Page 1

Instruction #I-77000, Rev 2

MODELS

# 77000-3 ________

# 77000-6 ________

# 77000-10 ________

USER’S INSTRUCTION MANUAL FOR THE INSTALLATION,

OPERATION & MAINTENANCE OF THE

FALLTECH 77000 TEMPORARY HORIZONTAL LIFELINE

SYSTEM

FALLTECH

ALEXANDER ANDREW, INC.

10240 S Alameda St

South Gate, CA 90280-5551

Phone (800) 719-4619 Fax (323) 752-5613

1

Page 2

Instruction #I-77000, Rev 2

WARNING

This is a design compatible component for a comprehensive FallTech™ Personal Fall

Arrest or Fall Restraint System. Each component includes an instruction manual. These

instructions must be provided to the user of this equipment prior to use. AS A USER,

YOU MUST READ, UNDERSTAND AND FOLLOW THE MANUFACTURER’S

INSTRUCTIONS, LABELS AND WARNINGS for each component part of the complete

system before using it. If you do not understand the Instruction, Labels and Warnings for

the use and maintenance of this component, have them explained to you. ANY MISUSE

OF THIS COMPONENT, ANY ALTERATION OR MODIFICATION OF IT, OR

FAILURE TO PROPERLY FOLLOW THESE USER’S INSTRUCTIONS, MAY

RESULT IN SERIOUS INJURY OR DEATH.

If any additional information is required to use this product, it will be supplied with this

product. Fall arrest equipment used in conjunction with the FallTech™ Temporary

Horizontal Lifeline System will also be supplied with instructions.

FALLTECH

ALEXANDER ANDREW, INC.

10240 S Alameda St

South Gate, CA 90280-5551

Phone (800) 719-4619 Fax (323) 752-5613

2

Page 3

Instruction #I-77000, Rev 2

1.0 PRODUCT DESCRIPTION AND APPLICATIONS

FallTech™ Part Numbers:

77000-3: 30’ Temporary Horizontal Lifeline System, 2 users maximum

77000-6: 60’ Temporary Horizontal Lifeline System, 2 users maximum

77000-10: 100’ Temporary Horizontal Lifeline System, 2 users maximum

The FallTech™ Temporary Horizontal Lifeline System is designed to be used in

applications where a fall hazard exists, but there is no means of arresting a fall. The

Temporary Horizontal Lifeline System attaches to stationary anchorage points, I Beam

Clamps, Pipe Rack Stanchion Systems or Steel I Beam Post Systems.

This system has been designed and tested to be used with FallTech™ Personal Fall

Arrest Equipment (PFAS) only. It has been designed for personal fall arrest use only. It

is not intended for other applications. It is not intended to be used for suspending

equipment. The 77000 Temporary Horizontal Lifeline System is an engineered system,

and has been designed according to the application.

2

1

4

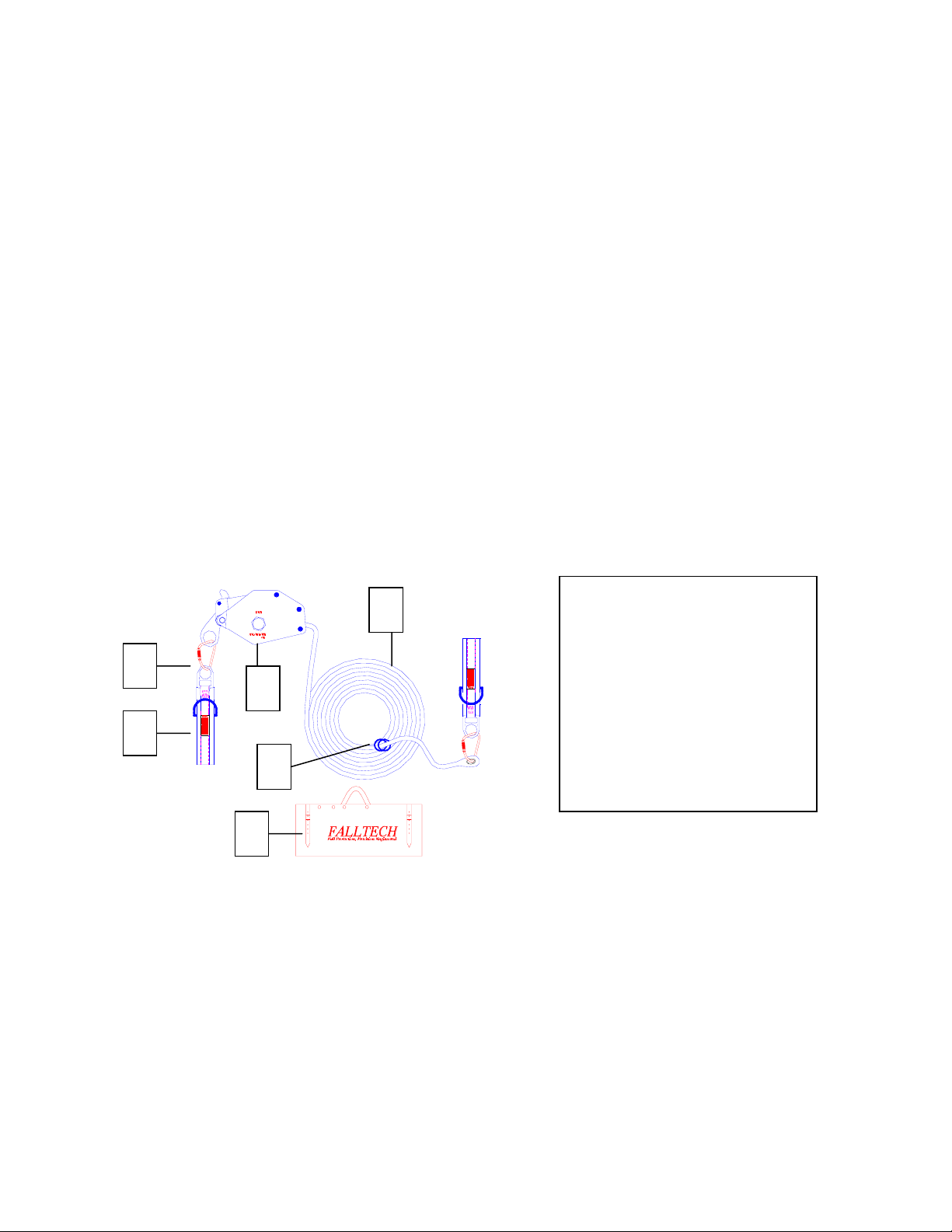

1. Anchor sling (2)

2. Self-locking carabiner

(2)

3. Horizontal line

3

tensioning device

4. Polyester rope lifeline

5. O-Rings (2)

5

6. Storage bag

6

FALLTECH

ALEXANDER ANDREW, INC.

10240 S Alameda St

South Gate, CA 90280-5551

Phone (800) 719-4619 Fax (323) 752-5613

3

Page 4

Instruction #I-77000, Rev 2

2.0 PRODUCT SPECIFICATIONS

Lifeline

Diameter 5/8”

Weight 13.1 lbs. per 100 ft

Material of Construction 12 Strand Polyester Fiber Rope

Average Breaking Strength 17,100 lbs.

Specific Gravity 1.38

Elongation 1.4% stretch at 10% of Break Strength

2.3% stretch at 20% of Break Strength

3% stretch at 30% of Break Strength

Chemical Resistance High resistance to acids

Line Tensioner

Material of Construction Steel with corrosion resistant finish

Minimum Breaking Strength 5,600 lbs.

Anchor Slings

Material of Construction:

Web Polyester

Small D-Ring Drop forged – alloy steel. Standard finish,

Yellow cadmium.

Large D-Ring Plating: Zinc to ASTM B-663, Zinc Spec. QQZ,

Class 2, 0.0005 + Silica Seal.

Webbing - Min. Tensile Strength 6,000 lbs.

D-Ring – Min. Tensile Strength 5,000 lbs.

Proof Loaded 100% up to 3,600 lbs.

Carabiners

Material of Construction Heat treated alloy steel. Finish is plated to BS1706-

FE-ZN5C.

Min. Breaking Load 11,000 lbs.

Proof Loaded 100% to 3,600 lbs.

O-Rings

Inside Diameter 3”

Outside Diameter 3-3/4”

Material of Construction Drop forged alloy steel.

Min. Tensile Strength 5,000 lbs.

Proof Loaded 100% up to 3,600 lbs.

FALLTECH

ALEXANDER ANDREW, INC.

10240 S Alameda St

South Gate, CA 90280-5551

Phone (800) 719-4619 Fax (323) 752-5613

4

Page 5

Instruction #I-77000, Rev 2

3.0 SYSTEM REQUIREMENTS

Personal Fall Arrest System Components

The FallTech™ horizontal lifeline system has been designed to be used with approved

FallTech™ components and sub-systems only. Non-approved components and subsystems may be incompatible and could affect the overall system. These components

must meet all applicable OSHA and ANSI standards. A full body harness like those

manufactured by FallTech™ must be used with this system.

System Components

Connectors (snap hooks, carabiners, D-rings) used to attach to the system O-ring(s) must

support a minimum of 5,000 lbs. Only use connectors that are compatible in shape, size,

and strength. Failure to do so may cause accidental roll-out. DO NOT use non-locking

connectors.

Structural Anchor Points

Anchor points must be stiff and capable of supporting a minimum of 5,000 lbs. Anchor

points must also be able to support 5,000 lbs in all directions of a potential fall.

Anchorage Connectors

Connectors must be capable of holding 5,000 lbs without breaking. Connectors must be

compatible with the connection point.

Sub-System Connections

A sub-system connection is the component used to attach the users harness to the

horizontal lifeline. Sub-system connections typically are self-retracting lifelines and

lanyards

Limitations Of System

System Capacity – The FallTech™ 77000 Temporary Horizontal Lifeline System has a

maximum capacity of two workers. There must also be adequate clearance beneath the

walking/working surface (see section titled “Clearance” below) for the system to function

properly. The maximum worker’s weight, including tools, cannot exceed 310 pounds

each. Consult your FallTech™ sales representative if you have any questions concerning

your application.

Corrosion – Harsh environments can cause corrosion of metal parts. The Temporary

Horizontal Lifeline System should not be left in corrosive environments for extended

periods of time. Additional inspections may be necessary to verify that the lifeline and

components are in good working condition.

Electrical Hazards – User should always use extreme caution when working near

electrical sources.

FALLTECH

ALEXANDER ANDREW, INC.

10240 S Alameda St

South Gate, CA 90280-5551

Phone (800) 719-4619 Fax (323) 752-5613

5

Page 6

Instruction #I-77000, Rev 2

Heat – Do not use this device in extremely high temperatures. When performing any

type of metal work, such as welding, cover fall arrest equipment.

Moving Machinery – If it is necessary to work above moving machinery, maintain a safe

distance between the moving parts and yourself, clothing, and personal protective

equipment.

Sharp Edges – Fall arrest equipment should always be protected from sharp edges. Sharp

or abrasive edges can cause excessive wear to equipment. If it is necessary to work

around these types of surfaces, always use a wear pad or barrier.

Clearance – There must be sufficient clearance beneath the structure to ensure that

workers do not contact an obstruction below. The following factors MUST be

considered when working with a horizontal lifeline system:

• Vertical displacement of horizontal

• Maximum free fall distance - 6 feet

lifeline

• Displacement of harness D-ring - 1 foot • Deployment of shock absorber - 3.5 feet

• Safety margin – 2 feet • Horizontal lifeline is mounted above the

workers head

Contact your FallTech™ representative for additional information.

Swing Falls – It is important to work as close as possible under the horizontal lifeline to

minimize swing fall hazards. A swing fall hazard is a result of a worker walking and/or

working too far away from the horizontal lifeline. In the event of a fall, a worker that is

not close to the horizontal lifeline will swing in a pendulum like motion and could hit an

obstruction, causing a serious injury. To minimize this type of hazard, work as closely as

possible to the horizontal lifeline and carefully evaluate any obstructions below the

working surface.

4.0 IMPORTANT DO’S AND DON’TS

NOTE: The components, materials and anchorage of a personal fall arrest system must

be selected by a Competent Person to match the system’s application, and workplace

hazards and environment.

FALLTECH

ALEXANDER ANDREW, INC.

10240 S Alameda St

South Gate, CA 90280-5551

Phone (800) 719-4619 Fax (323) 752-5613

6

Page 7

Instruction #I-77000, Rev 2

DO DON’T

Use this device only with compatible

Repair or modify this device.

components from FallTech.

Inspect equipment before each use. Ignore warnings issued by Fall Protection

Manufacture.

Store equipment in a safe, dry area. Modify or repair Fall Arrest equipment.

Contact manufacture for instructions.

Keep all literature and instructions in a safe

place for easy, quick reference.

Use this equipment unless you have been

fully trained by a competent person and

fully understand how to use this equipment.

Keep all inspection documents updated. Use this device if it has been exposed to

corrosion, chemicals, excessive heat,

flames, electrical charge, or shows signs of

any physical damage or deformation.

Keep all labels on fall protection

equipment readable.

Use this device if your total combined

weight (body, clothing, tools, etc.) exceeds

310 lb.

Use extreme caution when rigging this

equipment.

Plan for a rescue if a worker becomes

unconscious or incapacitated and falls.

Use anchorage points unless they have

been designed for fall protection.

Rely on the sound of a closing snap hook.

Visually inspect it to ensure a proper

attachment.

Call FallTech™ at (800) 719-4619 if the

device is damaged or does not function

according to the correct operation

explained in section 3 of this manual.

Use this system if you are pregnant, a

minor, or have reduced tolerance to fall

forces by reason of age, physical or

medical condition, or other pre-existing

disorders.

DO NOT USE THIS DEVICE IF IT HAS BEEN USED AS PART OF A SYSTEM

THAT HAS ARRESTED A FALL. IF IT HAS BEEN USED IN SUCH A SYSTEM, IT

MUST BE REMOVED FROM SERVICE IMMEDIATELY AND SENT TO

FALLTECH FOR INSPECTION AND SERVICING.

5.0 FALL PROTECTION PLAN

As an employer, you must be aware of the factors which affect the safety of your workers

before, during and after a fall. Having a Fall Protection Plan ready before work is the

best way to ensure the ultimate safety and well-being of your employees.

Your Fall Protection Plan must include:

FALLTECH

ALEXANDER ANDREW, INC.

10240 S Alameda St

South Gate, CA 90280-5551

Phone (800) 719-4619 Fax (323) 752-5613

7

Page 8

Instruction #I-77000, Rev 2

1. Proper Anchorage: A Properly selected anchorage point is critical to the success of a

personal fall arrest system (PFAS). The anchorage point must be rigid and allow for

a 2:1 safety factor.

2. Free Fall Limitations: Free fall distance must be taken into consideration when

designing a fall protection system. Potential free falls may not exceed 6 ft. To

reduce free fall distance, keep anchorage points above your working level.

Note: ANSI A10.14 requires personal fall arrest systems to be rigged so that the

potential free fall is not greater than 5 ft.

3. Fall Clearance Distance: Measure the distance between the working level and the

next obstruction. Then, design a system that will not allow a worker to come in

contact with the obstruction or next level.

4. Swing Falls: If a worker is not directly under an anchorage point, a swing fall may

result. To minimize this hazard, evaluate the entire situation, and plan accordingly

for a safe clearance distance, or consider a horizontal lifeline. Contact FallTech for

assistance.

5. Rescue and evacuation plan. You must provide a means of rescue and evacuation for

workers should a fall occur.

6. Immediately dispose of equipment which has been subjected to fall arrest forces.

6.0 OPERATION AND INSTALLATION OF FALLTECH TEMPORARY

HORIZONTAL LIFELINE SYSTEM

One complete temporary horizontal lifeline system includes the following components:

Part

Description Qty

Number

7372 Anchor Slings 2

7450 Self-locking carabiners 2

7349 Horizontal lifeline tensioning device 1

Varies Rope Lifeline 30’, 60’, 100’

7401 O-Rings 2

5007L Equipment Bag 1

INSTALLATION OF LIFELINE TO SUPPORT STRUCTURE USING ANCHOR

SLINGS

NOTE: Although anchor slings are included with system, self-locking carabiners may be

attached directly to an approved anchor point.

1. Wrap polyester anchor sling around one support structure. Sling must be wrapped

around column at least twice and fit up snugly against structure.

2. Take one self-locking carabiner and attach to smaller D-ring on anchor sling.

3. Wrap second anchor sling around opposite support structure. Repeat steps #1 and #2.

FALLTECH

ALEXANDER ANDREW, INC.

10240 S Alameda St

South Gate, CA 90280-5551

Phone (800) 719-4619 Fax (323) 752-5613

8

Page 9

Instruction #I-77000, Rev 2

4. Connect thimbled end of lifeline to one of the anchor slings using a self-locking

carabiner.

5. Tighten horizontal lifeline by pulling loose rope end at lifeline tensioner. Using a

solid piece of steel stock, tighten the lifeline by turning the nut clockwise. Proper

tension will be achieved when inner cam wheel turns and HLL rope remains

stationary. Do not over tension lifeline.

6. Once horizontal lifeline has been tensioned properly, push unfastening lever against

tensioner. See Figure #1.

FIGURE #1

7. Take excess horizontal lifeline and tie in knot close to tensioner.

8. Use only FallTech™ approved shock absorbing lanyards or self-retracting lifelines

for attachment to horizontal lifeline. Shock absorbing lanyards cannot be directly

attached to horizontal lifeline; they must be attached to the O-rings included with

system. Each O-Ring is rated for one shock absorbing lanyard or self-retracting

lifeline attachment.

DISMANTELING HORIZONTAL LIFELINE SYSTEM

With a screw driver or connecting type bar, raise unfastening lever. Loosen lifeline by

sliding through tensioner. Disconnect self locking carabiner from anchor sling D-Ring or

anchorage point. Loosen anchor slings and remove from support structure.

IMPORTANT: If you fall, remove the horizontal lifeline system from service and

immediately report incident to your supervisor or the safety department.

7.0 MAINTENANCE & STORAGE

1. Inspection must be carried out by a competent person trained in the inspection and

replacement of the system. A record log of all servicing and inspection dates for this

system should be maintained by the company safety officers at intervals of no less

FALLTECH

ALEXANDER ANDREW, INC.

10240 S Alameda St

South Gate, CA 90280-5551

Phone (800) 719-4619 Fax (323) 752-5613

9

Page 10

Instruction #I-77000, Rev 2

than twice per year. This system and all components must be withdrawn from service

if subjected to fall arresting forces. Only original FallTech™ Replacement parts are

approved for use in this device. Contact your FallTech™ distributor or FallTech™

Customer Service Department at (800) 719-4619 if you have any questions.

2. Maintenance and storage of equipment shall be conducted by the user’s organization

in accordance with FallTech™ instructions. Unique issues which may arise due to

conditions of use shall be addressed with FallTech™.

3. Equipment which is in need of or scheduled for maintenance shall be tagged “DO

NOT USE” and removed from service.

4. Hardware should be wiped clean with a rag to remove dirt and grease. Lubricate with

a light oil to insure good working order and protect against corrosion. Wipe off

excessive amounts of oil to avoid the accumulation of dirt.

5. Store in a clean, dry area free from excessive heat, steam, sunlight, harmful fumes,

corrosive agents and rodents.

WARNING: DO NOT USE FALL PROTECTION EQUIPMENT THAT HAS NOT

BEEN MAINTAINED AND STORED PROPERLY.

8.0 INSPECTION

Inspection procedures for in field visual inspection:

1. The FallTech™ Systems shall be inspected by the user before each use and

additionally by a Competent Person other than the user at intervals of no less than

twice a year. If equipment is in a very harsh and/or corrosive environment, additional

inspections may be necessary. Detailed inspections must be recorded. A

comprehensive Inspection Checklist is included with all FallTech™ instructions.

2. If an inspection reveals defects that could affect the function of the Personal

Protective Equipment, remove from service immediately and discard or all Protection

equipment, damage, or inadequate maintenance of the system, the components

affected shall be permanently removed from service to undergo adequate corrective

maintenance before return to service.

3. Remove the system from service if:

• The system has arrested a fall;

• The system has not been inspected in the last six months;

• The label(s) is missing or illegible;

• Alteration of any components;

• Inspection reveals excessive wear, cracks, or signs of deformation.

Only FallTech™ manufacturing personnel or entities authorized in writing by the

manufacturer shall make repairs to the equipment. No unauthorized repairs or

modifications are allowed.

FALLTECH

ALEXANDER ANDREW, INC.

10240 S Alameda St

South Gate, CA 90280-5551

Phone (800) 719-4619 Fax (323) 752-5613

10

Page 11

Instruction #I-77000, Rev 2

Inspection Guidelines:

Every time the horizontal lifeline is used, inspect it for excessive wear or damage. If

there are any defective conditions, remove immediately from service immediately.

Inspect all termination hardware and cables for cuts, abrasions or excessive wear.

Excessive wear is a signal to retire cable from service and replace with new cable and

hardware. NOTE: Remove the sources of damage away from the system.

Check clearance below the walking/working surface including obstructions in the path of

a potential fall. If there are any sharp or dangerous obstructions below walking/working

surface, remove from the path of a possible fall.

Maintenance:

1. Inspect all hardware for distortion and deformation. Check for visible cracks,

excessive wear and tear, corrosion and chemical erosion. Also, remove hardware if

there are sharp edges.

2. Inspect anchor points for physical damage, wear or corrosion that could affect their

function in the event of a fall.

3. Inspect carabiners and snaphooks to ensure that gate operates properly.

4. Inspect all hardware for correct operation, broken or missing pieces, and loose or

missing items.

5. Inspect all synthetic lifelines for cuts, fraying, fluffing, abrasion, melting and

chemical wear.

6. Inspect synthetic harnesses and lanyards for the same items outlined in #5, in addition

to inspecting for discoloration, damaged stitching, and exposed warning labels.

7. Inspect all labels to ensure that the Personal Fall Protection equipment has been

inspected by a Competent Person. Labels must be readable at all times.

FALLTECH

ALEXANDER ANDREW, INC.

10240 S Alameda St

South Gate, CA 90280-5551

Phone (800) 719-4619 Fax (323) 752-5613

11

Page 12

Instruction #I-77000, Rev 2

INSPECTION LOG INSPECTION LOG

Manufacturer: Manufacturer:

Model No: Model No:

Mfg. Date: Mfg. Date:

INSPECTION LOG INSPECTION LOG

Manufacturer: Manufacturer:

Model No: Model No:

Mfg. Date: Mfg. Date:

INSPECTION LOG INSPECTION LOG

Manufacturer: Manufacturer:

Model No: Model No:

Mfg. Date: Mfg. Date:

Part Inspection

Date

Inspector Comments Pass/Fail Corrective

Action

Approved

By

Taken

Anchor

Sling

Self-locking

carabiner

Tensioner

Lifeline

O-Rings

WARRANTY

FallTech warrants to the purchaser that the product is free from defects in material and

workmanship, and agrees to replace any defective product within one (1) year from date

of installation or use by the owner, provided that this period shall not exceed two (2)

years from the date of shipment. This warranty is non-transferable. Warranty covers

defects in material or workmanship; it does not cover conditions resulting from normal

wear and tear, neglect, abuse or accident. All returns must have return authorization,

obtained from Customer Service, and all shipments of returned goods must be prepaid.

FALLTECH

ALEXANDER ANDREW, INC.

10240 S Alameda St

South Gate, CA 90280-5551

Phone (800) 719-4619 Fax (323) 752-5613

12

Loading...

Loading...