hazards

without exposure to swing-fall conditions. The PFAS selected

must limit the fall distance in order to avoid contact with the next

lower level in the event of a fall.

Anchorage connectors should be selected on the basis of their

suitability for attachment to the anchor point to ensure a

compatible and secure connection.

The exposure of the anchorage connector to sharp edges,

abrasive surfaces and other physical/structural hazards should

be considered when evaluating compatibility.

The competent person shall calculate the weight of all authorized

persons when fully equipped to ensure that they are within the

maximum capacity of the PFAS.

A full body harness meeting the requirements of Z359 shall be

selected, and it shall be sized to fit the user as per the

manufacturer’s instructions.

Connectors that are selected shall be suitably sized and shaped

so as to be compatible with the devices to which they will be

attached.

The competent person shall select the method of protecting the

equipment from damage by workplace conditions, in accordance

with the manufacturer’s instructions.

The competent person shall check the equipment instructions

and markings to ensure compliance with the appropriate

standards and will ensure that manufacturer’s instructions;

markings and warnings are read and followed.

If the PFAS that is selected is made up of components from

different manufacturers, the competent person will ensure that

these components are compatible.

FallTech strongly encourages that the following points also be

considered in the course of product selection, in addition to the points

above:

Select the anchorage connector that is most appropriate for your

application and for the anchor point to which it will be attached.

While sling-style anchors are popular because of their versatility,

they are not always the best choice where sharp or angular

edges are present on the structure to which they are attached.

Select a full body harness of appropriate durability for your

workplace which contains all of the attachment elements that you

will require. Never attach any SRL to anything other than the

back/dorsal d-ring or the front/chest d-ring of your full body

harness.

Depending on workplace conditions and hazards, you may need

to employ multiple systems or different combinations of

components. Do not try and force the system to fit the

application. Use of the correct equipment is the best policy.

Section 5: Anchorage Considerations

OSHA 1910.66 and 1926.502 state that anchorages used for

attachment of a PFAS must be independent of any anchorage being

used to support or suspend platforms, and must support at least 5,000

lbs. per user attached, or be designed, installed and used as part of a

complete PFAS which maintains a safety factor of at least two, and is

supervised by a qualified person (architect, structural engineer, etc.).

The anchorage to which this SRL is attached must capable of

sustaining static loads (in all directions applied by the personal fall arrest

system) of at least twice the maximum anticipated dynamic load - with

certification of a qualified person (architect, structural engineer, etc.), or

5,000 lbs in the absence of certification. If multiple personal fall arrest

systems are being attached to the same anchorage, the minimum values

stated above must be multiplied by the number of users.

Ensure that the anchorage connector that you are using is compatible

with the anchor point to which you are attaching it. If you are using this

SRL with a Horizontal Lifeline, tripod or davit, ensure that it is compatible

with these systems by checking the manufacturer’s instructions for these

19

20

Page 11

systems for the minimum performance requirements of deceleration

devices.

Be sure that your anchorage is mounted overhead or above the level

of the back d-ring of your full body harness. Be sure to calculate your

clear-fall (as discussed in section 2.9) and to avoid swing fall hazards.

Ensure the fall path is clear of obstructions and impalement hazards.

Section 6: Employer and User Training

6.1: Special notes for the Employer

As an employer, you may be obliged to provide Personal Protective

Equipment (to include Personal Fall Arrest and Fall Protection

Equipment) along with an appropriate amount of training to your

employees so that they will be adequately prepared to use this

equipment in the course of their work. If you are unsure about your duty

to provide fall protection, consult Title 29 CFR, section 1926.501 which

can easily be viewed at www.osha.gov. Another important resource for

employers is the Consensus standard on Managed Fall Protection:

ANSI Z359.2-2007.

Equally important is the subject of product/equipment selection. If

you are obliged to provide fall protection equipment for your employees,

be sure to consult with or appoint a competent or qualified person to

select and prescribe equipment that is suitable to address the specific

hazards which may be present on your job-site or in your facility. There

are different products for different applications, and under many

circumstances, these products are not interchangeable. If you have

questions as to whether this product is suitable for your application,

please contact FallTech for assistance.

It is important to note that improper use of fall arrest equipment can

be just as dangerous as not using it at all. Failure to adequately train

and supervise your employees may result in serious injury or death. It is

critical to have a training program supported by documentation,

refresher/remedial training and to establish best practices where the

employment of all PPE is concerned.

6.2: User Training

It is the responsibility of the user of this equipment to read and fully

understand these instructions before employing this product as part of a

Personal Fall Arrest System (PFAS). Every user of fall protection should

be provided a four to eight hour course of instruction for the Authorized

21

Person. Training must also be provided in the use of each component of

the user’s PFAS and in the recognition of fall hazards. During the course

of this training, the user may not be exposed to a fall hazard.

In the absence of a formal training program, FallTech has designed

these instructional materials to act as an abbreviated course of

instruction in an effort to give the user an over-view of fall arrest. This

manual does not constitute a comprehensive training program, and it is

not all-inclusive. Be sure to consult www.osha.gov for details on OSHA

requirements for training. FallTech has additional services available to

assist with end-user training – contact a FallTech sales professional for

additional details.

As a minimum, training should address the following points:

ABCD’s of Fall Arrest (as discussed in Section 2).

Recognition of fall hazards.

Fall hazard elimination and control methods.

Applicable fall protection regulations and standards.

The responsibilities of designated p ersons (Authorized,

Competent, Qualified).

How to use written fall protection procedures.

Inspection of equipment components and systems before use.

Fall protection rescue procedures.

Installation and use of products common to your duties, job-site

or facility.

It is important to note that improper use of this equipment can be just

as dangerous as not using it at all. Failure to read, understand and

follow these instructions may result in serious injury or death.

Section 7: Fall Protection Plan

Title 29 CFR, section 1926.500 – 503 requires that an employer have

a written fall protection plan where fall hazards exist. The best way to

address a fall hazard is to eliminate it entirely or to employ a passive

system to restrict access to the hazard (i.e. guardrails, netting, covers,

etc.) Fall arrest products are the last line of defense in the hierarchy of

fall protection, and should be used as a last resort by employees who

have been thoroughly trained. The accepted fall protection hierarchy is

as follows:

Eliminate the fall hazard.

Passive fall protection (guardrails, safety nets, barriers, etc.).

Fall Restraint (prevent the worker from having access to the fall

hazard by using a fixed lanyard which is short enough to restrict

access to the hazard).

22

Page 12

Fall Arrest (utilizing Personal Fall Arrest Systems).

Administrative Controls (use of warning lines, controlled access

zones or monitors).

Two exceptional resources for developing a written fall protection

plan are OSHA 1926 Subpart M, Appendix E and ANSI Z359.2-2007. All

ANSI standards are available for purchase at www.ansi.org in the estandards store.

7.1: The Fall Protection Plan

As a minimum, a fall protection plan should identify and/or address

the following points:

Any and all fall hazards which may exist on your job-site

or in your facility.

Steps that have been taken to eliminate each fall hazard.

Equipment that has been or will be employed to address

each fall hazard.

Provisions for 100% continuous fall protection in the

vicinity of all fall hazards.

Training procedures for all authorized persons.

Identification of acceptable anchorages for positioning,

restraint and fall arrest.

Clear-fall requirements.

Use and egress from the system.

Limitations on use of the system (maximum Free-fall,

arrest force and maximum number and permitted

locations of authorized persons who may use the system).

Procedures for installation, use and removal of the

system.

Detailed instructions for inspection of systems and system

components to include rejection criteria and replacement

procedures.

A detailed plan and procedures for the rescue of a worker

who may be involved in a fall event.

7.2: Rescue Plan

In the event of a fall, OSHA requires that a prompt rescue be

provided. In order to facilitate a prompt and effective rescue, it is

important to have a Rescue Plan as part of your overall Fall Protection

Plan.

23

The rescue plan should include detailed procedures for summoning a

professional rescue agency (such as the local fire department) and/or for

performing self-rescue or in-house rescue.

For detailed assistance in formulating and maintaining an effective

rescue plan, see ANSI Z359.2-2007.

7.3: Suspension Trauma

Suspension Trauma (also referred to as orthostatic intolerance) is a

condition that can arise from being suspended in a full-body harness for

a prolonged period of time while awaiting rescue after a fall. Under these

circumstances, blood circulation can be restricted allowing a large

volume of blood to accumulate or pool in the veins of the user’s legs.

This condition can result in a variety of symptoms, some of which include

light-headedness, loss of consciousness, difficulty concentrating and

palpitations.

Following a rescue, Suspension Trauma can be so acute as to cause

cardiac arrest when the large volume of un-oxygenated blood

overwhelms the heart. This severity of this condition can be greatly

reduced by using any one of a variety of devices offered to alleviate

Suspension Trauma, such as FallTech’s ReliefPak and by providing a

prompt rescue in the event of a fall.

For additional details on Suspension Trauma, refer to OSHA’s Safety

and Health Information Bulletin SHIB 03-24-2004 at www.osha.gov.

Section 8: Product Inspection

Inspection is a critical element in the employment of any fall

protection equipment. In order to protect authorized persons who are

using this SRL, it is important that the employer establishes procedures

that has layers of inspection to ensure that any mechanical or functional

deficiencies are recognized before the product is put into use.

8.1: Issuing

If the SRL is to be kept in a locker or tool crib between periods of use,

the person responsible should inspect the product upon issuing and

receipt to ensure that it is in proper working order. If any deficiency is

noted, this should be logged on the inspection record and the product

should be removed from service and handled in accordance with the

employer’s lock-out/tag-out policy. If this SRL exhibits a deficiency, it

should be immediately removed from service and replaced.

24

Page 13

8.2: Daily/Incidental Use

OSHA 1910.66 and OSHA 1926.502 (as well as ANSI Z359.1-2007

and ANSI A10.32-2004) specifically require that the user inspect all

fall protection equipment prior to each use to ensure proper

function and to ensure that the equipment is in serviceable

condition. Failure to do so may result in serious injury or death.

FallTech requires that the following steps be taken during each

inspection prior to use of this DuraTech Series Cable SRL:

1. Check the load-indicating swivel carabiner at the attachment

end of the SRL. If the red indicator is visible between the swivel

mechanism and the carabiner body, then the SRL has been

subjected to fall arrest forces and must immediately be removed

from service.

2. Pull approximately 4 feet of cable out of the unit and hand-lock

the unit by pulling sharply on the line. Repeat this procedure

three times – if the unit does not lock up each time, or if it “slips”

after locking up, immediately remove the unit from service and

have it replaced.

3. Ensure that the SRL cable extends and retracts freely.

4. Using gloved hands to avoid injury, pull the complete length of

webbing out of the unit and look for kinks, knots, fraying,

corrosion, surface contamination or evidence of damage from an

electrical arc or welding splatter. Surface contamination should

be removed with a damp rag and a simple solution of soapy

water. Any damage to the cable may indicate an unsafe

condition, and the SRL should be removed from service.

5. In the event that the cable should become locked, and will not

pay out from the housing, this condition can easily be remedied

in the field by taking the steps below:

a. Lay the SRL on a flat surface.

b. Place one hand on the SRL housing, holding it tightly

against the flat surface.

c. With the other hand, grasp the load-indicating swivel

carabiner by the eye, just below the ball and spring buffer

assembly.

d. Slowly push the cable into the housing until the buffer

assembly is entirely compressed.

e. Slowly release the pressure on the buffer assembly, and

then pull the cable out of the housing – it should now be

unlocked and in working order.

25

f. This condition can be avoided by using the tagline as

discussed in Section 3.4, paragraphs 5 and 6.

6. Inspect the exit bushing for excessive wear, sharp edges or

burring. If these conditions exist and are beginning to cause

damage to the cable, remove the SRL from service.

7. Inspect the carabiner gates at the anchorage and attachment

ends of the product to ensure proper locking function. If the

gates do not close and lock automatically, then the SRL should

be removed from service.

8. Check the SRL housing and anchorage handle for signs of

cracking or denting. Also check for loose screws and any bent,

cracked or damaged parts. If the SRL exhibits any structural

damage, then remove it from service immediately.

9. Ensure that all metal components are free of corrosion, and that

there is no evidence of cracking, denting or distortion.

10. Ensure that all labels and warnings remain attached and that

they are legible.

11. If the SRL fails to pass inspection on any of these points, or if

there is any doubt as to whether it is in proper working order,

immediately remove it from service.

8.3: Mandatory Semi-Annual Inspection

ANSI Z359.1-2007 requires that all fall protection equipment be

inspected by a competent person other than the user at least once each

year. FallTech strongly encourages that all fall protection equipment be

inspected by a competent person other than the user at least once every

six months.

This inspection should be noted in the inspection log on pages 27

and 28, along with any deficiencies. This inspection should also be used

as an opportunity to counsel any authorized persons with respect to any

deficiencies that they may have failed to note in their daily inspections.

26

Page 14

FallTech DuraTech Series Cable SRL

Model #:_______________

Serial #:_______________

Mfg. Date:_____________

Inspection

Date

Inspector Comments Pass/Fail Corrective

Inspection Log

Action to be

Taken

Approved

By

FallTech DuraTech Series Cable SRL

Model #:_______________

Serial #:_______________

Mfg. Date:_____________

Inspection

Date

Inspector Comments Pass/Fail Corrective

Inspection Log

Action to be

Taken

Approved

By

27

28

Page 15

Section 9: Maintenance and Storage

The service life of your FallTech DuraTech Series Cable SRL will depend

on two factors: The environmental conditions of your working

environment along with proper care (specifically, maintenance and

storage).

Keeping the SRL clean and free of contaminants will greatly increase

the service life and will ensure that the SRL will be in proper working

order in the event that you need it to arrest a fall. The following steps

should be taken periodically:

1. Always wear gloves when handling the cable element of the

SRL.

2. Using a damp rag and a mild soap and water solution, wipe

down the SRL housing to remove soil and surface contaminants.

Ensure that the labels are legible at all times.

3. Use a damp rag and a mild soap and water solution to clean the

cable element of the SRL. Allow it to air dry and then use a rag

that is damp with a light machine oil to condition the cable.

4. Use a damp rag to clean the surfaces of any connecting

hardware.

5. If there is an excessive build up of paint, oil, dirt tar or other

contaminants that cannot be removed, remove the SRL from

service and have it replaced.

6. Store in a cool, dry location away from direct sunlight and where

it will not be exposed to chemical vapors.

7. This SRL should be hung on a rack or a peg or stored flat on a

shelf.

8. Do not throw the SRL into a pile or a locker or storage box, as

this may damage the housing.

FallTech DuraTech SRL’s are fully serviceable; high-performance

products utilizing a variety of specialized materials. In order to assure

your safety and to extend the service-life of this quality product,

recertification is required every two years.

Details regarding the FallTech Repair, Service and Recertification

Program were included with this product when it was shipped from the

factory. Following each recertification, service or repair, the original 2

year warranty is automatically extended, ensuring that your investment is

protected under the same terms as a brand-new product.

For additional details on maintenance, repairs, service or

recertification of your DuraTech SRL; contact FallTech or your FallTech

Distributor

Section 10: Specifications

This section contains important information regarding the

performance and construction of this product. Pease read and be

familiar with this and all information contained in this instruction manual.

10.1: Mandatory Disclosures

This instruction manual addresses foreseeable hazards, uses and

applications. If you have questions about your application that are not

addressed in this document, contact FallTech for additional guidance.

It is the responsibility of the employer/issuer of this equipment to

ensure that it is used in a manner consistent with these instructions.

Failure to do so could result in series injury or death.

For further reading and additional information, see Section 10.4 for a

listing of relevant standards with which you should be familiar.

10.2: Performance Specifications

DuraTech Galvanized Cable SRL’s

Model #s: 7226, 7227, 7229, 7232, 7265, 7266, 7267, 7268, 726575,

7211, 7212

Component Material Rating

Housing Cast/Machined Aluminum Alloy n/a

Drum Cast/Machined Aluminum Alloy n/a

Main Shaft CNC Machined Aluminum Alloy n/a

Pawls/Ratchet Manganese Bronze Alloy n/a

Pressure Plate Chro-Moly Alloy Steel n/a

Cable 3/16” 7 x 19 Galvanized Steel 4,000 lbs

Attachment Carabiner Chro-Moly Alloy Steel 5,000 lbs

Overall static strength: > 3,000 lbs

* Arrest Forces: < 800 lbs

* Deceleration Distance: < 24”

Maximum Capacity: 310 lbs

* When tested in accordance with ANSI Z359.1-2007

29

30

Page 16

DuraTech Stainless Cable SRL’s (“S-series”)

Model #s: 7226S, 7227S, 7229S, 7232S, 7267S, 7268S,

7211S, 7212S, 7213S

Component Material Rating

Housing Cast/Machined Aluminum Alloy n/a

Drum Cast/Machined Aluminum Alloy n/a

Main Shaft CNC Machined Aluminum Alloy n/a

Pawls/Ratchet Manganese Bronze Alloy n/a

Pressure Plate Chro-Moly Alloy Steel n/a

Cable 3/16” 7 x 19 Stainless Steel 4,000 lbs

Attachment Carabiner Chro-Moly Alloy Steel 5,000 lbs

Overall static strength: > 3,000 lbs

* Arrest Forces: < 800 lbs

* Deceleration Distance: < 24”

Maximum Capacity: 310 lbs

* When tested in accordance with ANSI Z359.1-2007

DuraTech Stainless Cable SRL’s (“SS-series”)

Model #s: 7226SS, 7227SS, 7232SS, 7266SS, 7268SS, 726575SS

Component Material Rating

Housing Cast/Machined Aluminum Alloy n/a

Drum Cast/Machined Aluminum Alloy n/a

Main Shaft CNC Machined Aluminum Alloy n/a

Pawls/Ratchet Manganese Bronze Alloy n/a

Pressure Plate Stainless Steel n/a

Cable 3/16” 7 x 19 Stainless Steel 4,000 lbs

Attachment Carabiner Stainless Steel 5,000 lbs

Overall static strength: > 3,000 lbs

* Arrest Forces: < 800 lbs

* Deceleration Distance: < 24”

Maximum Capacity: 310 lbs

* When tested in accordance with ANSI Z359.1-2007

DuraTech Heavyweight Cable SRL’s (“HW-series”)

Model #s: 7226HW, 7227HW, 7232HW, 7265HW, 7268HW,

7211S, 7212S, 7213S

Component Material Rating

Housing Cast/Machined Aluminum Alloy n/a

Drum Cast/Machined Aluminum Alloy n/a

Main Shaft CNC Machined Aluminum Alloy n/a

Pawls/Ratchet Manganese Bronze Alloy n/a

Pressure Plate Chro-Moly Alloy Steel n/a

Cable 3/16” 7 x 19 Galvanized Steel 4,000 lbs

Attachment Carabiner Chro-Moly Alloy Steel 5,000 lbs

Overall static strength: > 3,000 lbs

* Arrest Forces: < 900 lbs

* Deceleration Distance: < 30”

Maximum Capacity: 400 lbs

* When tested in accordance with ANSI Z359.1-2007

31

10.3: Labels and Markings

Labels are an important part of the product and should be referred to

often to keep these important details fresh. The labels located on the

front of the housing (shown in figure 10.1) identify the product and

provide key details with respect to the products rating. There is also

information pertaining to the use of the product along with critical

warnings. Failure to heed these warnings may result in serious injury or

death.

The labels on the back of the SRL housing have information

regarding the proper installation and inspection of this product. These

are shown in figure 10.2.

Figure 10.3 is the service label. Be sure to use a permanent marker

to log the date that the product is put into service. This label should be

inspected every six months during the competent person inspection to

ensure that the product is within the recertification parameters discussed

in Section 9 of this manual.

The labels shown below must be present on the product and must be

legible. If they are not, remove the product from service.

Figure 10.1: Located on front housing

32

Page 17

Figure 10.2: Located on back housing

Figure 10.3: Located on side of housing

In addition to these printed labels, your DuraTech SRL will also have

a round brass tag affixed to the captive-eye on the load-indicating

carabiner. This tag is embossed with the serial number and either the

date of manufacture or the date of the last recertification. Do not remove

this tag – it is an important piece of back-up information in the event the

product labels are damaged or removed.

10.4: Standards and references

Below is a listing of standards that are applicable to the construction

and use of this product. FallTech strongly encourages that all employers

acquire and utilize these documents for the creation of your own fall

protection policies and your individual fall protection plans. Users of this

product should also be familiar with this information as well.

OSHA Standards bear the force of law on a federal level. Some

states have their own regulations which are locally enforced – check with

your State Department of Labor for specific requirements which may be

enforced in your area. OSHA Standards can be accessed for free at

www.osha.gov.

29 CFR 1926 (Subpart M)

1926.500: Scope, Application and Definitions

1926.501: Duty to Have Fall Protection

1926.502: Fall Protection Systems Criteria & Practices

1926.503: Training Requirements

ANSI standards are voluntary consensus standards, and are

generally regarded among the best practices where fall protection is

concerned. Some states have incorporated one or more of the ANSI

standards by reference, meaning that they may be enforced by some

state or local agencies. Check with your State Department of Labor for

further details. ANSI standards are available for purchase through the estandards store at www.ansi.org.

ANSI Z359.1-2007: Safety Requirements for Personal Fall Arrest

Systems, Subsystems and Components

ANSI Z359.2-2007: Minimum Requirements for a Comprehensive

Managed Fall Protection Program

ANSI Z359.12-2009: Connecting Components for Personal Fall Arrest

Systems

ANSI A10.32-2004: Fall Protection Systems for Construction and

Demolition Operations

33

34

Page 18

Notes

FallTech warrants to the buyer that all products are free from defect in

material and workmanship at the time of shipment. Obligation under this

warranty is limited to product replacement for the period of two (2) years

from the date of installation or use by the owner, provided that this period

shall not exceed two (2) years from the date of shipment. This warranty

is not transferable. No other person or firm is authorized to assume or

assign for FallTech any other warranty in connection with the sale or use

of this product.

Furthermore, this warranty is void if any product is changed or altered

in any way, or if the product is used in a manner other than for which it is

intended. This warranty only covers defects in material and

workmanship; it does not cover conditions resulting from normal wear

and tear, neglect abuse or accident.

Warranty

35

Alexander Andrew, Inc. (dba FallTech)

1306 South Alameda Street

Compton, CA 90221

Toll Free: (800) 719-4619

Phone: (323) 752-0066

Fax: (323) 752-5613

www.falltech.com

36

MSRL02 ALX

Loading...

Loading...