Page 1

®

VON DUPRIN

Installation Instructions

22 Rim Device

Devices covered by these instructions:

22 Rim Device

22-F Fire Exit Rim Device

BEFORE STARTING INSTALLATION

1. Check hardware schedule for strikes, fasteners, and other special requirements.

2. Check carton label for trim, strikes, options, and order number.

3. Read all instructions, including instructions provided with any options used:

trim, alarm kit, glass bead kit, latch guard kit, and rod guard kit.

4. Gather special tools required: • #10-24 tap • 13/32” dia. drill bit

• #25 drill bit • Hacksaw

• 1/8” dia. drill bit • 7/8” dia. hole saw

• 1/4” dia. drill bit

This product is covered by the following patent numbers:

3,767,238 4,167,280 4,427,223 4,437,693 4,466,643

Copyright © 2003 Ingersoll-Rand. All rights reserved.

911333_00(9)

Page 2

GENERAL INFORMATION

Review pages 2 and 3 so you can identify the hardware and understand the terminology used in the instructions.

See page 10 for the “Metric Conversion Table” if needed.

These exit devices can be installed on the door widths listed below:

Device Size

Code/Standard Requirement

Door Size

Standard 3’ (32”) NFPA101 24-3/4” to 36”

Standard 4’ (44”) NFPA101 30-3/4” to 48”

!

NOTE

Dogging panic device during high traffic periods

will increase life of device. To dog, depress pushbar

and turn hex key one-quarter turn clockwise.

MAINTENANCE

Von Duprin 22 exit devices are designed and built to be maintenance free; however, such factors

as installation, severity of use, environmental conditions, and changes in the condition of the door

opening may require that maintenance and/or device adjustment be performed. The following

guidelines are recommended to the building owner to insure proper device operation:

1. Check device operation for smooth operation periodically.

2. Check strikes (keeper) and latches to insure they are secure.

3. Check latches and other moving parts for binding or sluggish operation due to dirt or chemical

buildup. Clean parts with soap and water and then lubricate with graphite-based or silicone

lubricants. Do not use petroleum-based lubricants.

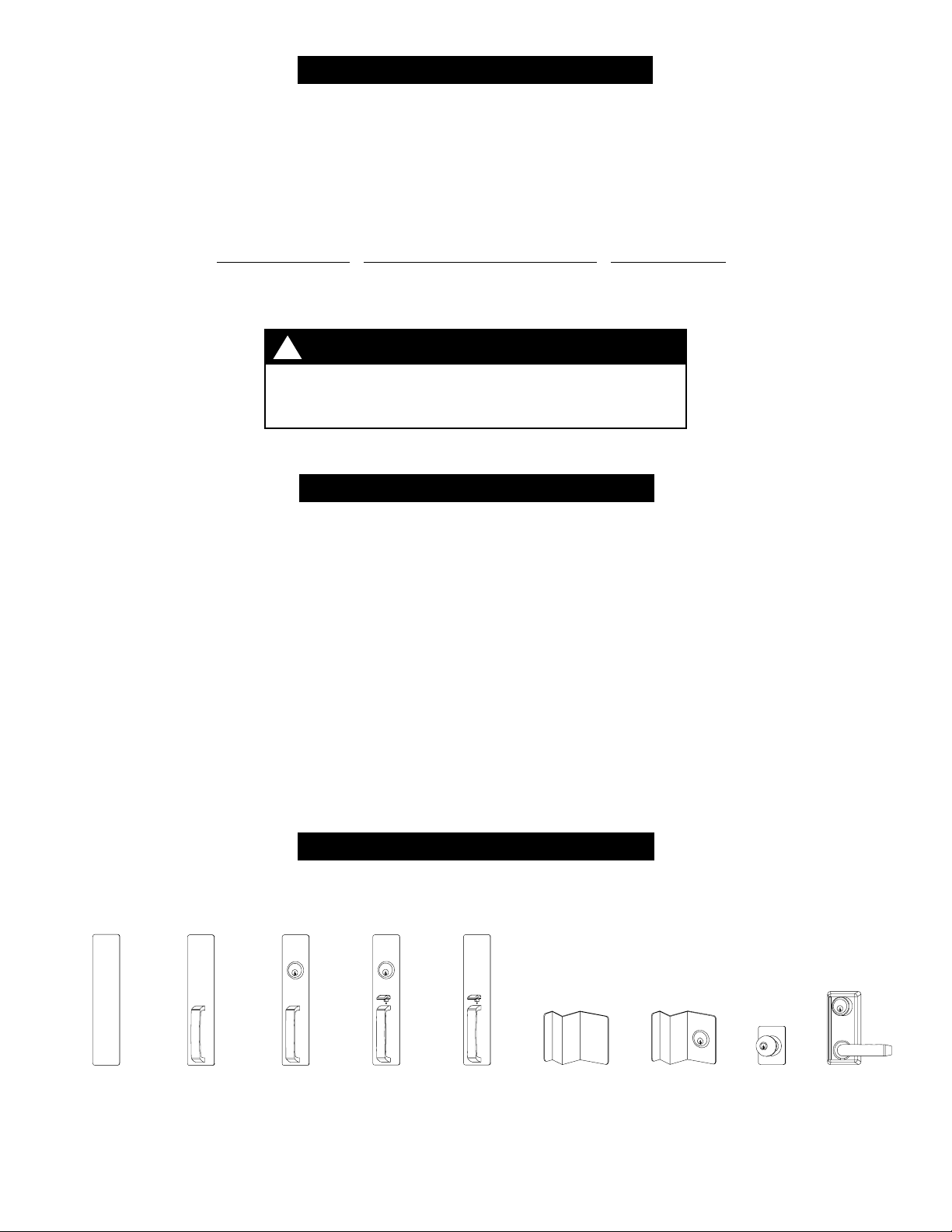

OUTSIDE TRIM

No outside trim supplied for EO (exit only) application

Escutcheon

(optional for

EO application)

911333_00(9) Page 2 of 12

DT

(pull when

dogged)

NL

(key retracts

latch bolt)

TP

(key locks

thumbpiece)

TP-BE

(thumbpiece;

unlocked)

DT

(pull when

dogged)

NL

(key retracts

latch bolt)

K

(key locks

knob)

L

(key locks

lever)

Page 3

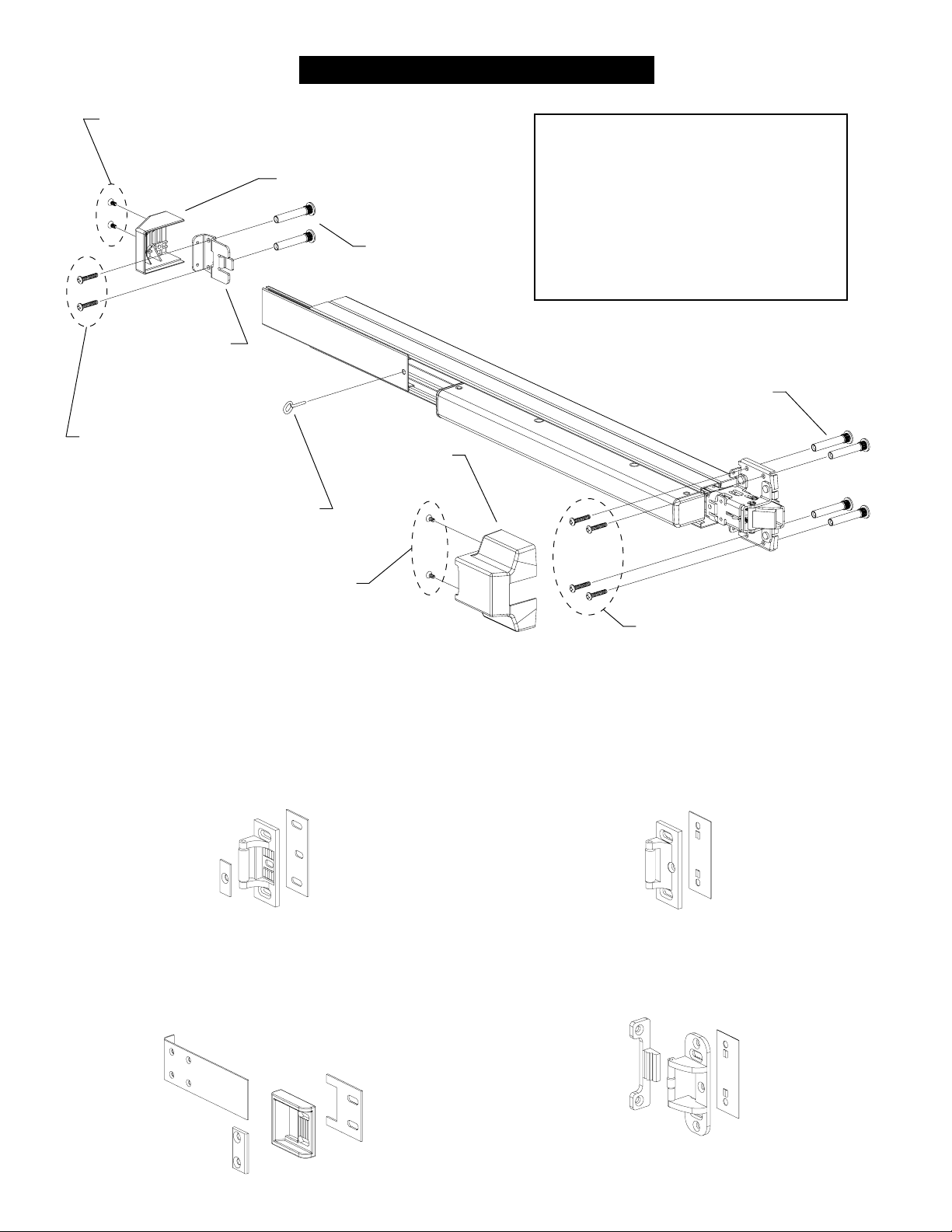

22/22-F PARTS LIST

#8-18 x 1/2” undercut flat head machine screws

(from mechanism end cap package)

Mounting Screw Package

Mechanism case end cap

Mechanism

case mounting

bracket

From mounting

screw package

Dogging key

(panic device)

#8-18 x 1/2” undercut

flat head machine screws

(from mechanism end cap package)

#425 sex bolts

(optional)

Center case

cover

#10-24 x 3/4”machine screws (2)

#10-24 x 1”machine screws (6)

#10-24 x 1-1/8”machine screws (2)

#10-24 x 1-1/2”machine screws (6)

#10 x 1-1/4”sheet metal screws (8)

#425 sex bolts

(optional)

From mounting screw package

Strike Packages

299 Strike Package

(panic device)

#10-24 x 3/4” machine screws (3)

#10 x 1-1/2” wood screws (3)

Strike

Strike

plate

1409/1439 Strike Package (1409 shown)

(panic device, aluminum frame, 1/2” blade stop)

#10-12 x 10-24 x 1-1/4” combinartion screws (2)

Flat head drive rivets (4)

Wear strip

Strike

Adjustment

block

Shim

Shim

299F Strike Package

(fire exit device, single door)

#10-24 x 3/4” machine screws (3)

#10 x 1-1/2” wood screws (3)

Strike

Shim

499F Strike Package

(fire exit device, double door)

#10-24 x 3/4” machine screws (7)

Strike

Strike

hook

Shim

911333_00(9) Page 3 of 12

Page 4

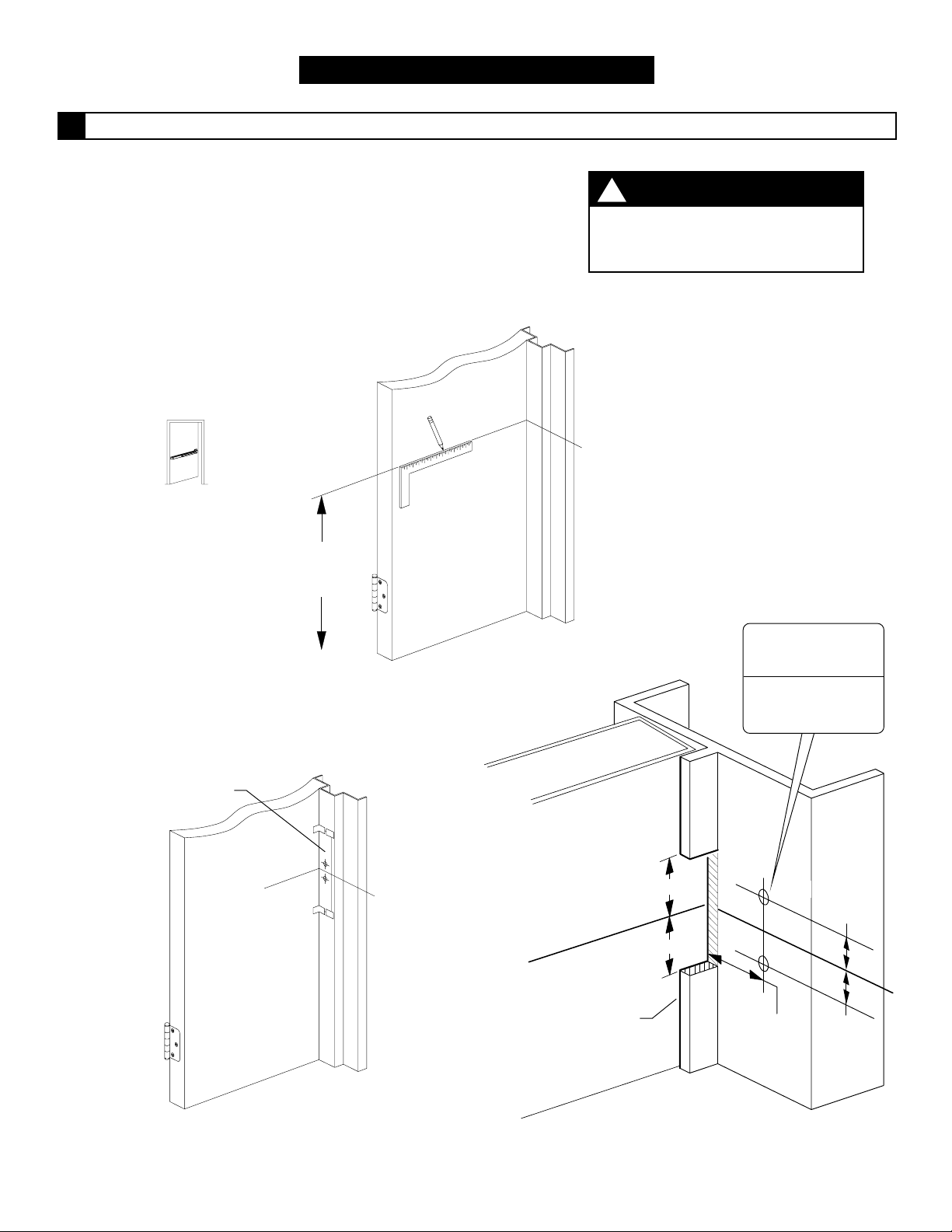

INSTALLATION

For single door, prepare frame for 299, 299F, 1409/1439 strike.

1

1.1. Mark centerline C location as shown in Figure 1-1.

L

1.2. For 299 or 299F strike: Tape strike template to frame

aligned with center line C as shown in Figure 1-2.

L

Mark and prepare mounting holes per template.

For 1409/1439 strike: Prepare frame as shown in Figure 1-3.

RHR shown

C

L

LHR opposite

39-13/16”

to finished

floor

!

NOTE

For double door, mullion is

already prepared for 499F strike.

Skip this step and go to Step #2.

Template

C

#25 Drill

#10-24 tap

MetalWood

Figure 1-1

1/8” Drill pilot

1” deep

Cut -out

L

C

L

Blade stop

7/8”

7/8”

C

L

1-9/16” to

face of

door

7/16”

7/16”

Figure 1-2. 299 or 299F Strike

911333_00(9) Page 4 of 12

Figure 1-3. 1409/1439 Strike

Page 5

Install strike. Use TWO SCREWS ONLY at this time.

2

299 (shown)

or 299F Strike

499F Strike

Door

Door

Stop

Use screws from 299/299F

strike package

#10-24 flat head machine

3/4”

for metal frame

#10 flat head wood

1-1/2”

for wood frame

Use screws from 499F

strike package

#10-24

flat head machine

3/4”

Install strike flush with door side

of stop for 1409 and 1/16” past

door side of stop for 1439

1409/1439

Strike

(1409 shown)

1409/1439

Wear Strip

Door side

of stop

Wear

strip

Mullion

Use screws from

1409/1439 strike package

#10-12 x 10-24 oval

head combination

1-1/4”

1. Center wear strip on strike as shown.

2. Mark and drill 1/8” dia. holes (4 places).

3. Install wear strip with flat head drive rivets

(4 places) from 1409/1439 strike package.

911333_00(9) Page 5 of 12

Page 6

Cut device if necessary.

3

3.1. Device length A must be at least 1-1/2” shorter than B .

A

B

Measure from

inside of stop

Measure from end of center case cover

(not from tip of latch bolt)

3.2. If necessary, cut device so A is at least 1-1/2” shorter than B .

Cover plate flush

with end of pushbar

!

If using ALK exit alarm option, install

ALK cover plate before cutting device.

Tape

Cover plate

Measure

from strike

NOTE

Pushbar

Prepare door for device.

4

4.1. Cut center case template for 1409/1439

strike or for 299/299F/499F strike.

4.2. Tape center case template to inside of door

aligned with center line C as shown.

4.3. Mark and prepare holes per template.

4.4. Prepare door for outside trim (see trim

instructions).

RHR shown

LHR opposite

911333_00(9) Page 6 of 12

L

Place cut edge of

template against stop

C

L

299/299-F/499-F Strike 1409/1439 Strike

C

L

Page 7

Install device to door at center case.

5

5.1. If using cylinder in trim, install tailpiece guide (packaged with trim) in device.

Device cylinder cam

Bottom of

center case

Align tailpiece guide

to match tailpiece

5.2. Install device to door at center case.

Tailpiece guide

Tailpiece

Use screws from device mounting screw package

1”

#10-24 pan head machine

for

metal door surface mount,

sex bolts on 1-3/4” door, or

outside trim on 1-3/4” door

1-1/2”

#10-24 pan head machine

for

sex bolts on 2-1/4” door or

outside trim on 2-1/4” door

#425 sex

bolts (shown)

or outside trim

optional

1-1/4”

#10-24 pan head sheet metal

for

wood door surface mount

911333_00(9) Page 7 of 12

Page 8

Install mechanism case mounting bracket and mechanism case end cap.

6

Slide in

1

mechanism

case mounting

bracket

Bracket flush against

mechanism case

Mark mounting

2

holes and prepare

per chart

Use screws from end

cap package

1/2”

#8-18 undercut flat

head machine

Device level

on door

Surface Mount

Metal Door: #25 drill and #10-24 tap inside

Wood Door: 1/8” pilot drill, 1” deep, inside

Sex Bolts

Metal Door: 1/4” drill inside, 13/32” drill outside

Wood Door: 13/32” drill thru

Install mechanism

case end cap

34

Install

mounting

screws

Use screws from device mounting screw package

3/4”

#10-24 pan head machine

for

metal door surface mount or

sex bolts on 1-3/4” door

If necessary, add strike adjusting shim under strike for 3/16” dimension shown.

7

#10-24 pan head machine

sex bolts on 2-1/4” door

3/16” between center

case cover and strike

Center case

cover

1-1/8”

#10-24 pan head sheet metal

for

wood door surface mount

1-1/4”

for

Frame

911333_00(9) Page 8 of 12

Strike

Shim

Page 9

Prepare remaining strike mounting holes and install screws.

8

299 or 299F Strike

Strike plate

(299 strike only)

Door

#25 drill and #10-24 tap,

#10-24 flat head machine

Use screw from 299/299F strike package

499F Strike

Metal frame:

1/8” drill x 1” deep

#10 flat head wood

3/4”

#25 drill and #10-24 tap,

#10-24 flat head machine

3/4”

Wood frame:

1-1/2”

Door

Strike hook

Use screws from 499F

strike package

Mullion

499F Strike Hook

Center strike hook on device 1/16” from mullion.

Clearance from

mullion

1/16”

Mullion

Inside face

of door

Strike hook

C

L

device

and strike

Mullion

Metal door:

#25 drill and #10-24 tap,

#10-24 flat head machine

3/4”

Use screws from 499-F

strike package

Wood door (#425 sex bolts):

1/4” drill inside,

13/32” drill outside

911333_00(9) Page 9 of 12

Page 10

Metric Conversion Table

inches mm inches mm inches mm inches mm inches mm inches mm

1/16 2

1/8 3

3/16 5

1/4 6

13/32 10

7/16 11

1/2 13

5/8 16

3/4 19

7/8 22

125

1-1/16 27

1-1/8 29

1-1/4 32

1-1/2 38

1-9/16 40

1-11/16 43

1-3/4 45

2-1/4 57

24-3/4 629

30-3/4 781

32 813

36 914

39-11/16 1008

39-13/16 1011

44 1118

48 1219

911333_00(9) Page 10 of 12

Page 11

STRIKE TEMPLATE

Refer to Step 1 (p. 4)

when using this template

C device

L

CENTER CASE TEMPLATE

Template to scale

(dimensions in inches)

LHR

5/8”

1-1/16”

C

L

Refer to Step 4 (p. 6)

when using this template

Template to scale

(dimensions in inches)

5/8”

5/8”

LHR

1-11/16”

C

L

1-1/16”

Prepare holes 2 places:

Metal frame:

#25 drill and #10-24 tap

Wood frame:

1/8” drill x 1” deep

Cut strike template along

this line and place on stop

with this edge against door

7/8” dia. for

NL, K, L, and

TP trim only

Prepare holes 4 places:

Surface Application (no outside trim):

Metal door: #25 drill and #10-24 tap inside

Wood door: 1/8” drill x 1”deep pilot holes

#425 Sex Bolts or Outside Trim:

Metal door: 1/4” drill inside and 13/32” outside

Wood door: 13/32 drill thru

Cut on this line for 1409/1439 strike

For 1409/1439 strike cut center case template along

this line and place on door with this edge against stop

For 299/299F/499F strike place center case

template on door with this edge against stop

1-11/16”

911333_00(9) Page 11 of 12

Page 12

C device

L

STRIKE TEMPLATE

Refer to Step 1 (p. 4)

when using this template

911333-00

RHR

1-11/16”

C

L

CENTER CASE TEMPLATE

Refer to Step 4 (p. 6)

when using this template

Template to scale

(dimensions in inches)

5/8”

5/8”

Template to scale

(dimensions in inches)

RHR

5/8”

1-1/16”

C

L

1-11/16”

7/8” dia. for

NL, K, L, and

TP trim only

Prepare holes 4 places:

Surface Application (no outside trim):

Metal door: #25 drill and #10-24 tap inside

Wood door: 1/8” drill x 1”deep pilot holes

#425 Sex Bolts or Outside Trim:

Metal door: 1/4” drill inside and 13/32” outside

Wood door: 13/32 drill thru

For 1409/1439 strike cut center case template along

this line and place on door with this edge against stop

For 299/299F/499F strike place center case

template on door with this edge against stop

1-1/16”

Prepare holes 2 places:

Metal frame:

#25 drill and #10-24 tap

Wood frame:

1/8” drill x 1” deep

Cut on this line for 1409/1439 strike

Cut strike template along

this line and place on stop

with this edge against door

911333_00(9) Page 12 of 12

Loading...

Loading...