Page 1

TECHNICAL

SUPPORT

SERVICE

RANGE:

PRODUCT:

TECHNICAL STUDY

technical

Fagor /Edesa 2006

Document No: 11238

Date: 13/11/06

Washer-Dryer

Page 2

How to use this manual

technical

© Copyright by Fagor Electrodomésticos S.Coop. 2006. All rights reserved. The

total or partial reproduction of this document, by any procedure and on any type of

media, is prohibited without written authorisation from the holder of the usage rights.

Breach of this copyright will be pursued in conformity with applicable legislation and

may lead to criminal charges.

FAGOR ELECTRODOMESTICOS reserves the right to introduce, without prior

notifi cation, any modifi cations to the characteristics of its manufactured products.

!

I

Electrical hazard: This identifies potential risks

for the product. Such risks may cause permanent

damage to the product

Warning:

This identifies information or circumstances that

may cause personal injuries or death.

Important: This identifies information that is critical for a

correct understanding of the product.

This document is intended for all persons rendering technical support services

(T.S.S.). It is designed to facilitate the repair of the product described. It provides

documentary support for technical consultations.

This manual contains notes warning about safety issues:

Page 3

Table of contents

technical

1.- Warnings and precautions ...................................1

2.- Features .................................................................2

3.- Description of operation .......................................4

3.1.- General description ............................................................. 4

3.1.1.- Start-up ................................................................. 5

3.1.2.- Locking .................................................................. 6

3.1.3.- Extra rinse ........................................................... 6

3.1.4.- Flot/Anti-crease ..................................................... 7

3.1.5.- Programme progress ............................................ 7

3.1.6.- Power failure ......................................................... 8

3.2.- Diagram of drying function .................................................. 9

3.3.- Programme table ............................................................... 10

3.4.- Components ...................................................................... 11

3.5.- Circuit confi guration .......................................................... 14

3.6.- Troubleshooting ................................................................. 16

3.6.1.- T.S.S. Programme ............................................... 16

3.6.2.- Safety mechanisms and criteria .......................... 17

3.6.3.- Imbalance detection ............................................ 18

3.6.4.- Operation in case of imbalance .......................... 19

3.7.- Assembly and disassembly instructions ............................ 23

3.8.- Diagrams and drawings .................................................... 25

Page 4

Warnings and precautions

technical

1

1.- Warnings and precautions

The maximum recommended amount of clothes to be dried is the equivalent of 1.5

kg dry weight of delicate fabrics, and 2.5 kg dry weight of other fabrics. Therefore,

if a full load of clothes is washed, and is then to be dried, this load must be divided

into two loads for drying.

Putting in excessively delicate articles such as curtains, woollens, silk, or items which contain materials such as foam rubber or similar materials is not recommended.

To prevent drying after the wash, set the drying timer in the Stop position.

Drying

The drying is carried out by hot air circulating in a closed circuit system and steam

condensation by mains water cooling.

It is therefore important that the water inlet tap remains open.

Simultaneously, the drainage pump starts up at regular intervals throughout the

whole of the drying process to remove the cooling water together with that resulting

from condensation.

For the last few minutes of the drying cycle, the circulating air is not heated. This

allows temperatures inside to balance out, thus preventing wrinkle formation.

Interrupting this fi nal timing is not recommended.

The time required for drying depends on the size and type of fabric, and the size of

the load.

Page 5

Description of operation

technical

2

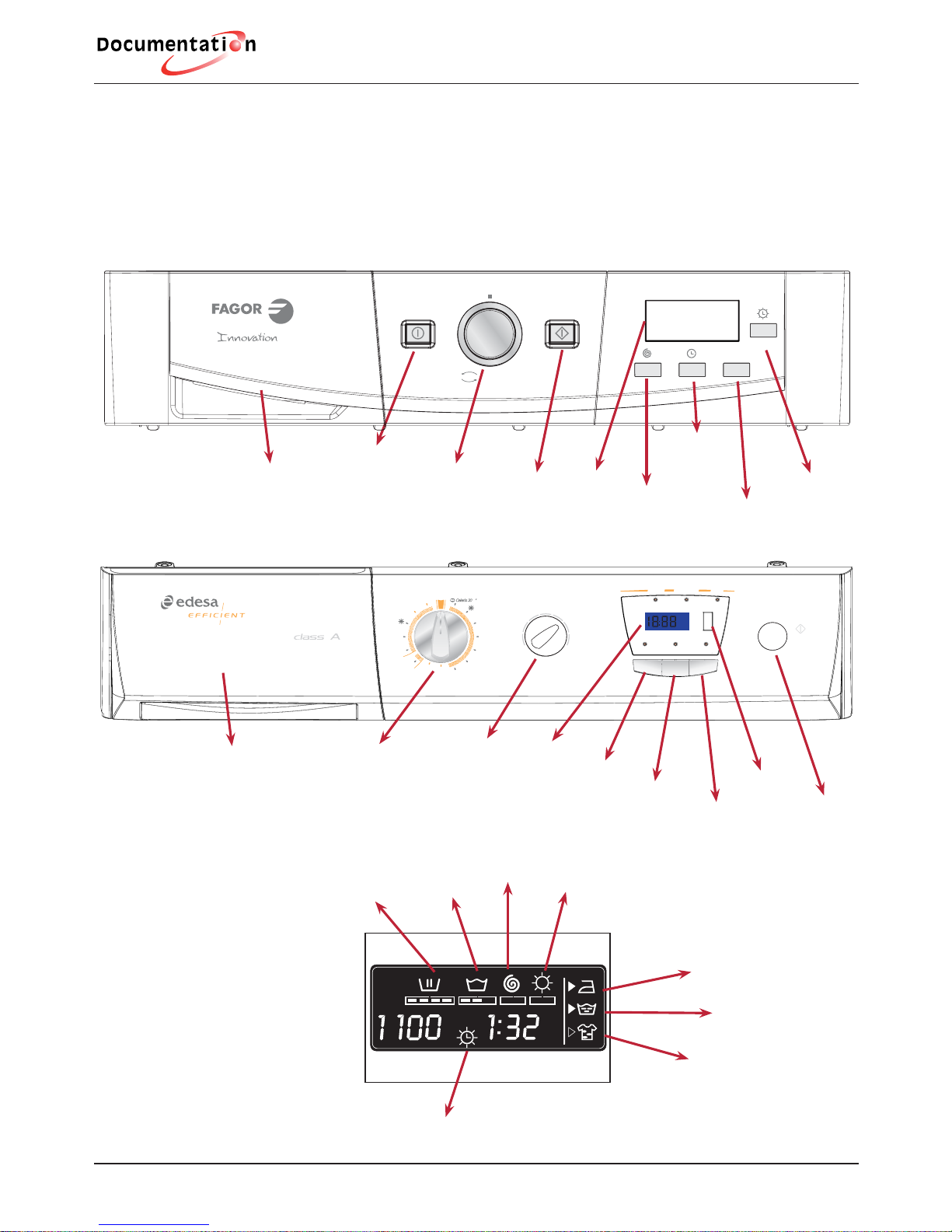

3.- Description of operation

3.1.- General description

Select

3FS-3611

TurboTime

ABS

6

kg

1100

r.p.m.

Class

A

Detergent

drawer

ON/OFF

button

Programme

selector

Start

Pause

LCD

Display

Spin + flot

button

Time

delay

button

Additional

functions

button

Drying time

button

O

30ºC

40º

60º

90º

Pre-wash 60º

Spin

35º

Celeri s 30

1100

r.p.m

100

200

Anti-

crease

0

INTENSIVE

WASH

EASY

IRON

DRYING

TIME

Rinse

6Kg

400

600

800

DELICATE

30º

40º

WOOL

COTTON

PARO

INICIO

Normal drying

Delicate drying

SPIN

EXTRA

RINSE

WASH

DRYING

END

Detergent

drawer

LCD

Display

Programme

selector

Spin + flot

button

Intensive

wash button

Easy iron

button

ON/OFF

button

Drying time

button

Extra

rinse

key

EDESA

Pre-wash

Wash

Spin

Dry

Easy iron

Anti-crease/fl ot

Intensive Wash

Time delay

FAGOR

Page 6

Features

technical

3

2.- Features

The wash options must always be selected after

selecting the wash programme. Any change of

programme during the selection annuls the options

which were previously selected.

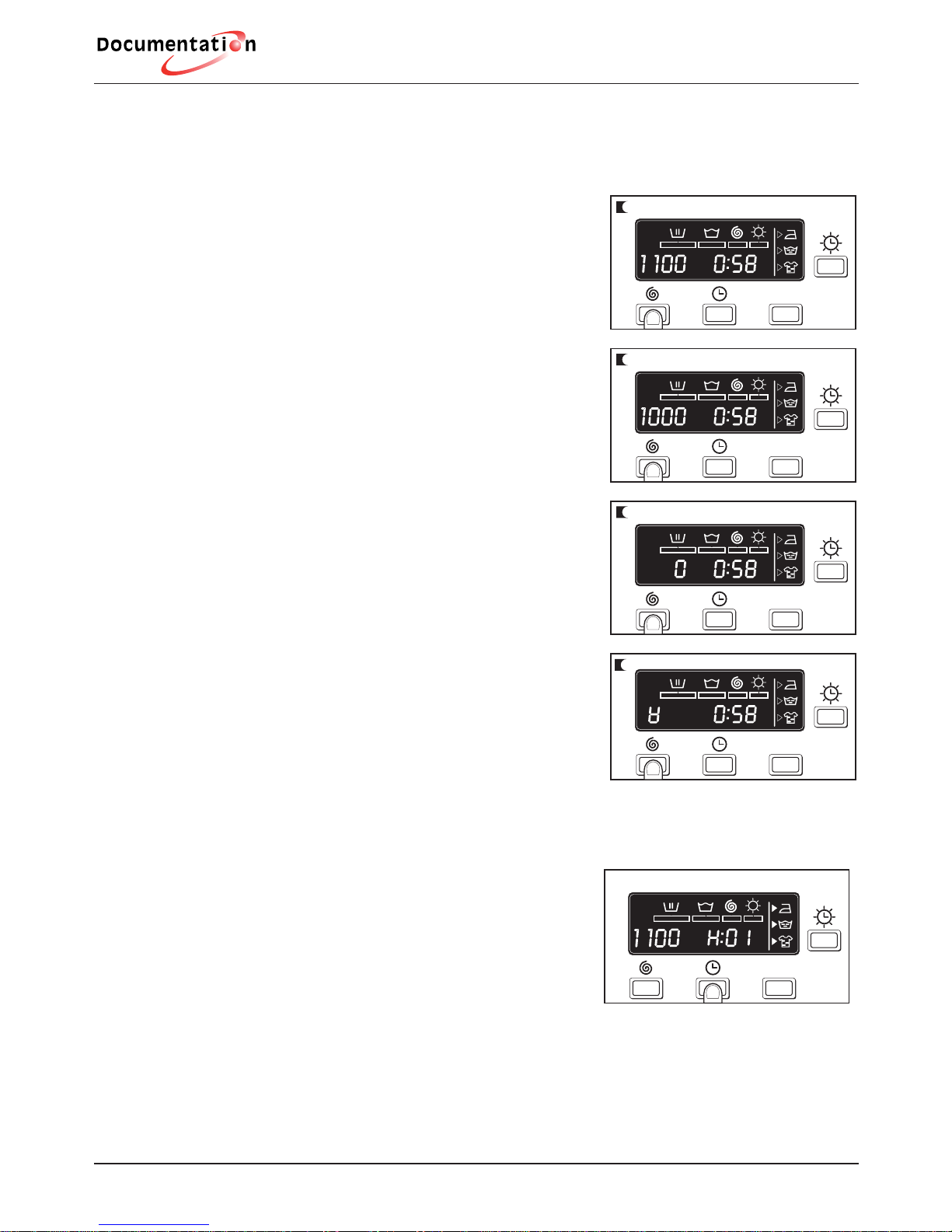

a) Spin selection and anti-crease (fl ot) button.

The selected programme has an associated spin

speed.

b) This can be modifi ed by pressing the spin button

repeatedly - the spin speed in revolutions will

decrease by 100 each time until 400 is reached.

c) Skip spin option. Press the spin button

once more to reach the skip spin option. This

programme, without a fi nal spin, is used to prevent

creases from forming when washing special

fabrics

d) Option: fl ot/anti-crease. This stops at the fi nal

rinse, leaving the clothing fl oating in water. When

the function is deactivated, the washer continues

the programme, draining and spinning. This is

used when you are not at home, for example,

to delay the spin until you have arrived so that

creases are not caused by the clothes being spun

and then left in the drum.

Time delay

Time delay selection. A delay of up to 24 hours

may be selected. The delay must be selected

after choosing the wash programme.

To select the time delay in hours press the clock

button. Each time the button is pressed delays

the start time by one hour. Cancel time delay To

cancel time delay press the clock button repeatedly. The delay will be cancelled by reaching 24 hours and then pressing once more.

Changing to another programme also cancels the delay.

b

c

a

d

Select

Select

Select

Select

Select

Page 7

Features

technical

4

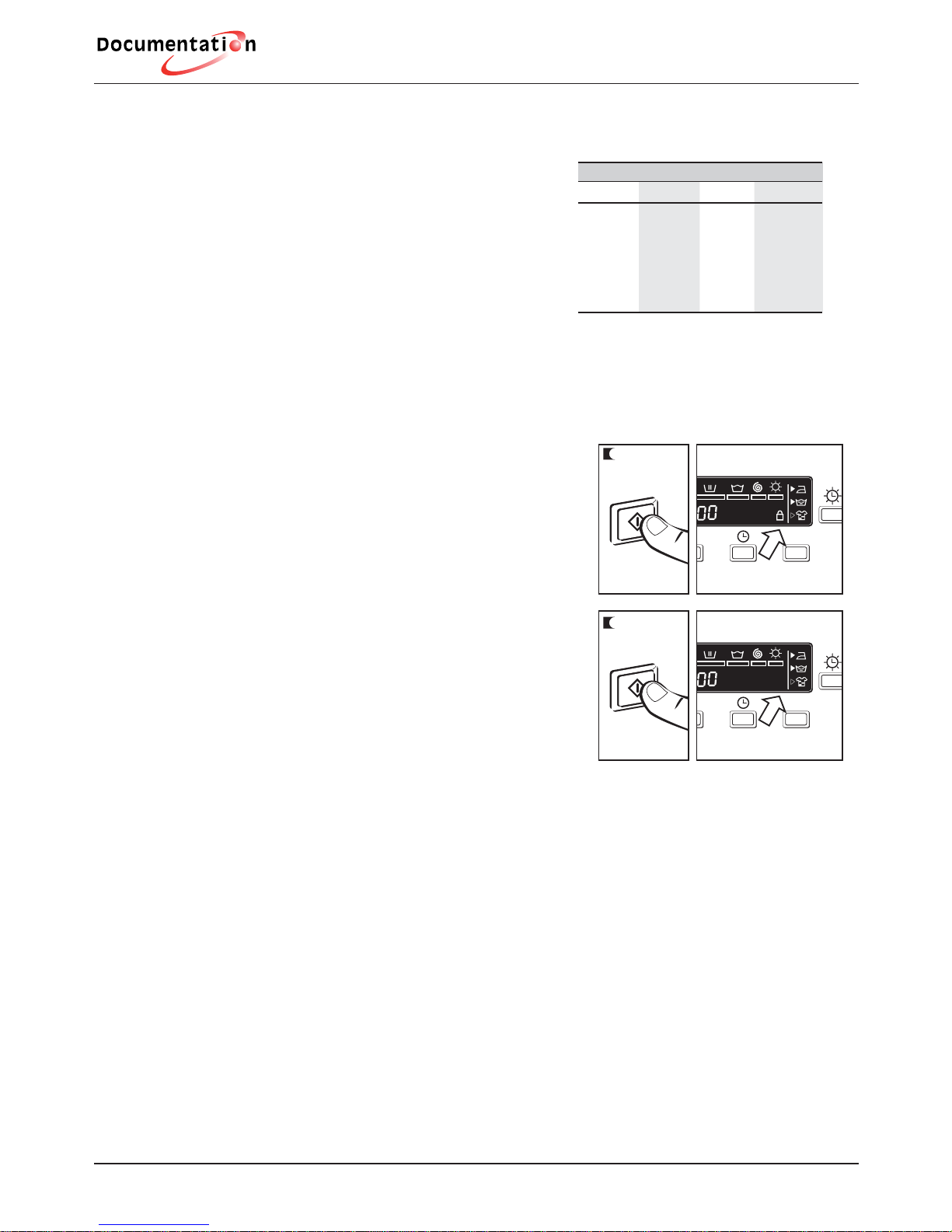

Additional functions

Button for selecting additional functions according to programmes.

a) There are 3 options: easy iron, intensive

wash, extra rinse. Press the button to display

the required option.

b) By clicking several times you can choose

between various combinations, of one, two,

and even three additional functions at the same

time, depending on the chosen programme.

•Button: Easy iron. This option reduces the

formation of creases in garments by performing

a special programme with special movements

to fluff up the garments after the spin and make

ironing easier.

•Button: Extra rinse. This increases

the intensity of the final rinse applied to the clothing. This is recommended for

large loads and garments belonging to users with sensitive skin. Increases water

consumption!

•Button: Intensive Wash. This option, specially recommended for very dirty or

stained garments, gives better results by lengthening the wash cycle.

Important: If the ON/OFF button is pressed or there is any change of programme

during the selection, all the options which were previously selected are cancelled.

DEMO programme

The DEMO programme is a special exhibition programme which allows the

operation of Innova washing machines in shops without faults due to water inlet,

emptying, door open, etc, being displayed.

To select or annul this programme, press the spin and select buttons simultaneously

for 8 seconds.

b

Select

Select

a

Page 8

Description of operation

technical

5

3.1.1.- Start-up

To select the wash and dry programme, follow

these steps:

a) Turn the machine on with the ON / OFF button.

b) Pull the programme selector out to activate it.

c) Select the wash programme by turning the programme selector control (see programme table).

To select the drying time, follow these steps:

a) Press the drying time button to select the drying

time. The screen will display the time, which is

increased each time the drying time button is

pressed.

Important: If a wash + dry option is selected, the

load may not be greater than 4 kg. (1.5 kg for delicate wash programmes).

When the programme is selected, the following information will be displayed:

1- Phases of the wash and dry programme

Wash

Rinse

Spin

Dry

2- Spin speed in revolutions/min

3- Programme number (for a few seconds), and then its duration.

4- Additional functions

Easy iron

Extra rinse

Intensive Wash:

a

a

b

c

1

234

Page 9

Description of operation

technical

6

There are 4 types of programme available

Normal programmes

Delicate programmes.

Additional programmes

Drying programmes

3.1.2.- Locking

a) The Lock function is activated by holding down

the Start/Pause button for 3 sec. The lock must

be activated after having selected the wash programmes and all related options, as well as the

delay required.

Once the lock has been activated, the machine

will not respond to any button, not even the Start

button or the wash programme selector.

In these circumstances, the only button which will

affect the washer is the OFF button, which will,

logically, stop the programme. However when it

is turned ON again, the programme will continue

from the point where it stopped, i.e., pressing

OFF does not cancel the childproof lock.

b) The locking mechanism is only deactivated

when the wash programme ends.

3.1.3.- Extra Rinse Option

- Adds one rinse to the selected programme, at the start of the rinse phase

- The washer has three rinses, the fi rst two with water intake through the wash tray

and the last with intake through the softener tray.

- Skip Spin Option: This option eliminates the spins the washing machine would

normally carry out in the selected programme

Normal Delicate Additional Drying

PROGRAMMES

Normal cold

Fast 30ºC

Normal 30 ºC

Normal 40 ºC

Normal 60 ºC

Normal 90 ºC

Pre-wash 60 ºC

Delicate cold

Delicate 30ºC

Delicate 40ºC

Delicate 60ºC

Rinses

Spin

Normal drying

Delicate drying

Empty/End

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

a

b

Select

Select

Page 10

Description of operation

technical

7

3.1.4.- Flot/Anti-crease Option

- With this option the programme stops before emptying the last rinse; for the

programme to continue, the Flot option must be unlocked

Note: The wash options must always be selected after selecting the wash

programme. A change of programme during the selection, or after the wash has

been started, cancels the options which were previously selected, and only the new

programme’s spin speed is lit up.

3.1.5.- Programme progress

When the programme has started, the screen can

display the current wash phase, as well as the

remaining time. As the programme continues, the

active phases will be displayed successively in the

upper part of the screen. The remaining programme time is also displayed in the screen. It is updated periodically, but not minute-by-minute.

Any option button may be selected, as long as

the wash phase in which it takes effect has not passed, and when the programme

permits that option. Pressing the delay button during the wash has no effect on the

washer-dryer. Pressing the Start/Pause button during the wash puts the washer in

the PAUSE state.

Important: If during the wash and dry cycle the programme is changed using

the selector, the washer-dryer is left in the PAUSE state, and the programme is

annulled. To add or remove an article, press the start/pause button and make sure

that the water is not above the door overfl ow level, and that the interior temperature

is not high. Press the start/pause button again to re-start the washer from the same

phase of the cycle in which it was stopped.

3.1.6.- Power failure

When the supply returns after a power failure, the washer continues to work as

normal, from the point at which it stopped (its memory lasts a few hours). The same

thing happens if the ON/OFF button is pressed.

Page 11

Description of operation

technical

8

Programme

No.

Wash load Time Consumption in

Kw

Water

consumption

14 normal 4 Kg 180 min 2,9 Kw 48 L

15 delicate 3 Kg 180 min 1,8 Kw 27 L

The vibration when drying is movement for 57 sec, then stopped for 3 sec.

The water inlet of the electrically operated valve for drying is activated 20 minutes

into the selected programme.

During the drying process, the drainage pump works in cycles of 5 sec. on, then

55 stopped.

At the start of the drying programme, water comes in for 3 sec through the

detergent tray. This is to prevent steam leaving through the detergent tray.

The drying programme can take from a minimum of 20 minutes up to a maximum

of 180 minutes, in 10-minute increments.

If the cold water intake is greater than 0.35 litres per minute when the drying

process is complete the clothes will be damp and hot.

3.2.- Diagram of drying function

Cold water

inlet

Condenser

Humid air

Electric pump

Drain

Drum

Outer Drum Casing

Hot air

Double cycled Thermostat 170º

700 + 700W drying elements

Single cycled thermostat 85º

Turbine

Dry air

safety 95º

0.35l/m

ow

Page 12

Description of operation

technical

9

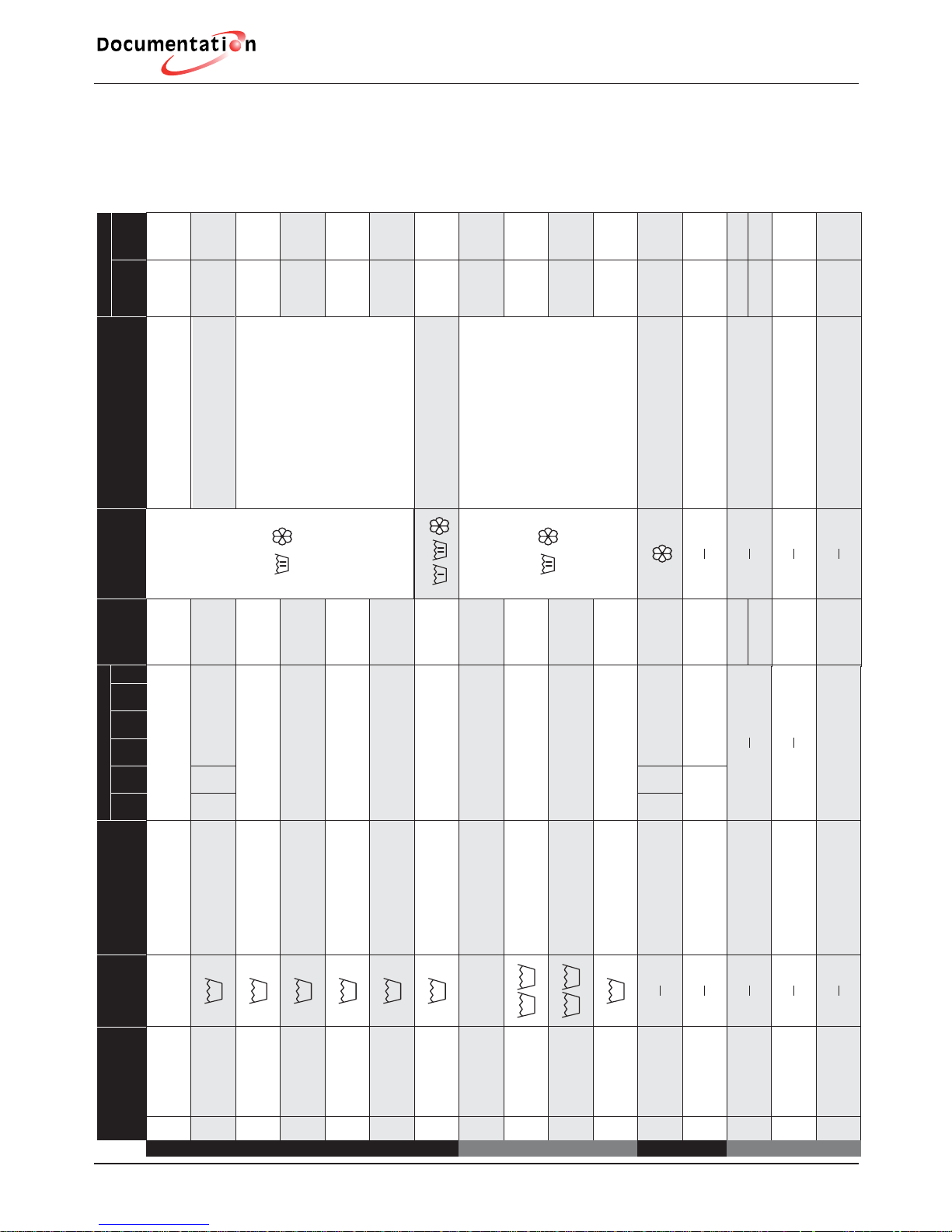

3.3.- Programme table:

YES NO YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YESNO

NO

1

2

3

4

5 (*)

6

7

8

9

10

11

12

13

14

15

16

Normal cold

Normal 30 ºC

Normal 40 ºC

Normal 60 ºC

Normal 90 ºC

Delicate cold

Delicate 30 ºC

Delicate 40 ºC

Delicate 60 ºC

Rinses

Spin

Normal drying

Delicate drying

Drainage/End

Normal programmeDelicate programmesAddit. progr.Drying programmes

Cold

Cold

30

30

40

60

90

60

40

60

40

3030

YES NO

Extra

Rinse

Intensive

Wash

Easy

iIroning

Select

Spin

Skip

Spin

Ani-crease

Recommended

temperature

Max.

load

(Kg)

Programme

Type of material

Buttons for possible options

Fast 30 ºC

Cotton/Linen

delicate colours

very slightly soiled

Cotton/Linen

white/coloured

very slightly soiled

Cotton/Linen

delicate colours

slightly soiled

Cotton/Linen

Solid colours

Slightly soiled

Cotton/Linen

Solid colours

Normal soiling

Cotton/Linen

White

Very dirty

Pre-wash 60ºC

Cotton/Linen

White/solid colours

Very dirty

Synthetic/mix

Cotton delicate colours

Very slightly soiled

Synthetic/mix

Cotton delicate colours

Slightly soiled

Synthetic/mix

Cotton delicate colours

Normal soiling

Synthetic/mix

Cotton white/solid colours

Normal soiling

Cotton/mix cotton

Synthetic/Delicate

Wool/wool mix

Cotton/mix cotton

Synthetic/Delicate

Wool/wool mix

Cotton/linen

Synthetic/mixed

Cotton/mix cotton

Synthetic/Delicate

Wool/wool mix

0,15/49

0,20/30

0,40/49

0,65/49

1,02/49

1,90/55

1,45/60

0,15/55

0,35/55

0,60/55

1,00/55

0,05/30

0,05/0

2,8/48

1,8/27

1,2/26

0,00/0

60

30

82

87

91

110

105

50

50

55

70

23

10

160

100

95

2

Emptying and long nal spin

Normal drying

Delicate drying

6

1,5

6

6

6

6

6

3

3

3

3

6

6

4

3

1,5

6

Wash

products

compartment

Programme

description

TURBO TIME PLUS

Total wash

load

KWh/litres

Approx.

duration

(minutes)

Max.

load

(kg)

Normal wash, rinses,

automatic additive absorption

if required, and long nal spin

SHORT wash, rinses,

automatic additive absorption

if required, and long nal spin

Normal wash, rinses,

automatic additive absorption

if required, and long nal spin

Pre-wash, normal wash, rinses,

automatic additive absorption

if required, and long nal spin

Delicate wash, rinses,

automatic additive absorption

if required, and gentle nal spin

Rinses, automatic

additive absorption if required,

and long nal spin

Emptying and end of programme.

Takes the programme to the nal position

Page 13

Description of operation

technical

10

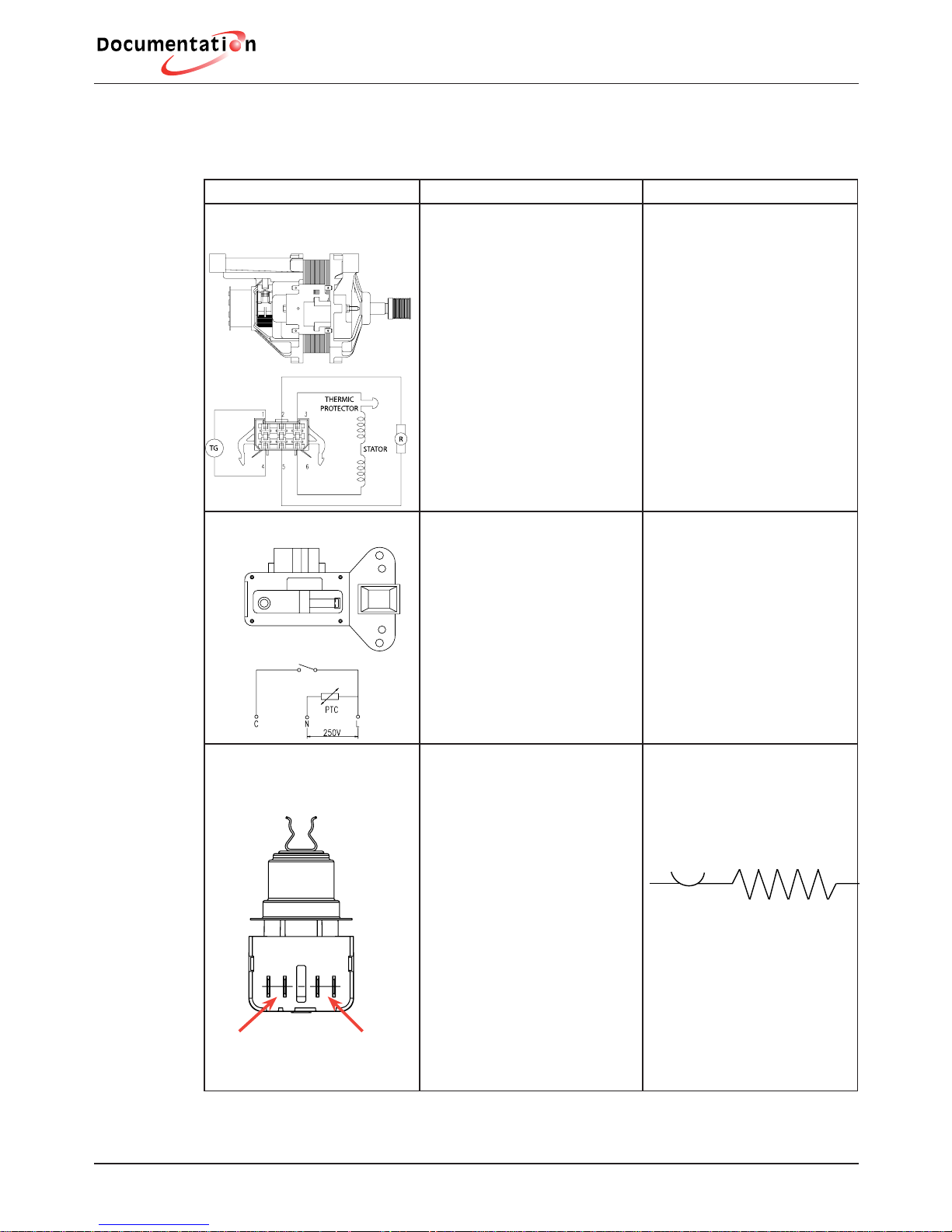

3.4.- Components

Door lock

Used in machines with

variable spin and makes

rotating movements when

washing and spinning.

Motor power supply:

- Clockwise, power 220V.

, contacts 2 and 3. Bridge

between contacts 5 and 6.

- Anti-clockwise, power

220V. , contacts 3 and 5.

Bridge between contacts 2

and 6.

Motor

Voltage: 220V / 50 Hz

Stator resistance: 1.3

Rotor resistance: 1.7

Tachogenerator

resistance: 184

Tachogenerator voltage:

1.2 V / 1,000 rpm

Opens hatch lock

Voltage: 220 V /

50 Hz 16 Amp.

Between 40 and

75 second delay

Component

NTC Safety Thermostat

NTC

Resistance

thermostat

Safety

Component

The electronic card

reads the NTC (variable

resistance), and

determines whether the

water temperature has

reached the selected

temperature in the

programme to complete

the heating phase

NTC (see values in the

table)

Safety thermostat

96ºC Contact normally

closed

-20ºC Thermostat resets

96 ºC

Heating

resistance

Function Features

Page 14

Description of operation

technical

11

NTC Temperature / Resistance values

Temperature(ºC) <30 30 35 40 57 60 80 90

Resistance (K Ω) >40 39 31 26 13 11 5 4

Component Function Features

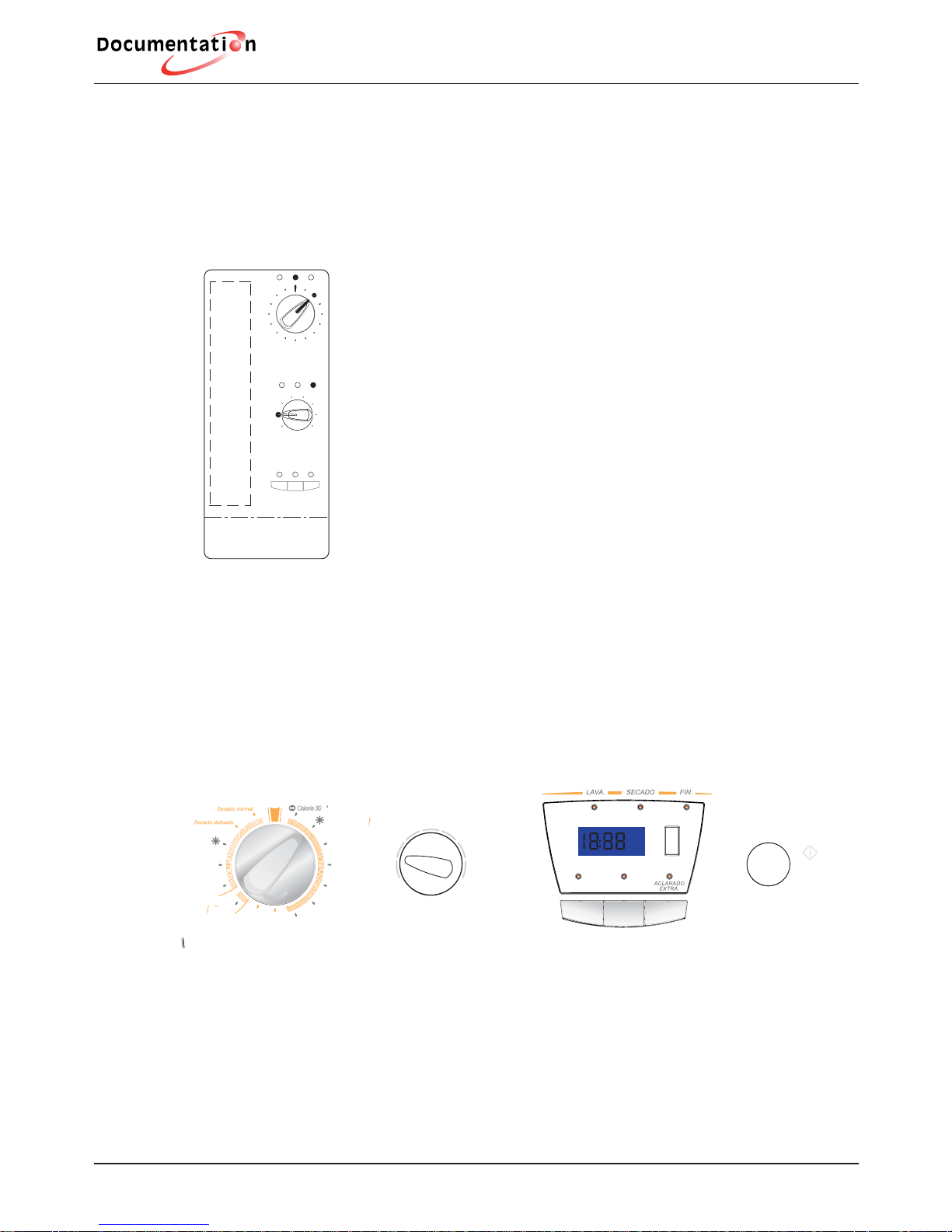

Drainage pump

Drains the water from

inside the drum

Voltage: 220 v / 50 Hz

Drainage rate: 16 litres/

minute

Maximum drainage

height: 1 metre

Winding resistance: 163.4

Power 30 Watt.

Quadruple valve

The pressure switch

is activated in the

following conditions:

When the level reaches

12 litres, the wash

level. (11-12)

- When the level

exceeds 33 litres

(overflow), the

drainage pump is

activated (safety).

(11-16)

- The rinse level is

performed according

to the time of the

microprocessor of the

electronic card.

Level 1

102 / 72 ± 3

Overflow safety

310 ± 10

12 Water outlet

14 Heating

16 Overflow

11 Common

11

12

14

16

Presostato

Water input during prewash, wash and softener.

Voltage 220 V/50 Hz

Electrically operated valve

fl ow for pre-wash, wash

and softener is 7 litres per

minute.

Electrically operated valve

fl ow for drying is 0.35

litres per minute.

Value: 3,750

Page 15

Description of operation

technical

12

Component

Function

Features

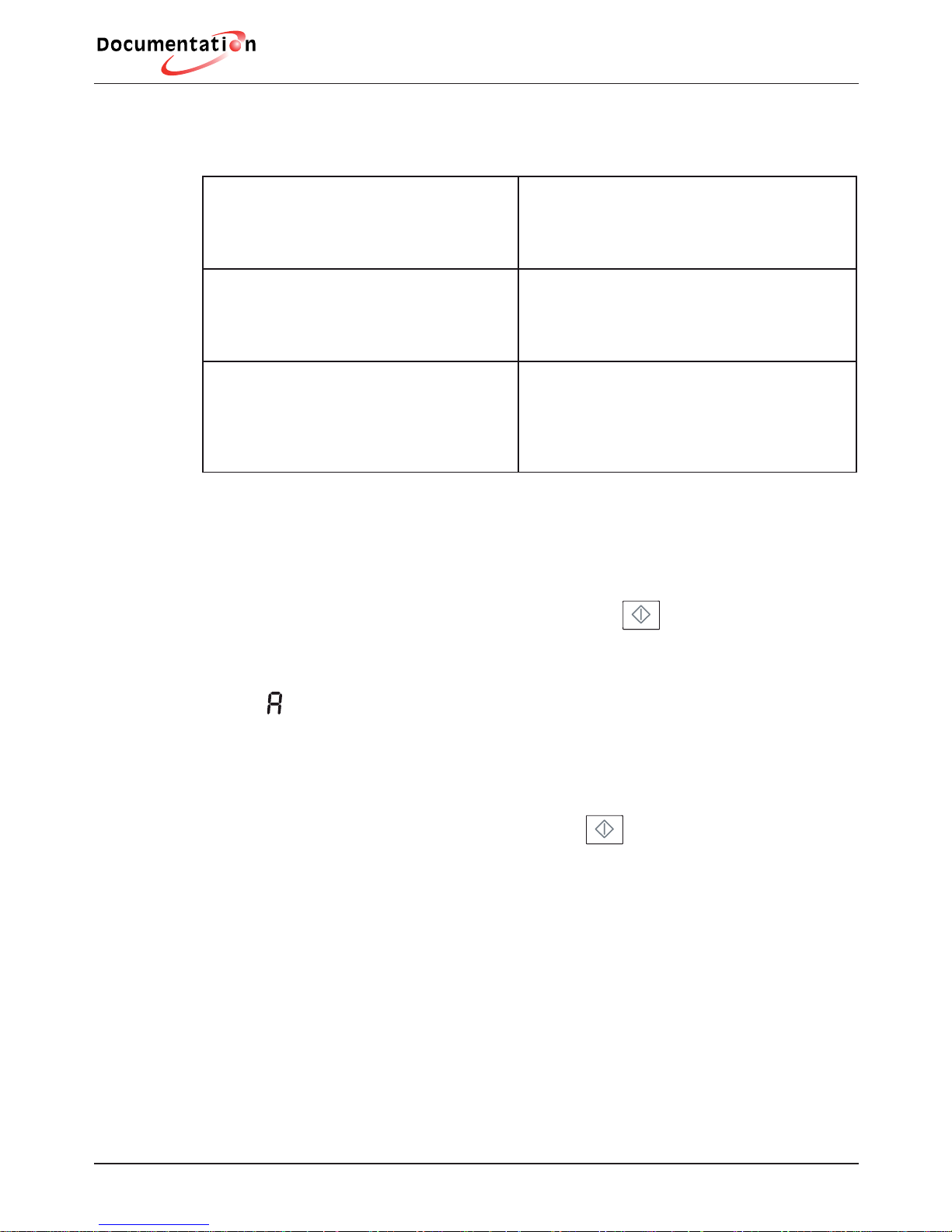

Heating resistance Heating element

Resistance: 25,4

Material: Real stainless steel

Power: 1850w

Voltage: 220 v

Display

Circuit

Power circuit

Voltage: 220 v / 50 Hz

Important:

It is necessary to configure the circuit before

starting the machine.

(follow configuration

instructions)

Voltage: 220 v / 50 Hz

Display circuit

Power circuit

Page 16

Description of operation

technical

13

3.5.- Fagor circuit confi guration:

3.1.3.- Fagor circuit configuration:

If the circuit is not configured, it will go into

To change the configuration, follow these steps:

1.- Turn the machine off

2.- Press the start / pause button and keep it pressed (until step 5)

3.- Press the button for 1 second until the LCD screen lights up

4.- Press the spin button and wait 2 seconds until the letter is displayed

on the LCD screen

5.- Release all keys simultaneously

6.- The door lock will be locked

7.- Press the spin button and the configuration digits are displayed

(the last digit of the LCD will flash).

8.- Pressing the Time Delay button changes the parameter to be adjusted,

starting with the KG digit and following the sequence:

KG – RPM – RECIRCULATION – COLD WATER – DOOR OPENING– KG - ….….

Pressing the SPIN button changes the value of the parameter; the possible values

are limited to the circuit’s hardware reference and the selected KGs. If the KGs

are changed after having selected the RPM, and the previous RPM value is not

permitted for the newly selected KGs, the RPM will re-adjust to the value closest

for the newly selected KGs.

1200

RPM

RECIRCULATION PUMP

YES 00 / NO 0

COLD WATER

YES 0 / NO 8

DOOR OPENING

YES 8 / NO 0

KG

6

Select

Select

status as soon as it is plugged in

(go to step no. 7). If the circuit is configured it enters the current configuration.

Page 17

Description of operation

technical

14

Confi guring an Edesa Circuit:

When a circuit is replaced or changed, it must be confi gured.

To confi gure the circuit, follow these steps.

1.- Move the function selector knob to position 0.

2.- Set the r.p.m. selector to position 2 (0 r.p.m.)

3.- Press the Start/Pause key and keep it pressed.

4.- Keeping the Start/Pause button pressed, set the selector to

programme nº 2 (cold position * ), and the end LED comes on.

5.- Keeping the Start/Pause button pressed, press the intensive

wash button, and the phase LEDs for the wash, rinse, and end

come on. The LCD screen displays the letter A, and we release

the Start/Pause button and intensive wash button simultaneously.

6.- Press the intensive wash button and the rinse LED fl ashes,

and E00 is displayed in the LCD screen. If it has no LCD screen,

the confi guration LEDs come on.

7.- Check that the LEDS which are lit correspond to the ones

indicated in the label stuck on the body of the washer’s tray.

8.- Validate the confi guration by pressing the start/stop button until the intensive

wash, extra rinse and easy iron fl ash; the TSS test programme is then activated.

LS-1136

LF5M005W5

EDESA

(P2)

6 Kg.

(Position 2)

1100 r.p.m.

2

3

4

5

6

7

8

1

REF. BARCODE

CONTROL PANEL (COD. 39)

XXXX

XXXXXXX

O

30ºC

40º

60º

90º

Prelavado 60º

Centrifug.

35º

Celer is 30

C

E

N

T

R

I

F

U

G

.

1100

r.p.m

100

200

Anti-

arrugas/vi ncos

0

LAVA.

INTENSIVO

FÁCIL

PLA

NCHADO

TIEMPO

SECADO

Aclarado

Enxag.

400

600

8

00

30º

40º

LANA LA

ALGODON COTON

PARO

INICIO

Page 18

Description of operation

technical

15

KG - Drum capacity

6: 6 kg

KG options depending on circuit references /

washing machine model.

HOT WATER

0: Cold water

8: Hot water

If the circuit does not have this option it will

always be 0.

R.P.M. (Revolutions per minute).

These values depend on the hardware

reference and the KGs selected. 1400,

1300, 1200, 1100, 900, 800 ...

DOOR OPENING

0: WITHOUT door opening

8: WITH instant door opening

If the circuit does not have this option it will

always be 0.

RECIRCULATION

0: WITHOUT Recirculation Pump

00: WITH Recirculation Pump

If the circuit does not have this option it will

always be 0.

Circuit checking (see table 1)

Once the circuit has been configured, it is checked

by pressing the start/pause button for 3 sec. until

the digits stop flashing. After 3 sec. it exits the

configuration process, entering the TSS programme

entrando en el programa SAT (See table 1)

• Fagor T.S.S. Programme:

In order to check the operation of the washing machine’s electric components,

the T.S.S. programme can be activated by following these steps:

1.- General ON / OFF switch (LCD off)

2.- Press the start / pause button and keep it pressed

3.- Hold down the ON/OFF switch until the LCD screen lights up.

4.- Press and hold down the select spin button and wait approx. 2/ 3 sec., until the

letter is displayed on the screen

5.- Release all buttons simultaneously

6.- Press the spin button and wait until the digits on the screen (LCD) appear

(the last button on the right flashes).

7.- Press and hold down the start / pause button until all the digits

on the screen are flashing.

8.- The number 1 will be displayed on the screen – then follow the instructions in

table 1, below.

6

5

4

3

2

1

Page 19

Description of operation

technical

16

3.6.- Troubleshooting

3.6.1.- T.S.S. Programme

PROGRAMME

SELECTION MODE

TIME

(approx)

1

Drying Motor Power supply + Resistance 1

(3.6 Amp)

5

seconds

2

Drying Motor Power supply + Resistance 1 and 2

(7 Amp)

5

seconds

1

Water input via Pre-wash electrically operated

valve +

Movement of wash motor with inversion

15 sec.

2 Emptying + Spin 6 min.

3

Water inlet via the electrically operated valve for

washing until wash level is reached

pressure

switch

level

4 Heating resistance activated until 40 ºC is reached 10 min.

5

Water intake through the three electrically

operated valves

5 sec.

Emptying + movement of wash motor with

inversion

1.5 min.

STOP

The programme ends and the selected wash

programme is displayed

Note: Whenever it is necessary to go on to the next step, press the start/

pause button or turn the programme selector one position towards the right or

left.

Once the TSS programme has ended, the programme may be repeated by

pressing the START button.

Page 20

Description of operation

technical

17

3.6.2.- Seguridades criterios

SAFETY

MECHANISMS

FAULT CONDITION WASHER ACTION RESET

(End of safety)

FILLING

F01

EV ON 8 min. and PN

OFF (empty)

(except in reliability

programme)

It remains on pause with

door lock ON

Any of these conditions

resets the safety:

1. – Power is lost (supply

or ON/OFF switch).

2.- Change of programme

selector position.

UNBALANCED

F03

Detects imbalance in

18 attempts (15 min)

of low imbalance level

(see spin table)

It performs 2 attempts

with the high imbalance

level, limiting the speed

to C1.

Even if it spins at this

speed, it will indicate the

fault (see spin table).

NTC

F05

NTC in short circuit or

open circuit It performs the selected

programme but without

heating

NO HEATING

F06

B < 5º C / 15 min.

(excepto en programa

fiabilidad)

EMPTYING

F02

EB ON 6 min. and PN

ON (full)

STOP

(End of programme)

OVERFULL

F07

Drainage pump cuts

out or loses electricity

supply

F07

Electronic operated

valve cuts out

DOOR LOCK

F04

Door lock ON and

also detects failure

of both control triacs

of the door lock (both

open)

PROGRAMME

SELECTOR

F08

Selector in short

circuit or open circuit

Performs DELICATE cold

programme (only in User

Mode)

MOTOR

F09

Tachogenerator

motor lock fault (three

consecutive attempts) STOP

End of programme

Door lock always closed

INVERSION

WITH MOTOR

STOPPED

F10

Does not invert the

direction until the

motor stops (Max.

time (1 min.)

The fault indicator disap-

pears, as in previous

cases but the door lock is

kept closed.

To unlock it, keep it OFF.

B= pending increase in temperature when heating

Page 21

Description of operation

technical

18

3.6.3.- Imbalance Detection

DETECTION LEVEL WHEN WASHING 650 gr.

DETECTION LEVEL FOR LOW SPIN 750 gr.

DETECTION LEVEL FOR HIGH SPIN 1520 gr.

Note: These data are for a belt tension of 120 Hz and a SELNI motor

Function in the stop programme end

While PN is kept off

(empty)

Door lock OFF & Pump OFF.

Power failure: It is ready to start a new programme

(pause status).

It is in PAUSE status.

When Start is pressed: restarts a new programme

While PN is kept on

(full)

Door lock OFF & Pump in cycles:

(1 minute On , 1 minute OFF)

In case of overflow, the first pump cycle is:

(6 minutes On , 1 minute OFF)

Power failure: stays in the same situation.

It is always in START status.

When Start is pressed: stays in the same situation.

Will show fault F2 while this condition exists.

Memory function for power cuts

Maintains programme memory for at least 2 hours.

When spinning, the step times are always reset

Changes in the programme selector

A programme change means that the programme will start again from the starting

position.

Page 22

Description of operation

technical

19

3.6.4.- Imbalance Operation

1. - Spin attempts

If an imbalance is detected, the present phase will restart at second 25.

The number of attempts is limited to 18 (15 minutes).

After 18 spin attempts, it checks whether the imbalance level is lower than the high

imbalance level (1520 g).

If it is lower, follow the spin sequence but limit the speed to C1 (minimum spin speed

position on the rpm selector).

The number of attempts here is 2. If it also fails to start after these two attempts,

move to the next programme step.

The spin time indicated in the steps of the electronic programmer is not reduced by

the spin attempts in which an imbalance is detected.

2. - Reading the pressure switch

If the pressure switch is activated when the spin peak between imbalance readings

1, 2 and 3 is reached, the machine continues to spin normally until the next

imbalance reading.

If the pressure switch is activated during any other spin, the motor stops and wait

until you read “empty” on the pressure switch. The current phase will then restart.

The spin time indicated in the steps of the electronic programmer is not reduced by

waiting to read “empty” on the pressure switch

3.- Spinning in the TSS programme

Spinning in the TSS programme does not include the fi rst 42 seconds of the spin

cycle.

4. – Skip spin

It will perform a Very Delicate Spin for 60 seconds.

Page 23

Description of operation

technical

20

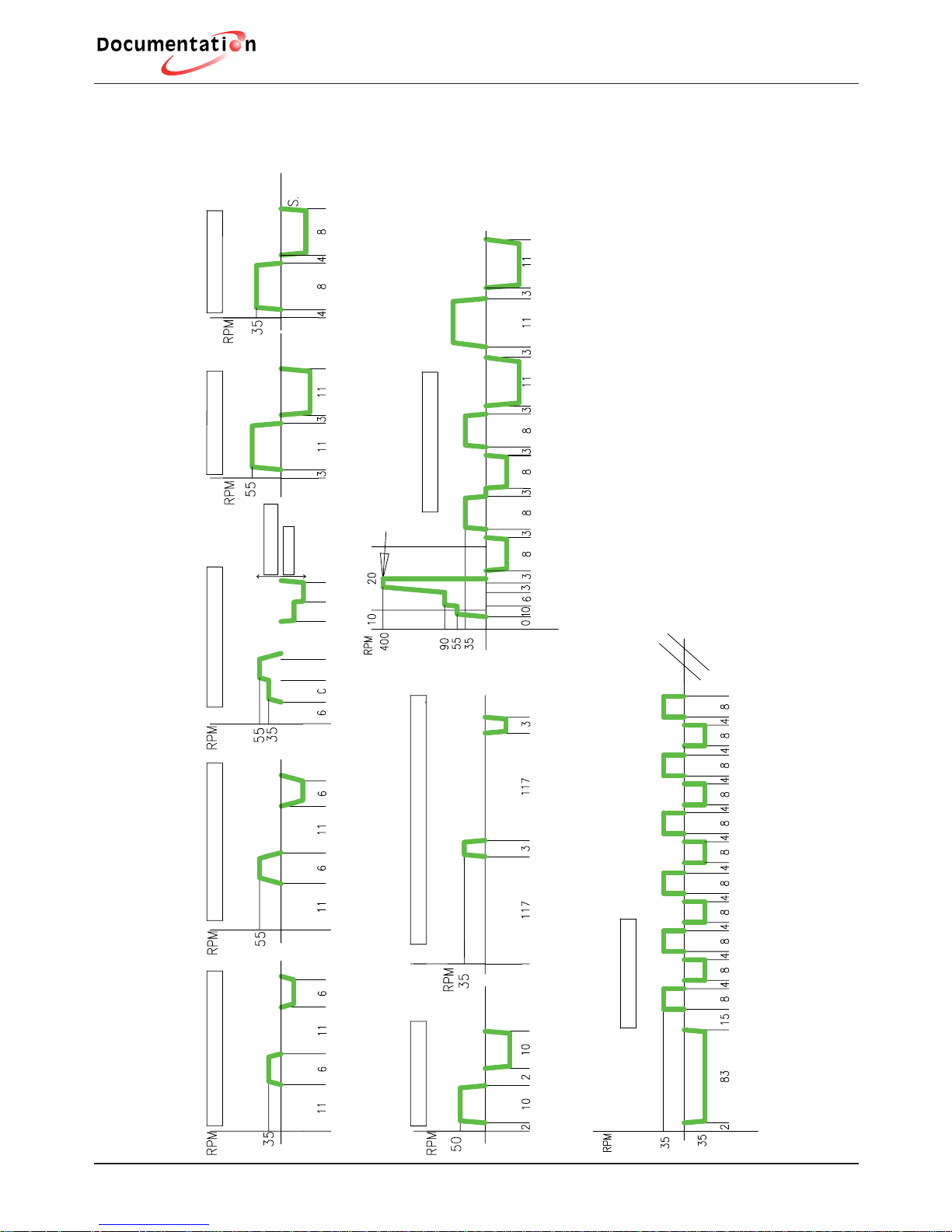

Wash vibrations

SEMI DELICATE VIBRATION

SEMI-DELICATE VIBRATION

SUPER VIBRATION

PLUS VIBRATION

FLOT VIBRATION (max. time 2 hours)

NON-DETECTION OF

OVERFLOW AREA

ANTICLOCKWISE

CLOCKWISE

NORMAL VIBRATION

VERY DELICATE VIBRATION

T.S.S. VIBRATION

EXTRA VIBRATION

SEC.

SEC.

SEC.

SEC.

SEC.

SEC.

SEC.

SEC.

Page 24

Description of operation

technical

21

Easy iron phase

NORMAL SPIN AND EASY IRON /ELECTRONIC WASHING MACHINES E2002

PHASE 0 EASY IRON

PHASE 1 EASY IRON

PHASE 2 EASY IRON

PHASE 3 EASY IRON

MACHINE MODEL

RPM

SELECTOR

IMBALANCE TEST

IMBALANCE TEST

IMBALANCE TEST 1 and 2

IMBALANCE TEST 1 and 2

Page 25

Description of operation

technical

22

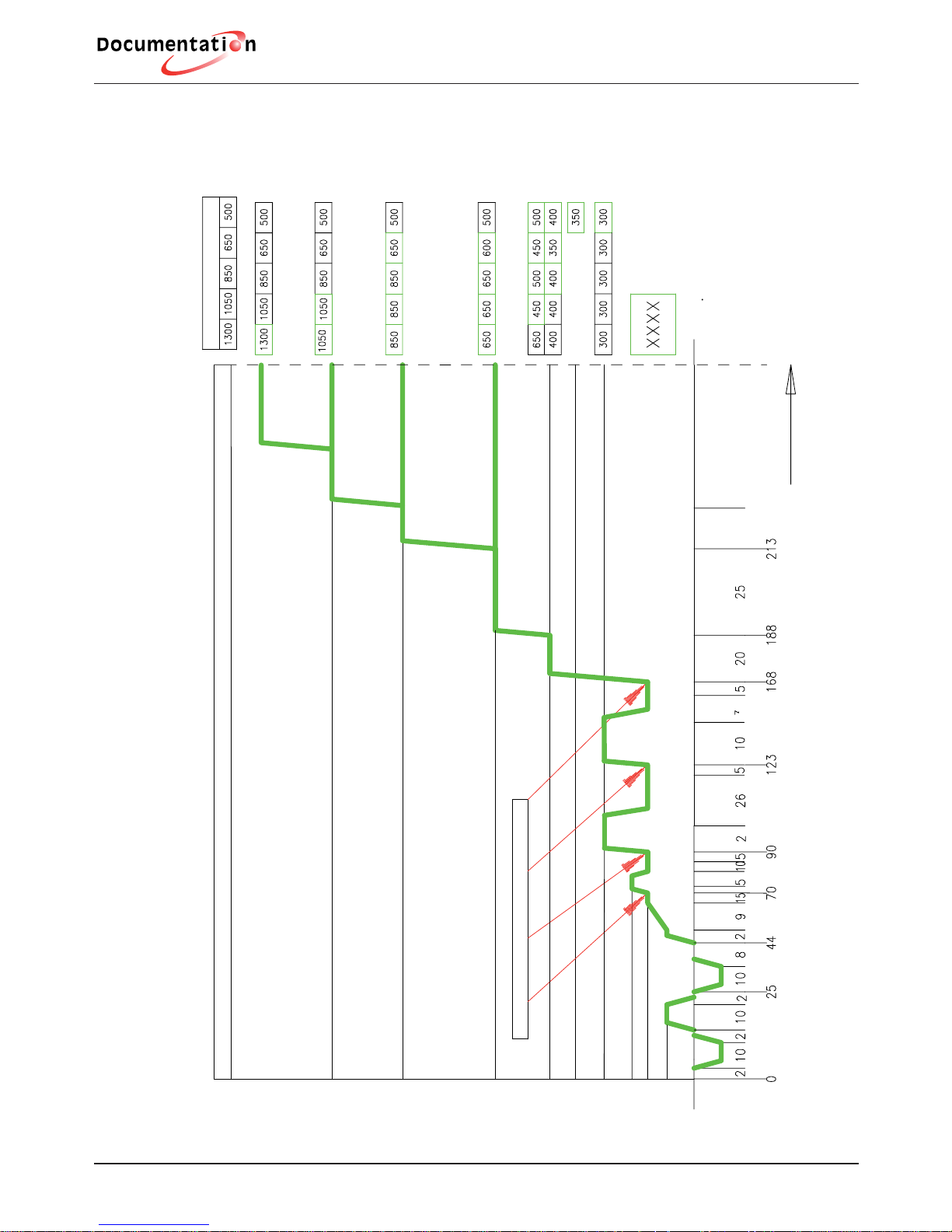

Normal spin diagram

PHASE 0 NORMAL SPIN

Step 7

Step 6

Step 5

Step 4

Step 3

Step 2

Step 1

Step 0

IMBALANCE TEST 1, 2,

3

RPM SELECTOR

POSITIONS

SEC

Depending on

the programme

140

35

90

RPM

MACHINE MODEL

Page 26

Description of operation

technical

23

3.7.- Assembly and disassembly instructions

(A) Disassembly of the Evoluta Condensation Chamber

Undo the three screws that fi x the condensation chamber to the drum (Thor

screws)

Disconnect thermostat cables

Disconnect fan motor cables

Loosen the 2 screws which hold the Evoluta to the Muffl er Duct

Remove the anti-return duct (bracket)

(B) Changing the Fan Motor

Remove the Evoluta condensation chamber (A)

Undo the 5 fi xing screws

Remove the fan (take care, as the central bolt has a left-hand thread)

Undo the three screws which fi x the fan to the evoluta cover

(C) Changing the single cycled Thermostat

Remove the Evoluta condensation chamber (A)

Remove the fan motor

Undo the thermostat fi xing bolt (this bolt is inside the Condensation chamber)

N/C 85 degrees

(D) Change Element – Double Thermostat

Remove the Evoluta Condensation chamber (A)

Undo the three fi xing screws for the upper counterweight

Loosen the two screws which hold the Evoluta to the Muffl er Duct

Put a wedge support in between the unit and the base of the upper coun

terweight to raise up the Counterweight-Chamber

Loosen the two screws which hold the double thermostat

Loosen the two screws which hold the element

It is advisable to fi t a new seal to the newly installed element

Page 27

Description of operation

technical

24

(F) Changing the Muffl er Duct

Loosen the screws which hold the Counterweight to the Muffl er Duct

Loosen the two screws which hold the Chamber-Evoluta to the Muffl er Duct

Undo the three fi xing screws for the counterweight

Disconnect the electric cables

Page 28

Description of operation

technical

25

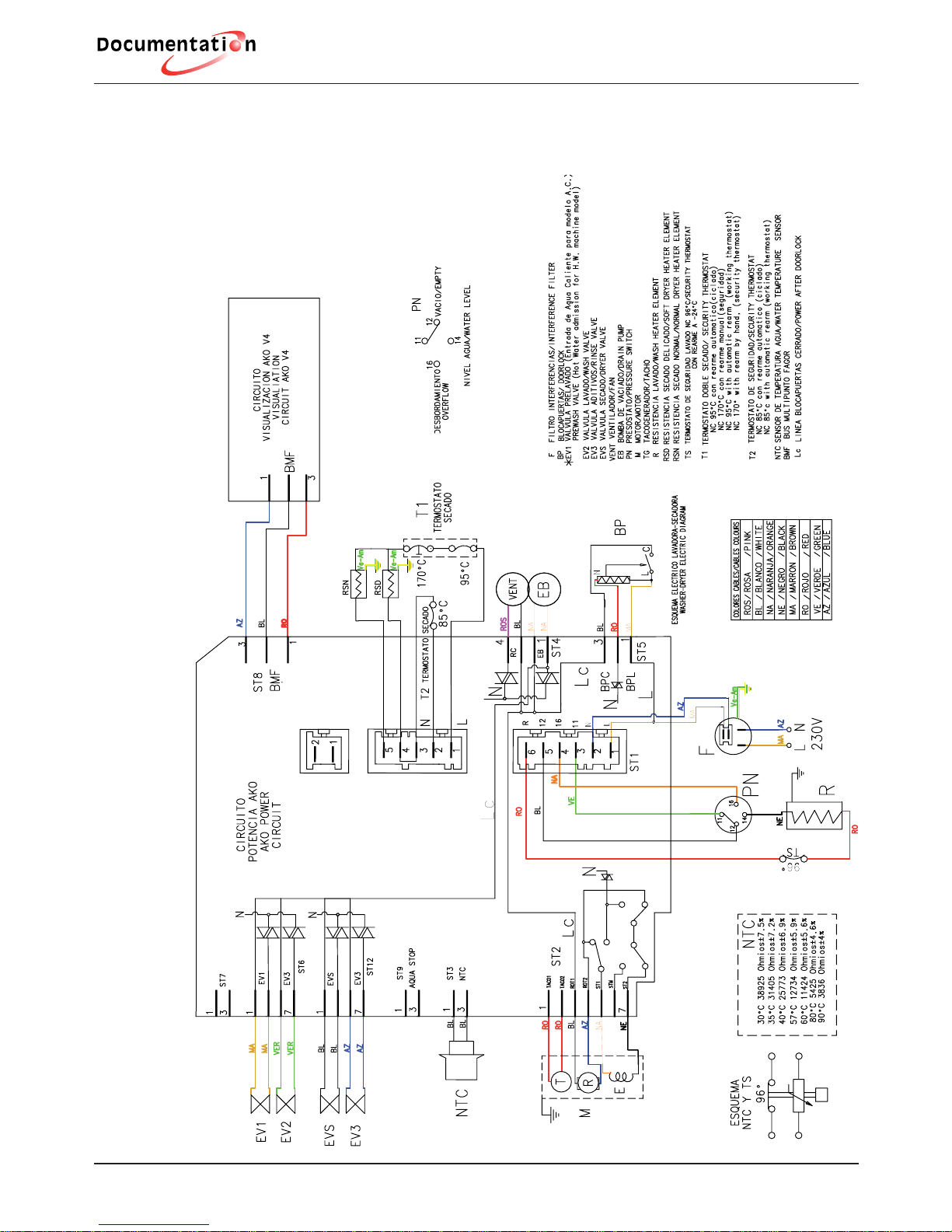

3.8.- Drawings and diagrams

Page 29

© FAGOR ELECTRODOMESTICOS, S.COOP. 2006

Bº San Andrés, s/n

20500 Mondragón (Gipuzkoa)

Spain

Loading...

Loading...