Page 1

Installation Instructions

®

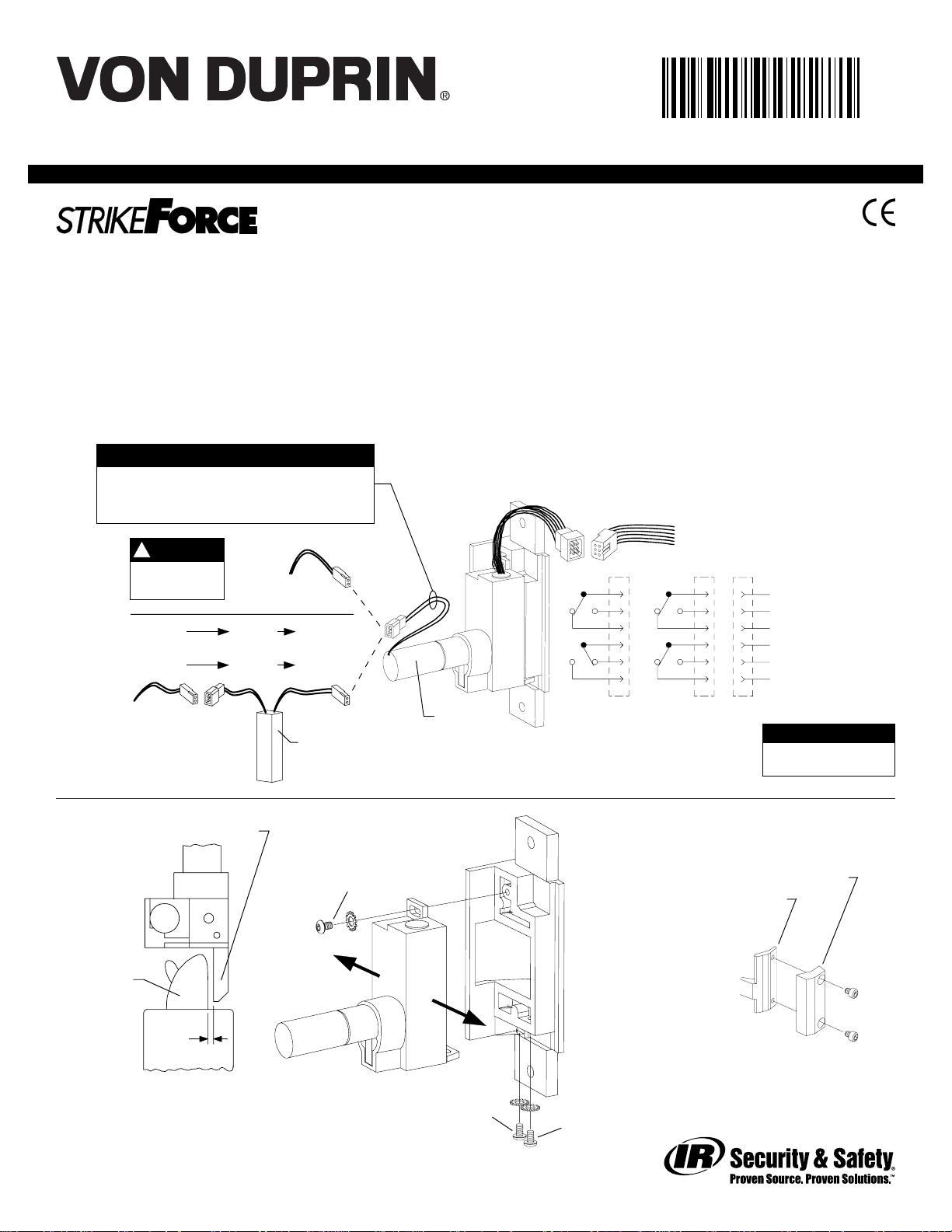

931225-00

6223/6223DS Electric Strike

Double Door Closed Back Mortise or Cylindrical Application

89/336/EEC

Notes: Deadbolt will not function with this strike.

1. For lock or device preparation, see their directions.

2. Prepare door for strike (see other side).

3. Wire strike (Figure 1). (Switches on 6223DS only.)

Wiring

for DC

supply

Wiring

for AC

supply

Check with factory for retrofit applications.

SOLENOID POWER REQUIREMENTS

Yellow solenoid wires = 12 VDC, 0.57 A

Black solenoid wires = 24 VDC, 0.29 A

(also shown on strike label)

NOTE

!

DC input is

{

nonpolarized.

12 VAC SO-12 12 VDC

or

24 VAC SO-24 24 VDC

12 VDC

or

24 VDC

{

Use crimp

connectors to

splice field wiring

to P1 leads

P1 J1A P1A

P1

J1

SO-12 or SO-24

Figure 1

4. Test strike: Apply solenoid power. Fail secure (FSE) lip unlocks.

Fail safe (FS) lip locks. Figure 1 shows status of switches.

5. Install strike with two #12-24 screws. Make sure clearance

between latch bolt and strike lip is 1/32” (Figure 2). If not,

uninstall strike, adjust (Figure 3), and reinstall.

6. If latch bolt does not extend far enough to actuate tripper,

install extension (Figure 4). (Tripper on 6223DS only.)

7. Test door: With strike unlocked, door opens with latch bolt

extended. When door closes, latch bolt rides over strike lip.

Solenoid

P2

J2

S1

S2

Fail safe (FS)J2Fail secure (FSE)

Switches shown with tripper

depressed, strike lip closed and locked

(switches and tripper on 6223DS only)

1

2

3

4

5

6

J2

Use crimp connectors to

splice field wiring to P2

leads; insulate unused leads

S1

S2

1

2

3

4

5

6

Red (C)

Blue

Yellow

White (C)

Gray

Violet

P2

SWITCH RATINGS

Standard: 5 A, 30 VDC

Gold: 0.25 A, 30 VDC

(monitors

}

(monitors

}

strike lip)

S1

tripper)

S2

Strike lip

A

Latch bolt

1/32”

Top view;

faceplate not

shown for clarity

Figure 2

931225_00(4) Copyright © 2004 Ingersoll-Rand. All rights reserved.

Figure 3

B

Extension

Tripper

To adjust strike,

loosen screws A, B,

and C and move

backbox sideways

as necessary

Figure 4

C

Page 2

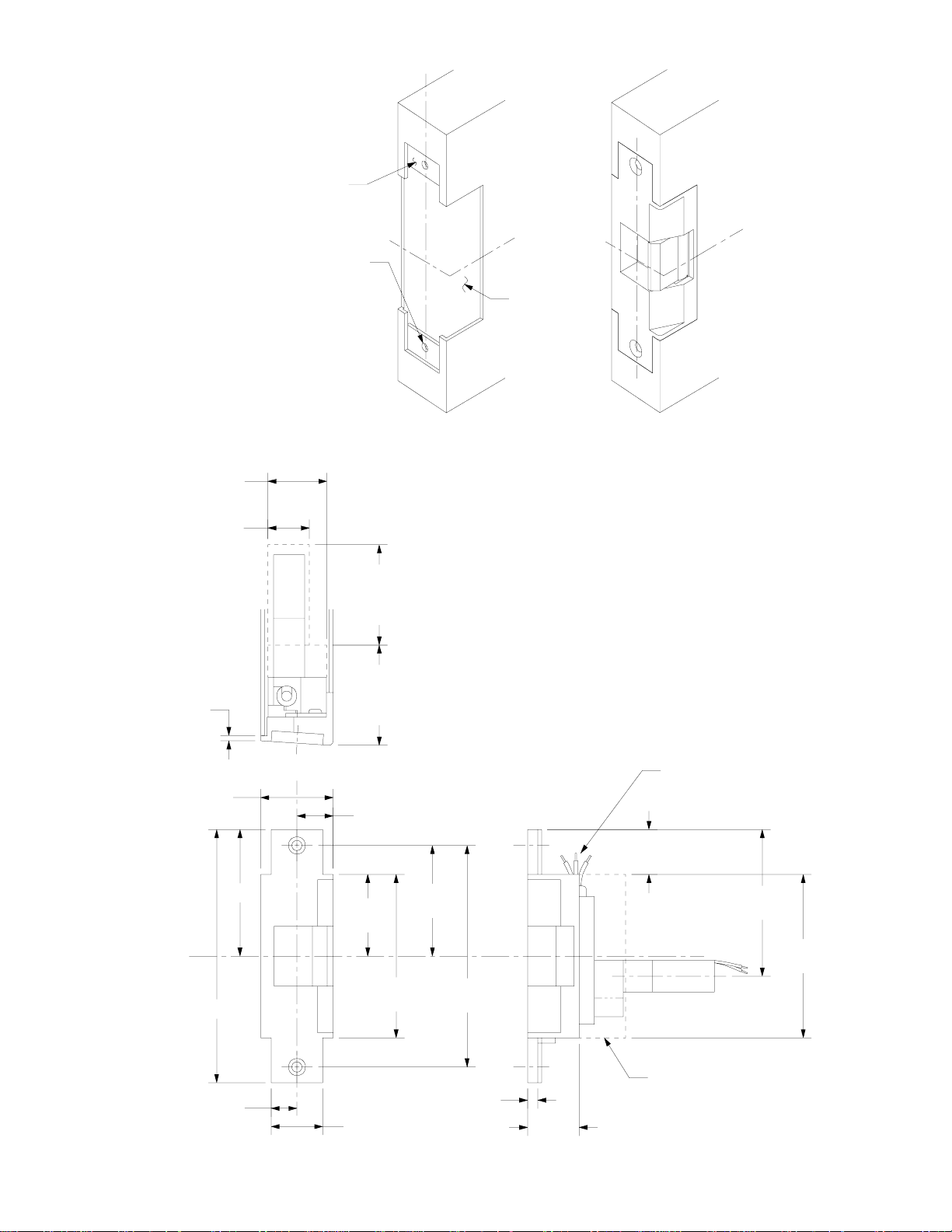

Reinforce for strike

attachment as required

1-7/16” minimum

clearance

LHR shown

RHR opposite

RHR door

shown inactive

#16 drill and

#12-24 tap

2 places

C door

L

C strike

L

Suggested

cutout

Door Preparation for Strike

1” dia. minimum

clearance

Strike

backbox

assembly

1/8”

1-3/4”

C strike

L

and

latch bolt

6”

3”

2-3/8”

minimum

clearance

2-3/8”

minimum

clearance

7/8”

1-15/16”

3-7/8”

2-5/8”

6” long lead wires

1/2” dia. minimum

wiring access

1-1/16”

3-1/2”

3-7/8”

5-1/4”

931225_00(4)

5/8”

1/4”

1-1/4”

1-1/4”

Strike Dimensions and Required Clearances

Minimum

clearance

Loading...

Loading...