Page 1

110 Dual Fuel

110 Dual Fuel

Professional 110 Dual Fuel

Falcon 110 Dual Fuel

Users Guide

Installation & Service Instructions

Australia U108600 01

Page 2

Australia

Pease note

This instruction covers 4 diff erent models. Although the some of the

illustrations may look diff erent to your particular model we hope the

meaning is clear.

Be safe

Warning

Accessible parts will become hot in use. To avoid burns and scalds

children should be kept away

You need clean fresh air - so does your cooker. Burner fl ames produce

exhaust gases, heat and moisture. Make sure that the kitchen is well

ventilated: keep natural ventilation holes open or install a powered cooker

hood that vents outside. If you have several burners on or use the cooker

for a long time, open a window or turn on an extractor fan. For more detail

see the Installation Instructions.

We recommend you read ‘General Safety Instructions‘ (especially if you

have not used a dual fuel cooker before) where we describe some basic

guidelines on how to use a duel fuel cooker safely.

Gas and Electricity on

Make sure that the gas supply is turned on and that the cooker is wired in

and switched on. The cooker needs electricity.

Peculiar smells

When you fi rst use your cooker it may give off a slight odour. This should

stop after a little use.

Before using for the fi rst time, to dispel manufacturing odours, turn

the ovens to 240°C and run for an hour.

Make sure the room is well ventilated to the outside air, by opening

windows or turning on a cooker hood for example. We recommend

that people with respiratory or allergy problems should vacate the

area for this brief period.

Turn on the grill and run for 30 minutes with the grill pan in position,

pushed fully back, and the grill door open.

Installation

Failure to install the appliance correctly could invalidate any warranty or

liability claims and lead to prosecution

This appliance shall be installed in accordance with the regulations in

force and only in a well ventilated space. Read the instructions before

installing or using this appliance.

This appliance should not be installed in a boat or caravan.

2

Page 3

Contents

Australia

Hotplate burners Page 4

The Griddle Page 5

Warmer Page 5

The Grill Page 6

The Ovens Page 7

The Clock Page 8

Cooking using the timer Page 9

Oven cooking Page 10

Oven shelves Page 10

The Handyrack Page 11

Oven light Page 11

The Browning Element Page 11

Storage Page 11

Moving your cooker Page 12

Oven cooking guide Page 13

Cleaning your cooker Page 14

Troubleshooting Page 17

General Safety Instructions Page 19

Installation Page 22

Servicing Notes Page 31

Technical Data Page 35

Conversion to another gas Page 36

Circuit Diagram Page 38

3

Page 4

Australia

Hotplate burners

1

The drawing by each knob indicates which burner that

knob controls.

Press the igniter button, and push in and turn a knob

to the large fl ame symbol (

match.

). Alternatively light with a

2

Adjust the fl ame height to suit by turning the knob.

On this cooker the low position is beyond high, not

between high and off . The small fl ame marks the ‘low

position’. Turn the knob towards it after the contents of

a pan have boiled.

5

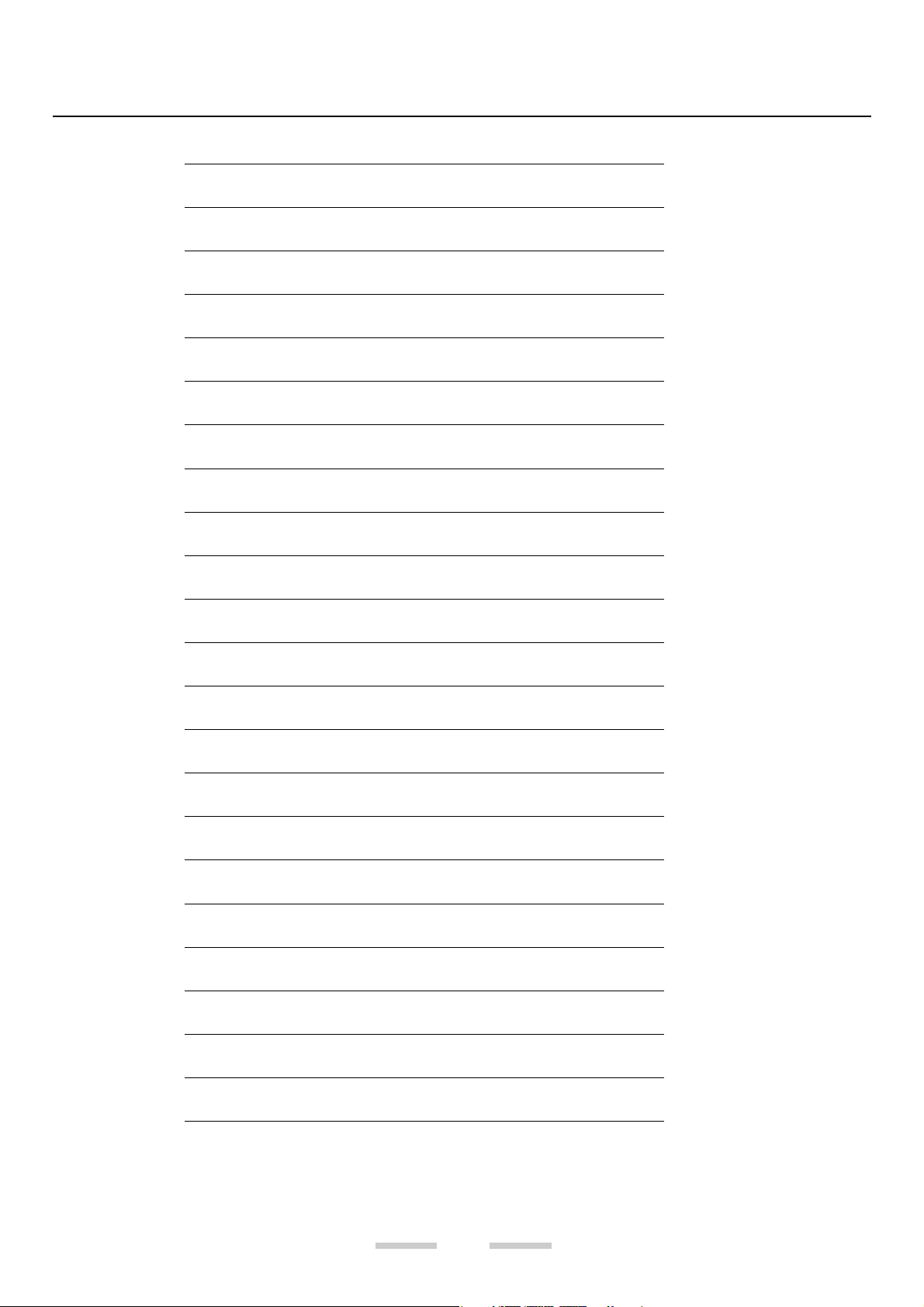

Avoid using unstable and misshapen pans that may tilt

easily and pans with a very small base diameter e.g. milk

pans, single egg poachers. The minimum pan diameter

recommended is 120mm.

Pans and kettles with down turned base rims should not

be used.

6

The Wok burner is designed to provide even heat over

a large area. It is ideal for large pans and stir frying. For

heating smaller pans the smaller burners may be more

effi cient.

If a burner fl ame goes out, turn the control knob off

and leave it for one minute before relighting it.

You can remove the burner parts for cleaning,

see the ‘Cleaning your cooker’ section of these

instructions.

3

Make sure fl ames are under the pans. Using a lid will

help the contents boil more quickly.

Pans and kettles with concave bases or down turned

base rims should not be used.

4

Simmering aids, such as asbestos or mesh mats, are NOT

recommended. They will reduce burner performance

and could damage the pan supports.

You should wipe the enamel top surface of the

cooker around the hotplate burners as soon as

possible after spills occur. Try to wipe them off

while the enamel is still warm.

4

Page 5

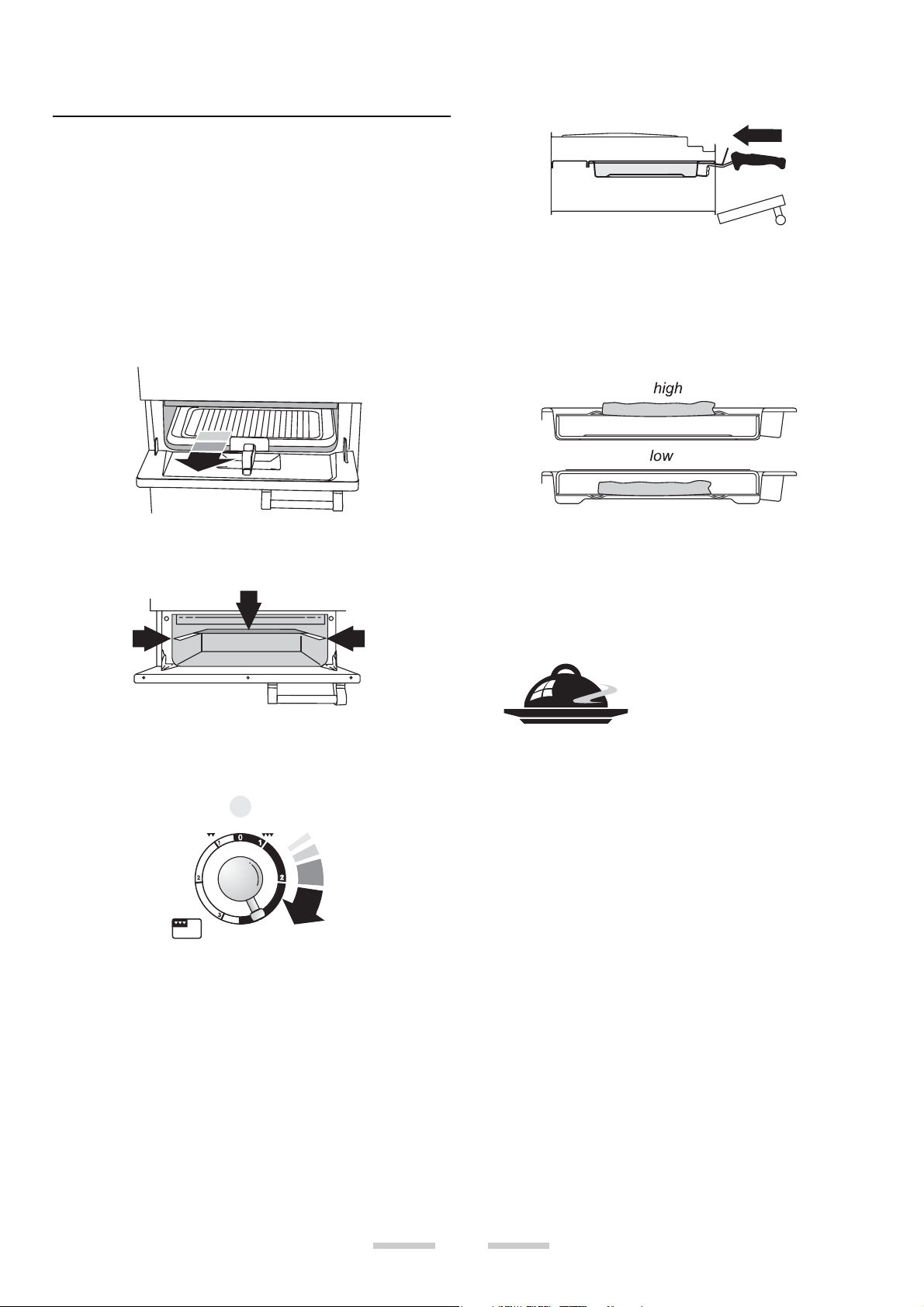

The Griddle

1

The griddle fi ts a single pan support, front to back. It is

designed for cooking food on directly. Don’t use pans of

any kind on it. The griddle surface is non-stick and metal

cooking utensils (e.g. spatulas) will damage the surface.

Use heat resistant plastic or wooden utensils.

2

Don’t put it crossways - it will not fi t properly and will be

unstable.

Don’t put it on the Wok burner - it is not designed to fi t

the Wok burner pan support.

Australia

5

Always leave space around the griddle for the gases to

escape. Never fi t two griddles side by side. Large pans

should also be spaced well apart. The maximum pan

base diameter is 250mm.

Use the following heat settings as a guide for

griddle cooking.

High/medium:

Drop scones, Bacon, Chops, Steak, Burgers.

Medium/low:

Potato cakes, Eggs, Fish cakes.

Experience will soon familiarise you with the

correct setting to use for cooking.

3

Position the griddle over the hotplate burners resting

on the pan support. The griddle can be lightly brushed

with cooking oil before use. Light the hotplate burners.

Adjust the fl ame heights to suit.

4

Preheat the griddle for a maximum of 5 minutes before

adding food. Leaving it longer may cause damage.

You can reduce the heat by turning the control knobs

towards the lower position (marked with the small

fl ame symbol).

After cooking allow the griddle to cool before

cleaning.

Warmer

Use the warmer for keeping food warm while the

fi nal touches are put to a meal. Turn the control

knob anti-clockwise to the on position. The ‘HOT’

indicator lights up. For best results, pre-heat a

covered serving dish for 10 minutes before adding

food to it.

CAUTION: If a crack in the Warmer surface

becomes visible, due to accidental damage etc.,

isolate the appliance from the electricity supply

immediately by turning it off at the wall and

arrange for its repair.

DO NOT RECONNECT THE COOKER TO THE ELECTRICITY

SUPPLY UNTIL AFTER REPAIR!

5

Page 6

Australia

The Grill

Caution: Accessible parts may be

hot when the grill is in use. Young

children should be kept away.

Before using for the fi rst time, to dispel

manufacturing odours, turn on the grill and run

for 30 minutes with the grill pan in position,

pushed fully back, and the grill door open

Make sure the room is well ventilated to the

outside air, by opening windows or turning on a

cooker hood for example.

4

For best results preheat for 2 minutes with the grill pan

in position. After placing your food on the grill pan grid,

slide the grill pan onto the side supports. Adjust the

heat to suit by turning the knob.

Make sure it is pushed right in and touches the back

stop.

Never close the grill door when the grill is on.

1

Remove the pan from the bottom of the grill

compartment.

2

After placing your food on the grill tray pan, slide

the grill pan onto the side supports just below the

elements. Make sure it is pushed right in and touches

the backstop.

3

The grill has two elements that allow either the whole

area of the pan to be heated or only the right hand half

of the grill pan to be heated.

Turn the knob to position 3.

5

The grill pan grid can be turned over to give two grilling

positions.

Never close the grill door while the grill is on.

Don’t leave the grill on for more than a few

moments, without the grill pan underneath it.

For best results, especially with toast, preheat the

grill with the grill pan in the cooking position for

two minutes before use.

The grill trivet can be removed and the food

placed on it while you are waiting for the grill

to preheat.

You can brown the top of dishes cooked in the

oven, under the grill by placing the dish onto the

base of the grill pan which can easily slide along the

fl oor of the grill cavity.

6

Page 7

The Ovens

During use the appliance becomes

hot. Care should be taken to avoid the

touching heating elements inside the

oven.

Before using for the fi rst time, to dispel

manufacturing odours, turn the ovens to 240°C

and run for an hour.

To clear the smell make sure the room is well

ventilated to the outside air, by opening

windows or turning on a cooker hood for

example. We recommend that people with

respiratory or allergy problems should vacate

the area for this brief period.

The clock must be set to the time of day before the

ovens will work. See ‘The Clock’ section of these

instructions for how to set the clock.

Before using for the fi rst time, heat the ovens to

200°C for 30 minutes to dispel manufacturing

odours. Open a window to clear the smell.

Australia

3

Turn the oven knob to the temperature you need.

4

The oven indicator light will glow until the oven has

reached the temperature you selected. It will then cycle

on and off during cooking.

1

The Left hand Oven

The left hand conventional oven is fi tted with two

heating elements, one visible in the top of the oven and

the second under the oven base.

Be careful to avoid touching the top element and

element defl ector when placing or removing items from

the oven.

2

The Right hand Fan Oven

The fan in the right hand oven circulates hot air

continuously which means faster more even cooking.

The recommended cooking temperatures for a fanned

oven are generally lower than a non-fanned oven.

5

During cooking, food naturally produces steam,

particulary when cooking foods with high water

content (e.g. oven chips). There may be some steam

visible at the grille at the rear of the hotplate and the

bottom of the left hand door. This is perfectly normal.

Steam can condense to water droplets on the cool

outer trim or the oven door. It may be necessary during

cooking to wipe away any moisture with a soft cloth.

This will also help to prevent soiling and discolouration

of the oven exterior by cooking vapours.

Take care when opening the oven door as there may

be a momentary puff of steam when the oven door

is opened. Stand well back and allow any steam to

disperse

7

Page 8

Australia

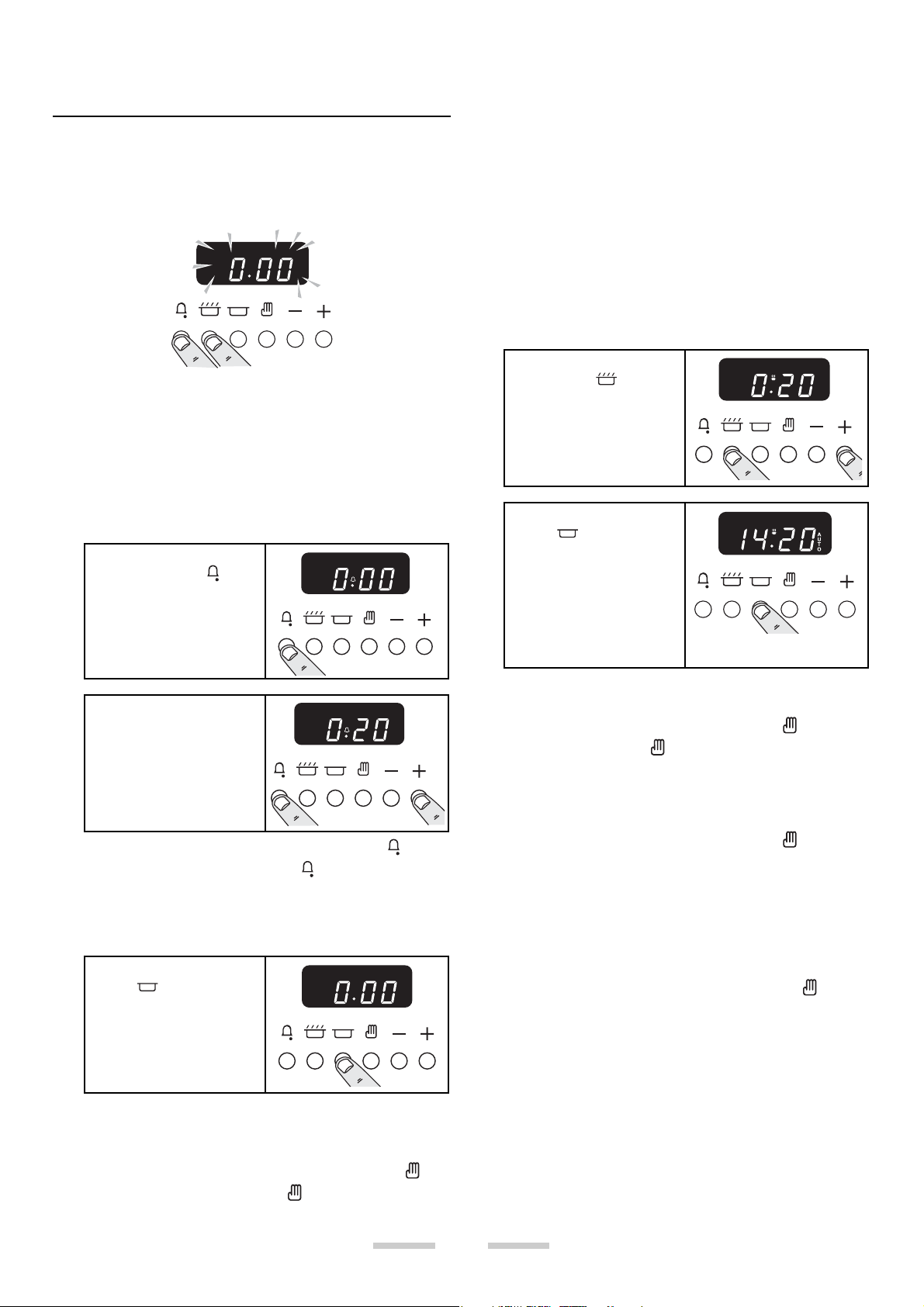

The Clock

You can use the timer to turn the ovens on and off .

The clock must be set to the time of day before the

ovens will work.

To set the time of day

Press and hold as above. At the same time, press

(-) or (+) until the correct time shows. Don’t forget

it’s a 24 hour clock. If you make a mistake or press

the wrong button, turn off the power supply for a

minute or two and start again.

To time something that’s cooking

(minute minder)

Press and hold the

Minute Minder (

).

To start and stop the oven

automatically

Before you set the clock, you must have two

numbers clearly in mind.

The ‘cook period’, which is the period of time you

want the oven to cook.

The ‘stop time’, which is the time of day you want

the oven to stop cooking.

You cannot set a start time directly - this is set

automatically by setting the cooking period and

stop time.

Press and hold the

Cook Time (

At the same time press

(-) or (+) until your

required ‘cook period’

shows.

Press and hold the Stop

Time ( ) button.

At the same time press

(-) or (+) until your

required ‘stop time’

shows.

AUTO will show in the

display.

) button.

At the same time press

(-) or (+) until the time

you want to cook for is

shown.

You can check time remaining by pressing and

cancel the beeper by pressing

To stop automatically

Use when you have started the oven manually.

Press and hold the Stop

Time (

At the same time press (-) or (+) until your required

‘Stop Time’ shows. AUTO will show in the display.

When your cooking is fi nished the beeper sounds.

TURN THE OVEN KNOB TO 0 FIRST, then press

once to stop the beep, press

manual cooking.

) button.

again to return to

Set the oven to the required temperature. When

your cooking is fi nished the beeper sounds. TURN

THE OVEN KNOB TO 0 FIRST, then press

stop the beep, press

cooking.

If you are out, don’t worry about the beeper going

off , it stops after a while. When you return, TURN

THE OVEN KNOB TO 0 FIRST, then press

return to manual cooking.

again to return to manual

once to

twice, to

AUTO is showing, you want to reset to

manual cooking.

When cancelling an automatic setting, any cooking

time already set must be returned to 0.00 before

you can return to manual, by pressing the

button.

8

Page 9

Australia

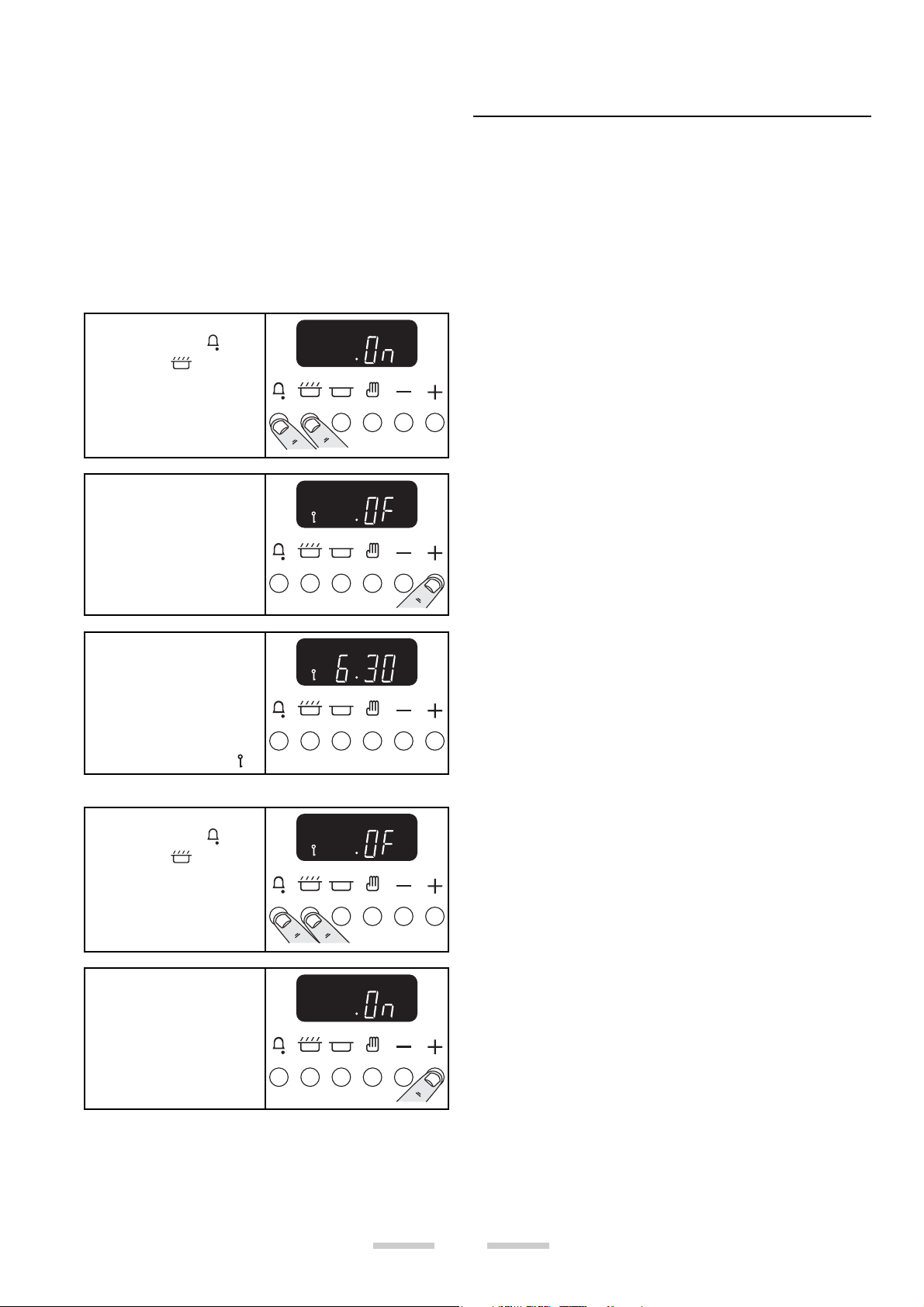

Clock Special Features

Key Lock

When the key lock is activated, the clock can be

operated as usual but the oven is locked and will

not come on. This means that your child could

select a cook program but the program will not be

activated and oven will not be switched on.

To activate the key lock

Make sure that the clock is in manual mode and

cancel any active programs.

Hold the

Minute Minder (

Cooktime ( ) buttons

for about 8 seconds.

‘On’ will appear on the

display.

Press the ‘+’ button

once.

‘Of’ will appear on the

display.

) and

Cooking using the timer

The timer can be used to turn just one oven or

both on and off automatically. The start and stop

time must be the same for both ovens but diff erent

cooking temperatures can be set.

If you want to turn one of the ovens on at the

same time as the timer is set for automatic

cooking, you must wait until the timer has

turned on the oven/ ovens fi rst. Then you can

adjust either of them manually in the normal

way.

You can set the oven to turn on any time over the

following 24 hour period

If you want to cook more than one dish,

choose dishes that require approximately the

same time. However, dishes can be ‘slowed

down’ slightly by using small containers

and covering them with aluminium foil,

or ‘speeded up’ slightly by cooking smaller

quantities or placing in larger containers.

Very perishable foods such as pork or fi sh should be

avoided if a long delay period is planned, especially

in hot weather.

The clock oven control

functions are now

locked.

After a few seconds the

display will revert to

show the time of day

and the key symbol (

To turn off the key lock

Hold the

Minute Minder (

Cooktime ( ) buttons

for about 8 seconds.

‘Of’ will appear on the

display.

Press the ‘+’ button

once. ‘On’ will appear

on the display.

After a few seconds the display will revert to show

the time of day.

).

) and

Don’t place warm food in the oven.

Don’t use an oven already warm.

Don’t use if an adjoining oven is warm.

Avoid using wine or beer if there is a delay period,

as fermentation may take place.

To avoid curdling, cream should be added to

dishes just before serving.

Fresh vegetables, which may discolour during a

delay period, should be coated in melted fat or

immersed in a water and lemon juice solution.

Many frozen foods are ideal for delayed

cooking and can be placed in the oven while

still frozen.

Fruit pies, custard tarts or similar wet mixtures on

top of uncooked pastry are only satisfactory if there

is a short delay period. Dishes containing leftover

cooked meat or poultry should not be cooked

automatically if there is a delay period.

Whole poultry must be thoroughly defrosted

before placing in the oven.

Check that meat and poultry are fully cooked

before serving.

9

Page 10

Australia

Oven cooking

The wire shelves should always be pushed fi rmly to

the back of the oven.

Baking trays meat tins etcetera should be placed

level centrally on the oven’s wire shelves. Keep all

trays and containers away from the sides of the

oven, as overbrowning of the food may occur.

For even browning, the maximum recommended

size for a baking tray is 340mm by 340mm.

Cooking high moisture content foods can

create a ‘steam burst’, when the oven door is

opened. When opening the oven stand well

back and allow any steam to disperse.

When the oven is on, don’t leave the door open

for longer than necessary,

otherwise the knobs may get

very hot.

• Always leave a ‘fi ngers

width’ between dishes on

the same shelf. This allows

the heat to circulate freely

around them.

• The Cook & Clean oven

liners (see Cleaning your

cooker) work better when

fat splashes are avoided.

Cover meat when cooking.

• To reduce fat splashing when you add vegetables

to hot fat around a roast, dry them thoroughly or

brush lightly with cooking oil.

• Suffi cient heat rises out of the oven while

cooking to warm plates in the grill compartment.

• If you want to brown the base of a pastry dish,

preheat a baking tray for 15 minutes before

placing the dish in the centre of the tray.

• Where dishes may boil and spill over during

cooking, place them on a baking tray.

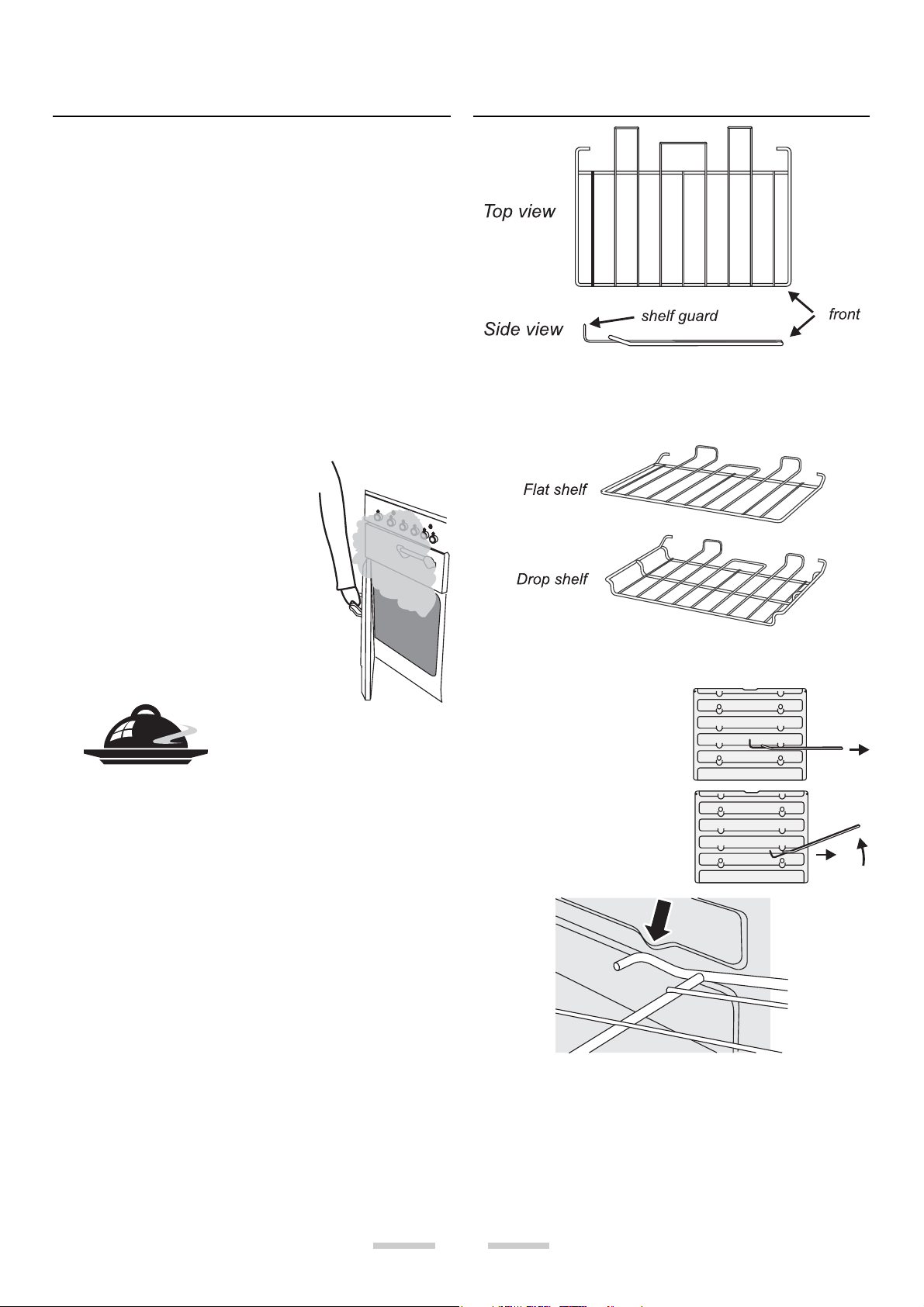

Oven shelves

the shelf guard should be at the back pointing upwards

As well as the fl at shelves some models are

supplied with a drop shelf. The drop shelf increases

the possibilities for oven shelf spacing.

The oven shelves can be easily removed and

refi tted.

Pull the shelf forward until

the back of the shelf is

stopped by the shelf stop

bumps in the oven sides.

Lift up the front of the

shelf so the back of the

shelf will pass under the

shelf stop and then pull

the shelf forward.

10

To refi t the shelf, line up the shelf with a groove

in the oven side and push the shelf back until the

ends hit the shelf stop. Lift up the front so the shelf

ends clear the shelf stops, and then lower the front

so that the shelf is level and push it fully back.

Page 11

Australia

The Handyrack

The maximum weight that can be held by the

Handyrack is 5.5kg (12lb). It should only be used

with the supplied meat tin, which is designed to fi t

the Handyrack. Any other vessel could be unstable.

The Handyrack fi ts to the left hand oven door only.

Food cooking on it is easy to attend to, because it’s

accessible when the door is open. It can be fi tted at

two diff erent heights. One of the oven shelves must

be removed and the other positioned to suit.

When the Handyrack is used in its highest position,

other dishes can be cooked on the bottom shelf

position of the oven or standing on the base of the

oven

When the Handyrack is used in its lowest position,

other dishes can be cooked on the second shelf

position of the oven or standing on the base of the

oven.

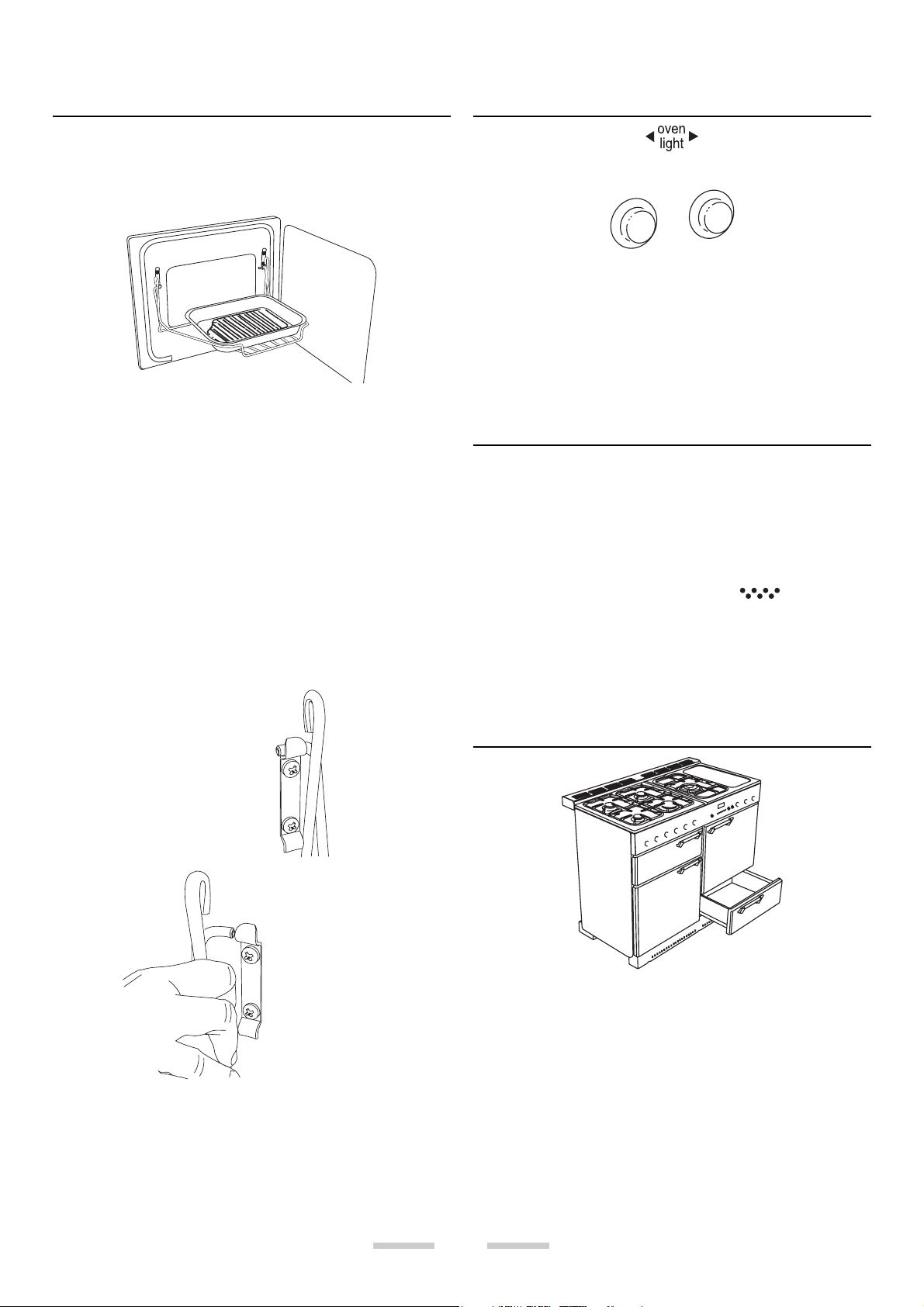

Oven light

Press the appropriate button to turn on one of the

oven lights.

If one of the oven lights fail, turn off the power

supply before you change the bulb. See the

‘Troubleshooting’ section for details on how to

change an oven light bulb.

The Browning Element

The Browning Element is positioned in the top of

the left hand oven. It can be used at the end of a

normal cooking period to give extra browning to au

gratin dishes or give a crisper fi nish to meat.

After the normal cooking is fi nished turn the left

hand oven thermostat knob clockwise to the

browning position, indicated by (

control panel.

Only the browning element will operate when the

thermostat is turned to this position. The top and

base cooking elements will automatically switch off .

) on the

To fi t the

Handyrack, locate

one side of it on the

door bracket.

Storage

Then spring the

other side out to

clip it onto the

other bracket.

The bottom drawer is for storing oven trays and

other cooking utensils. It can get very warm, don’t

store anything in it that may melt or catch fi re. The

drawer can be removed completely by pulling it

right out and up.

11

Page 12

Australia

The oven control settings and cooking times given in the table opposite are intended to

be used only as a guide. Individual tastes may require the temperature to be altered to

provide a preferred result.

When baking in the right hand fanned oven, use the minimum cooking time shown in the

table. Food is cooked at lower temperature in a fan oven than in a conventional oven. When

using recipes, reduce the temperature by 10°C and the cooking time by 5-10 minutes. The

temperature in the fanned oven does not vary with height in the oven - so you can use any

shelf.

Always leave at least one runner space between shelves when 2 tier cooking. Place baking

trays, individual cake tins or baking dishes centrally on the oven shelf. For best results preheat the oven until the oven indicator light goes out.

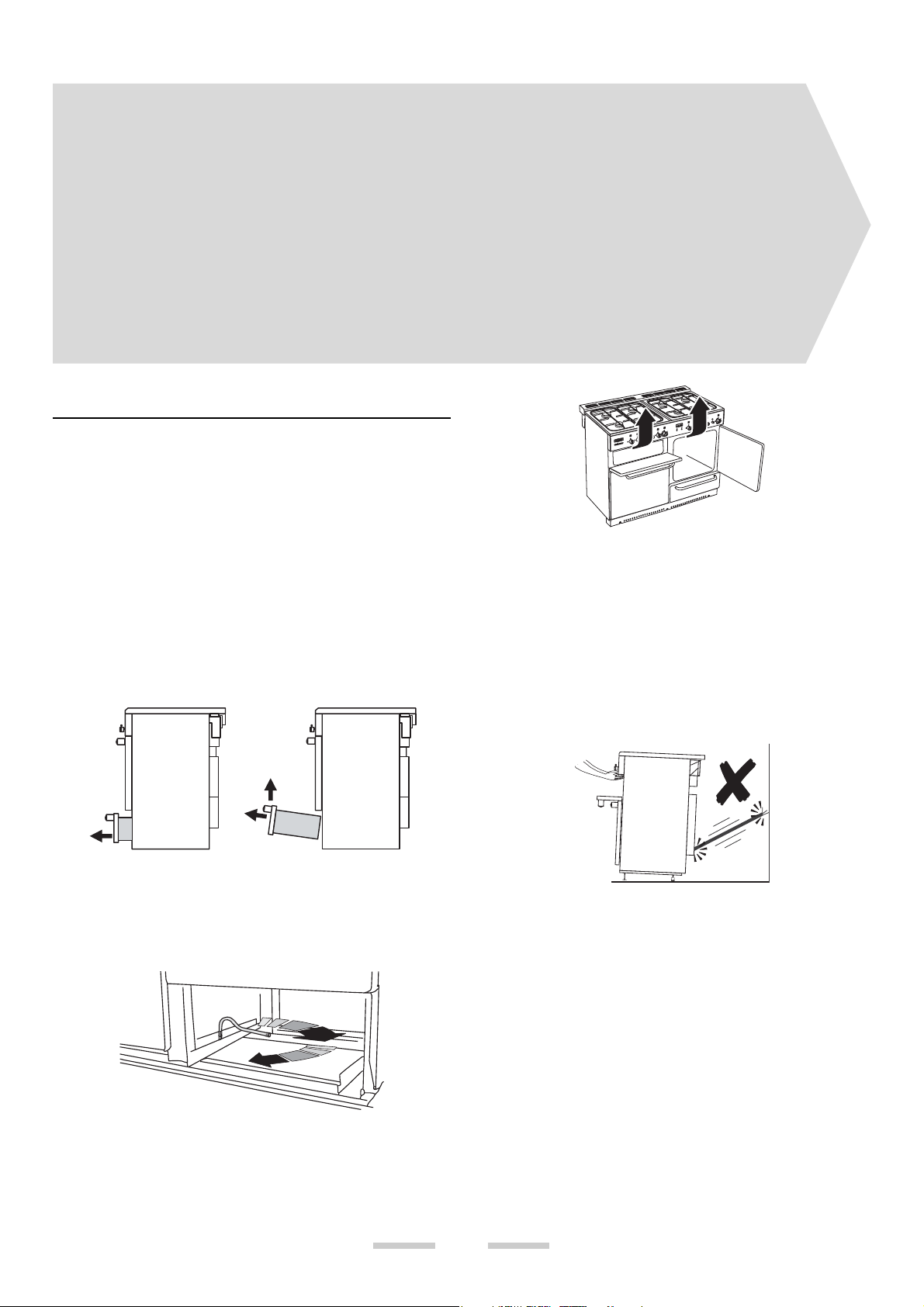

Moving your cooker

Switch off the electricity supply.

The cooker is heavy; two people may be

required to move it. The cooker is fi tted with

one roller at the front and two at the back.

There are also two screw down levelling feet

at the front.

The front roller, designed for moving the cooker can

be wound down. The levelling tool which controls

this roller is in the storage drawer compartment.

Remove the storage drawer (by pulling it

right out and lifting it up slightly) and you

should see the levelling tool.

Open the grill door and right hand oven door so

that you can get a good grip on the bottom of the

fascia panel as you move the oven.

Do not move the oven by pulling the hand

rail, door handles or knobs.

Move the oven a bit at a time, checking behind it

to make sure the gas hose is not caught. Make sure

both electricity and gas cables have suffi cient slack

to move the cooker forward as you go along.).

Your installer may not have left the levelling tool

in place. If not, locate it as shown. If you cannot

fi nd the levelling tool, contact your installer.

See the front of the Installation section of these

instructions.

Turn the levelling tool clockwise, two full

(180°) turns. It will be stiff . The front of the

oven will rise slightly as the roller drops

down.

If a stability chain is fi tted, release it as you

ease the cooker out.

When you replace the cooker, wind it down off the

rollers by turning the levelling tool anti-clockwise.

This is important. It will stop the cooker moving

accidentally, while in use.

Refi t the stability chain.

12

Page 13

Australia

Oven cooking guide

LH Convection Oven RH Fan Oven

Shelf

Food Temperature

FISH

190°C 3 180°C Fillets 15-20mins.

190°C 3 180°C Whole 10mins.per 500g + 10mins.

190°C 3 180°C Steaks according to thickness.

ROAST MEATS

Beef with bone 160°C 2-3 150°C 20-25mins. per 500g + 20-25mins.

200°C 2-3 190°C 15-20mins. per 500g + 15-20mins.

Beef without bone 160°C 2-3 150°C 30-35mins. per 500g + 30-35mins.

200°C 2-3 190°C 20-25mins. per 500g + 20-25mins.

Lamb 160°C 2-3 170°C 30-35mins. per 500g + 30-35mins.

200°C 2-3 190°C 25-35mins. per 500g + 25-30mins.

Pork 160°C 2-3 150°C 35-40mins. per 500g + 35-40mins.

200°C 2-3 190°C 25-30mins. per 500g + 25-30mins.

Stuff ed and rolled - Add approx. 10 mins. per 500g to above cooking times or cook at 200°C for 20mins. then 160°C for

remainder.

THOROUGHLY THAW FROZEN JOINTS AND POULTRY BEFORE COOKING.

POULTRY

Chicken 160°C 2-3 150°C 20-25mins. per 500g + 20-25mins.

200°C 2-3 190°C 15-20mins. per 500g + 15-20mins.

Turkey 160°C 2 150°C 20-25mins. per 500g + 20-25mins.

200°C 2 190°C 15-20mins. per 500g + 15-20mins.

Stuff ed Poultry - Cook at 200°C or at 200°C for 20mins. then 160°C for remainder. Prepacked (fresh or frozen) follow packers

cooking times

Casserole 140-150°C 2-3 140°C 2-4hrs according to recipe

Yorkshire Pudding 220°C 4 200°C Large tin 30-35mins. Individual 10-20mins.

CAKES

Very Rich Fruit 140°C 2 140°C 45-50mins. per 500g mixture

Rich fruit (180mm) 150°C 2 145°C 21/2-3hrs.

Madeira (180mm) 160°C 2 150°C 80-90mins.

Queen Cakes 190°C 3 & 5 or 3 180°C 15-25mins.

Scones 220°C 2 & 4 or 3 210°C 10-15mins.

Victoria Sandwich 180°C 2 & 4 or 3 170°C 20-30mins.

PASTRIES

Plate Tart 200°C 2 & 4 190°C 45-50mins. Interchange after 25mins.

Fruit Pie 200°C 2 & 4 190°C 35-40mins.

Tartlets 200°C 4 190°C 15-20mins. according to size.

Puff Pastry 220°C 2,3 or 4 200°C 20-40mins. according to size.

Bread 220°C 2 & 4 200°C 20-30mins.

Meringues 110°C 3 100°C 2-21/2hrs

PUDDINGS

Baked Egg Custard 160°C 3 150°C 45mins.-1hr.

Baked sponge pudding 190°C 3 180°C 40-45mins.

Milk pudding 140-150°C 3 150°C 2-3hrs.

500g is approximately 1lb (1lb 2oz)

Position Temperature Approximate Cooking Time

13

Page 14

Australia

Cleaning your cooker

Essential information

Before thorough cleaning isolate the electricity

supply. Remember to switch on the electricity

supply before use.

Never use paint solvents, washing soda,

caustic cleaners, biological powders,

bleach, chlorine based bleach cleaners,

coarse abrasives or salt. Don’t mix diff erent

cleaning products - they may react together

with hazardous results. Do not use a steam

cleaner on your cooker.

Recommended cleaning materials are shown

in the table at the end of this section.

If you want to move your cooker for cleaning, see

the section called ‘Moving your cooker’.

All parts of the cooker can be cleaned with hot

soapy water - but take care that no surplus water

seeps into the appliance.

The Wok burner

The Wok burner is a little more complicated but it

also can be taken apart for cleaning.

For cleaning materials see the ‘Cleaning Table’ at the

end of this section.

Grill

The grill pan and grid should be washed in hot

soapy water. After grilling meats or any foods that

soil, leave to soak for a few minutes in the sink

immediately after use. Stubborn particles may be

removed from the grid by using a nylon brush.

Hotplate burners

Some models have a separate trim ring, which fi ts

on the burner head.

The burner heads and caps can be removed for

cleaning. Make sure they are absolutely dry before

replacing.

The LH hotplate

Wok burner

A inner burner cap, B outer burner cap

C inner burner head D outer burner head

E Wok burner base

When reassembling the Wok burner, turn over the

large base ring and fi nd the ‘D’ shaped area.

burner base underside of burner head

Turn the head until the ‘D’ matches the one on the

burner base. Turn the head over and place it on the

burner base.

A cap, B head, C notch, D base, E electrode

When refi tting the burner head, make sure that

the notch lines up with the electrode or hole in the

base. Check that the burner head is level and that

the cap is fi tted centrally on the burner head.

14

Page 15

To fi t the small inner burner, fi nd the larger

electrode notch in the burner rim. Line this up with

the white ignition electrode and place the inner

burner on the large base ring.

A electrode notch B ignition electrode

Now fi t the two trim rings, making sure that they

are sitting down properly.

Griddle

Always clean the griddle after use. Allow to cool

completely before removing. Immerse the griddle

plate in hot soapy water. Use a soft cloth or, for

stubborn stains, a nylon washing up brush.

NEVER USE CAUSTIC OR ABRASIVE CLEANERS AS

THESE WILL DAMAGE THE SURFACE.

Control Panel and Doors

Avoid using any abrasive cleaners including cream

cleaners, e.g. Jif, on brushed Stainless Steel surfaces.

For best results use a liquid detergent.

The control panel and control knobs should only

be cleaned with a soft cloth wrung out in clean

hot soapy water - but take care that no surplus

water seeps into the appliance. Wipe with a clean

dampened cloth then polish with a dry cloth. The

oven doors should only be cleaned with a soft cloth

wrung out in clean hot soapy water.

Australia

stainless steel window doors only

Carefully lift off the outer door panel. The inside

face of the glass panels can now be cleaned - take

care not to disturb or wet the door insulation.

Please note that the door is triple glazed but the

inner two panels are fi xed and should not be

separated. After cleaning carefully refi t the outer

door panel and replace the side fi xing screws.

The Ovens

The ovens have removable panels that have been

coated with a special enamel that partly cleans

itself. This does not stop all marks on the lining, but

helps to reduce the amount of manual cleaning

needed.

The Cook & Clean panels work better above

200°C. If you do most of your cooking below

this temperature, occasionally remove the

panels and wipe with a lint free cloth and hot

soapy water. The panels should then be dried

and replaced and the oven heated at 200°C

for about one hour. This will ensure the Cook

& Clean panels are working eff ectively.

Don’t use steel wool (Brillo) or any other materials

that will scratch the surface. Don’t use oven

cleaning pads.

Removing the Oven Linings

Some of the lining panels can be removed for

cleaning and for cleaning behind. Remove the

shelves fi rst.

Stainless Steel Cookers with window doors

If the inside face of the glass on window door

model becomes marked, the oven door front panel

can be taken off so that the glass panels can be

cleaned.

Move the cooker forward to gain access to the

sides (see the ‘Moving the cooker’ section of these

instructions).

Open the oven door slightly and remove the front

panel fi xing screws from the door sides (two each

side).

On some models the

right hand fanned

oven has a removable

oven roof - if fi tted

slide the roof liner

forward and remove.

15

Page 16

Australia

Cleaning Table

Hotplate

Part Finish Recommended Cleaning Method

Hotplate Top Enamel or

Stainless Steel

Pan Supports, Wok Cradle (some

models only)

Warming Zone (some models

only)

Burner Caps Enamel Cream cleaner, nylon scourer. Dishwasher

Burner Trim Rings (some models

only) and Burner Head

Griddle Plate (some models only) Non-Stick Surface Allow to cool. Wash in hot soapy water. Do not use

Enamel coated

Cast Iron or

Stainless Steel

Toughened Glass Hot soapy water, cream cleaner/scourer if necessary.

Aluminium Cif or other cream cleaner with a soft cloth. Be careful not

Outside of cooker

Part Finish Recommended Cleaning Method

Door, Door surround and

Storage Drawer exterior.

Sides and Plinth Painted surface Hot soapy water, soft cloth

Splashback/Rear Grille Enamel or

Control panel Paint, Enamel or

Control Knobs/Handles Plastic/ Chrome Warm soapy water, soft cloth.

Oven Door Glass/Glass Lid Toughened glass Hot soapy water, cream cleaner/scourer if necessary.

Enamel or paint Hot soapy water, soft cloth.

Stainless Steel E Cloth (Comet) or Vileda Microfi bre Plus All Purpose Cloth

Stainless Steel

Stainless Steel

Hot soapy water, soft cloth. Any stubborn stains remove

gently with a nylon scourer.

Cif Cream Cleaner- Faberge Lever and a nylon scourer.

Dishwasher.

to be over vigorous.

abrasive cleaners/scourers. Dishwasher.

Any stubborn stains, remove gently with a liquid

detergent.

Freudenberg Household Products LP (supermarket)

Hot soapy water, soft cloth. Cream cleaner, with care, if

necessary.

Warm soapy water. Do not use abrasive cleaners on

lettering.

Oven and Grill

Part Finish Recommended Cleaning Method

Sides, fl oor & roof of oven NOT COOK & CLEAN OVEN

PANELS (see below)

Cook & Clean Oven Panels

(some models only)

Oven Shelves, Handyrack, Grill

Trivet.

Grill Pan/Meat Tin (some

models only)

Cleaners listed are available from Supermarkets or

electrical retailers as stated. Cleaner manufacturerin

Italics

For enameled surfaces use a cleaner that is approved

for use on vitreous enamel. The vitreous enamel

association has a list of approved cleaners. Contact

them via their website www.ive.org.uk or telephone:

01527 893031.

Enamel Any proprietary oven cleaner that is suitable for enamel.

CAUTION: CORROSIVE/CAUSTIC OVEN CLEANERS FOLLOW MANUFACTURERS INSTRUCTIONS. Do not allow

contact with the oven elements.

Special enamel

that partly cleans

itself

Chrome An oven interior cleaner that is suitable for chrome. Soap

Enamel Hot soapy water. Soap fi lled pad (Brillo). Dishwasher.

This surface cleans itself at 200°C and above, or the panels

can be removed and washed with hot soapy water and a

nylon brush. (see ‘The Ovens’ in ‘Cleaning your cooker’)

fi lled pad. Dishwasher.

Regular cleaning is recommended. For easier

cleaning, wipe up any spillages immediately.

To help keep your oven clean, cover meat

when roasting, with foil or use a roasting

bag. Brush vegetables with fat before placing

around the meat.

16

Page 17

Australia

The side panels of either oven can be removed.

Each side of the oven is fi xed with four fi xing

screws. You don’t have to remove the screws to

remove the oven linings. Lift each side panel

upwards and they will slide off the screws. Then pull

them forwards.

Once the linings are removed, the oven enamel

interior can be cleaned.

When replacing the linings fi t the side linings fi rst.

Troubleshooting

Hotplate ignition or hotplate burners faulty

Is the power on? Is the clock illuminated? If not

there maybe something wrong with the power

supply.

See ‘power supply’ section further on.

Are the sparker (ignition electrode) or burner slots

blocked by debris? Is the burner trim correctly

located? Are the burner caps correctly located?

See the section entitled ‘Cleaning’

Hotplate burners will not light

If only one or all the hotplate burners will not

light, make sure that the parts have been replaced

correctly after wiping or removing for cleaning.

Check that there is not a problem with your gas

supply. You can do this by making sure that other

gas appliances you may have are working.

Do the burners spark when you push the button? If

not check the power is on - is the clock illuminated?

A crack has appeared in the Warmer plate’s surface

Disconnect the cooker immediately from the power

supply and arrange for its repair. Don’t use the

cooker until after the repair. See the HELP leafl et for

how to contact a service person.

Steam is coming from the oven

When cooking foods with a high water content (e.g.

oven chips) there may be some steam visible at the

rear grille. Take care when opening the oven door

as there may be a momentary puff of steam when

the oven door is opened. Stand well back and allow

any steam to disperse.

The oven fan is noisy

The note of the oven fan may change as the oven

heats up - this is perfectly normal.

What cleaning materials are recommended for the

cooker?

See the ‘Cleaning’ section of the Easy Guide for a full

list of recommended cleaning materials. We do not

recommend Mr. Muscle, as it contains chemicals

that may damage the surfaces of your cooker.

The knobs get hot when I use the oven or the grill,

can I avoid this?

Yes, this is caused by heat rising from the oven or

the grill, and heating them up. Don’t leave the oven

door open. Make sure that the grill pan is pushed

right back to the ‘back stop’ when grilling.

17

Page 18

Australia

If there is an installation problem and I don’t get

my original installer to come back to fix it who

pays?

You do. Service organisations will charge for their

call outs if they are correcting work carried out by

your original installer. It’s in your interest to track

down your original installer.

Current Operated Earth Leakage Breakers

Where the cooker installation is protected by a

30 milliamp sensitivity residual current device

(RCD), the combined use of your cooker and other

domestic appliances may occasionally cause

nuisance tripping. In these instances the cooker

circuit may need to be protected by fi tting 100mA

device. This work should be carried out by a

qualifi ed electrician.

Food is cooking too slowly, too quickly, or burning

Cooking times may diff er from your previous

oven. Check that you are using the recommended

temperatures and shelf positions. See the ‘Oven

cooking guide’ section. The oven control settings

and cooking times are intended to be used only

as a guide. Individual tastes may require the

temperature to be altered either way, to get

the results you want. Try cooking at a higher

temperature setting.

The oven is not cooking evenly

Do not use a tin or baking tray larger than 340mm x

340mm.

If you are cooking a large item, be prepared to turn

it round during cooking.

If two shelves are used, check that space has been

left for the heat to circulate. When a baking tray is

put into the oven, make sure it is placed centrally

on the shelf.

Check that the door seal is not damaged and that

the door catch is adjusted so that the door is held

fi rmly against the seal.

A dish of water when placed on the shelf should be

the same depth all over. (For example, if it is deeper

at the back, then the back of the cooker should be

raised up or the front lowered). If the cooker is not

level arrange for your supplier to level it for you.

Oven not coming on when turned on manually

Is the power on? Is the clock illuminated? If not

there may be something wrong with the power

supply. Is the cooker supply on at the isolator

switch? Is the clock fl ashing 0.00? If so set it to the

correct time of day. Has the Timer been set to AUTO

by mistake? If AUTO is showing on the clock display,

press the ‘cook period’ button and reduce any set

cooking time showing to 0.00, with the (+) and (-)

buttons. Press the

solve the problem contact a service person.

button twice. If this does not

Is the key symbol ( ) showing in the display? See

the Clock section of the instructions for more

information on the key lock feature of the clock.

Oven not coming on when automatic cooking

Timer set correctly but oven knob left OFF by

mistake?

Is the key symbol (

the Clock section of the instructions for more

information on the key lock feature of the clock.

Oven temperature getting hotter as the cooker gets

older

If turning the knob down has not worked or only

worked for a short time then you may need a

new thermostat. This should be fi tted by a service

person.

Grill not cooking properly

Are you using the pan and trivet supplied with

the cooker? Is the pan being used on the runners,

not the fl oor of the compartment? Is the grill tray

pushed fully back to stop?

The oven light is not working

The bulb has probably blown. You can buy a

replacement bulb (which is not covered under the

guarantee) from a good electrical shop. Ask for an

Edison screw fi tting 15w 240v lamp, FOR OVENS. It

must be a special bulb, heat resistant to 300 °C.

Disconnect from the electricity supply.

Make sure the oven is cool. Open the oven door

and remove the oven shelves.

Unscrew the bulb cover by turning anticlockwise. It

may be very stiff .

Taking care to protect your fi ngers in case the bulb

should shatter, unscrew the old bulb.

Fit an Edison screw fi tting 15w 240v lamp, FOR

OVENS. It must be a special bulb, heat resistant to

300°C.

Screw in the new bulb, screw back the bulb cover.

Turn on the electricity supply and check that the

bulb now lights.

) showing in the display? See

18

Page 19

General Safety Instructions

Australia

This appliance must be installed by a Authorised

Person in accordance with the installation

instructions. The installation must comply with

the relevant regulations and also the local gas and

electricity supply companies requirements.

If you smell gas

Don’t turn electric switches on or off .

Don’t smoke

Don’t use naked fl ames

Do turn off the gas at the meter or cylinder

Do open doors and windows to get rid of the gas

Call your gas supplier.

Guidelines in case of Abnormal

Operation

The burners fl ames should be a blueish colour with,

at most, a slight yellowish fringe.

If the fl ame burns with a long white tip you should

call an Authorised Gas Service Centre.

allow the cooker to cool and then switch off at

the mains and before cleaning or carrying out any

maintenance work, unless specifi ed otherwise in

this guide.

All parts of the cooker become hot with use

and will retain heat even after you have

stopped cooking.

Take care when touching cooker, to minimize

the possibility of burns, always be certain that

the controls are in the OFF position and that it is

cool before attempting to clean the cooker. Avoid

touching heating elements.

Use dry oven gloves when applicable - using

damp gloves might result in steam burns

when you touch a hot surface. Never operate

the cooker with wet hands.

Do not use a towel or other bulky cloth in place of

a glove. They might catch fi re if they touch a hot

surface.

Clean with caution. If a wet sponge or cloth

is used to wipe spills on a hot surface, be

careful to avoid steam burns. Some cleansers

can produce noxious fumes if applied to a

hot surface.

DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS

APPLIANCE WHILE IT IS IN OPERATION.

WHERE THIS APPLIANCE IS INSTALLED IN MARINE

CRAFT OR IN CARAVANS, IT SHALL NOT BE USED AS

A SPACE HEATER.

This appliance is designed for domestic

cooking only. Use for any other purpose

could invalidate any warranty or liability

claim.

The use of a gas cooking appliance results in the

production of heat and moisture in the room in

which it is installed. Ensure that the kitchen is well

ventilated: keep natural ventilation holes open or

install a mechanical ventilation device, (mechanical

extractor hood).

Prolonged intensive use of the appliance may call

for additional ventilation, for example opening a

window, or more eff ective ventilation, for example

increasing the level of mechanical ventilation

where present.

The cooker should be serviced by a Authorised

Person and only approved spare parts used. Have

the installer show you the location of the cooker

control switch. Mark it for easy reference. Always

Do not use unstable saucepans and position the

handles away from the edge of the hotplate.

The appliance is not intended for use by young

children or infi rm persons without supervision. Babies,

toddlers and young children should not be allowed

near the cooker at any time. They should never be

allowed to sit or stand on any part of the appliance.

Teach them not to play with controls or any other part

of the cooker.

Never store anything of interest to children in

cabinets above a cooker - children climbing on the

cooker to reach them could be seriously injured.

Clean only parts listed in this guide.

In the interests of hygiene and safety the cooker

should be kept clean at all times as a build up in fats

and other food stuff could result in a fi re.

Always keep combustible wall coverings or curtains

etc. a safe distance away from your cooker. For

more detail see the Installation section of these

instructions.

Do not store or use fl ammable liquids or

materials in the vicinity of this appliance.

19

Page 20

Australia

This includes some cleaning solvents and

chemicals used in dry cleaning.

Do not use water on grease fi res. Never pick up

a fl aming pan. Turn the controls off . Smother a

fl aming pan on a surface unit by covering the pan

completely with a well fi tting lid or baking tray. If

available use a multipurpose dry chemical or foam-

type fi re extinguisher.

Never leave the hotplate unattended at high

heat settings. Pans boiling over can cause

smoking and greasy spills may catch on fi re.

Never wear loose-fi tting or hanging clothes while

using the appliance. Be careful when reaching

for items stored in cabinets over the hotplate.

Flammable material could be ignited if brought

in contact with a hot surface unit and may cause

severe burns.

Take great care when heating fats and oils, as

they will ignite if they get too hot.

Use a deep fat thermometer whenever possible to

prevent overheating fat beyond the smoking point.

Never leave a chip pan unattended. Always

heat fat slowly, and watch as it heats. Deep

fry pans should be only one third full of

fat. Filling the pan too full of fat can cause

spill over when food is added. If you use a

combination of oils or fats in frying, stir them

together before heating, or as the fats melt.

Foods for frying should be as dry as possible. Frost

on frozen foods or moisture on fresh foods can

cause hot fat to bubble up and over the sides of

the pan. Carefully watch for spills or overheating

of foods when frying at high or medium high

temperatures. Never try to move a pan of hot fat,

especially a deep fat fryer. Wait until the fat is cool.

Only certain types of glass, glass-ceramic,

earthenware or other glazed containers are

suitable for hotplate cooking; others may

break because of the sudden change in

temperature.

Do not allow anyone to climb, stand or hang

on any part of the cooker.

Do not use aluminium foil to cover shelves, linings

or the oven roof.

Make sure that your kitchen is well ventilated

at all times. Use extractor fans or hoods

when fi tted.

Never heat unopened food containers. Pressure

build up may make container burst and cause

injury.

The cooker is designed for cooking foods only

and must not be used for any other purpose.

The oven should NOT be used for heating the

kitchen, not only does this waste fuel but the

control knobs may become overheated.

When the oven is on DO NOT leave the oven

door open for longer than necessary.

The specifi cation of this cooker should not be

altered.

This appliance is heavy, take care when

moving it.

When the cooker is not in use ensure that the

control knobs are in the off position.

When the grill is on, do not use the top of the

fl ue (the slot along the back of the cooker) for

warming plates, dishes, drying tea towels or

softening butter.

When using an electrical appliance near the

hotplate, be sure that the cord of the appliance

does not come into contact with the hotplate.

If you fi nd a crack in the Warmer surface

immediately disconnect the appliance from

the supply and arrange for its repair.

Take care that no water seeps into the appliance

20

Page 21

Australia

Service and spares

Firstly, please complete the appliance details below and keep them safe for future reference - this information

will enable us to accurately identify your particular appliance and help us to help you. Filling this in now will

save you time and inconvenience if you later have a problem with your appliance. It may also be of benefi t

to keep your purchase receipt with this leafl et. You may be required to produce the receipt to validate a

warranty fi eld visit.

Retailers Name & Address

Andi Appliances Pty Ltd.

1 Stamford Road, Oakleigh, VIC 3166.

Tel No : (03) 9569 1255 Fax No : (03) 9569 1450 Email : Service@andico.com.au

Name of Appliance:

Appliance Serial Number *

Fuel Type:

Date of Purchase

Installers Name & Address

Date of Installation

.* This information is on the appliance data badge

Dual Fuel

If you have a problem

In the unlikely event that you have a problem with your appliance, please refer to rest of this booklet,

especially the problem solving section, fi rst to check that you are using the appliance correctly.

If you are still having diffi culty, contact you retailer

Please note

If your appliance is outside the 12-month warranty period, our service provider may charge for this visit.

If you request an engineer to visit and the fault is not the responsibility of the manufacture, our service

provider reserves the right to make a charge.

Appointments not kept by you may be subject to a charge.

Out of Warranty

We recommend that our appliances are serviced regularly throughout their life to maintain the best

performance and effi ciency. The frequency of service will depend on usage - for normal usage once a year

should suffi ce.

Service work should only be carried out by an Authorised Person.

Spare Parts

To maintain optimum and safe performance, we recommend that only genuine spare parts are used. Do not

use re-conditioned or unauthorised controls. Contact your retailer.

21

Page 22

Australia

Installation

Dear Installer

Before you start your installation, please complete the details BELOW.

If your customer has a problem relating to your installation they will be able to

contact you easily.

Thank you

Installer’s Name

Installer’s Company

Installer’s Telephone number

22

Page 23

You must be aware of the following safety

requirements & regulations

Australia

Safety Requirements/Regulations

The cooker must be installed in accordance with

these instructions by an authorised person.

The installation must be in accordance with

AS 5601/AG 601 - Gas Installations, local gas fi tting

regulations, municipal building codes, electrical

wiring regulations and any other relevant statutory

regulations.

Install in a well-ventilated space. Read the

instructions before installing or using this

appliance.

In your own interest and that of safety, it is law that

all gas appliances be installed by an authorised

person. Failure to install the appliance correctly

could invalidate any warranty or liability claims and

lead to prosecution.

Before installation, ensure that cooker is suitable

for your gas type and supply voltage. See the data

badge. This appliance can be converted for use on

Propane.

This appliance is designed for domestic cooking

only. Use for any other purpose could invalidate

any warranty or liability claim.

Ventilation Requirements

Ventilation must be as specifi ed by

‘AS 5601/AG 601 - Gas Installations’.

The room containing the appliance should have

an adequate air supply .

An appliance should be installed in a location

for complete combustion of gas, proper fl ueing

and to maintain ambient temperature of the

immediate surrounding at safe limits, under

normal operation condition.

Failure to install appliances correctly is

dangerous and could lead to prosecution.

Location of Cooker

This appliance should not be installed in a

boat or caravan.

The cooker may be installed in a kitchen/kitchen

diner but NOT in a room containing a bath or

shower.

Conversion

If the appliance is to be converted to another

gas we recommend that this is done before

installation. See the Conversion section of this

instruction for more details.

23

Page 24

Australia

You will need the following equipment to complete the

cooker installation satisfactorily

Anti-tip bracket

If the cooker is to be

supplied with gas through

a fl exible hose, an anti-tip

bracket and restraint chain

must be fi tted (both are

supplied with the cooker).

Gas Pressure Tester Flexible Gas Hose

A suitable hose and

restraining chain are

supplied with the cooker.

If a diff erent hose is used it

must be in accordance with

the relevant standards.

You will also need the following tools:

1. Electric drill

2. Masonry drill bit

(only required if fi tting the cooker on a stone or concrete fl oor)

3. Rawlplugs

(only required if fi tting the cooker on a stone or concrete fl oor)

Multimeter

(for electrical checks)

4. Steel tape measure

5. Cross head screwdriver

6. Flat head screwdriver

7. Spirit level

8. Pencil

9. Adjustable spanner

10. Screws for fitting stability bracket

24

Page 25

Positioning the Cooker

Clearances (see AS 5601/AG 601)

1 Overhead - Measurement A

The minimum height of any surface above the cooker is

650mm above the hotplate

Range hoods and exhaust fans shall be installed in

accordance with the manufacturer’s instructions. However,

in no case shall the clearance between the highest part of

the hob of the cooking appliance and a range hood be less

than 650 mm or, for an overhead exhaust fan, 750 mm.

2 Side clearances - Measurements B & C

Where B, measured from the periphery of the nearest

burner to any vertical combustible surface, or vertical

combustible surface covered with toughened glass or sheet

metal, is less than 200 mm, the surface shall be protected

to ensure that the combustible surface does not exceed

65ºC above ambient*. Even with the surface protected

the dimension B should not be less than 135mm above

hotplate level.

*The fi xing of 5mm thick ceramic tiles to the surface or

attaching fi re resistant material to the surface and covering

with sheet metal with a minimum thickness of 0.4mm to a

height C of not less than 150 mm above the hotplate should

satisfy this requirement.

Australia

3 Side clearances - Measurement E

3 Where D, the distance from the periphery of the nearest

burner to a horizontal combustible surface is less than

200 mm, then E shall be 10 mm or more, or the horizontal

surface shall be above the trivet. See insets above.

For safety reasons curtains must not be fi tted immediately

behind the cooker.

We recommend a gap of 1110mm between units to allow

for moving the cooker. Do not box the cooker in; it must still

be possible to move the cooker in and out for cleaning and

servicing. The cooker should not be placed on a base.

A clearance of 130mm is required if the cooker is near a

corner of the kitchen to allow the oven doors to open.

Unpacking the Cooker

Do not take any packaging off the cooker until it is directly

in front of the place it is to be installed (unless it will not fi t

through a door in its outer packaging).

Cut the banding straps and lift off the top packing, leaving

the cooker standing on the base packaging. See the loose

unpacking sheet.

25

Page 26

Australia

Moving the Cooker

The cooker is very heavy. Take great care.

We recommend two people manoeuvre the cooker. Ensure

that the fl oor covering is fi rmly fi xed, or removed to prevent

it being disturbed when moving the cooker around. You will

need the levelling tool.

From the back tilt the cooker forward and remove the rear

half of the polystyrene base pack.

Repeat from the front and remove the front half of the poly

base. Pull the drawer out to its furthest point.

Make 10 complete (360°) turns clockwise. (This means

turning and removing the levelling tool 20 times).

Make sure you lower BOTH REAR ROLLERS. There are two

adjusting nuts, one for each roller, at both the front bottom

corners of the cooker.

Unfold the rear edge of pack base tray. Carefully push the

cooker backwards out of the base pack. Push the cooker

close to its fi nal position, leaving just enough space to get

behind it.

Lift up the ends of the plastic clips (one each side) to release

the catches holding the drawer to the side runners and at

the same time pull the drawer forward and away from the

side runners. For safety’s sake push the drawer runners back

out of the way.

Fit the levelling tool on the rectangular adjuster as shown

below.

LOWER THE FRONT ROLLER by doing 14 complete (360°)

turns clockwise. (This means turning and removing the

levelling tool 56 times).

Now LOWER THE TWO REAR ROLLERS.

First fi t the levelling tool on the hexagonal adjusting nut as

shown below.

Levelling

You are recommended to use a spirit level on a shelf in one

of the ovens to check for level.

Place the cooker in its intended position taking care not to

twist it within the gap between the kitchen units as damage

may occur to the cooker or the units.

The rollers can be adjusted to level the cooker. To adjust

the height of the rear of the cooker use the levelling tool

supplied to turn the adjusting nuts at the front bottom

corners of the cooker.

Adjust the height of the front roller to level the cooker. Turn

clockwise to raise the cooker and anticlockwise to lower.

When you are satisfi ed with the height and level raise the

front of the cooker by one turn of the front roller adjuster.

Screw down the front feet to meet the fl oor. Screw the front

roller adjuster anticlockwise to raise the front roller so that

the front of the cooker is supported on the feet, not the

front roller, to prevent accidental movement of the cooker.

Leave the levelling tool on the adjuster with the handle of

the tool facing the rear of the cooker, so that the customer

can use it if they wish to move the cooker.

Replace the drawer by locating on side runners and push in.

26

Page 27

Australia

Fitting the splash back

The cooker can be installed with or without the supplied

splashback. To fi t the splash follow the instructions below.

view from the rear of the cooker

The splash back is fi tted using 4 screws in the rear edge

of the fl ue grille, two at each end. Remove the outer two

screws and loosen the inner pair. Fit the splash over the

inner screws and then refi t the outer two screws. (see

fi gure).

(Classic model only)

Kit contents

Key No No Of Description

1 1 Anti-Tip Bracket Base

2 1 Anti-Tip Bracket extension

3 2 M5 screw

The cooker must be set to the correct height and leveled

before the anti-tip bracket is installed.

Floor Attachment

Key No’s 1 and 2 can be assembled as shown below using

Key No. 3.

Fit the Handles (Classic model only)

Remove the 4mm Allen screws from the doors with the

hexagon key tool. Use the screws to fi t the door handles.

The handles should be above the fi xings.

Remove the 4mm Allen screws from the top corners of the

control panel and fi x the front handrail in position.

Dimension ‘A’ should be set to give a clearance of about

6 mm above the center channel of the cooker base.

The assembled bracket should be fi rmly secured to the fl oor

to give a minimum engagement of 50 mm in the center

channel of the cooker base.

Anti-Tip Device

WARNING

An anti-Tip bracket and chain should be fi tted when the

cooker is connected to a fl exible gas supply.

Unless properly installed, the cooker could be tipped by

leaning on the door. Injury might result from spilled hot

liquids or from the cooker itself.

27

Page 28

Australia

Wall Attachment

When fl oor attachment is impracticable and provided that

the anti-tip bracket base can be securely fi xed to a solid wall

or wall stud. Discard Key No 2.

For both fl oor and wall attachment it is essential

to use the appropriate fi xing screws and to

ensure that the Anti-Tip Bracket is fi rmly

attached .

Gas Connection

The Gas sup ply needs to terminate with a down facing

bayonet. The rear cover boxes limit the position of the

supply point.

Because the height of the cooker can be adjusted and

each connection is diff erent it is diffi cult to give precise

dimensions. Ideally the house supply connection should be

in the shaded area shown in the diagram. Means of isolation

must be provided at the supply point by either an approved

quick-connect device or a Type 1 manual shut-off valve.

The hose should be fi tted so that both inlet and outlet

connections are vertical so that the hose hangs downwards

in a ‘U’ shape.

The connector is located below the hotplate level at the

rear of the cooker.

A fl exible connection is supplied with the cooker. If it is

necessary to use another hose it must be to A.S. 1869 class

B and suitable for your gas type. If in doubt contact, your

supplier.

To prevent strain on the connections to the cooker the

restraining chain should be used.

view from the back

A position for gas supply connector

B appliance gas inlet

Fix the supplied hook securely to the fabric of the building.

Measure the length of chain required. Use the clamp

supplied to clamp onto the gas pipe as shown.

28

Page 29

WARNING SERVICING TO BE CARRIED OUT ONLY BY AN AUTHORISED PERSON

Disconnect from electricity before servicing. Check appliance is safe when you have finished.

Hook the other end of the chain to the wall fi xing.

After completing the gas connection, check the cooker

is gas sound with a pressure test. When checking for gas

leaks do not use washing up liquid - this can corrode. Use a

product specifi cally manufactured for leak detection.

Natural Gas

The adjustable spring loaded governor is pre-set to give a

nominal pressure of 1kPa on NG. Connect to the Rp 1/2 inlet

on the underside of the governor.

Propane

This cooker is supplied ready for use on natural gas. A

conversion kit for Propane gas is supplied with the cooker

- see the conversion instructions in the next section.

Pressure testing

Pull the cooker forward, if necessary, to gain access to the

rear.

The pressure test point is accessible on the connector block

at the centre rear. Remove the test nipple screw and fi t a

pressure gauge to the test point. Turn on and light 2 of the

hotplate burners.

See Technical data section at the back of this book for test

pressures.

Make sure that the mains characteristics (voltage, nominal,

power, etc.) match the ratings indicated on the data plate

affi xed to the lower right hand cooker upright (remove

storage drawer). The cooker is preset for a single-phase

earthed electrical connection. It is essential to install a

multi-pole circuit breaker that completely disconnects the

appliance from the mains, with a minimum contact break

distance of 3mm.

WARNING: THIS APPLIANCE MUST BE EARTHED

The appliance must be connected to an effi cient earthing

circuit. If the electricity network is not equipped with an

earth connection, then it must be installed separately in

compliance with local regulations. Earthing is a safety

measure required by law, and must be performed with

particular care by a qualifi ed technician, who must also

check that the electricity supply characteristics are correct.

The cable size used should be suitable for the appliance

load and in accordance with local regulations. Please note

the maximum cable sizes are 6mm

and 10mm2 for the 3 pronged links.

Access to the mains terminal is gained by removing the

electrical terminal cover box on the back panel. Connect

the mains cable to the correct terminals for your electrical

supply type (see fi g.). You may need to move the links to

suit you connection type. Check that the links are correctly

fi tted and that the terminal screws are tight. Secure the

mains cable using the cable clamp.

2

for the screw terminals

Electrical Connection

This appliance must be installed by a qualifi ed

electrician to comply with the relevant

regulations and also the local electricity supply

company requirements.

This shows the single-phase connection.

These appliances are of type X with regard to protection

against over heating of the surrounding surfaces.

Fixed Wiring.

For connection to fi xed wiring i.e. fl exible conduit, remove

the electrical terminal cover box on the back panel. Remove

two screws and blanking plate from the bottom fl ange of

the cover box, so as to allow the conduit through.

29

Page 30

WARNING SERVICING TO BE CARRIED OUT ONLY BY AN AUTHORISED PERSON

Disconnect from electricity before servicing. Check appliance is safe when you have finished.

Fix conduit to conduit mounting bracket on the back panel.

Connect mains cable to correct terminals for your electrical

supply type. Check that the links are correctly fi tted and the

terminal screws are tight. Replace electric terminal cover

box making sure that the conduit is clear of the bottom

fl ange.

Current Operated Earth Leakage Breakers

Where the installation is protected by a 30 milliamp

sensitivity residual current device (RCD), the combined

use of your cooker and other domestic appliances may

occasionally cause nuisance tripping. In these instances the

cooker circuit may need to be protected by fi tting 100mA

device. This work should be carried out by a qualifi ed

electrician.

Fitting the plinth

Loosen the 3 screws along the front bottom edge of the

cooker. Hook the central keyhole over the central screw.

Twist and fi t each end keyhole over their respective screws.

Tighten the fi xing screws.

Oven check

The clock must be set to the time of day before the ovens

will work.

Press and hold as shown.

At the same time, press - or + until the correct time shows.

Don’t forget it’s a 24 hour clock.

If you make a mistake or press the wrong button, turn off

the power supply for a minute or two and start again.

Turn on the oven and check that the oven fan starts to turn

and that the oven starts to heat up. Turn off the oven.

Customer care

Please complete your details in this Guide, inform the user

how to operate the cooker and hand over the Instructions.

Thank you.

Oven Light

Press the oven light switch and check that the light is

working.

NB The oven light bulb is not included in the

guarantee

Hotplate check

Check each burner in turn. Push in tap and turn to the large

fl ame symbol ( ). Press ignition switch on control panel.

Grill

Open the grill compartment door. Turn on the grill control

and check that the grill heats up.

30

Page 31

WARNING SERVICING TO BE CARRIED OUT ONLY BY AN AUTHORISED PERSON

Disconnect from electricity before servicing. Check appliance is safe when you have finished.

Servicing Notes

This appliance must be serviced by a Authorised Person in

accordance with the instructions.

When servicing or replacing gas carrying components

disconnect from gas before commencing operation and

check appliance is gas sound after completion. When

checking for gas leaks use a liquid leak detector at all joints

and connections to check for leaks in the system. Use a

product specifi cally manufactured for leak detection.

Leak testing of the appliance shall be conducted in

accordance to the manufacturer’s instructions.

CAUTION: DO NOT USE A FLAME TO CHECK FOR

GAS LEAKS.

Do not use re-conditioned or unauthorised gas controls.

Disconnect from electricity supply before commencing

servicing, particularly before removing any of the following:

control panel, side panels, cooktop tray, or any of the

electrical components or cover boxes. Before electrical

reconnection check that the appliance is electrically safe.

1 To Remove the Control Panel

Disconnect from electricity supply.

Classic model only

Remove the handrail by removing the 2 end bracket

fi xing screws.

2. To Remove Hotplate Trays

Disconnect from electricity supply.

Pull the cooker forward to gain access to the rear

Left hand tray

From the rear remove the screws securing the fl ue

grille to the hotplate tray. Remove pan supports,

burner heads and caps. Remove the 4 screws and

washers holding the hotplate tray to the frame.

Raise the front of the hotplate then withdraw.

Right hand tray

From the rear remove the screws securing the fl ue

grille to the hotplate tray. If the LH hotplate has

not been removed, slacken the screws holding

the L H tray. Remove pan support, burner head,

caps and trim rings. Remove the screws holding

the Wok burner to the hotplate. Remove the

two screws and washers holding the RH tray to

the frame. Press the Wok burner down slightly

and, taking care not to damage the Wok burner

electrode, slide the tray about 30mm to right to

clear the locating brackets on the R H side. Lift tray

slightly at the front and taking care not to stress

the Warmer/lead junction, disconnect the leads

to the Warmer neon and separate the leads at the

piggybacks. Withdraw the hotplate.

Reassemble in reverse order ensuring that the leads are

reconnected. When replacing the RH hotplate take care not

to damage the ignition electrode of the Wok burner.

It is important that the rear fi xing screws are refi tted as they

from part of the cooker earthing.

On some models there is a separate plate.

Pull off the push fi t control panel end caps at each end

and remove the end fi xing screws under the end cap.

Open the oven door & or grill door and remove the fi xing

screws underneath the control panel. NB some models have

a plate under the control panel held in place by the bottom

fi xing screws.

Pull off all the control knobs.

Other models

Slide the control panel to the right.

Pull the control panel forward. Take care not to damage or

strain the wiring.

Disconnect the wiring from the rear. Reassemble in reverse

order. When replacing leads refer to the wiring diagram.

Check operation of timer.

A fl ue grill, B cooker backsheet, C earthing/fi xing screws

On others it is a tag on the cooker backsheet.

It is important that the tag is on the outside and that both

fi xing screws are fi tted.

A fl ue grill, B cooker backsheet, C earthing/fi xing screws

Check for correct burner operation.

31

Page 32

WARNING SERVICING TO BE CARRIED OUT ONLY BY AN AUTHORISED PERSON

Disconnect from electricity before servicing. Check appliance is safe when you have finished.

3. To Remove Side Panels

Disconnect from electricity supply.

Remove the Control Panel - see 1. Pull the cooker forward.

Remove the 4 retaining screws for each panel (1 at the front

base, 1 on the top and 2 at the rear).

Reassemble in reverse order.

4. To Remove Ignition or light Switch

Remove the Control Panel - see 1.

NB. The old switch may be destroyed during removal.

Remove the old switch from its bezel by griping the switch

body behind the control panel and twisting sharply. The

switch bezel can then be removed by folding back its

locking wings and pushing forward. Fit the new bezel to the

control panel by fi rst lining up the raised key on its body

with the cutout in the control panel and pushing it in from

the front. Assemble the new switch to the bezel by lining up

the key sections and pushing home. Fit the new button by

pushing in from the front.

Replace Control Panel in reverse order and test for ignition.

5. To Remove Clock

Disconnect from electricity supply.

Remove the Control Panel (See 2). Pull off the timer control

button(s).

Remove the timer/mounting bracket assembly from the

control panel by removing the fi xing screws.

Remove the timer from its mounting bracket by depressing

the plastic lugs on the timer case, at the same time pulling

the unit forward.

Reassemble in reverse order. When replacing leads refer to

the wiring diagram. Check operation of timer.

BEFORE SERVICING ANY GAS CARRYING COMPONENTS

TURN OFF GAS SUPPLY.

6. To Remove a Thermostat

Remove control panel and appropriate hotplate tray. Open

oven door. Remove oven furniture. For RH oven, remove

thermostat phial cover (2 screws).

Unclip the thermostat phial from the clips in the oven back.

For LH oven pull cooker forward to gain access to the cover

box at the rear of the cooker. Remove the four screws

securing the cover and lift clear.

Feed the thermostat capillary out of the oven. Disconnect

wiring from thermostat. Remove 2 screws holding

thermostat to mounting panel. Fit new thermostat and