Falcon G2102 C, G2112 C/2, G2112 C Installation And Servicing Instructions

G2102 C CONVECTION OVEN RANGE

G2112 C & G2112 C/2 CONVECTION

OVENS

INSTALLATION and SERVICING INSTRUCTIONS

These appliances must be installed and serviced by a competent person as stipulated by the Gas

Safety (Installation & Use) Regulations.

IMPORTANT

The installer must ensure that the installation of the appliance is in conformity with these instructions and

National Regulations in force at the time of installation. Particular attention MUST be paid to –

BS7671 I.E.E. Wiring Regulations

Electricity At Work Regulations

Gas Safety (Installation & Use) Regulations

Health And Safety At Work etc. Act

Local and National Building Regulations

Fire Precautions Act

Detailed recommendations are contained in

Institute

Of Gas Engineers published documents:

IGE/ UP/ 1, IGE/ UP/ 2

BS6173 and BS5440

The appliances have been CE-marked on the basis of compliance with the Gas Appliance Directive, EMC

and Low Voltage Directive for the Countries, Gas Types, Gas Pressures and voltages as stated on the

Data Plate.

WARNING - TO PREVENT SHOCKS, ALL APPLIANCES MUST BE EARTHED

On completion of the installation, these instructions should be left with the Engineer-in-Charge for reference

during servicing. Further to this, The Users Instructions should be handed over to the User, having had a

demonstration of the operation and cleaning of the appliance.

IT IS MOST IMPORTANT THAT THESE INSTRUCTIONS BE CONSULTED BEFORE INSTALLING AND

COMMISSIONING THIS APPLIANCE. FAILURE TO COMPLY WITH THE SPECIFIED PROCEDURES

MAY RESULT IN DAMAGE OR THE NEED FOR A SERVICE CALL.

PREVENTATIVE MAINTENANCE CONTRACT

In order to obtain maximum performance from this unit we would recommend that a Maintenance Contract

be arranged with SERVICELINE. Visits may then be made at agreed intervals to carry out adjustments and

repairs. A quotation will be given upon request to the contact numbers below.

WEEE Directive Registration No. WEE/DC0059TT/PRO

At end of unit life, dispose of appliance and any replacement parts in a safe manner,

via a licensed waste handler.

Units are designed to be dismantled easily and recycling of all material is encouraged

whenever practicable.

Falcon Foodservice Equipment

Head Office and Works

Wallace View, Hillfoots Road, Stirling, FK9 5PY, Scotland.

Serviceline

PHONE: 01438 363 000

T100970 Ref.2

Warranty Policy Shortlist

Warranty does not cover:Correcting faults caused by incorrect installation of a product.

Where an engineer cannot gain access to a site or a product.

Repeat commission visits.

Replacement of any parts where damage has been caused by misuse.

Engineer waiting time will be chargeable.

Routine maintenance and cleaning.

Gas conversions i.e. Natural to Propane gas.

Descaling of water products and cleaning of water sensors where softeners/conditioners are not fitted,

or are fitted and not maintained.

Blocked drains.

Independent steam generation systems.

Gas, water and electrical supply external to unit.

Light bulbs.

Re-installing vacuum in kettle jackets.

Replacement of grill burner ceramics when damage has been clearly caused by misuse.

Where an engineer finds no fault with a product that has been reported faulty.

Re-setting or adjustment of thermostats when unit is operating to specification.

Cleaning and unblocking of fryer filter systems due to customer misuse.

Lubrication and adjustment of door catches.

Cleaning and Maintenance

Cleaning of burner jets

Poor combustion caused by lack of cleaning

Lubrication of moving parts

Lubrication of gas cocks

Cleaning/adjustment of pilots

Correction of gas pressure to appliance.

Renewing of electric cable ends.

Replacement of fuses

Corrosion caused by use of chemical cleaners.

SECTION 1 – INSTALLATION

Important: Check that no damage has occurred to the appliance or power cable during

transit.

If damage has occurred do not install/use the appliance.

Installation, periodic testing, repair and fixed wiring connections should only be

undertaken by a competent electrician.

Ensure that the mains power cable is routed free from the appliance to avoid damage.

We recommend supplementary electrical protection with the use of a residual current

device.

Take care when removing or replacing cast iron components as they are heavy items.

Pan Support - 5kg

UNLESS OTHERWISE STATED, PARTS WHICH HAVE BEEN PROTECTED BY THE MANUFACTURER

ARE NOT TO BE ADJUSTED BY THE INSTALLER.

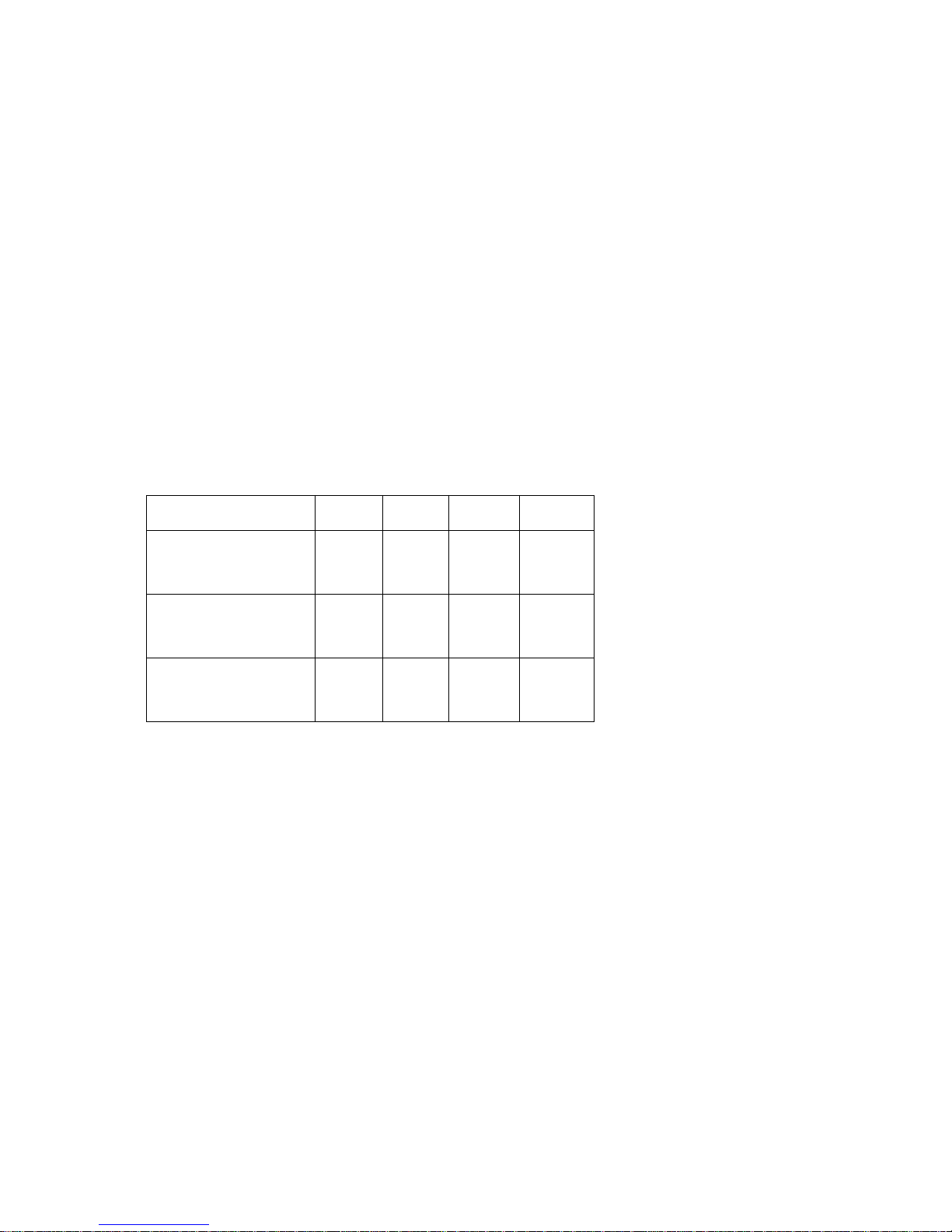

1.1 MODEL NUMBERS, NETT WEIGHTS and DIMENSIONS

MODEL

WIDTH

mm

DEPTH

mm

HEIGHT

mm

WEIGHT

kg

G2102 C

RANGE

900

770

870

221

G2112 C

OVEN ON STAND

900

770

1310

190

G2112 C/2

DOUBLE TIER OVEN

900

770

1465

362

1.2 SITING

All units, other than G2112 C oven on stand, must be installed on a non-combustible floor. All units

must be situated on a level surface. Although the appliance feet are adjustable to facilitate levelling,

the adjustment range is limited.

A clearance of at least 150mm must be allowed from any combustible wall.

If practicable, it is recommended that a space of at least 400mm be allowed from any side wall to

provide clearance for adjusting the rear levelling bolts, and to effect the removal of the RH side

panel to facilitate servicing.

A vertical clearance of 1200mm minimum must be allowed between the top edge of flue outlet and

any overlying combustible surface.

If unit is being installed as part of a suite, it is also recommended that it be positioned at the RH end

to provide unrestricted access for servicing the controls, etc. Furthermore, if installed in a suite,

either central or adjacent to a wall, with a boxed-in void at the rear, it is vitally important that the void

be adequately ventilated to ensure a supply of air to the motor cooling fan at the rear of the oven.

Important

Care must be taken not to disturb the air for combustion admission and evacuation of products of

combustion on appliances fitted with open burners.

1.3 VENTILATION

This appliance must be installed in a suitably ventilated room in accordance with the regulations in

force.

Adequate ventilation, whether natural or mechanical, must be provided to ensure sufficient fresh air

for combustion and for removal of combustion and cooking vapours.

The fresh air requirement for this appliance at a rate of 3M³/hour per kW is 150M³ of fresh air per

hour.

This appliance is to be installed with sufficient ventilation to prevent the occurrence of unacceptable

concentrations of substances harmful to health in the room which they are installed.

The appliance flue discharges vertically at the rear. There must be no direct connection of the flue

to outside air or to a mechanical extraction system. Standing the appliance below a ventilated

canopy is the most suitable arrangement.

Recommendations for ventilation for catering appliances are given in BS 5440:2.

For multiple installations, the requirements should be added together. Installation should be made in

accordance with local and/or national regulations applying at the time, and a competent installer

must be employed.

Care must be taken not to disturb the air for combustion admission and evacuation of products of

combustion on appliances fitted with open burners.

1.4 GAS SUPPLY

The incoming service must be of sufficient size to supply full rate without excessive pressure drop. A

gas meter is connected to the service pipe by the Gas Supplier. Any existing meter should be

checked by the Gas Supplier to ensure the meter is of adequate capacity to pass the required rate

of gas.

Installation pipe work should be fitted in accordance with IGE/UP/2. The pipe should be of adequate

size but not smaller than the gas inlet.

Gas supply tubing or hose shall comply with the national requirements in force, and shall be

periodically examined and replaced as necessary. The tubing or Flexible hose must not exceed

1.5m in length.

Connections are as follows:

G2102 C Range:

Rp3/4• (3/4" BSP female)

G2112 C Oven:

Rp1/2 (1/2"BSP female)

An isolating cock must be located close to the appliance to allow shut-down during an emergency or

servicing. The installation must be tested for gas soundness and purged as specified in IGE/UP/1.

The position of the isolating cock must be made known to the user of the equipment and/or

supervisor.

The isolating cock must be easily accessible to the users of the appliance.

Note

The G2102 C open top range is supplied complete with the necessary pipework for linking oven and

open top burner sections. The governor necessary for open top burners is incorporated in this

pipework for Natural Gas operation. The oven control valve incorporates a governor for the oven

and an extra governor must not be fitted to any of these appliances and an extra governor must not

be fitted to any of these appliances.

1.5 ELECTRICAL SUPPLY

Installation, periodic testing, repair and fixed wiring connections should only be

undertaken by a competent electrician.

The oven is equipped with a length of 3-core flexible cord for connecting to an electrical supply. A

standard 13 amp socket outlet can be used, in which case the plug must be fitted with a 3 amp fuse.

If the supply is through a distribution fuse box, it must be via a fuse having a maximum rating of 5

amps.

We recommend supplementary electrical protection with the use of a residual current device (RCD).

1.6 WATER SUPPLY

Not applicable to these appliances.

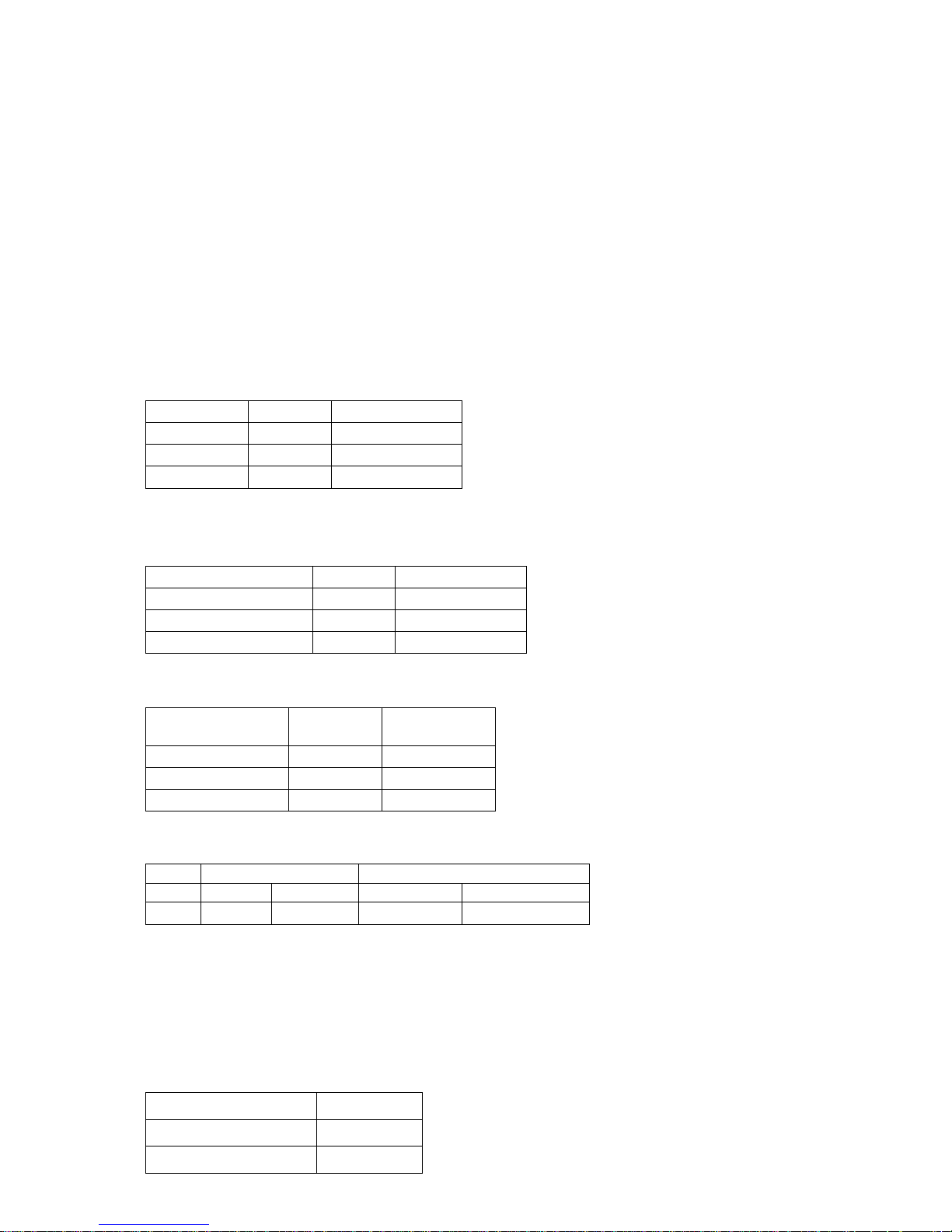

1.7 TOTAL GAS RATES -

Natural I2H and Propane Gas I3P

Model

kW (net)

Btu/hr (gross)

G2102 C

49.8

187,000

G2112 C

18

67,600

G2112 C/2

36

135,100

1.7.1 Individual Burner Ratings -

Natural I2H and Propane Gas I3P

Burner type

kW (net)

Btu/hr (gross)

Open Top (x6)

5.3

20,000

Oven

18

67,600

Oven Pilot/Ignition

0.25

940

1.8 INJECTOR DIAMETERS - Natural I2H & Propane Gas I3P

Natural

Gas I2H

Propane

Gas I3P

Open top

Ø1.92mm

Ø1.2mm

Oven

Ø3.3mm

Ø2.2mm

Oven Pilot

G29.2

G24.1

1.9 GAS PRESSURE

Supply Pressure

Burner Operating Pressure

Nat I2H

Prop I3P

Nat I2H

Prop I3P

mbar

20

37

15

37

1.10 BURNER ADJUSTMENTS

1.10.1 Burner Aeration

All burners have fixed aeration, and no modifications to the size of air-entry should be attempted.

1.10.2 Open Top Gas Tap – Low Position Screw Details

The Open Top Low Position flow to burner is governed by the size of the fixed hole in Low Position

Screw as detailed below: - The screw is located to Right hand side of the gas tap spindle.

Turndown Flow

1.1kW

Natural Gas I2H

No.76

Propane Gas I3P

No.51

1.11 FAN UNIT

This fan has two impellors, directly mounted on the motor shaft. The main impellor is inside the

oven, its purpose being to circulate air across the heat-exchangers and around the cooking space,

while a smaller, externally mounted impellor serves to cool the motor and control compartment. The

fan turns anticlockwise when viewed from inside the oven chamber.

SECTION 2 - ASSEMBLY and COMMISSIONING

2. 1 ASSEMBLY

2.1.1 G2102 C Open Top Range

Important: Before installation, ensure that no damage has occurred to the appliance or

flexible power cord.

If there are signs of damage, DO NOT INSTALL THE APPLIANCE.

Installation, periodic testing, repair and fixed wiring connections should only be undertaken

by a competent electrician.

a) Unpack unit, open oven doors and remove inter-connecting pipework (and governor on natural

gas appliances) from inside.

b) Fit interconnecting pipework, leaving incoming pipe entry facing in desired direction to suit

service pipe.

c) Place unit into desired location, if necessary adjust levelling bolts. Access to these, at front, is

gained upon removing burner grille below oven doors. The rear bolts are accessible via

openings in outer back panel. Do not raise unit more than is absolutely necessary to effect

levelling.

d) Connect gas supply and test for gas soundness.

e) Connect electrical supply ensuring flexible cord does not make contact with flue or other hot

areas.

The wires of flexible cord must be connected to supply as follows:

Brown to Live

Blue to Neutral

Green/Yellow to Earth

This appliance MUST be earthed.

We recommend supplementary electrical protection with the use of a residual current device (RCD).

2.1.2 G2112 C Oven on Legs

Installation procedure is as Section 2.1.1, but omits (b) and for (c) it is not necessary to remove

lower front panel. Levelling is effected by turning lower parts of the feet.

2.1.3 G2112 C Oven on Stand

Installation procedure is as follows:

a) Unpack oven and stand that is packed separately in a dismantled state.

b) Assemble stand (see Figure 1) using the following procedure:

1. Position bottom shelf (A) over frame (B) and secure stand legs (C) to frame (B) using M8

fixings to secure from below.

2. Fit adjustable legs (D) to frame (B) using M6 fixings provided.

3. Using pliers or a similar tool, bend and remove tabs from front brackets.

Loading...

Loading...