Page 1

NMD 11-04

INSTRUCTION

LEAFLET

AND

GUARANTEE

RIGID FRAME AND FORKS – LIFETIME

All rigid frames and forks (with the exception of suspension forks, suspension

frames and rear shocks) - lifetime warranty.

COMPONENT PA RTS – 1 YEAR

All other components (including suspension forks, suspension frames and rear

shocks) - 1 year warranty.

All the above warranties apply, provided the bicycle has been properly cared

for, maintained and used, and are warranted against manufacturing or material

defects for the warranty period stated. This warranty is applicable from the date of

purchase for the original owner only, who must produce proof of purchase in order

to validate any claim. Claims must be submitted through your retailer. This warranty

does not include labour and transportation charge. The company can accept no

responsibility for consequential or special damage. This warranty applies only in

the case of defective components and does not cover the effects of normal wear

and tear or damage caused by accident, abuse, excessive loads, neglect, improper

assembly, alteration of original specification, improper maintenance or the addition

of any item inconsistent with the original intended use of the cycle.

No bicycle is indestructible and no claims will be accepted for damage caused

by improper use, competition use, stunt riding, ramp jumping, leaping or

similar activities. Our bicycles conform to BS 6102: Part 1: 1992 as set by the

British Institute Testing Services. We reserve the right to change or amend any

specifications within this brochure without notice. All information and specifications

within this brochure are correct at the time of going to press.

NOTIC E

In offering this warranty, Falcon Cycles Ltd in no way seeks to diminish the

statutory rights of the consumer.

Pleas e ref e r to o u r webs i te fo r the l a t est i n forma t i on.

http: / /www.falc o ncycl e s .co.u k

FALCON CYCLES LTD, P.O. BOX 3, BRIDGE STREET, BRIGG,

NORTH LINCOLNSHIRE, DN20 8PB

TEL: (01652) 656000 FAX: (01652) 650040

CYCLES LTD

1

Page 2

Complete this Section and keep it in a safe place. In the event of your machine being

lost or stolen this information should be passed on to the police.

Name ...........................................................................................................................................

Address .......................................................................................................................................

.....................................................................................................................................................

Model Name & Type ...................................................................................................................

Serial No....................................Frame Size & Colour................................................................

Extras and Identifying Marks .....................................................................................................

...................................................................................................................................................

..................................................................................................................................................

FALCON CYCLES LTD

This bike has been designed, developed and sourced fully built by Falcon Cycles Ltd. North

Lincolnshire.

Falcon has carefully selected and developed the product with some of the best suppliers throughout

the world. These suppliers have satisfied the exacting quality standards that have been developed by

Falcon, a company with over a century long reputation for quality and craftsmanship.

All Falcon Cycles Ltd are built to conform to British Standards.

Suspension frames and forks and rear shock absorbers are covered by a separate guarantee.

Included in this manual are details on how to prepare your bicycle for riding, how to maintain your

bicycle to keep it roadworthy, information on accessories and recommendations and tips for a safe and

correct riding position.

Please ensure that the Bicycle Log Sheet below is completed at the time of purchase. The details will

be of value to the police in the unfortunate event of your bicycle ever being lost or stolen. They also act

as a record of your guarantee.

FRAME NUMBER

The frame number is located on the BS6102 label

at the bottom of the seat tube or stamped on the

bottom bracket shell or seat tube. We strongly

recommend that you have either the frame number

or your post code stamped on to your bicycle.

xxxxxx

Dealerʼs Address or Stamp

Date of purchase

2

Service

Dealer Stamp:

Date:

Dealer Stamp:

Date:

Dealer Stamp:

Date:

Dealer Stamp:

Date:

Highly Recommended for safety & support of warranty claims. At 6-monthly

intervals or more frequently if high mileage or subject to heavy use.

Page 3

YOUR BICYCLE — OWNERʼS RESPONSIBILITY

In this leaflet we describe and illustrate how to ride safely and keep your bicycle in a safe

trouble free operating condition.

Ownerʼs Responsibility and Important Points

Point 1

Carefully and thoroughly read this leaflet and follow the instructions.

Point 2

Any major service or adjustments on your bicycle should be carried out by a

professional repairer; however if this service is not available and you wish to make

adjustments yourself, this manual contains important tips on how to do it

.

CAUTION: Any adjustments you make are entirely at your own risk.

Point 3 To use your bicycle for freestyle and stunt riding, competitive events, off-road use or

any similar activities can be dangerous and you are warned that you assume the risk

for personal injury, damages or losses incurred from such use. The Retailer shall not

be liable to the purchaser of the bicycle or to third parties for consequential or special

damages.

Point 4 Bicycles are built with a variety of equipment and accessories, and you should

familiarise yourself with their function and purpose, to make sure you can operate

them correctly.

LOCATION OF PARTS WITH

ROUTINE MAINTENANCE CHECKS AND LUBRICATION

R

Q

P

Half Yearly — Remove and clean, lubricate chain, derailleur gears and all cables. Check and replace as required.

Refer to table of Recommended torque values - page 7.

O

N

N

M

L

K

S

J

I

H

H

G

G

F

E

E

D

C

B

A

NB — Wash cycle weekly with warm soapy water and polish dry with a soft cloth

T

3

A - Headset

Remove, clean and regrease

bearings yearly, checking if

replacements required.

B -

Stem Nuts

Ensure stem nuts and bolts are

tight. See page 7.

C -

Handlebars

Check handlebar bolt is tight.

Check brake levers securely

mounted to bars and brakes stop

smoothly and efficiently. See

page 7.

D -

Brakes

Lightly oil exposed cables

monthly. Maintain adjustment and

replace brake blocks when worn,

brake cables when frayed.

E -

Reflectors (front & rear)

Ensure reflectors are secure

and undamaged. Replace if

necessary.

F -

Front Suspension unit

(Dealer adjustment only)

G -

Tyres

Check for cuts and wear.

Maintain pressure indicated on

tyre wall for maximum efficiency.

H - Wheel

Reflectors

Check monthly. Securely fixed.

I -

Disc Brakes - Front

(Routine maintenance by your

dealer recommended.)

J -

Wheel Hubs

Grease bearings monthly. Adjust

cones to avoid free play from

side to side.

K - Pedals with Reflectors

Check all fittings are secure.

L - Cranks

Grease bearings monthly. Check

that axle bolts or cotterpin bolts

are tight. Check for free play in

bottom bracket.

Yearly, remove, clean and

regrease hub axles, bottom

bracket set and headset.

M - Chain

Keep lightly oiled weekly, clean

and lubricate half yearly.

N - Wheels

Check that axles are sealed

and secured properly. Rims

should be kept free from wax, oil,

grease and glue. Check for loose

or missing spokes.

O - Bottom Bracket

Clean, regrease yearly checking

for wear.

P -

Gears

Front and Rear — Lightly

oil moving parts. Maintain

adjustments of front and rear

derailleurs.

Q -

Disc Brake - Rear

(Routine maintenance by your

dealer recommended).

R - Seat and Stem Nuts

Be sure seat and

stem nuts are tight. See page 7.

S - Pedals

Lightly oil bearings monthly.

T - Frame Number

Page 4

SAFE CYCLING AND SAFETY TIPS

Before you ride your bicycle at any time make sure it is in a safe operating condition. Particularly

check that your:-

• Bicycleʼs nuts, bolts and parts are tight and not worn or damaged.

• Riding position is comfortable.

• Brakes are operating effectively.

• Steering is free with no excessive play.

• Wheels run true and hub bearings are correctly adjusted.

• Wheels are properly secured and locked to frame/fork.

• Tyres are in good condition and inflated to correct pressure.

• Pedals are securely tightened to pedal cranks.

• Gears are correctly adjusted.

• All reflectors are in position.

After you have made any adjustments to your bicycle, check that all nuts and bolts are securely

tightened and cables are free from kinks and fixed securely to the bicycle frame.

Every six months (more frequently if high mileage or subject to heavy use) your bicycle should

be professionally checked to ensure that it is in correct and safe working order. A ʻService

Recordʼ is provided for your use.

Do Notʼs when riding

• Do not ride on same side of road as oncoming traffic.

• Do not ride two abreast.

• Do not carry a passenger unless cycle is equipped to do so.

• Do not swerve in and out of traffic.

• Do not hang items over the handlebars to impede steering or catch in the front wheel.

• Do not hold on to another vehicle.

• Do not ride too close behind another vehicle.

CAUTION: Wet Weather Riding No brakes work as well under wet or icy conditions as they do

under dry conditions. In wet weather special precautions must be taken to assure safe stopping.

Ride slower than normal and apply your brakes well in advance of anticipated stops.

CAUTION: Night Riding We recommend you minimise the time you ride after dark. If you

should have to be out on your bicycle at night you must to comply with the law, use a headlight

(white) and a taillight (red) on your bicycle in addition to the all-around reflectors that are

fitted. For added safety wear light coloured clothing with reflective stripes. Check that the

reflectors are firmly secured in their correct position and clean and not obscured. Damaged

reflectors must be replaced immediately.

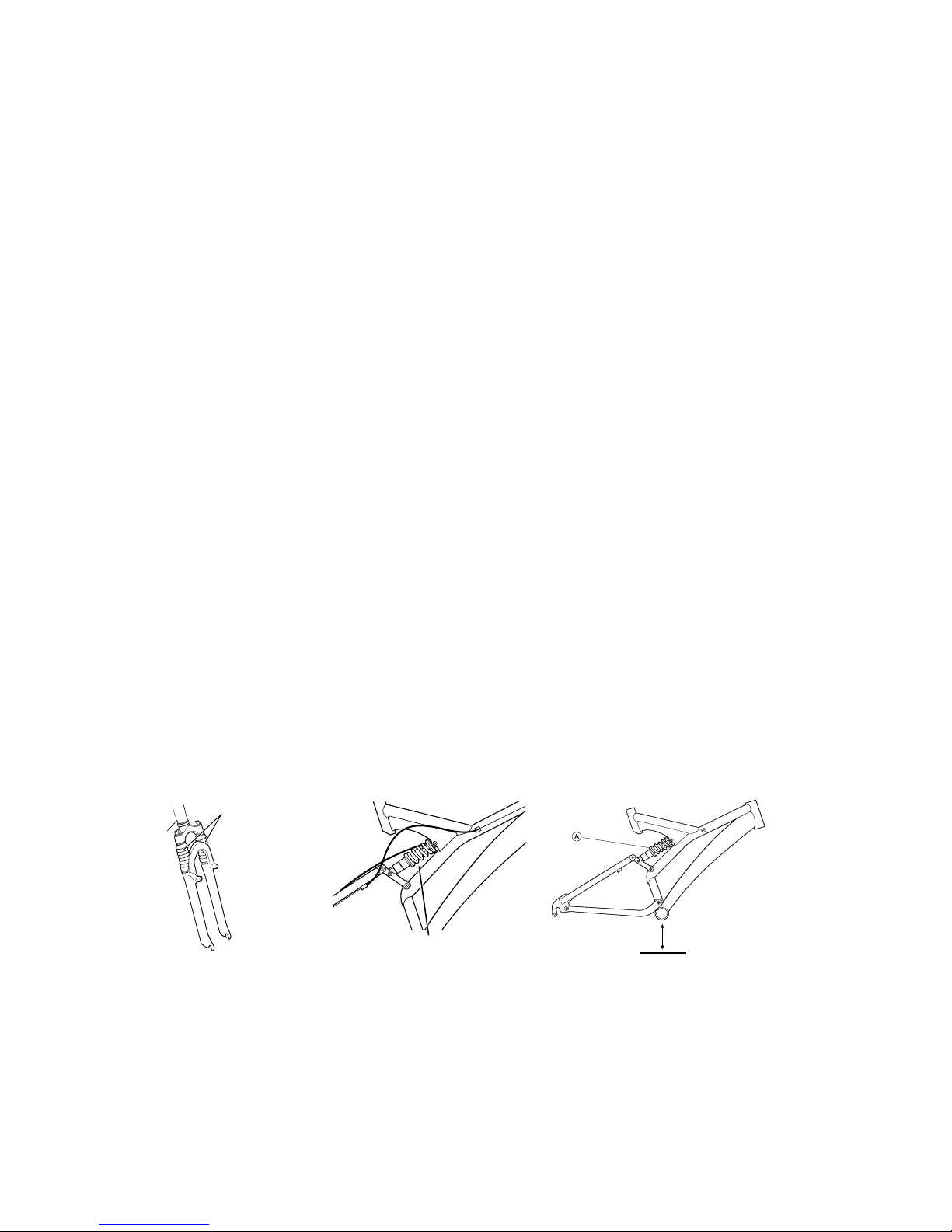

CAUTION: Suspension Units Your cycle may be fitted with suspension units built into parts

of the frame and forks. We recommend these are serviced by your dealer as required. More

details may be found in the suspension manufacturerʼs handbook.

Front Suspension Unit

Frame Suspension Unit

Pre Load Adjustment

We recommend that Pre-Load load for optimum safe riding should be set as follows.

1 Pre-Load alters the amount of bottom bracket drop when seated on the saddle. We

strongly recommend you set Pre-Load so as to experience no more than 1" (25mm) of

sag. Measured as a decrease in bottom bracket height.

To adjust Pre-Load, grasp knurled adjuster (A) and spring, and either:

2 Increase Pre-Load by turning to compress the spring

3 Decrease Pre-Load by turning to allow spring extension.

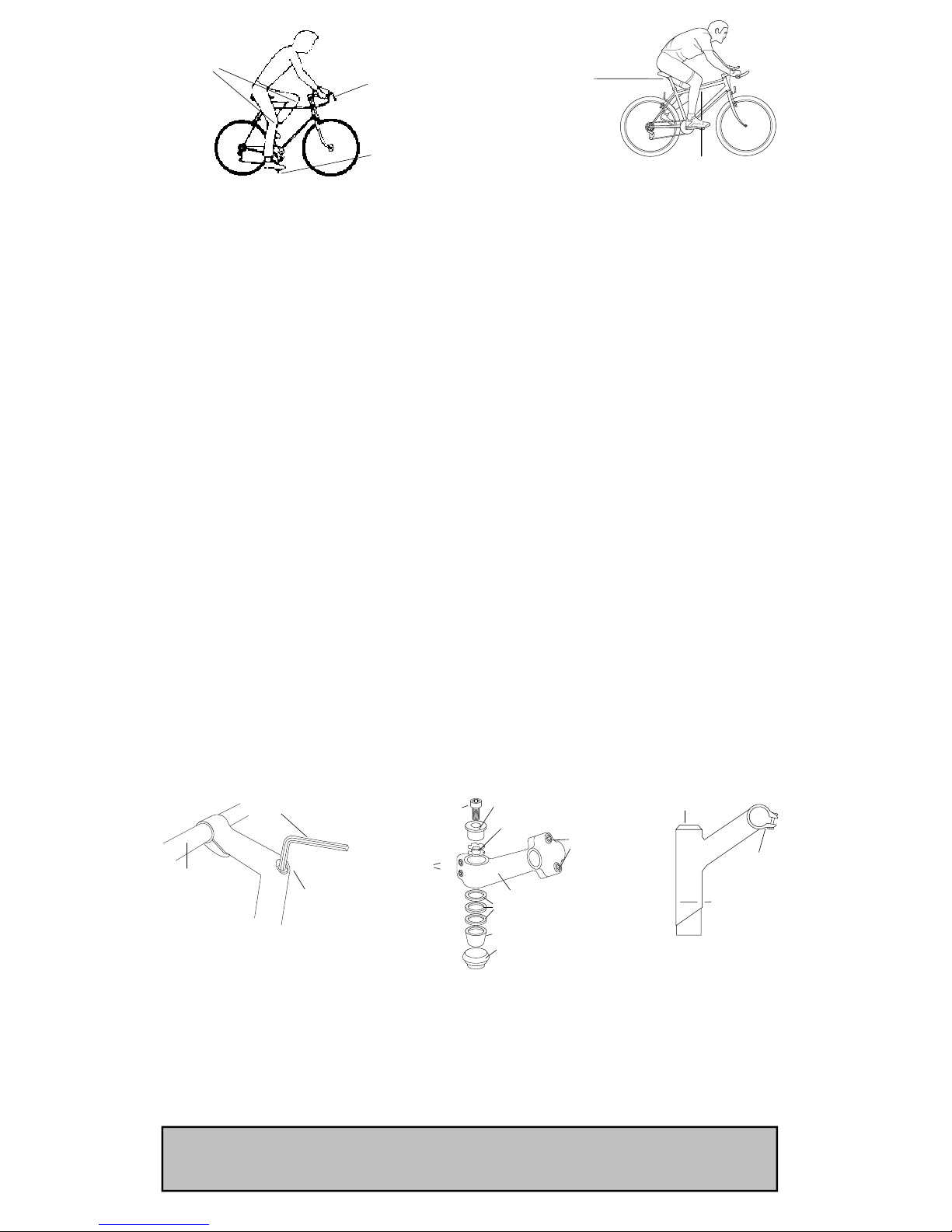

Riding Position

It is important that you and your bicycle are fitted to each other, not only for comfort and riding

ease but for control and safety. Normally your Dealer will custom fit your bicycle to you but the

following few pages should help you to find your most comfortable, safe and efficient position.

4

Bottom Bracket Height

Pre Load Adjust

Page 5

SEAT

Seat Adjustment

Loosen the nut on the seat-post clamp enough to allow the saddle to move forward and back.

The seat can then be aligned forward and back and the angle can also be adjusted (it is

recommended that the seat be parallel to the ground).

To adjust the seat up and down, loosen the binder-bolt on the seat tube, position the seat and

re-tighten the binder-bolt.

CAUTION: Insert the seat-post to a point above the insertion mark. The MINIMUM INSERTION

MARK should not be visible. Securely tighten the seat-post binder bolt/nut by using a 6 mm Allen

key or a 13 mm spanner. Test by grasping the seat and attempting to turn. Keep tightening until

the seat will no longer turn.Please refer to table of torque values Page 7

WARNING: Bicycle should not be ridden if seat adjustments are not properly tightened.

5

Allen head

Binder-bolt

Normal 13mm

Binder-bolt

Saddle

Seat Post

Minimum

Insertion mark

Seat posts differ according to saddle types

and accordingly the procedure for fitting

varies. If in doubt consult your dealer.

Close

Op

en

Seat Forwards

or Backwards

Seat Angle

End of

Seat Pillar

Seat Pillar adjustment—

Suspension frames.Take care

when inserting seat pillar that the

protruding end cannot interfere

with the frame suspension unit

during use. If in doubt consult

you dealer about adjustment.

CYCLING POSITION — Seat

Saddle Angle

The seat should be horizontal or parallel with the ground. Slight variation around the horizontal

may suit individual comfort but if excessive angles are felt necessary check other aspects of your

position.

Saddle Height

The correct seat height is determined by sitting on the seat with your leg fully extended. Your

heel (in flat shoes) should just touch the pedal when it is positioned at its lowest point. When

riding normally with the ball of your foot on the pedal your knee should be slightly flexed at the

bottom of the pedal stroke (see diagram following).

Saddle Forwards/Backwards Position

With the ball of one foot on the pedal and the cranks parallel to the ground the saddle should

be adjusted backwards or forwards to a position whereby the pedal centre is directly below the

knee joint.

Very small changes in saddle position can have a substantial effect on performance and

comfort. Consequently, whenever you make a change to your saddle position, make only

one directional change at a time and make the changes in small increments, until you have

found the point at which you are most comfortable.

Page 6

6

Knees slightly

bent

Handlebar Stem

approximately level

with seat or slightly

lower

Pedal at bottom

position

Loosen saddle from seat

pillar to adjust forwards

or backwards. Tighten

when set correctly

The saddle should be moved forwards or backwards so that the

knee is directly above the pedal when the crank is parallel to

the ground.

HANDLEBARS AND STEMS

As your cycle may be fitted with a standard ʻquillʼ stem or an A-Head stem, you must always check

that all the bolts are tight before cycling.

STANDARD STEM

: Loosen expander bolt so that expander wedge is not tight in bottom of

handlebar stem. Gently tap the top of the expander bolt to further loosen the wedge if necessary.

When the expander wedge is loose, move the handlebars up or down until you find the optimum

height at which you can easily reach the brake levers and comfortably grasp the handlebars. Usually

this height is level with, or slightly lower than, the top of the saddle. Be sure the stem is in line with

the front wheel.

CAUTION: A minimum insertion ring is marked on the handlebar stem and this marking

should remain in the head tube. Under no circumstances should the minimum height

insertion mark be visible on the handlebar stem. It must be down in the head tube.

When desirable height has been achieved, align the handlebar with the front wheel and securely

tighten expander bolt. It is extremely important to tighten the expander bolt sufficiently, so that when

the wheel is held between your legs and the handlebars are twisted, the handlebars do not move.

Do not over tighten, as it may increase risk of injury to the rider. Position grip portion of handlebars

horizontally and securely tighten the binder bolt.

Note: On models equipped with stem mounted gear levers the levers may be moved up or down to

the riderʼs most comfortable position. When moving them, be certain that the levers face upwards

and that the cables are not twisted.

Refer to table of recommended torque values on page 7.

Note: Whenever the handlebar stem is removed from the head tube then the expander bolt should

be lightly greased.

Note: On some ATB’s raising the stem requires brake cable adjustment. Do not attempt this if low

profile brakes are fitted with a stem mounted cable stop.

A-HEAD STEM

: Has 2 steerer clamp bolts on the back of the stem, which clamp around the

steerer tube. Loosen these bolts to align the stem with the front wheel. Re-tighten the steerer

clamp bolts.

CAUTION: Do not adjust the top compression bolt, this should be pre-set to eliminate bearing

play, overtightening will cause premature wear.

Contact your retailer for service.

Handlebar Position

The position of the handlebar should be set to allow a comfortable and easy reach of gear control

and brake levers.

When riding, your weight should be so balanced that your hands rest lightly on the handlebars.

This prevents strain on wrists and forearms when pedalling. If you alter the riding position,

remember to tighten all nuts and bolts securely

.

Refer to table of recommended torque values - page 7.

CAUTION:

NEVER EXTEND THE HANDLEBAR STEM OR SEAT POST ABOVE THE MINIMUM INSERTION

MARK AS THIS IS DANGEROUS

6mm Allen Key

Handlebar

Stem Expander Bolt

(Allen Head)

Recessed Type

Minimum

Insertion

Mark

Stem

Binder

Bolt

Stem Expander

bolt

Standard Stem

Steerer

Clamp Bolts

A-Head Type

Compression Bolt

Compression Cap

Extension

Spacers

Bearing Seat

Top cup with Bearings

inside

5 Star Washer

Stem Binder

Bolts

Page 7

COTTERLESS CRANKS ADJUSTMENT

IMPORTANT

Please check if the chainwheel and cranks of your new bicycle are of the cotter less type

as illustrated on page 3.

If so, to ensure trouble free operation it is important that the nuts securing these item to the

bottom bracket axle are tightened as securely as possible.

It is strongly recommended that the tightness of the nuts be checked after the first two

weeks of use and a maximum of three monthly intervals thereafter.

BRAKES

WARNING

For safe riding it is important to completely understand the operation of your bicycleʼs

brake system. Improper use of your bicycleʼs brake system may result in a loss of control or

an accident, which could lead to severe injury. Because each bicycle may handle differently,

be sure to learn the proper braking technique (including brake lever pressure and bicycle

control characteristics) and operation of your bicycle. This can be done by consulting your

professional bicycle dealer and this ownerʼs manual, and by practicing your riding and

braking technique.

The bicycle is equipped with two independant brake mechanisms. One on the front wheel

and the other on the rear wheel. The brakes are operated by hand levers fastened to the

handlebars. The right lever controls the front brake and the left lever controls the rear brake.

To stop with safety:

1. Operate the rear brake (left lever) slightly before the front brake (right lever).

2. Apply firm pressure to both front and rear brake levers.

CAUTION: If the front brake is applied with too much pressure, the rider may be thrown off

the bicycle.

3. Never apply the front brake on a turn. This is especially dangerous when cornering or

riding on slippery or loose surface roads.

CAUTION: Brakes are less effective in wet weather. Ride slower and allow more distance

for stopping.

Note: Do not ride your bicycle if the braking system is not working correctly. If you are in

doubt, take your bicycle to your dealer.

7

TABLE OF RECOMMENDED TORQUE VALUES

DESCRIPTION TORQUE

1 Stem Expander Bolt 20Nm 15lb-ft

(where fitted)

1A A-Head Steerer Clamp Bolts 10Nm 8lb-ft

(where fitted)

2 Stem Binder Bolt 10Nm 8lb-ft

3 Brake Fixing Bolt (non disc) 5Nm 4lb-ft

Applies to both front and rear brake

4 Front Axle Nut 30Nm 22lb-ft

5 Chain Wheel Securing Bolt 38Nm 28lb-ft

6 Pedal 40Nm 30lb-ft

7 F/Derailleur Cable Fixing Bolt 4Nm 3lb-ft

8 R/Derailleur Cable Fixing Bolt 4Nm 3lb-ft

9 Rear Axle Nut 30Nm 22lb-ft

10 Seat Pin

(Hexagonal Head) 10Nm 8lb-ft

Seat Pin

(Allen Head) 10Nm 8lb-ft

11 Front and Rear 3Nm 2.5lb-ft

Reflector Mounting Nut

12 Saddle Clamp Bolt

(Hexagonal Head) 15Nm 11lb-ft

1A

1

2

3

4

5

6

7

8

9

10

11

12

13

Page 8

BRAKE ADJUSTMENT PROCEDURE — Caliper brakes

The brakes on your bicycle should have been adjusted correctly by your dealer; however, as

cables do stretch, it is important to check the adjustment of your brakes after your first ride. Most

brakes will need some adjustments after being used the first few times. Your brakes are correctly

adjusted when there is a 1.5 mm gap between the brake blocks and the brake track of the wheel

rim.

Do not adjust brakes to allow brake blocks to contact wheel rim when brake levers are in the off

position. The fine adjustment of the brakes is made by the following procedure:

1. Turn adjustor A to set blocks C just clear of rim by 1.5 mm.

2. Ensure that the brake blocks meet the rim parallel and central to the rim brake tracks. Adjust

by nuts D if necessary, then tighten securely.

3. When all fine adjustment is taken up on adjustor A, it will be necessary to reset the cables as

follows:

a. Turn adjustor A all the way down as far as it will go into its mounting.

b. Loosen cable clamp bolt B. Press both brake shoes firmly against wheel rim.

c. Pull brake cable wire through its clamp bolt.

d. Tighten cable clamp bolt B securely.

Note: If one brake shoe is closer to the rim than the other first check that the wheel has been

centred between the forks then adjust the brakes as necessary.

To adjust brakes that have central Caliper adjuster simply turn screw as shown until brakes

centralise.

BRAKE MAINTENANCE — Caliper brakes

To maintain cable brakes in efficient working order, regularly check the brake adjustment and

lightly lubricate brake pivots and springs. Oil the exposed parts of the cable to prevent corrosion.

Slow or inefficient braking often indicates that the brake cables themselves require lubrication.

As this job requires the removal of the complete brake cable, we recommend strongly that this

service is done professionally.

Note: To assure smooth braking, wheels must run true and be correctly adjusted, with the rim

brake tracks free from dents and kinks. The brake blocks should be in correct alignment with the

rim brake track. See your dealer if you are in any doubt

regarding wheel and brake adjustment.

Protect yourself from frayed cable ends by maintaining the

end pieces fitted over the cable ends.

Brakes should function freely and release fully. If brakes bind,

first check for clean-liness and proper lubrication. If brakes

still bind, return your bicycle to your dealer for adjustment.

8

To centre side pull brakes first slacken the retaining nut and then centre the brake using a

spanner on the front retaining nut.

CAUTION: Before riding, test your brakes. Make sure that the quick release mechanism is

returned to its normal correct position, otherwise your brakes will not operate effectively.

Calliper Arm

Tyre

Wheel Rim

Brake Shoe

Brake Shoe

Quick Release

Mechanism

Return Spring

Page 9

1. Pass the inner cable through the inner

cable lead, and after setting so that the total

of the clearances between the left and right

shoes and the rim is 2 mm, tighten the cable

fixing bolt.

To release the brake inner cable from the V brake, squeeze the two brake arms together until the

brake blocks contact the rim and remove the inner cable pipe from the cable end bracket.

To re-connect again squeeze the two brake arms together and relocate the inner cable pipe in

the cable end bracket.

INNER CABLE ADJUSTMENT

INNER CABLE QUICK RELEASE

ʻVʼ BRAKE SYSTEM

9

2. Adjust the balance with the spring tension adjustment screws.

BRAKE MAINTENANCE — Disc Brakes

Your cycle may arrive with factory fitted disc brakes — the latest technology in cycle braking!

If you have purchased your cycle from a professional cycle shop your brakes should have been

set up correctly. You will only have to do routine maintenance as the brake pads wear. (This is

described later on in this section).

If you purchased your cycle from a mail-order source you may have to set up the brakes before

you use your cycle.

The notes that follow are not exhaustive. If you need further assistance, please refer to the disc

brake leaflet that should accompany the cycle. If you do not have such a leaflet please take your

cycle to a professional cycle shop.

BRAKE LEVER AND BRAKE PAD TRAVEL ADJUSTMENT.

You can alter the amount of braking pressure by altering the travel of the brake lever and by the

proximity of the brake pads to the brake disc.

To alter the travel of the brake lever adjust screw A (see Fig.

1). Unscrewing screw A reduces the amount of lever travel

and by tightening it increases the lever travel. If you have fully

unscrewed screw A and the lever travel is still excessive you will

have to adjust the space between the pads and the disc.

A

Fig.1

Inner Cable Lead

Pipe

Cable End

Bracket

Cable Fixing

Bolt

3. Depress the brake lever about 10 times as in normal brake

operation and check that everything is operating correctly and

that the shoe clearance is correct before using the brakes.

Depress about

10 times

BRAKE BLOCK REPLACEMENT- Caliper and V Brakes

All brake blocks are provided with grooves that indicate the

wear on each block. When the grooves are worn down to a

flat surface, replace the blocks(in pairs) immediately.

Wear Indicator Groove

Page 10

BRAKE LEVER AND BRAKE PAD TRAVEL ADJUSTMENT — cont.

Tighten screw A (Fig. 1) up to the brake lever. Go to Fig. 2 and insert a 2.5mm Allen key into

the smaller hole inside allen key hole B. Rotating the allen key clockwise pushes the outer

brake pad forward by approx. 0.8 mm. After each turn, check the brake travel, and the braking

Once the correct amount of travel has been reached, centre the brake Calliper on the disc by

adjusting screw C (Fig. 3). When the brake pads are centered on the disc the wheel should spin

freely, though there may be a slight amount of noise until the pads “bed” in.

If your cycle came from, or has recently been overhauled by a professional repair shop, you

B

Fig.2

Smaller

keyhole inside

main hole.

C

Fig.3

BRAKE PAD WEAR AND REPLACEMENT

When you check your brake pads due to

falling performance, check their thickness.

If they are less than 1 mm thick (Fig. 4) they

will need replacing.

1 mm

Min

Fig.4

To fit new pads, remove the brake Calliper

from the fork or frame by unscrewing allen

bolts D (Fig. 5). Unscrew, (anti-clockwise),

the smaller allen bolt inside allen bolt B

(Fig. 2). Lift up and pull the inner pad

downwards, using the protruding part E

(Fig. 6). Slide a thin slot screwdriver under

the outer pad (Fig. 7) and lift it up. Hold the

screwdriver in this position and remove the

pad with a pair of long-nosed pliers

D

Fig.5

10

Page 11

Remove the springs from the the worn out pads and fit them onto the new pads. Replace the

new pads, keeping them slightly inclined, into the seat of the Calliper. Check that the spring

hooks correctly onto the small piston. (When pulling downwards the pads should not come out).

Refit the Calliper to the fork or frame and adjust screw C (Fig. 3) until the pads and the disc are

centered and the wheel spins freely. (Again there may be some noise from the brake until it “beds

E

Fig.6 Fig.7

DERAILLEUR GEARS INTRODUCTION

The derailleur gear is so named because it works on the derailing principle to move the chain

from one sprocket to another. The number of gears is determined by multiplying the number of

sprockets on the rear freewheel by the number of chainrings on the front crank set.

By using different combinations of sprocket and chainwheel sizes, a wide range of gear ratios are

available. The highest gear is when the large chainwheel is coupled with the small sprocket and

the lowest gear is when the small chainwheel is combined with the largest rear sprocket.

The wide range of gears allows you to combat all prevailing conditions while pedalling at the

constant and efficient rate of sixty revolutions per minute.

DERAILLEUR GEAR MAINTENANCE

To help ensure that your derailleur gear works efficiently and to prolong its life, it must be kept

clean and free from excess dirt build up and should be properly lubricated.

GEAR CHANGING

The riderʼs left gear lever controls the front derailleur and chain wheels.

The right gear lever controls the rear derailleur and sprockets.

The large rear sprockets generate low gears for hill climbing. The small rear sprockets develop

high gear ratios for speed work and downhill riding.

The small front chainring produces low gear ratios while the larger front chainrings produce

higher gear ratios.

To operate your derailleur gear system efficiently and reduce damage, wear and reduce noise to

a minimum, avoid using the maximum crossover gear ratios of large chainring/large rear sprocket,

small chainring/small rear sprocket.

CAUTION: For positive gear selection, observe these four precautions:

1. Change only when pedals and wheels are moving in a forward motion.

2. Reduce pedal pressure while changing gears.

3. Never back pedal when changing gear.

4. Never force the gear levers.

Gear selection should be made in anticipation of need since forward motion of the bicycle is

required when changing gear. It is advisable to change to a low gear before stopping in order to

be in the proper gear when you start up. On hills, change gear early while still maintaining forward

pedalling speed.

11

Page 12

12

SIS ADJUSTMENT

If your bicycle is equipped with the Shimano Index System (SIS) you can pre-set the gear shifter

to change gear simply by clicking the shifter up or down to the required gear. The next few pages

and diagrams show how to set this up (if your dealer has not already done it). If you have any

problems you should get your dealer to set the SIS up.

Top adjustment

Turn the top rear adjustment screw on the gear mechanism so that, looking from the rear, the

guide pulley is below the outer line of the top gear.

Low adjustment

Turn the low gear adjustment screw so that the guide pulley moves to a position directly below

the low gear.

1. Operate the shifting lever to shift the chain from the top gear to 2nd gear.

*If the chain will not move to the 2nd gear, turn the cable adjusting barrel to increase the

tension 1 (counter clockwise)

*If the chain moves past the 2nd gear, decrease the tension 2 (clockwise)

CABLE

ADJUSTMENT

BARREL

TOP2nd

3rd

Be sure to perform oil maintenance at each part of the transfer mechanism. The optimum oil is

dry molybdenum oil or the equivalent.

LOW

ADJUSTMENT

SCREW

LOW GEAR

GUIDE

PULLEY

TOP

ADJUSTMENT

SCREW

TOP GEAR

OUTER SLIDE

GUIDE

PULLEY

COUNTER

CLOCKWISE

CLOCKWISE

CABLE ADJ.

BARREL

1

2

2. Next, with the chain on the 2nd gear,

increase the inner cable tension while turning

the crank forward. Stop turning the cable

adjusting barrel just before the chain makes

noise against the 3rd gear. This completes

the adjustment.

Front Derailleur

The adjustment of the sideways movement of the front changer is by means of two gear stop

screws situated on the body of the changer mechanism. The inner screw limited the inner travel

of the changer cage, the outer limits the outward movement

Use the following procedure for adjustment:

1. While turning the pedals forward select the middle (on a triple chainset) or the top chainring

then select the smallest rear sprocket.

2. While turning the pedals adjust the inner screw on the front changer so that the chain will just

drop into the lower ring with the gear lever fully forward.

3. Select the largest rear sprocket. If there is any evidence of chain rub adjust the inner screw

until this just ceases.

4. With the chain still on the largest rear sprocket select the ring below the largest at the front.

Adjust the outer screw so that the chain just selects the outer chainring when the gear lever

is moved through its full arc range.

Page 13

13

5. Select the smallest rear sprocket, if there is any evidence of chain rub adjust the outer screw

until this just ceases. The lower edge of the outside plate should be positioned approximately

1-3 mm above the largest outside chainring. If a biopace chain set is fitted as indicated on the

chainring the clearance should be measured above the highest point of the ring.

6. If a chainwheel disk is fitted, make sure there is sufficient clearance between changer cage

and chainwheel disk.

7. If problems continue to arise, the bicycle should be checked by a professional repairer.

1-3mm

Inside front changer

Chainwheel dis

k

Adjusting screws

Operating wire

from left hand

gear control

Outside front changer

Outside Chainwheel

Middle Chainwheel

Inner Chainwheel

VIEW FROM SIDE

Outer adjusting screw

sets outer movement limit

Chainwheel disk

Front changer cage

Inner adjusting screw

sets inner movement

limit

Using the adjusting screws set the limit for the

movement of the front changer cage

VIEW FROM ABOVE

STI RAPIDFIRE

STI Rapidfire lever uses two push levers mounted conveniently under the bar in front of the

thumb. Using lever (A) you can shift one gear at a time, or shift down the entire block with a full

stroke push. Using lever (B) you can shift up the sprocket with the same capability.

STI OPERATION

Rear Gear Operation

Right Hand Lever.

Lever (A) — operated

by your right hand

thumb pressing away

from your body (shifting

from a small sprocket to

a larger sprocket)

2) To shift two gears at a time

from a small sprocket to a larger

sprocket press Iever A twice

Example: from 2nd to 4th

3) To shift three gears at a

time from a small sprocket to

a larger sprocket press lever

A three times

Example: from 2nd to 5th

Lever (B) - operated by pulling with your your right hand forefinger or pushing with

your thumb depending on model of shifter. (shifting from a large sprocket to a small sprocket)

When lever (B) is pulled once,

there is a one-step shift from a

larger gear to a smaller gear

Example: from 3rd to 2nd

1

2

3

Clic

k

Click

Click

Right hand lever viewed from below

Right hand lever viewed from below

1) To shift one gear at a time

from a small sprocket press

lever A once

Example: from 2nd to 3rd

3 2

4 2

5 2

3 2

Rear gear changer. Right hand lever

Lever B

Lever A

Page 14

14

STI OPERATION

Front Gear Operation

Lever (A) - operated by your left hand thumb pressing away from your body (shifting from a small

chainwheel to a larger chainwheel)

When it is pressed once, there is a shift of one gear

from a smaller chainwheel to a larger chainwheel.

Example: from mid-range to largest chainwheel

Lever A

Lever (B) - operated by pulling with your left hand forefinger or pushing with your thumb

depending on model of shifter.

(shifting from a large chainwheel to a smaller chainwheel)

If your front gears do not operate smoothly, it may be that your front gear cable and front changer

need adjustment. You can adjust your front gear cable by using the outer adjustment bolt on the

left hand lever. This will adjust your front changer so that it has minimum clearance between the

chain and the inside left hand side of the chain guide.

When it is pulled once, there

is a shift of one gear from a

large chainwheel to a smaller

chainwheel.

Example: from largest

chainwheel to mid-range

Cable tension adjustment

1. Set the chain to the largest rear sprocket, and, at the front, use the Rapidfire to shift from the

largest chainwheel to the intermediate chainwheel.

Shift

Largest chainwheelLargest sprocket Largest sprocket Intermediate chainwheel

2. Adjust, by using the outer adjustment bolt, so that there is the

minimum clearance, but so that the chain and the plate (inside the

chain guide) do not contact.

Minimum clearance

between chain and

inside left of change

r

A B

Front gear changer. Left hand lever

Outer adjustment bolt

Front gear changer. Left hand lever

Lever B

Lever A

You can shift the triple front chainwheels with the same precise STI action, 1 or 2 chainwheels at a

time, using levers (A) and (B) on the left hand lever

Left Hand Lever.

Page 15

15

Never remove the lever cover.

Do not loosen the lever cover installation bolt.

Lever (B)

New Cable

Old Cable

Right hand lever, rear gear

Gear Inner Wire Replacement & Connection

STI Adjustment — Noise prevention mechanism

If chain noise occurs, due to overshifting,

when a shift is made from the smallest

chainwheel to the intermediate

chainwheel, the overshifting can be

adjusted by gently pressing lever (b) to

move the front derailleur slightly toward

the small chain wheel, thus activating

the noise prevention mechanism.

Installation to the Handlebar

Move lever (a) (and lever (A) when

installing the right hand lever) so that

the installation bolt can be seen and

then use an Allen key to install a torque

of 6 - 8 Nm (4.5 - 6lb-ft).

Allen Key

Lever b

Lever (a)

Press Lever

(a) to

reveal the

installation

bolt

Left hand lever operating front

gear changer viewed from below

Installation of the brake cables

Use the 1.6 mm diameter inner cable and the 5 mm diameter outer casing.

1. Insert the cable barrel nipple through the brake lever body.

2. Mount the nipple into the retaining hole in the lever.

3. Ensure the brake adjusting bolt and nut are seated correctly in the lever.

4. Adjust the lever adjustment screw to obtain the desired grip width

5. Before riding, test the brakes several times to ensure everything is seated correctly and

that the brakes are functioning properly. Readjust as necessary.

IF IN DOUBT ABOUT BRAKE FUNCTIONING

CONSULT YOUR LOCAL DEALER.

Wire holding plate

Holding nut

Groove

Outer adjustment bolt

Dust Cover

Lever adjustment

screw

Left hand lever viewed from below

Cable barrel nipple

Adjust grip width

using lever adjustment screw

For the rear, press lever (B) six times or more, and then, for the front, press lever (b) three or

four times.

Push out the old cable through the lever cover and replace with the new cable.

Left hand lever, front gear

Lever (b)

New Cable

Old Cable

Page 16

16

GRIP SHIFT Service Instructions

Lubrication

If re-greasing should become

necessary due to excessive

exposure to water and grit:

1. Disassemble and wash parts in

kerosene or degreaser. Blow parts

clean with compressed air before

lubricating.

2. Using a silicone based teflon

grease, apply to areas shown. Phil

Wood waterproof grease may be

substituted.

Cable Changes

1. Rotate Grip Shift until cable is fully released and disconnect cable from derailleur.

2. Remove cover.

3. Separate Grip Shift assembly by pulling outward. The spring may unseat from the spring

cavity.

4. Remove and discard old cable.

5. Lubricate shifter before reassembling. See “Lubrication” above.

6. Replace with Grip Shift approved cable only. Thread new cable through housing cable inlet

hole.

Around tube

Spring Cavity

Cable Groove

Cable Inlet Hole

Housing

Spring

Grip

Cover

All

Detente

Notches

Cable

Grooves

GRIP

7. Loop the cable around housing. Exit cable through barrel adjuster.

8. Put the spring in spring cavity. If necessary apply a small amount of grease to hold spring

in place.

9. Slide grip over housing. Rotate grip to align

gear indicator mark with the largest number

on grip. Lift the loop of cable off the housing

and lay the cable into the groove in grip.

Push the grip inward while pulling the cable

out of the barrel adjuster until grip is flush

with housing.

10. Replace cover.

11. Check for proper assembly by rotating grip

and listening for indexing clicks.

12. Adjust indexing per derailleur manufacturers specifications.

Housing

Grip

Cover

Groove

WARNING: Do not use lithium grease

Page 17

17

REVOSHIFT

MOUNTING THE SHIFTING LEVER

Install the brake lever in a position where it will

not obstruct brake operation. Do not use in a

combination which causes brake operation to

be obstructed.

Tightening torque:

2 Nm (1.5lb -ft)

Suitable

Allen Key

Suitable

Allen Key

GEAR SHIFTING OPERATION

REPLACING THE INNER CABLE

1. Turn the lever to the initial position (low position

for the front lever; top position for the rear lever).

2. Loosen the lever fixing bolt, and then rotate the lever until the cover

fixing bolt can be turned (Fig. 1)

After this, remove the cover fixing bolt and then remove the cover (Fig 2)

3. Pull out the inner cable and replace it with the new inner cable (Fig. 3)

4. After installing the cover, rotate the lever to return it to its original position, then tighten the

lever fixing bolt.

Lever fixing bolt

Cover fixing bolt

FIG. 1

FIG. 2

Inner Cable

FIG. 3

Pedalling

becomes

heavier

Pedalling becomes

lighter

Pedalling

becomes

lighter

Pedalling

becomes

heavier

Page 18

18

TYRE CARE AND WHEEL ADJUSTMENTS

To obtain maximum life and full benefit from your tyres, it is essential to maintain the

recommended pressure indicated on the tyre sidewall.

Unnecessary hard braking and skidding greatly reduces tyre life. Make sure your tyres do not

come into contact with oil, petrol, paraffin or other rubber solvents.

Make sure that your wheels run true and are in correct alignment to avoid chafing the tyre

sidewall against the bicycle frame or fork tubes.

Tyres should regularly be inspected for wear and cuts. Check that the tyre tread pattern is clearly

showing all around the outside edge of the tyre. Check there are not any breaks, cuts or uneven

wear in the tyre. Tyres should be replaced if damaged.

Tyre punctures can be caused by careless riding over sharp stones, holes in the road, or by

hitting curbstones

If you are storing your bicycle for a long period of time, it is advisable to store the machine with

the tyres off the ground to prevent them from becoming distorted.

To inflate tyres, a foot pump or normal bicycle inflator fitted with a suitable valve connector should

be used along with an accurate tyre pressure gauge.

Wheels should be checked regularly for spoke tension. Perform this check more frequently if the

bicycle is used on rough roads.

STANDARD REAR WHEEL - ADJUSTMENT AND REMOVAL

To Remove Wheel

Move the chain onto the smallest rear sprocket. Disengage the brake quick release lever if your

bicycle is so equipped. Loosen both axle nuts by turning in a counter clockwise direction. Pull the

derailleur mechanism gear for additional clearance. Remove the rear wheel by sliding forward

and out of the frame.

To install wheel, locate the top section of the chain on the small sprocket and replace the wheel

into the frame by pushing back and centralising between the chainstays. While holding the wheel

in this position, tighten the axle nuts in a clockwise direction.

The wheel should turn freely and have very little side play.

Reset rear brake quick release mechanism and check brake for proper operation.

Quick Release Rear Wheel

Removal and installation of rear wheel fitted with quick release mechanism. Use same procedure

as for standard rear wheel, with the exception of loosening axle nuts. Operate the quick release

lever by pulling away from the wheel and turning release lever 180° to release the wheel.

When installing the rear wheel, use the same closing and adjusting procedure as outlined for

quick release front wheel.

Check quick release lever is in the correct and fully locked position before each ride.

Reset rear brake quick release mechanism and check brake for proper operation.

Front wheel

Remove axle nuts, washers, and axle retention

device if fitted. The axle cone bearing adjustment

should permit smooth rotation of wheel. Cone

locknut should be securely fastened against

axle cone to prevent loosening. Place the

front wheel between the fork blades with axle

retention device and the projecting prongs

of

the retention device securely fitting the slot in the

fork or with standard washers securely placed in

position on to the wheel axle in the place of the

retention washer.

Replace locking washers and nuts at both ends

gradually and alternately in order to keep the

wheel centered.

CAUTION:

Front wheel must be installed with retention

devices securely placed into slots of fork blades

or washers if fitted. This will ensure positive

locking of front wheel to front fork.

Retention device or standard washer

Nut

Nut

Axle

Nut

Front Hub

Cone

Front Fork

Retention

washer

(if fitted)

Cone Locknut

Page 19

TYRE CARE AND WHEEL ADJUSTMENTS CONTINUED

QUICK RELEASE FRONT WHEEL

1. To remove the front wheel, first release the front wheel brake. Then open the

quick-release lever on the axle and pull the wheel from the forks.

2. To install, fit wheel into forks with quick release lever on the left side. Close quick-

release, and tighten adjuster until snug. Release quick-release lever and further

tighten adjuster approximately 3/4 of a turn. Lock and check that the quick-release has

embossed the fork ends. It may be necessary to tighten or loosen the adjuster slightly.

Make certain to reset the quick-release front brake to ensure proper operation.

3. Wheel must be clear frame and fork by at least 1/16".

4. The wheel should turn freely and have very little side-play.

5. Check quick-release lever is correct and fully locked position before each ride.

FITMENT OF BELL

1. Remove screw from bell clamp.

2. Position in a convenient spot near the left hand or right hand handlebar grip.

3. Replace screw & tighten securely.

4. Rotate the “Ping Arm” to a comfortable position.

5. Check quick-release lever is correct and fully locked position before each ride.

Spring

Spring

Adjusting nut

Quick Release Lever

Closed

Open

Locked position

Retaining Device

WARNING! Do not attempt to ride the cycle until you are

absolutely sure that the quick release lever is fully closed and

securely tightened. Children should check with their parents to

ensure that this has been tightened correctly.

Ping Arm

Brake Lever/Shifter

Grip

Position Bell on left hand or right hand side of the handlebar as required.

19

Page 20

1. Fit to chainside of cycle.

2. The pedal tightens in a clockwise direction

3. Locate thread by hand, fit and tighten.

4. Use spanner to finish tightening (be careful)

Check for the letters “L” or “R” on the ends of the pedals to show which side the pedal needs to

be fitted to.

1. Fit to non chainside of cycle.

2. The pedal has a special thread to tighten in a anti-clockwise direction

3. Locate thread by hand, fit and tighten.

4. Use spanner to finish tightening (be careful)

R

L

R

Tighten Clockwise

L

Tighten Anti-clockwise

R

L

PEDAL IDENTIFICATION

TO FIT RIGHTHAND PEDAL

TO FIT LEFTHAND PEDAL

WARNING

20

Loading...

Loading...