Fairchild FSDL0365RL, FSDL0365RL, FSDL0365RN, FSDL0365RN, FSDM0365RL Schematic [ru]

...

FSDL0365RN, FSDM0365RN

www.fairchildsemi.com

Green Mode Fairchild Power Switch (FPS

Features

• Internal Avalanche Rugged Sense FET

• Consumes only 0.65W at 240VAC & 0.3W load with

Advanced Burst-Mode Operation

• Frequency Modulation for low EMI

• Precision Fixed Operating Frequency

• Internal Start-up Circuit

• Pulse by Pulse Current Limiting

• Abnormal Over Current Protection

• Over Voltage Protection

• Over Load Protection

• Internal Thermal Shutdown Function

• Auto-Restart Mode

• Under Voltage Lo ck out

• Low Operating Current (3mA)

• Adjustable Peak Current Limit

• Built-in Soft Start

Applications

• SMPS for VCR, SVR, STB, DVD & DVCD

• SMPS for Printer, Facsimile & Scanner

• Adaptor for C amcorder

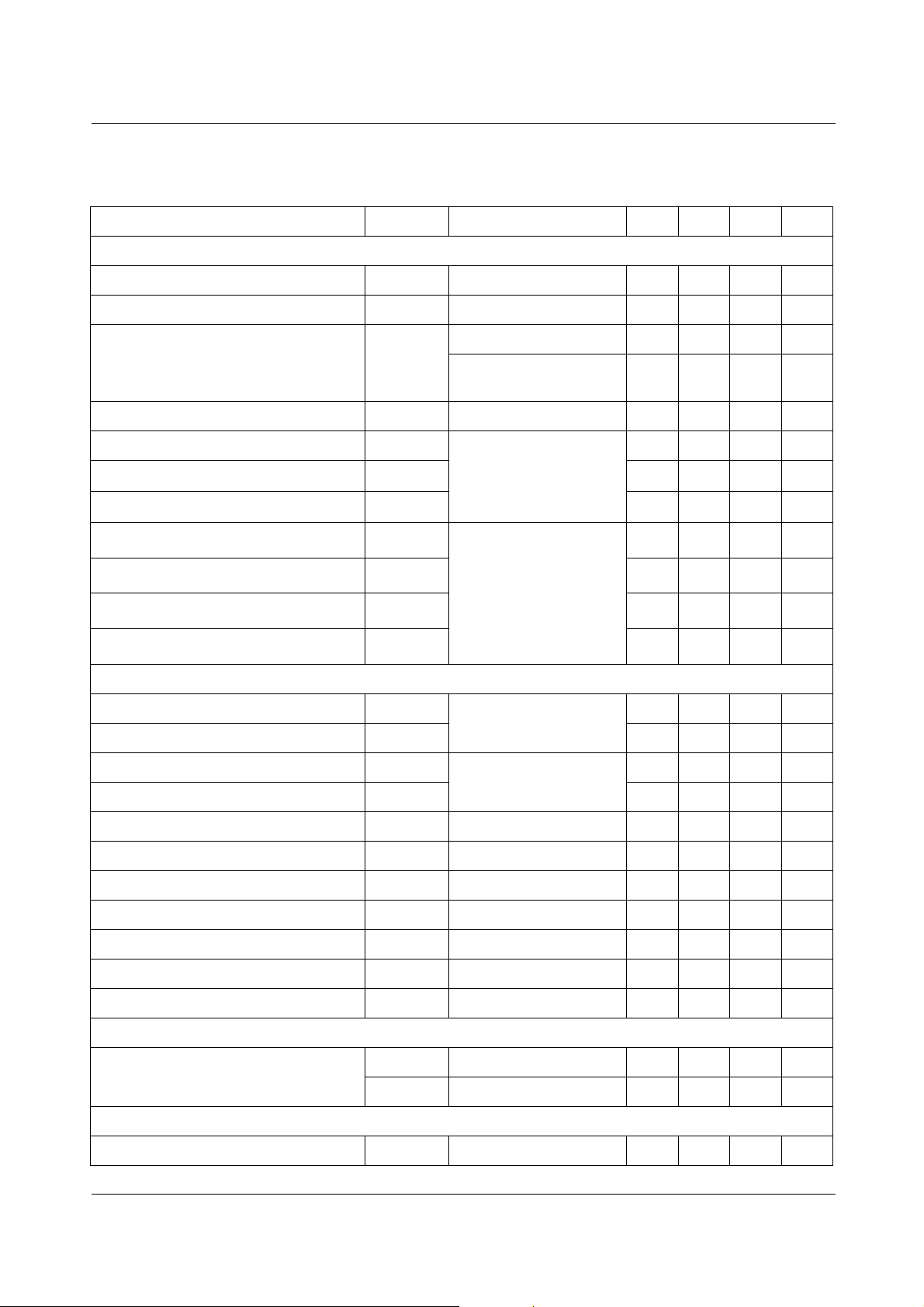

PRODUCT

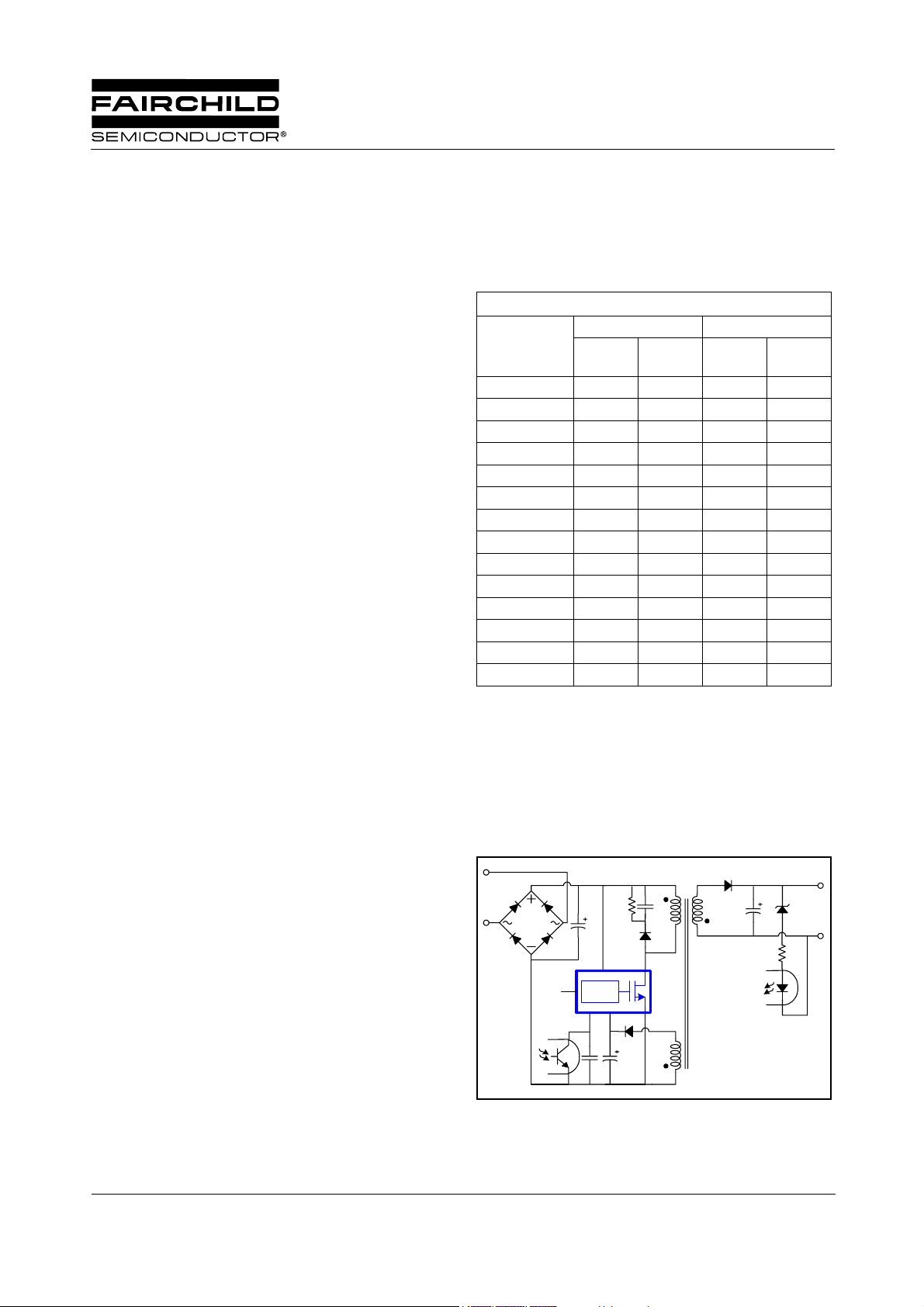

FSDL321 11W 17W 8W 12W

FSDH321 11W 17W 8W 12W

FSDL0165RN 13W 23W 11W 17W

FSDM0265RN 16W 27W 13W 20W

FSDH0265RN 16W 27W 13W 20W

FSDL0365RN 19W 30W 16W 24W

FSDM0365RN 19W 30W 16W 24W

FSDL321L 11W 17W 8W 12W

FSDH321L 11W 17W 8W 12W

FSDL0165RL 13W 23W 11W 17W

FSDM0265RL 16W 27W 13W 20W

FSDH0265RL 16W 27W 13W 20W

FSDL0365RL 19W 30W 16W 24W

FSDM0365RL 19W 30W 16W 24W

OUTPUT POWER TABLE

230VAC ±15%

Adapt-

(1)

er

Open

Frame

TM

(3)

(2)

)

85-265VAC

Adapt-

(1)

er

Open

Frame

(2)

Description

The FSDx0365RN(x stands for L, M) ar e integrated Pulse

Width Modulators (PWM) and Sense FETs specifically

designed for high performance offlin e Switch Mode Power

Supplies (SMPS) with minimal external components. Both

devices are integrated high voltage power switching regulators which combine an avalanche rugge d Sense FET with a

current mode PWM control block. The integrated PWM controller features include: a fixed oscillator with frequency

modulation for reduced EMI, Under Voltage Lock Out

(UVLO) protection, Leading Edge Blanking (LEB), optimized gate turn-on/turn-off driver, Thermal Shut Down

(TSD) protection, Abnormal Over Current Protection

(AOCP) and temperature compensated precision current

sources for loop compensation and fault pro tection circu itry.

When compared to a discrete MOSFET and controller or

RCC switching converter solution, the FSDx0365RN reduce

total component count, design size, weight a nd at the same

time increase efficiency, productivity, and system reliability.

Both devices are a basic platform well suited for cost effective designs of flyback converters.

Table 1. Notes: 1. Typical continuous power in a non-ventilated enclosed adapter measured at 50°C ambient. 2.

Maximum practical continuous power in an open fr ame

design at 50°C ambient. 3. 230 VAC or 100/115 VAC with

doubler.

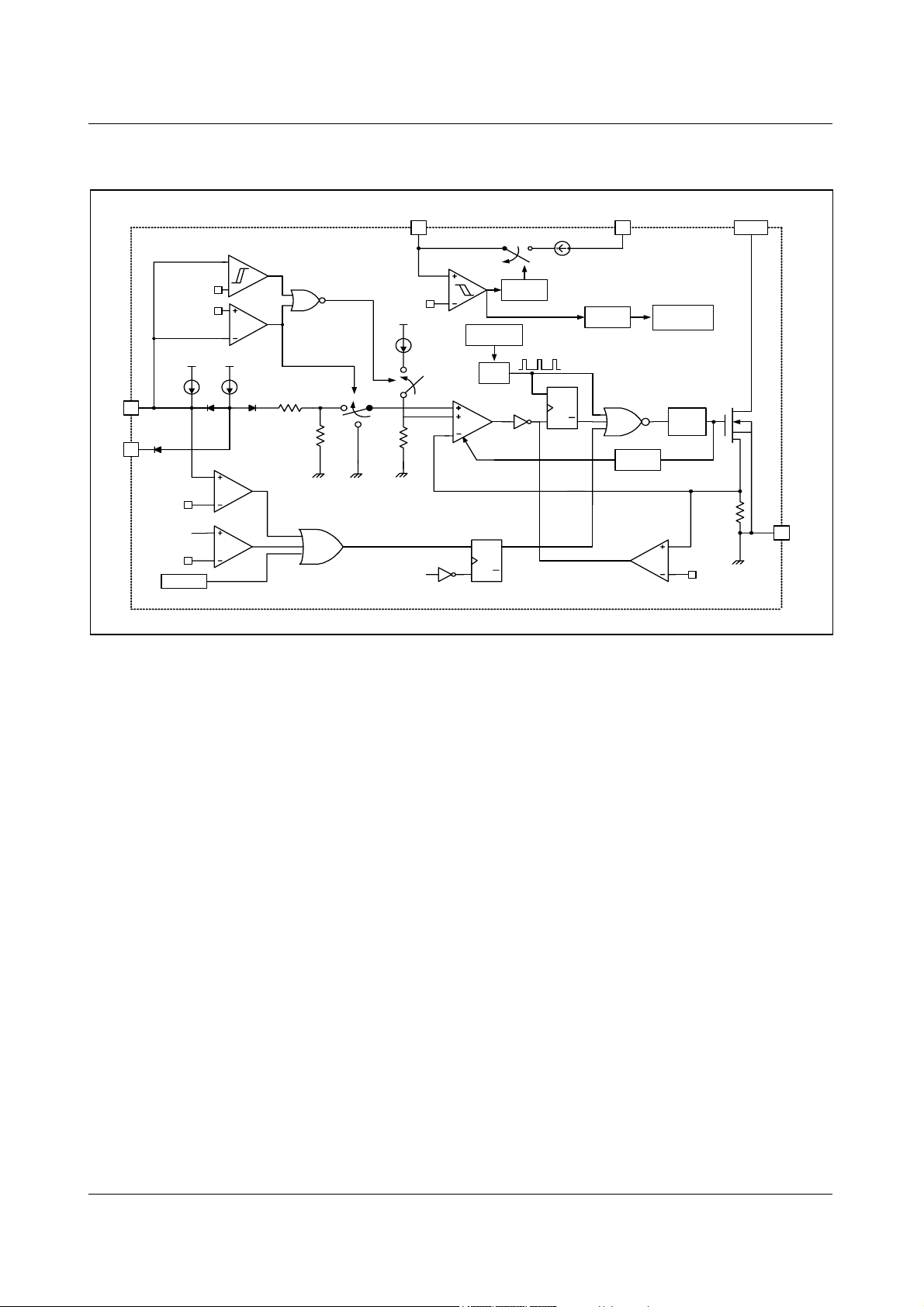

Typical Circuit

AC

IN

Drain

Vstr

Ipk

PWM

Vfb Vcc

Figure 1. Typical Flybac k Application

Source

DC

OUT

©2004 Fairchild Semiconductor Corporation

Rev.1.0.5

FSDL0365RN, FSDM0365RN

Internal Block Diagram

Vcc

2 6,7,8

+

V

BURL/VBURH

-

8V/12V

Burst

Vcc

I

B_PEAK

V

BURH

Vcc Vcc

I

FB

V

delay

3

I

FB

Normal

2.5R

I

pk

4

V

SD

R

Soft start

Vcc good

Freq.

Modulation

OSC

PWM

SQQ

R

Vcc

Vovp

TSD

Vcc good

SQQ

R

I

start

Vstr

Vref

AOCP

5

LEB

Internal

Bias

Gate

driver

Vocp

Drain

1

GND

Figure 2. Functional Block Diagram of FSDx0365RN

2

Pin Definitions

Pin Number Pin Name Pin Function Description

1 GND Sense FET source terminal on primary side and internal control ground.

Positive supply voltage input. Although connected to an auxiliary transformer winding, current is supplied from pin 5 (Vstr) via an internal switch during

2Vcc

3Vfb

4Ipk

5Vstr

6, 7, 8 Drain

startup (see Internal Block Diagram section). It is not until Vcc reaches the

UVLO upper threshold (12V) that the internal start-up switch opens and device power is supplied via the auxiliary transformer winding.

The feedback voltage pin is the non-inverting input to the PWM comparator.

It has a 0.9mA current source connected internally while a capacitor and optocoupler are typically connected externally. A feedback voltage of 6V triggers over load protection (OLP). There is a time delay while charging

between 3V and 6V using an internal 5uA current source, which prevents

false triggering under transient conditions but still allows the protection

mechanism to operate under true overload conditions.

Pin to adjust the current limit of the Sense FET. The feedback 0.9mA current

source is diverted to the parallel combination of an internal 2.8kΩ resistor

and any external resistor to GND on this pin to determine the current limit.

If this pin is tied to Vcc or left floating, the typical current limit will be 2.15A.

This pin connects directly to the rectified AC line voltage source. At start up

the internal switch supplies internal bias and charges an external storage

capacitor placed between the Vcc pin and ground. Once the Vcc reaches

12V, the internal switch is disabled.

The Drain pin is designed to connect directly to the primary lead of the transformer and is capable of switching a maximum of 650V. Minimizing the

length of the trace connecting this pin to the transformer will decrease leakage inductance.

FSDL0365RN, FSDM0365RN

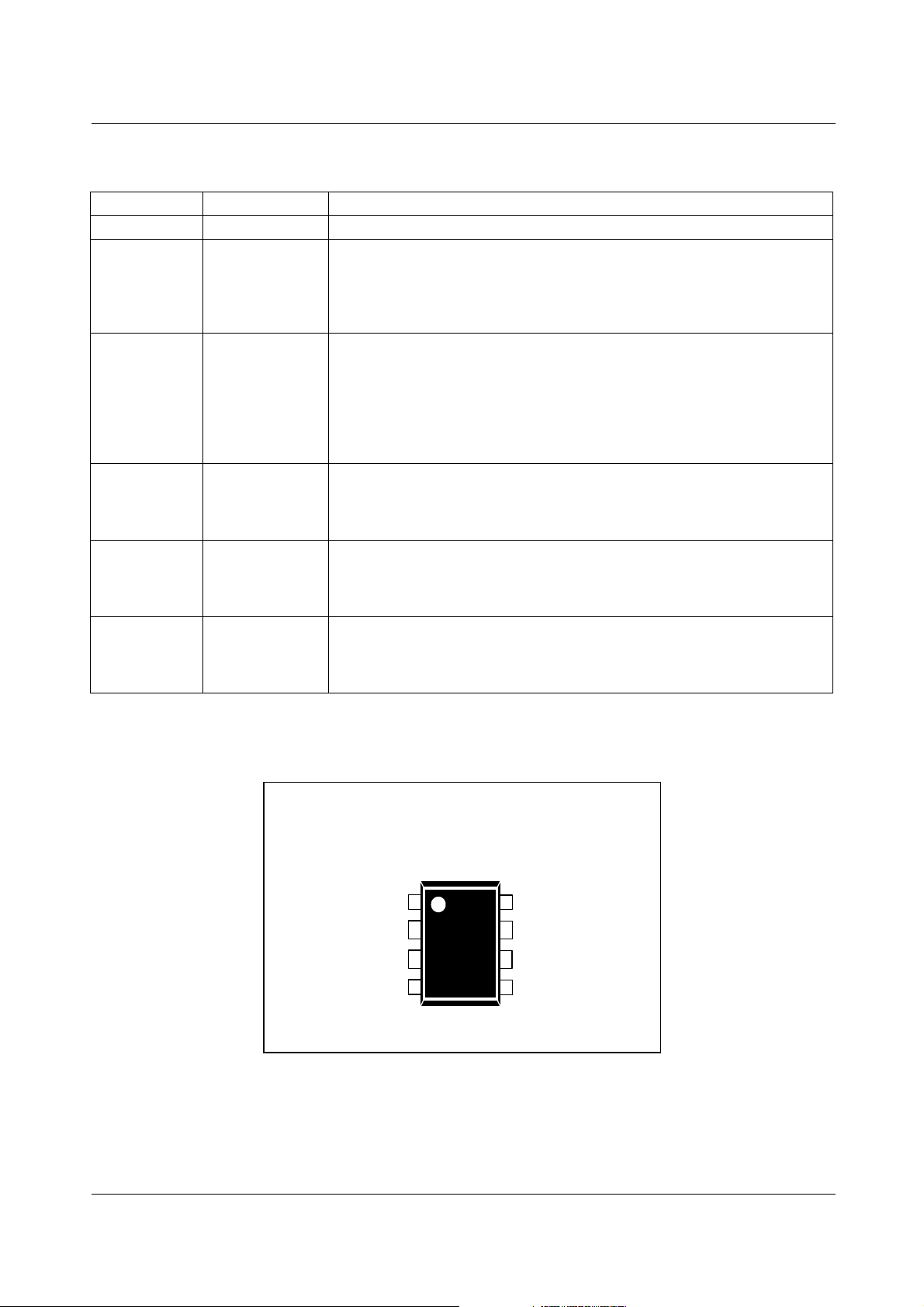

Pin Configuration

8DIP

8DIP

8DIP8DIP

8LSOP

8LSOP

8LSOP8LSOP

Drain

Drain

1111

GND

GNDGND

2222

Vcc

Vcc

VccVcc

Vfb

Vfb

VfbVfb

3333

44445

Ipk

Ipk

IpkIpk

Figure 3. Pin Configuration (Top View)

8888GND

7777

6666

5

55

DrainDrain

Drain

Drain

DrainDrain

Drain

Drain

DrainDrain

Vstr

Vstr

VstrVstr

3

FSDL0365RN, FSDM0365RN

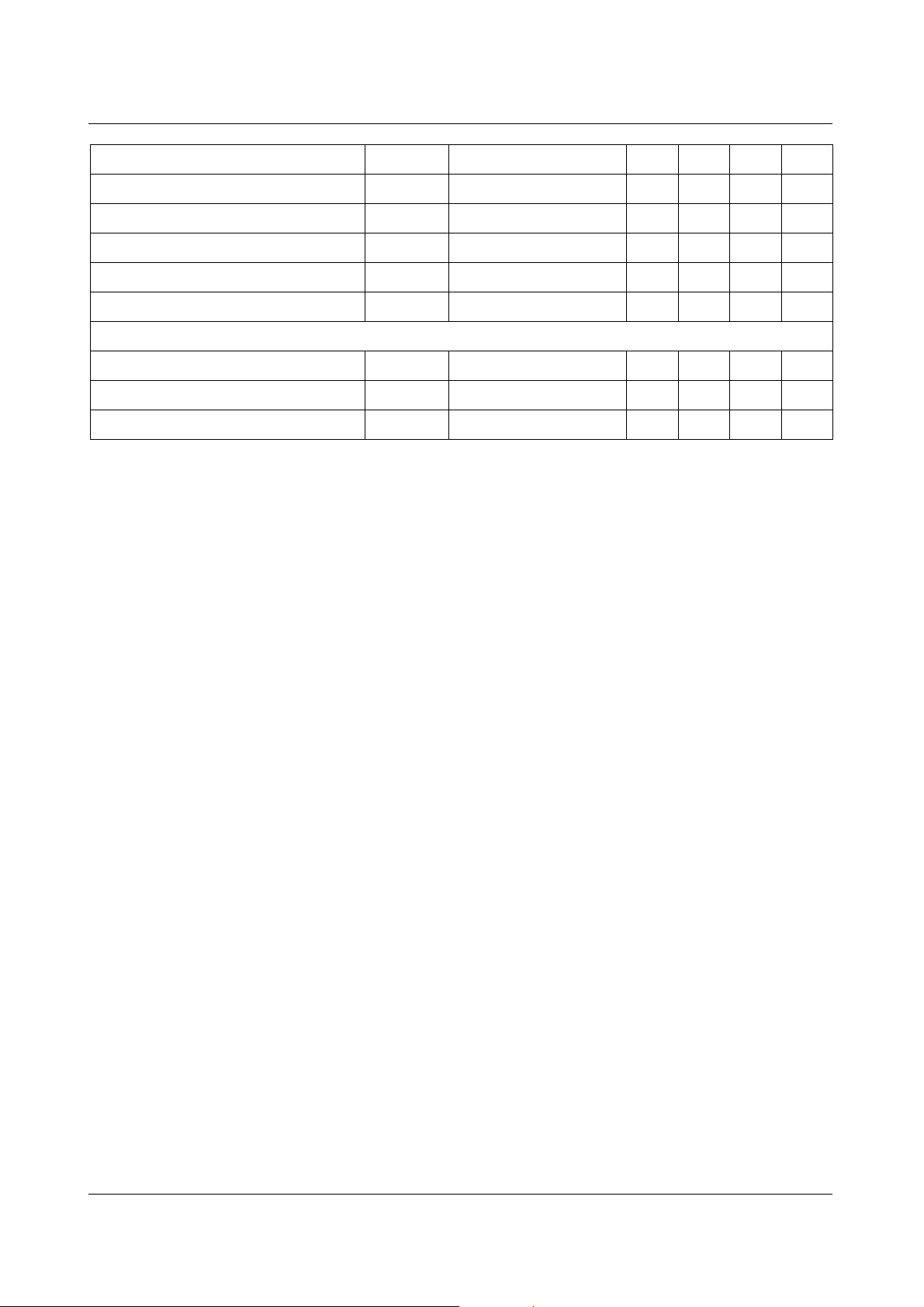

Absolute Maximum Ratings

(Ta=25°C, unless otherwise specified)

Characteristic Symbol Value Unit

Drain Current Pulsed

Single Pulsed Avalanche Energy

(1)

(2)

Maximum Supply Voltage V

Analog Input Voltage Range V

Total Power Dissipation P

Operating Junction Temperature. T

Operating Ambient Temperature. T

Storage Temperature Range. T

Note:

1. Repetitive rating: Pulse width limited by maximum junction temperature

2. L = 51mH, starting Tj = 25°C

3. L = 13µH, starting Tj = 25°C

4. Vsd is shutdown feedback voltage ( see Protection Section in Electrical Characteristics )

I

DM

E

AS

CC,MAX

FB

D

J

A

STG

12.0 A

127 mJ

20 V

-0.3 to V

SD

1.56 W

+150 °C

-25 to +85 °C

-55 to +150 °C

DC

V

Thermal Impedance

Parameter Symbol Value Unit

8DIP

(1)

Junction-to-Ambient Thermal

Junction-to-Case Thermal

Note:

1. Free standing with no heatsink.

2. Measured on the GND pin close to plastic interface.

3. Soldered to 0.36 sq. inch(232mm2), 2 oz.(610g/m2) copper clad.

θ

JA

θ

JC

(2)

85.74 °C/W

30.38 °C/W

(3)

4

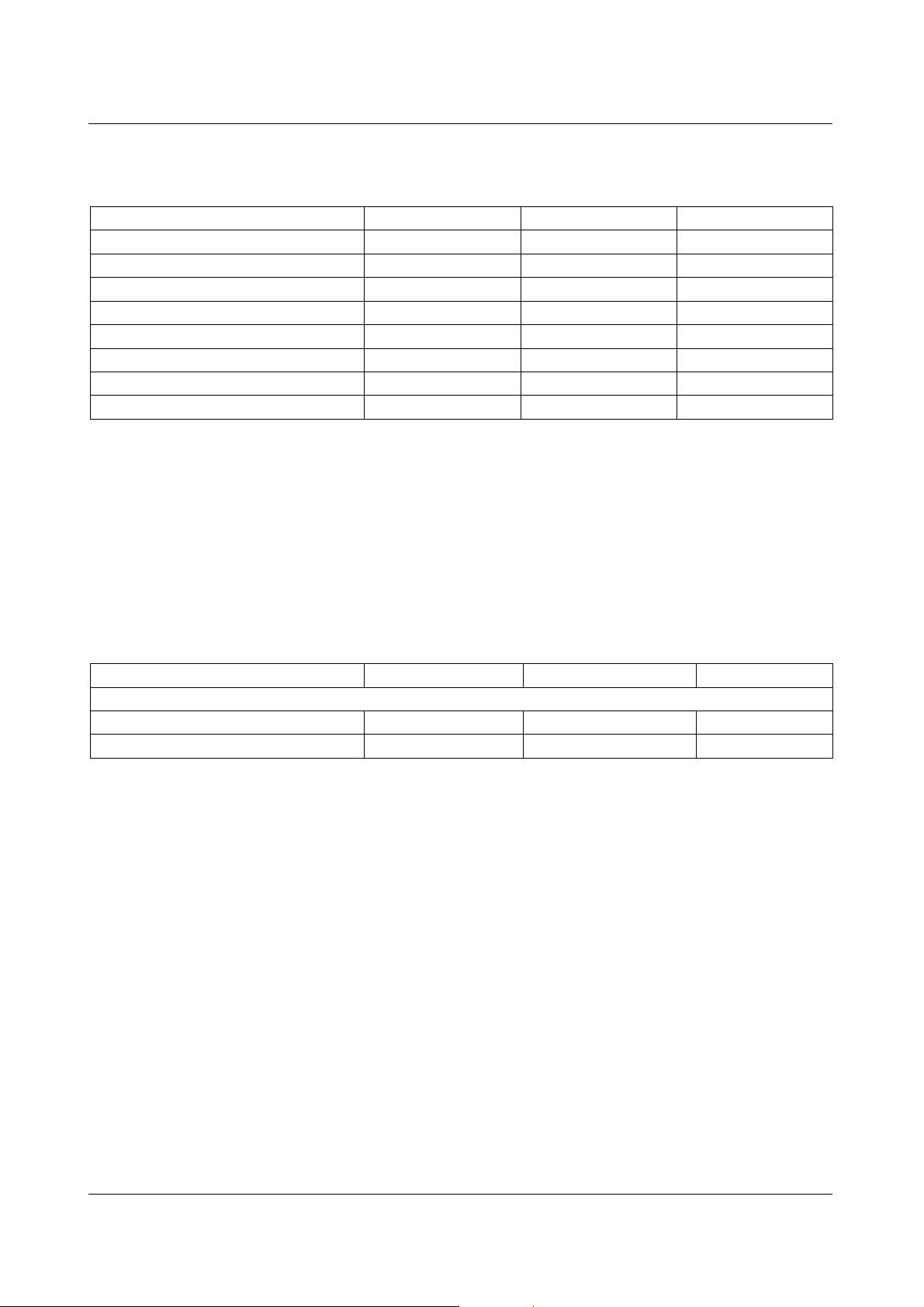

Electrical Characteristics

(Ta = 25°C unless otherwise specified)

Parameter Symbol Condition Min. Typ. Max. Unit

Sense FET SECTION

FSDL0365RN, FSDM0365RN

Startup Voltage (Vstr) Breakdown BV

Drain-Source Breakdown Voltage BV

Off-State Current

(Max.Rating =660V)

On-State Resistance

(1)

I

R

DS(ON)

Input Capacitance C

Output Capacitance C

Reverse Transfer Capacitance C

Turn On Delay Time T

D(ON)

Rise Time T

Turn Off Delay Time T

D(OFF)

Fall Time T

CONTROL SECTION

Output Frequency F

Output Frequency Modulation F

STR

DSS

DSS

VCC=0V, ID=1mA 650 - - V

VGS=0V, I

VDS=660V, V

=0.8Max.Rating,

V

DS

V

=0V, T

GS

=50µA 650 - - V

D

=0V - - 50 µA

GS

=125°C

C

- - 200 µA

VGS=10V, ID=0.5A - 3.6 4.5

ISS

OSS

RSS

VGS=0V, VDS=25V,

F=1MHz

V

=325V, ID=1.0A

- 34 -

R

DS

(Sense FET switching

- 315 - pF

-47-

-9-

- 11.2 - ns

time is essentially

- 28.2 -

independent of

operating temperature)

- 32 -

F

OSC

61 67 73 KHz

FSDM0365R

±1.5 ±2.0 ±2.5 KHz

MOD

Ω

pF

pF

ns

ns

ns

Output Frequency F

OSC

45 50 55 KHz

FSDL0365R

Output Frequency Modulation F

Frequency Change With Temperature

(2)

Maximum Duty Cycle D

Minimum Duty Cycle D

Start threshold voltage V

Stop threshold voltage V

±1.0 ±1.5 ±2.0 KHz

MOD

--25°C ≤ Ta ≤ 85°C - ±5 ±10 %

71 77 83 %

MAX

000%

MIN

VFB=GND 11 12 13 V

START

VFB=GND 7 8 9 V

STOP

Feedback Source Current IFB VFB=GND 0.7 0.9 1.1 mA

Internal Soft Start Time T

VFB=4V 10 15 20 ms

S/S

BURST MODE SECTION

V

BURH

- 0.4 0.5 0.6 V

Burst Mode Voltages

V

BURL

- 0.25 0.35 0.45 V

PROTECTION SECTION

Drain to Source Peak Current Limit I

Max. inductor current 1.89 2.15 2.41 A

OVER

5

FSDL0365RN, FSDM0365RN

Current Limit Delay

Thermal Shutdown T

(3)

T

- 500 - ns

CLD

- 125 140 - °C

SD

Shutdown Feedback Voltage VSD 5.5 6.0 6.5 V

Over Voltage Protection V

Shutdown Feedback Delay Current I

Leading Edge Blanking Time T

18 19 - V

OVP

DELAY

LEB

V

=4V 3.5 5.0 6.5 µA

FB

200 - - ns

TOTAL DEVICE SECTION

Operating Current I

Start Up Current I

Vstr Supply Voltage V

Note:

1. Pulse test: Pulse width

2. These parameters, a lthough gua ranteed, are tested in EDS (wafer test) process

3. These parameters, a lthough gua ranteed, are not 100% tested in produ ction

≤

300uS, duty ≤ 2%

VCC=14V 1 3 5 mA

OP

VCC=0V 0.7 0.85 1.0 mA

START

STR

VCC=0V 35 - - V

6

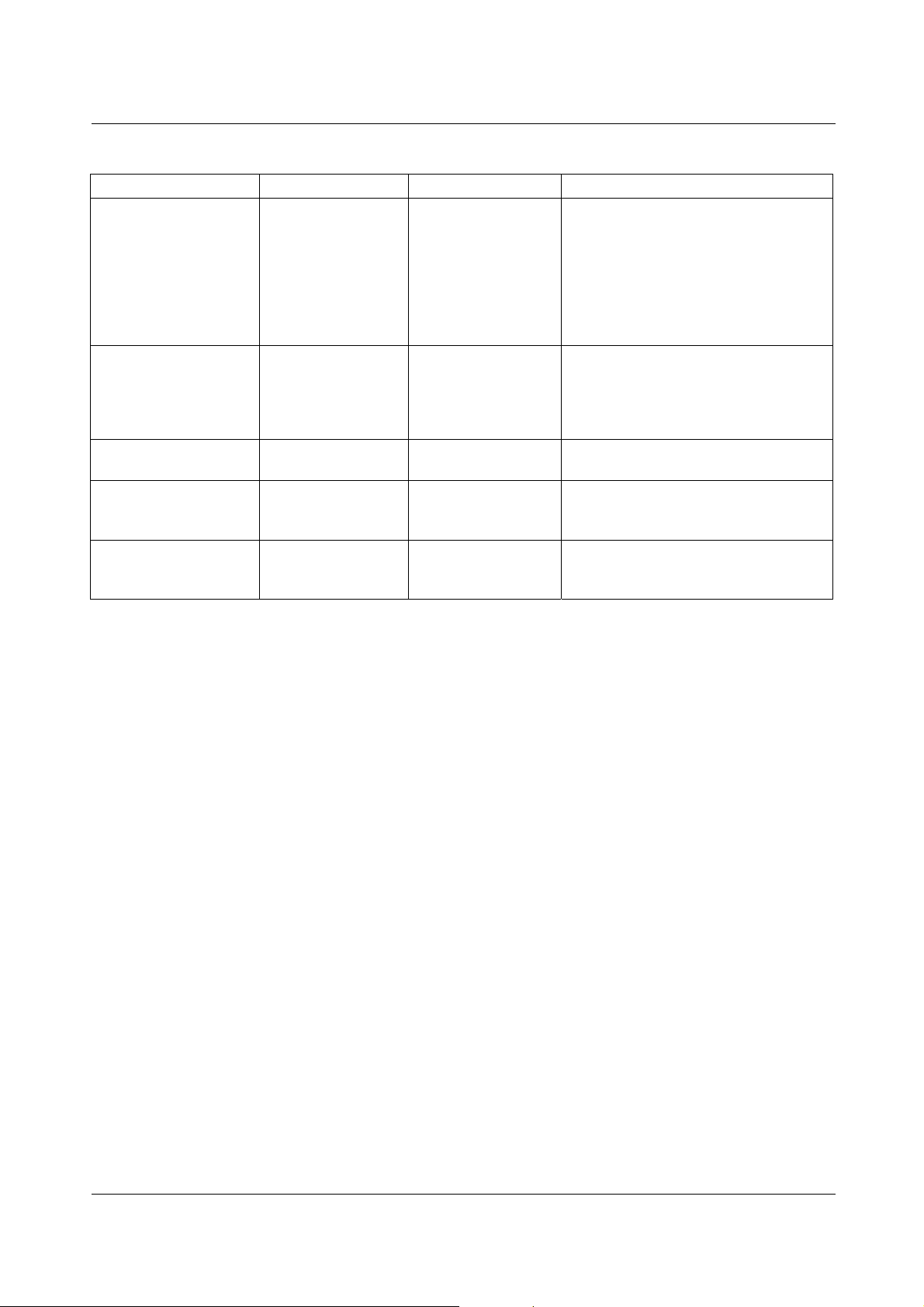

FSDL0365RN, FSDM0365RN

Comparison Between KA5x0365RN and FSDx0365RN

Function KA5x0365RN FSDx0365RN FSDx0365RN Advantages

Soft-Start not applicable 15mS • Gradually increasing current limit

during soft-start further reduces peak

current and voltage component

stresses

• Eliminates external components used

for soft-start in most applications

• Reduces or eliminates output

overshoot

External Current Limit not applicable Programmable of

default current limit

Frequency Modulation not applicable ±2.0KHz @67KHz

±1.5KHz @50KHz

Burst Mode Operation not applicable Yes-built into

controller

Drain Creepage at

Package

1,02mm 7.62mm • Greater immunity to arcing as a result

• Smaller transformer

• Allows power limiting (constant overload power)

• Allows use of larger device for lower

losses and higher efficiency.

• Reduced conducted EMI

• Improve light load efficiency

• Reduces no-load consumption

• Transformer audible noise reduction

of build-up of dust, debris and other

contaminants

7

Loading...

Loading...