Page 1

GAS CHIEFTAIN RANGES

BOILING TABLES AND OVENS

USERS INSTRUCTIONS

SECTION 1 - GENERAL DESCRIPTION

SECTION 2 - LIGHTING and OPERATIONS

SECTION 3 - COOKING HINTS

SECTION 4 - CLEANING and MAINTENANCE

These appliances have been CE-marked on the basis of compliance with the Gas Appliance Directive

for the Countries, Gas Types and Pressures as stated on the Data Plate.

These appliances MUST BE installed by a qualified person in compliance with the INSTALLATION AND

SERVICING INSTRUCTIONS and National Regulations in force at the time. Particular attention MUST be paid to the

following:

Gas Safety (Installation & Use) Regulations

Health and Safety at Work Act

Furthermore, if a need arises to convert the appliance for use with another gas, a qualified person must be consulted.

Those parts which have been protected by the manufacturer MUST NOT be adjusted by the User.

Users should be conversant with the appropriate provisions of the Fire Precautions Act and the requirements

of the Gas Safety Regulations. In particular the need for regular servicing by a qualified person to ensure

the continued safe and efficient performance of the appliance.

WARNING - TO PREVENT SHOCKS, ALL APPLIANCES WHETHER

GAS OR ELECTRIC, MUST BE EARTHED.

Upon receipt of the User's Instruction manual, the installer must instruct the responsible person(s) of the correct

operation and maintenance of the appliance.

This equipment is ONLY FOR PROFESSIONAL USE, and shall be operated by QUALIFIED persons. It is the

responsibility of the Supervisor or equivalent to ensure that users wear SUITABLE PROTECTIVE CLOTHING and to

draw attention to the fact that, some parts will, by necessity, become VERY HOT and will cause burns if touched

accidentally.

WEEE Directive Registration No. WEE/DC0059TT/PRO

At end of unit life, dispose of appliance and any replacement

parts in a safe manner, via a licensed waste handler.

Units are designed to be dismantled easily and recycling of all

material is encouraged whenever practicable.

T100628 Ref.2

Falcon Foodservice Equipment

HEAD OFFICE AND WORKS

Wallace View, Hillfoots Road, Stirling. FK9 5PY. Scotland

SERVICELINE CONTACT

Phone: 01438 363 000 Fax: 01438369 900

Page 2

2

SECTION 1 -

GENERAL DESCRIPTION

Training and Competence

To help ensure the safe use of this appliance, there is a requirement for you to provide whatever information,

instruction, training, and supervision as is necessary to ensure, so far as is reasonably practicable, the health and

safety of all users.

For further help and information on training and competence we would refer you the Health and Safety Executive

website; www.hse.gov.uk document ref: health and safety training INDG345. International customers should default

to the health and safety guidelines provided by your government body.

Risk Assessment

As part of managing the health and safety of your business, you must control any risks identified in your commercial

kitchen. To do this, you need to think about what might cause harm to people and decide whether you are taking

reasonable steps to prevent that harm. This is known as risk assessment. It is important to consider the environment

around the appliance as well as the appliance itself. For example, oil or food spills will present a significant risk to

users so the need to immediately clean up such spills must be reflected in staff training.

For further help and information on risk assessments, we would refer you to you the Health and Safety Executive

website; www.hse.gov.uk document ref: risk assessment INDG163. International customers should default to the

health and safety guidelines provided by your government body.

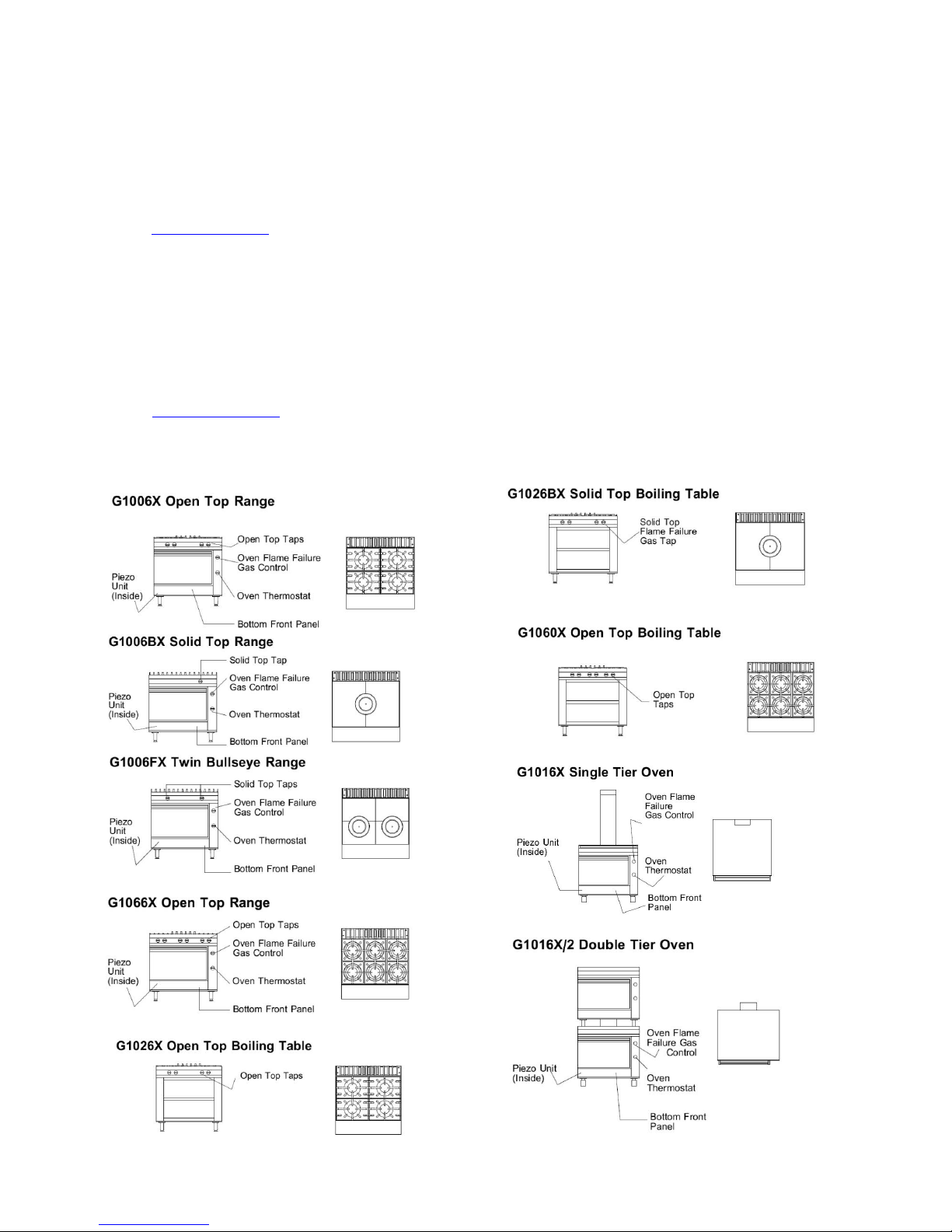

1.1 Control Knob Details

Page 3

3

SECTION 2 - LIGHTING and OPERATIONS

LIGHTING THE BURNER

2.1 Open Top Burners

All taps incorporate a flame failure facility. The burners are of equal power and the tap which controls a

specific burner is identified by the icon adjacent to the tap. See Figures 1 and 2.

Figure 1. G1006X and G1026X Open top Figure 2. G1006X and G1060X Open Top

To Light a Burner

Turn control knob to full flame position. Push knob in fully and apply a light to burner. Continue to hold knob

in for 20 seconds before release. Observe that burner remains lit.

If a burner fails to light, wait 3 minutes and repeat.

To Extinguish the Burner

Turn tap fully clockwise to OFF position.

Using the Open Top

The open top burner can support pot sizes of 220mm to 300mm diameter.

For best energy performance, the pan should be centred over the burner. Avoid flames licking up the side of

pan as this wastes energy and overheats handles. Adjust gas control to suit pan diameter.

Very large pans are best located over the front burners.

2.2 SOLID TOP

2.2.1 G1006BX / G1026BX

The single solid hotplate is composed of two filling plates,

one ring and one centre bullseye. A radial burner is located

centrally below hotplate and is operated by the relative

control knob. See Figure 3 to identify tap markings.

2.2.2 G1006FX

The twin hotplate version has four filling plates, two rings and two centre bullseyes. Burners are located

centrally below toward front of each hotplate. The controls are indicated by corresponding markings on fascia.

See Figure 3 to identify markings.

Warning - If burner is extinguished intentionally or otherwise, NO attempt to re-light the appliance should be

made until at least 3 minutes have elapsed.

The procedure for lighting a burner is as follows (Refer to Figure 3) –

1.

Remove centre bullseye using special tool provided.

2.

Have an ignition device ready in one hand.

3.

With other hand, push control knob in and turn it anti-clockwise until knob marking is aligned with ignition

symbol on panel.

4.

Apply ignition device to pilot, keep knob pushed in.

5.

Release knob after approximately 20 seconds. Pilot should remain lit. If not, push in control knob and

turn it clockwise to off position. Wait 3 minutes, and then repeat from Step 2.

6.

Having established pilot flame, replace centre bullseye.

7.

Turn knob anti-clockwise to full flame symbol.

8.

If desired, burner can be turned down to low or simmer setting by turning knob fully anti-clockwise to the

small flame symbol.

To Turn the Burner Off

9.

To extinguish a burner, but leave the pilot lit, turn knob to ignition symbol on panel.

10.

To extinguish a burner, push knob in and turn to off position.

Note - Most turning movements of control knob have to be preceded by pushing it in.

Page 4

4

Using the Solid Top

Getting the best out of this type of heat source is largely a matter of experience, coupled with the

requirements of the task in hand. For certain applications, such as heating a pot quickly, it is expedient to

remove centre ring and place pot directly over burner. If it is necessary to heat the entire surface, the ring

must be in position. Note: The minimum temperature of the hottest point of the Solid Top is 400˚C.

In the interests of economy, it is recommended that the appliance should not be left unattended on full setting.

If it is necessary to keep the hob area hot for any length of time, the control should be set to low.

Never leave the gas on without a pot when the centre ring has been removed as such practice wastes

energy. The hottest area of the plate is the centre of the bullseye and toward the rear. The front and sides are

cooler.

Never leave an operating appliance unsupervised and always turn appliances off at the end of service.

Never add cold liquids to hot oil as an explosion may occur.

2.3 Oven

The oven controls are located on RH side of appliance. These consist of a thermostat and a flame failure gas

control. A piezo igniter is located behind lower hinged panel to ignite oven pilot burner.

Warning - If pilot burner is extinguished either intentionally or otherwise, no attempt to re-light the gas should

be made until at least 3 minutes have elapsed.

The procedure for lighting oven burner is as follows:

1.

Lower bottom front panel.

2.

Turn thermostat knob to 275ºC.

3.

Push flame failure gas control in and turn it anti-clockwise to ignition position.

4.

Holding flame failure gas control fully in, press igniter button and observe that pilot lights. If it does not

light, repeatedly press igniter button until it does.

5.

When pilot is lit, continue to hold flame failure gas control fully in for 20 seconds then release it. If pilot

goes out, push in flame failure gas control and turn it clockwise to off position. Wait for 3 minutes, and

then repeat from 3.

6.

When pilot is established, turn flame failure gas control anti-clockwise to full flame position (large flame

symbol), thus lighting the main burner.

7.

Close bottom front panel.

Low Flame Setting

8.

Push in flame failure gas control and turn it anti-clockwise to low flame position (small flame symbol). This

setting provides gentle heat only and is not suitable for heavy load cooking.

To Turn the Burner Off

9.

To turn down main burner to ignition rate, turn flame failure gas control to ignition symbol position.

10.

To turn off main burner and pilot, push in flame failure gas control and turn it to OFF position. Turn

thermostat knob to OFF position also.

Using the Oven

Oven temperature is controlled automatically by a thermostat. Leave flame failure gas control full on during

the period the oven is in use. The following cooking charts give basic temperatures and times required, but for

best performance, the following instructions should be carried out.

Shelves

Two shelves are supplied with appliance, which can be supported in any of four different positions within the

oven. When two shelves are used, they should be positioned with at least one shelf space left between them

(i.e. top and third top or second top and bottom positions). Always push shelves all the way to oven rear and

ensure they are inserted correctly.

Shelf stops at the rear should be pointing upwards.

Tray Size

Tray sizes up to a maximum of 650mm x 530mm can be used. Smaller trays should be placed centrally on the

shelves.

The oven accommodates 2/1 gastronorm trays.

Pre-heat Time

Allow at least 45 minutes to heat the oven up from cold before loading with food.

Put the food in quickly to minimise heat loss and close the door firmly after insertion.

Page 5

5

SECTION 3 - COOKING HINTS

Care must be taken by the operator to avoid burns if opening the oven doors when chamber is hot.

3.1 Small cakes, scones, etc

When preparing two trays, the upper tray will be cooked first, it should then be removed from the oven and the

lower tray raised to the upper position.

3.2 Yorkshire Puddings, etc, in baking tins

When cooking on two shelves, the upper and lower tins should be interchanged half-way through the cooking

process.

3.3 Fruit cakes in large tins

Cooking time will vary considerably according to weight, richness, and depth of mixture. When cooking on two

shelves, tins should be interchanged halfway through the cooking process.

Approximate centre oven temperatures are indicated in the following table.

ºC

Condition

125 - 150

Low Heat

175

Moderate

200 - 225

Fairly Hot

250

Hot

275

Very Hot

Cooking Charts

Pastry

Temp.

Setting

Shelf

Position

Time

Fruit Pies

225

3 for single

tray.

2 & 4 for

two trays

35 to 45 mins

Plate Tart

225

30 to 40 mins

Puff & Rough Puff Tarts

250

15 to 25 mins

Sausage Rolls

250

20 to 25 mins

Scones

260

10 to 15 mins

Puddings

Temp.

Setting

Shelf

Position

Time

Custard

165

40 to 60 mins

Milk

150

45 to 90 mins

Yorkshire Pudding

240

33 to 40 mins

Cakes

Temp.

Setting

Shelf

Position

Time

Slab Cake (Rich)

150

3 for single

tray.

2 & 4 for two

trays

3 hours

1½” Slab Sponge

200

25 to 35 mins

Queen Cakes

200

20 to 25 mins

Sponge Sandwich

200

20 to 25 mins

Very Rich Cake (Xmas)

150

3

2 to 2½ hours

Bread Rolls

250

As Slab Cake

15 to 25 mins

Page 6

6

SECTION 4 - CLEANING and MAINTENANCE

When removing heavy items to aid cleaning or maintenance, particular care should be taken. A manual handling risk

assessment is the best way to determine the level of risk to anyone using or maintaining this equipment. To help with

such an evaluation, we have included the weights of individual components that may present significant risk.

For further help and information on manual handling and associated risk assessment, we would refer you to the

Health and Safety Executive website; www.hse.gov.uk document ref: manual handling at work INDG143.

International customers should default to the health and safety guidelines provided by your government body.

The cleaning of fryers or other appliances that use hot oil, present significant risks to end users, and particular care

should be taken. Cold water and hot oil, for example, are an explosive mix and should be avoided at all costs.

Other useful references for health and safety issues

www.hse.gov.uk

Essentials of health and safety at work ISBN978

Noise at work INDG362

Safe systems of work

Other notes added to the body of the instructions.

Take care when removing cast iron components when cleaning, as they are heavy items.

Pan Supports – 12kg each

Solid Top Castings – 24kg each

Twin Bullseye Castings – 12kg each

Flue – 13.5kg

It is advised that the appliance be cleaned daily after use. This should be carried out using hot soapy water, ensuring

that it be thoroughly rinsed and dried after any such cleaning. Grease should be removed with nylon or scotch

cleaning pads. Take care, especially when these are new as they cause scratching.

A smooth-bladed metal scraper is handy to remove deposits of burned on grease from hob fillings.

Before removing any of the parts described below, note how they are arranged and replace in the same position.

4.1 OPEN HOTPLATES

Pan supports, burners and spillage trays can be easily removed for cleaning. After washing, dry the burners

thoroughly and remove any excess water from inside. The burners are interchangeable.

Ensure that burner caps are located correctly.

Pan Supports

Clean with warm soapy water. Abrasives such as fine steel wool, proprietary cleaning pads and nylon pan

scrubbers should only be used with care, in cases of extreme overspill.

Dry pan supports thoroughly by hand.

NEVER LEAVE TO DRY NATURALLY.

After drying, apply a light film of vegetable oil to the supports to prevent oxidation.

4.2 SOLID HOTPLATES

Plates can be removed for cleaning access. Having gained access, clear accumulated debris which may have

gathered in the burner tray, particularly that which has gathered at the hotplate support edges.

Warning - The castings are very heavy and care should be taken during handling of such components.

4.3 OVEN

The oven linings are stainless steel and can be cleaned easily. Wipe down with a soapy cloth while the oven

is still warm.

Shelf runners can be removed as follows:-

Lift upward and pull the bottom edge toward the oven centre before dropping the runner. To replace

a runner, ensure that the long leg is at the top. Replace the shelves correctly.

Base linings can be removed by lifting the rear lining slightly and pulling out the base panels.

Cleaning Note

Important

Never clean with a jet of water or steam clean.

Never clean appliances whilst they are hot.

All spills on to the appliance and on the floor should be cleaned up immediately.

Loading...

Loading...