Page 1

Contemporar

y Falcon Cooker H

ood

s

Revision: 02/02/2009

1

ENGLISH

2

Installation

, Operation

& Maintenance

Instructions

FRAN«AIS

4

Guide díInstallation,

D

íUtilisation et

Conseils d

íEntretien

NEDERLA

ND

S

8

Instructies voor

mont

age, gebruik

en onderhoud

CT900

CT1090

Contemporar

y Falcon Cooker H

ood

s

Contemporain Hotte

s Falcon

M

oderne Falcon - Dunstabzugshauben

Eigentijds Falcon

Afzuigk

appen

M

odern Falcon KÂpor

DEU

TS

CH

E

6

Mont

age-,

Gebrauchs- &

Wartungsanleit

ung

SVENSK

10

Installations-

,

dan

v

‰ndnings-

och underh

Âllsanvisningar

Clarence

Stree

t, Royal leamington Spa,

Warwi

ckshire, CV31 2AD

, Engl

and

.

Tel

: +44 (0)

1926 457400

Fax: +44 (0)

1926 450526

E-mail: Consumers@falc

onappliance

s.co.uk

www.falc

onappliance

s.co.uk

Falcon is a business name of AGA RANGEMASTER GROUP PLC

Page 2

Contemporar

y Falcon Cooker H

ood

s

Revision: 02/02/2009

2

Installation

, Operation

& Maintenance Instruction

s

SECTION 1 INTRO

DUC

TION 2

SECTION 2 EXTRACTION PERFORMANC

E 2

SECTION 3 IMPORTANT INFORM

ATION 2

SECTION 4 INSTALLATION 2

4.1 Removing Grease Filter

s

4.2 Blower

Ex

hau

st Position

4.3 Duct Installation

4.4 Fixing the Hood to the Wall

4.5 C

onnecting the Ducting

4.6 Electrical Installation

SECTION 5 OPERATING INST

RUC

TIONS 3

SECTION 6

MAINTENANC

E 3

SECTION 7 SPECIFICATIONS 3

FIGURE 1:

DIMEN

SIONS AND FIXING DETAILS 3

SECTION 1. INTRO

DUC

TION

Your r

ange cooker is a semi-professional unit which gives you the power and flexib

ili

ty to

realise your full potential in the kitc

hen

. Inevitabl

y, during the cooking process, there will

be hea

t, v

apours

and fumes produced

. Your Falcon extractor has

been desi

gned to

complement the range cooker both in looks

and performance in order to create the ideal

environmen

t for creative cooking

.

SECTION 2. EXT

RAC

TION PERFORM

ANC

E

The mo

st important influence on the performance o

f the extractor is the design o

f the

ducting which takes the ex

hau

st air from the extractor to the outside wall louvre

. The duct

route s

hould be a prime consideration during the initial st

ages o

f the kitc

hen design.

Please note the following:

The extractor is provided with a spigot suitable for c

onnecting

150mm diameter

du

ct.

Note: 150mm is the minimum duct diameter consistent with efficient extraction

.

The ex

hau

st duct route l

ength should be kept a

s short as possible with a

s few

bends as possible.

The mo

st efficien

t configuration is to duct straigh

t thr

ough an outside wall so try to

position the cooker again

st an outside wall w

hen designing your kitchen layout.

The

hood can be vented either to the top exhau

st or the rear exhau

st position. Use

the position which gives the shorte

st duct route l

ength and least number of bend

s.

(The blower will need to be rotated for ducting directl

y thr

ough the rear exhau

st

position.)

A route with more than two 90

bends w

ill significantly degrade the performance o

f

the extraction system

. If possible, avoid having a 90

bend a

t the extractor ex

hau

st

spigot; k

eep bend radii as large as possible to maintain a smooth airflow wit

hou

t

vortice

s; avoid kin

ks in flexible ducting; pull flexible ducting taut over

straight runs to

ensure tha

t the internal surface is a

s smooth as possible.

SECTION 3. IMPORTANT INFORMATION

The following minimum headroom is required to accomm

odate the cooker

and hood

:

For a small charge customised replacement chimne

ys can be pr

oduced to suit your

r

equirements.

The minimum distance betw

een the r

ange hob burners

and the bottom of the extractor is

essential to prevent overheating of the extractor

and i

ts com

ponen

ts.

If you are fitting a Falcon splas

hba

ck t

hen the cooker-to-

hood clearance is dictated b

y the

splas

hba

ck height of

800mm excluding fl

ange

s.

Please also note that a 90

bend in the flexible ducting w

ill r

equire

215mm minimum

head

-

room to give a smooth radius with no kinking

.

R

equirements of the relevant authorities concerning the discharge of exhau

st air mu

st be

complied with

.

Attent

ion:

This appliance r

equires an earth connection.

Ensure that the s

upply voltage correspond

s to that marked on the rating label inside the

extractor

.

The extractor mu

st be isolated from the electrical s

upply before carrying out any cleaning

or maintenance operations.

Pay particular attent

ion to fire risk

when frying. To minimise the risk of fire, a

ll

instruct

ions relating to cleaning the grease filters and removing grease deposits

must be adhered to.

D

o not flam

b

È under the extractor.

SECTION 4. INSTALLATION

4.1 Remov

ing the Grease

Filter(s)

Place extractor on i

ts backplate on a horizontal surface.

To remove the grease filters pull/li

ft the filter release lever away from the

hood base

. Thi

s

releases the retaining clips allowing the filter to be carefully lifted awa

y from the

hood

.

Take care not to scratch the hood

.

The four internal fixing holes, blower assembly

and spigot blanking plate can now be

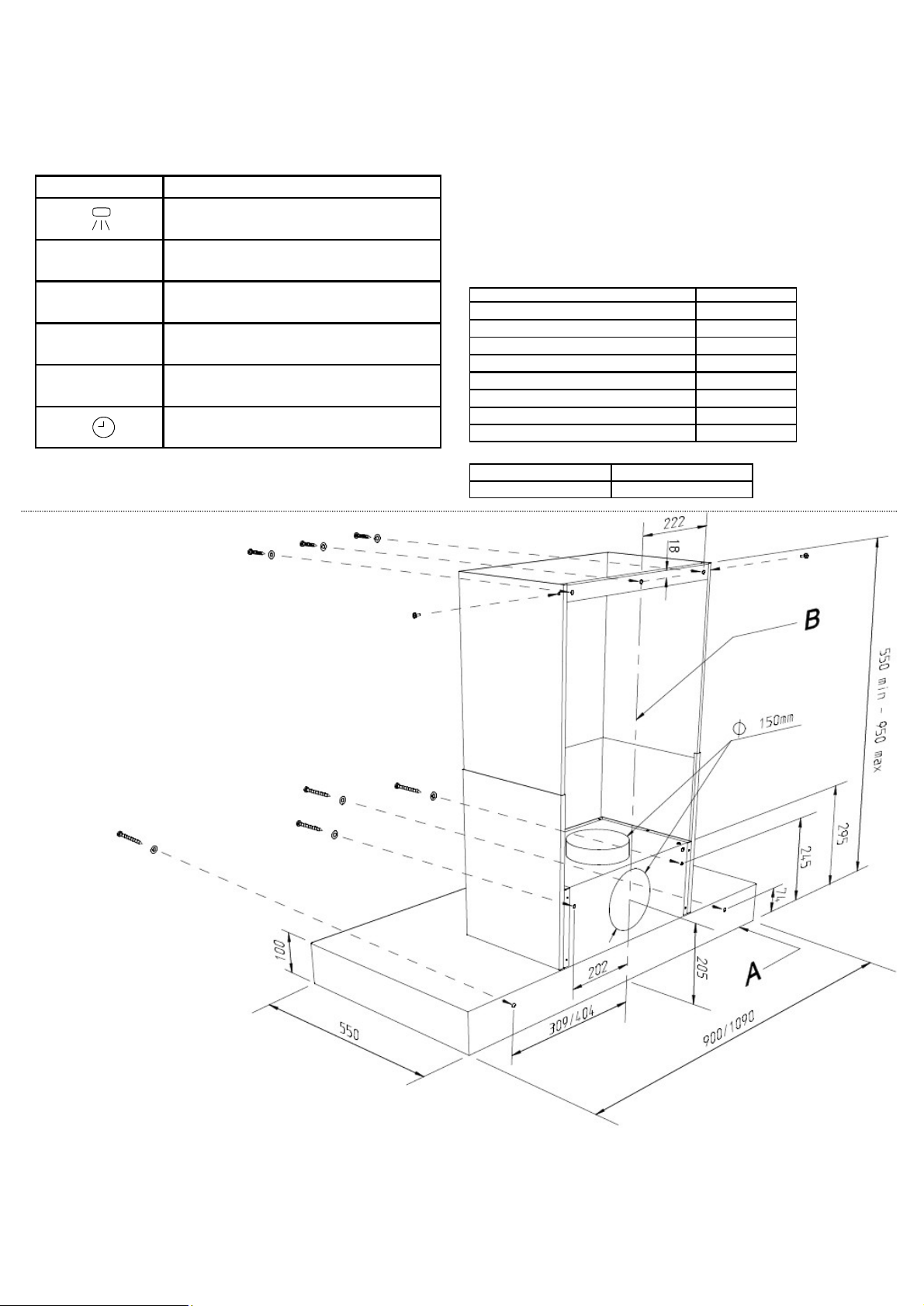

accessed through the openings in the baseplate. (See Figure 1).

4.2 B

lower Exhaust Position

The

hood can be vented either to the top exhau

st or the rear exhau

st position

. Each

exhau

st position has 4

studs onto which can be bolted either the blower assembly or a

blanking plate.

Bolt blower assembl

y to chosen ex

hau

st position and the blanking plate to the

unused

position.

W

hen changing the exhau

st position

, care s

hould be taken no

t to excessively pull or twist

the cable attac

hed to the blower.

4.3 Duct Installat

ion

Make a hole in the wall or ceiling to take the

150mm diameter ducting from the extractor

exhau

st spigot to the outside

.

The ex

hau

st duct route l

ength should be kept a

s short as possible with a

s few bends a

s

possible - see Section 2

.

Knock a hole in the outside wall to match the internal measurements of the louvre.

4.4

Fixing the Hood to the Wall

If you are fitting a Falcon Splas

hba

ck it mu

st be fitted before the

hood

.

Full instruct

ions for mounting the hood are given in Figure 1

.

Note: The decorative chimney can be removed to ease handling o

f the

hood

.

The s

upporting wall must be of

good quality, have an even surface and be

sturdy

enough

to s

upport the extractor.

Fixings must be used which are suitable for the type of wall construction.

4.5 C

onnect

ing the Duct

ing

C

onne

ct ducting to extractor exhau

st spigot. This may have to be

done prior to fixing the

extractor to the wall

. You ma

y find this easier with the chimney removed

. The chimney i

s

attached using M4 machine screws which can be accessed thr

ough the filter

opening(s).

W

hen the extractor is in position

, check that the duct has not

been flatt

ened or kinked

along i

ts route

.

C

onne

ct the ducting to the wall louvre spigot or alternative outside termination

.

Secure the louvre to the outside wall

. Ensure that any air fins are directed downwards.

Refit the grease filter(s)

.

4.6

Electrical Installat

ion

The extractor is a stationary

appliance desi

gned to be connected b

y fixed wiring to the

electrical supply. A competent electrical technician mu

st perform the electrical installation

.

The extractor mu

st be fed from a

230Va

c single phase electrical supply using a switc

hed

spur fitted with a 3A fuse. The spur should be located adjacent to the extractor/cooker so

that the s

upply can be disconnected from the extractor using the switch

. The means o

f

disc

onnecting from the s

upply mu

st have a minimum contact s

eparation of 3mm in all

pole

s. Alternatively a m

eans of disc

onnection in the fixed wiring according to the relevant

wiring rules mu

st be fitted.

A s

upply cord for connecting the spur to the extractor is included

.

The main

s s

upply is c

onnected to the free

end o

f thi

s cord as follow

s:

Cooker-to-hood clearance (min):

800 mm

H

ood height including chimney:

550ó950 mm

M

inimum ceiling height with standard chimney:

2290mm

INCOMING SUPPLY CORD CONNECTIONS

Cor

e

Core Colou

r

Liv

e

B

row

n

Neutra

l

B

l

ue

Protective Eart

h

G

r

een/Yello

w

The ex

hau

st air mu

st not be discharged into a flue which is used for ex

hausting

fumes from

appliance

s s

upplied with

energy other t

han electricity, e.g. oil or gas

-

fired central

heating boiler

s, gas-fired water

heaters, etc.

A

dequate ventilation o

f the room mu

st be provided w

hen the cooker, extractor

and

appliance

s s

upplied with

energy other t

han electricity (e.g. gas-fired or oil-fired

heat-

ers, etc.) are used simultaneousl

y. The room mu

st be provided with vents to allow a

constant flow of fresh air

.

War

ning

Proper care mu

st be taken to ensure that the

negative pressure

s caused by high

performance extraction

systems do not adversely affe

ct the safe

operation of certain

types of fuel-burning appliances (gas, oil or solid fuel), including those installed in

the kitc

hen and possibly also those installed in other parts of the

house

.

Where such fuel-burning appliances are installed,

adequate ventilation MUST be

provi

ded in the room of installation, located and sized such tha

t the

negative pres-

sure in the room created by the extractor

does not exceed 4Pa

.

In case of

doub

t, do not

operate the extractor and fuel-burning

appliance(s) simulta

-

neously and consult an

appropriate (for the fuel type) expert for advice

.

ELECTRICAL HAZ

ARD

DISCONNEC

T ELECTRICAL SUPPLY

B

EFORE PROCEEDING FURTHER

Page 3

Contemporar

y Falcon Cooker H

ood

s

Revision: 02/02/2009

3

SECTION 5. OPERATING INST

RUC

TIONS

a

. Switch power on at the fused spur

.

b

. The extractor has 6 push-buttons which

illuminate w

hen selected

. Their function

s

are summarised in the table below

.

c. The extractor controller will automatically switch o

ff the

appliance i

f there has

been

no operator action for 4

hours.

d

. After 30 hours accumulated running GR

EASE FILTER SATURATION will be sig-

nalled by all 6 indicator

s flashing. Reset by pressing Push-button

FAN OFF (delay)

.

SECTION 6. MAINTENANC

E

R

egular maintenance is essential to ensure good performance and l

ong-life

.

To clean the

stainless steel surfaces of the extractor use a proprietary cleaning agen

t. Do

not use abrasive cl

eaning materials or produ

cts.

Clean the grease filters in a dishwasher or by

hand-washing in hot water and detergen

t.

Wash the filters at least every 2 months - s

ooner if the extractor is used extensivel

y.

To remove the grease filters pull the chrome effe

ct filter release lever away from the

hood

base

. This releases the retaining clips allowing the filter to be carefully lifted awa

y from

the

hood. Care s

hould be taken no

t to scratch the hood

.

To maintain the immaculate appearance o

f the extractor,

and to minimise fire ri

sk, ensure

that grease

deposi

ts on the extractor surfaces are kep

t to a minimum by regular cleaning

.

To access the hal

ogen lamps for replacement lever off the chrome ring immediatel

y

surr

ounding the matt glass with a

screwdriver. Only replace with bulbs o

f the same type

and rating

.

SECTION 7. SPECIFICATIONS

H

ood weights:

Blower airflow, nominal: 1,

000 m3/hr

Noise level: 56d

BA

S

upply voltage: 230

V~ 50H

z

Hal

ogen lamp voltage: 12

V

Blower power i

npu

t: 1 @

300

W

Hal

ogen lamp power: 2

x 20W

Total power:

340

W

Fuse size for electrical supply: 3A

Blower spigot diameter: 150

mm

CT900

26Kg

CT1092

29Kg

Pushbutton Funct

ion

LIGH

TS ON/OFF

0 1

FAN ON SPEED 1 (min);

FAN OFF (immediate

stop)

.

2

FA

N ON

SPEED

2

3

FA

N ON

SPEED

3

4

FA

N ON

SPEED 4 (max

)

FAN OFF AFTER 10 MINUTE DELAY to clear resi

dual

fumes; indicator flashes during time-ou

t.

FIGURE 1

HOOD DIMEN

SIONS

A

nd

FIXING HOLE DETAILS

Met

hod 1

1. Mark a horizontal line (A) in the position o

f the

hoods bottom

edge - i

f you have

alr

ead

y fitted a splas

hba

ck t

hen the top edge o

f this w

ill serve.

2. Mark a vertical centre line o

f the range cooker

and the hood (B)

.

3. Mar

k the positions of at least four fixing hole centre

s, as shown

above

.

4

. If using the rear exhau

st spigot position, mark and kno

ck out a hole suitable to

accommodate 150mm dia. ducting as detailed in the installation manual.

5. Remove the grease filter

s to gain access the internal fixing holes and the chimney

to access the external fixing holes (if using)

.

6

. Secure

hood using fixing

s suitable for the wall construction in the previously marked

positions.

Met

hod 2

1. Remove the grease filter

s to gain access the internal fixing holes in the

hood rear

.

2

. If using the rear exhau

st spigot position, mark and kno

ck out a hole suitable to

accommodate 150mm dia. ducting as detailed in the installation manual.

3

. Offer the hood up to the wall in the desired position and mar

k the wall thr

ough the

fixing holes in the

hood rear

. This is a 2 person job.

4

. Secure

hood using fixing

s suitable for the wall construction in the previously

marked positions.

Page 4

Contemporain Hotte

s Falcon

Revision: 02/02/2009

4

GUIDE díInstallation,DíUtilisation et Conseils díEntretien

SECTION 1 INTRO

DUC

TION 4

SECTION 2 PERFORMANCE DE L

íEXTRACTION 4

SECTION 3

REN

SEIGNEMENTS IMPORTANTS 4

SECTION 4 INSTALLATION 4

4.1 Sortir les filtre

s ‡ graisse

4.2 Situation de

l

íÈchappement du ventilateur

4.3 Installation de la conduite

4.4 Comment attacher la hotte conte le mur

4.5 Comment raccorder la conduite

4.6 Installation Èlectrique

SECTION 5 INST

RUC

TIONS DíUTILISATION 5

SECTION 6

MAIN

TIEN 5

SECTION 7 SPECIFICATIONS 5

D

ESSIN 1:

DIMEN

SIONS ET D…TAILS FIXATION 5

SECTION 1. INTRO

DUC

TION

L

íÈlÈment le plus important pour une bonne performance de la hotte est le conduit qui

Èvacue líair vers líextÈrieur.Ce conduit doit etre une prioritÈ dËs le dÈbut de la conception

de votre cuisine.

SECTION 2. PERFORM

ANCE D

E LíEXTRACTION

L

íÈlÈment le plus important pour une bonne performance de la hotte est le conduit qui

Èvacue líair vers líextÈrieur.Ce conduit doit etre une prioritÈ dËs le dÈbut de la conception

de votre cuisine.

Veuillez noter les ÈlÈments suivants :

La hotte e

st fournie avec un

adaptateur

appropri

È ‡ fixer au conduit de 150mm de

diamËtre.

A

noter:

150mm est le dim

Ëtre minimum du conduit permettant une extraction effica-

ce.

La l

ongeur du c

onduit díextraction doit Ítre aussi limiteÈ que possible avec le moins

de coudes possible.

La configuration la plus efficace est díÈvacuer directement par un mur extÈrieur.

Ainsi il e

st conseill

È de placer le fourneau contre un mur extÈrieur quand on conÁoit

le plan de la cuisine

.

O

n peu

t faire

Èvacuer la fumÈe par líorifice supÈrieur ou par líorifice arriËre. La

turbine de ventilation devra

Ítre pivotÈ pour la position díÈvacuation par líarriËre.

Un c

onduit avec plus de 2 c

oudes a 90

∞ dÈgradera díune faÁon significative la per-

formance du

systËme díextraction. Si possible Èvitez díavoir un coude de 90∞ ‡ la

sortie, ut

ilisez de

s c

oudes dont les diametre

s sont aussi gr

ands que possibles

pour

maintenir un flux d

íair continu sans tourbillonnements; Èvitez des entortillements

de

s c

onduits flexibles; Ètirez le conduit flexible pour síassurer que la surface interne

soit aussi lisse que possible.

SECTION 3. IMPORTANT INFORMATION

Pour une petite charge de

s chemin

Èes adaptÈes aux besoins du client de rechange

peuven

t Ítre produites.

La distance minimum enter les br

˚leurs de la plaque du forneau et le bas de la hotte est

essentielle

pour empÍcher la surchauffe de la hotte et de ses piËces.

Si vous voulez protÈger le mur entre le fourneau et la hotte avec une credence Falcon

veuillez bien noter la

hauteur minimum de

800mm du tabl

eau ci-dessu

s.

En cas díun coude ‡ 90∞ du conduit il faut respecter un encombrement minimum de

215mm. Cela permettra de courber le conduit sans faire de faux-pli

.

Il faut respecter les

normes en vigueur concernant le rejet de

líair.

Attent

ion:

Cet

appareil doi

t Ítre mis ‡ la masse. Assurez-vous

que le voltage d

íalimentation corres-

pond

‡ celui marquÈ sur líetiquette de classement ‡ líinterieur de la hotte.

La hotte devra Ítre mise hors tension avant de faire des opÈrations de nettoyage ou

d

íentretien.

Il faut absolument faire attention au risque du feu quand l

íon est en train de frire. Pour

minimiser le risque de feu

, tous le

s conseil

s concer

nant le nettoy

age de

s filtre

s ‡ graisse

doivent Ítre respectÈs.

Ne pas

approcher de flamme sous la hotte.

SECTION 4. INSTALLATION

4.1 D

Èmontage des filtres ‡ graisse

Mettez la plaque arri

Ëre sur une surface horizontale.

Pour enlever le

s filtre

s ‡ graisse, tirez le levier de filtre et retirez le filtre.

Les quatre trous de fixation interne, le ventilateur et la plaque d

íobturation sont accessi-

ble

s par les trous dans la pl

aque arri

Ëre. (dessin 1).

4.2

Position du ventilateur.

La hotte peu

t Ítre ventileÈ soit par la position díÈchappement supÈrieur soit pas la posi-

tion d

íÈchappement arriËre. Chaque position díÈchappement a quatre goujons auxquels

on peut positi

onner soit le montage ventilateur soit

une plaque

.

Positionner le ventilateur

‡ la position díÈchappement dÈsirÈe et la plaque ‡ la position

non utili

sÈe.

En c

hangeant la position d

íÈchappement il faut faire attention de ne pas tirer ou entortiller

excessivement le cable Èlectrique díalimentation du ventilateur

4.3

Installat

ion du conduit

Faites un trou

dans le mur ou le plafond par lequel on

peu

t faire passer le conduit de

150mm de diam

Ëtre de la hotte ‡ líextÈrieur.

La l

ongueur du c

onduit devra

Ítre limitÈe au plus court possible avec le moins de coudes

possible ñ voir section 2

.

Faites un trou

dans le mur extÈrieur correspondant aux mesures internes de la grille de

ventilation.

4.4 Comment fixer la

hotte contre le mur

Si vous fixez

une cr

edence Falcon elle doi

t Ítre installÈe avant la hotte.

Des instruction

s compl

Ëtes pour monter la hotte sont donnÈes (dessin 1).

A

noter: La partie d

Ècorative de la hotte peut Ítre enlevÈe pour faciliter la manoeuvre de

la hotte.

Le mur recevant líappareil devra Ítre de bonne qualitÈ avec une surface plane et Ítre

suffisamment solide

pour s

upporter la hotte.

Le

s fixations appropri

Èes ‡ la nature de la construction du mur devront Ítre utilisÈes.

4.5 Comment raccorder le conduit

Fixez le conduit ‡ líadaptateur. Il se peut quíon soit obligÈ de le faire avant de fixer le

ventilateur contre le mur. Il est conseill

È díenlever la partie dÈcorative avant cette man-

úuvre. La cheminÈe est attachÈe en utilisant des vis machine M4 qui peuvent Ítre accÈ-

d

Ès par la/les ouverture(s) ‡ filtre.

Q

uand le ventilateur est en place, vÈrifiez que le conduit ne soit pas aplati ou entortillÈ

sur son parcour

s.

Raccordez le conduit ‡ la grille de ventilation du mur ou ‡ une terminaison extÈrieure

alternative.

Fixez bien la grille de ventilation au mur extÈrieur. Assurez-vous

que les ailettes se

dirigen

t vers le bas.

Remplacez le

s filtre(s) ‡ graisse.

4.6

Installat

ion Èlectrique

L

íextracteur est un appareil fixe destinÈ ‡ Ítre branchÈ au secteur par installation Èlectri-

que fixe

. Un technicien

Èlectricien compÈtent doit realises líinstallation Èlectrique.

Le ventilateur devra Ítre alimentÈ avec une prise comprenant un fusible de 3A en mono-

pha

sÈ 230V. Líinterrupteur devra Ètre situÈ ‡ cotÈ du ventilateur/fourneau pour que le

courant puisse

Ítre coupÈ du ventilateur. Le fusible devra avoir un contact minimum de

sÈparation de 3mm entre tous ses pÙles. Si non un moyen different de couper líinstalla-

tion

Èlectique doit Ítre prÈvu et conforme au rËglement Èlectrique en vigueur.

Un c‚ble pour relier la prise au ventilateur est inclu.

LíÈvacuation peut se faire dans un conduit existant ‡ condition que les fluides

de ce conduit soient produits exclusivement par des appareils Èlectriques. Sont

exclus les c

onduits de chauffage central, de chauffe-ea

u ‡ gaz ou ‡ fioul etc.

Il faut ve

iller

‡ avoir une ventilation adÈquate de la piËce quand la hotte du

fourneau et les appareils ‡ Ènergie autre que líÈlectricitÈ (e chauffe-ea

u ‡ gaz

ou ‡ fioul etc) sont en marche simultanÈment. La piËce doit Ítre pourvue

díorifices pour permettre une arrivÈe díair frais constante.

Attent

ion!

Il faut bien veiller

‡ ce que le systËme díextraction de haute performance níaffecte pas

le

bon foncti

onnement des autres

appareils ‡ combustibles (gaz, fioul, etc...) quíils

soient

dans la cuisine ou

dans d

íautres parties de la maison.

L

‡ o˘ sont installÈs ces appareils ‡ combustibles, IL FAUT prÈvoir une ventilation

ad

Èquate qui prend en compte la capacitÈ díextraction dela hotte falcon.Lí Ècart entre

la ventilation et líextraction par la hotte ne doit pas excÈder 4Pa.

En cas de

doute ne faites pas functionner la hotte et l

íappareil ‡ combustible simulta-

n

Èment et consultez un expert (du combustible) appropriÈ pour vous bien conseiller.

D

Ègagement minimum entre le fourneau et la hotte:

800mm

Hauteur de la hotte y compris chemin

Èe:

550ó950 mm

Hauteur requise du plaf

ond

avec cheminÈe standard:

2290mm

CODE CONNEC

TION COULEURS DES DIFF…RENTS FILS

Fai

scea

u

C

ouleur de faiscea

u

C

onducteu

r

Marr

on

Neutre

B

l

eu

Terr

e

V

ert/J

aune

…LECTRICIT…=DANGER

COU

PEZ Lí…LECTRICIT… AVANT DE CONTINUER

Page 5

Contemporain Hotte

s Falcon

Revision: 02/02/2009

5

SECTION 5. CONSEILS DE MISE EN ROUTE

a

. Branchez le fusible

.

b. La hotte comporte six

boutons-

poussoirs qui s

íilluminent quand on les enfonce.

Leurs fonction

s sont rÈsumÈes sur le tableau ci-dessou

s.

c. La comm

ande de la hotte c

oupera automati

quement l

íappareil síil y a un dÈlai de 4

heures de non foncti

onnemen

t.

d

. Apr

Ës 30H de fonctionnemen

t, la saturation des filtre

s ‡ graisse sera signalÈe par un

clignotement des 6 boutons - pour rÈinitialiser, appuyez sur le bouton FAN OFF.

SECTION 6. ENTRETIEN

Un entretien rÈgulier est essentiel pour assurer une bonne performance durable Pour

nettoyer le

s surfaces de l

íacier inoxydable de la hotte servez-vous díun agent de nettoya-

ge de qualitÈ appropriÈe. Il ne faut pas utiliser des matÈriels ou des produits de nettoya-

ge abrasi

fs.

Nettoyez le

s filtre

s ‡ graisse dans un lave-vaisselle ou

‡ la main avec de líeau chaude et

un d

Ètergent. Lavez les filtres tous les 2 mois- plus frÈquemment si líextracteur est en

usage fr

Èquent.

Pour enlever le

s filtre

s ‡ graisse, tirez le levier de filtre et retirez le filtre.

Pour entretenir

l

íapparence immaculÈe de la hotte et pour minimiser le risque de feu ñ

assurez-vous que les

dep

Ùts de graisse sur les surfaces de la hotte soient nettoyÈ regu-

lierenment.

Pour remplacer les lampes enlever la bague de serrage du verre (levier par un tournevis)

et enlever le verre mat. Remplacer avec des lampe

s du meme type.

SECTION 7. SPECIFICATIONS

Poids des Hottes:

CT900

26Kg

CT1090

29Kg

D

ESSIN 1

DIMEN

SIONS DE LA HOTTE

ET

D

…TAILS DE LA FIXATION DES TROUS

M

Èthode 1

1. Mar

quez une li

gne horizontale (A) dans la position d

ÈsirÈe de la base de la hotte.

2. Mar

quez une li

gne centrale verticale du fourneau et la hotte (B).

3. Mar

quez les centres de trous de fixation comme indi

qu

Ès ci-dessu

s

4

. Si vous vous servez de l

íÈvacuation arriËre, marquez et faites un trou pour accepter

un conduit díun diamËtre de 150mm comme dÈtaillÈ dans le guide díinstallation.

5

. Fixez la hotte en vou

s servant de

s fixations qui conviennen

t ‡ la construction du

mur dans les postions d

Èj‡ marquÈes. Les trous de fixation sont rÈvÈlÈs quand les

filtre

s sont enlevÈes comme dÈtaillÈ dans le guide díinstallation.

M

Èthode 2

1

. Enlevez le

s filtre

s comme dÈtaillÈ dans le guide díinstallation pour accÈder aux

trous de fixation ‡ líarriËre de la hotte.

2

. Si vous choisissez l

íÈvacuation par líarriËre, marquez et faites un trou convenable

pour accepter un conduit díun diamËtre de 150mm comme dÈtaillÈ dans le guide

d

íinstallation.

3

. PrÈsentez la hotte contre le mur dans la situation dÈsirÈe. Deux personnes sont

n

Ècessaires pour cette opÈration. Marquez le mur par les trous de fixation dans la

partie arri

Ëre de la hotte.

4

. Fixez la hotte en vou

s servant de

s fixation

s conv

enables pour la construction du

mur aux positions dÈj‡ marquÈes.

Boutons-Poussoirs

Fon

c

t

ion

LUM

I»RE ON/OFF

0 1

VITESSE 1 (min);

OFF (A

RR

T IMM…DIAT).

2

VITESSE 2

3

VITESSE 3

4

VITESSE

4 (max)

ARRET APRES 10 MINUTES

pour Èliminer les

derniere

s v

apeurs - líindicateur clignote durant

l

íoperation.

Souffleur Ècoulement díair nominal: 1,

000 m3/

h

Niv

eau de Brui

t:

56d

BA

Voltage

Èlectrique:

230

V~ 50H

z

Voltage de la lampe halog

Ëne: 12V

Souffleur consommation d

íÈnergie: 1 @

300

W

Puissance de la lampe halog

Ëne: 2 x 20W

Energie Totale:

340

W

Fusible recomm

and

È pour líÈnergie Èlectrique: 3A

DiamÈtre de líadaptateur du ventilateur:

150

mm

Page 6

M

oderne Falcon-Dunstabzugshauben

Revision: 02/02/2009

6

Mont

age-, Gebrauchs- & Wartungsanleit

ung

ABS

CHN

ITT 1 EINL

EITUNG

6

ABS

CHN

ITT 2 ABSAUGLEISTUNG

6

ABS

CHN

ITT 3 WICHTIGE INFORM

ATIONEN

6

ABS

CHN

ITT 4 MONTAGE

6

4.1 Entfernen der Fettfilter

4.2 Geb

l

‰seabzugposition

4.3

Schachtmontage

4.4 Wandmontage

4.5 Ablu

ftschachtanschluss

4.6 Elektroinstallation

ABS

CHN

ITT 5 GEBRA

UCHSANLEITUNG

7

ABS

CHN

ITT 6 WARTUNG

7

ABS

CHN

ITT 7 TE

CHNISCHE D

ATEN

7

ABBILDUNG 1

: ABMESSUNGEN

UND ANSCHLUSSM

ASSE

7

ABSCHN

ITT 1. EINLEITUNG

Ihr Herd ist ein semi-professionelle

s Ger

‰t. Dies gibt Ihnen die Mˆglichkeit und

Flexibili

t‰t, in der K¸che Ihr volles Potenzial zu entfalten. W‰hrend des Kochvorgangs

entwickeln sich zwangsl

‰ufig Hitze, D‰mpfe und D¸nste. Ihre Falcon-Abzugs

haube

wurde in Aussehen und Leist

ung als P

endan

t zu ihrem Herd entworfen, um eine ideale

Umgebung

f¸r kreatives Kochen zu schaffen.

ABSCHN

ITT 2. ABSAUGLEISTUNG

Den wichtigsten Einfluss auf die Leistung der Dunstabzugshaube hat das Design de

s

Abluftschachts, welcher die abgesaugte Lu

ft vom Dunstabzug zum Luftgitter in der

Auflenwand transportiert. Die Ausrichtung des Abluftschachts sollte eine wichtige

‹berlegung in der Anfangsphase einer K¸chenplanung sein.

Bitte

beachten Sie:

Die Dunstabzugshaube i

st mit einem Abluftstutzen f¸r den Anschluss eines

Schachtes mit 150 mm Durchmesser versehen

.

Hinwei

s:

150 mm sind der minimale Durchmesser de

s Schachtes f¸r einen

durc

hgehend effizienten Abzug.

Die L‰nge des Abluftschachts sollte mˆglichst kurz und mit wenigen Biegungen

versehen sein

.

Die effizienteste Anordnung i

st,

den

Schacht ger

adewegs durch eine Auflenwand zu

ziehen

. Versuchen Sie also den Herd bei der Planung Ihrer K¸che an einer

Auflenwand zu platzieren.

Die Haube kann entw

eder durch den oberen oder

den hinteren Abluftausgang

bel¸ftet werden. Benutzen Sie den Ausgang, der den k¸rzesten Schacht und die

wenigsten Bˆgen ermˆglicht. (Das Gebl‰se muss bei Auswahl des hinteren

Abluftaus

gangs gedreht wer

den.)

Ein Verlauf mit mehr als zwei 90∞-Bˆgen wird die Leistung des Abluftsystems

deutlich vermindern

. W

enn m

ˆglich, vermeiden Sie einen 90∞-B

ogen am

Abluftstutzen der Dunstabzugs

haube. Halten Sie die Radien der Bˆgen so grofl wie

m

ˆglich, um einen glatten Luftzug ohne Wirbel zu gew‰hrleisten. Vermeiden Sie

Knicke in flexiblen Rohren

. Ziehen Sie flexible Rohre

stra

ff ¸ber gerade Strecken, um

eine m

ˆglichst glatte Innenfl‰che sicherzustellen.

ABSCHN

ITT 3. WICHTIGE INFORMATIONEN

Die folgende Mindestbauh

ˆhe ist notwendig, um gen¸gend Platz f¸r den Herd und die

H

aube zu gew‰hrleisten.

G

egen eine kleine Geb¸hr kˆnnen individuelle Ersatzkamine Ihren Anforderungen

entsprechend angefertigt wer

den

.

Der Mindestabstand zwisc

hen Kochstelle und Dunstabzugs

haube i

st notwendig, um ein

‹berhitzen der Dunstabzugshaube und ihrer Komponenten zu vermeiden.

W

enn Sie ei

nen Falcon-Spri

tzschutz

anbri

ngen, wird der Abstand zwisc

hen Herd

und

H

aube von dem

800 mm hohen Spri

tzschutz

ohne Flansche vor

gegeben

.

Bitte

beachten Sie

au

flerdem, dass ein 90∞-B

ogen im flexiblen Schacht eine

Mindestbauh

ˆhe von 215 mm benˆtigt, um einen glatten Radius ohne Knicke zu

erhalten.

Anforder

ungen der einschl

‰gigen Behˆrden bez¸glich Abgabe von Abluft m¸ssen

eingehalten werden

.

Achtung:

Diese

s Ger

‰t benˆtigt einen Erdanschluss.

Stellen Sie sicher, dass die Versorgungsspannung mit dem N

ennwert ¸bereinstimmt, der

sich auf dem Aufkl

eber an der Innenseite der Dunstabzugs

haube befi

nde

t.

Die Dunstabzugs

haube muss von der

Stromversorgung getr

enn

t sein, bevor Reini

gungs-

oder Wartungsarbeiten durchge

f¸hrt werden kˆnnen.

Beim Braten ist das Brandrisik

o besonders zu b

eachten. Um das Risiko eines

Brandes

zu minimieren, m¸ssen alle Anweisungen bez¸glich Reinigung der

Fettfilter

und Entfernen der Fettablagerungen b

eachtet werden.

Flambiere

n Sie nicht unter der Dunsta

bzugshaube.

ABSCHN

ITT 4. MONTAGE

4.1

Entfernen der Fe

ttfilter

Die Dunstabzugs

haube auf einer waagerechten Oberfl‰che auf ihre R¸ckwand legen.

Um die Fettfilter zu entfernen, den Griff zur Filterfreigabe vom B

oden der Haube

wegziehen/anheben

. Auf diese Weise wer

den die Sicherungsclips gel

ˆst und der Filter

k

ann vorsichtig aus der Haube entnommen wer

den

. Achten Sie darau

f, die Haube nicht

zu verkratzen.

Die vier i

nneren Mont

agelˆcher, die Gebl‰segruppe und die Abdeckplatte des

Abluftstutzens kˆnnen nun durch die ÷ffnungen in der Grundplatte erreicht werden.

(si

ehe Abbildung 1).

4.2 Ge

bl‰seabzugposition

Die H

aube kann entw

eder durch den oberen oder

den hinteren Abluftausgang bel¸ftet

wer

den

. J

eder Abluftaus

gang besi

tzt 4 Gewindebolzen, an

denen entw

eder die

Gebl

‰segruppe oder eine Abdeckplatte angeschraubt werden kann.

Bri

ngen Sie die Gebl

‰segruppe am ausgew‰hlten Abluftausgang und die Abdeckplatte

am

ungenu

tzten Aus

gang an

.

Bei

ƒnderung des Abluftausgangs sollte darauf geachtet werden, das am Gebl‰se

befindliche Kabel nich

t zu star

k zu ziehen oder zu verdr

ehen

.

4.3 Schachtmontage

Bri

ngen Sie ein Loch in Wand oder Decke ein, um

den

Schacht mit 150 mm

Durchmesser vom Ablu

ftstutzen der Dunstabzugs

haube nach au

flen zu leiten.

Die L

‰nge des Abluftschachts sollte mˆglichst kurz und mit wenigen Biegungen versehen

sein ñ siehe Abschnitt 2.

Schl

agen Sie ein Loch in die Au

flenwand, das den inneren Maflen des Luftgitters

entsprich

t.

4.4 Wandmontage

W

enn ein Falcon-Spri

tzschutz

angebracht wer

den soll, mu

ss dies vor dem Einbau der

H

aube geschehen

.

Die v

ollst

‰ndige Anleitung zur Montage der Haube finden Sie in Abbildung 1.

H

inweis: Der dekorative Kamin k

ann zur einfacheren Handhabung der Haube entfern

t

wer

den

.

Die gew‰hlte Wand muss von guter Qualit‰t sein, eine ebene Oberfl‰che haben und

stabil genug sein, um die Dunstabzugshaube zu halten.

Es

m

¸ssen f¸r den jeweiligen Wandtyp geeignete Befestigungselemente benutzt werden.

4.5 A

bluftschachtanschluss

Den Schacht mit dem Abluftstutzen der Dunstabzugs

haube verbinden. Dies muss

vielleicht vor dem Anbringen der Dunstabzugshaube an der W

and durc

hge

f¸hrt werden.

Die

s f‰llt mit entferntem Kamin leichter. Der Kamin ist mit M4-Maschi

nenschrauben

befestigt

und kann durch die Filter

ˆffnung(en) erreicht werden.

Nach Ausrichtung der Dunstabzugshaube sicherstellen, dass der

Schacht auf

ganzer

L

‰nge weder flachgedr¸ckt noch geknickt wurde.

Den Schacht mit dem Stutzen des W

andluftgitters oder alternativen Au

flenanschl¸ssen

verbi

nden

.

Das Luftgitter an der Au

flenwand befestigen. Sicherstellen, dass die Bel¸fter nach unten

ausgerichte

t sind

.

Die Fe

ttfilter wieder

anbri

ngen

.

4.6

Elektroinstallat

ion

Die Dunstabzugs

haube i

st ein ortsgebundene

s Ger

‰t, das mit einer festen Verkabelung

an die

Stromversorgung angeschlossen wird. Ein kompetenter Elektrotechniker mu

ss die

Elektroinstallation vornehmen

.

Die Dunstabzugs

haube muss mit einer ei

nphasi

gen

Stromversorgung von 230-Volt-

Wechselstrom

¸ber eine eigene, geschaltete Leistung betrieben werden, die mit einer 3

-

A-Sicher

ung ausgestattet i

st. Die Stichleitung sollte

neben der Dunstabzugshaube/Herd

li

egen, damit die Versor

gung der Dunstabzugshaube durch Bet‰tigung des Schalters

unterbrochen wer

den kann. Der

Schalter zum Abschalten der Versor

gung muss eine

Kontakttrennung von mindestens 3 mm an allen Polen haben

. Alternativ mu

ss ein

Schalter gem

‰fl den einschl‰gigen Verkabelungsvorschriften in der festen Verkabelung

eingebaut wer

den

.

Eine Zuleit

ung zum Anschluss der

Stichleitung an die Dunstabzugs

haube i

st im

Lieferumf

ang enthalten.

Die H

auptversor

gung wird wie folgt an das freie Ende dieser Zuleitung angeschlossen

:

Abst

and zwisc

hen Herd

und H

aube (min)

:

800 mm

H

aubenh

ˆhe inkl. Kamin:

550ó950 mm

M

indestdecke

nhˆhe bei Standardkamin:

2.290 mm

Die abgesaugte Lu

ft darf nicht in einen Kaminschacht entl¸ftet werden, der

f¸r die Aufnahme von D‰mpfen aus nicht elektrisch betriebenen Ger‰ten,

z. B. ˆl-

oder gasbetri

ebene Zentralheizungskessel, gasbetri

ebene

Wassererhitzer, etc. verwendet wird.

Eine angemessene Bel¸ftung des Raumes muss gew‰hrleistet werden, wenn

der Herd, die Dunstabzugs

haube sowie nicht elektrisch betri

ebene Ger‰te

(

z. B. Gas-

oder ÷lherde, etc.) gleichzeitig genutzt werden. Der Raum muss

¸ber L¸ftungsschlitze verf¸gen, die eine konstante Frischluftzufuhr

erm

ˆglichen.

Achtung

Achten Sie besonders gr

¸ndlich darauf, dass sich der durch Hochleistungs

-

Abluftsysteme entst

ehende Unterdruck nicht nachte

ilig auf die sichere

B

enutzung bestimmter

Ty

pen von Ge

r

‰ten mit Brennstoffbefeuerung (Gas, ÷l

oder feste Brennstoffe) auswirkt. Dies gil

t f¸r solche Ger‰te, die in der K¸che

und m

ˆglicherweise auch in anderen Teilen des Hauses angeschlossen sind.

In R‰umen mit derartigen Ger‰ten MUSS eine angemessene Bel¸ftung

gew‰hrleistet werden, die durch Position und Grˆfle den durch die

Dunstabzugs

haube im Raum entst

ehenden Unterdruck unter 4 Pa h

‰lt.

Im Zweifelsfall die Dunstabzugshaube und Ge

r

‰te mit Brennstoffbefeuerung

nicht gleichzeitig betrei

ben und einen fachkundigen

Experten (je nach

Brennstoff) zurate zi

ehen

.

GEFƒHRLICHE ELEKTRISCHE SPANNUNG

VOR DEM WEITEREN VERF

AHRENSTROMVERSORGUNG ABSCHA

LTEN

EINGEHENDE

KAB

ELVERBI

NDUNGEN

S

pannung

sf¸hrend Braun

Nullleite

r

B

l

au

Schutzer

de

G

r

¸n/gelb

Page 7

M

oderne Falcon-Dunstabzugshauben

Revision: 02/02/2009

7

ABSCHN

ITT 5. GE

BRAUCHSAN

LEITUNG

Einschalten der

Stromversorgung an der Stichleitung mit Sicher

ung

.

Die Dunstabzugs

haube hat 6 Tasten, die bei Auswahl aufleuchten

. Ihre Funktionen

wer

den in der unten

st

ehenden Tabelle zusammengefa

sst.

Der Dunstabzugsregler schaltet da

s Ger

‰t automatisch aus, wenn 4 Stunden lang keine

Bet‰tigung erfolgt.

Nach 30 Betriebsst

unden wird durch alle 6 blinkenden Lampen

FETTFILTER

WECHSELN si

gnalisiert. Zur

¸ckstellen durch Dr¸cken der GEBLƒSE AUS-Taste

(Verzˆgerung).

ABSCHN

ITT 6. WARTUNG

R

egelm

‰flige Wartung ist unumg‰nglich, um eine gute Leistung und ein langes Leben zu

gew‰hrleisten.

Zur Reini

gung der Edelstahloberf

l

‰chen der Dunstabzugshaube ein geeignetes

Reini

gungsmittel verw

enden

. Keine sc

heuernden Reini

gungsmaterialien oder -produkte

verwenden

.

Reini

gung de

s Fettfilters in einer Geschirrsp

¸lmaschine oder per Handw‰sche in heiflem

Wasser und Sp

¸lmittel. Filter mindestens alle zwei Monate waschen ñ ˆfter, wenn die

Dunstabzugs

haube h

‰ufig benutzt wird.

Um die Fettfilter zu entfernen, den Griff zur Frei

gabe des Chromeffektfilter

s vom Boden

der Haube wegziehen/anheben

. Auf diese Weise wer

den die Sicherungsclips gel

ˆst und

der Filter kann vorsichtig aus der Haube entnommen wer

den. Darauf achten, die Haube

nicht zu verkratzen.

F¸r einen einwandfreien Zustand der Dunstabzugshaube und ein minimales Brandrisiko

sicherstellen, da

ss Fettabl

agerungen auf der Dunstabzugsoberfl‰che durch regelm‰flige

Reini

gung auf einem Minimum

gehalten werden

.

Um die Halogenlampen zu wechseln,

den Chromring dire

kt an der matten Gla

sscheibe

mit einem

Schr

aubendreher

abhebeln. Nur mit Gl¸hlampen desselben Typs und mit

gleicher N

ennleist

ung austauschen

.

ABSCHN

ITT 7. TE

CHNISCHE DATEN

Haubengewichte

Drucktast

e

Fun

ktion

LEUCHTEN

EIN / AUS

0 1

GEBLƒSE EIN, STUFE 1 (min.);

GEB

L

ƒSE AUS (sofortiger Stopp).

2

GEB

L

ƒSE EIN, STUFE 2

3

GEB

L

ƒSE EIN, STUFE 3

4

GEB

L

ƒSE EIN, STUFE 4 (max.)

GEBLƒSE AUS MIT 10 MINUTEN VERZ÷GERUNG

zum Absaugen der restlichen D

‰mpfe; Anzeige blinkt,

w

‰hrend die Zeit abl‰uft.

A

bbildung 1

Haubenma

fle

U

nd

Details zu Montage

lˆchern

Met

hode 1

1

. Eine w

aagerechte Linie (Linie A) an der unteren Kante der Haube markieren ñ wenn

bereits ein Spritzschutz

angebracht wurde, k

ann dessen obere Kante verw

ende

t

wer

den

.

2

. Eine senkrechte Mitte

llinie von Herd und H

aube markieren (Linie B)

.

3. Die Positi

onen von mindesten

s vier Montage

l

ˆchern wie oben beschrieben

markieren.

4

. Bei Benutzung des hinteren Abluftausgangs ein Loch, da

s f

¸r den Schacht mit 150

mm Durchmesser

geeignet i

st, gem

‰fl der Montageanleitung markieren und

herausbrechen

.

5. Die Fe

ttfilter entfernen, um Z

ugang zu den inter

nen Mont

age

l

ˆchern zu erhalten und

den Kamin entfer

nen, um die exter

nen Mont

agelˆcher (bei Bedarf) freizulegen.

6

. Zum Befesti

gen der Haube

f¸r den jeweiligen Wandtyp geeignete

Befestigungselemente an den bereits erstellten Markierungen verw

enden

.

Met

hode 2

1. Die Fe

ttfilter entfernen, um Z

ugang zu den inter

nen Mont

agelˆchern in der

H

aubenr¸ckwand zu erlangen.

2

. Bei Benutzung des hinteren Abluftausgangs ein Loch, da

s f

¸r den Schacht mit 150

mm Durchmesser

geeignet i

st, gem

‰fl der Montageanleitung markieren und

herausbrechen

.

3. Die H

aube an die gew¸nschte Position halten und die Wand durch die

Mont

agelˆcher in der R¸ckwand der Haube markieren. Hier

zu sind 2 Personen

notwendig.

4

. Zum Befesti

gen der Haube

f¸r den jeweiligen Wandtyp geeignete

Befestigungselemente an den bereits erstellten Markierungen verw

enden

.

Gebl

‰seluftzug, nominal 1.

000 m

3

/

h

Ger

‰uschpegel: 56 dBA

Versorgungsspannung: 230

V ~ 50 Hz

Hal

ogenlampenspannung: 12

V

Gebl

‰seleistungseingang: 1 mit 300

W

Hal

ogenlampenleist

ung: 2

x 20 W

Gesamtleistung: 340

W

Sicher

ungsgrˆfle f¸r elektrische Versorgung: 3 A

Durchmesser Gebl

‰sestutzen:

150 mm

CT900

26Kg

CT1092

29Kg

Page 8

Eigentijds Falcon

Afzuigk

appen

Revision: 02/02/2009

8

Instructies Voor Mont

age

, Gebruik en Onderhoud

.

Hoofdstuk 1: Inleiding 8

Hoofdstuk 2: Eigenschappen

8

Hoofdstuk 3: Bel

angrijke informatie 8

Hoofdstuk 4: Installatie

8

4.1 Verwijdering van de vetfilters

4.2 Afvoer aansluiting

4.3 Installeren afvoer

4.4 Montage afzuigkap

4.5 Montage van de afvoer

4.6 Elektrische

aansluiting

Hoofdstuk 5: Gebruiksaanwijzing 9

Hoofdstuk 6: O

nderhoud

9

Hoofdstuk 7: Specificatie

s 9

Figuur 1: Afmeti

ngen en mont

age details 9

Hoofdstuk 1. Inleiding

Uw fornuis is

een semi-professi

oneel

apparaa

t. U kunt hierop de mee

st verfij

nde

erechten bereiden

. Het is onvermijde

lij

k, dat er tij

dens he

t koken hitte on

tstaat en er

dampen en geuren vrijkomen. Uw Falcon afzuigkap is ontwor

pen om

qua uitvoering en

prestatie uw fornuis te completeren. Deze combinatie maa

kt koken voor u tot een

dage

lij

ks terugker

end fee

st.

Hoofdstuk 2. Eigenschappen

Het bel

angrij

kste

punt om de damp

naar buiten a

f te voeren is

een dege

lijk afvoerk

anaal.

Bij het ontwerp van de keuken moet hier terdege rekening mee wor

den gehouden

.

Let u a.u.b. op de navolgende punten

.

De afzuigkap hee

ft

een manchet voor de aansluiting van

een 150 mm afvoerslang

.

De afvoerslang moet zo kort m

oge

lij

k zijn met zo min moge

lijk bochten

.

U krijgt de mee

st efficiente afzuiging, als het fornuis met de afzuigkap erboven t

egen

een buitenmuur

staat en de afvoer direct

door de buitenmuur loop

t.

De afzuigkap kap kan aan de bovenzijde of

aan de achterzijde wor

den aangesloten

op de afvoersl

ang

. Gebruik de aansluiting die z

onder te veel bochten, direct

naar

buiten loopt en derhalve voor het beste afzuigresultaat zorgt.

Een afvoersl

ang met meer

dan twee bochten van 90 gr

aden zal de afzuiging

aanzienlij

k vermi

nderen

. Zo weinig m

oge

lijk bochten is bepalend voor

een goede

afzuiging in uw keuken

.

SECTION 3. BELANGRIJK

E INFORMATIE

Minimum hoogtes afzuigkap

t.o.v. het fornui

s:

Het is bel

angrijk om niet af te wijken van de minimum a

fst

and tussen bovenzijde fornui

s

en onderzijde afzuigkap

,

daar

anders oververhitting van de afzuigkap en zelfs het in de

brand vli

egen er van het gevolg zou k

unnen zijn.

Indien u

een achterw

and (fit eerste) boven he

t fornuis monteer

t,

dan hee

ft u automatisch

de a

fst

and van 800 mm tussen fornuis en afzuigkap.

Een glad bocht van 90∞ in een 150mm afvoerslang moet een minimum klaring van

215mm.

Belangrijk:

De afzuigkap moet geaard zijn.

Let erop dat de netspanning correspondeert met de spanning die aangegeven is op he

t

plaatje

aan de binnenkan

t van de afzuigkap.

Voor he

t sc

hoonmaken, of onderhoudswerkzaamheden, moet de afzuigkap

uitgeschakeld worden door de stekker uit het stopcontact te halen of de

hoofdschakelaar

uit te zetten.

H

oud bij bakken of frituren altijd de pan goed in de gaten, oververhitte olie is licht

ontvlam

baar.

Flambeer nooit onder de afzuigkap.

Hoofdstuk 4. Installatie

4.1 Het verwijderen van de vetfilter(s)

Leg de afzuigkap met de achterkant op een horizontaal

oppervla

k.

Verwijder de vetfilters dmv het oplichten van de

hendel

aan de afzuigkap. Haal de filters

voorzichtig uit de afzuigkap

, z

onder de kap te besc

hadigen

.

U kunt nu bij de interne ophanging en de afvoeraansluiting is ook bereikbaar.

(zie figuur 1)

.

4.2 Afvoer Aans

luiting

De afzuigkap kan

naar keuze

aan de bovenzijde of

aan de achterzijde wor

den

aangesloten. Beide

aansluiti

ngen hebben 4 tapeinden, waar u de afvoerslang of de

afdekplaat aan kunt bevesti

gen

.

Bevestig de afvoerslang aan de door u

benodigde aansluiting en bevestig op de andere

aansluiting de afdekplaat.

Let erop, dat u bij het verwisselen van de afdekplaa

t, de stroomk

abel niet besc

hadig

t.

4.3

Installeren Afvoer

Maak

een gat in de muur of plaf

ond en voer de

150mm afvoersl

ang van de

afzuigkapmanchet naar buiten

.

H

oud de l

engte van de afvoer zo kort m

oge

lij

k, me

t zo min moge

lijk bochten (zie

hoofdstuk 2).

Maak

een passend gat in de buitenmuur.

4.4 Montage Af

zuigkap

Indien u

een Falcon achterwand gebruikt,

dan moet u deze voor u de afzuigkap ophang

t

monteren.

Voor montage

instructies

zie figuur 1.

Let

op: de decoratieve

schacht kan verwijderd worden. De afzuigkap is

dan beter

hanteerbaar.

Overtuig u dat de muur glad en

sterk genoeg is om de afzuigkap

aan op te hangen

.

Gebruik de juiste bouten om de afzuigkap op te

hangen

.

4.5 Montage van de Afvoer

Bevestig de afvoerslang aan de manchet op de afzuigkap. Bij

aansluiting

aan de

achterzijde van de afzuigkap voor

ophanging eerst de afvoersl

ang bevesti

gen

.

Gebruik de M4 schroeven om de

schacht te verwijderen/ op

hangen

. Via de filteropening

(en) kunt u er makke

lijk bij.

Let erop dat er

geen knik in de afvoerslang zit als de afzuigkap

aan de muur hang

t.

Bevestig de afvoerslang aan het muurrooster

.

Indien de afvoersl

ang aan een rooster is bevestigd,dient de luch

tstroom

naar

beneden te

blazen

.

4.6

Electrical Installat

ion

Sluit de afzuigkap

aan op de netspanning met

een 2 polige

stekker met randaarde

.

De afzuigkap wordt geleverd met

aansluitsnoer z

onder stekker

.

Minimale

hoogte bovenzijde fornui

s tot

onderzijde afzuigkap

800 mm

Afzuigkap

hoogte met st

andaard

schacht

550ó950 mm

M

inimum plaf

ond hoogte voor afzuigkap met standaar

d

schacht

2290 mm

Elektrische Aans

luitingen

Liv

e

B

rui

n

Neutraa

l

B

lauw

Aar

de

G

r

oen/Gee

l

De afzuigkap mag niet wor

den aangesloten op afvoerkanalen van

verbr

andings apparaten, bv geijser

s, boilers en centrale

verwarmings installatie

s, etc. etc.

Zorg voor een luchttoevoer die even groot is als de

hoeveelheid

afgevoerde lucht. Dit is extra bel

angrijk indien er in het zelfde

vertrek ook

een ander verbr

andings apparaat b

.v.

een geijser

aanwezig is.

R

aadpleeg bij twijfel en/of vragen over dit onderwerp uw gasbedrij

f.

Waarchuwing

Als er in de keuken zowel de afzuigkap als

apparaten, die niet op

elektriciteit (b.v. gas

apparaten ) wor

den gebruikt,

dan moet ervoor

wor

den gezorgd, dat de keuken voldoende geventileerd word

t.

Indien er in de keuken onvol

doende

sc

hone lucht word

t

aangevoerd, dat moet er extra ventilatie worden aangebrach

t.

R

aadpleeg bij twijfel en/of vragen een speciali

st.

Ver

wijder

bij kortssluiting of stroomstoring eerst de

stekker, alvorens verder te gaan.

Page 9

Eigentijds Falcon

Afzuigk

appen

Revision: 02/02/2009

9

Hoofdstuk 5. Gebrui

ksaa

nwijzing

Zet de afzuigkap

aan via het

bedieningspaneel.

De afzuigkap

hee

ft zes drukk

noppen. De k

nop i

s verlicht als hij is ingeschakeld

. Zie

onderst

aande tabel voor de diverse functies.

Indien de afzuigkap vier uur on-onderbroken is i

ngeschakeld, dan

schakelt hij

automatisch uit.

Na 30 uur gebruik moet he

t vetfilter wor

den gereinigd. U wordt hierop opmerkzaam

gemaa

kt

doordat alle zes de lampjes kni

pperen. U kun

t ze ui

tschakelen

door op de

ventilator-timer knop te drukken

.

Hoofdstuk 6. Onder

houd

R

egelmatig onderhoud bevordert het

gebruik en levensduur van de afzuigkap.

Gebruik een huis

houde

lij

k sc

hoonmaakmiddel om de afzuigkap

sc

hoon te maken.

Gebruik geen

sc

huurmiddelen

.

U kunt de filters in de vaatwasser reini

gen, of met de

hand in warm water met

een

sc

hoonmaakmiddel. Maak de filters minimaal

eens per 2 maanden

sc

hoon, of eerder

indien de afzuigkap erg intensief wordt gebruikt.

De filters een voor

een verwijderen door ze met een hand te onderst

eunen en de

afsluithendel lo

s te maken

.

T

eneinde uw afzuigkap in goede

staat te

houden en brandgevaar te vermij

den

. Verwijder

dan vetresten van de buitenkan

t van uw afzuigkap

.

Om de lampen te verv

angen verwijder de chroom ring onmi

dde

llijk r

ond de glas door

hem op te t

illen met een

schroevedraaier en vervijder het glas. Alleen verv

angen met

lam

pen van hetzelfde type.

Hoofdstuk 7. Specificaties

Gewicht Af

zuigkap:

Afzuigc

apaciteit (nominale): 1,000 m3/hr

Geluidsnivo: 56d

BA

Elektrische

aansluiting:

220-240

V~ 50H

z

Hal

ogeen lamp voltage: 12

V

Motor: 1 @ 300

W

Hal

ogeen lamp verlichting: 2

x 20W

Totale elektrische aansluiting :

340

W

Zekering: 3

A

Afvoer diameter:

150

mm

CT900

26Kg

CT1092

29Kg

Drukknop Functie

Verlichting Aan/Uit

0 1

Motor Aan

St

and 1 (min)

,

Motor Uit.

2

Motor Aan

St

and 2

3

Motor Aan

St

and 3

4

Motor Aan

St

and 4 (max)

Motor uit, stopt na 10 minuten om rest dam

pen a

f te

zui

gen, de indicator kni

ppert tijdens werki

ng

.

FIG

UUR 1

AFZUIGKAP AFM

ETINGEN

En

B

EVESTIGINGSGATEN

Moge

lijkheid 1

1

. Trek een horizontale lijn ( A ) langs de onderzijde van de afzuigkap

. Bij

gebruik van

een achterw

and

, kunt u de bovezijde ervan horizontaal gebruiken.

2

. Trek een vertikale

lijn v

anuit het mi

dden van he

t fornuis en de afzuigkap (

B ).

3. Markeer de positie

s van de bevestigingsgaten zoals op de tekening boven te zien

i

s.

4

. Als u de

aansluiting

aan de achterkant

gebruikt, teken

dan een cirkel en maak

dan

een ga

t voor de 150mm afvoersl

ang (zie

hoo

fstuk 4.2)

.

5

. Bevestig de afzuigkap aan de w

and met schroeven,die ervoor geschi

kt zijn. De

gaten zijn te zien als de filter

s zijn verwijderd

, zie hoofdstuk 4.4

.

Moge

lijkheid 2

1

. Verwijder de vetfilters (zie hoofdstuk 4) om de bevestigingsgaten in de achterkant

van de afzuigkap te

gebruiken.

2

. Indien u de afvoer aan de achterzijde van de afzuigkap gebruikt, maak dan een ga

t

voor de 150mm afvoersl

ang (Zie

hoofdstuk 4).

3. H

oud de afzuigkap in de gewenste positie tegen de muur en markeer de gaten in

de achterkant van de afzuigkap. Doe dit met 2 pers

onen

.

4

. Bevestig de afzuigkap met

bouten, die geschikt zijn voor de muur, in de voora

f

gemarkeerde positie

.

Page 10

M

odern Falcon kÂpor

Revision: 02/02/2009

10

Installations-, an

v‰ndnings- och

underh

Âllsanvisningar

DEL 1

: INLEDNIN

G 10

DEL 2: UTSUGNIN

GSF÷RM≈GA 10

DEL 3

: VIKTIG INFORM

ATION 10

DEL 4

: INSTALLATION 10

4.1 Ta bor

t fettfilter

4.2 Fl‰ktutsugets placering

4.3 Truminstallation

4.4 F

‰sta kÂpan i v‰ggen

4.5 Ansluta trumman

4.6 Elektrisk installation

DEL 5

: ANVƒNDNINGSANVISNINGAR 11

DEL 6: UNDERH

≈LL 11

DEL 7

: SPECIFIKATIONER 11

Figur 1: M≈TT OCH FƒSTANORDNINGAR 11

D

EL 1. INLEDNING

R

ange-spisen

‰r en halvprofessionell enhet som ger dig mˆjlighet att fˆrverkliga din fulla

potential i

kˆket. Under matlagningen kommer oundvikligen v‰rme, Ânga och os att bildas.

Falcon-fl‰kten ‰r utformad fˆr att komplettera Range-spisen, b

Âde n‰r det g‰ller utseende

och prestanda

, fˆr att Âstadkomma den idealiska miljˆn fˆr kreativ matlagning.

D

EL 2. UTSUGNINGSF÷RM≈GA

Den faktor som har

stˆrst inverkan p fl‰ktens prestanda ‰r utformningen av trumman som

fˆr utsugsluften frÂn fl‰kten till ventilationsgallret p ytterv‰ggen. Dragningen av trumman ska

vara ett av de fr‰msta ˆverv‰gandena under de fˆrsta stegen n‰r kˆket planeras. T‰nk pÂ

fˆljande:

Fl‰kten har en muff som passar anslutning till en kanal med 150 mm diameter.

Obs:

150 mm

‰r den minsta kanaldiameter som ger effektiv utsugningsfˆrmÂga.

Utloppskanalens l

‰ngd ska vara s kort som mˆjligt och med s f bˆjar som mˆjligt.

Me

st effektivt ‰r att dra trumman rakt genom en ytterv‰gg, s fˆrsˆk placera spisen

mot en ytter

v‰gg n‰r kˆket planeras.

KÂpans utlopp kan antingen dras uppÂt eller bakÂt. Anv‰nd det l‰ge som ger den

kortaste kanall‰ngden och det minsta antalet bˆjar. (Fl‰kten mÂste vridas om kanalen

ska g direkt till det bakre utloppsl‰get.)

En dr

agning med mer ‰n tv 90-gradersbˆjar minskar avsev‰rt utsugningssystemets

prestanda. Undvik om m

ˆjligt att placera en 90-gradersbˆj vid utloppsmuffen, hÂll

b

ˆjarnas radie s stor som mˆjligt fˆr att uppn ett mjukt luftflˆde utan virvlar, undvik

veck p bˆjliga kanaler och dra bˆjliga kanaler sp‰nt l‰ngs raka str‰ckningar fˆr att

s‰kerst‰lla att den inre ytan ‰r s sl‰t som mˆjligt.

D

EL 3. VIKTIG INFORMATION

Fˆljande ‰r de minsta mÂtt som kr‰vs fˆr att spis och kÂpa ska f plats:

Minimia

vstÂndet mellan h‰llens br‰nnare och fl‰ktkÂpans underkant mÂste fˆljas fˆr att undvika

ˆverhettning av fl‰ktkÂpan och dess komponenter.

Om ett Falcon-st‰nkskydd monteras, avgˆrs avstÂndet mellan spis och kÂpa av

st‰nkskyddets hˆjd, 800 mm exklusive fl‰nsar.

T‰nk ocks p att en 90-gradersbˆj p bˆjlig kanal kr‰ver minst 215 mm hˆjd fˆr att

Âstadkomma en mjuk bˆjradie utan veck.

F

ˆreskrifter frÂn myndigheter betr‰ffande utsl‰pp av utloppsluft mÂste fˆljas.

Observera:

Den h‰r enheten kr‰ver jordanslutning.

Kontrollera a

tt matningssp

‰nningen ˆverensst‰mmer med uppgifterna p skylten inuti

fl‰ktkÂpan. Sp‰nningen mÂste brytas innan nÂgra rengˆrings- eller underh

ÂllsÂtg‰rder utfˆrs.

Var

s‰rskilt fˆrsiktig vid stekning. Minimera brandrisken genom att fˆlja alla anvisningar

om reng

ˆring av fettfilter och borttagning av fettavlagringar.

Flambera

inte

under f

l‰ktkÂpan

D

EL 4. INSTALLATION

4.1 Bortta

gning av fe

ttfilter

L

‰gg fl‰kten med baksidan nedÂt p en vÂgr‰t yta.

Ta bor

t fettfiltren genom att dra/lyfta filtersp

‰rrspaken bort frÂn kÂpans nederdel. DÂ lossar

kl‰mmorna och filtret kan fˆrsiktigt lyftas bort frÂn kÂpan. Var fˆrsiktig s att du inte repar

kÂpan.

Nu kommer du

Ât de fyra inre f‰sthÂlen, fl‰ktenheten och muffens t‰ckplatta genom

ˆppningarna i bottenplattan. (se figur 1).

4.2

Fl‰ktutsugets placering

KÂpans utlopp kan antingen dras uppÂt eller bakÂt. Vid varje utlopp finns fyra pinnbultar, d‰r

anti

ngen fl

‰ktenheten eller en t‰ckplatta kan skruvas fast.

Skruva fa

st fl‰ktenheten vid det valda utloppet och t‰ckplattan p det andra utloppet.

Var

fˆrsiktig n‰r du byter utloppsl‰ge, s att du inte i onˆdan drar i eller vrider kabeln som

‰r f‰st vid fl‰kten.

KÂpan levereras monterad fˆr utlopp uppÂt (vanligast). Installation med det bakre utloppsl‰get

‰r svÂrare ‰n uppÂt, varfˆr kanalen ofta dras genom v‰ggen ovanfˆr fl‰ktkÂpan och dˆljs av

skorstenen. Det ger en b

ˆj som nÂgot minskar dess prestanda (se del 2).

4.3

Truminstallat

ion

Gˆr ett hÂl i v‰ggen eller taket och dra 150 mm-k

analen fr

Ân fl‰ktkÂpans utlopp till utsidan.

Utl

oppskanalens l

‰ngd ska vara s kort som mˆjligt och med s f bˆjar som mˆjligt, se del 2.

Gˆr ett l‰mpligt hÂl i ytterv‰ggen. Obs: Fˆr att kanalen oskadad ska kunna g igenom

v‰ggen och fˆr att avslutande anslutningar ska kunna gˆras, kr‰vs oftast ett hÂl som ‰r

stˆrre ‰n 150 mm i diameter.

4.4

F‰sta kÂpan i v‰ggen

Om du monterar ett Falcon-st‰nkskydd mÂste det monteras fˆre kÂpan.

Full

st‰ndiga anvisningar fˆr montering av kÂpan finns i figur 1.

Obs: Dekoration

sskorstenen kan tas bort fˆr att underl‰tta hanteringen av kÂpan.

V‰ggen d‰r kÂpan f‰sts mÂste vara av god kvalitet, ha en j‰mn yta och vara tillr‰ckligt

kraftig fˆr att b‰ra fl‰ktkÂpan.

F‰stelement som passar v‰ggtypen mÂste anv‰ndas.

4.5 Ansluta trumman

Anslu

t trumman till fl

‰ktkÂpans utlopp. Vid utlopp bakÂt kanske detta mÂste gˆras innan

fl‰ktkÂpan f‰sts p v‰ggen. Det kan vara l‰ttare om skorstenen ‰r borttagen. Den ‰r f‰st

med M4-skruvar, som kan n

Âs genom filterˆppningarna.

N

‰r fl‰ktkÂpan sitter p plats kontrollerar du att kanalen inte har plattats till eller fÂtt veck.

Anslu

t k

analen till ventilationsgallret p v‰ggen, eller en alternativ yttre

avslutnings

anordning

.

F‰st avslutningen i ytterv‰ggen. Se till att eventuella luftfl‰nsar ‰r riktade nedÂt.

S‰tt tillbaka fettfiltren.

4.6

Elektrisk installat

ion

Fl‰ktkÂpan ‰r en fast monterad enhet som ‰r avsedd fˆr fast anslutning till eln‰tet. En

beh

ˆrig elektriker mÂste utfˆra elinstallationen.

Fl‰ktkÂpan mÂste anslutas till 230 V enfas v‰xelstrˆm via en strˆmbrytare och 3 A s‰kring.

Strˆmbrytaren ska placeras n‰ra fl‰ktkÂpan/spisen s att strˆmmen till fl‰ktkÂpan kan brytas

med strˆmbrytaren. Strˆmbrytaren mÂste minst ha 3 mm kontaktseparation fˆr alla poler.

Alternativt kan en brytarfunktion i den fasta anslutni

ngen, i enlighet med g‰llande fˆreskrifter,

monteras.

Anslutningskabel mellan

strˆmbrytaren och fl‰ktkÂpan medfˆljer.

Elmatni

ngen ansluts t

ill den fria

‰nden av denna kabel enligt fˆljande:

AvstÂnd mellan spis och kÂpa (minimum):

800 mm

KÂpans hˆjd med standardskorsten:

550ó950 mm

Minsta takhˆjd med standardskorsten:

2290 mm

ANSLUTNING A

V INKOMMANDE MATNINGSLEDNING

Ledar

e

F‰rg

Fas Brun

Noll

a

B

l

Â

Skyddsjord

G

r

ˆn/gul

Avluften

fÂr inte sl‰ppas ut i en kanal som anv‰nds som rˆkkanal frÂn

enheter som

v‰rms med annat ‰n el, t.ex. olje- eller gaseldade

v‰rmepannor,

gaseldade varmvattenberedare o

sv.

T

illr‰cklig ventilation av rummet mÂste anordnas om spiskÂpan och enheter

som

v‰rms med annat ‰n elenergi (gas- eller oljeeldade

v‰rmare osv.)

an

v‰nds samtidigt. Rummet mÂste vara fˆrsett med ventilationsˆppningar

som m

edger ett konstant flˆde av friskluft.

Var

ning

Fˆrsiktighet mÂste iakttas fˆr att s‰kerst‰lla att det undertryck som

orsakas av uts

ugning

ssystem med hˆga prestanda inte negativt pÂverkar

s‰ker anv‰ndning av vissa typer av br‰nnanordningar (fˆr gas, olja eller

fast br

‰nsle). Det g‰ller bÂde sÂdana som finns monterade i kˆket och

eventuellt ‰ven p andra platser i huset.

Om sÂdana anordningar finns M≈STE tillr‰cklig ventilation finnas i det

rum d

‰r de ‰r installerade, placerad och dimensionerad s att det

undertryck som fl

‰ktkÂpan skapar i rummet inte ˆverskrider 4 Pa.

Vid tveksamhet, anv

‰nd inte fl‰ktkÂpan och br‰nnanordningen

samt

idigt och rÂdfrÂga en (fˆr br‰nsletypen) l‰mplig expert.

RISK

F÷R ST÷TAR

K

OPPLA FR≈N SPƒNNINGSMATNINGEN

I

NNAN DU

FORTS

ƒTTER

Page 11

M

odern Falcon kÂpor

Revision: 02/02/2009

11

D

EL 5. ANVƒNDNINGSANVISNINGAR

St‰ng av strˆmmen med strˆmbrytaren.

PÂ fl‰ktkÂpan finns 6 knappar som t‰nds n‰r de trycks in. Deras funktion finns sammanfattad i

nedan

stÂende tabell.

Fl‰ktkÂpans styrenhet st‰nger automatiskt av enheten om inga Âtg‰rder har vidtagits under

fyra timmar.

Efter 30 timmars sammanl

agd an

v‰ndning markeras FETTFILTER MƒTTAT genom att alla

sex indikeringslamporna blinkar

. ≈terst‰ll genom att trycka p knappen FLƒKT AV

(

fˆrdrˆjning).

D

EL 6.

UNDERH

≈LL

R

egelbundet underh

Âll kr‰vs fˆr att s‰kerst‰lla goda prestanda och lÂng livsl‰ngd.

R

eng

ˆr fl‰ktkÂpans rostfria stÂlytor med ett d‰rfˆr avsett rengˆringsmedel. Anv‰nd inte

r

epande r

eng

ˆringsmaterial eller medel.

R

eng

ˆr fettfilter i diskmaskin eller genom handdiskning i varmt vatten och diskmedel. Rengˆr

filtren min

st var

annan m

Ânad, oftare om fl‰kten anv‰nds mycket.

Ta bor

t fettfiltren genom att dra

den krom

ade filtersp‰rrspaken bort frÂn kÂpans nederdel. DÂ

lossar kl

‰mmorna och filtret kan fˆrsiktigt lyftas bort frÂn kÂpan. Var fˆrsiktig s att du inte

r

epar kÂpan.

Du

beh

Âller fl‰ktkÂpans perfekta utseende och minimerar brandrisken genom att s‰kerst‰lla

a

tt fettavlagingarna p

fl‰ktens ytor hÂlls borta genom regelbunden rengˆring.

D

EL 7. SPECIFIKATIONER

Vikt:

Fl‰ktens luftflˆde, nominellt: 1,

000 m3/hr

Bullerni

vÂ:

56d

BA

Matningssp‰nning:

220-240

V~ 50H

z

Hal

ogenlampsp

‰nning: 12V

Fl‰kteffekt: 1 @

300

W

Hal

ogenlampeffe

kt: 2 x 20W

Total effe

kt:

340

W

Rekomm

enderad

s‰kring fˆr elmatning: 3A

Fl‰ktens muffdiameter:

150

mm

CT900

26Kg

CT1092

29Kg

kna

pp Funkt

ion

BELYSNING P≈/AV

0 1

FLƒKT P≈ HASTIGHET 1 (min),

F

L

ƒKT AV (omedelbart stopp).

2

F

L

ƒKT P≈ HASTIGHET 2

3

F

L

ƒKT P≈ HASTIGHET 3

4

F

L

ƒKT P≈ HASTIGHET 4 (max)

FLƒKT AV stopp efter tio minuters fˆrdrˆjning fˆr utv‰dring

a

v kvarvarande o

s. Indikeringslampan blinkar

under

denna

tid

.

FIGUR 1

K

≈PANS M≈TT

Och

FƒSTH≈LENS PLACERING

Metod 1

1. Dra en

vÂgr‰t linje (linje A) d‰r kÂpans undre kant ska placeras. Om ett st‰nkskydd

r

edan har montera

ts

duger dess ˆverkant.

2. Dra en lodr

‰t linje vid spisens och kÂpans

centrum (linje B).

3. Markera placeri

ngen

f

ˆr centrum av minst fyra f‰sthÂl enligt ovan.

4

. Om det bakre utl

oppsh

Âlet ska anv‰ndas, markera och gˆr ett hÂl som passar en 150

mm kanal, enligt anvisni

ngar i installations

handboken

.

5

. F

‰st kÂpan i de markerade l‰gena med f‰stelement som passar v‰ggkonstruktionen.

F‰sthÂlen syns n‰r filtren tas bort enligt anvisningarna i installationshandboken.

Metod 2

1

. Ta bor

t filtren enligt anvisningar i installations

handboken

s att du kommer Ât f‰sthÂlen

i

kÂpans baksida.

2

. Om det bakre utl

oppsh

Âlet ska anv‰ndas, markera och gˆr ett hÂl som passar en 150

mm kanal, enligt anvisni

ngar i installations

handboken

.

3. H

Âll upp kÂpan p v‰ggen i ˆnskat l‰ge och gˆr m‰rken p v‰ggen genom f‰sthÂlen

i

kÂpans baksida. Tv personer erfordras fˆr detta.

4

. F‰st kÂpan i de markerade l‰gena med f‰stelement som passar v‰ggkonstruktionen.

Loading...

Loading...