Page 1

PULL-DOWN KITCHEN

T

E

F

L

O

N

®

T

E

F

L

O

N

AND BAR / PREP FAUCETS

ASME A112.18.1 / CSA B125.1

Models

63052LF & 63952LF

Series

BELO®

Write purchased model number here.

WARNING: THIS FAUCET IS NOT TO BE USED WITH PORTABLE DISHWASHERS!

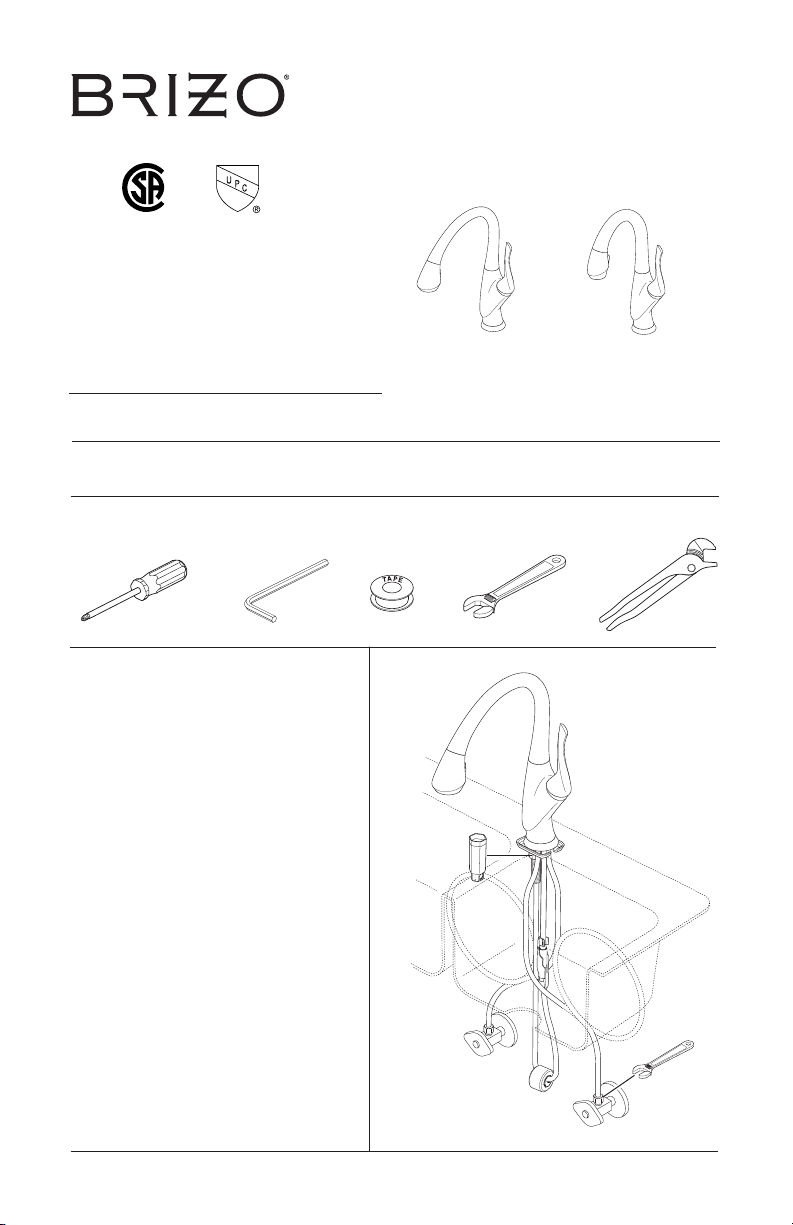

You may need the following tools:

1/8"

For easy installation of your Brizo®

faucet you will need:

• To READ ALL the instructions

completely before beginning.

• To READ ALL warnings, care, and

maintenance information.

62435 Rev. A

1

9/28/09

Page 2

TABLE OF CONTENTS:

Warranty ------------------------------------------------------------- Page 2

Installation Instructions ----------------------------------------------- Pages 3-13

Plastic Sleeve Installation --------------------------------------------- Page 10

Setting The Handle Limit Stop ----------------------------------------- Page 13

Maintenance -------------------------------------------------------- Page 14

Replacement Parts -------------------------------------------------- Pages 15 & 16

Lifetime Faucet and Finish Limited Warranty

All parts and finishes of the Brizo® faucet are

warranted to the original consumer purchaser to

be free from defects in material & workmanship

for as long as the original consumer purchaser

owns their home. Delta Faucet Company

recommends using a professional plumber for

all installation & repair.

Delta will replace, FREE OF CHARGE,

during the warranty period, any part or finish

that proves defective in material and/or

workmanship under normal installation, use

and service. Replacement parts may be

obtained by calling 1-877-345-BRIZO (2749)

(in the U.S. and Canada) or by writing to:

In the United States:

Delta Faucet Company

Product Service

55 E. 111th Street

Indianapolis, IN 46280

In Canada:

Masco Canada Limited, Plumbing Group

Technical Service Centre

420 Burbrook Place

London, ON N6A 4L6

This warranty is extensive in that it covers

replacement of all defective parts and even finish,

but these are the only two things that are

covered. LABOR CHARGES AND/OR DAMAGE

INCURRED IN INSTALLATION, REPAIR, OR

REPLACEMENT AS WELL AS ANY OTHER

KIND OF LOSS OR DAMAGES ARE

EXCLUDED. Proof of purchase (original sales

receipt) from the original consumer purchaser

must be made available to Delta for all warranty

claims. THIS IS THE EXCLUSIVE WARRANTY

BY DELTA FAUCET COMPANY, WHICH DOES

NOT MAKE ANY OTHER WARRANTY OF ANY

KIND, INCLUDING THE IMPLIED WARRANTY

OF MERCHANTABILITY.

This warranty excludes all industrial, commercial

& business usage, whose purchasers are hereby

extended a five year limited warranty from the

date of purchase, with all other terms of this

warranty applying except the duration of the

warranty. This warranty is applicable to Brizo®

faucets manufactured after January 1, 1995.

Some states/provinces do not allow the exclusion

or limitation of incidental or consequential

damages, so the above limitation or exclusion

may not apply to you. Any damage to this faucet

as a result of misuse, abuse, or neglect, or any

use of other than genuine Delta® replacement

parts WILL VOID THE WARRANTY.

This warranty gives you specific legal rights, and

you may also have other rights which vary from

state/province to state/province. It applies only for

Brizo® faucets installed in the United States of

America, Canada, and Mexico.

© 2009 Masco Corporation of Indiana

2

Page 3

1

A. C.

1

2

2

1

B.

Bend

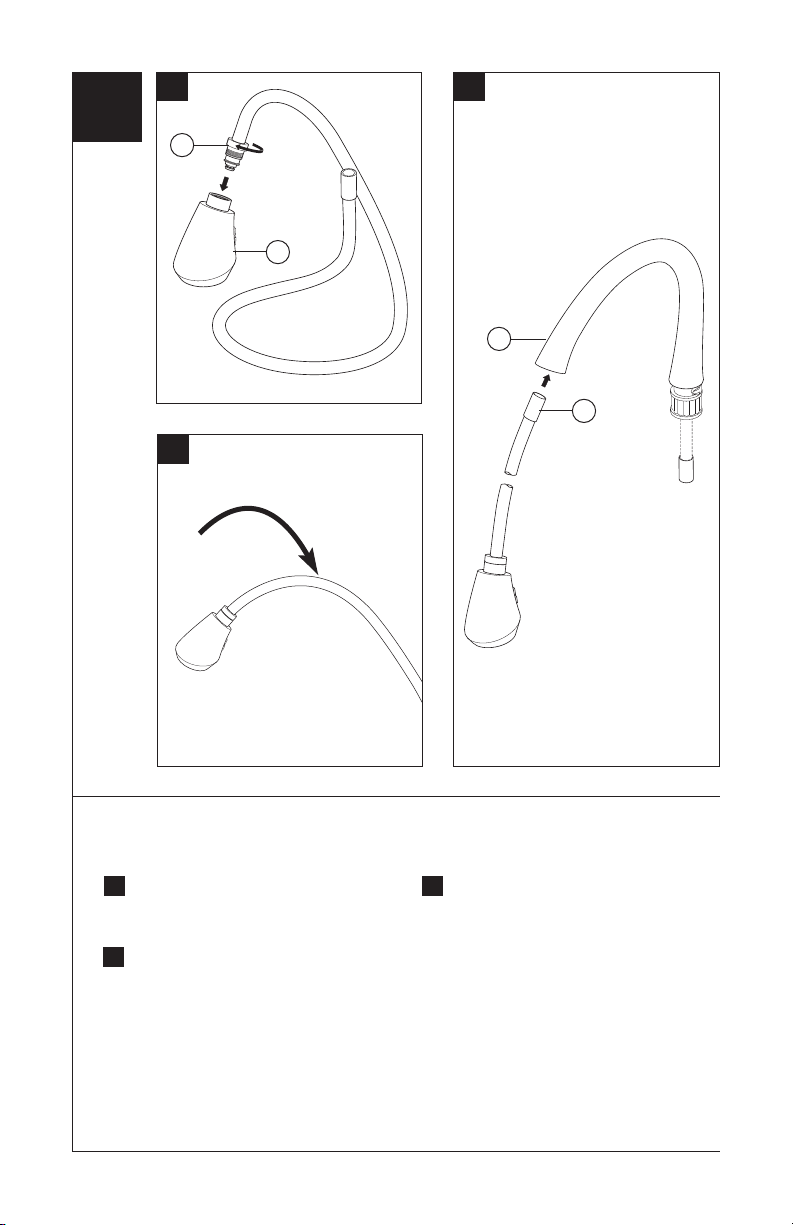

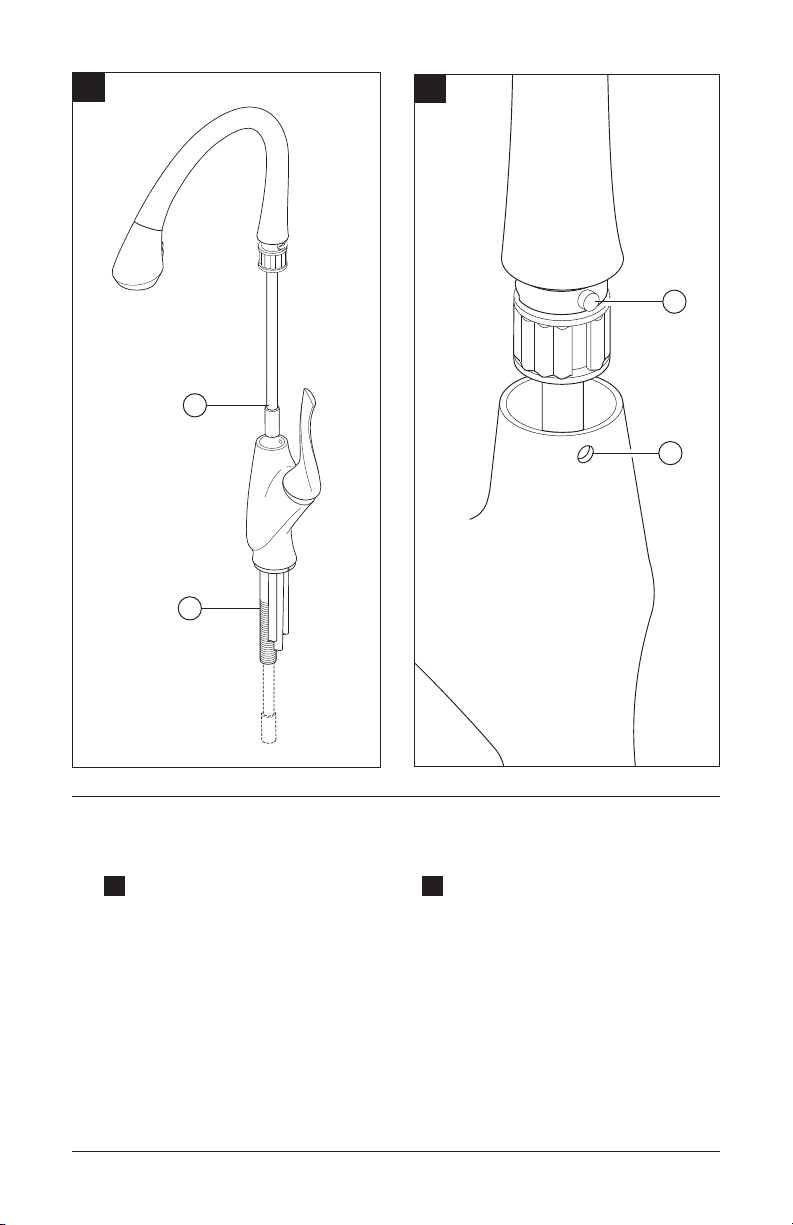

Hose Installation

Thread hose (1) into spray wand (2).

A.

To allow for easier assembly, bend

B.

hose near wand as shown.

Insert hose (1) into and through spout

C.

sub-assembly (2).

3

Page 4

2

A.

1

2

3

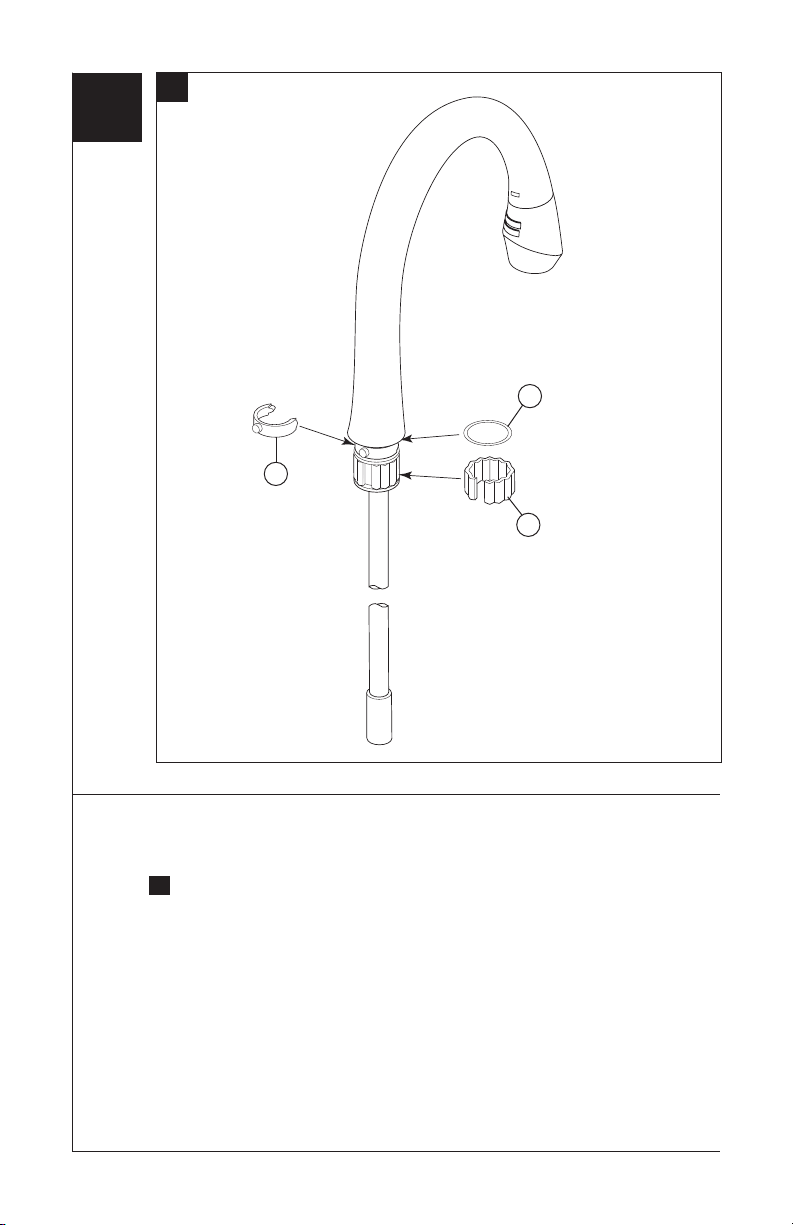

Spout Assembly

Verify friction washer (1), spout clip (2) and spout ring (3) are present on

A.

spout assembly.

4

Page 5

B.

C.

1

1

2

2

Spout Assembly (Continuation)

Insert hose (1) through guide in hub

B.

and out through mounting shank (2).

Align button (1) on spout clip with hole

C.

5

in hub (2), then insert spout into hub.

Use back-and-forth motion to insert

spout assembly into hub until clip

button slips into hole. Rotate spout

assembly to ensure smooth

operation. USE CAUTION NOT TO

PINCH FINGERS.

Page 6

3

A. B.

2

1

3

2

1

6

4

7

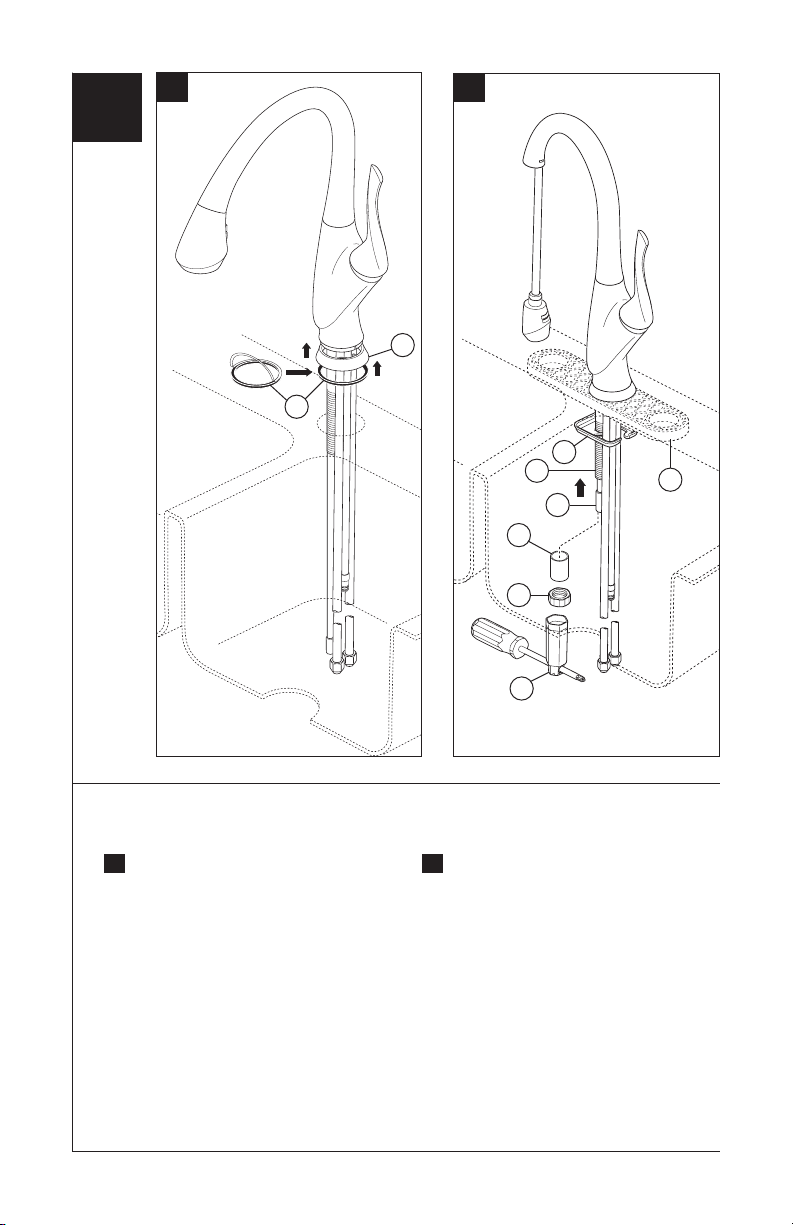

Faucet Installation - Center Mount

Remove adhesive backing on trim

A.

ring gasket (1) and press into place

on trim ring (2). Place trim ring on

bottom of spout hub. Insert supply

tubes through mounting hole in sink.

Your faucet is designed for a hole

diameter of 1 3/8" +/- 1/4" (35 mm

+/- 6 mm) and a deck thickness of

up to 3" (76 mm). Maximum deck

thickness of soap dispenser is

3" (76 mm).

Push hose (1) partially up into mounting

B.

shank (2). Install the mounting bracket

(3) and nut (4) onto the mounting shank

using wrench (5). For decks up to 1 3/8"

(35 mm) thick use spacer (6) provided

between nut and mounting bracket.

Note 1: The wrench provided is

designed to be used with a variety of

tools: flat/Phillips head screwdrivers,

wrenches, etc. Note 2: For thin gauge

sinks (not recommended), use the

thin deck aid (7) RP49588 as shown

for single and 3 hole installations

to help support the deck. HINT: Turn

the spout tube opposite the handle to

balance the assembly when mounting.

6

5

Page 7

3

Optional

4

6

5

3

7

Optional Escutcheon Installation

For optional installations using the 10"

escutcheon, order RP49588 (specify finish)

not supplied. Replace the trim ring with the

10" escutcheon (1) and gasket (2). Push

hose (3) partially up into mounting shank.

Mount as shown above using the

two 1/4-20 studs (4), nuts and washers

(5), bracket (6) with nut and wrench (7).

The wrench provided is designed to

be used with a variety of tools:

flat/Phillips head screwdrivers,

wrenches, etc.

1

2

4

5

7

Page 8

4A

A. B.

3

2

2

1

2

3

1

4

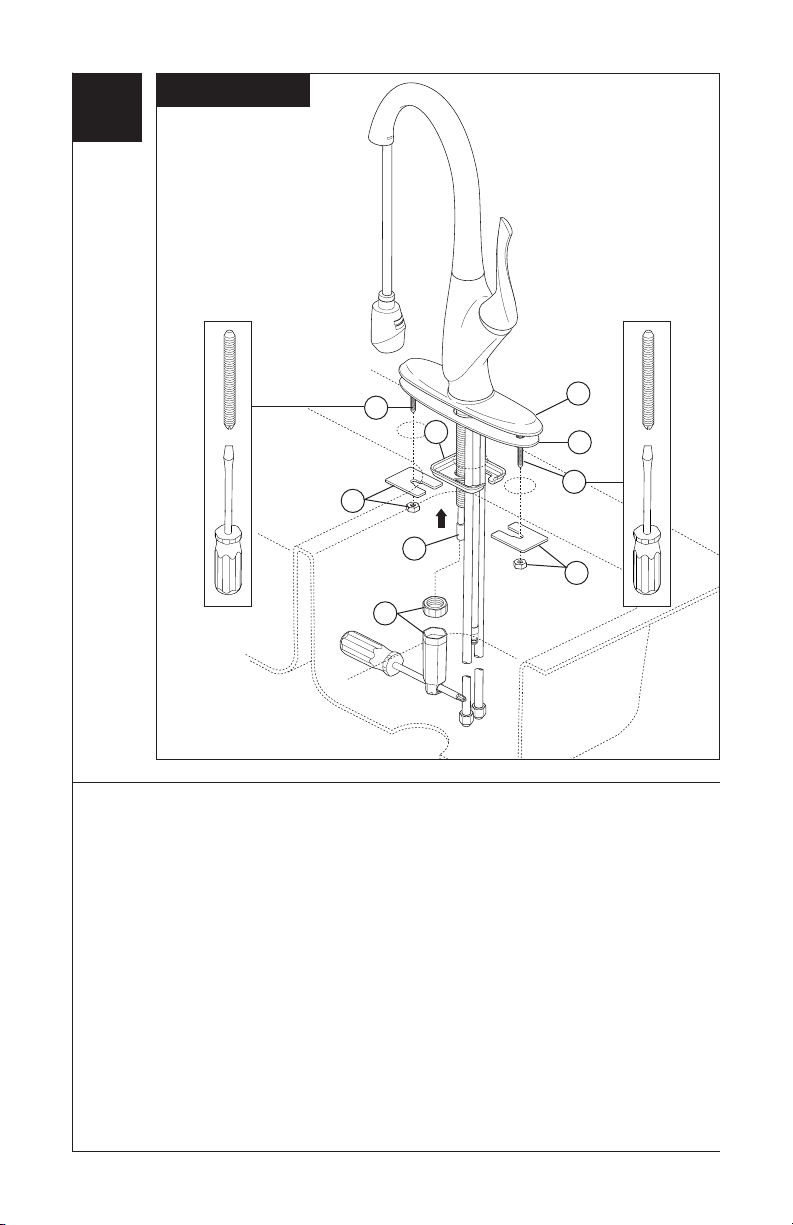

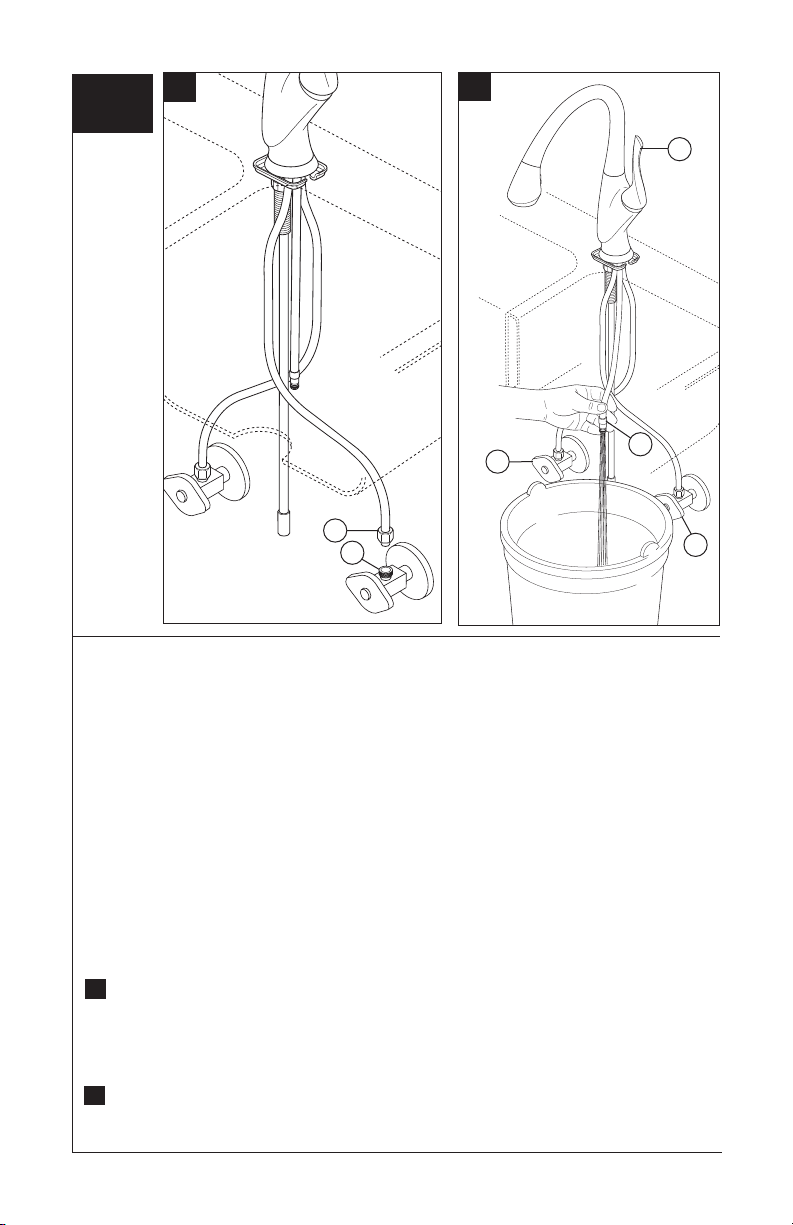

Water Line Connections

Ensure all fittings and end connections

A.

are free of debris. Faucet fittings (1)

are 3/8" compression, with ends

colored red for hot and blue for cold.

Loop tubing (2) if it is too long. Note:

Recommended tubing minimum

bend diameter is 8". Secure metal

nut (3) on faucet tube to supply valve

connection (4) and hand tighten, then

tighten one additional turn with wrench.

DO NOT OVERTIGHTEN. Repeat

for other tube. WARNING: Do not

use pipe dope or other sealants on

water line connections.

2

Place bucket under faucet quick

B.

connect fitting (1), open both supply

valves (2) and turn faucet valve on by

operating handle (3) for one minute.

Important: This flushes away any

debris that could cause damage

to internal components. When

complete, close both supply valves

and turn faucet valve off to shut off

water flow.

8

Page 9

4B

A.

B.

3

1

2

Custom Fit Connections

NOTICE: If you determine the PEX supply

tubing for this faucet is too long and must

be shorter to create an acceptable

installation, be sure to read the instructions and plan ahead. When cutting the

supply tubing the installer accepts the

responsibility to do so in a way that allows

a leak-free joint to be created. Delta is not

responsible for tubing that is cut too short

or cut in a way that will not allow for a

leak-free joint.

For custom fit installations, you must use

RP50952 sleeves supplied with model and

nuts included on supply lines. Tube cut must

be straight. See plastic sleeve installation

instructions found in RP50952 and included in

this document (page 11) for more information.

Secure metal nut (1) on faucet tube to supply

A.

valve connection (2) and hand tighten, then

tighten an additional 2 turns with wrench. DO

NOT OVERTIGHTEN. Repeat for other tube.

WARNING: Do not use pipe dope or other

sealants on water line connections.

Place bucket under faucet quick connect

B.

fitting (1), open both supply valves (2) and

2

1

2

turn faucet valve on by operating handle (3)

for one minute. Important: This flushes

away any debris that could cause

damage to internal components. When

complete, close both supply valves and turn

faucet valve off to shut off water flow.

Potential Problems and Remedies

l Tubing is not cut perpendicular to the

axis of the tub: carefully make an

additional cut, being careful not to cut the

tube too short.

l Tubing is cut too short: buy a coupling

union and a replacement supply line that

mate together from a store. The coupling

union end intended to connect to the

faucet must mate to the standard 3/8"

connection nuts and plastic sleeves

supplied with the faucet.

l The plastic sleeve or connection nut is

lost: purchase a replacement nut and/or

plastic sleeve that are designed to seal

with PEX tubing. NOTICE: DO NOT use a

metal sleeve, RP51243 gasket (supplied

with faucet) or ferrule in the place of the

plastic sleeve supplied, it may not

create a leak-free joint.

9

Page 10

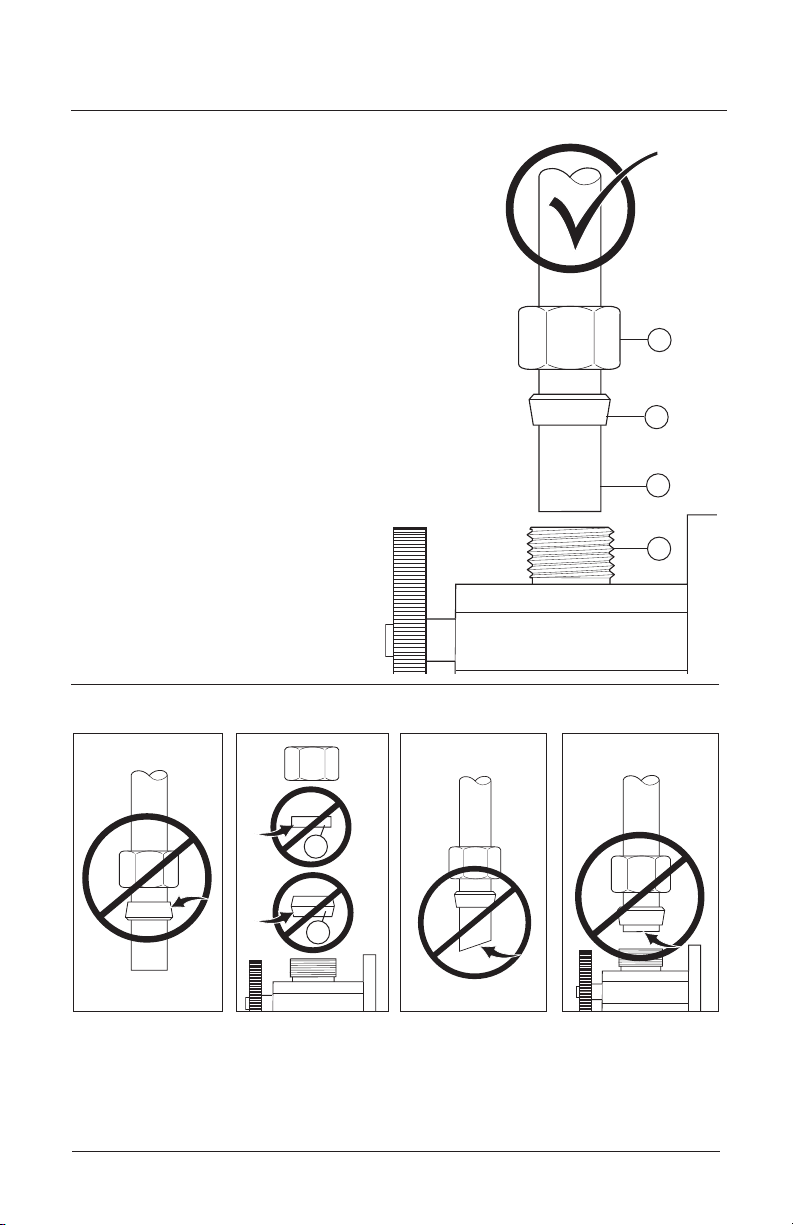

Custom Fit Connections - Plastic Sleeve Installation Instructions

Correct method

1. Identify desired length of tube (1). Leave 1" - 2"

of extra length to allow for easier installation and

cut tube. Ensure cut is straight and burr free.

2. Slide nut (2) and plastic sleeve (3) onto cut tube.

Ensure sleeve is oriented as shown.

3. Insert tube into outlet tting (4). Tube should

touch bottom of hole inside fitting.

4. Slide plastic sleeve down tube until it engages

top of fitting. WARNING: Failure to use plastic

sleeve in the correct orientation will result in

disconnection and possible water damage.

5. Slide nut over plastic sleeve. With wrench,

tighten nut 2 turns past finger tight.

2

3

1

4

Incorrect Installation

Do not install sleeve

upside down.

Do not use RP51243

gasket (1) supplied

with PEX tubing or

brass ferrule (2)

supplied with

valve stops.

1

2

Ensure cut is straight.

Ensure tube is fully

inserted into stop

before sliding sleeve

down to engage top

of fitting.

10

Page 11

5

A.

B.

C.

1

2

D.

1

D.

1

2

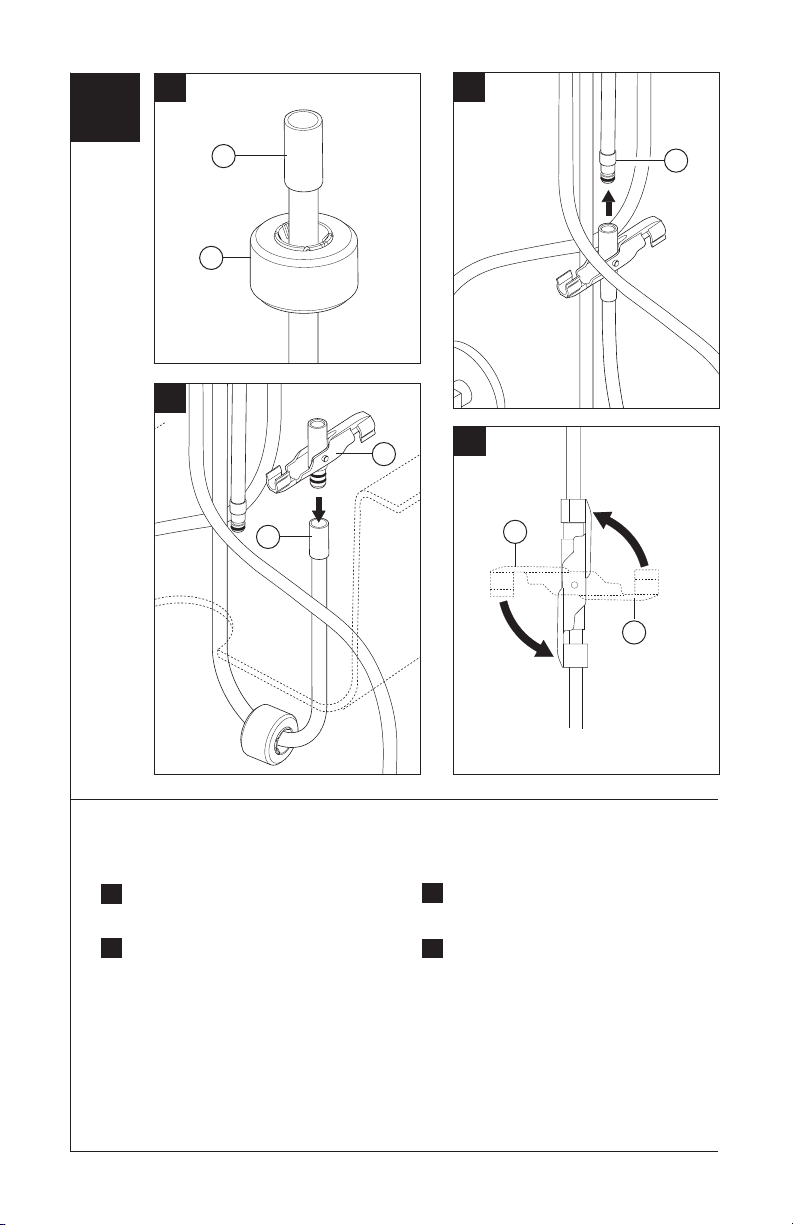

Sprayer Hose Connections

Insert hose end (1) through hose

A.

weight assembly (2).

Insert check-valve adapter (1) into

B.

pull-out hose fitting (2). Ensure

weight does not slide off hose.

1

1

Insert faucet outlet quick connect fitting

C.

(1) into adapter.

Rotate arms of adapter (1) to secure

D.

assembly to pull-out hose and faucet

outlet tube.

11

Page 12

6

A.

B.

3

2

OR

Unlock

4

Lock

1

1

5

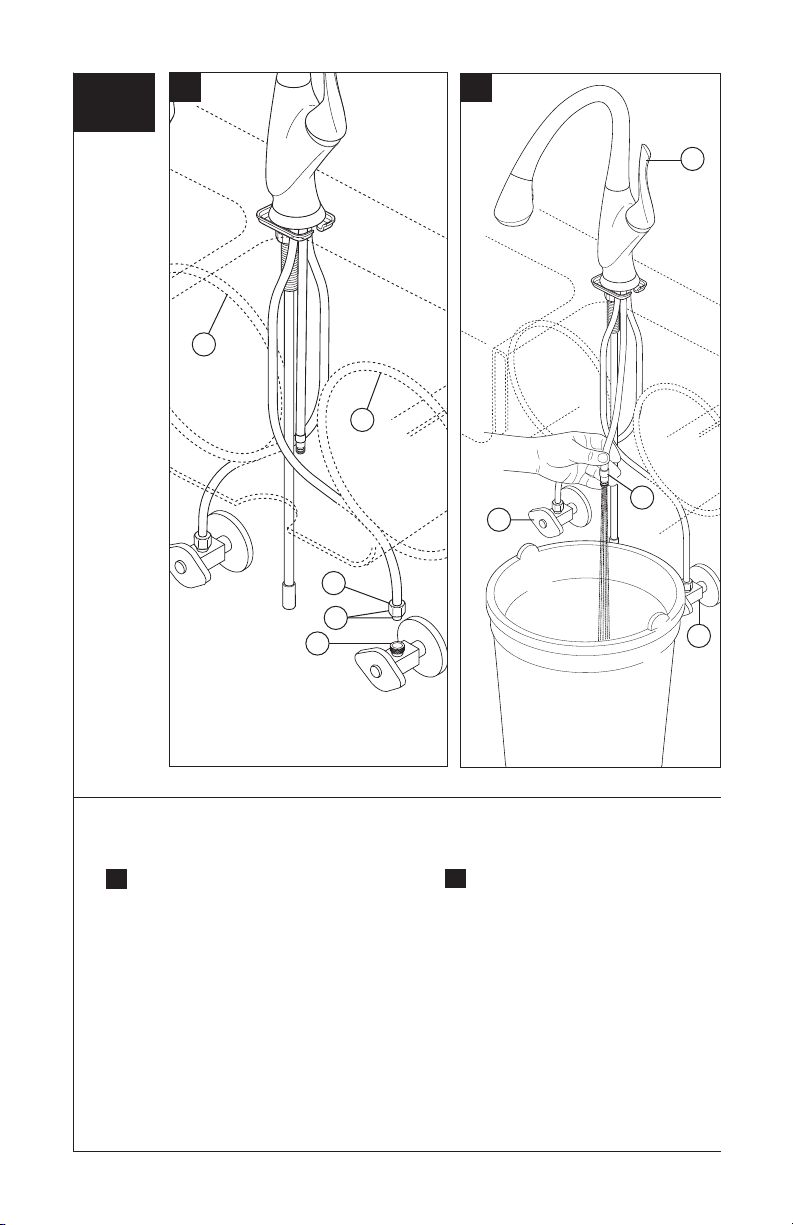

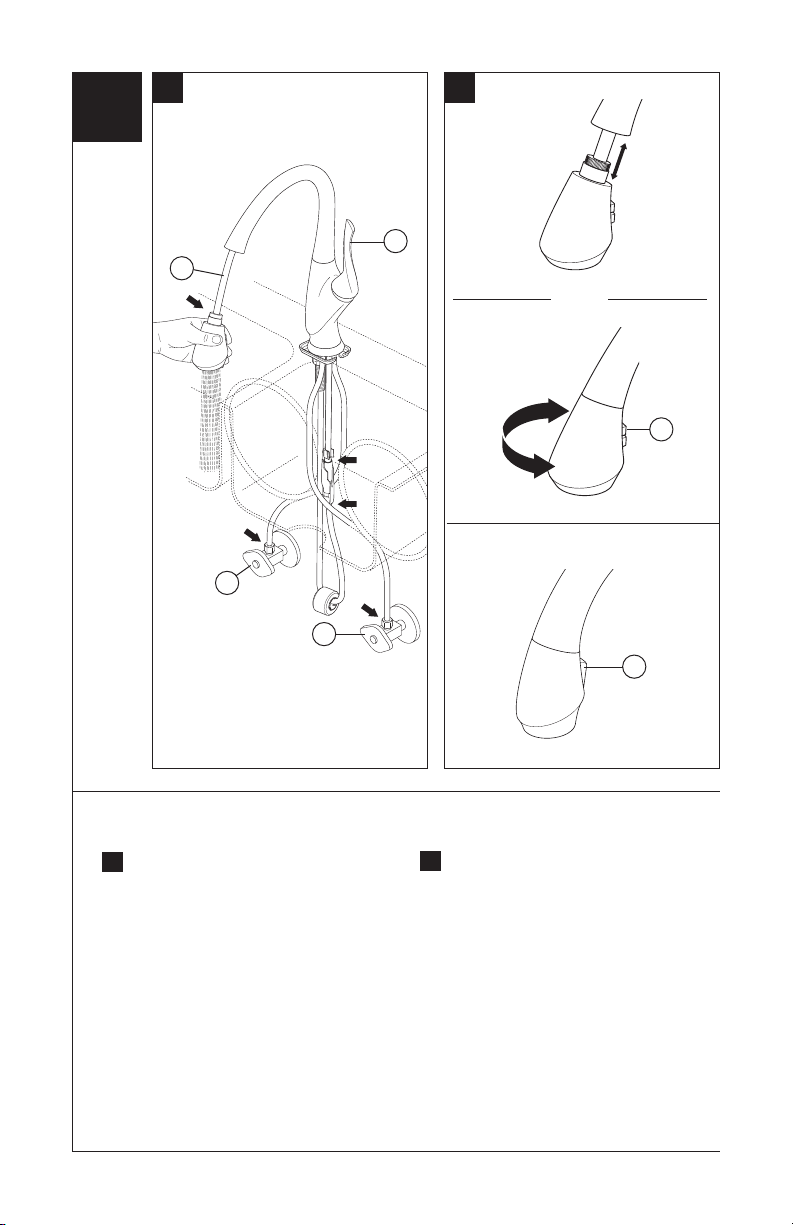

Faucet Inspection and Operation

Turn on hot and cold water supplies

A.

(1). Pull the hose assembly (2) out of

the spout. Be sure to hold the end of

the sprayer down into the sink and turn

faucet handle (3) to the mixed position

for one minute. Check all connections at

arrows for leaks. Re-tighten if necessary,

but do not overtighten.

Sprayer will lock into position when

B.

brought into proximity of the spout

magnet. The sprayer can be removed by

either pulling directly out from the spout

or by twisting 90° in either direction

which will cause the magnets to repel

and the head to decouple from the

spout (recommended). Check the

operation of the sprayer by operating the

trigger (4) from aerator to spray. The

diverter will remain in the last diverted

mode. To reduce or pause ow, push

selector button further into wand. The

bar/prep faucet is a two function sprayer

only. Press button (5) to choose

between modes.

12

Page 13

7

1

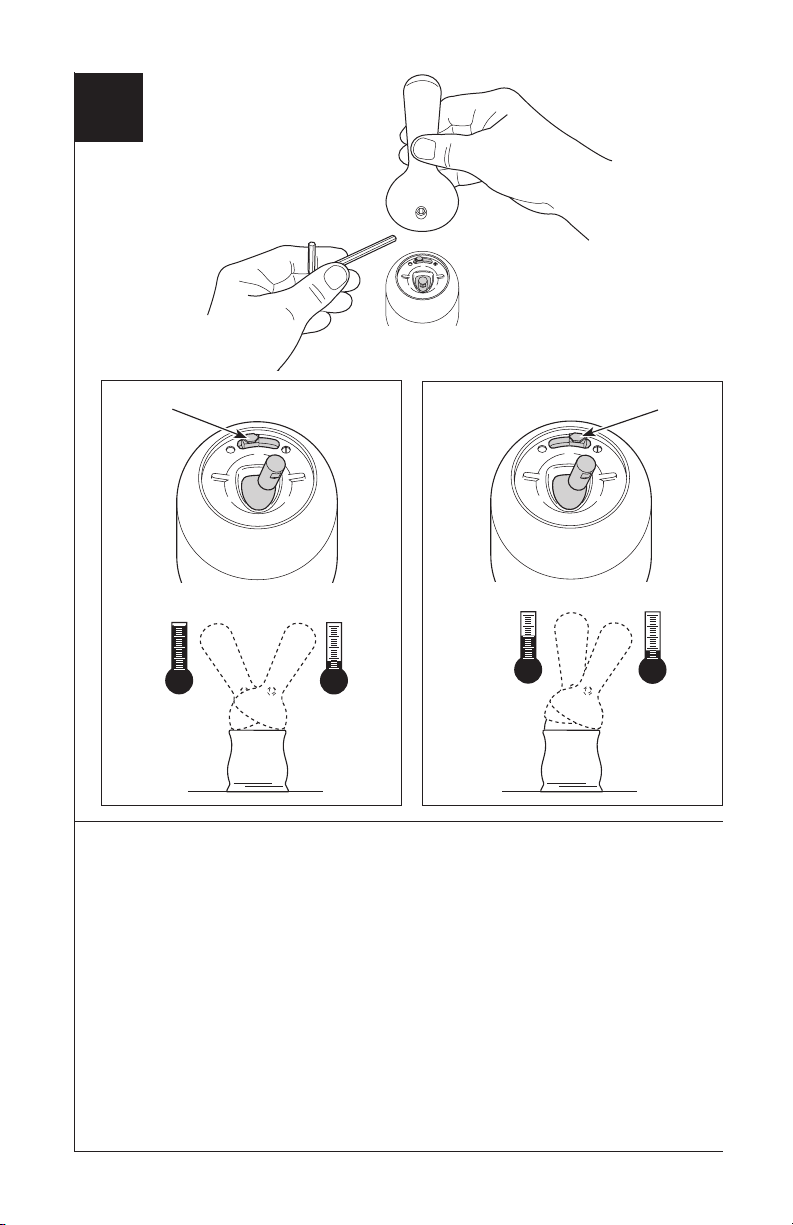

Setting The Handle Limit Stop (Optional)

This faucet includes an integrated

handle limit stop that has two positions.

Position 1, to the left, allows full handle

motion (the full range between “all cold”

to “all hot”). The faucet is set in position

1 in the factory. Position 2, to the right,

allows half of the normal handle motion

(“all cold” to “mixed hot/cold”).

The handle limit stop can be adjusted

by the homeowner once the faucet is

installed. Setting the handle limit stop in

position 2 may help to prevent scalding

because it limits the amount of hot water

in the mix; however, this handle limit stop will

not always prevent scalding because it does

not compensate for incoming pressure or

sudden water temperature changes.

To change positions of the handle limit

stop: remove the handle; move the

valve stem to the all cold position so the

water is on; change the position of the

handle limit stop; turn off the water; reinstall

the handle.

2

13

Page 14

1

2

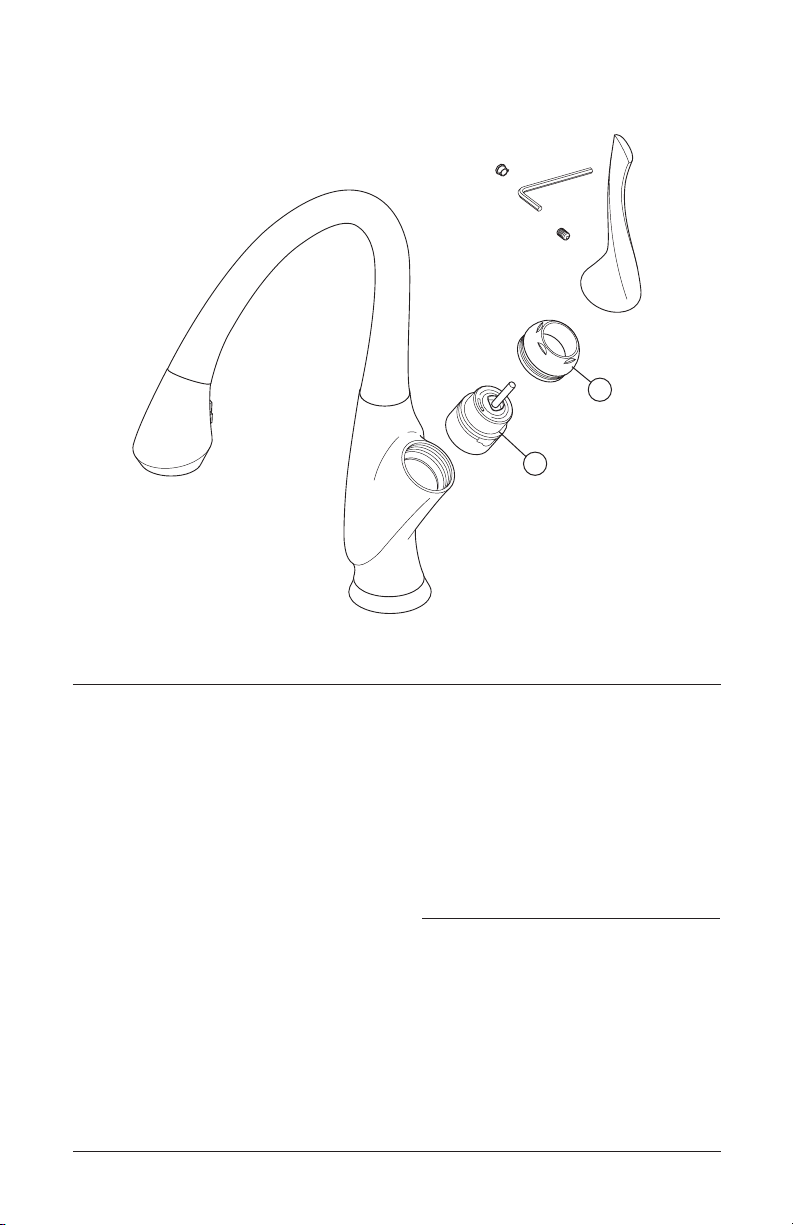

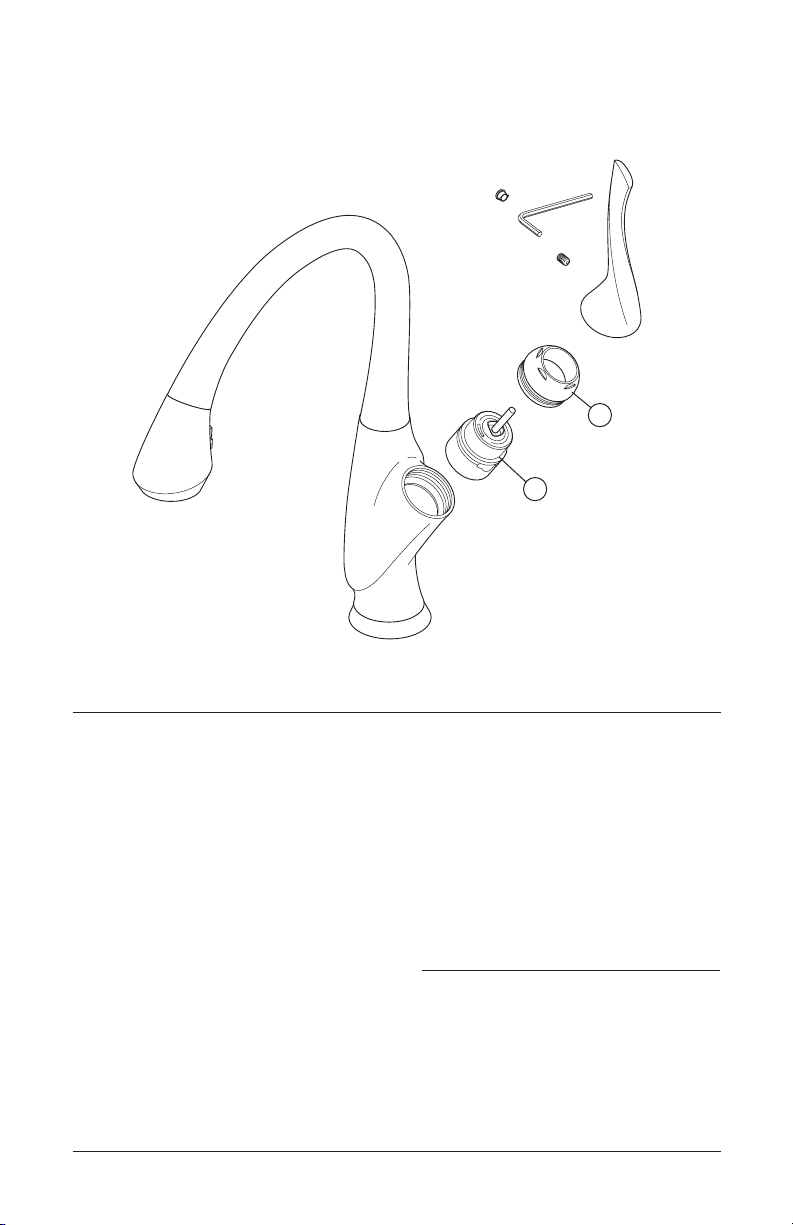

Maintenance

If faucet leaks from under handle:

Remove handle and ensure cap (1) is tight.

If leak persists–SHUT OFF WATER

SUPPLIES. Replace valve cartridge (2).

If faucet leaks from spout outlet–SHUT

OFF WATER SUPPLIES. Replace valve

cartridge (2).

Cleaning And Care

Care should be given to the cleaning

of this product. Although its finish is

extremely durable, it can be damaged

by harsh abrasives or polish. To clean,

simply wipe gently with a damp cloth and

blot dry with a soft towel.

Backflow Protection System

Your Brizo® Faucet pull-down spout

incorporates a backow protection system

that has been tested to be in compliance

with ASME A112.18.3 and

ASME A112.18.1 / CSA B125.1. It

incorporates two certified check valves in

series, which operate independently.

Note: A small amount of water may run

out the spout or drip for a very short

period after the faucet is shut off. This is

a natural occurrence caused by the long

exible hose.

14

Page 15

LLAVES DE AGUA/GRIFOS

®

T

E

F

L

O

N

T

E

F

L

O

N

DE CAÑO EXTRAÍBLE

PARA COCINAS Y BARES /

MULTI-PROPÓSITO

ASME A112.18.1 / CSA B125.1

Modelos

63052LF y 63952LF

Series

BELO®

Escriba aquí el número del modelo comprado.

ADVERTENCIA: ¡SESTA LLAVE NO SE DEBE UTILIZAR CON MAQUINAS

LAVAPLATOS PORTATILES!

Usted puede necesitar:

1/8"

Para instalación fácil de su llave

Brizo® usted necesitará:

• LEER TODAS las instrucciones

completamente antes de empezar.

• LEER TODOS los avisos, cuidados, e

información de mantenimiento.

62435 Rev. A

1

9/28/09

Page 16

Índice:

Garantía ------------------------------------------------------------ Página 2

Instrucciones para la Instalación -------------------------------------- Páginas 3-13

Instalación de la Manga Plástica -------------------------------------- Página 10

Fijando la parada de límite de la manija -------------------------------- Página 13

Mantenimiento ------------------------------------------------------ Página 14

Piezas de Repuesto ------------------------------------------------- Páginas 1 5 y 16

GarantÍa Limitada De Por Vida de la Llave y su Acabado

Todas las piezas y acabados de la llave Brizo®

están garantizados al consumidor comprador

original, de estar libres de defectos de material y

fabricación, por el tiempo que el consumidor

comprador original sea dueño de su casa. Delta

Faucet Company recomienda que use un

plomero profesional para todas las instalaciones

y reparaciones.

Delta reemplazará, LIBRE DE CARGO, durante el

período de garantía, cualquier pieza o

acabado que pruebe tener defectos de material y/

o fabricación bajo instalación normal, uso y

servicio. Piezas de repuesto pueden ser obtenidas

llamando al 1-877-345-BRIZO (2749) (en los

Estados Unidos y Canada) o escribiendo a:

En los Estados Unidos:

Delta Faucet Company

Product Service

55 E. 111th Street

Indianapolis, IN 46280

En Canada:

Masco Canada Limited, Plumbing Group

Technical Service Centre

420 Burbrook Place

London, ON N6A 4L6

Esta garantía es extensiva en lo que cubre el

reemplazamiento de todas las piezas

defectuosas y hasta el acabado, pero éstas son

las únicas dos cosas que están cubiertas.

CARGOS DE LABOR Y/O DAÑOS INCURRIDOS

EN LA INSTALACIÓN, REPARACIÓN, O

REEMPLAZAMIENTO COMO TAMBIÉN

CUALQUIER OTRO TIPO DE PÉRDIDA O

DAÑOS ESTÁN EXCLUÍDOS. Prueba de

compra (recibo original de venta) del comprador

consumidor original debe de ser disponible a

Delta para todos los reclamos. ESTA ES LA

GARANTÍA EXCLUSIVA DE DELTA FAUCET

COMPANY, QUE NO HACE CUALQUIER OTRA

GARANTÍA DE CUALQUIER TIPO,

INCLUYENDO LA GARANTÍA IMPLÍCITA DE

COMERCIALIZACIÓN.

Esta garantía excluye todo uso industrial,

comercial y de negocio, a cuyos compradores se

les da una garantía limitada extendida de cinco

años desde la fecha de compra, con todos los

otros términos de esta garantía aplicados,

excepto el de duración de ésta. Esta garantía es

aplicable a las llaves de Brizo® fabricadas

después de Enero 1, 1995.

Algunos estados/provincias no permiten la

exclusión o limitación de daños incidentales o

consecuentes, de manera que la limitación o

exclusión arriba escrita puede no aplicarle a

usted. Cualquier daño a esta llave, resultado del

mal uso, abuso, o descuido, o cualquier otro uso

de piezas de repuesto que no sean genuinas de

Delta® ANULARÁN LA GARANTÍA.

Esta garantía le da derechos legales específicos,

y usted puede, también tener otros

derechos que varían de estado/provincia a

estado/provincia. Es aplicable sólo a las llaves

®

Brizo

instaladas en los Estados Unidos de

America, Canada y Mexico.

© 2009 Masco Corporación de Indiana

2

Page 17

1

A. C.

1

2

2

1

B.

Doble

Instalación de la Manguera

Enrosque la manguera (1) en el

A.

mango del rociador (2).

Para permitir un ensamble más fácil,

B.

doble la manguera cerca del mango

como se muestra.

Introduzca la manguera (1) en y a

C.

través del sub-ensamble del

surtidor (2).

3

Page 18

2

A.

1

2

3

Ensamble de Surtidor

Verique si la arandela de fricción (1), gancho del surtidor (2) y el aro del surtidor

A.

(3), están presentes en el ensamble del surtidor.

4

Page 19

B.

C.

1

1

2

2

Ensamble de Surtidor (Continuación)

Introduzca la manguera (1) por la

B.

guía en el cuerpo y hacia fuera por

la espiga de instalación (2).

Alinee el botón (1) en el gancho del

C.

surtidor con el agujero en el cuerpo

(2), luego introduzca el surtidor en el

cuerpo. Use un movimiento de vaivén

para introducir el ensamble del surtidor en el cuerpo hasta que el botón

del gancho quede introducido en el

agujero. Gire el ensamble del surtidor

para asegurar un funcionamiento

suave. USE CAUTELA PARA NO

PELLIZCARSE LOS DEDOS.

5

Page 20

3

A. B.

2

1

3

2

1

6

4

7

5

Instalación de la Llave de Agua – Instalación de Centro

Quite el adhesivo al dorso del

A.

empaque del aro de accesorio (1)

y oprima en su sitio en el aro de

accesorio (2). Coloque el aro de

accesorio en el fondo del cuerpo del

surtidor. Introduzca las tuberías de

suministro de agua a través del orificio para la instalación del fregadero.

Su llave de agua está diseñada para

un orificio de 1 3/8” +/- 1/4” (35 mm

+/- 6 mm) de diámetro y un grosor

de la encimera de 3” (76 mm). El

grosor máximo de las encimeras

para los dispensadores de jabón es

3” (76 mm).

Deje pasar la manguera (1) parcialmente

B.

hacia arriba en la espiga de instalación (2).

Instale el soporte de la instalación (3) y la

tuerca (4) en la espiga de instalación usando

la llave de tuercas (5). Para encimeras

de un grosor hasta 1 3/8” (35 mm) use

un separador (6) incluido, entre la tuerca

y el soporte de instalación. Nota 1: La

llave de tuercas incluida está diseñada

para usarse con una variedad de

herramientas: destornilladores de cabeza

plana/Phillips, llaves de tuercas, etc.

Nota 2: Para fregaderos delgados (no se

recomienda), use el refuerzo (7) RP49588

para soporte de la encimera como se

muestra para instalación sencilla y de 3

orificios. SUGERENCIA: Cuando haga

la instalación gire el caño del surtidor en

dirección opuesta a la manija para balancear

el ensamble.

6

Page 21

3

Opcional

4

6

5

3

7

Instalación de una Chapa Opcional

Para instalaciones opcionales usando la

chapa o chapetón de 10”, ordene la pieza

RP49588 (especifique el acabado) no se

incluye. Reemplace el aro de accesorio

por la chapa de 10” (1) y el empaque (2).

Pase la manguera (3) parcialmente hacia

arriba por la espiga de instalación.

Instale como se muestra arriba usando los

pernos de 2 1/4-20 (4), las tuercas y

arandelas (5), el soporte (6) con la

tuerca y la llave de tuercas (7). La llave

de tuercas incluida está diseñada

para usarse con una variedad de

herramientas: destornilladores de

cabeza plana/Phillips, llaves de

tuercas, etc.

1

2

4

5

7

Page 22

4A

A.

B.

3

2

2

1

2

3

1

4

Conexiones a la Línea de Agua

Asegúrese que todos los accesorios y

A.

las conexiones finales estén libres de

residuos. Los accesorios (1) son de

compresión de 3/8”, con los extremos

de color rojo para el agua caliente

y azul para el agua fría. Enlace las

tuberías (2) si es muy larga. Nota: La

curva mínima recomendada es de

8" de diámetro. Fije la tuerca de metal

(3) en el tubo de la llave de agua a la

conexión (4) y apriete a mano, luego

apriete con una vuelta adicional con

una llave de tuercas. NO APRIETE

DEMASIADO. Repita con el otro tubo.

AVISO: No use compuesto para

tuberías u otros selladores en las

conexiones de la tubería de agua.

B.

8

2

Coloque un cubo por debajo de la

conexión rápida de la llave de agua (1)

y abra por un minuto ambas válvulas

(2) y manija (3) de suministro de agua.

Importante: Esto limpia cualquier

residuo que pudiera causar daño a

los componentes internos. Cuando

termine cierre ambas válvulas y manija

de suministro de agua.

Page 23

4B

A. B.

3

1

2

Conexiones Especiales

AVISO: Si usted determina que la tubería

PEX para el suministro de agua para esta

llave de agua es muy larga y debe

recortarse para crear una instalación

aceptable, asegúrese leer las instrucciones y planifique de antemano. Cuando

corte la tubería de suministro el instalador

acepta la responsabilidad de hacerlo de

una manera que permite crear una

articulación sin filtraciones. Delta no se

responsabiliza por las tuberías que se han

cortado demasiado cortas o cortadas de

una manera que no permite una articulación libre de filtración.

Para instalaciones hechas a la medida, usted

debe usar mangas RP50952 incluidas con el

modelo y las tuercas incluidas en las tuberías

de suministro. El cor te del tubo debe ser recto.

Vea las instrucciones para la instalación de

la manga plástica incluida con el RP50952 y

para más información incluida en este

documento (página 11).

Fije la tuerca de metal (1) ubicada en el tubo

A.

de la llave de agua o grifo a la conexión de la

válvula de suministro (2) y apriete a mano,

luego apriete 2 vueltas adicionales con la

llave de tuercas. NO APRIETE DEMASIADO.

Repita con la otra tubería. AVISO: No use

compuesto para tuberías u otros

selladores en las conexiones de la

tubería de agua.

Coloque un cubo por debajo de la conexión

B.

2

rápida de la llave de agua (1) y abra

por un minuto ambas válvulas (2) y

la manija (3) de suministro de agua.

Importante: Esto limpia cualquier

residuo que pudiera causar daño a los

componentes internos. Cuando termine

cierre ambas válvulas y la manija de

suministro de agua.

Problemas Potenciales y Soluciones

l La tubería no está cortada

perpendicular al eje de la bañera:

cuidadosamente haga un corte

adicional, teniendo cuidado de no cortar

el tubo demasiado corto.

l La tubería está cortada demasiado

corta: compre en un almacén un

acoplamiento de unión y una tubería de

suministro de repuesto que acoplen. El

extremo de la unión de acoplamiento que

es para conectar a la llave de agua debe

acoplar con las tuercas estándares de

3/8" y mangas de plástico incluidas con la

llave de agua / grifo.

l La manga plástica o la tuerca de

conexión se ha perdido: compre una

tuerca de repuesto y/o manga plástica

diseñada para sellar con la tubería PEX.

AVISO: No use una manga de metal,

RP51243 empaque (suministrado con el

grifo) o casquillo, en vez de la manga

incluida puede no crear una articulación

sin filtración.

1

2

9

Page 24

Instrucciones para la Instalación del la Manga Plástica

Método Correcto

1. Identique la longitud deseada del tubo (1). Deje

1” – 2” de soltura para una instalación más fácil y

sin rebabas. Asegure que el corte sea recto y

sin rebabas.

2. Resbale la tuerca (2) y la manga plástica (3)

sobre el tubo cortado. Asegure la manga se

orienta según lo demostrado.

3. Introduzca el tubo dentro del accesorio (4). El

tubo debe tocar el fondo del agujero dentro

del accesorio.

4. Deslice la manga plástica hacia abajo en el

tubo hasta que encaje el la parte superior

del accesorio. AVISO: El no usar la manga

plástica en la orientación correcta resultará

en desconexión y posible daño por agua.

5. Deslice la tuerca sobre la manga plástica. Con

la llave de tuercas, apriete la tuerca dándole 2

vueltas más de si fuera apretado a mano.

2

3

1

4

Instalación Incorrecta

No instale la manga

boca abajo.

No use RP51243

empaque (1)

suministrado con el

tubería de PEX o el

casquillo de bronce

(2) suministrado con

las válvulas de cierre.

1

2

Asegúrese que el

corte esté recto.

Asegúrese que el

tubo este completamente introducido

dentro del tope antes

de deslizar la manga

hacia abajo para encajar la parte superior

del accesorio.

10

Page 25

5

A.

B.

C.

1

2

D.

1

D.

1

2

1

Conexiones de la Manguera con Rociador

Introduzca el extreme de la manguera

A.

(1) por el ensamble de la pesa de la

manguera (2).

Introduzca el adaptador de la válvula

B.

de retención (1) en el accesorio

extraíble de la manguera (2).

Asegúrese que la pesa no se deslice

de la manguera.

Introduzca el empalme de conexión

C.

rápida en el extremo de salida de agua

del grifo (1) en el adaptador.

Gire el adaptador (1) para fijar el

D.

ensamble a la manguera extraíble y el

tubo de salida de la llave de agua.

1

11

Page 26

6

A.

B.

3

2

o

abrir

4

cerrar

1

1

5

Inspección de la Llave de Agua / Grifo y Funcionamiento

Abra los suministros de agua caliente y

A.

fría (1). Hale la manguera extraíble (2)

del surtidor. Asegúrese de sujetar el

extremo de rociador hacia el fregadero y

abra la llave de agua con la manija (3) a

la posición mixta por un minuto.

Examine todas las conexiones en los

puntos señalados con flechas donde

pudiera haber filtraciones. Apriete

de nuevo si es necesario, pero no

apriete demasiado.

El rociador quedará jo en su posición

B.

cuando se acerca al imán del surtidor.

El rociador puede sacarse halándolo

directamente hacia fuera del surtidor o

girándolo 90° en cualquier dirección que

hará que los imanes se repelen y la

cabeza de desconecte del surtidor (se

recomienda). Examine el funcionamiento del rociador al operar el gatillo (4) del

aireador al rociador. El desviador

permanecerá en el último modo que

usó. Para reducir o parar el ujo, oprima

el botón de selección más adentro en el

mango. La llave de agua para bares /

multi-propósito es de sólo dos funciones

de rocío. Oprima el botón (5) para

escoger entre los modos.

12

Page 27

7

1

Fijando la parada de límite de la manija (opcional)

Esta llave de agua incluye una manija

integrada, que tiene dos posiciones, para

limitar la temperatura. La posición 1, a la

izquierda, permite el movimiento completo

de la manija (el alcance completo entre el

agua “totalmente fría” hasta “totalmente

caliente”). La fábrica preselecciona la

llave de agua (grifo) a la posición 1. La

posición 2, a la derecha, permite la mitad

del alcance de movimiento normal de la

manija (“totalmente fría” a la posición “mixta

caliente/fría”).

Una vez que la llave de agua (grifo) se

ha instalado, el límite rotacional de la

manija puede ajustarse por el propietario

de la residencia. Ajustando la manija de

ajuste del tope del límite de la temperatura

a la posición 2 puede ayudar a prevenir

escaldaduras porque limita la cantidad de

agua caliente en la mezcla; sin embargo,

esta manija que limita la temperatura del

agua no siempre prevendrá escaldaduras

porque no compensa la presión del agua

de entrada o cambios repentinos de la

temperatura del agua.

Para cambiar las posiciones de la manija

que limitan la temperatura: quite la

manija; cambie la posición de la espiga de

la válvula a la posición totalmente fría de

manera que el agua este abierta; cambie la

posición de la manija que limita la temperatura; cierre el agua; reinstale la manija.

13

2

Page 28

2

1/8"

1

Mantenimiento

Si la llave de agua tiene una filtración

por debajo de la manija:

Quite la manija y asegúrese que la tapa (1)

está apretada.

Si la filtración persiste – CIERRE LOS

SUMINISTROS DE AGUA. Cambie el

cartucho de la válvula (2).

Si la llave de agua tiene una filtración

desde la salida del surtidor – CIERRE

LOS SUMINISTROS DE AGUA. Cambie el

cartucho de la válvula (2).

Limpieza Y Cuidado

De Su Llave

Tenga cuidado al ir a limpiar este producto.

Aunque su acabado es sumamente durable,

puede ser afectado por agentes de limpieza

o para pulir abrasivos. Para limpiar su llave,

simplemente frótela con un trapo húmedo y

luego séquela con una toalla suave.

Sistema de protección

contra el contraflujo

Su llave de agua tipo deslizable Delta tiene

un sistema de protección contra el

contraujo, incorporado, que ha sido

probado para cumplir con los requisitos de

ASME A112.18.3 y ASME A112.18.1 /

CSA B125.1. Este incorpora en la pieza

de mano dos válvulas de retención o

checadoras certificadas en una serie, las

cuales operan independientemente

Nota: Una cantidad pequeña de agua

puede escurrirse del surtidor o gotear

por un período corto de tiempo después

de cerrar el agua. Esto es una ocurrencia

natural causada por la manguera

larga exible.

14

Page 29

ROBINETS D’ÉVIER DE BAR ET

®

T

E

F

L

O

N

T

E

F

L

O

N

D’ÎLOT À BEC RÉTRACTABLE

ASME A112.18.1 / CSA B125.1

Modèles

63052LF & 63952LF

Seria

BELO®

Inscrivez le numéro de modèle ici.

MISE EN GARDE : NE PAS RACCORDER DE LAVE-VAISSELLE MOBILES À CE ROBINET!

Articles dont vous pouvez avoir besoin:

1/8 po

Pour installer votre robinet

Brizo® facilement, vous devez:

• LIRE TOUTES les instructions avant

de débuter;

• LIRE TOUS les avertissements ainsi

que toutes les instructions de

nettoyage et d’entretien;

62435 Rev. A

1

9/28/09

Page 30

TABLE DES MATIÈRES

Garantie -------------------------------------------------------------- Page 2

Instructions d’installation ----------------------------------------------- Pages 3-13

Installation du manchon de plastique ------------------------------------- Page 10

Plaçant l’arrêt de limite de poignée ------------------- ------------------- Page 13

Maintenance ---------------------------------------------------- ------ Page 14

Pièces de rechange --------------------------------------------------- Pages 1 5 e t 16

GARANTIE À VIE LIMITÉE DES ROBINETS ET DE LEURS FINIS

Toutes les pièces et les finis du robinet Brizo®

sont protégés contre les défectuosités de

matériau et les vices de fabrication par une

garantie qui est consentie au premier acheteur

et qui demeure valide tant que celui-ci demeure

propriétaire de sa maison. Delta recommande

de faire appel à un plombier compétent pour

l'installation et la réparation du robinet.

Pendant la période de garantie, Delta remplacera

GRATUITEMENT toute pièce ou tout fini,

présentant une défectuosité de matériau ou un

vice de fabrication pour autant que l'appareil

ait été installé, utilisé et entretenu correctement.

Pour obtenir des pièces de rechange, veuillez

communiquer par téléphone au numéro

1-877-345-BRIZO (2749) (aux États-Unis ou

au Canada) et par écrit à l'une des adresses

suivantes :

Aux États-Unis

Delta Faucet Company

Product Service

55 E. 111th Street

Indianapolis, IN 46280

Au Canada

Masco Canada Limited, Plumbing Group

Technical Service Centre

420 Burbrook Place

London, ON N6A 4L6

La présente garantie s'applique au remplacement

de toutes les pièces défectueuses, y compris le fini,

et elle ne couvre que ces éléments. LES FRAIS

DE MAIN-D'OEUVRE ET (OU) LES DOMMAGES

PROVOQUÉS AU COURS DE L'INSTALLATION,

DE LA RÉPARATION OU DU REMPLACEMENT

D'UN ÉLÉMENT AINSI QUE LES PERTES OU

DOMMAGES DE TOUTE AUTRE NATURE NE

SONT PAS COUVERTS PAR LA GARANTIE. Toute

réclamation en vertu de la présente garantie doit

être adressée à Delta, accompagnée de la preuve

d'achat (original de la facture) du premier acheteur.

CETTE GARANTIE EST LA SEULE OFFERTE PAR

DELTA FAUCET COMPANY OU DELTA FAUCET

CANADA, SELON LE CAS. ELLE EXCLUT TOUTE

AUTRE GARANTIE, Y COMPRIS LA GARANTIE

IMPLICITE DE QUALITÉ MARCHANDE.

Les robinets installés dans un établissement

industriel ou commercial ou dans une place

d'affaires sont protégés par une grantie étandue de

cinq ans qui prend effet à compter de la date d'achat.

Toutes les autres conditions de la garantie de cinq

ans sont identiques à celle de la présente garantie.

La présente garantie s'applique à tous les robinets

Brizo® fabriqués après le 1er janvier 1995.

Dans les États ou les provinces où il est interdit

d'exclure ou de limiter les responsabilités à l'égard

des dommages indirects ou fortuits, les exclusions

et les limites susmentionnées ne s'appliquent pas.

Les dommages résultant d'une mauvaise utilisation,

d'une utilisation abusive de la négligence ou de

l'utilisation de pièces autres que des pièces d'origine

Delta® RENDENT LA GARANTIE NULLE ET

SANS EFFET.

La présente garantie vous donne des droits précis

qui peuvent varier selon votre lieu de résidence. Elle

ne s'applique qu'aux robinets Brizo® installés aux

États-Unis, au Canada et au Mexique.

© 2009 Division de Masco Indiana

2

Page 31

1

A. C.

1

2

2

1

B.

courbez

Installation du flexible

Vissez le exible (1) dans la

A.

poignée du bec-douchette (2).

Pour faciliter l’installation, courbez

B.

le exible près de la poignée

comme le montre la figure.

Introduisez le exible (1) dans le bec

C.

et faites-le glisser de part en part du

bec (2).

3

Page 32

2

A.

1

2

3

Installation du bec

Assurez-vous que la rondelle de frottement (1), l’agrafe du bec (2) et l’anneau du

A.

bec (3) se trouvent sur le bec.

4

Page 33

B.

C.

1

1

2

2

Installation du bec (suite)

Introduisez le exible (1) dans le

B.

guide du porte-bec, puis dans la

tige de montage (2).

Faites correspondre le bouton (1) sur

C.

l’agrafe du bec avec le trou dans le

porte-bec (2), puis introduisez le bec

dans le porte-bec. Imprimez un mouvement de va-et-vient au bec pour

l’introduire dans le porte-bec jusqu’à

ce que le bouton de l’agrafe pénètre

dans le trou. Faites pivoter le bec pour

vous assurer qu’il pivote en douceur.

PRENEZ GARDE DE VOUS PINCER

LES DOIGTS.

5

Page 34

3

A. B.

2

1

3

2

1

6

4

7

5

Installation du robinet –

Montage dan le trou au centre de l’évier

Enlevez l’endos adhésif sur le joint

A.

circulaire (1) et placez-le contre

l’anneau de finition (2). Exercez une

pression sur le joint. Placez l’anneau

de finition contre le dessous du

porte-bec. Introduisez les tubes

d’alimentation dans le trou de montage de l’évier. Le robinet est conçu

pour un trou d’un diamètre de 1 3/8

± 1/4 po (35 mm ± 6 mm) et pour un

comptoir d’une épaisseur maximale

de 3 po (76 mm). L’épaisseur maxi-

male admissible pour le distributeur

de savon est de 3 po (76 mm).

Introduisez le flexible (1) partiellement

B.

dans la tige de montage (2). Installez

le support (3) et l’écrou (4) sur la tige

de montage à l’aide de la clé (5). Si le

comptoir a 1 3/8 po (35 mm) d’épaisseur

ou moins, placez la cale (6) fournie entre

l’écrou et le support de montage.

Note 1 : La clé fournie est conçue

pour être utilisée avec une variété

d’outils : tournevis à extrémité plate

ou Phillips, clés, etc. Note 2 : Si

l’évier est mince (non recommandé),

supportez le comptoir avec la plaque

de renfort (7) RP49588, comme le

montre la figure, qu’il s’agisse d’une

installation dans un ou trois trous.

Conseil : Placez le bec du côté opposé

à celui de la manette pour équilibrer le

robinet pendant le montage.

6

Page 35

3

Facultative

4

6

5

3

7

1

2

4

5

Installation de la plaque de finition facultative

Pour une installation nécessitant la plaque

de finition facultative de 10 po, commandez le kit RP49588 (précisez le fini) non

fourni. Remplacez l’anneau de finition par

la plaque de finition de 10 pouces (1) et le

joint (2). Poussez le flexible (3) partiellement vers le haut dans la tige de montage.

Montez la plaque comme le montre la figure ci-dessus à l’aide des goujons

2 1/4 - 20 (4), des écrous et des rondelles

(5) et du support (6) avec l’écrou et la

clé (7). La clé fournie est conçue pour

être utilisée avec une variété d’outils :

tournevis à extrémité plate ou Phillips,

clés, etc.

7

Page 36

4A

A.

B.

3

2

2

3

1

4

Branchement à la tuyauterie

Assurez-vous que tous les raccords sont

A.

exempts de corps étrangers. Le

branchement est effectué au moyen de

raccords de robinetterie (1) 3/8 po à

compression. L’extrémité du raccord d’eau

chaude est rouge et celle du raccord d’eau

froide est bleue. Faites une boucle avec le

tube (2) s’il est trop long. Note : Le

diamètre minimal de la courbure doit être

d’au moins 8 po. Vissez l’écrou métallique

(3), qui se trouve sur le tube du robinet, sur

le raccord du robinet d’alimentation (4) et

serrez-le à la main, puis faites un tour

supplémentaire avec une clé. PRENEZ

GARDE DE TROP SERRER. Raccordez

l’autre tube de la même manière.

MISE EN GARDE : N’utilisez pas de pâte

à joint ni d’autres produits d’étanchéité

sur les raccords de tuyauterie.

2

Placez un seau sous le raccord

B.

rapide (1), puis ouvrez les deux

robinets d’alimentation (2) et la

poignée (3) et laissez-les ouverts

une minute. Important : Cette

opération vise à évacuer les

débris qui pourraient abîmer

les composants internes.

Fermez ensuite les deux robinets

d’alimentation et la poignée.

1

2

8

Page 37

4B

A.

B.

3

1

2

Spéciaux Tuyauterie Branchement

NOTIFICATION : Si le tube d’alimentation

en PEX de ce robinet est trop long et

doit être raccourci, lisez les instructions

et prenez le temps de réfléchir. Vous

devez couper le tube de manière à

obtenir un joint étanche. Delta n’accepte

aucune responsabilité si le tube a été

coupé trop court ou d’une manière qui

empêche le joint d’être étanche.

Dans le cas des installations sur mesure,

vous devez utiliser les manchons RP50952

fournis avec le robinet et les écrous qui se

trouvent sur les arrivées d’eau. Le tube doit

être coupé d’équerre. Pour obtenir plus de

renseignements, veuillez consulter les

instructions d’installations des manchons

en plastique qui se trouvent dans le kit

RP50952 et qui sont incluses dans le

présent document (page 11).

Vissez l’écrou métallique (1), qui se trouve

A.

sur le tube du robinet, sur le raccord du

robinet d’alimentation (2) et serrez-le à la

main. Serrez-le à la main, puis faites deux

tours à l’aide d’une clé. PRENEZ GARDE

DE TROP SERRER. Raccordez l’autre tube

de la même manière. MISE EN GARDE :

N’utilisez pas de pâte à joint ni d’autres

produits d’étanchéité sur les raccords

de tuyauterie.

Placez un seau sous le raccord rapide (1),

B.

puis ouvrez les deux robinets d’alimentation

(2) et la poignée (3) et laissez-les ouverts

une minute. Important : Cette opération

vise à évacuer les débris qui pourraient

abîmer les composants internes.

Fermez ensuite les deux robinets

d’alimentation et la poignée.

Problèmes possibles et correctifs

l Le tube n’est pas coupé d’équerre :

l Vous avez coupé le tube trop court :

l Vous avez perdu un manchon en

2

Faites une nouvelle coupe en prenant

garde de ne pas trop raccourcir le tube.

Achetez un raccord-union et un tube

d’arrivée d’eau de rechange dans un

magasin. L’extrémité du raccord-union

à raccorder au robinet doit être

compatible avec les écrous 3/8 po

standard et les manchons en plastique

fournis avec le robinet.

plastique ou un écrou de

raccordement : Achetez un écrou et/

ou un manchon en plastique conçus

pour former un raccord étanche avec

un tube PEX. NOTIFICATION : Évitez

d’utiliser un manchon métallique,

RP51243 le joint (fournie avec le

robinet) ou une virole à la place du

manchon en plastique fourni. Le joint

ne sera pas étanche.

1

2

9

Page 38

Instructions d’installations de le manchon en plastique

Bonne méthode

1. Identifiez la longueur désirée du tube (1). Laissez

1 à 2 pouces de la longueur supplémentaire pour

faciliter l’installation et coupez le tube. Faites une

coupe d’équerre et enlevez les bavures.

2. Glissez l’écrou (2) et la manchon en plastique (3)

sur le tube coupé. Assurez la manchon est

orienté comme montré.

3. Introduisez le tube dans le raccord (4). Le tube doit

toucher le fond du trou à l’intérieur du raccord.

4. Faites glisser le manchon en plastique dans le

tube jusqu’à ce qu’il pénètre dans la partie

supérieure du raccord. MISE EN GARDE : Si le

manchon en plastique n’a pas été installé

dans l’orientation correcte, le raccord peut se

défaire et l’eau peut occasionner des

dommages.

5. Faites glisser l’écrou sur le manchon en plastique.

Serrez-le à la main, puis faites deux tours à

l’aide d’une clé.

2

3

1

4

Installation Incorrecte

N’installez pas le

manchon à l’envers.

N’utilisez pas

RP51243 le joint

(1) fournie avec la

tuyauterie de PEX ou

la bague en cuivre

(2) fournie avec les

robinets d’arrêt.

1

2

Assurez-vous que

la coupe est droite.

Assurez-vous que le

tube est introduit

entièrement dans le

robinet d’arrêt avant

de faire glisser le

manchon vers le bas

pour le xer à la partie

supérieure du raccord.

10

Page 39

5

A.

B.

C.

1

2

D.

1

D.

1

2

1

Branchement du flexible de la douchette

Introduisez l’extrémité du flexible (1)

A.

dans la masselotte du flexible (2).

Introduisez l’adaptateur à clapets

B.

(1) dans le raccord du flexible (2).

Prenez garde que la masselotte se

libère du flexible.

Introduisez le raccord rapide du robinet

C.

(1) dans l’adaptateur à clapets.

Faites pivoter les bras de l’adaptateur

D.

(1) pour le bloquer sur le flexible de

la douchette et le flexible de sortie du

robinet.

1

11

Page 40

6

A.

B.

3

2

ou

déverrouiller

4

Verrouiller

1

1

5

Inspection et utilisation du robinet

Rétablissez l’alimentation en eau

A.

chaude et en eau froide (1).Tirez le

flexible (2) hors du bec. Tenez l’extrémité

de la douchette dans l’évier et amenez

la manette du robinet (3) à la position

de mélange de l’eau chaude et de l’eau

froide. Laissez couler l’eau une minute.

Vérifiez l’étanchéité de tous les raccords

aux endroits indiqués par les flèches.

Serrez les raccords de nouveau au

besoin, mais pas excessivement.

La douchette se bloque lorsqu’on la

B.

place à proximité de l’aimant du bec.

Pour séparer la douchette du bec, tirez

directement sur celle-ci ou tournez-la

dans un sens ou dans l’autre à 90° et

ainsi utiliser la force de répulsion des

aimants (méthode recommandée).

Vériez le fonctionnement de la

douchette en actionnant la gâchette (4)

pour passer du mode aération au mode

pulvérisation. L’inverseur conserve le

dernier mode sélectionné. Pour réduire

ou interrompre l’écoulement, enfoncez le

bouton sélecteur davantage dans la

poignée. Le robinet d’évier de bar et

d’îlot est doté d’une douchette à deux

fonctions seulement. Enfoncez le bouton

(5) pour passer d’un mode à l’autre.

12

Page 41

7

1

Plaçant l’arrêt de limite de poignée (facultatif)

Ce robinet est muni d’une butée de

température maximale à deux positions. La

position 1, à gauche, permet le déplacement

de la manette entre les deux extrémités de

la plage de température (eau très froide et

eau très chaude). C’est la position sélectionnée en usine. La position 2, à droite, permet

le déplacement de la manette sur la moitié

de la plage de température (eau très froide

et eau mitigée).

Il est possible de régler la butée de tempéra-

ture maximale de la manette au moment de

l’installation du robinet. Un réglage à la position 2 peut empêcher l’ébouillantage parce

que cette position limite la quantité d’eau

chaude dans le mélange. Toutefois, ce

réglage de la butée de température

maximale de la manette ne constitue pas

une garantie absolue contre l’ébouillantage

parce qu’il n’offre aucune protection

contre les uctuations de la pression

d’alimentation ou les changements de

température soudains.

Pour modifier la position de la butée de

température maximale de la manette :

enlevez la manette; amenez l’obturateur à

l’extrémité de la plage du côté eau froide

pour faire s’écouler l’eau; modiez la position de la butée de température maximale;

fermez le robinet; réinstallez la manette.

2

13

Page 42

1/8 po

2

1

Entretien

Si le robinet fuit par le dessous de la

manette :

Enlevez la manette et assurez-vous que le

chapeau (1) est fixé solidement.

Si la fuite persiste, COUPEZ L’ARRIVÉE

D’EAU. Remplacez la cartouche de la

soupape (2).

Si le robinet fuit par la sortie du bec,

COUPEZ L’ARRIVÉE D’EAU. Remplacez la

cartouche (2).

Instructions De Nettoyage

Il faut le nettoyer avec soin. Même si son fini

est extrêmement durable, il peut être abîmé

par des produits fortement abrasifs ou des

produits de polissage. Il faut simplement le

frotter doucement avec un chiffon humide et

le sécher à l'aide d'un chiffon doux.

Dispositif anti-siphonnage

Le bec rétractable de votre robinet Delta

comporte un dispositif anti-siphonnage

qui a été éprouvé et qui est conforme

aux normes ASME A112.18.3 et

ASME A112.18.1 / CSA B125.1. Ce

dispositif se compose de deux clapets

indépendants homologués, montés en

série dans le tube rigide, qui sont

non réparables.

Note : Un peu d’eau peut s’écouler du

bec ou dégoutter pendant une très courte

période après la fermeture du robinet.

Cela est normal en raison de la longueur

du exible.

14

Page 43

RP6092

Nuts & Washers

Tuercas y Arandelas

Écrous et Rondelles

RP50576▲

(model 63952)

Spout Assembly

Ensamble del Tubo de Salida

Bec

RP50583▲

(model 63052 & 63352)

Sprayer Assembly

(includes aerator)

Ensamble de rociador

(incluye el aireador)

Pulvérisateur

(inclut aérateur)

RP50577▲

(model 63952)

Sprayer Assembly

(includes aerator)

Ensamble de rociador

(incluye el aireador)

Pulvérisateur

(inclut aérateur)

RP40533

Studs

Pernos

Goujons filetés

RP50584

Gasket

Empaque

Joint

RP50581

Spout Ring,

Friction Washer

& Clip

Aro para el Surtidor,

Arandela de Fricción

y Clip

Anneau du bec, rondelle de frottement

et agrafe

RP50952

Cut -To - Fit Hose Ferrules

Casquillos cortados a

la medida

Bagues d’extrémité pour

tubes coupés

RP50580▲

(models 63052 & 63352)

Spout Assembly

Ensamble del Tubo de Salida

Bec

RP50582▲

(All Models)

Lever Handle

Manijas de Palanca

Manette

RP50585▲

Set Screw,

O-Ring & Button

Tornillo de

Presión, Anillo-O

y Botón

Vis de calage,

joint torique et

bouton

RP50586▲

Cap

Casquete

Embase

RP50587

Valve Assembly

Ensamble de

la válvula

Soupape

RP49588▲

Optional 10" Escutcheon, Mounting Screws,

Nuts, Washers and gasket

Chapa opcional de 10", Tornillos para la

Instalación, Tuercas, Arandelas y Empaques

Plaque de finition facultative de 10 po, vis de

montage, écrous, rondelles et joint

RP49149

Steel Weight Assembly

Ensamble de la Pesa de Acero

Masselotte en acier

▲Specify Finish

▲Especifíque el Acabado

▲Précisez le Fini

RP37490

Thin Deck Aid

Sostén para

Bordes Delgados

Plaque de renfort

15

RP13938

O-Ring

Anillo “O”

Joint torique

RP51243

Inlet Gaskets

Empaques para el

tubo de entrada

Joints côté

alimentation

RP50588▲

Trim Ring and Gasket

Aro de Accesorio

Anneau de finition

RP40524

Gasket Only

Sólo el Empaque

Joint seulement

RP50590

Hose Assembly

Ensamble de la manguera

Tuyau souple

Page 44

RP49589▲

Dispenser Assembly

Ensamble del Dispensador

Distributeur

RP49640▲

Vase Only - Metal

Sólo el recipiente - Metal

Vase seulement - Métal

RP21908

Pump

Bomba

Pompe

RP50578▲

Body Assembly

(includes base &

gasket)

Ensamble del Cuerpo

(incluye base y

empaque)

Corps

(inclut base et joint)

RP40527

Mounting Bracket,

Nut and Spacer

Abrazadera para

la Instalación,

Tuerca y Separador

Fixation, écrou et cale

RP21945

Nut / Tuerca / Écrou

RP21904

Bottle

Botella

Bouteille

RP40526

Nut Only

Tuerca

Écrou seulement

RP40531

Wrench

Llave

Rondelle

RP30395

Vented Funnel

Embudo con Ventiladero

Entonnoir

RP53429

Adapters

3/8"-24 UNEF to 1/2"-20 UN &

3/8"-24 UNEF to 1/2"-14 NPSM

Adaptadors

3/8”-24 UNEF to 1/2”-20 UN y

3/8”-24 UNEF to 1/2”-14 NPSM

Adapteurs

3/8 po-24 UNEF to 1/2 po-20 UN et

3/8 po-24 UNEF to 1/2 po-14 NPSM

RP50578▲

Body Assembly

(includes base &

gasket)

Ensamble del Cuerpo

(incluye base y

empaque)

Corps

(inclut base et joint)

RP50579▲

Base & Gasket

Base y Empaque

Base et joint

RP21945

Nut / Tuerca / Écrou

RP49587▲

Vase Assembly - Metal*

Ensamble – Recipiente

de Metal*

Vase en métal*

RP50589

Adapter Assembly

with Check Valves

Ensamble del Adaptador con

Válvula de Retención

Adaptateur avec clapets

▲Specify Finish

▲Especifíque el Acabado

▲Précisez le Fini

16

Loading...

Loading...