Factory Direct Hardware 9947EOF User Manual

OPTIONAL EQUIPMENT - CONTINUED

VON DUPRIN

®

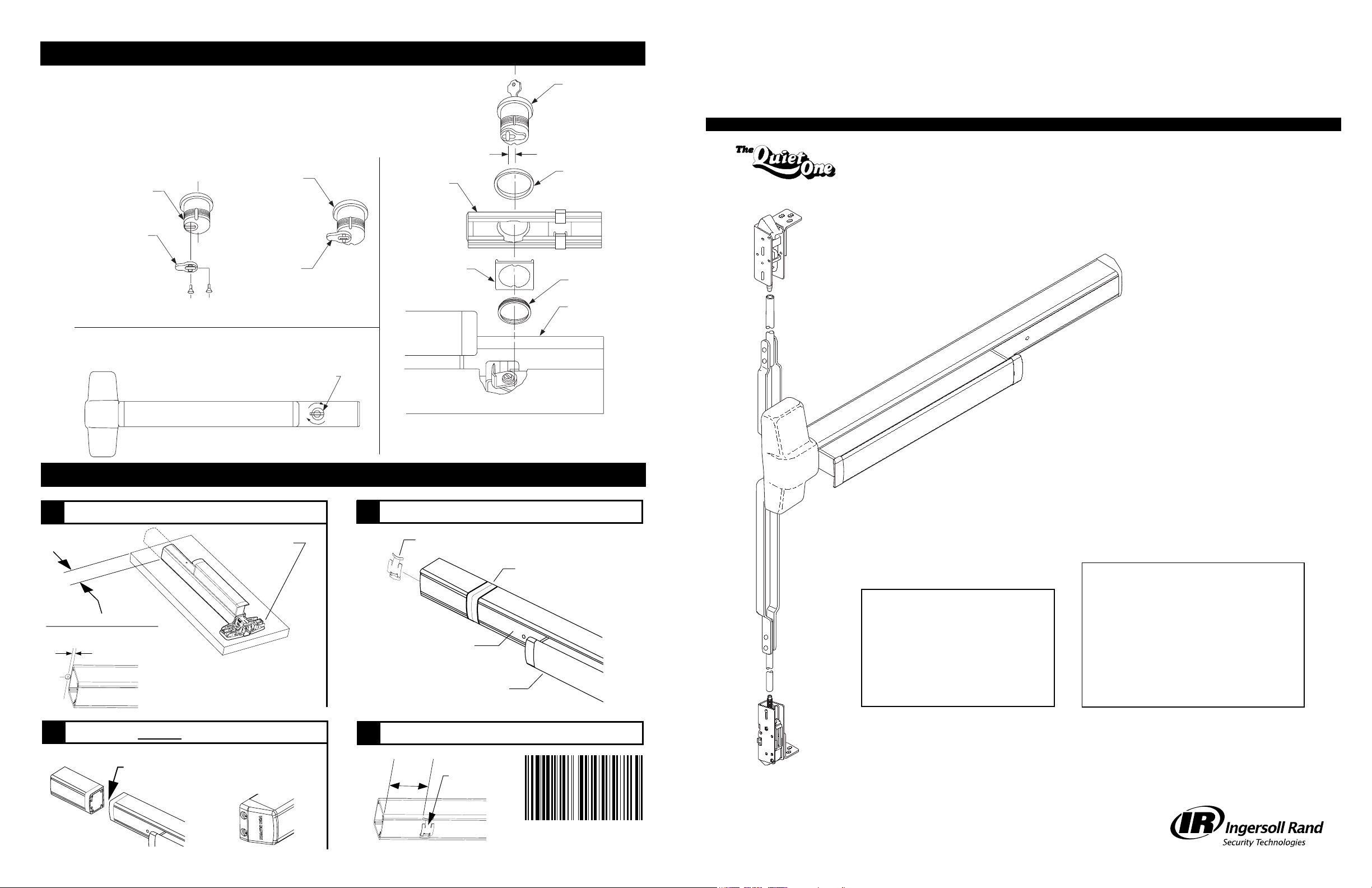

CD (CYLINDER DOGGING)

1. Remove mortise cylinder cam and reinstall in reverse (Figure 6).

2. Insert key and rotate cam to install the cylinder to the cover plate

3. Remove key to slide cover plate in position in the mechanism case.

(Figure 7).

Std. mortise

cylinder

Mortise

cylinder

cam

Std. mortise

cylinder

Mortise

cylinder

cam

CD function conversion

Figure 6

Dogging procedure

Turn cylinder key clockwise approx. 1/

8 turn for standard dogging

Offset toward

pushbar

Dogging

plate cover

Cylinder

locating washer

Std. mortise

cylinder

Cylinder

collar

Cylinder

lock nut

Mechanism

case

Installation Instructions

®

98/9947 Concealed Vertical Rod Exit Device

Metal Door Applications

Depress pushbar

Measure amount to cut off device.

1

2” Minimum clearance

(with endcap removed)

5/16”

Note

If 5/8” diameter wire access hole

has been predrilled in door, cut

device 5/16” from center of hole.

Cut device square.

3

Cut device square

and remove all

burrs

Device aligned

with mounting

holes

NOTE: Device must

be cut square for

proper end cap fit

CUT DEVICE

Tape and mark area being cut.

2

(flush to pushbar)

Slide anti-rattle clip into device.

4

2”

min.

Figure 7

Remove anti-rattle clip

Cover plate

Pushbar

Anti-rattle

clip inside

Tape

Devices covered by these instructions:

98/9947 Concealed Vertical Rod Exit Device

98/9947-F (Fire) Concealed Vertical Rod Exit Device

CD98/9947 (Cylinder Dogging) Concealed Vertical Rod Exit Device

EL98/9948-F (Electric Latch Retraction) Concealed Vertical Rod Exit Device

Index:

• Screw chart ................................... 2

Special tools needed:

• Door preparation chart .............. 3

• Device installation ....................4-5

5/64” hex wrench

#10-24 tap

Drill bits: #25, 1/8”, 1/4”,

5/16”, 13/32”

• Adjust rods .................................... 6

• Frame preparation chart ............ 6

• Optional equipment ................ 7-8

• Cut device ..................................... 8

Please give these instructions to building owner after device is installed

This product is covered by the

following patent numbers:

3,767,238 4,427,223

3,854,763 4,466,643

4,167,280 4,741,563

911376-00

911376-00(4)

© 2006 Ingersoll-Rand Company Limited

8

SCREW CHART

OPTIONAL EQUIPMENT - CONTINUED

A

B

C

#10-24 x 1”

- Packaged with trim -

#10-24 x 3/4”

#10-16 X 3/8” Thread cutting

#10-24 x 1-1/2”

#10-24 x 1-3/8”

#10-24 x 1-7/8”

#10-24 x 1-1/8”

Surface mount or

Sex bolts (1-3/4” door)

Sex bolts (2-1/4” door)

990 trims (1-3/4” door)

990 trims (2-1/4” door)

Surface mount or

Sex bolts (1-3/4” door)

Sex bolts 2-1/4” door

End cap

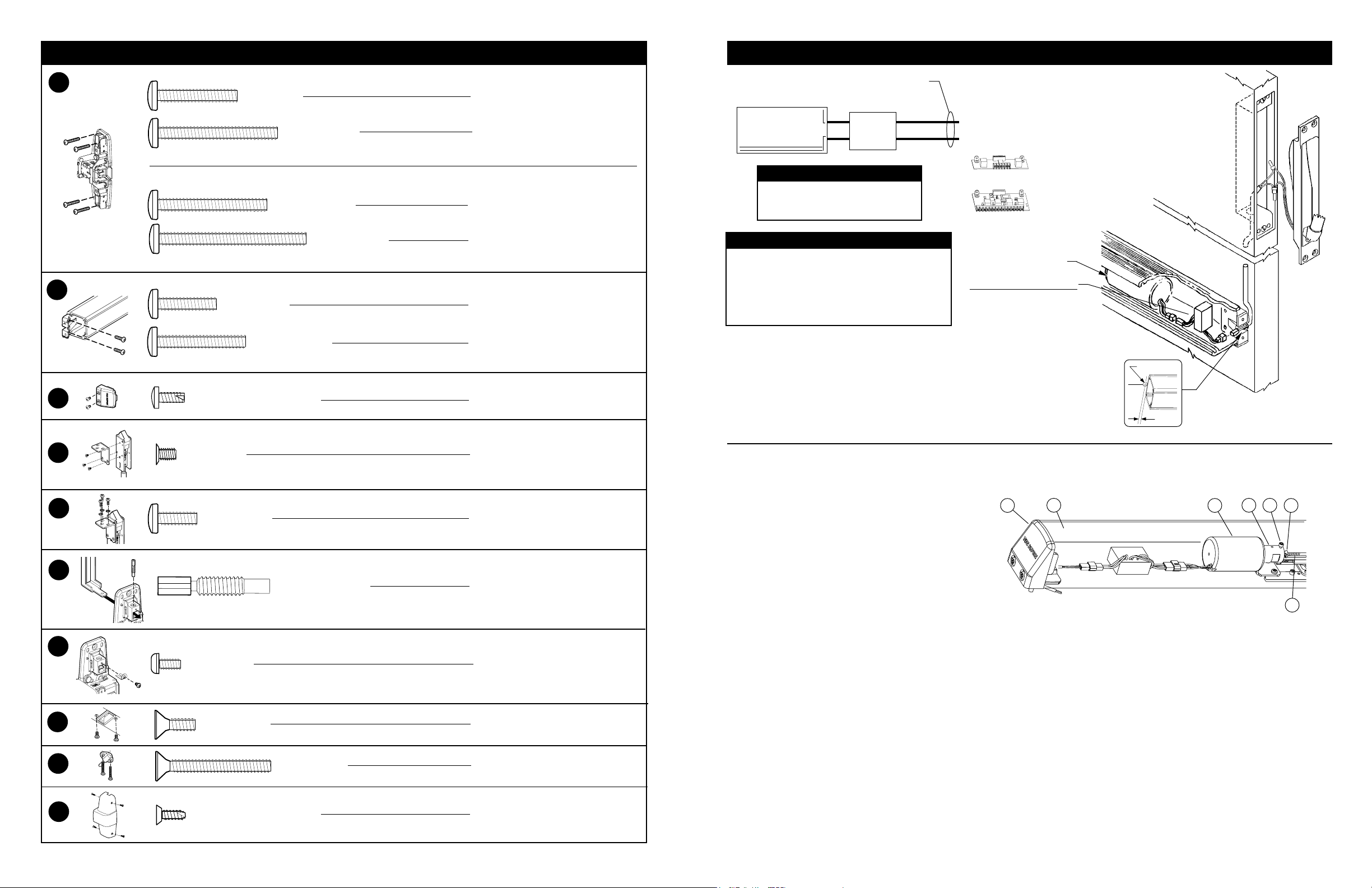

12 AWG required for distances up to 200’

14 AWG permitted for distances 0-100’

EL

Solenoid

ELECTRICAL SPECIFICATIONS

Voltage: 24 VDC

Current: 16 A inrush (0.3 sec.)

0.25 A holding

When power is applied to the potted circuit

board, the solenoid receives a momentary

signal to retract and a separate signal to hold

as long as power is applied. When attempting

to retract solenoid again, power must be

removed from the circuit and reapplied.

Potted

circuit

board

NOTE

Black

Black

EL WIRING

Solenoid draws 16 A inrush current from PS873.

Solenoid must be wired to a PS873 logic board:

}

If 871-2 logic board, refer

to Von Duprin instructions

941352.

If other 873 logic board,

refer to Von Duprin

instructions 941356.

Solenoid

Potted Circuit Board

Install after device has

been mounted on door

Do not cut device with potted

circuit board installed

Troubleshooting solenoid operation

If the solenoid fails to retract the latch bolt when power is applied, recheck wiring for

proper connections.

If solenoid retracts latch bolt momentarily but will not remain in energized position:

1. Check wiring for proper connections, guage, and distances.

2. Check for latch bolt binding caused by improper strike installation, warped door, etc.

Also check adjustment of vertical rods.

5/8” dia.

C

L

5/16”

Electric

power

transfer

Drill 5/8”dia. wire access hole

thru device side of door.

D

#10-32 X 1/4”

Bracket to latch

EL ADJUSTMENT PROCEDURE

A. Check for proper function:

E

F

G

H

J

1. Make sure device is not dogged.

#10-24 X 1/2”

Rod adjusting screw

#8-32 X 5/16”

#10-24 X 1/2”

I

#8-18 x 3/8” Thread cutting

#10-24 X 1-1/2”

Bracket to door

Retaining clip

Retaining clip

338 strike

Ratchet release

Center case cover

2. Depress pushbar and make sure latch bolts

retracts and extends fully (see page 6 Figures 1 & 3).

3. Electrically energize solenoid and hold.

4. Check latch bolt(s) for full retraction (must

clear strike (see page 6 Figures 1 & 3).

5. Release solenoid and check latch bolt

extension (see page 6 Figures 1 & 3).

6. Continue to Section B if device does not

function electrically.

B. Determine if dogging rod adjustment is too long or short:

1. The dogging rod adjustment is too long if latch bolt

does not retract and clear strike (see Section C for

adjustment).

2. The dogging rod adjustment is too short if latch bolt

does not fully extend or latch bolt fully retracts but

solenoid releases while energized (see Section D for

adjustment).

C. Adjust solenoid if dogging rod is too long (see Figure 5):

1. Remove end cap c and dogging cover d.

2. Loosen cap screw e.

3. Hold plunger g depressed in solenoid housing h.

Note: Push hard against plunger g to overcome

an internal spring in solenoid housing h.

4. Turned threaded bushing f in to shorten dogging

rod i so latch bolt fully retracts.

5. Tighten cap screw e.

Note: Cap screw e must be tightened against

flat on threaded bushing f. Apply a few

drops of Loc-Tite 222 to threads of cap

screw e.

6. Replace dogging cover d and end cap c.

7. Return to Section A to check for proper function.

1

2

2

6

Figure 5

D. Solenoid adjustment if dogging rod adjustment

is too short (see Figure 5):

1. Remove end cap c and dogging cover d.

2. Loosen cap screw e.

3. Hold plunger g depressed in solenoid housing h.

4. Turn threaded bushing f out to lengthen

dogging rod i so plunger g just bottoms in

solenoid housing h and latch bolt is fully retracted.

Note: Push hard against plunger g to overcome

5. Tighten cap screw e.

6. Replace dogging cover d and end cap c.

7. Return to Section A to check for proper function.

an internal spring in solenoid housing h.

Note: Cap screw e must be tightened against flat

on threaded bushing f. Apply a few drops of

Loc-Tite 222 to threads of cap screw e.

35

4

7

7

Loading...

Loading...