Page 1

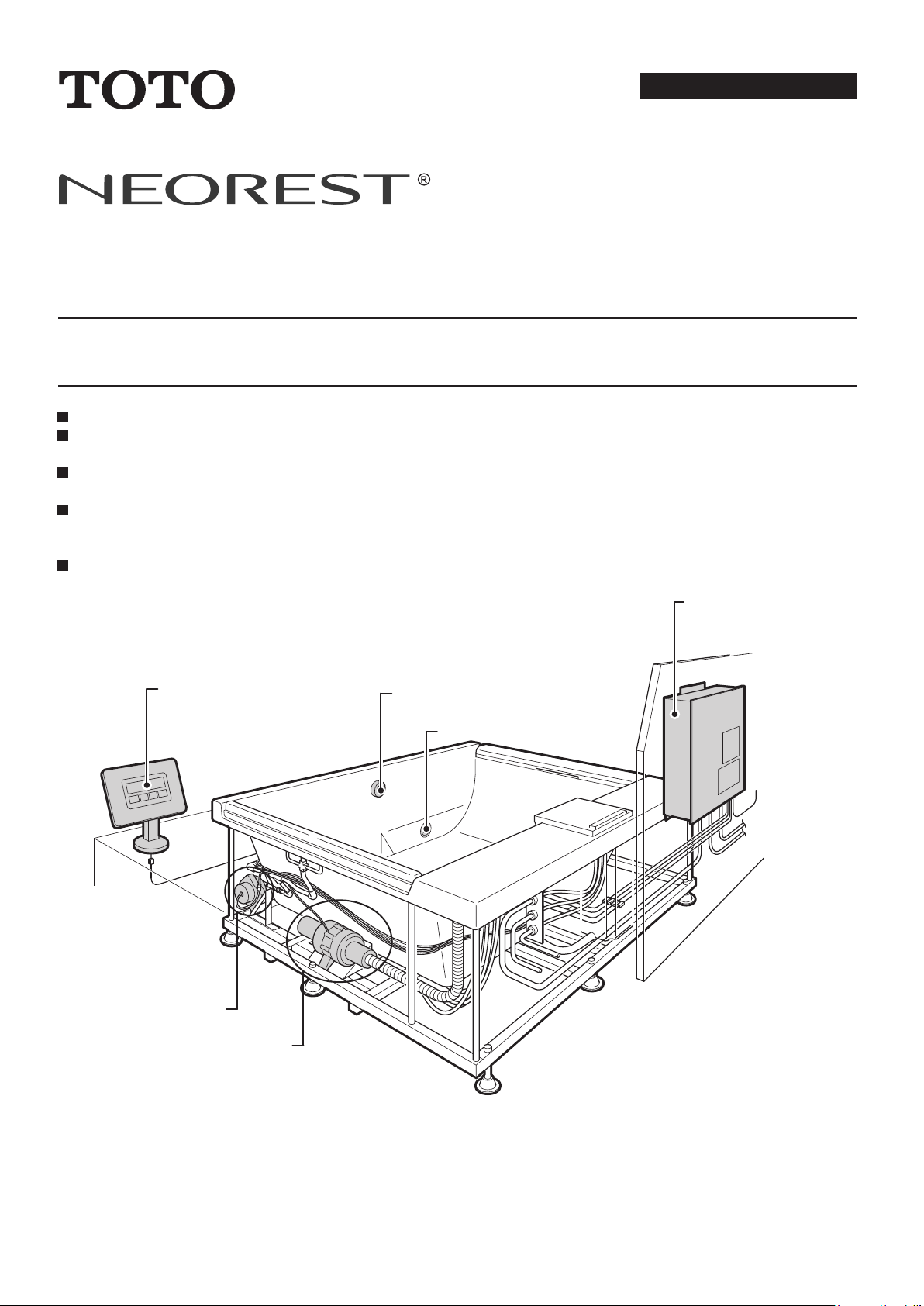

Function module

Controller stand

Overflow fitting

Pump

Blower

Underwater illumination

Installation Manual

AIRBATH™

Please install the product properly, in accordance with the descriptions in this manual so that full use can be made

of the product's functions.

After installing the product, please tell the customer how to use the product fully.

Thank you for choosing to use the Toto NEOREST®AIRBATH™ on this occasion.

Please install the product properly, in accordance with the descriptions in this manual so that

full use can be made of the product's functions.

Please be sure to discuss the procedures for the bathtub installation, the various phases of

construction for the function module, and the electrical and plumbing work before starting.

After completing the construction, please explain the operation to the customer and give this

Installation Manual and the accompanying "Instruction Manual" to the customer.

Note also: Please be sure to fill in the required items in the warranty.

Please be aware that the parts numbers listed in the Installation Manual may be revised.

Page 2

Page 3

Table of contents

1. IMPORTANT SAFETY INSTRUCTIONS .....................................................4 ~ 7

1-1 Bathtub............................................................................................................................5

1-2 Function module..............................................................................................................6

2. Contents of set ..........................................................................................8 ~ 9

2-1 Bathtub ............................................................................................................................8

2-2 Cables..............................................................................................................................8

2-3 Controller Stand...............................................................................................................9

2-4 Function module..............................................................................................................9

3. Dimension Drawings and Specifications ............................................10 ~ 12

3-1 Bathtub, Controller stand and Function Module............................................................10

3-2 List of Specifications ....................................................................................................12

4. Installation Procedure ....................................................................................13

5. Installation Precautions .........................................................................14 ~ 16

5-1 Bathtub ..........................................................................................................................14

5-2 Function module............................................................................................................15

5-3 Clean-up Shower Installation Conditions ......................................................................16

5-4 Function module installation locations ..........................................................................17

6. Installation requirements .......................................................................18 ~ 39

6-1 Building a base for the bathtub ~ seating the bathtub ..................................................18

(1) Building a base .............................................................................................................................18

(2) Plumbing and connecting the drain pipes ....................................................................................18

(3) Seating the bathtub.......................................................................................................................19

6-2 Finishing ........................................................................................................................20

(1) Fixing the bathtub in place............................................................................................................20

(2) Plumbing and connecting the hot/cold pipes and the fill-tub pipe ................................................20

(3) Connecting the cables ..................................................................................................................20

(4) Finishing the tiles ..........................................................................................................................21

6-3 Controller stand installation ...........................................................................................22

(1) Marking the pilot hole, drilling the hole and installing the plug.....................................................22

(2) Attach the base .............................................................................................................................23

(3) Install the slip ring .........................................................................................................................24

(4) Controller stand installation ..........................................................................................................25

6-4 Function module installation..........................................................................................26

(1) Advance preparation.....................................................................................................................26

(2) Function module installation .........................................................................................................26

(3) Positioning of holes for function module installation screws ........................................................27

(4) Function module installation .........................................................................................................28

(5) Plumbing the equipment ...............................................................................................................28

(6) Inspecting for leaks in the fill-tub plumbing ..................................................................................29

(7) Plumbing the hot, cold and fill-tub pipes.......................................................................................30

(8) Electrical work...............................................................................................................................31

6-5 Confirmation and trial operation ....................................................................................33

3

Page 4

1. IMPORTANT SAFETY INSTRUCTIONS

Please be sure to

observe the

warning and

caution symbols!

READ AND FOLLOW ALL INSTRUCTIONS. SAVE THIS INSTRUCTION with your instruction

●

●

manual.

INSTALL TO PERMIT ACCESS FOR SERVICING.

INSTALL THIS UNIT IN ACCORDANCE WITH THE NATIONAL ELECTRICAL CODE (NEC) NFPA 70 AND CANADIAN

ELECTRICAL CODE, PART 1.

Please read these "Important safety instructions" carefully before beginning the installation work and install the product

correctly.

This Installation Manual has a number of different symbols intended to allow proper and safe installation of the product, to

prevent harm to the end user, to prevent damage to property and to prevent harm to construction workers. These symbols

have the following significance.

Symbol

Warning

Caution

The following symbols can be found in the Installation Manual or on the product and are intended to help the construction

worker install the product safely and properly. Please read the descriptions carefully and install the product correctly.

Symbol

Indicates "prohibited" activity that must not take place.

Indicates "required" activity that must take place.

After completing the installation, please check for safety problems such

as loose fittings or leaks.

The Instruction Manual that is packed with the product is a valuable

source of product information to help the end user use the product

safely and correctly. Please take good care of it and keep it from getting

lost or soiled. After the construction is complete, please give the manual

to the end user or the construction superintendent.

This symbol indicates that errant handling after disregarding this symbol could result in death

or serious personal injury.

This symbol indicates that errant handling after disregarding this symbol could result in

personal injury or cause physical damage.

Meaning

Meaning

4

Page 5

1-1 Bathtub

Install the product securely, in accordance with the

Installation Manual.

Always do this

Improper installation can cause leaks that damage or

ruin household property.

Do not drop or strike the bathtub with hard objects.

Warning

Prohibited

Prohibited

Always do this

Always do this

Prohibited

Doing so could crack or scratch the bathtub or cause leaks that damage or ruin household property.

Do not stand on bathtub while working.

Doing so could cause one to slip and fall or could otherwise damage the product.

Install the drainage pipes securely, in accordance with

the procedure.

Improper installation could lead to leaks that damage

or ruin household property.

After opening the box, please immediately dispose of

unneeded packaging.

Wooden frames, nails, cardboard or sealing straps

could cause injury.

Additionally, children or pets might put vinyl bags over

their heads, leading to unanticipated accidents.

Do not install on or near gas, kerosene or other combustible or flammable substances. Otherwise a fire

could result.

5

Page 6

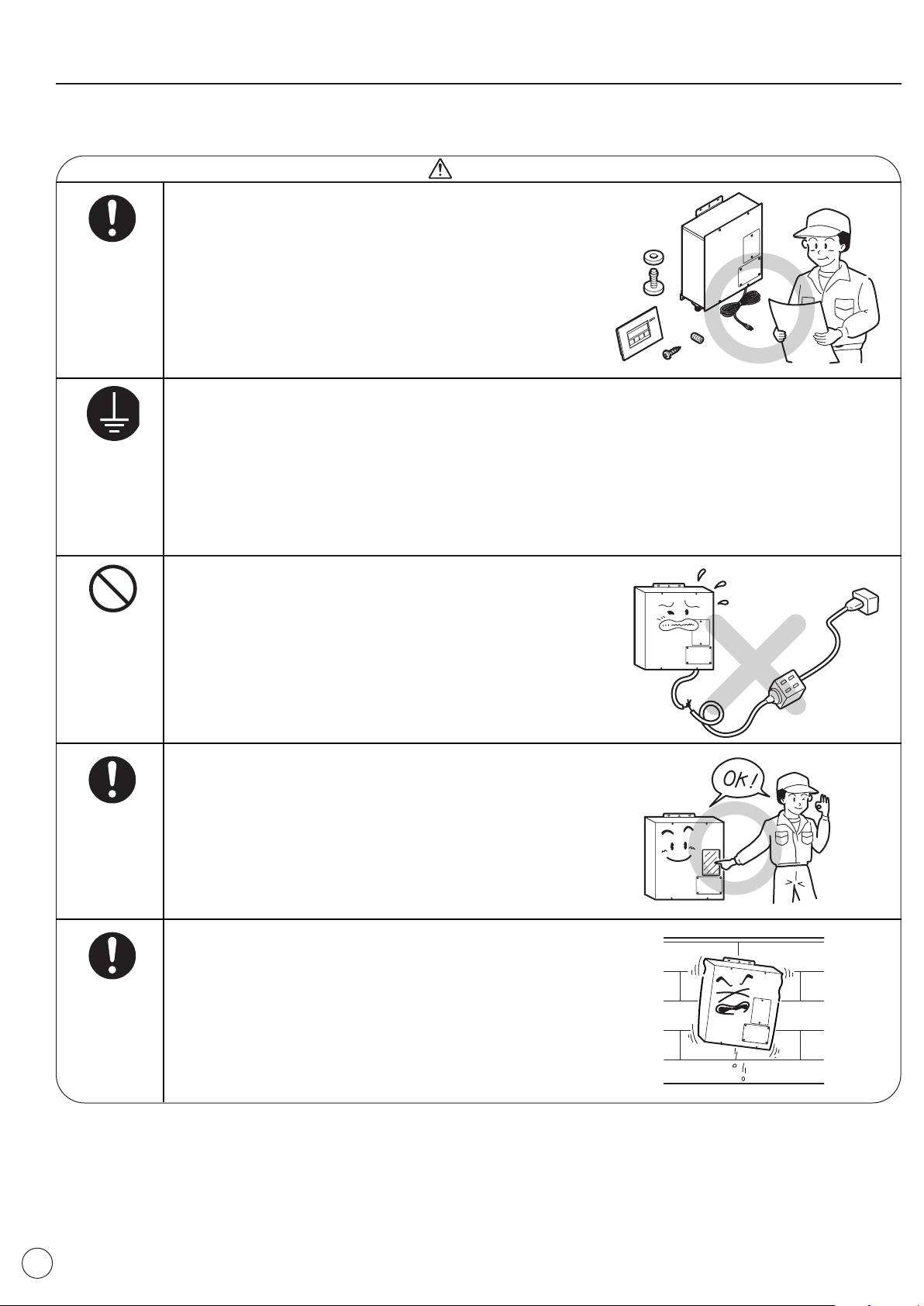

1-2 Function module

Install securely, in accordance with the Installation

Manual.

Always do this

Improper installation can lead to electric shocks or fire.

Additionally, it could cause water leaks that damage or

ruin household property.

Be sure to have a qualified individual (certified electrician) carry out all electrical work in accordance

with the relevant laws and regulations.

Warning

Connect Ground

Prohibited

Always do this

Improper work can lead to problems or short circuits.

All electrical connections must be in accordance with local codes, ordinances, and the National

Electrical Code (NEC).

If you are unfamiliar with methods of installing electrical wiring and appliances, you should secure the

services of a qualified licensed electrician.

Do not modify the power supply cord, use it with an

extension cord or combine it with other equipment

using multiple plugs.

Doing so could lead to shocks, overheating or fire.

After the installation, test the ground fault circuit

interrupter (GFCI) protecting this appliance and

periodically check it in accordance withe the

manufacturer's instructions.

An improperly functioning GFCI could lead to electric

shock or fire.

6

Always do this

Be sure that the equipment is installed in a stable

place with sufficient load-bearing strength, as set forth

in the Installation Manual.

Improper installation could cause the equipment to fall

or topple over, causing injury.

Page 7

Always do this

Always do this

Prohibited

Warning

When installing the function module using a metal lath

or wire lath support, be certain not to connect the

function module and support electrically.

Doing so could lead to electric shock, overheating or

fire.

CAUTION: To reduce the risk of electrical shock

disconnect power before servicing from the supply

circuit.

Do not install on or near gas, kerosene or other combustible or flammable substances.

Otherwise a fire could result.

Prohibited

Always do this

Prohibited

Always do this

Do not install in locations with high humidity, such as bathing areas or where water might pool.

Otherwise product problems or electric shock could result.

Warning

Always implement the countermeasures for preventing freezing.

It is possible that the pipes could freeze, rupturing the pipes or equipment.

Use no water other than standard tap water.

The use of well water could cause corrosion, which could lead to leaks.

If installing the product in a location where damage from water leaking from the function module is

anticipated, be sure to waterproof the floor.

If there were to be a leak, it could damage the floor or floors below.

7

Page 8

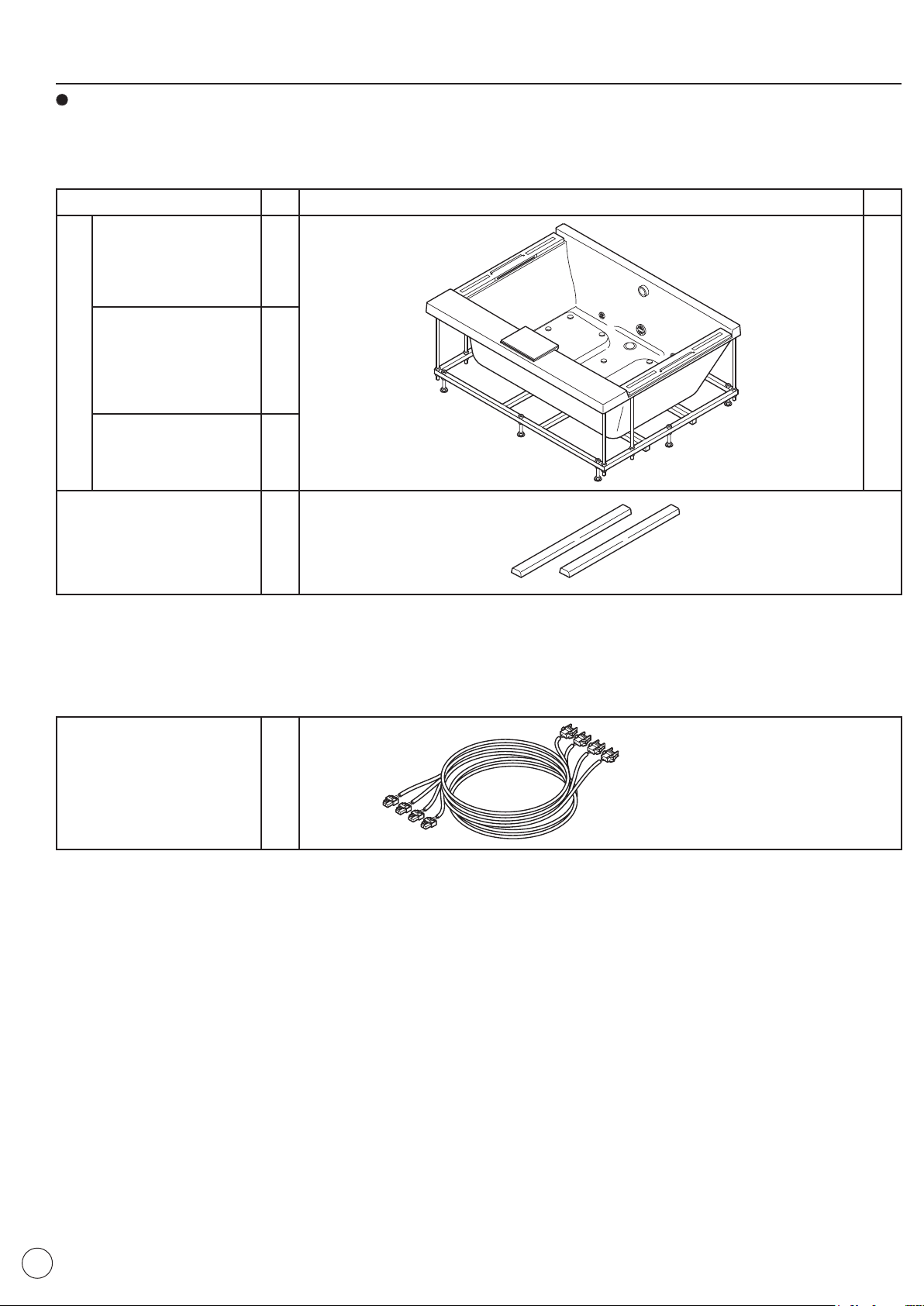

2. Contents of set

After unpacking the product, please confirm the numbers of parts as shown below.

2-1 Bathtub

Part Name Qty Shape of Bathtub Qty

Installation Manual 3

Owner's Manual 3

Cleaning tool

Headrests

2-2 Cables

Junction Cables 3

1

1

2

<Breakdown>

*Power supply junction cable

*Signal junction cable

*Air blower junction cable

8

Page 9

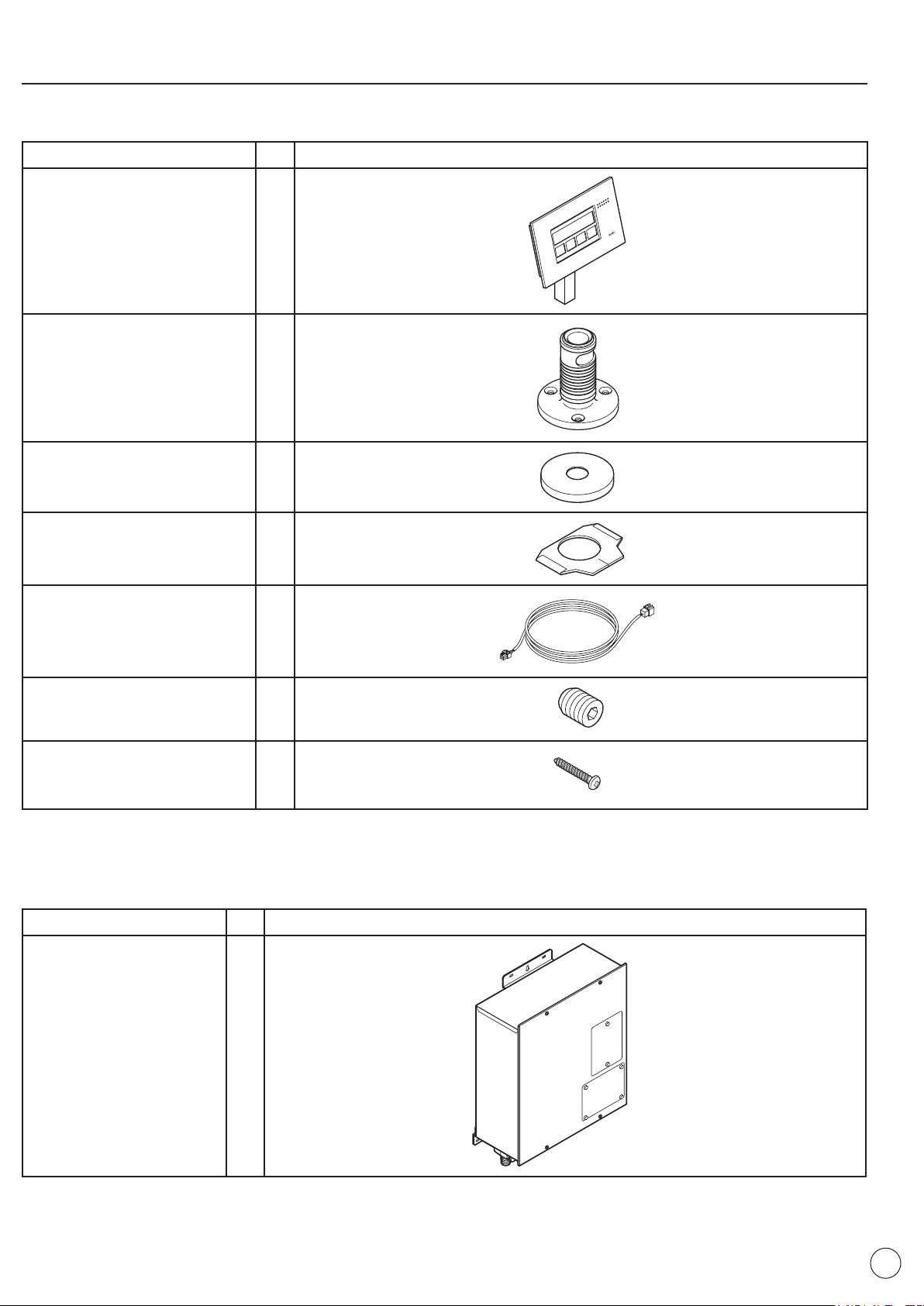

2-3 Controller stand

Product Name Qty

Controller stand assembly 1

Base assembly 1

Base cover 1

Slip ring assembly 1

Controller splitter cord 1

Set screw with hexagonal hole

M4 x 4 long

Phillips head tapping screw

4 x 30 (holds base in place)

(with O-Ring safety sheet)

(Slip Ring inside)

2

3

(1 Spare)

2-4 Function module

Part Name Qty

Function Module

(including mounting

hardware)

1

9

Page 10

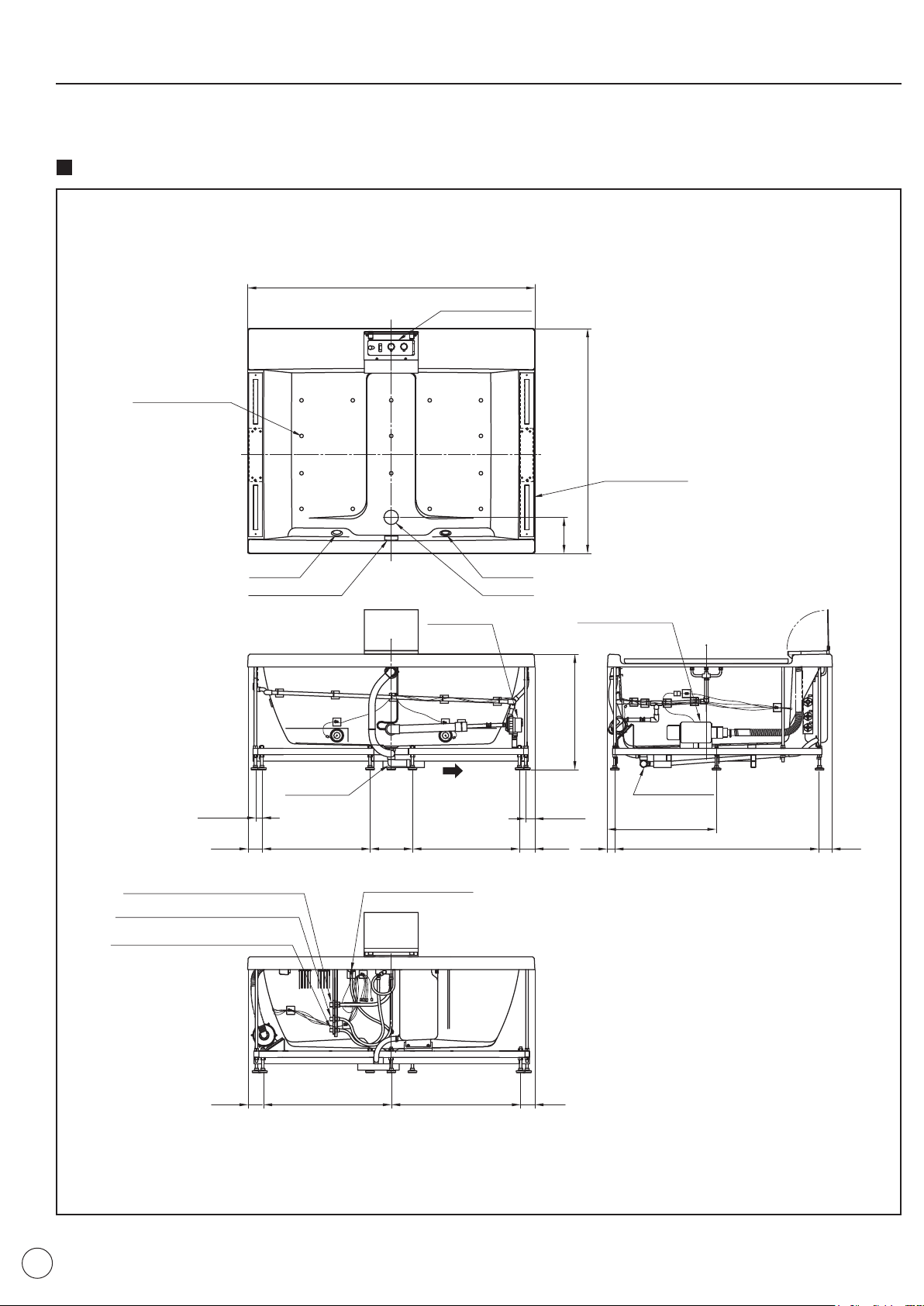

3. Dimension Drawings and Specifications

Air blower nozzle

(15 positions)

Headrest base

Air blower

5

2

7

1800

0

141

722

684

81128247

56

56

9667126667196

9680480496

Typ

Typ

Typ

Shower Box

Underwater lighting

Drain valve

Underwater lighting

Overflow

Shoulder

warmer pump

Drain elbow

Drainage

direction

Drain Fitting

for 1-1/2”

nominal pipe

Bath connection (TUB) (NPT 3/4)

Shower connection (H) (NPT 1/2)

Shower connection (C) (NPT 1/2)

Water Level Sensor

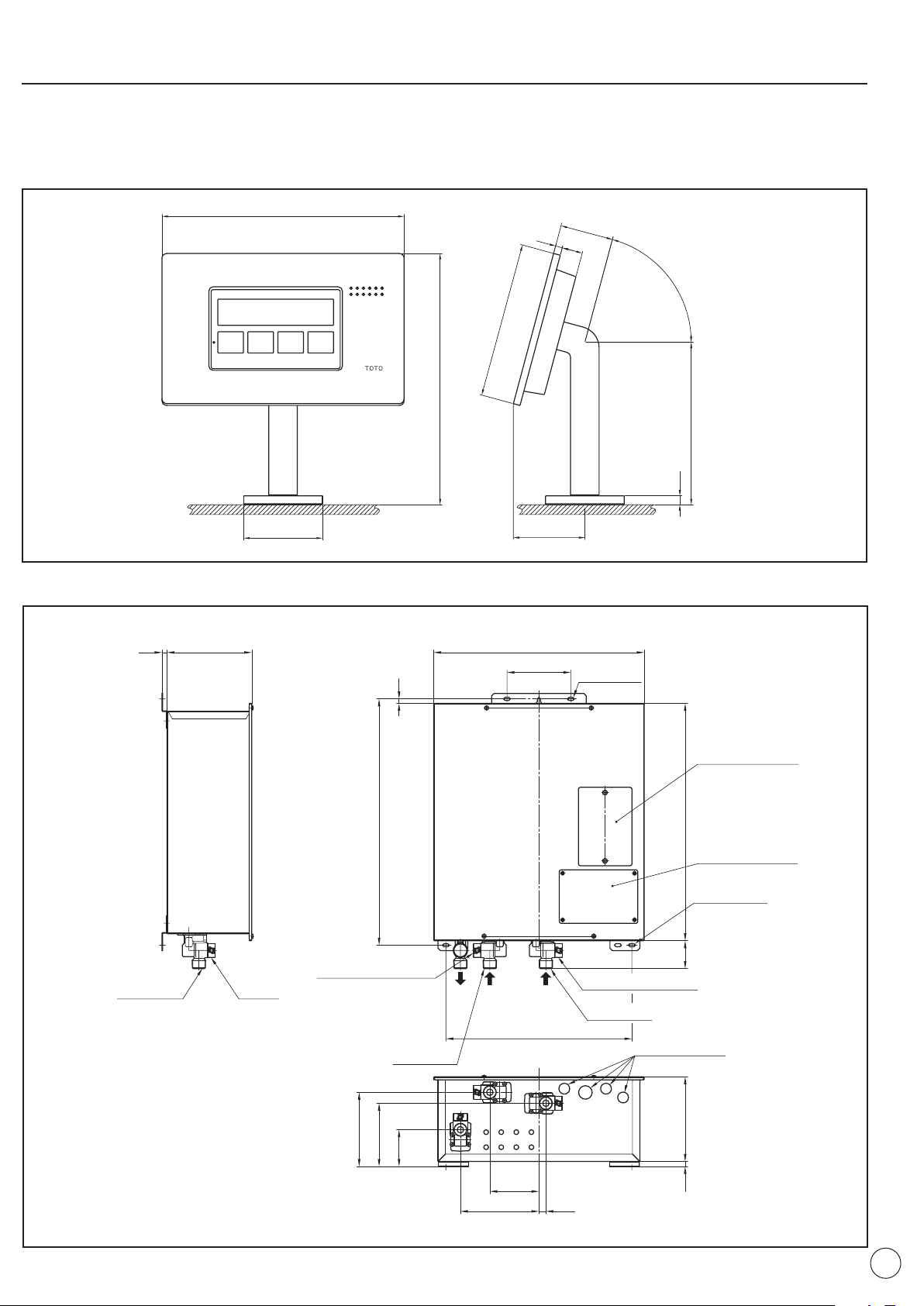

3-1 Bathtub, Controller stand and Function Module

Bathtub

10

Page 11

■■

73

5

52

246

7

1

2

85

1

φ80

9

°

5

7

4

5

5

6

1

HCTUB

Tub Connecting Port

Cold Water Supply Connecting Port

Drain Valve with Strainer

Hot Water Supply Connecting Port

Drain Valve with Strainer

Cord Access Port

Inspection Port (GFCI)

Inspection Port

(Line Connections)

6×14 Slots

6×14 Slots

373

49

4

94

1

721

4

7

99

158 14

0

710

1

674

6

5

128

42217010

9

Drain Valve

D

C

B

A

A - Supply circuit

B - Air blower

C - Controller stand

(remote)

D - Water sensor

Controller stand

■■

Function Module

11

Page 12

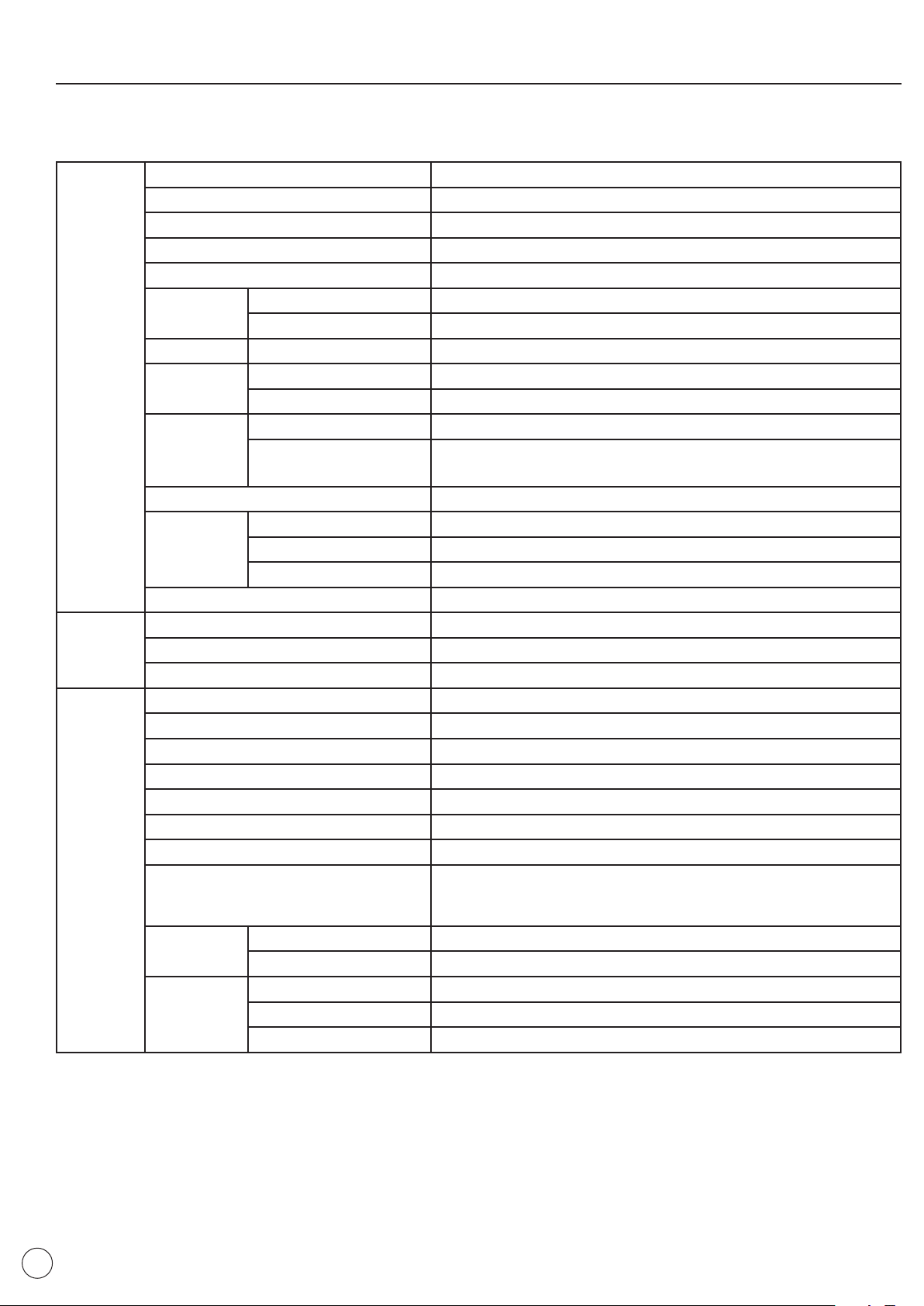

3-2 List of Specifications

External Dimensions 70 7/8" x 55 1/2" x 28 1/2" (1800 mm W, 1410 mm D, 725 mm H)

Weight 353 lbs. (160 kg)

Capacity 161 Gallons (610 L) to overflow line

Drain time 9 minutes 15 seconds

Material Acrylic Synthetic Marble

Number of drains 1

Tub filling flow rate Maximum 35 L/min.

Intake ports 1

Outlet ports 2

Lighting modules 2

Colors

Hot supply (shower) NPT 1/2

Cold supply (shower) NPT 1/2

Fill-tub (hot) NPT 3/4

Hot water supply 140 to 158°F (60 to 70°C)

Cold water supply 32 to 86°F (0 to 30°C) (No freezing)

Hot water supply NPT 3/4

Cold water supply NPT 3/4

Hater water NPT 3/4

AIRBATH™

Controller

Stand

Function

Module

Tub filling

Air blower Number of jets 15 on the bottom of the AIRBATH™

Shoulder

warmer

Underwater

lighting

Water pressure used (Clean-up shower) 0.08 to 0.75 MPa

Connecting

port diameter

Other Fill-tub fittings, 2-handle tube cleaning shower, headrest

Outside dimensions 9 5/8" x 4 1/2" x 10" (246 mm W, 113 mm D, 255 mm H)

Weight 6.2 lbs. (2.8 kg) (including the controller)

Rotation angle 90 °

Outside dimensions See dimensional diagrams

Weight 37.5 lbs. (17 kg)

Rated voltage 120 VAC

Rated frequency 60 Hz

Rated current 5.9 A

Rated power consumption 710 W

Installation location Indoor

Water pressure

water

temperature

Connecting

port diameter

3 types of patterns, 10 individual colors (controlled from the

function module)

29 to 108.75 psi (0.20 to 0.75 MPa) (The pressure differential of

the cold water is to be greater than that of the hot water and kept

within 0.lMPa.)

12

Page 13

4. Installation Procedure

6-1 Building a base for the bathtub ~ seating the bathtub (P. 18, P. 19)

(1) Building a base (P. 18)

(2) Plumbing and connecting the drain pipes (P. 18)

(3) Seating the bathtub (P. 19)

6-2 Finishing (P. 20, P. 21)

(1) Fixing the bathtub in place (P. 20)

(2) Plumbing and connecting the hot/cold pipes and the fill-tub pipe (P. 20)

(3) Connecting the cables (P. 20)

(4) Finishing the tiles (P. 21)

6-3 Controller stand installation (P. 22)

(1) Marking the pilot hole, drilling the hole and installing the plug (P. 22)

(2) Attach the base (P. 23)

(3) Install the slip ring (P. 24)

(4) Controller stand installation (P. 25)

6-4 Function module installation (P. 26 to P. 32)

(1) Advance preparation (P. 26)

(2) Function module installation (P. 26)

(3) Positioning of holes for installing the function module installation screws (P. 27)

(4) Function module installation (P. 28)

(5) Plumbing the equipment (P. 28)

(6) Inspecting for leaks in the fill-tub plumbing (P. 29)

(7) Plumbing the hot, cold and fill-tub pipes (P. 30)

(8) Electrical work (P. 31, P. 32)

6-5 Confirmation and trial operation (P. 33 to P. 39)

13

Page 14

5. Installation Precautions

(Doing so could cause damage.)

(Doing so could cause damage.)

(Doing so could cause damage.)

(Doing so could cause damage.)

(Doing so could discolor the tub.)

5-1 Bathtub

Bathtub

●●

Before installing the bathtub,

check the bathtub itself and the

1

plumbing for problems.

Do not place lit cigarettes on

the bathtub or direct the flame

4

of a blowtorch at it.

Do not place anything heavy on

the tub or anything in the tub for

2 3

standing on.

Do not install the tub with the

rim surface as its sole support.

5 6

Do not remove the protective

sheet on the tub. Also, the

bathtub should be protected

with cardboard or other material

until the bathroom construction

is finished.

Do not install the bathtub

outdoors or in a location where

the sun will hit it all day

(solarium or similar room).

When transporting the bathtub, do not carry by the hoses or plumbing or strike it with anything hard.

7

● When disposing of a NEOREST®AIRBATH™ , please ask a certified disposal professional to dispose of it.

14

Page 15

5-2 Function module

Power supply cord (6.6 ft (2 m))

Junction cable

(23 ft (7 m) or 49 ft (15 m))

• Signal junction cable

• Air blower junction cable

• Shoulder warmer junction cable

• Underwater illumination

junction cable

Fill-tub route

Cold water

supply route

Hot water supply route

Drain Valve

Water heater

Hot water supply

Cold water

NPT1/2

NPT3/4

NPT3/4

Drain Pipe

The function module requires a hot water supply temperature of at least 140°F (60°C). (No more than 158°F (70°C).

If the supply temperature of the hot water is too low, it won't be possible to fill the tub to the temperature setting on

the controller.

The function module mixes the supply of hot and cold water and runs hot water out of the fill-tub outlet, so the

temperature of the water flowing out will be lower than the temperature of the water being supplied to the function

module.

The pressure of the hot and cold water supplied to the function module must be at least 29 psi (0.20 MPa) (when

flowing). (No more than 108.75 psi (0.75 MPa)).

The pressure differential of the cold water is to be greater than that of the hot water and kept within

14.5 psi (0.10 MPa).

If the pressure is low, the water won't flow out like a waterfall. Additionally, it will take longer for the tub to fill with hot

water.

Supply Equipment Specifications

o Supply Pressure 29 to 108.75 psi (0.20 to 0.75 MPa)

o Supply Temperature 140 to 158°F (60 to 70°C)

o Hot water usage

• Max. temperature 113°F (45°C)

• Max. flow rate 9.2 gal/min. (35 L/min.)

• Max. capacity 145 gal. (550 L)

The diameter of the function module connector is NPT 3/4. Please do not make the diameter of the plumbing smaller

than the diameter of the connector to the function module.

The use of equipment below full capacity could lead to problems for the clients.

It is necessary to have space between the tip of the water pipe drainage. If not the water could backflow.

15

Page 16

5-3 Clean-up Shower Installation Conditions

● When attaching the Clean-up Shower, please observe the following conditions of use.

(1) Confirmation of water pressure

Supply hot/cold water pressure:

❈ If the supply water pressure exceeds 108.75 psi (0.75 MPa), please reduce the pressure to around 29 psi

(0.20 MPa) using a commercially available pressure-reducing valve.

Minimum required pressure: 11.6 psi (0.08 MPa)

{

Maximum water pressure: 108.75 psi (0.75 MPa)

(2) Confirmation of hot water supply temperature

● Please keep the hot water supply temperature no higher than 158°F (70°C).

Note also that for safety, we recommend a hot water supply temperature of 140°F (60°C).

● Please do not use steam in place of a hot water supply.

(3) Plumbing

● Please do not connect the hot and cold water backward.

Note also that in order to reduce resistance, the shortest distance possible should be used for the hot water supply

pipe from the hot water heater and insulation should be wrapped around the plumbing.

● Please implement countermeasures for freezing such as wrapping insulation around the pipes.

16

Page 17

5-4 Function module installation locations

Within 7m

Within 7m

Please locate the function module in a place where freezing and moisture from indoor water will not be a problem.

Please leave a space of at least 2 ft. (600 mm) in front of the equipment so that inspections or repairs can be made.

Also, please do not locate it on a second-story wall or other place without access.

Please locate the function module in a place that is strong enough to bear its weight and a margin (40 lbs (18 kg)).

Please take the following into consideration when deciding where to place the function module.

- The length of the cables to the equipment (pumps and the like) that will be installed with the bathtub

A 23 ft. (7 m) or 49 ft. (15 m) cable is provided.

- A height which allows the plumbing to be inclined so that the bathtub can be drained more easily when removing the

water.

Please install in a location that will not cause damage if there is water leakage.

If you install in a location that can cause damage please add water protection and appropriate drainage on the floor.

If the tub installation is downstairs the function module should be within 23 ft. (7 m) of the top of the tub (see diagram).

If the tub installation is upstairs the function module should be within 23 ft. (7 m) of the top of the tub (see diagram).

In this case the supplied water pressure should be 29 psi (0.20 MPa) above head pressure.

17

Page 18

6. Installation requirements

Inspection port

(within 15 inches)

Junction cable

Cold water

supply

Hot water

supply

Fill-tub pipe

1

00

or

m

ore

1

800

1

00

or

m

ore

5

00

or

m

ore

(In

spe

cti

on

por

t s

pace

)

0

1

4

1

1

0

0

Bathtub rim reference line

W

ithin

15 inches

W

ith

in

15

inc

hes

W

ith

in

15

inc

hes

(In

spe

cti

on

por

t s

pace

)

*B

athtub

ce

nte

r

m

odul

e

(In

spe

cti

on

por

t s

pace

)

*1

*1

(Inspection

po

rt space

)

1-1/2” Nominal Pipe

Arrange on site

Approximately

700 mm

Upper surface of rim

6-1 Building a base for the bathtub ~ seating the bathtub

(1) Building a base

Please allow at least 100 mm or more clearance beyond the external dimensions when determining the position of the

bathtub.

Please set up the hot/cold water supply pipes and the fill-tub pipe on the side with the inspection port.

Also, please set aside space for inspection ports at the rear of the bathtub center module or the function module

(pump) (one or the other of *1).

Please fit the hot/cold water pipes with anti-backwash valves and shut-off valves.

(2) Plumbing and connecting the drain pipes

For a directly connected drain

Please connect the plumbing to the drain fittings of the bathtub in advance.

18

All of the plumbing is to be arranged on site.

Please refer to the provided template (0GU5079).

Page 19

(3) Seating the bathtub

Connecting pipe

Cold water supply line (NPT 1/2)

Fill tub line (NPT 3/4)

Hot water supply line (NPT 1/2)

Level

Level

Adjuster leg

Lock nut

(Hexagonal)

● Please attach the plumbing that will connect the hot and cold water supplies and the fill-tub line to the bathtub.

● Please make the bathtub level.

● The feet of the bathtub are adjuster bolts, so please loosen the lock nut (hexagonal) and adjust it until it is level.

● After using a level to make fine adjustments to bathtub, please tighten the lock nuts on the adjuster legs.

19

Page 20

6-2 Finishing

Mortar Mortar

Tag

Connector

Controller Stand Connector

(see 6-3 Controller Stand Installation (4))

(1) Fixing the bathtub in place

● Please fix the bathtub in place using mortar or a powerful adhesive.

Caution: Please be careful not to get any mortar or adhesive on the bathtub itself.

(2) Plumbing and connecting the hot/cold pipes and the fill-tub pipe

● Please connect the connecting plumbing installed on the bathtub to the hot/cold water supply pipes and the fill-tub

pipe that were set up in advance.

(3) Connecting the cables

● Please connect the fill-tub unit and the connecting junction cables to the respective cables on the bathtub side.

❈ Check the tags on the junction cable and the bathtub-side cables when making the connections.

20

Page 21

(4) Finishing the tiles

Deck

Inspection port

(at least 15 x 15 inches)

Inspection port

(at least 15 x 15 inches)

Inspection port

(at least 15 x 15 inches)

Controller Stand Attachment Module

Tile insertion

Within

5 mm

Within

5 mm

Joint backing

material

Joint backing

material

Silicone

Silicone

Convoluted

Flexible

Tubing

Bathtub

within 3mm

Tile insertion

● Please build a deck around the perimeter with an apron and tiles.

❈ Before installing the deck, please fill the bathtub with water, test run it and check for leaks around the pipe

connections. Please refer to the POO concerning test runs.

❈ Before tiling the deck surface, determine the position of the remote control stand and insert a sheathing pipe for the

cable.

❈ Be sure to leave a gap in the space between the bathtub and the tiles and then fill in the gap between the bathtub

and the tiles using an alcohol-free type of silicone.

❈ Please arrange for a joint-backing material on site.

Also, when forming the deck apron, please be sure to affix the joint-backing material to the deck surface or the back

surface of the bathtub rim before putting the tub in place. It may not be possible to apply the joint-backing material

after the bathtub has been put in place.

21

Page 22

6-3 Controller stand installation

°54

°

54

Groove

Movable range of remote controller stand

❈ 45° to the left and right of the front

Front

Groove in base

Back of base

Drill

Pilot hole

Plug

Pilot hole

(1) Marking the pilot hole, drilling the hole and installing the plug

➀ Cut the conduit sheath for the wires that protrude from the surface of the deck.

➁ Place the base so that the conduit sheath stays in the center and, being careful of the installation direction, mark the

three places where the holes will be that will secure the base

❈ Please be careful of the position of the groove and the front during installation and fix it in place, keeping the

movable range of the remote controller in mind.

➂ Drill the pilot holes the size of the plug where the marks were made.

(Please choose plugs that fit the 4 x 30 Philips head tapping screws.)

➃ Check that the position of the hole is not in a hollow part of the tile

surface. If it is hollow, please fix it in place using an adhesive tapping

anchor.

➄ Place the plug in the pilot hole and pound it in.

➅ To keep water from seeping through, seal the gap between the plug and

the hole.

22

Page 23

(2) Attach the base

Deck

installation screws

Base

Power

Screwdriver

Protective sheet

Base

Base cover

➀ Use the screws that came with the base to attach it so that it faces the right direction.

Do not remove the protective sheet on the base.

• Doing so could cause problems or make the unit malfunction, due to debris or damage to the O ring.

Prohibited

• This will make it more difficult to install the slip ring and could bend or damage the slip ring.

➁ Attach the base cover.

23

Page 24

(3) Install the slip ring

Slit

Front surface

Slip ring holder

Back surface

Slit

Slip ring

Slip ring

Protective sheet

Place the slip ring on the base, being careful not to confuse the front and back surfaces of slip ring holder.

Be sure to attach the slip ring.

• Not installing it could bring the base cover and stand into contact and damage the base cover.

Always do this

Install the slip ring very carefully.

• If the slip ring becomes "stretched" or "misshapen", it may not perform its intended function.

Always do this

Remove the slip ring holder from the base while leaving the slip ring in place by tearing off the part of the slip ring

holder with the slit in it to the right and left.

Remove the protective sheet on the base.

Please remove the protective sheet carefully. Otherwise, the slip ring could become damaged or misshapen.

24

Page 25

(4) Controller stand installation

Controller

stand

Connector

Front

Allen head set screw

Front

Front

➀ After connecting the splitter cord that comes with the unit to the signal relay cable (6-2 Finishing (3)), remove it from

the base through the conduit sheath and connect it to the controller stand itself.

➁ Press the controller stand into the base.

➁ Tighten the included Allen head set screw in the hole in the back of the controller stand. After turning the screw until it

stops, turn it 180 to 360° backward from where it stopped turning.

❈ Please be careful not to let the screw protrude when doing so.

Always turn back the screw.

• Neglecting to do so could keep the remote controller stand from moving back and forth.

Always do this

25

Page 26

6-4 Function module installation

Bathtub

Bathtub

Water

Hot

water

Drain

Water removal valve

Anti-backwash valve

Anti-backwash valve

Shut-off valve

Shut-off valve

Function Module

(1) Advance preparation

➀ Install shut-off valves and anti-backwash valves on the hot and cold water supply pipes.

➁ Run the pipes and cables for the connection between the bathtub and the function module.

❈ Install a water removal valve on the fill-tub pipes and make arrangements for a suitable water drainage process.

(2) Function module installation

● The weight of the equipment will hang on the installation wall, so it should be reinforced if it isn't strong enough.

The supporting structure should be capable of supporting at least 40 lbs (18 kg).

● When installing the equipment, do not drop it or hit it against anything.

Doing so could break or damage the parts inside the equipment.

● Be sure to install it on a vertical wall.

● The plumbing that is connected to the equipment should be installed so that there will be no safety problems with

respect to earthquakes, other vibration or physical impact and caulking material should be used to seal the points

where the hot and cold water and the power lines pass through the walls.

26

Page 27

(3) Positioning of holes for function module installation screws

Installation

plate

Function module

Tapping anchor

Tapping screw

Pilot hole

Position

hole

Function module

➀ Drill pilot holes for positioning the function module, pound in the curl plug (arranged on site) and use a tapping screw

for positioning. Then, hang the installation plate of the function module (above) on the tapping screw.

➁ Position the holes for the screws (two above and two below) and remove the function module briefly.

27

Page 28

(4) Function module installation

➀ Drill the pilot hole in the position determined for the screw and pound in the tapping anchor (arranged on site).

➁ Replace the function module on the tapping screws and fix the tapping screws (two above and two below) into place.

➂ Waterproof the area so that water cannot get into the building from the screws that secure the equipment.

(5) Plumbing the equipment

■■

Precautions when plumbing

• If the plumbing materials are specified by the relevant local and national plumbing authorities, comply with those

specifications.

• Be sure to flush filings, sand and debris from inside the pipes using water before connecting the function module.

• Use a union junction or similar means on the connection port and do not use excessive force.

• The diameter of the pipe is not to be less than the diameter of the function module connector (3/4).

• When the water pressure is high, either install a pressure-reducing valve or a device to prevent "water hammers."

(Recommended water pressure: 29 to 108.75 psi (0.20 to 0.75 MPa)).

• Keep the number of unions as small as possible and do not use complicated plumbing. Additionally, do not plumb in

such a way that air can become trapped in the pipes.

● Hot and cold water supply plumbing.

• Install an anti-backwash valve, a shut-off valve or a shut-off valve with an anti-backwash valve near the hot and cold

water supply ports.

• In order for the customer to have a pleasant experience using this equipment, a hot and cold water supply pressure of

29 to 108.75 psi (0.20 to 0.75 MPa) is required. If the water pressure is low, the equipment will not function properly

and could lead to trouble with the customer, so be prepared to install a booster pump as a countermeasure.

● Fill-tub plumbing.

• The pipes that are used with the fill-tub feature are to have a maximum length of 49.2 ft (15 m) and 10 changes of

direction.

• Please incline the pipes so that it will be easier to remove water from the pipes when draining water from the pipes.

• Please allow sufficient space for the end of the water-removal pipe and the drain opening.

If there is no space, backed up water could flow back inside.

28

Page 29

(6) Inspecting for leaks in the fill-tub plumbing

Booster pump

Gauge

Caution

• Do not apply additional pressure to the equipment.

Inspection pressure and time: 43.5 psi (0.30 MPa) for five minutes or longer.

➀ Install a valve on one end of the fill-tub plumbing. (Valve open.)

➁ Install a booster pump on the other end to feed water into the fill-tub plumbing.

➂ Once the air has been removed from the fill-tub plumbing and it has been filled with water, close the installed valve.

➃ Inspect for leaks.

Inspection pressure and time: 43.5 psi (0.30 MPa) for five minutes or longer.

• Use a pressure meter that suits the pressure being checked when inspecting the pressure.

• Be sure that there are no leaks or pressure drops across the gauge.

❈ Do not apply pressure to the equipment itself.

❈ If pressure leaks are discovered, run the test again after fixing the leaky areas.

29

Page 30

(7) Plumbing the hot, cold and fill-tub pipes

Insulate so that

there is no gap.

Wrap the insulation so that the waterremoval valve can be operated.

Insulate so that there

is no gap.

Anti-backwash valve

Shut-off valve

To bathtub

Water

Drain

Hot water (Water heater)

To drain line

Power supply cord

➀ Connect the pipes described so far to their respective connection ports on the function module.

➁ Open the shut-off valves on the hot and cold water supply lines and check to see that there are no leaks from the

joints.

➂ After connecting the cables and the bathtub equipment (Page 31), fill the tub and confirm that there is no water

leaking from the joints in the fill-tub pipes (two places: on the function module side and the bathtub side).

● Freezing prevention (Please implement this in locations where there is a risk of the equipment or pipes freezing.)

• To prevent freezing, insulation (insulating material, electric heaters, etc.) should be used that is appropriate to the

• Insulate the plumbing completely after checking to see that there are no leaks from the hot, cold or fill-tube water

• In order to be able to drain water from inside the pipes, do not wrap the water removal valve with insulation.

region.

lines.

30

Page 31

(8) Electrical work

Connector cover

Power supply terminal strip

Power supply cord

Grounding screw

Terminal strip

Air blower cord

● Power supply check.

Connect Ground

• All electrical connections must be in accordance with local codes, ordinances, and

the National Electrical Code (NEC).

If you are unfamiliar with methods of installing electrical wiring and appliances, you

should secure the services of a qualified licensed electrician.

Warning

Improperly performed work could result in breakdowns or current leaks that could

lead to electric shocks.

Install to permit access for servicing.

An equipment grounding terminal is provided in the field wiring compartment. To

reduce the risk of electric shock, this Terminal must be connected to the grounding

means provided In the electric supply panel with a conductor equivalent in size to

the circuit conductor supplying this equipment.

Install this unit in accordance with the National Electrical Code (NEC) NFPA 70 and

Canadian Electrical Code, Part 1.

Connect only to a branch circuit protected by an overcurrent protective device rated

not more than 15A.

The power supply for this function module is 120 V (60 Hz) and the power consumption is 710 W.

● Connecting the cable and the bathtub equipment

➀ Remove the cover on the connector

➁ Using a conduit joint (arranged on site), pull the power supply cord (arranged on site) through the hole in the bottom

and push it into the power supply terminal strip. During this operation, please be careful of the size of the wire and

the length of insulation that is stripped away.

❈ Proper size: AWG12 or 14

Stripped length: 0.55 in (14 mm)

Pull the grounding wire (arranged on site) through

the same hole and fix it to the ground with a screw.

➂ Using a conduit joint (arranged on site), pull the air-

blower cord (arranged on site) through the hole in

the bottom and fix it to the power supply terminal

strip with a screw.

When doing this, please make sure that the color of

the wire and the color of the terminal strip label

match.

31

Page 32

➃ Set up the clamp connector (3/4) that comes with the "Control Unit" of the power supply relay cable.

Clamp

connector (3/4)

Power supply relay cable

Clamp

connector (1/2)

Signal relay cable

Cover

Set up the clamp connector (1/2) that comes with the "Control Unit" of the signal relay cable.

Pull the cables ➄ and ➃ through their respective holes in the bottom and fix the clamp connectors in place.

➅ Attach the cover after connecting each of the connectors and you are finished.

32

Page 33

6-5 Confirmation and trial operation

1

Remove the operation

cover from the

Supplementary

protector.

Supplementary protector

operation cover

ON

OFF

3

Push the test button on

the Supplementary

protector.

Power supply

lever

Test button

ON

OFF

Power supply

lever

❈ If the power supply lever changes

from ON to OFF< then it is

functioning normally.

Set the power supply lever

on the Supplementary

protector to ON

2

Run trial operations as described in the Instruction Manual and, after confirming that the product runs normally, tell the

customer how to use it and deliver it to the customer.

■ Inspection

• After the unit is installed, please be sure to check the operation of the

Warning

Always do this.

Supplementary protector. An improperly functioning Supplementary

protector could lead to electric shock or fire

33

Page 34

■ Trial operation preparation

Cold water shut-off valve

Hot water

shut-off valve

Hot water heater

(Not included with the product)

Function module

Cold

waterwater

Hot water

Power supply cord

(when flowing)

1

Confirm that electric power is

being supplied.

This should be performed after

confirming that the bathtub is empty.

2

Supply temperature: 140 to 158°F (60 to 70°C)

Supply pressure: 29 to 108.75 psi (0.20 to 0.75 MPa)

Supply water

pressure: 29 to 108.75 psi

(0.20 to 0.75 MPa)

(when flowing)

Open the hot and cold water shut-off valves connected

to the function module.

❈The position of the water shut-off valve will vary from place to place.

Please supply hot and cold water to the function module by opening the shut-off valves.

Hot water

■ Trial operation

Please run the unit in order of operations (1) to (6).

❈ Do not apply pressure to the equipment itself.

(1) Bathtub data reset

➀ Open the bathtub drain valve and empty the bathtub.

➁ Set the On/Off button on the controller to OFF.

➂ Turn the to ON.

Please open the drain valve of the bathtub so that no water remains in the bathtub.

The draining operations will end automatically after approximately 2 minutes.

34

Page 35

(2) Fill-tub operation

➀ Close the drain valve in the bathtub and set the On/Off button on the controller to ON.

➁ Set to ON.

➂ Confirm that the fill-tub cascade is flowing out of the fill-tub outlet.

➃ Confirm that there are no leaks in the plumbing.

➄ Wait until the fill-tub feature finishes normally.

When the tub has been filled, a melody will play and then stop automatically.

(3) Air blower

❈ Please make sure that there is hot water in the tub after running the fill-tub feature.

➀ Set the On/Off button on the controller to ON.

➁ Set to ON.

➂ Confirm that there is air flowing out of the nozzles in the bottom of the bathtub.

➃ Confirm that there are no air or water leaks in the plumbing.

➄ Set to OFF.

(4) Shoulder warmer

❈ Please make sure that there is hot water in the tub after running the fill-tub feature.

➀ Set the On/Off button on the controller to ON.

➁ Set to ON.

➂ Confirm that there is water flowing out of the (two) shoulder warmer outlets.

➃ Confirm that there are no leaks in the plumbing.

➄ Set to OFF.

(5) Underwater illumination

➀ Set the On/Off button on the controller to ON.

➁ Set to ON.

➂ Confirm that the (two) lighting modules are turned on.

➃ Confirm that there are no leaks in the lighting modules.

➄ Set to OFF.

35

Page 36

(6) Purge operation

➀ Remove the drain plug in the bathtub and empty the bathtub.

➁ Set the On/Off button on the controller to OFF.

➂ Set to ON.

Please remove the drain plug in the bathtub so that the water in the bathtub will all run out.

The purge operation will end automatically after approximately two minutes.

■ Handling problems

If there are problems with operation, please refer to the section on troubleshooting in the Instruction Manual.

When an error code is displayed

Error Code Cause Response

032 Drain valve open ❈ Is the bathtub drain valve closed?

079 No hot water

152

262 Water level sensor open circuit

572 No water ❈ Is the water main/shut-off valve turned on?

C04

Other --- Please try again after resetting the error.

Incoming water temperature

problem

Shoulder warming pump rpm

problem

❈ Is sufficient hot water available from the water heater?

• Please check the temperature setting/operation of the water heater.

❈ Is hot water being supplied to the cold water connection port of

the function module?

• Please check the connections of the plumbing to the function

module.

❈ Is the water sensor cable connected?

❈ Is there a break in the water sensor cable?

❈ Is there enough hot water in the bathtub?

❈ Is debris blocking the intake port?

❈ Is the intake port blocked?

36

Page 37

Error reset method

Errors can be reset with the button that displays the error codes.

If the error codes aren't displayed

The lights on the controller don't work

• Is the controller cable connected?

• Is the controller cable broken?

• Is the power supply reaching the function module?

Air blower doesn't function

• Is the air pump cable connected?

• Is the air pump cable broken?

The underwater lighting doesn't turn on

• Is the underwater lighting cable connected?

• Is the underwater lighting cable broken?

❈Please refer to the Instruction Manual concerning other problems.

37

Page 38

■ Cleaning the strainer in the water drain lug

Hot water

connection

Hot water valveCold water valve

Cold water

connection

Close Close

Debris in the plumbing will collect in the strainer, so after connecting the plumbing and running water through it and after

the trial operations, please be sure to clean the strainer.

Caution

If the product won't be delivered to the customer for a long time or if it will not be used for a

long time, please remove the water from the function module and shut off the power. (See

Instruction Manual.)

❈ After the water has run out of the fill-tub outlet, the water inside the function module will still be quite hot. Please wait

until the equipment cools to avoid scalds or burns.

❈ Hot and cold water will run out of the water drain lug, so please place a bucket or other container underneath the

function module to catch the water.

➀ Close the hot/cold water valves in the plumbing connected to the connection ports.

❈ The location of the shut-off valves will vary with the installation site.

➁ Set the on the controller to ON and wait around 20 seconds.

❈ Please do this with the On/Off button set to ON.

➂ After confirming that no water is flowing out of the fill-tub outlet, turn the On/Off button to OFF.

• If the water continues flowing, please set the On/Off button to OFF again and start from step (1).

Sometimes, the controller will display error code 572.

• This is a notice that the water has been shut off. After resetting the error (See Page 37), set the On/Off

button to OFF and proceed to step (4).

38

Page 39

➃ Remove the water drain lugs in the hot and cold water connection ports.

Water drain lug

(with strainer)

Hot water

connector

Cold water

connector

Water drain lug

(with strainer)

Water drain lug

Packing

Toothbrush

Strainer

Packing

OpenOpen

Hot water

connector

Cold water

connector

Hot water valveCold water valve

❈ Hot water will come out of the function module when removing the water drain lugs, so please be careful.

❈ When the water drain lugs cannot be removed by turning them by hand, please put the end of a screwdriver or

other tool in the hole in the water drain lug and use that to turn them.

➄ Rinse the strainer with water while brushing it with a toothbrush.

❈ Please keep debris from scratching or getting on the packing. Otherwise, leaks could develop or debris could get

inside the function module, causing problems.

➅ Reattach the water drain lugs to the hot and cold water connectors as they were initially.

➆ Open the hot and cold water valves and check to see that there is no water leaking around the drain lugs.

39

Page 40

Recycled

TOTO USA INC. 1155 Southern Road, Morrow, GA 30260

Tel : (888) 295-8134

• Fax : (800)699-4889

www.totousa.com

Printed in USA © TOTO USA Inc.

0GU5076

11-9-07

Loading...

Loading...