Fairchild NDS8852H service manual

查询NDS8852H供应商

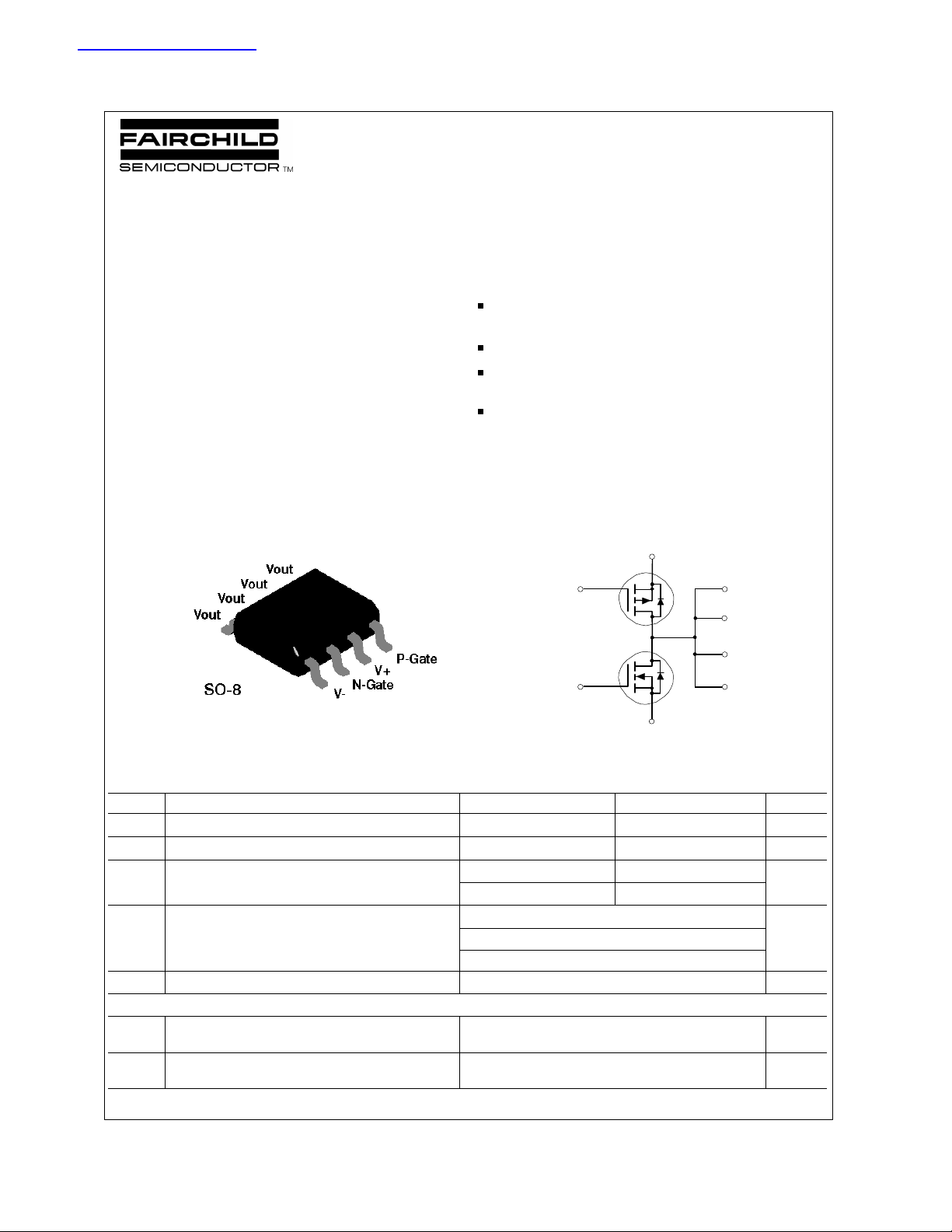

NDS8852H

Complementary MOSFET Half Bridge

General Description Features

February 1996

These Complementary MOSFET half bridge devices are

produced using Fairchild's proprietary, high cell density,

DMOS technology. This very high density process is

especially tailored to minimize on-state resistance, provide

superior switching performance, and withstand high energy

pulses in the avalanche and commutation modes. These

devices are particularly suited for low voltage half bridge

applications or CMOS applications when both gates are

connected together.

N-Channel 4.3A, 30V, R

P-Channel -3.4A, -30V, R

High density cell design or extremely low R

=0.08Ω @ V

DS(ON)

DS(ON)

=0.13Ω @ V

GS

GS

DS(ON)

=10V.

=-10V.

.

High power and current handling capability in a widely used

surface mount package.

Matched pair for equal input capacitance and power capability

.

________________________________________________________________________________

V+

P-Gate

N-Gate

V-

Vout

Vout

Vout

Vout

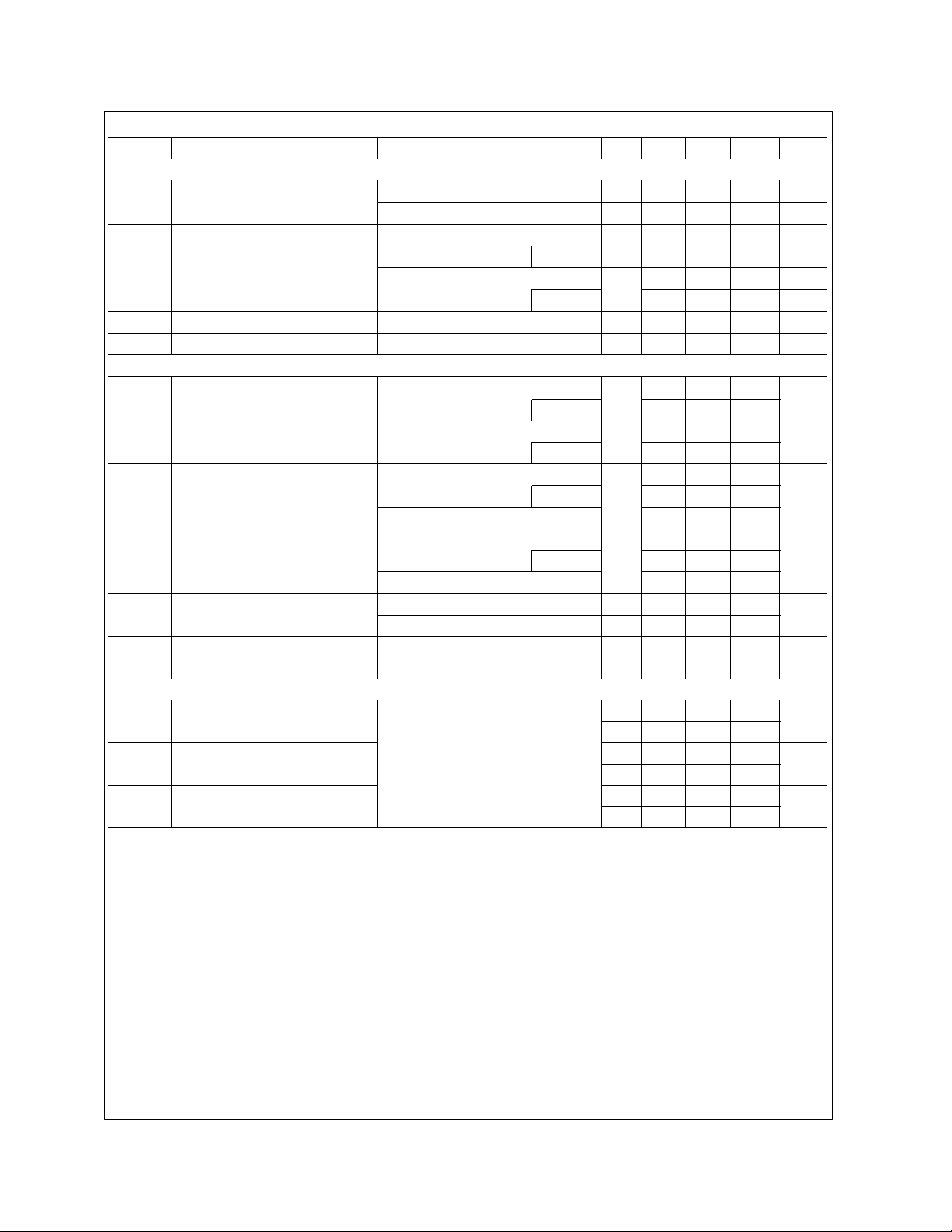

Absolute Maximum Ratings T

= 25°C unless otherwise noted

A

Symbol Parameter N-Channel P-Channel Units

V

DSS

V

GSS

I

D

Drain-Source Voltage 30 -30 V

Gate-Source Voltage 20 -20 V

Drain Current - Continuous (Note 1a & 2) 4.3 -3.4 A

- Pulsed 15 -10

P

D

Maximum Power Dissipation (Note 1a) 2.5 W

(Single Device) (Note 1b) 1.2

(Note 1c) 1

TJ,T

Operating and Storage Temperature Range -55 to 150 °C

STG

THERMAL CHARACTERISTICS

R

θ

R

θ

© 1997 Fairchild Semiconductor Corporation

Thermal Resistance, Junction-to-Ambient

JA

(Single Device) (Note 1a)

Thermal Resistance, Junction-to-Case

JC

(Single Device) (Note 1)

50 °C/W

25 °C/W

NDS8852H Rev. C1

Electrical Characteristics (T

= 25°C unless otherwise noted)

A

Symbol Parameter Conditions Type Min Typ Max Units

OFF CHARACTERISTICS

BV

I

DSS

I

GSSF

I

GSSR

DSS

Drain-Source Breakdown Voltage VGS = 0 V, ID = 250 µA N-Ch 30 V

VGS = 0 V, ID = -250 µA

Zero Gate Voltage Drain Current VDS = 24 V, V

VDS = -24 V, V

= 0 V N-Ch 2 µA

GS

TJ = 55oC

= 0 V P-Ch -2 µA

GS

TJ = 55oC

P-Ch -30 V

25 µA

-25 µA

Gate - Body Leakage, Forward VGS = 20 V, VDS = 0 V All 100 nA

Gate - Body Leakage, Reverse

VGS = -20 V, VDS= 0 V

All -100 nA

ON CHARACTERISTICS (Note 3)

V

R

GS(th)

DS(ON)

Gate Threshold Voltage

Static Drain-Source On-Resistance

VDS = VGS, ID = 250 µA

TJ = 125oC

VDS = VGS, ID = -250 µA

TJ = 125oC

VGS = 10 V, ID = 3.4 A

N-Ch 1 1.7 2.8 V

0.7 1.2 2.2

P-Ch -1 -1.6 -2.8

-0.85 -1.25 -2.5

N-Ch 0.06 0.08

TJ = 125oC 0.08 0.13

VGS = 4.5 V, ID = 2.8 A

0.08 0.11

VGS = -10 V, ID = -3.4 A P-Ch 0.11 0.13

TJ = 125oC

0.15 0.21

VGS = -4.5 V, ID = -2.8 A 0.17 0.2

I

D(on)

On-State Drain Current

VGS = 10 V, VDS = 5 V

N-Ch 10 A

VGS = -10 V, VDS = -5 V P-Ch -10

g

FS

Forward Transconductance

VDS = 15 V, ID = 3.4 A

N-Ch 6 S

VDS = -15 V, ID = -3.4 A P-Ch 4

DYNAMIC CHARACTERISTICS

C

iss

Input Capacitance N-Channel

VDS = 15 V, VGS = 0 V,

f = 1.0 MHz

C

oss

C

rss

Output Capacitance N-Ch 190 pF

P-Channel

Reverse Transfer Capacitance N-Ch 70 pF

VDS = -15 V, VGS = 0 V,

f = 1.0 MHz

N-Ch 300 pF

P-Ch 330

P-Ch 190

P-Ch 70

Ω

NDS8852H Rev. C1

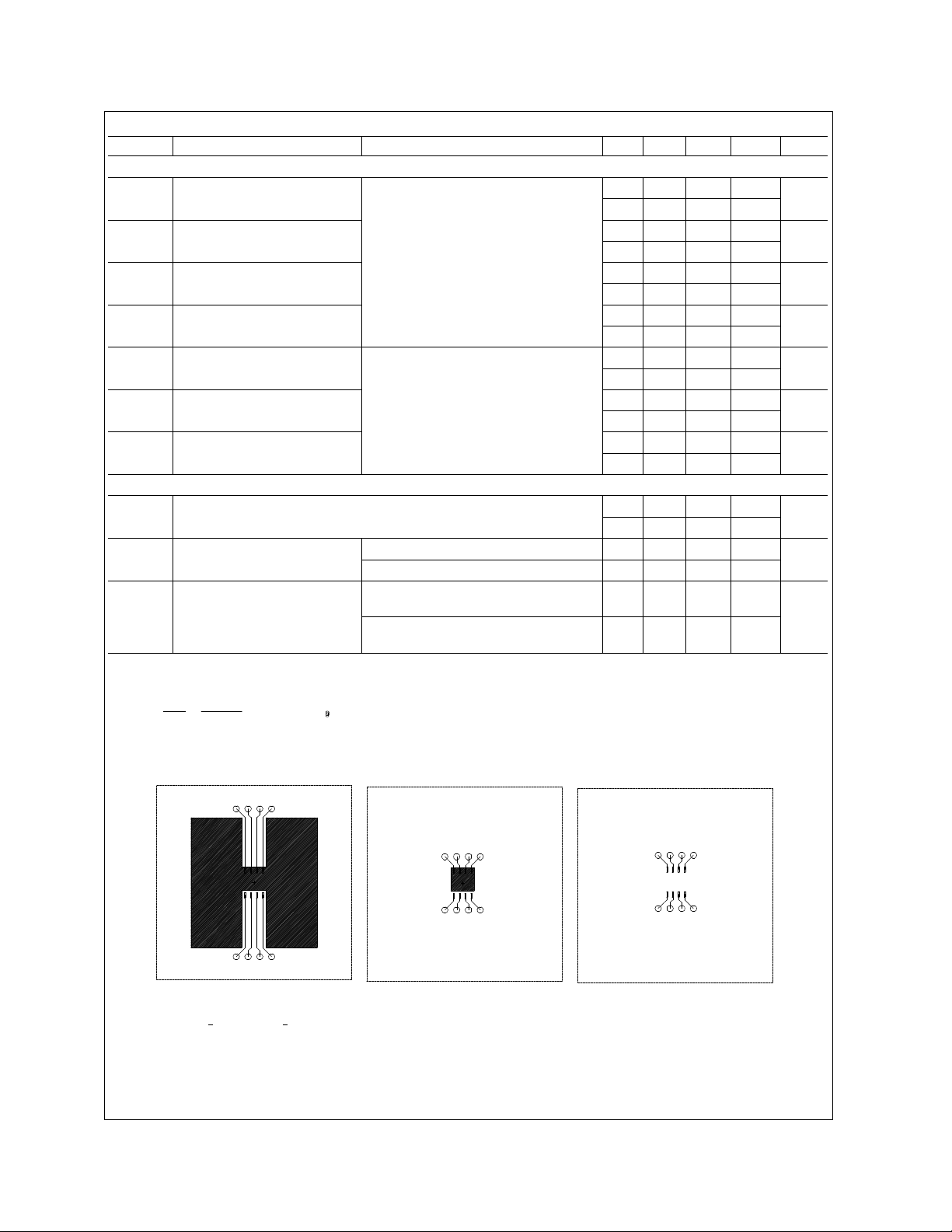

Electrical Characteristics (T

= 25°C unless otherwise noted)

A

Symbol Parameter Conditions Type Min Typ Max Units

SWITCHING CHARACTERISTICS (Note 3)

t

t

t

t

D(on)

r

D(off)

f

Turn - On Delay Time N-Channel

VDD = 10 V, ID = 1 A,

V

= 10 V, R

Turn - On Rise Time N-Ch 13 20 ns

GEN

GEN

= 6 Ω

P-Channel

Turn - Off Delay Time N-Ch 21 50 ns

VDD = -10 V, ID = -1 A,

V

= -10 V, R

GEN

GEN

= 6 Ω

N-Ch 10 15 ns

P-Ch 9 40

P-Ch 21 40

P-Ch 21 90

Turn - Off Fall Time N-Ch 5 50 ns

P-Ch 8 50

Q

g

Q

gs

Q

gd

Total Gate Charge N-Channel

VDS = 10 V,

ID = 3.4 A, VGS = 10 V

Gate-Source Charge N-Ch 1.5

P-Channel

VDS = -10 V,

Gate-Drain Charge N-Ch 2.6

ID = -3.4 A, VGS = -10 V

N-Ch 9.5 27 nC

P-Ch 10 25

P-Ch 1.6

P-Ch 2.7

DRAIN-SOURCE DIODE CHARACTERISTICS AND MAXIMUM RATINGS

I

S

Maximum Continuous Drain-Source Diode Forward Current N-Ch 2.1 A

P-Ch -2.1

V

SD

t

rr

Drain-Source Diode Forward

Voltage

VGS = 0 V, IS = 2.1 A

VGS = 0 V, IS = -2.1 A

Reverse Recovery Time N-Channel

VGS = 0 V, IF = 2.1 A, dIF/dt = 100 A/µs

P-Channel

(Note 2) N-Ch 0.8 1.2 V

(Note 2)

P-Ch -0.8 -1.2

N-Ch 100 ns

P-Ch 100

VGS = 0 V, IF = -2.1 A, dIF/dt = 100 A/µs

Notes:

1. R

is the sum of the junction-to-case and case-to-ambient thermal resistance where the case thermal reference is defined as the solder mounting surface of the drain pins. R

JA

θ

design while R

(t)

P

D

Typical R

is determined by the user's board design.

CA

θ

T

−T

T

J

=

R

θJ A

using the board layouts shown below on 4.5"x5" FR-4 PCB in a still air environment:

JA

θ

a. 50oC/W when mounted on a 1 in2 pad of 2oz cpper.

b. 105oC/W when mounted on a 0.04 in2 pad of 2oz cpper.

c. 125oC/W when mounted on a 0.006 in2 pad of 2oz cpper.

1a

−T

J

A

(t)

A

=

R

θ

J C

2

= I

(t) × R

DS (ON ) T

D

+R

(t)

θ

CA

J

1b

1c

is guaranteed by

JC

θ

Scale 1 : 1 on letter size paper

2. Pulse Test: Pulse Width < 300µs, Duty Cycle < 2.0%.

NDS8852H Rev. C1

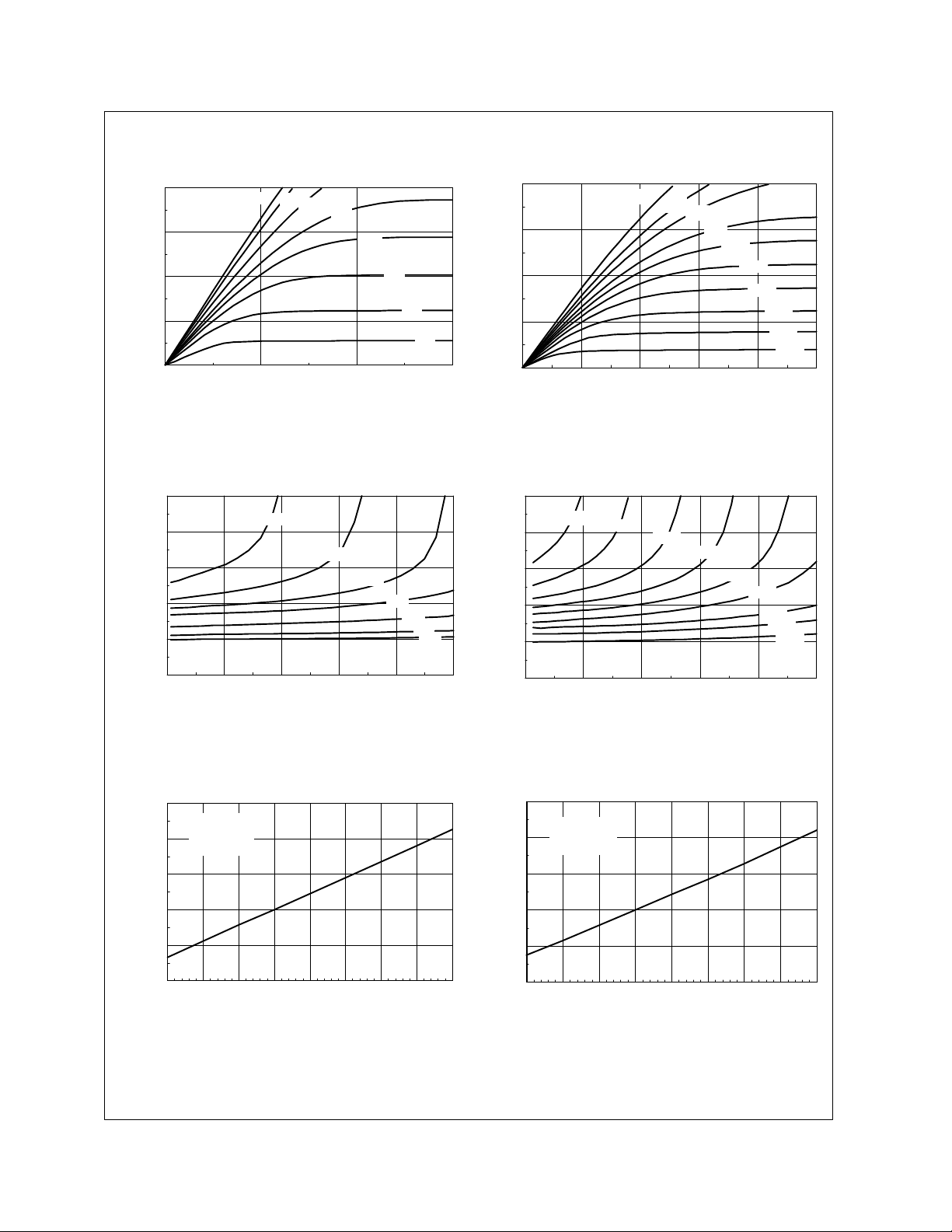

Typical Electrical Characteristics

20

15

10

5

D

I , DRAIN-SOURCE CURRENT (A)

0

0 1 2 3

V =10V

GS

8.0

6.0

5.0

V , DRAIN-SOURCE VOLTAGE (V)

DS

4.5

4.0

Figure 1. N-Channel On-Region Characteristics.

3

V = 3.5V

2.5

GS

4.0

2

1.5

DS(on)

R , NORMALIZED

1

DRAIN-SOURCE ON-RESISTANCE

0.5

0 3 6 9 12 15

I , DRAIN CURRENT (A)

D

4.5

5.0

Figure 3. N-Channel On-Resistance Variation with

Gate Voltage and Drain Current.

3.5

6.0

3.0

8.0

10

-20

-15

V = -10V

GS

-8.0

-7.0

-6.0

-5.5

-10

-5

D

I , DRAIN-SOURCE CURRENT (A)

0

V , DRAIN-SOURCE VOLTAGE (V)

DS

-5.0

Figure 2. P-Channel On-Region Characteristics.

3

V = -3.5V

2.5

GS

-4.0

-4.5

-5.0

2

1.5

DS(on)

R , NORMALIZED

1

DRAIN-SOURCE ON-RESISTANCE

0.5

I , DRAIN CURRENT (A)

D

-5.5

Figure 4. P-Channel On-Resistance Variation

with Gate Voltage and Drain Current.

-4.5

-6.0

-4.0

-7.0

-8.0

-3.5

-3.0

-5-4-3-2-10

-10

-15-12-9-6-30

1.6

I = 3.4A

1.4

1.2

DS(ON)

R , NORMALIZED

0.8

DRAIN-SOURCE ON-RESISTANCE

0.6

D

V = 10V

GS

1

-50 -25 0 25 50 75 100 125 150

T , JUNCTION TEMPERATURE (°C)

J

Figure 5. N-Channel On-Resistance Variation

with Temperature.

1.6

I = -3.4A

1.4

1.2

DS(ON)

R , NORMALIZED

0.8

DRAIN-SOURCE ON-RESISTANCE

0.6

D

V = -10V

GS

1

-50 -25 0 25 50 75 100 125 150

T , JUNCTION TEMPERATURE (°C)

J

Figure 6. P-Channel On-Resistance Variation

with Temperature.

NDS8852H Rev. C1

Loading...

Loading...