Page 1

LEVANTE G

Installation Instructions

Use and Care Information

Instructions d'installation

Utilisez et d'entretien

Instrucciones de instalación

Información de uso y cuidado

LEVG24SS300

LEVG30SS300

Page 2

CONTENTS

Section Page

Important safety instructions 3

Range hood dimensions 6

Installation height requirements 7

Parts 8

Tools needed 9

Before installation remove shipping materials 10

Only for Canadian market 11

Choose vertical or horizontal electrical connection knockout'sChoose vertical or horizontal electrical connection knockout's 12

Venting method options-ducted or ductless 14

Non ducted recirculation option 15

Ducted - 7" round outlet 16

Ducted - 3 1/4" x 10" rectangular outlet on top

Ducted - 3 1/4" x 10" rectangular outlet rear

Choosing the mounting method

Mounting range hood on wall

Mounting range hood under the cabinet

Connecting electricity

Operating the controls

Caring for lters

Replacing lighting

Wiring diagram

Warranty

18

19

20

21

25

27

28

29

31

32

33

2

Page 3

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS BEFORE YOU START

INSTALLING THIS RANGE HOOD

WARNING: - TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

a) Never leave surface units unattended at high settings. Boilovers cause smoking and

greasy spillovers that may ignite. Heat oils slowly on low or medium setting.

b) Always turn hood ON when cooking at high heat or when ambeing food (i.e. Crepes

Suzette, Cherries Jubilee, Peppercorn Beef Flambé).

c) Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or

lter.

d) Use proper pan size. Always use cookware appropriate for the size of the surface element.

WARNING: - TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A RANGE

TOP GREASE FIRE, OBSERVE THE FOLLOWING*:

a) SMOTHER FLAMES with a close-tting lid, cookie sheet, or metal tray, then turn off the

burner. BE CAREFUL TO PREVENT BURNS. If the ames do not go out immediately

EVACUATE AND CALL THE FIRE DEPARTMENT.

b) NEVER PICK UP A FLAMING PAN - You may be burned.

c) DO NOT USE WATER, including wet dishcloths or towels - a violent steam explosion will

result.

d) Use an extinguisher ONLY if:

1. You know you have a Class ABC extinguisher, and you already know how to operate

it.

2. The re is small and contained in the area where it started.

3. The re department is being called.

4. You can ght the re with your back to an exit.

* Based on "Kitchen Firesafety Tips" published by NFPA

WARNING - TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, do not use this fan with

any solid-state speed control device.

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK, OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have any questions,

contact the manufacturer.

2. Before servicing or cleaning unit, switch power off at service panel and lock the service

disconnecting means to prevent power from being switched on accidentally. When the

service disconnecting means cannot be locked, securely fasten a prominent warning

device, such as a tag, to the service panel.

CAUTION: For General Ventilating Use Only. Do Not Use To Exhaust Hazardous or Explosive Materials and Vapors.

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK, OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

1. Installation Work And Electrical Wiring Must Be Done By Qualied Person(s) In Accor-

dance With All Applicable Codes And Standards, Including Fire-Rated Construction.

2. Sufcient air is needed for proper combustion and exhausting of gases through the

ue (chimney) of fuel burning equipment to prevent backdrafting. Follow the heating

equipment manufacturer's guideline and safety standards such as those published by

the National Fire Protection Association (NFPA), and the American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE), and the local code authorities.

3

Page 4

!

3. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other

hidden utilities.

4. Ducted fans must always be vented to the outdoors.

ALL WALL AND FLOOR OPENINGS WHERE THE RANGE HOOD IS INSTALLED

MUST BE SEALED.

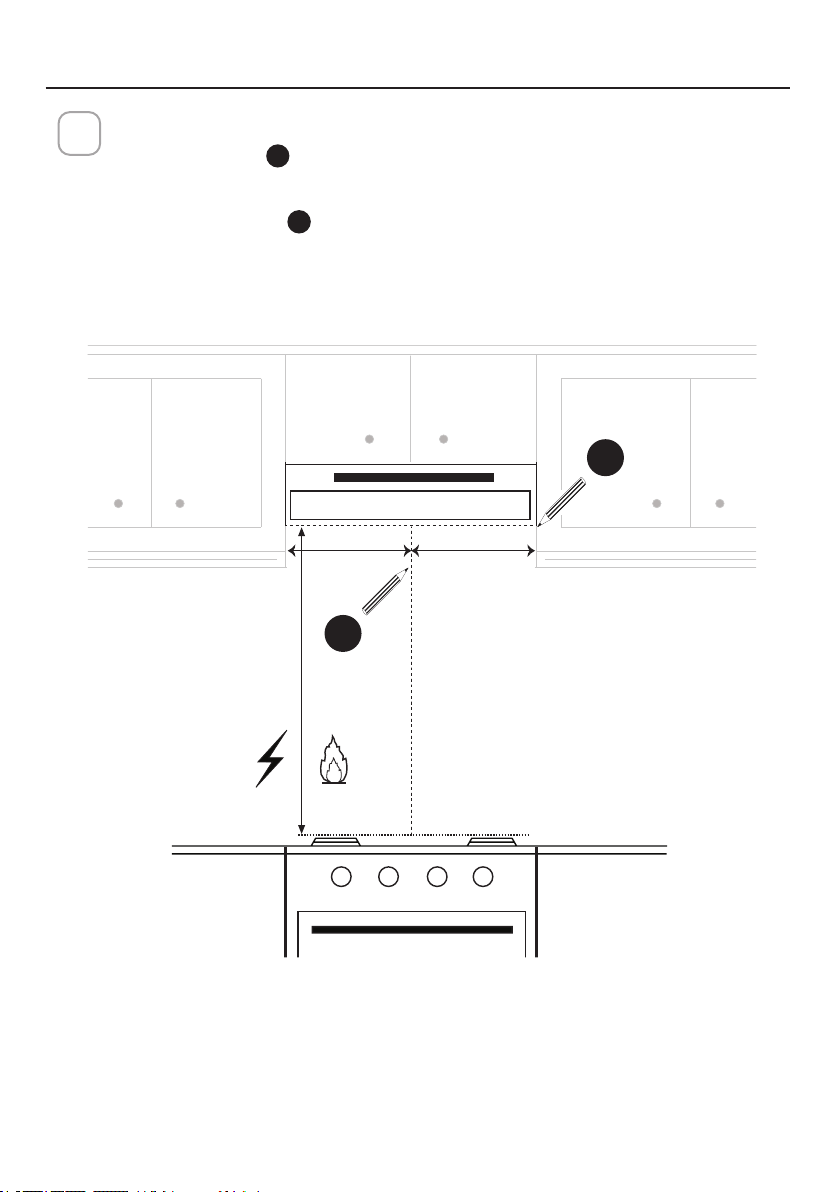

This Range Hood requires at least 24" of clearance between the bottom of the Range

Hood and the cooking surface or countertop. This hood has been approved by UL at this

distance from the cooktop.

This minimum clearance may be higher depending on local building codes. For gas cooktops

and combination ranges, a minimum of 30" is recommended and may be required.

Overhead cabinets on both sides of this unit must be a minimum of 18" above the cooking

surface or countertop. Consult the cooktop or range installation instructions given by the

manufacturer before making any cutouts.

MOBILE HOME INSTALLATION The installation of this Range Hood must conform to the

Manufactured Home Construction and Safety Standards, Title 24 CFR, Part 3280 (formerly

Federal Standard for Mobile Home Construction and Safety, Title 24, HUD, Part 280). See

Electrical Requirements"

VENTING REQUIREMENTS

Determine which venting method is best for your application. Ductwork can extend either

through the wall or the roof.

The length of the ductwork and the number of elbows should be kept to a minimum to

provide efcient performance. The size of the ductwork should be uniform. Do not install

two elbows together. Use duct tape to seal all joints in the ductwork system. Use caulking

to seal exterior wall or oor opening around the cap.

Flexible ductwork is not recommended. Flexible ductwork creates back pressure and air

turbulence that greatly reduces performance.

Make sure there is proper clearance within the wall or oor for exhaust duct before making

cutouts. Do not cut a joist or stud unless absolutely necessary. If a joist or stud must be cut,

then a supporting frame must be constructed.

WARNING - To Reduce The Risk Of Fire, Use Only Metal Ductwork.

CAUTION - To reduce risk of re and to properly exhaust air, be sure to duct air outside

– Do not vent exhaust air into spaces within walls or ceilings or into attics, crawl spaces,

or garages.

Cold Weather installations

An additional back draft damper should be installed to minimize backward cold air ow and a nonmetallic thermal break should be installed to minimize conduction of outside temperatures as part of the

vent system. The damper should be on the cold air side of the thermal break. The break should be as

close as possible to where the vent system enters the heated portion of the house.

WARNING

• Venting system MUST terminate outside the home.

• DO NOT terminate the ductwork in an attic or other enclosed space.

• DO NOT use 4" laundry-type wall caps.

• Flexible-type ductwork is not recommended.

• DO NOT obstruct the ow of combustion and ventilation air.

• Failure to follow venting requirements may result in a re.

4

Page 5

ELECTRICAL REQUIREMENTS

!

A 120 volt, 60 Hz AC-only electrical supply is required on a separate 15 amp fused circuit.

A time-delay fuse or circuit breaker is recommended. The fuse must be sized per local

codes in accordance with the electrical rating of this unit as specied on the serial/rating

plate located inside the unit near the eld wiring compartment.

ELECTRICAL INSTALLATION WITH WIRING BOX

THIS UNIT MUST BE CONNECTED WITH COPPER WIRE ONLY. Wire sizes must conform

to the requirements of the National Electrical Code, ANSI/NFPA 70 - latest edition, and all

local codes and ordinances. Wire size and connections must conform with the rating of

the appliance. Copies of the standard listed above may be obtained from:

National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

This appliance should be connected directly to the fused disconnect (or circuit breaker)

through exible, armored or nonmetallic sheathed copper cable. Allow some slack in

the cable so the appliance can be moved if servicing is ever necessary. A UL Listed,

1/2" conduit connector must be provided at each end of the power supply cable (at

the appliance and at the junction box).

When making the electrical connection, cut a 1 1/4" hole in the wall. A hole cut through

wood must be sanded until smooth. A hole through metal must have a grommet.

WARNING

• Electrical ground is required on this Range Hood.

• If cold water pipe is interrupted by plastic, nonmetallic gaskets or other

materials, DO NOT use for grounding.

• DO NOT ground to a gas pipe.

• DO NOT have a fuse in the neutral or grounding circuit. A fuse in the neutral

or grounding circuit could result in electrical shock.

• Check with a qualied electrician if you are in doubt as to whether the Range

Hood is properly grounded.

• Failure to follow electrical requirements may result in a re.

State of California Proposition 65 Warning (US only)

WARNING

This product contains chemicals known to the State of California to cause cancer

and birth defects or other reproductive harm.

For more information go to www.P65Warnings.ca.gov

5

Page 6

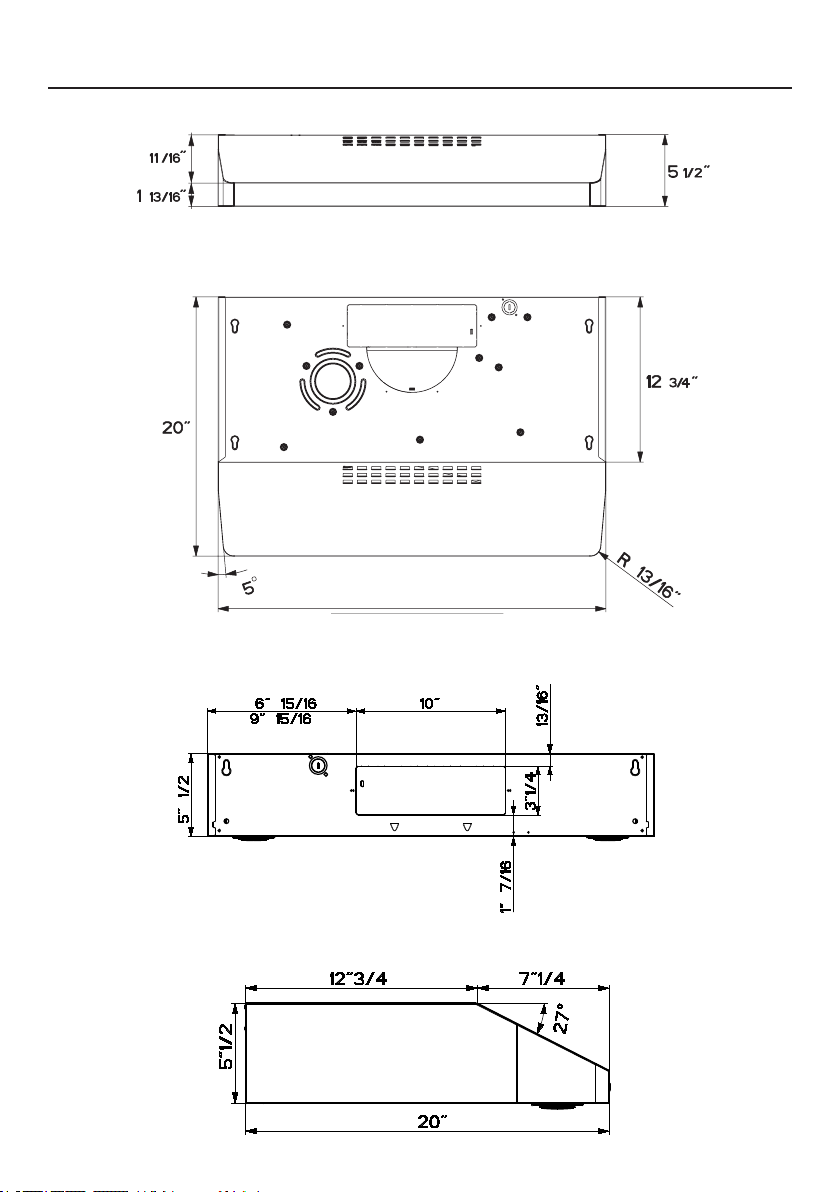

RANGE HOOD DIMENSIONS

7 1/4

3

7

1/4

23 15/16” - 29 15/16” - 35 15/16”

24" 30"

6

24"

30"

Page 7

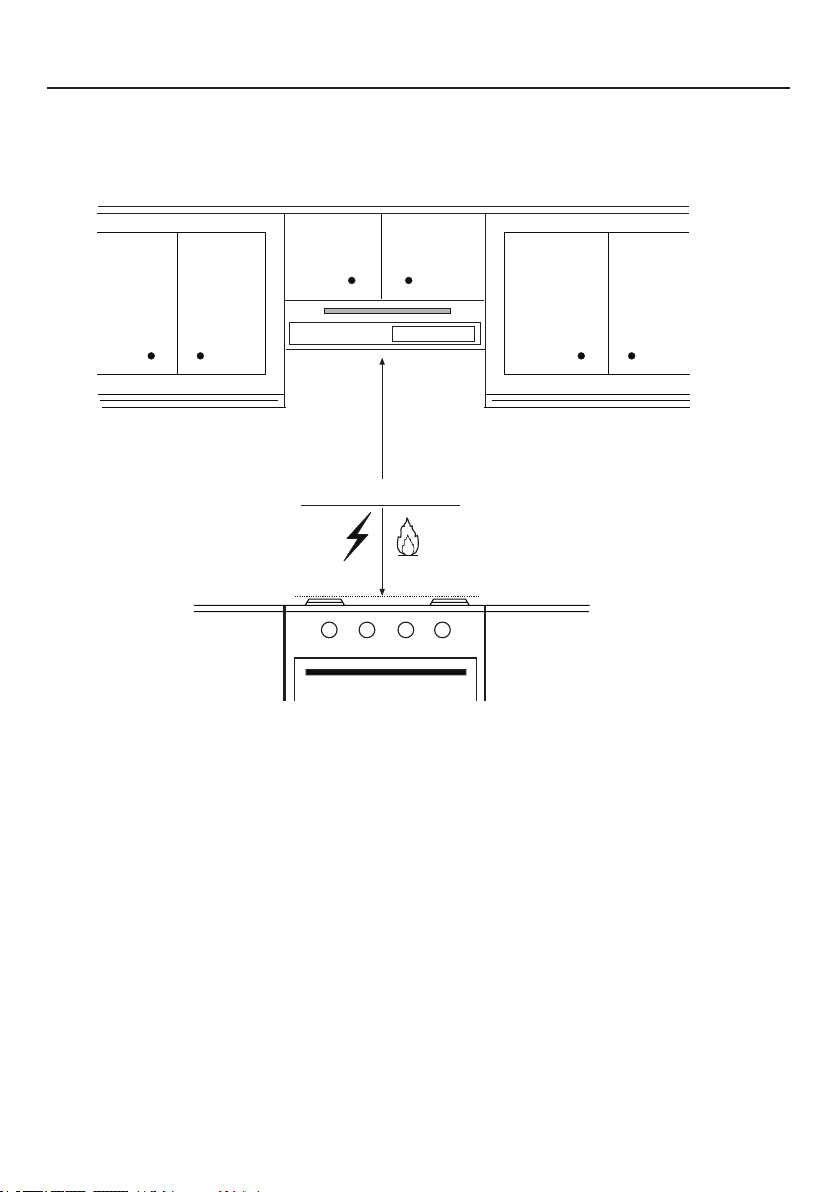

INSTALLATION HEIGHT REQUIREMENTS

MIN. 24" OVER ELECTRIC / MIN. 30" OVER GAS

Min. 24" - 30"

7

Page 8

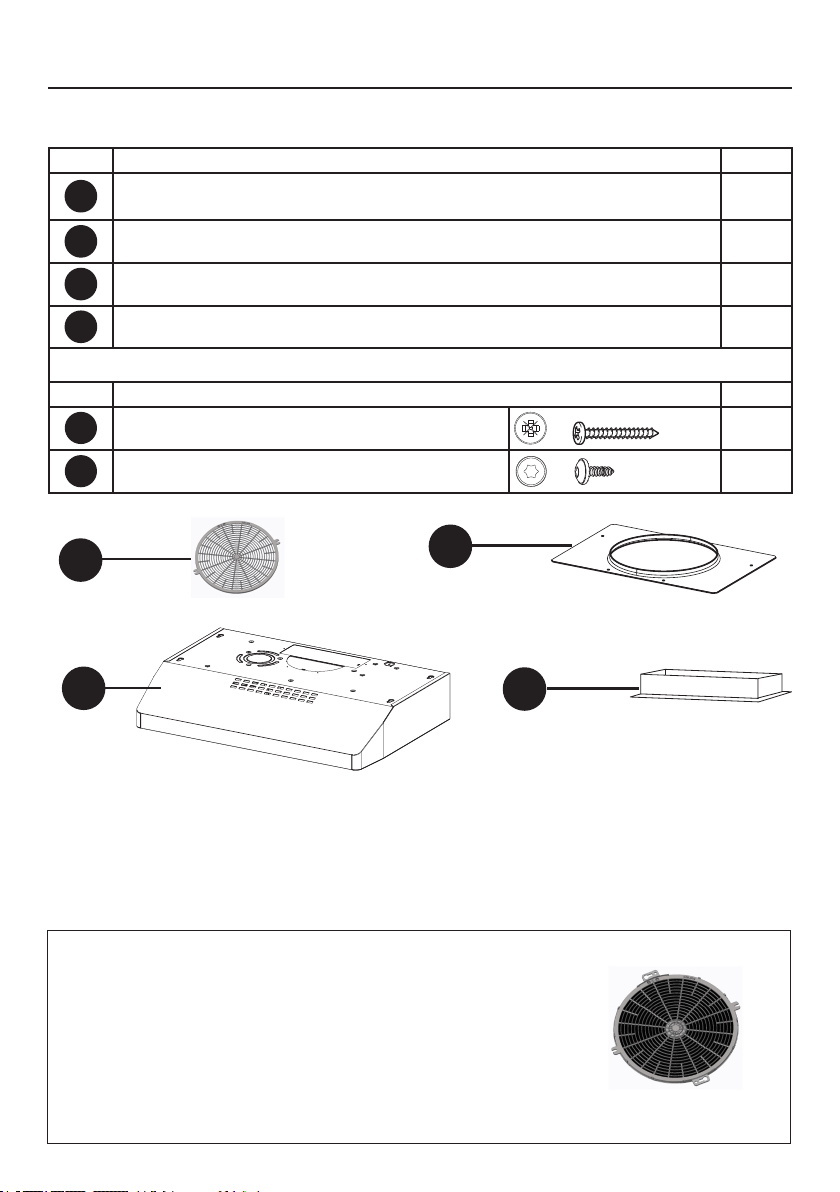

PARTS

PARTS INCLUDED

REF. PART

Hood body – Includes Controls, Light, Filters, Blower 1

A

Damper (3 1/4" x 10") 1

B

7" Round Flange 1

C

Grid (Only for Canadian Market) 1

D

REF

PART

E

Pozi Screws (3/16" x 1 15/16")

F

Torx Screws (1/8" x 3/8")

4

4

D

C

A

Available Accessories

Activated Charcoal Filter (FILTER5)

Note: The Charcoal Filter is attached with two screws

(See page 15 and Figure C).

The Charcoal Filters must be purchased with only Faber

authorized dealers.

B

8

Page 9

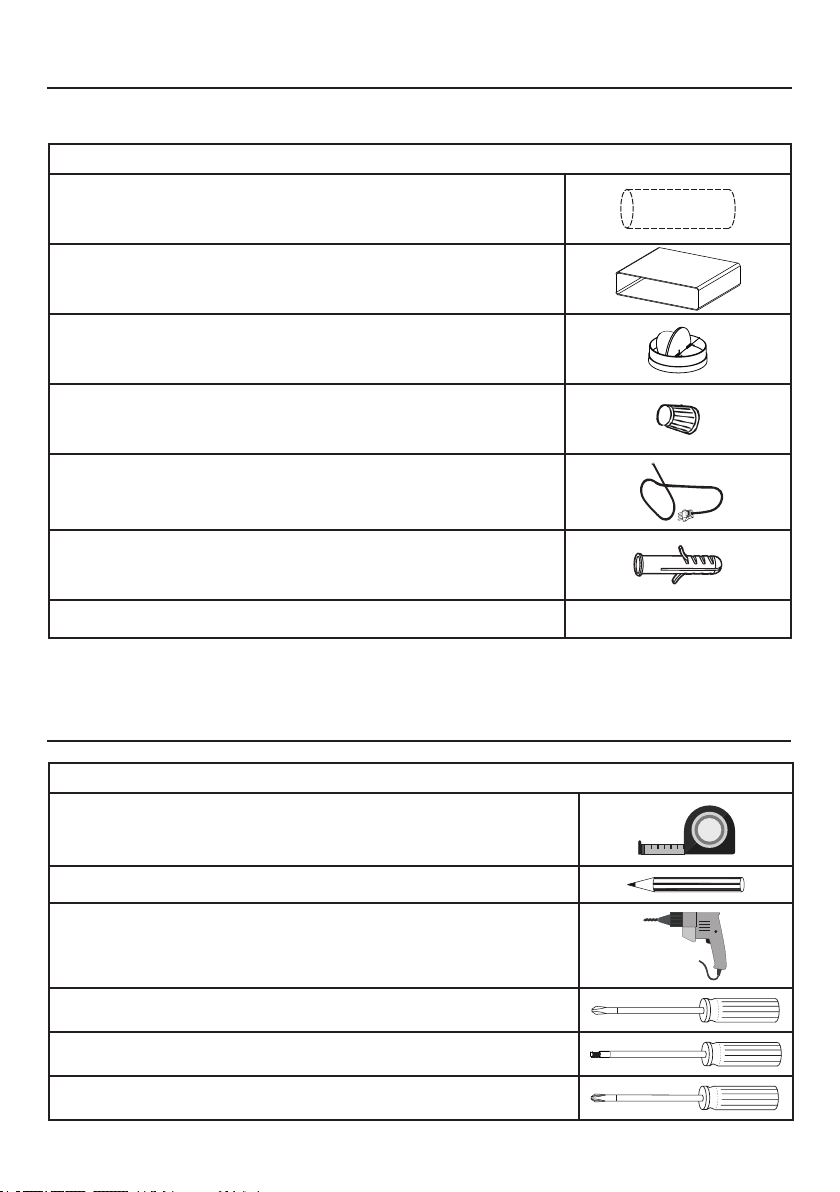

PARTS (cont.)

PARTS NEEDED

PART

7" Round Metal Ductwork

3 1/4" x 10" Rectangular Ductwork

7" Damper

Wire connectors.

Power Supply Cable.

Drywall plugs or other suitable wall fasteners based on

your installation.

Wall Cap/Roof Cap Needs to be purchased separately

-

TOOLS NEEDED

TOOL

Tape Measure

Pencil

Electric Drill with 5/16" Drill Bit

Phillips Screwdriver

Torx Screwdriver

Pozi Screwdriver

9

Page 10

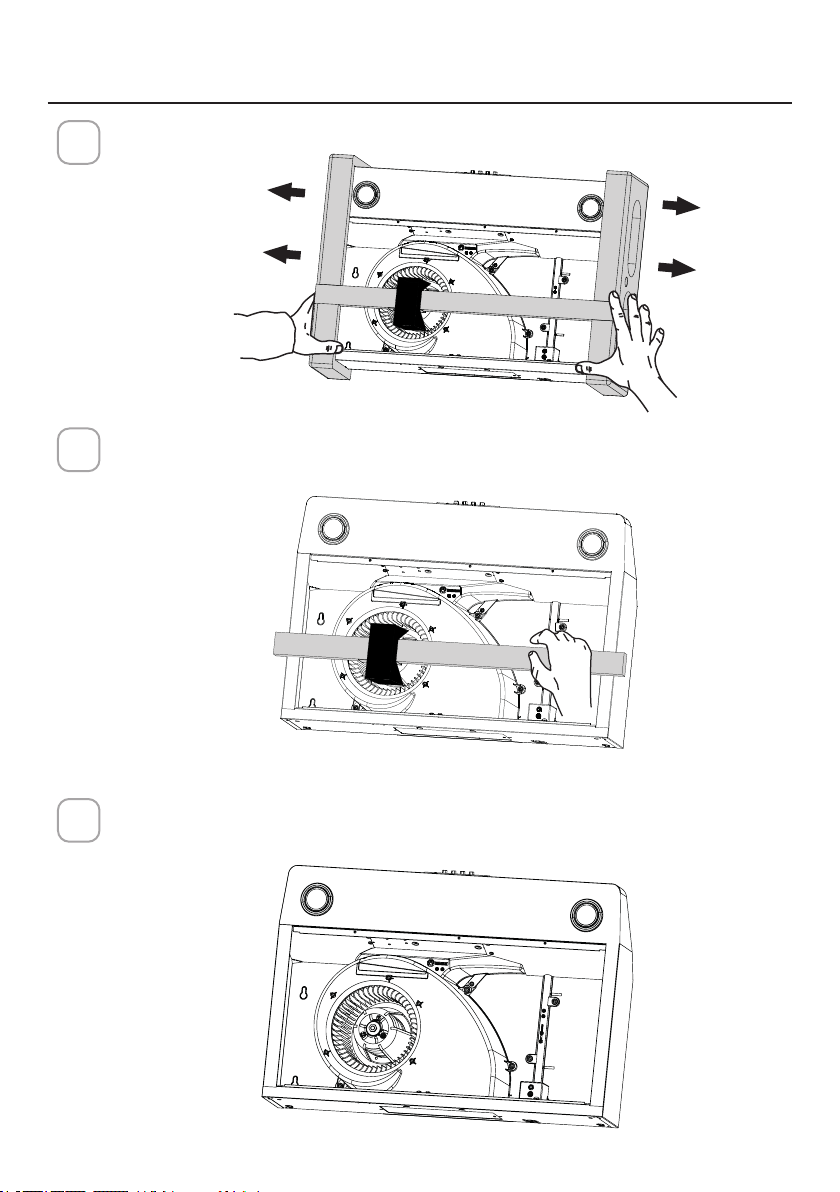

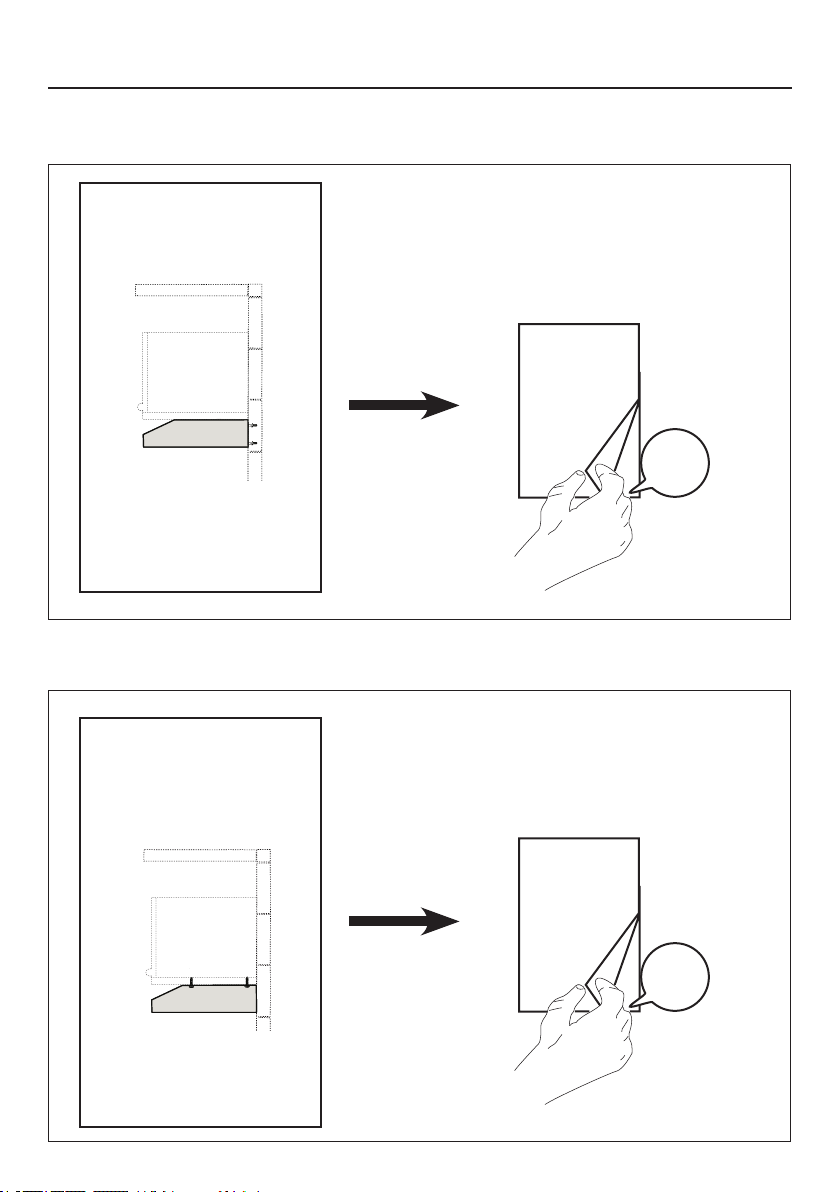

BEFORE INSTALLATION REMOVE SHIPPING

MATERIALS

Remove the side packaging.

1

Caution: Do not

pick up hood using

the wood bar

Remove the foam packaging and wood bar.

2

Ready for Installation.

3

10

Page 11

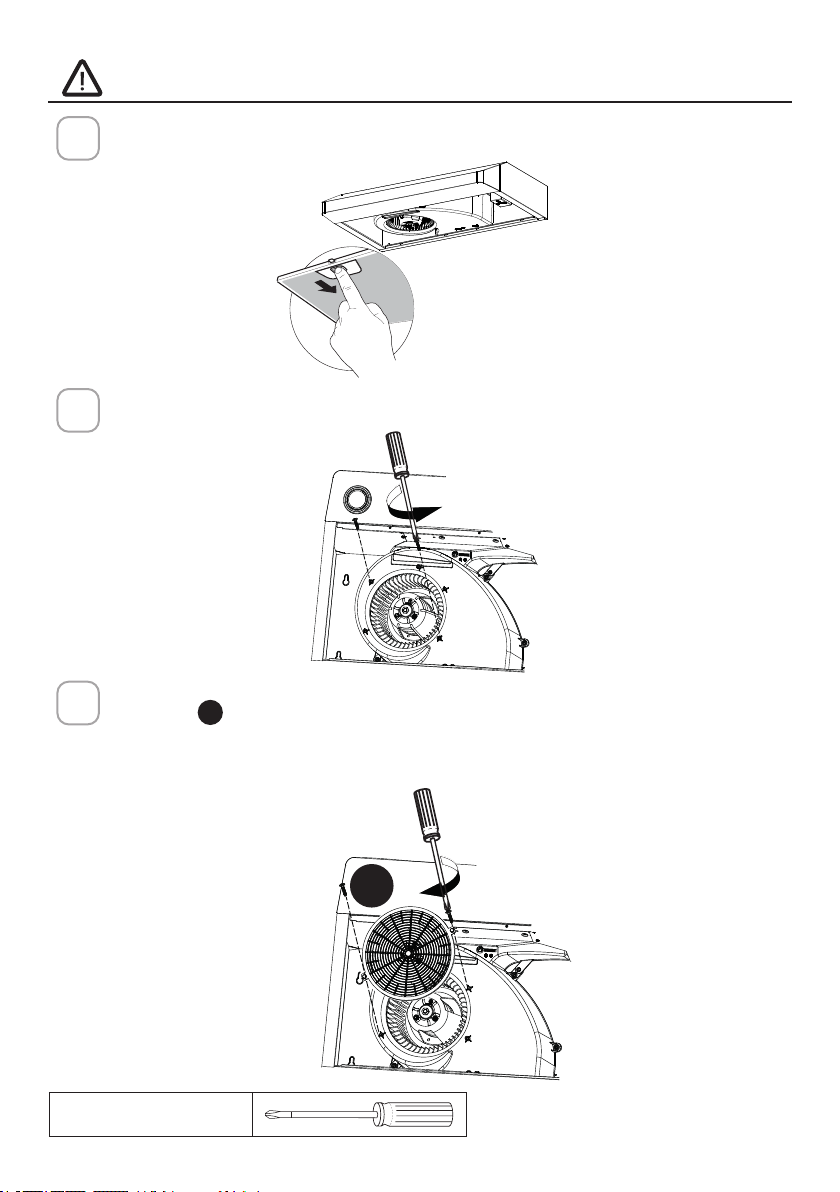

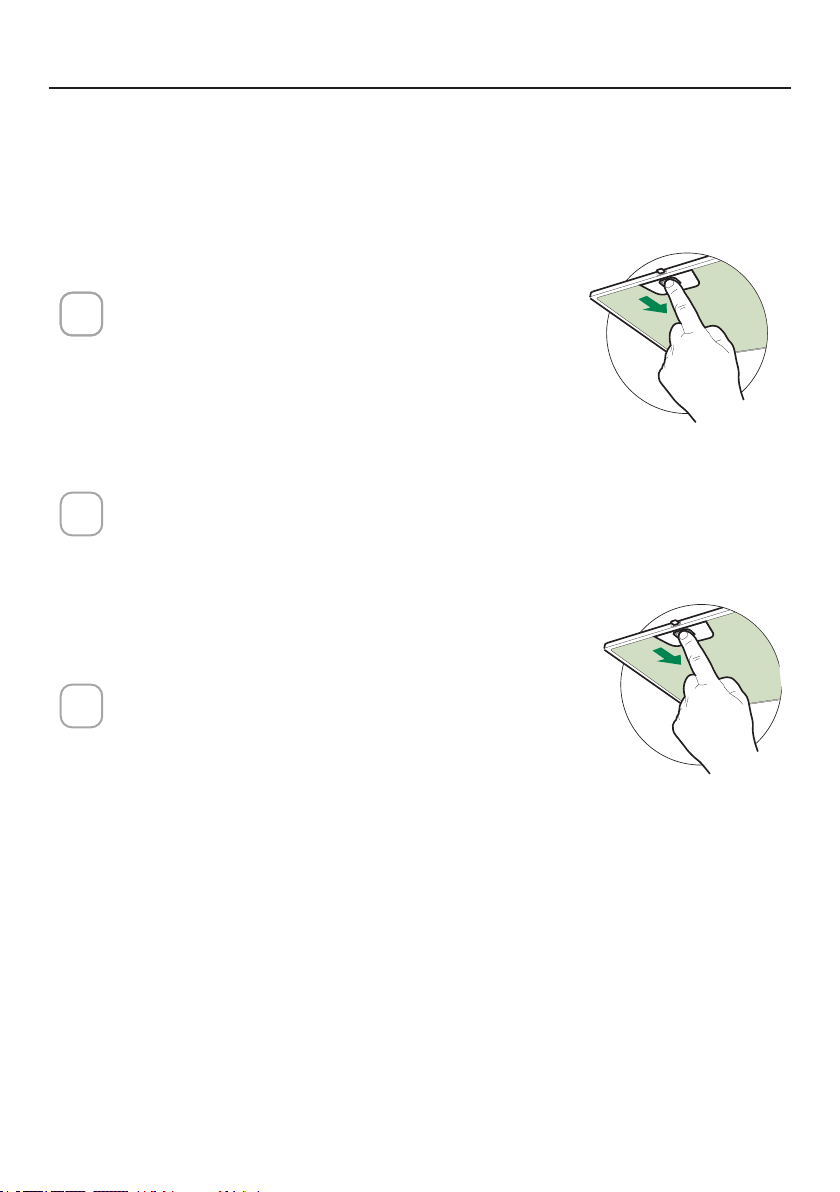

ONLY FOR CANADIAN MARKET

For ducted installations only:

1

Remove the lters one at a time by pushing towards the back of the hood and

pulling down at the same time.

Remove the screws as pictured.

2

Remove two of the screws from the motor assembly housing as pictured.

Install the screws as pictured.

3

Install Grid D with the two screws removed from step 2. Screw the protection

grid into the location shown in the picture below. (The correct location has a

rectangular cut out to accommodate the grid.)

Take care to screw the grid completely ush to avoid unwanted noise.

D

Phillips Screwdriver

11

Page 12

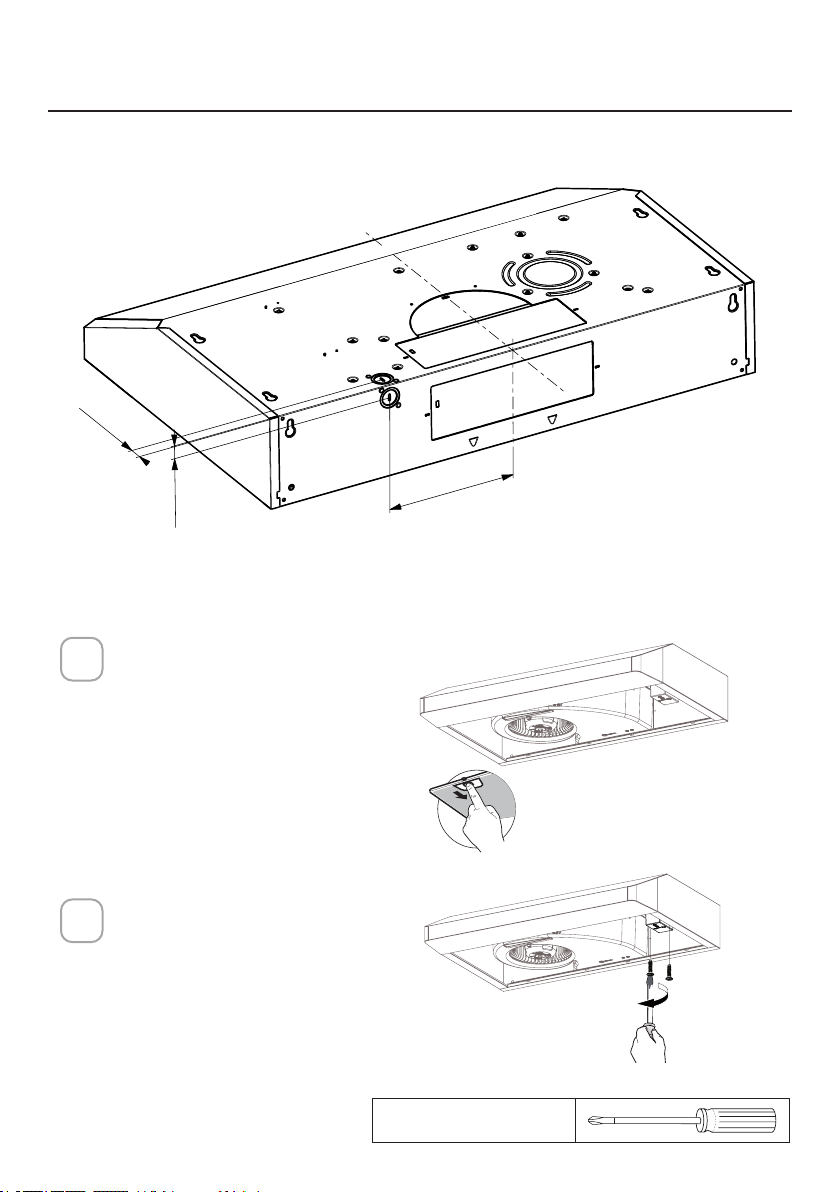

CHOOSE VERTICAL OR HORIZONTAL

ELECTRICAL CONNECTION KNOCKOUT'S

13/16"

13/16"

7" 1/2

Preparing the hood for electrical knockouts

Remove the lters one at

1

a time by pushing them

towards the back of the

hood and pulling down at

the same time.

Remove the wiring box

2

cover by unscrewing

the 2 screws.

Phillips Screwdriver

12

Page 13

Rear Hole (Horizontal)

3

Choose the rear hole for the electric connection and break with a screwdriver or other

tool.

During the installation thread Power Supply Cable through this hole.

Top Hole (Vertical)

4

Choose the top hole for the electric connection and break with a screwdriver or

other tool.

During the installation thread Power Supply Cable through this hole.

13

Page 14

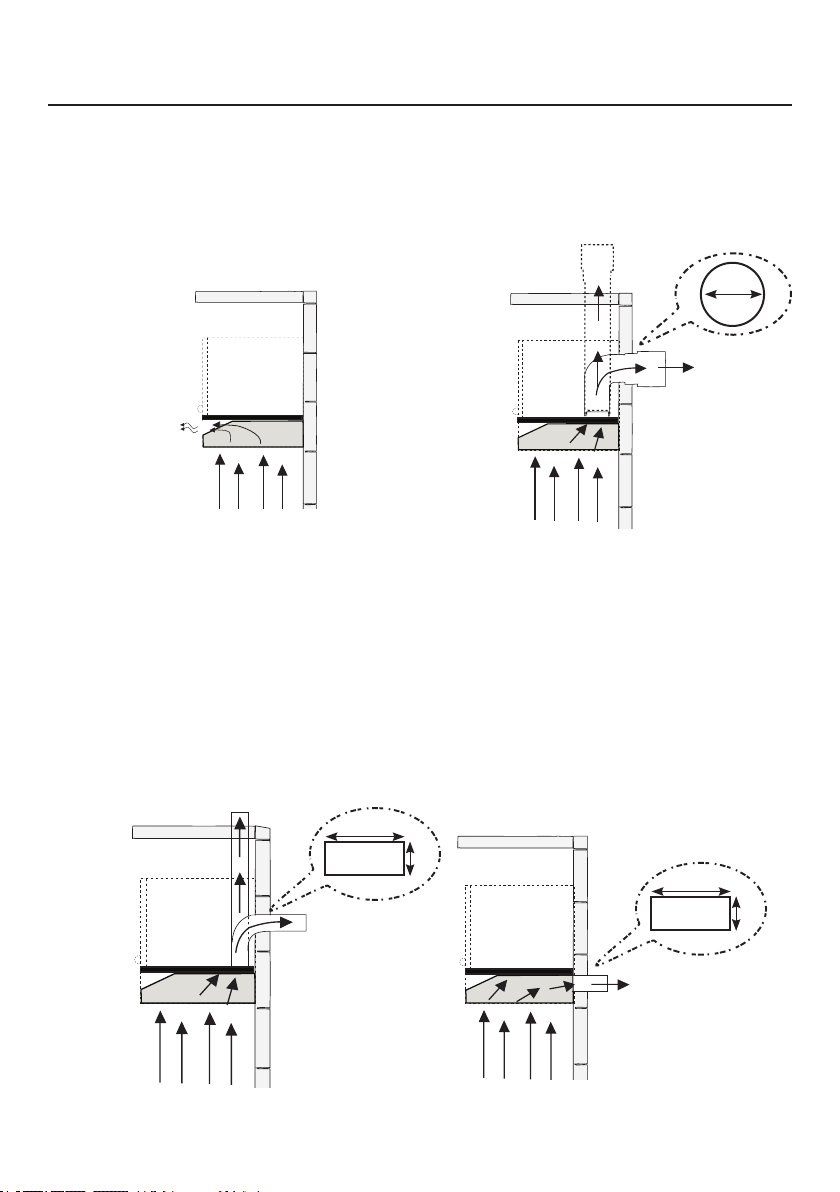

VENTING METHOD OPTIONS-DUCTED OR

DUCTLESS

NON DUCTED - RECIRCULATION

OPTION

Requires

purchase

of

Activated

Charcoal

Accessory

DUCTED WITH 7" ROUND OUTLET:

– Vertical

– Horizontal

Top

7"

Rear

Go to page 16Go to page 15

DUCTED WITH 3 1/4" X 10" RECTANGULAR OUTLET

– Vertical

– Horizontal

Top

10"

14

3 1/4"

Rear

10"

3 1/4"

Go to page 18

Page 15

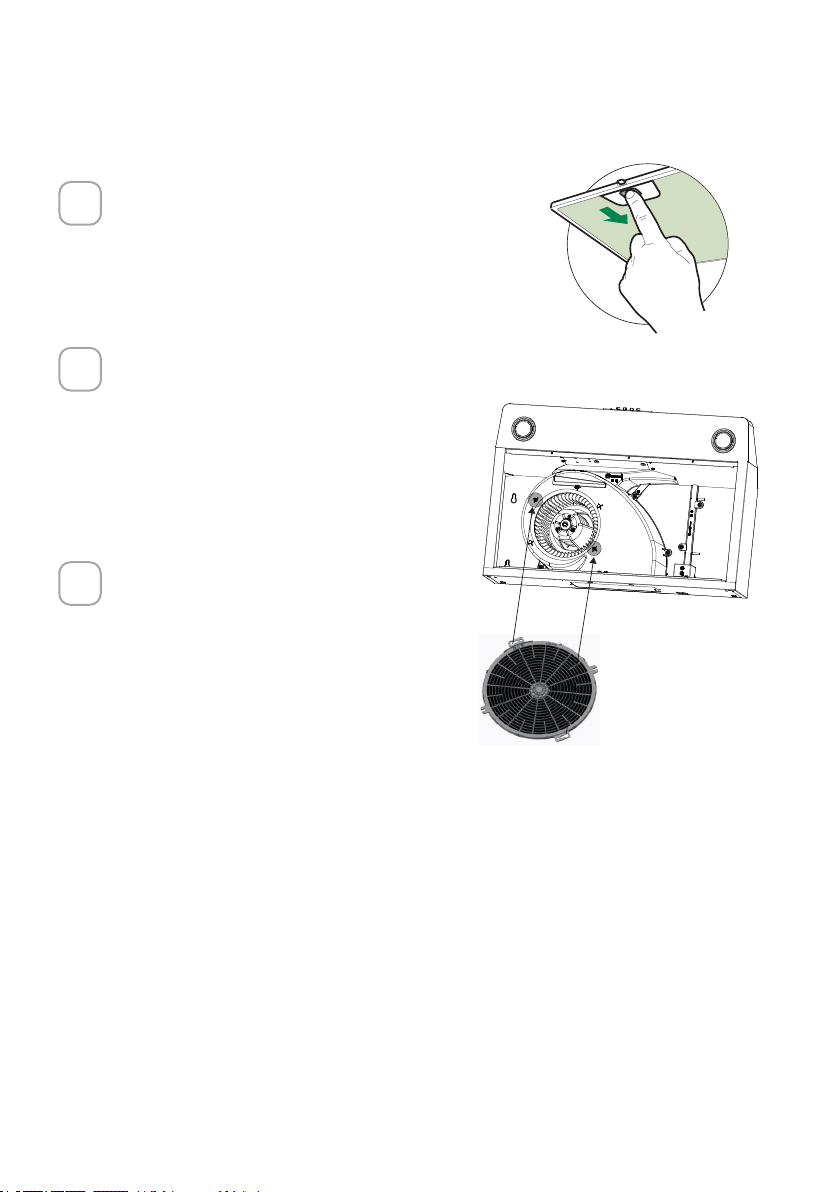

NON DUCTED RECIRCULATION OPTION

Remove the indicated blower cover

a

(do not discard the screw).

Cut the

b1

cover

where

indicated in

picture b1.

Discard /

b2

Recycle

upper

pieces of

blower

cover.

b3

Required Activated Charcoal

Filter Accessory - (FILTER5)

purchased separately.

Non Ducted installations only:

1. Remove the two screws located on the motor

housing in the location indicated.

2. Place the charcoal lter with the tabs against

the blower housing in the location indicated on

gure c. The front side of the FILTER5 will

have the keyhole mounting on the top surface

of the lter. A layer of charcoal will be visible

through the grills.

3. Use the two screws removed earlier to attach

the FILTER5 in place.

NOTE: For Non ducted installations the Canadian

Grid should NOT be used.

d

Reinstall the modied blower cover

with the same screw.

c

Reinstall the existing Grease Filters

after installing the Activated Charcoal

Filter before operating hood.

Go to page 20

15

Page 16

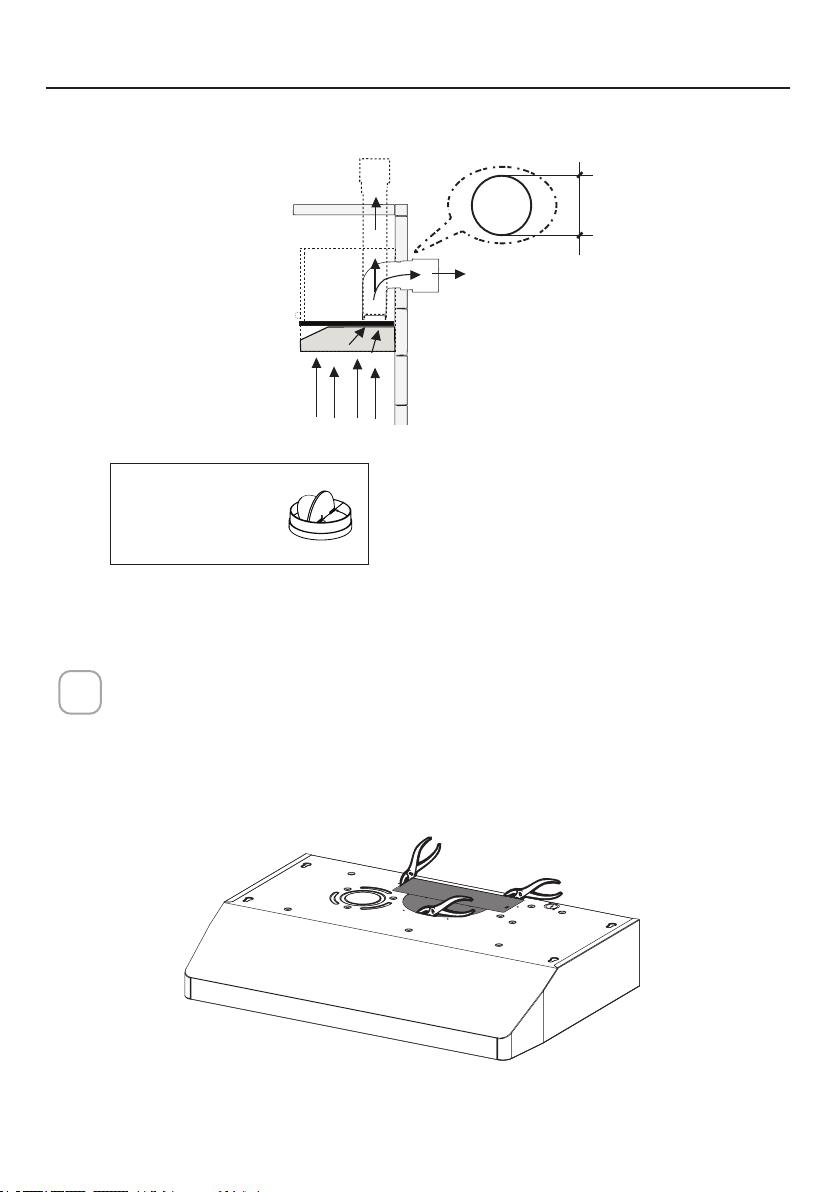

DUCTED - 7" ROUND OUTLET

Top

Required; 7" Round

Damper purchase

separately.

7"

Rear

Caution: If an elbow

is required, do it

as far away from

the hood's exhaust

opening as possible.

Cut where indicated.

1

Remove both the rectangular and semicircle areas with metal shears.

16

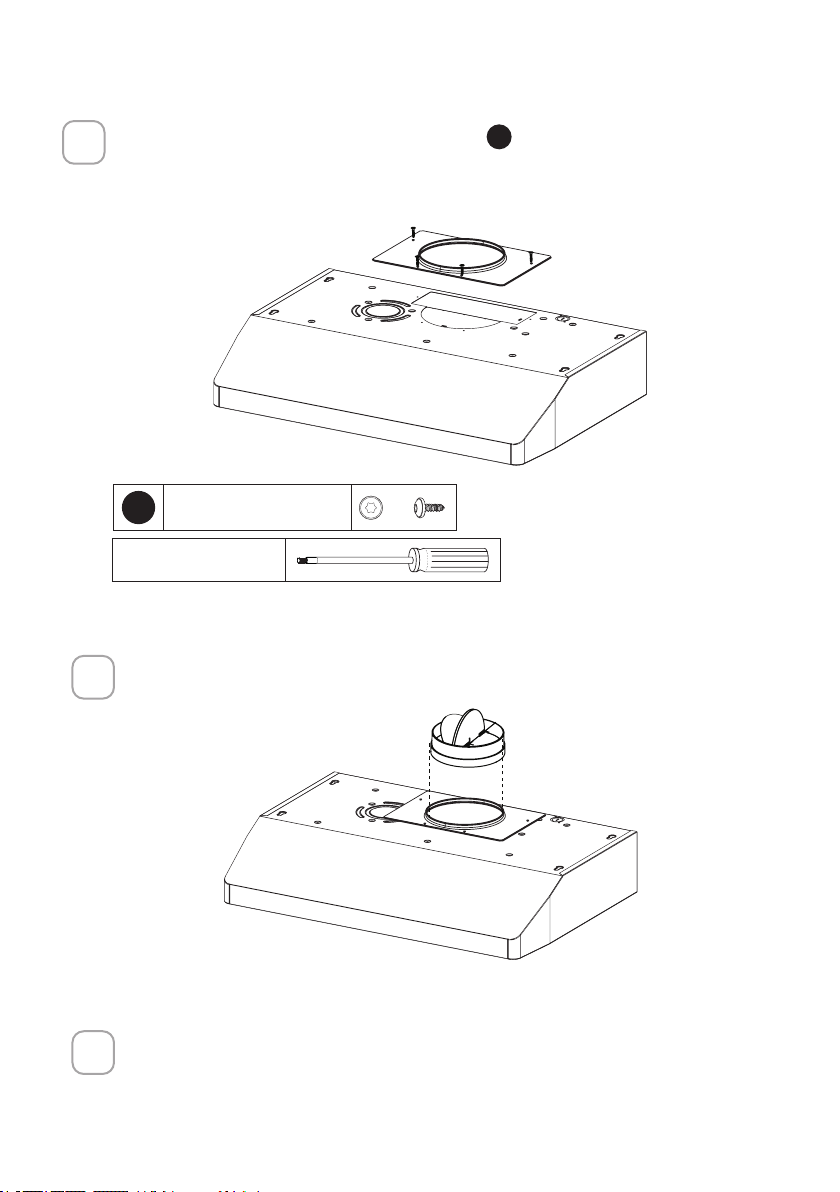

Page 17

Install the Flange with Flange transition screws F.

2

NOTE: The Flange must be mounted with the lip facing upward.

Only use the screws provided for the ange

Torx Screws (1/8" x 3/8")

F

Torx Screwdriver

Install 7" Round Damper purchased separately. Secure damper with foil duct tape.

3

Connect the 7" Round Metal Ductwork to the Roof or Wall Cap purchased separately

4

and then attach ductwork.

Go to page 20

17

Page 18

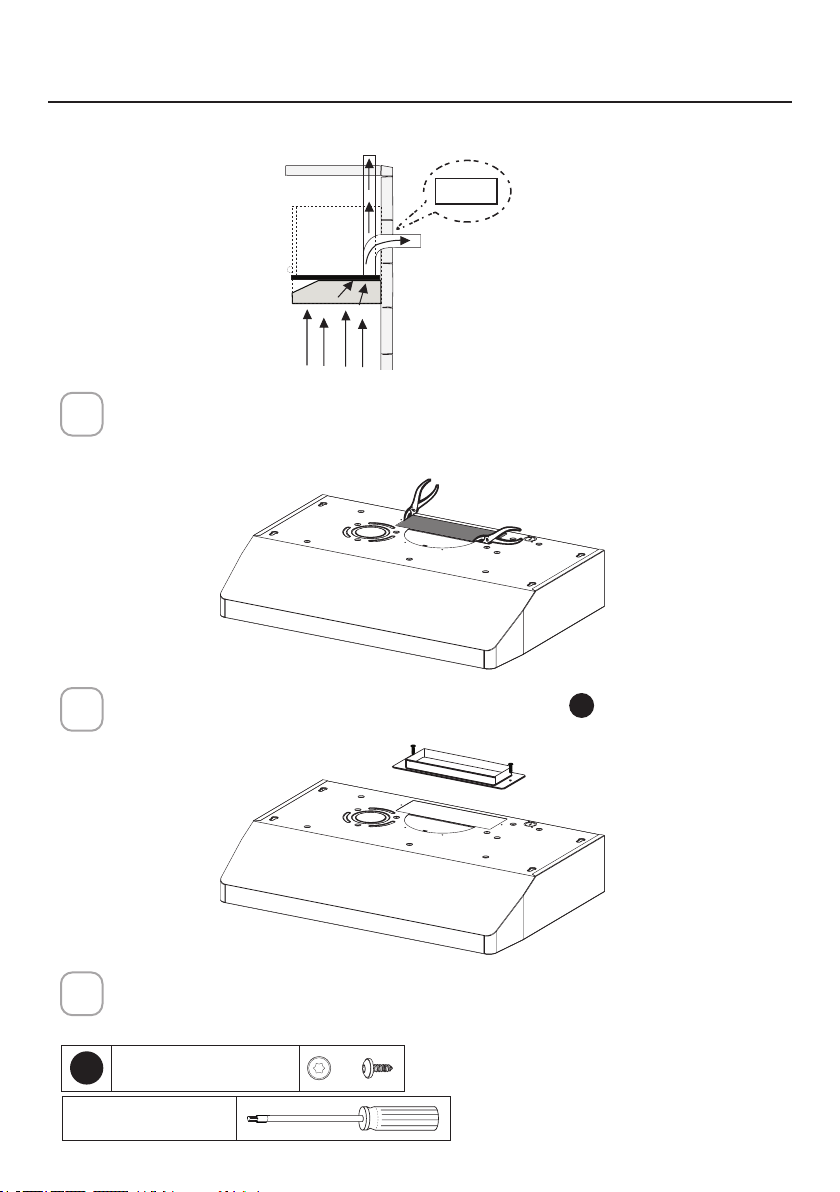

DUCTED - 3 1/4" X 10" RECTANGULAR OUTLET

ON TOP

Top

3 1/4" x 10"

Rear

Caution: If an elbow is required,

do it as far away from the

hood's exhaust opening as

possible.

Choose the rectangular upper air outlet or rectangular rear air outlet and cut where

1

indicated.(See page 19 for Rear Outlet)

Top

Install the included rectangular air outlet with two screws F.

2

Connect the metal ductwork to the Roof or Wall Cap purchased separately and

3

then attach ductwork.

Torx Screws (1/8" x 3/8")

F

Torx Screwdriver

18

Page 19

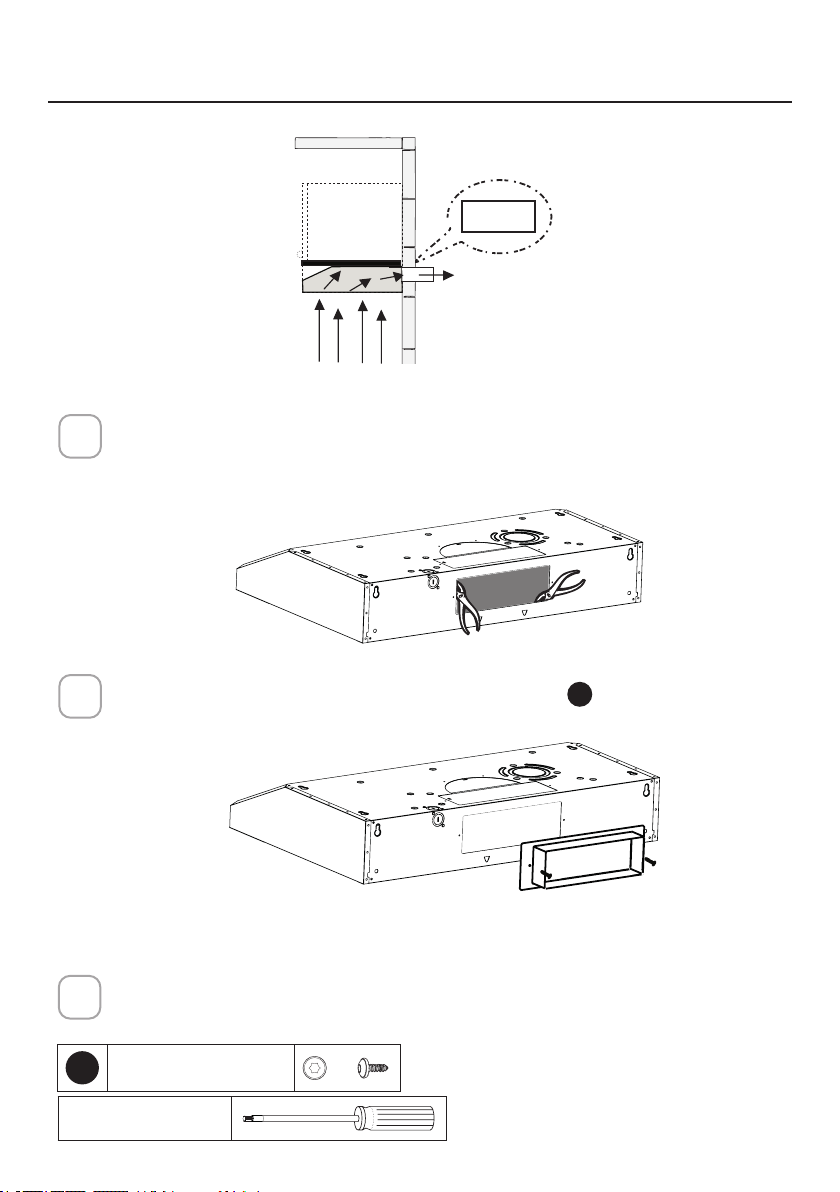

DUCTED - 3 1/4" X 10" RECTANGULAR OUTLET

REAR

3 1/4" x 10"

Rear

Caution: If an elbow is required,

do it as far away from the

hood's exhaust opening as

possible.

Use the rear air outlet and cut where indicated.

1

Rear

Install the included rectangular air outlet with two screws F.

2

Connect the metal ductwork to the Roof or Wall Cap purchased separately and

3

then attach ductwork.

Torx Screws (1/8" x 3/8")

F

Torx Screwdriver

Go to page 20

19

Page 20

CHOOSING THE MOUNTING METHOD

Installation for Mounting on the Wall

Page

21

20

Installation for Mounting to the cabinet

Page

25

Page 21

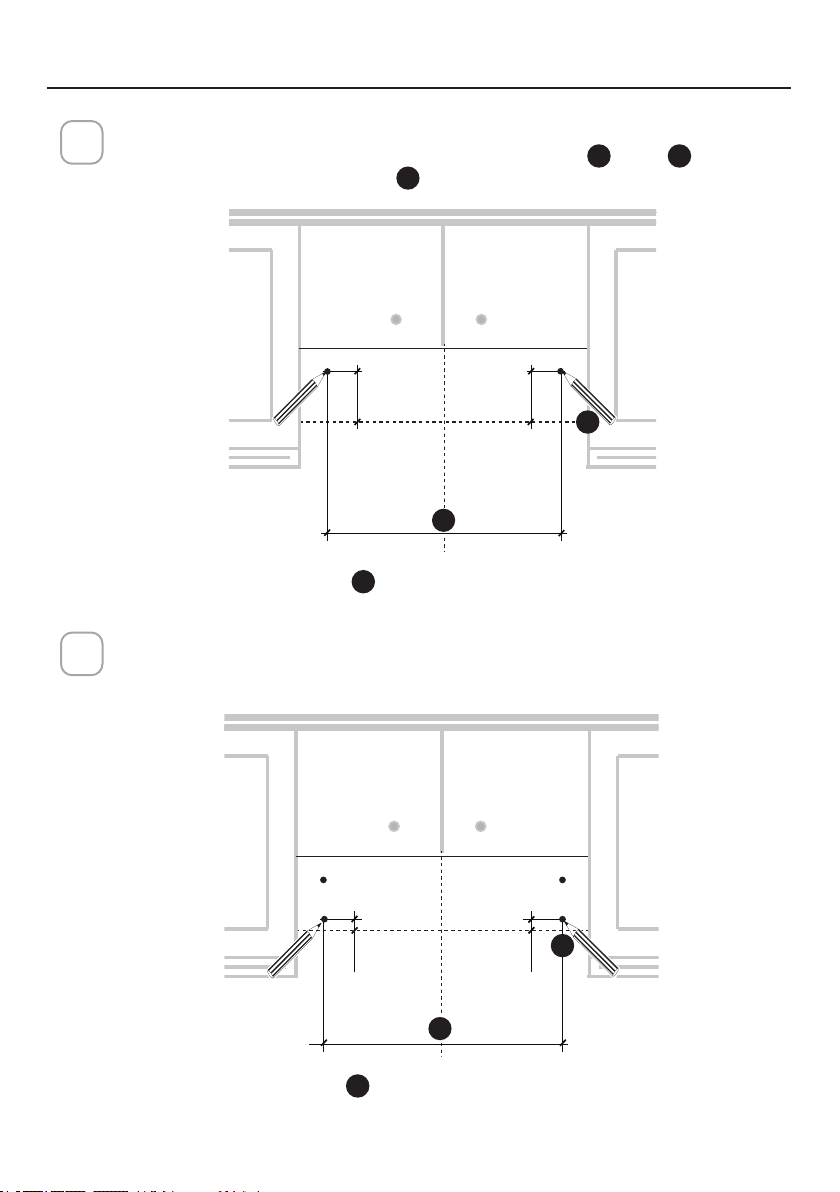

MOUNTING RANGE HOOD ON WALL

==

1

DRAW POSITIONING LINES

Draw a vertical line H from the supporting back wall to the ceiling or upper limit, at

the center of the area in which the hood will be installed.

Draw a horizontal line I from where the bottom edge of hood will be located, to

a minimum of 24" above an electric cooking surface and 30" above a gas cooking

surface.

H

I

Min. 24" Min.30"

MIN. 24" OVER ELECTRIC/MIN. 30" OVER GAS

21

Page 22

4 15/16”

1”

1”

4 15/16”

24” - - > A= 21

3/8

”

30” - - > A= 27

3/8”

36” - - > A= 33

3/8”

A

A

4 15/16”

4 15/16”

A

MOUNTING RANGE HOOD ON WALL

Mark the wall for the upper anchors.

2

Mark the wall where indicated 4 15/16" above the horizontal I line at J distance on

the left and right of the vertical line H .

H

24" = 21 24" = 21 3/83/8" "

J

30" = 27 30" = 27 3/83/8""

I

22

Mark the wall for lower anchors.

3

Mark 1” below the Step 2. Upper Anchors. Take care to keep level.

H

24" = 21 24" = 21 3/83/8""

J

30" = 27 30" = 27 3/83/8""

I

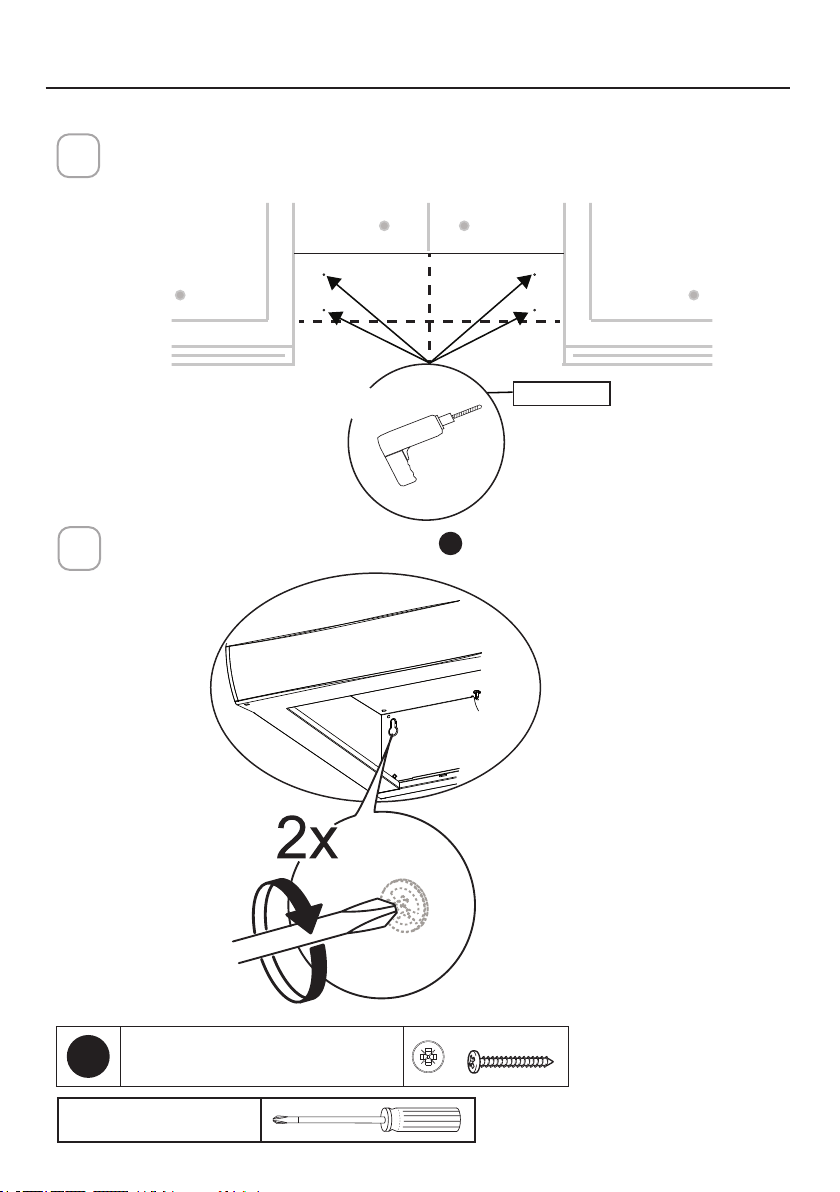

Page 23

´

;

MOUNTING RANGE HOOD ON WALL

Drill a 3/16th hole directly into the wall at the center points marked in step 3.

4

If fastener locations do not align with the studs, insert the purchased wall plugs in the holes.

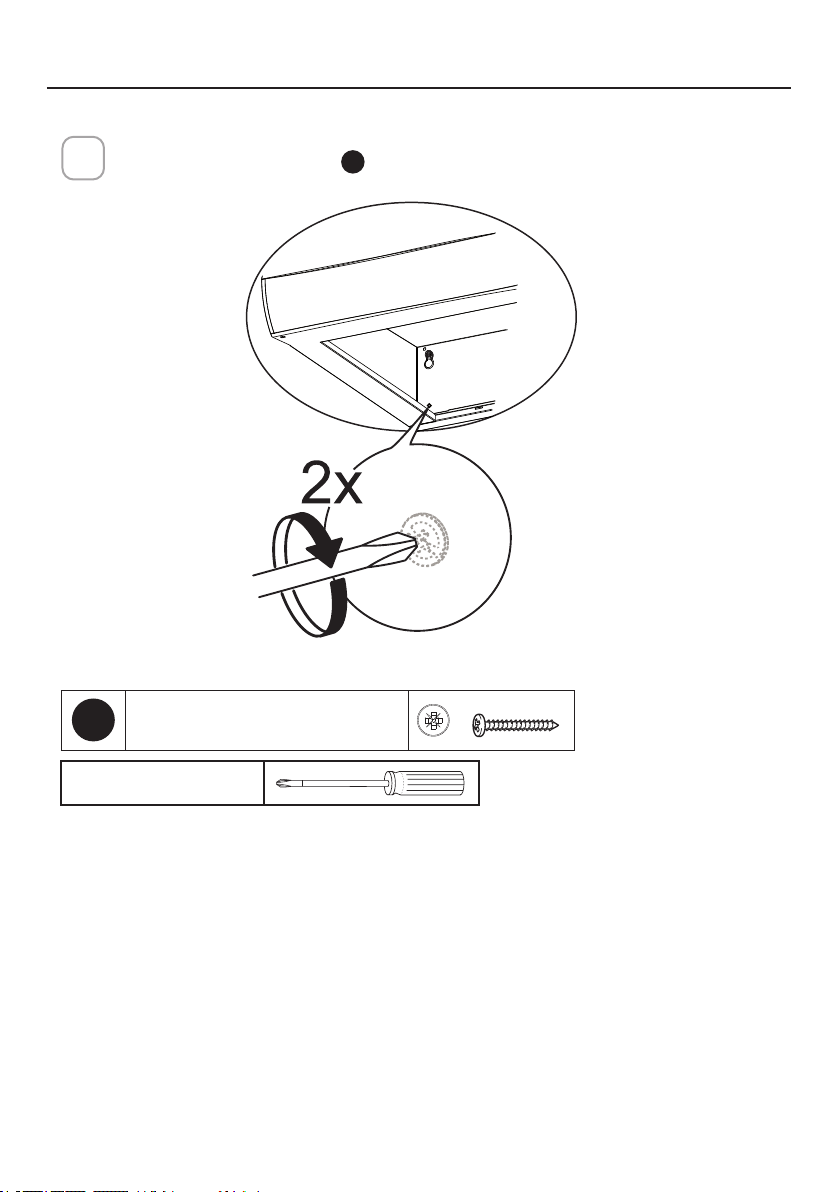

In upper holes use two of the supplied screws E to secure the hood body to the wall.

5

Pozi Screws (3/16" x 1 15/16")

E

Pozi Screwdriver

23

Page 24

MOUNTING RANGE HOOD ON WALL

6

Using two remaining screws E anchor the hood in lower holes as indicated.

Pozi Screws (3/16" x 1 15/16")

E

Pozi Screwdriver

CAUTION! For installations that have a recessed bottom, 1”X 2” x 12” (approximate length)

wood strips will need to be purchased and tted to provide a level mounting area. The 12C

Wall Mount Screws may work as fasteners, if not then 4 at head wood screws would need to

be purchased and used for this type of installation.

24

Page 25

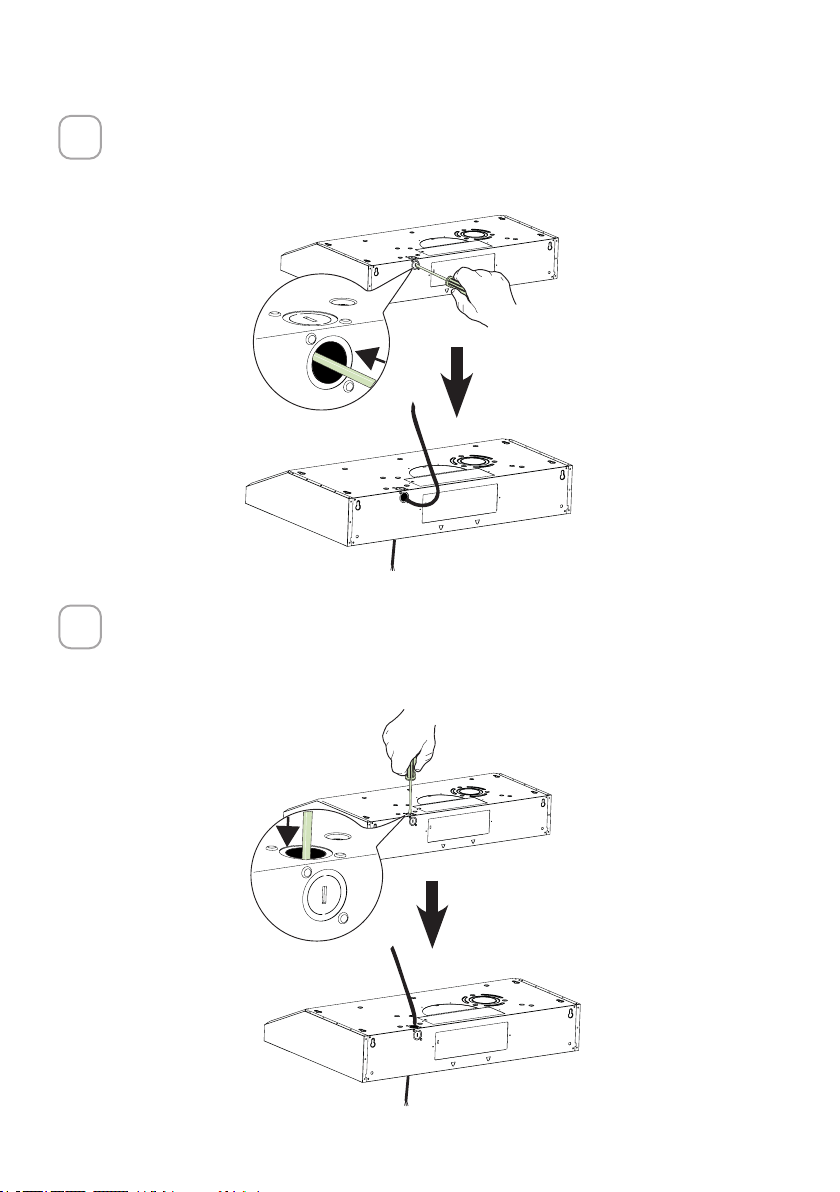

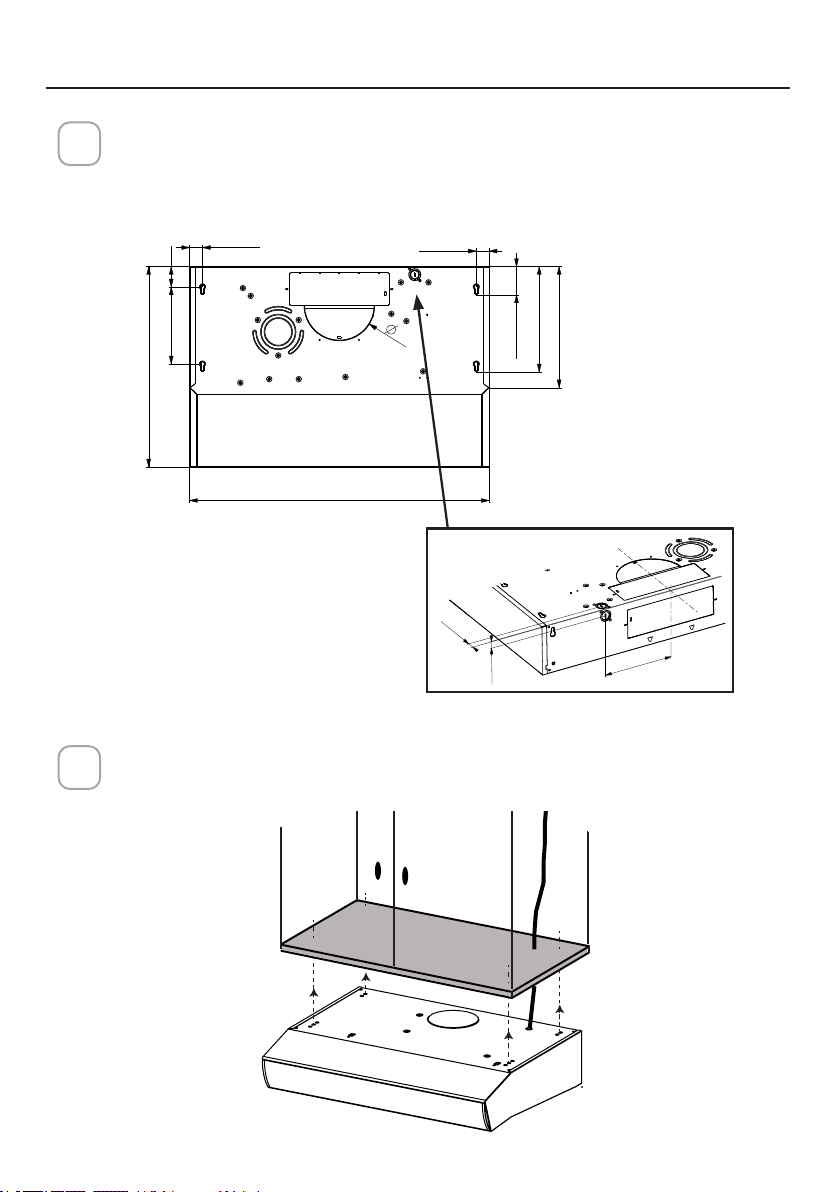

MOUNTING RANGE HOOD UNDER THE CABINET

5"1/2

20"

24.2°

1"3/4

20"

12"

12"3/4

1" 5/16

Created by

Denomination

GENERAL ASSEMBLY

Lang EN

Sheet

2

/3

Modif.by

Palazzi, Walter

Approved by

Approval date

Doc. status

7" 1/2

13/16"

13/16"

Locate the hole on the Range Hood for the power cord (See Section " CHOOSE

1

VERTICAL OR HORIZONTAL ELECTRICAL CONNECTION KNOCKOUT'S ") and pass

the cord through the appropriate hole.

Top View

1" 5/16

2" 13/16

12"

10" 1/2

BackView

7" 11/16 2"

24"-30"-36"

7"

23 15/16" - 29 15/16"

Lift the hood to the cabinet and pass the power cord through the appropriate holes

2

on the Range Hood and through the cabinet to the power source.

25

Page 26

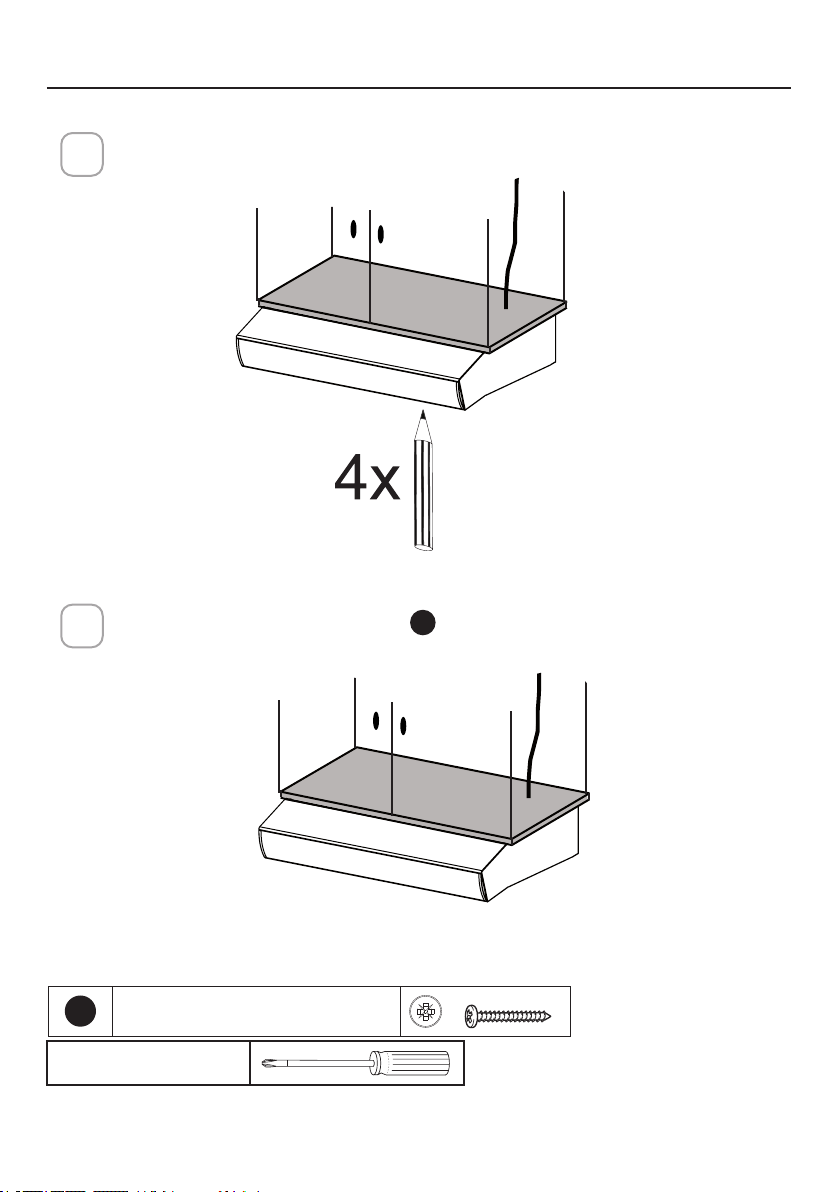

MOUNTING RANGE HOOD UNDER THE CABINET

Mark the holes for attaching the hood to the cabinet. Verify the measurement with

3

the diagram on the previous page.

Attach the Hood body with 4 screws E from the bottom available with the hood.

4

E

Pozi Screws (3/16" x 1 15/16")

Pozi Screwdriver

26

Page 27

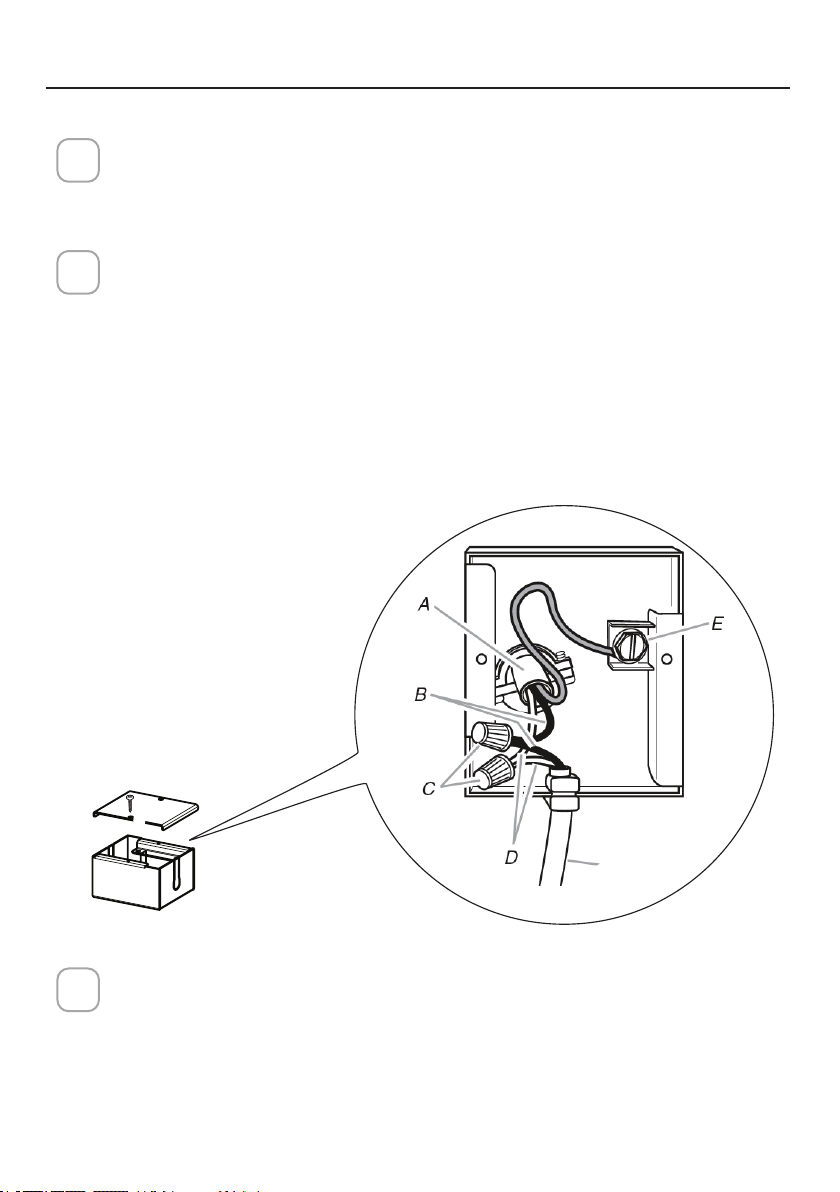

CONNECTING ELECTRICITY

Connecting the House Power.

1

Caution! Do not turn on the house power until the installation is complete.

• Feed the Power Supply Cable through the electrical knock out.

Wiring Box Connections.

2

• Attach the White lead of the Power Supply (A) to the White lead of the Range

Hood (D) with a twist-on type connector.

• Attach the Black lead of the Power Supply to the Black lead of the Range Hood

(B) with a twist-on type wire connector (C).

• Connect the Green (E) (Green and Yellow) ground wire under the grounding

screw.

Hood

wiring

Replace the eld wiring compartment cover and the grease lters

3

27

Page 28

OPERATING THE CONTROLS

FOR BEST RESULTS

Start the Range Hood several minutes before cooking to develop proper airow. Allow the

Range Hood to operate for several minutes after cooking is complete to clear all smoke and

odors from the kitchen.

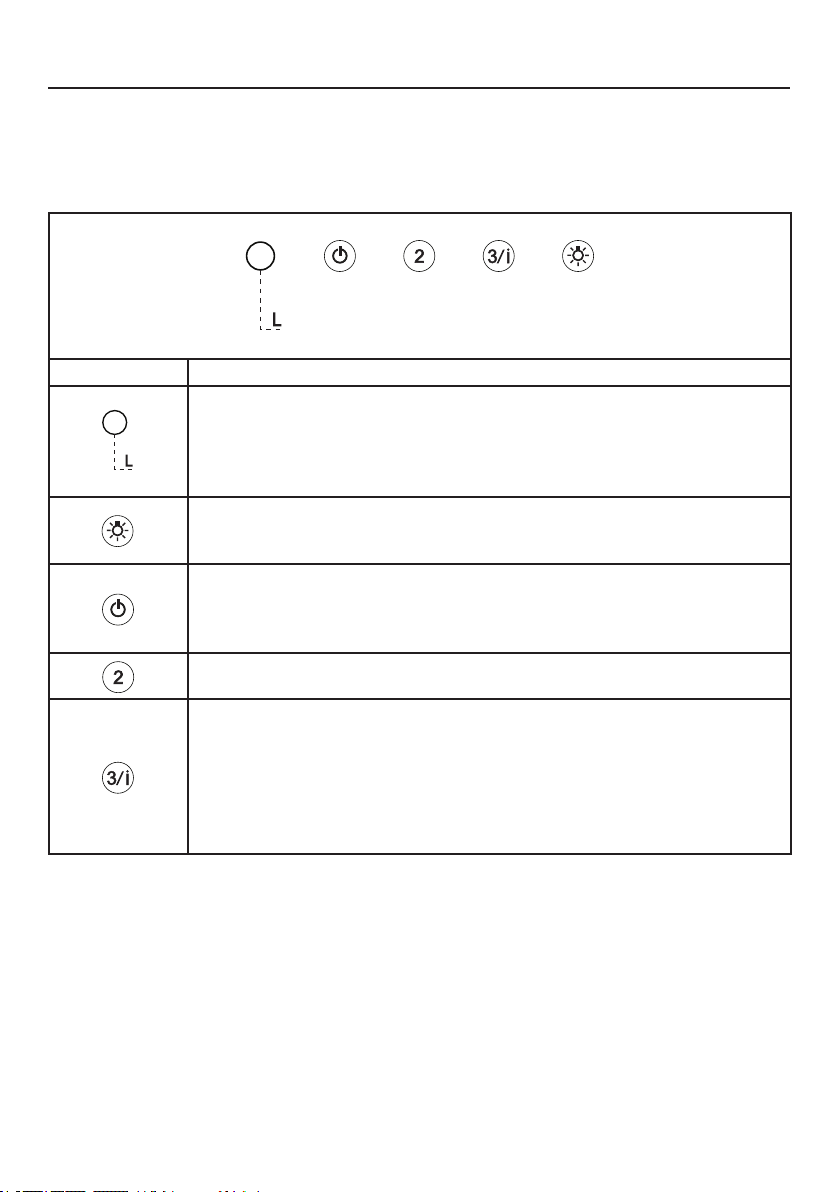

Button Function

LED indicator light (L) - indicates current speed with color

Green - speed 1

Orange - speed 2

Red - speed 3

Flashing Red - intensive speed

Light On/Off Button

On/Off switch for the Lights.

Press the button to turn the light ON and press again to turn it OFF.

Blower On/Off Button

On/Off button for the blower.

Press the button to turn the blower ON to speed one (indicated by green

LED) and press again to turn the hood off.

Blower Speed 2

Press this button to turn the hood onto speed #2. (indicated by orange LED).

Blower Speed 3 / Intensive

Press this button to turn the hood onto speed #3. (indicated by solid red

LED)

Hold down the speed 3 button for 2 seconds to activate the intensive speed.

The intensive speed setting is indicated by a blinking red light.

This operates the hood for 10 minutes on the highest speed and then returns

to the previous speed.

28

Page 29

CARING FOR FILTERS

Fitting the Hood canopy

260

13

495 - 675

Fitting the Hood canopy

260

13

495 - 675

CLEANING METAL GREASE FILTERS

The metal grease ltaers can be cleaned in hot detergent solution or washed

in the dishwasher.

They should be cleaned every 2 months use, or more frequently if use is

particularly heavy.

Remove the lter, pushing the lever to-

11

wards the back of the unit while pulling

downward.

2

Wash the lter without bending it. Leave

it to dry thoroughly before reinstalling. If

the surface of the lter changes color over

time, efciency will not be affected.

3

To reinstall the lter, push the lter up into

position while pulling the latch forward,

then release the latch to lock into place

NOTES:

• Cleaning in a dishwasher may dull the nish of the metal grease lters.

• Ensure that the lters are completely dry before installing them back into

the Range Hood.

CLEANING EXTERIOR SURFACES

Please note, abrasives and scouring agents can scratch range hood nishes

and should not be used to clean nished surfaces.

Stainless Steel nish cleaning instructions:

Clean exterior surfaces with a commercially available stainless steel cleaner.

29

Page 30

REPLACING ACTIVATED CHARCOAL FILTER

Fitting the Hood canopy

260

13

495 - 675

The Activated Charcoal Filters are not washable and cannot be regenerated,

and must be replaced approximately every 4 months of operation, or more

frequently with heavy usage.

Remove the grease lters.

1

Remove the old carbon

2

lter by removing the two

screws and then install the

new lter using the same

two screw holes.

Reinstall the grease lters.

3

30

Page 31

REPLACING LIGHTING

35 W halogen Type GU10 bulb

1

Remove the bulb (See the picture).

Replace the bulb with a new one of

2

the same type, making sure that you

insert the two pins properly into the

housings on the lamp holder and

twist to lock back in place.

Attention: The bulbs could be hot,

please wait some minutes before the

replacing.

Attention: It's possible to

upgrade

halogen with GU10 LED Max 5.5 W.

Check the reference in a picture.

the

GU10

Gu10 self-ballasted led

lamps – listed in accordance with ul

1993/nmx-j578/1-ance/

csa c22.2 No.

1993

31

Page 32

WIRING DIAGRAM

DOLCE CORRADO

Created by

Code

BLU

RED

BLK

GRY

12345

6

BLK

V1

MCFV2

ESZ

0-1

MOTOR

Y-G

Y-G

2

SPEED

BLKBLK

F

110-127V ~ 60Hz

WHTWHT

N

3/I

SPEED

0-1

LIGHT

N

LV4L

V3

WHT

12345

6

WHT

ORG

VLT

ORG

BLU

RED

M8-4V

BRW

ORG

Y-G

BLU

GRY

BLU

VLT

SEC.

-+

ELECTRONIC

TRNSFORMER

L N

BRW

GRY (red)

BLK (vlt)

1

2

12

12

GRYGRYGRY

1

LED

BLKBLKBLK

2

1

2

12

GRYGRY

LED

BLKBLK

DRAFT

VLT

LED

RED

VLT

LED

RED

32

Page 33

WARRANTY

FABER CONSUMER WARRANTY & SERVICE

All Faber products are warranted against any defect in materials or workmanship for the original purchaser

for a period of 1 year from the date of original purchase (requires proof of purchase). This warranty covers

labor and replacement parts. Faber, at its option, may repair or replace the product or components

necessary to restore the product to good working condition. To obtain warranty service, contact the dealer

from whom you purchased the range hood, or the local Faber distributor. If you cannot identify a local Faber

distributor, contact us at (508) 358-5353 for the name of a distributor in your area.

The following is not covered by Faber's warranty:

1. Service calls to correct the installation of your range hood, to instruct you how to use your range hood, to

replace or repair house fuses or to correct house wiring or plumbing.

2. Service calls to repair or replace range hood light bulbs, fuses or filters. Those consumable parts are

excluded from warranty coverage.

3. Repairs when your range hood is used for other than normal, single-family household use.

4. Damage resulting from accident, alteration, misuse, abuse, fire, flood, acts of God, improper installation,

installation not in accordance with electrical or plumbing codes or Faber documentation, or use of products

not approved by Faber.

5. Replacement parts or repair labor costs for units operated outside the United States or Canada, including

any non-UL or C-UL approved Faber range hoods.

6. Repairs to the hood resulting from unauthorized modifications made to the range hood.

7. Expenses for travel and transportation for product service in remote locations and pickup and delivery

charges. Faber range hoods should be serviced in the home.

THIS WARRANTY DOES NOT ALLOW RECOVERY OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING, WITHOUT

LIMITATION, DIRECT, INDIRECT, INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES, PERSONAL INJURY/WRONGFUL

DEATH OR LOST PROFITS FABER WARRANTY IS LIMITED TO THE ABOVE CONDITIONS AND TO THE WARRANTY PERIOD

SPECIFIED HEREIN AND IS EXCLUSIVE. EXCEPT AS EXPRESSLY SPECIFIED IN THIS AGREEMENT, FABER DISCLAIMS ALL

EXPRESS OR IMPLIED CONDITIONS, REPRESENTATIONS, AND W ARRANTIES INCLUDING, WITHOUT LIMITATION, ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PAR TICULAR PURPOSE

This warranty gives you specific legal rights that may vary from state to state.

Model#: ______________________________ Serial #: _____________________________

January 4, 2016

.

33

Page 34

TABLE DES MATIÈRES

Section Page

Importantes consignes de sécurité 35

Dimensions de la hotte 39

Exigences de hauteur d’installation 40

Pièces 41

Outils nécessaires 42

Avant l’installation, retirez les matériaux d’expédition 43

Uniquement pour le marché canadien 44

Choisissez des entrées défonçables deraccordement électrique verticales ou

horizontales

Options de méthode d’évacuation – avec ou sans conduit 47

Option de recirculation sans conduit 48

Sortie ronde avec conduit de 7pouces

Conduits métalliques rectangulaires de 31/4 x 10po sur le dessus

Conduits métalliques rectangulaires de 31/4 x 10po à l’arrière

Choix de la méthode de montage

Montage de la hotte sur un mur

Montage de la hotte sous un cabinet de cuisine

Branchements électriques

Utilisation des commandes

Entretien des ltres

Remplacement des lampes

Schéma de câblage

Garantie

45

49

51

52

53

54

58

60

61

62

64

65

66

34

Page 35

IMPORTANTES CONSIGNES DE SÉCURITÉ

VEUILLEZ LIRE ET CONSERVER LA PRÉSENTE NOTICE AVANT DE

COMMENCER L'INSTALLATION DE LA HOTTE DE CUISINE

AVERTISSEMENT: - POUR RÉDUIRE LE RISQUE D'UN FEU DE GRAISSE SUR LA TABLE

DE CUISSON:

a) Ne laissez jamais sans surveillance les éléments de la surface de cuisson à température

élevée. Les bouillonnements excessifs peuvent provoquer de la fumée et les débordements

de graisse peuvent s'enammer. L'huile doit être chauffée lentement, à une température

basse ou moyenne.

b) Assurez-vous de toujours mettre en marche la hotte lorsque vous cuisinez à température

élevée ou préparez un mets ambé (p.ex. crêpes Suzette, cerises jubilé, bœuf ambé).

c) Nettoyez régulièrement les ventilateurs d'aspiration. Assurez-vous de ne pas laisser de

la graisse s'accumuler sur le ventilateur ou le ltre.

d) Utilisez toujours des poêles et casseroles de la taille appropriée. Utilisez toujours des

ustensiles de cuisine de la taille adaptée à celle de l'élément chauffant.

AVERTISSEMENT: - POUR PRÉVENIR LES BLESSURES EN CAS DE FEU DE GRAISSE SUR

LA TABLE DE CUISSON, SUIVEZ LES RECOMMANDATIONS SUIVANTES*:

a) ÉTOUFFEZ LES FLAMMES à l'aide d'un couvercle hermétique, d'une plaque à biscuits ou

d'un plateau métallique, puis éteignez le brûleur. FAITES ATTENTION AUX BRÛLURES.

Si le feu ne s'éteint pas immédiatement, QUITTEZ LES LIEUX ET APPELEZ LES POMPIERS.

b) NE PRENEZ JAMAIS UNE CASSEROLE EN FLAMME - Vous pourriez vous brûler.

c) N'UTILISEZ JAMAIS DE L'EAU, ni un linge à vaisselle ou un torchon mouillé, pour éteindre

le feu. Cela pourrait provoquer une violente explosion de vapeur.

d) Utilisez un extincteur UNIQUEMENT si:

1. Vous êtes certain qu'il s'agit d'un extincteur de classe ABC et que vous connaissez

bien son mode d'emploi.

2. Le feu est de faible intensité et se limite à l'endroit où il a démarré.

3. Les pompiers ont déjà été appelés.

4. Une voie de sortie se trouve derrière vous pendant que vous éteignez les ammes.

*

D'après le guide «Kitchen Firesafety Tips» publié par la NFPA aux États-Unis

AVERTISSEMENT - POUR RÉDUIRE LE RISQUE D'INCENDIE OU DE CHOC ÉLECTRIQUE,

n'utilisez jamais ce ventilateur en association avec un dispositif de réglage de vitesse à

semi-conducteurs.

AVERTISSEMENT - POUR RÉDUIRE LES RISQUES D'INCENDIE, DE CHOC ÉLECTRIQUE OU

DE BLESSURE CORPORELLE, RESPECTEZ LES INSTRUCTIONS SUIVANTES:

1. Utilisez cet appareil uniquement de la façon prévue par le fabricant. Pour toute question,

communiquez avec le fabricant.

2. Avant de procéder à l'entretien ou au nettoyage de l'appareil, coupez l'alimentation au

niveau du panneau électrique et verrouillez-le pour vous assurer que l'électricité n'est pas

rétablie accidentellement. S'il n'est pas possible de verrouiller le dispositif d'interruption

de l'alimentation, afchez de façon ferme et bien visible un avis de danger, par exemple

à l'aide d'une étiquette sur le panneau.

ATTENTION: Destiné à un usage de ventilation générale uniquement. N'utilisez pas ce

dispositif pour l'aspiration de vapeurs ou de matériaux dangereux ou explosifs.

AVERTISSEMENT - POUR RÉDUIRE LES RISQUES D'INCENDIE, DE CHOC ÉLECTRIQUE OU

DE BLESSURE CORPORELLE, RESPECTEZ LES INSTRUCTIONS SUIVANTES:

1. L'installation et le branchement électrique doivent être réalisés par un technicien qualié

35

Page 36

et conformément à tous les codes et normes en vigueur, incluant ceux concernant la

construction à l'épreuve du feu.

2. An de garantir une combustion et une évacuation adéquates des gaz par les conduites

de la cheminée des appareils à combustion, une bonne aération est nécessaire pour

éviter le refoulement. Respectez les lignes directrices fournies par le fabricant du matériel

chauffant, ainsi que les normes de sécurité comme celles publiées par la National Fire

Protection Association (NFPA) et la American Society for Heating, Refrigeration and

Air Conditioning Engineers (ASHRAE) aux États-Unis, ainsi que les codes en vigueur

dans votre région.

3. Lorsque vous faites une ouverture ou percez dans un mur ou le plafond, veillez à ne

pas endommager les ls électriques ou d'autres dispositifs cachés.

4. Les ventilateurs canalisés doivent toujours être raccordés à l'extérieur.

TOUTE OUVERTURE DANS LE MUR OU LE PLANCHER À PROXIMITÉ DE LA HOTTE

DOIT ÊTRE SCELLÉE.

Un espace libre d'au moins 24" est requis entre le bas de la hotte et la surface de cuisson ou

le comptoir. Cette hotte a été homologuée par l'UL à cette distance de la surface de cuisson.

L’espace libre minimal requis peut-être plus grand, selon la réglementation en matière de

construction de votre région. Pour les cuisinières à gaz et les cuisinières combinées, un espace

minimal de 30" est recommandé et pourrait être exigé.

Les armoires suspendues de chaque côté de l'appareil doivent se trouver à au moins 18" de la

surface de cuisson ou du comptoir. Consultez la notice d'installation de la surface de cuisson

ou de la cuisinière fournie par le fabricant avant de pratiquer des ouvertures.

INSTALLATION DANS UNE MAISON MOBILE L'installation de cette hotte doit être conforme

à la Partie 3280 de la norme Manufactured Home Construction and Safety Standards, Title 24

CFR (précédemment la partie 280 de la norme Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD). Consultez la che technique électrique"

CRITÈRES DE VENTILATION

Déterminez quelle méthode de ventilation est mieux adaptée à votre application. Les conduits

peuvent passer par le mur ou le toit.

Pour garantir une meilleure efcacité, la longueur des conduits et le nombre de coudes doivent

être le plus limités que possible. Le diamètre des conduits devrait être uniforme. N'installez pas

deux coudes ensemble. Utilisez un ruban pour canalisations an de sceller tous les joints du

système de conduits. Utilisez un calfeutrage pour sceller les ouvertures dans le mur extérieur

ou le plancher, autour du clapet.

Il n'est pas recommandé d'utiliser des conduits exibles. Les conduits exibles provoquent

une contre-pression et de la turbulence qui diminuent grandement l'efcacité de l'appareil.

Assurez-vous que l'espace libre dans le mur ou le plancher est sufsant pour le conduit

d'évacuation avant de pratiquer les ouvertures. Ne coupez jamais une poutre ou un chevron,

sauf si c'est absolument nécessaire. S'il s'avère nécessaire de couper une poutre ou un chevron,

la construction d'un renforcement est requise.

AVERTISSEMENT - Pour réduire le risque d'incendie, utilisez uniquement des conduits

métalliques.

ATTENTION - Pour réduire le risque d'incendie et pour évacuer adéquatement l'air, assurez-

vous de raccorder les conduits à l'extérieur – Ne diffusez pas l'air d'évacuation dans des

espaces à l'intérieur des murs ou du plafond, ou encore à l'intérieur d'un grenier, d'une

galerie technique ou d'un garage.

36

Page 37

!

Installation dans les climats froids

Le système de ventilation doit prévoir un registre antirefoulement supplémentaire pour réduire le

ux d'air froid inverse, ainsi qu'une barrière thermique non métallique pour réduire la conduction des

températures extérieures. Le registre doit être installé du côté air froid par rapport à la barrière thermique.

La barrière thermique doit être positionnée le plus près que possible de l'endroit où le système de

ventilation pénètre dans la partie chauffée de la maison.

AVERTISSEMENT

• Le système de ventilation DOIT déboucher à l'extérieur.

• NE FAITES PAS déboucher les conduits dans un grenier ou un autre endroit

fermé.

• N’UTILISEZ PAS un clapet de sécheuse mural de 4".

• Il n'est pas recommandé d'utiliser des conduits exibles.

• N’ENTRAVEZ PAS le ux de l'air de combustion et de ventilation.

• Le non-respect des exigences en matière de ventilation pourrait entraîner un

incendie.

FICHE TECHNIQUE ÉLECTRIQUE

Une alimentation de courant alternatif de 120 volts à 60 Hz est requise sur un circuit à fusible

distinct de 15 ampères. Il est recommandé d'installer un fusible temporisé ou un disjoncteur.

Le fusible doit être calibré conformément aux codes en vigueur pour les caractéristiques

nominales électriques de l'appareil, indiquées sur la plaque signalétique située à l'intérieur

de l'appareil, à proximité du compartiment des câblages externes.

INSTALLATION ÉLECTRIQUE AVEC BOÎTIER DE CONNEXION

CET APPAREIL DOIT ÊTRE UNIQUEMENT BRANCHÉ À L'AIDE DE FILS DE CUIVRE. Le

calibre des ls doit être conforme aux critères de la dernière édition du National Electrical

Code, de l'ANSI/NFPA 70 et de l'ensemble des codes et réglementations en vigueur. Le

calibre des ls et les connexions doivent être adaptés aux caractéristiques nominales de

l'appareil. Il est possible de se procurer un exemplaire des normes indiquées ci-dessus en

communiquant avec:

National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269 (États-Unis)

Cet appareil devrait être branché directement au sectionneur à fusible (ou au disjoncteur)

par un câble exible de cuivre avec blindage ou gaine non métallique. Laissez un

peu de jeu dans le câble pour permettre le déplacement de l'appareil si des travaux

d'entretien s'avéraient nécessaires. Un raccord de conduit homologué par l'UL de 1/2"

doit être installé aux deux extrémités du câble d'alimentation (au niveau de l'appareil

et de la boîte de liaison).

Lors de la réalisation du branchement électrique, réalisez un trou de 1 1/4" dans le mur.

S'il s'agit d'un trou dans le bois, il doit être poncé pour le rendre lisse. S'il s'agit d'un

trou dans le métal, un passe-ls est requis.

37

Page 38

!

AVERTISSEMENT

• Une mise à la terre électrique est requise pour cette hotte.

• N'UTILISEZ PAS un tuyau d'eau froide pour la mise à la terre si celui-ci est

branché par des joints en plastique, par des rondelles non métalliques ou

d'autres matériaux.

• N'UTILISEZ PAS une conduite de gaz pour la mise à la terre.

• N'INSTALLEZ PAS un fusible sur le circuit neutre ou le circuit de mise à la

terre. La présence d'un fusible dans le circuit neutre ou de mise à la terre

peut entraîner un choc électrique.

• Consultez un électricien qualié si vous n'êtes pas certain de la mise à la terre

de la hotte.

• Le non-respect des exigences de la che technique électrique pourrait

entraîner un incendie.

Avertissement relatif à la proposition 65 de l’État de Californie (États-Unis

uniquement)

AVERTISSEMENT

Ce produit contient des éléments chimiques que l’État de Californie considère

comme étant cancérigènes ou causant des malformations congénitales ou d’autres

troubles de la reproduction.

Pour de plus amples renseignements, consultez le site www.P65Warnings.

ca.gov

38

Page 39

DIMENSIONS DE LA HOTTE

7 1/4

3

7

1/4

23 15/16” - 29 15/16” - 35 15/16”

24po

30po

24po - 30po

39

Page 40

EXIGENCES DE HAUTEUR D’INSTALLATION

24POUCES MINIMUM AU-DESSUS D’UNE SURFACE DE

CUISSON ÉLECTRIQUE/ 30POUCES MINIMUM AU-DESSUS

D’UNE SURFACE DE CUISSON AU GAZ

24 ou 30pouces minimum

40

Page 41

PIÈCES

PIÈCES INCLUSES

RÉF. PIÈCE

Corps de la hotte - Comprend les commandes, l’éclairage, les ltres, le

A

ventilateur

Amortisseur (3 1/4 x 10po) 1

B

Bride ronde de 7po 1

C

Grille (uniquement pour le marché canadien) 1

D

1

RÉF.

E

F

D

A

PIÈCE

Vis Pozi (3/16 x 115/16po)

Vis Torx (1/8 x 3/8po)

Accessoires disponibles

C

B

4

4

Filtre à charbon actif (FILTER5)

Remarque: le ltre à charbon est xé à l’aide de deux vis

(voir page48 et gureC).

Les ltres à charbon doivent être achetés auprès de

revendeurs Faber agréés.

41

Page 42

PIÈCES (suite)

PIÈCES NÉCESSAIRES

PIÈCE

Conduits métalliques ronds de 7po

Conduits métalliques rectangulaires de 31/4 x 10po

Amortisseur de 7po

Connecteurs de l.

Cordon d’alimentation électrique.

Chevilles pour cloisons sèches ou autres xations murales adaptées à votre installation.

Capuchon mural/ capuchon de toit. Doit être acheté

séparément

-

OUTILS NÉCESSAIRES

OUTIL

Ruban à mesurer

Crayon

Perceuse électrique avec foret de 5/16po

Tournevis à pointe Phillips

Tournevis Torx

Tournevis Pozi

42

Page 43

AVANT L’INSTALLATION, RETIREZ LES MATÉRIAUX

D’EXPÉDITION

Retirez l’emballage latéral.

1

Attention: ne

soulevez pas la

hotte à l’aide de la

barre en bois

Retirez l’emballage en mousse et la barre en bois.

2

Prêt pour l’installation.

3

43

Page 44

UNIQUEMENT POUR LE MARCHÉ CANADIEN

Pour les installations avec conduits uniquement:

1

Retirez les ltres un par un en les poussant vers l’arrière de la hotte et en les tirant

en même temps vers le bas.

Retirez les vis comme illustré.

2

Retirez deux des vis du carter de l’ensemble moteur, comme illustré.

Installez les vis comme illustré.

3

Installez la grille D avec les deux vis retirées à l’étape2. Vissez la grille de

protection à l’emplacement indiqué sur l’illustration ci-dessous. (L’emplacement

correct comporte une découpe rectangulaire pour s’adapter à la grille.)

Veillez à bien visser la grille pour éviter tout bruit indésirable.

Tournevis à pointe Phillips

44

D

Page 45

CHOISISSEZ DES ENTRÉES DÉFONÇABLES

DERACCORDEMENT ÉLECTRIQUE VERTICALES

OU HORIZONTALES

13/16"

13/16"

7" 1/2

Préparation de la hotte pour les entrées défonçables

Retirez les ltres un par

1

un en les poussant vers

l’arrière de la hotte et en

les tirant en même temps

vers le bas.

Retirez le couvercle du

2

boîtier de câblage en

dévissant les 2vis.

Tournevis à pointe Phillips

45

Page 46

Trou arrière (horizontal)

3

Choisissez le trou arrière pour le raccordement électrique et cassez l’entrée défonçable

avec un tournevis ou un autre outil.

Lors de l’installation, faites passer le câble d’alimentation dans ce trou.

Trou supérieur (vertical)

4

Choisissez le trou du dessus pour le raccordement électrique et cassez l’entrée

défonçable avec un tournevis ou un autre outil.

Lors de l’installation, faites passer le câble d’alimentation dans ce trou.

46

Page 47

OPTIONS DE MÉTHODE D’ÉVACUATION – AVEC

OU SANS CONDUIT

OPTION DE RECIRCULATION SANS

CONDUIT

Option avec conduit AVEC SOR-

TIE RONDE DE 7POUCES:

– verticale

– horizontale

Dessus

Exige

l’achat

d’un

accessoire

à charbon

actif

Rendez-vous à la page 49Rendez-vous à la page 48

CONDUITS MÉTALLIQUES RECTANGULAIRES DE 31/4 X 10PO

– verticale

– horizontale

7po

Arrière

Dessus

10po

3 1/4po

Arrière

10po

3 1/4po

Rendez-vous à la page 51

47

Page 48

OPTION DE RECIRCULATION SANS CONDUIT

Retirez le couvercle du ventilateur

a

b3

indiqué (ne jetez pas la vis).

b1

b2

Remettez en place le couvercle du

ventilateur modié avec la même vis.

Coupez le

couvercle

à l’endroit

indiqué sur

l’imageb1.

Jetez/

recyclez

les pièces

supérieures

du

couvercle du

ventilateur.

Accessoire de ltre à charbon

actif requis – (FILTER5) acheté

séparément.

Pour les installations sans conduit uniquement:

1. Retirez les deux vis situées sur le carter du

moteur à l’emplacement indiqué.

2. Placez le ltre à charbon avec les languettes

contre le boîtier du ventilateur, à l’emplacement

indiqué sur la gurec. Le trou de montage

en poire de la face avant du FILTER5 doit se

trouver sur la surface supérieure du ltre. Une

couche de charbon de bois sera visible à travers

les grilles.

3. Utilisez les deux vis retirées précédemment

pour xer le FILTER5 en place.

REMARQUE: Pour les installations sans conduit,

la grille pour le Canada ne doit PAS être utilisée.

d

48

c

Avant de faire fonctionner la hotte,

remettez les ltres à graisse existants

après avoir installé le ltre à charbon actif.

Rendez-vous à la page53

Page 49

SORTIE RONDE AVEC CONDUIT DE 7POUCES

Dessus

7po

Arrière

Attention : si un

coude est nécessaire,

installez-le aussi loin que

possible de l’ouverture

d’évacuation de la hotte.

Requis: amortisseur

rond de 7pouces

à acheter

séparément.

Coupez à l’endroit indiqué.

1

Retirez les zones rectangulaire et semi-circulaire avec des cisailles métalliques.

49

Page 50

Installez la bride avec les vis de transition de bride F.

2

REMARQUE: La bride doit être montée avec la lèvre tournée vers le haut.

Utilisez uniquement les vis fournies pour la bride

Vis Torx (1/8 x 3/8po)

F

Tournevis Torx

Requis: amortisseur rond de 7 pouces à acheter séparément. Fixer l’amortisseur à

3

l’aide de ruban adhésif pour conduit en aluminium.

50

Raccordez le conduit métallique rond de 7pouces au capuchon mural/ capuchon

4

de toit acheté séparément, puis xez le conduit.

Rendez-vous à la page53

Page 51

CONDUITS MÉTALLIQUES RECTANGULAIRES DE

31/4 X 10PO SUR LE DESSUS

Dessus

3 1/4 x 10po

Arrière

Attention : si un coude est

nécessaire, installez-le aussi

loin que possible de l’ouverture

d’évacuation de la hotte.

Choisissez la sortie d’air supérieure rectangulaire ou la sortie d’air arrière rectangulaire

1

et coupez à l’endroit indiqué (voir la page52 pour la sortie arrière)

Dessus

Installez la sortie d’air rectangulaire incluse avec deux vis F.

2

Raccordez le conduit métallique au capuchon mural/ capuchon de toit acheté

3

séparément, puis xez le conduit.

Vis Torx (1/8 x 3/8po)

F

Tournevis Torx

51

Page 52

CONDUITS MÉTALLIQUES RECTANGULAIRES DE

31/4 X 10PO À L’ARRIÈRE

3 1/4 x 10po

Arrière

Attention : si un coude est

nécessaire, installez-le aussi

loin que possible de l’ouverture

d’évacuation de la hotte.

Utilisez la sortie d’air arrière et coupez à l’endroit indiqué.

1

Arrière

Installez la sortie d’air rectangulaire incluse avec deux vis F.

2

Raccordez le conduit métallique au capuchon mural/ capuchon de toit acheté

3

séparément, puis xez le conduit.

Vis Torx (1/8 x 3/8po)

F

Tournevis Torx

52

Rendez-vous à la page53

Page 53

CHOIX DE LA MÉTHODE DE MONTAGE

Installation pour montage mural

Page54

Installation pour montage sous cabinet

Page55

53

Page 54

MONTAGE DE LA HOTTE SUR UN MUR

==

1

TRACEZ LES LIGNES DE PLACEMENT

Tracez une ligne verticale Hentre le mur de soutien arrière et le plafond ou la limite

supérieure, au centre de la zone dans laquelle la hotte sera installée.

Tracez une ligne horizontale I à partir de l’emplacement du bord inférieur de la

hotte, jusqu’à un minimum de 24pouces au-dessus d’une surface de cuisson électrique ou de 30pouces au-dessus d’une surface de cuisson au gaz.

H

I

54

24pouces

minimum

24POUCES MINIMUM AU-DESSUS D’UNE SURFACE

DE CUISSON ÉLECTRIQUE/ 30POUCES MINIMUM

AU-DESSUS D’UNE SURFACE DE CUISSON AU GAZ

30pouces

minimum

Page 55

4 15/16”

1”

1”

4 15/16”

24” - - > A= 21

3/8

”

30” - - > A= 27

3/8”

36” - - > A= 33

3/8”

A

A

4 15/16”

4 15/16”

A

MONTAGE DE LA HOTTE SUR UN MUR

Marquez l’emplacement des ancrages supérieurs sur le mur.

2

Marquez le mur à l’endroit indiqué à 12,5cm (415/16pouces) au-dessus de la ligne

horizontale à la distance I à J gauche et à droite de la ligne verticale H.

I

H

Marquez l’emplacement des ancrages inférieurs sur le mur.

3

Effectuez une marque à 2,5cm (1po) sous l’étape2. Ancrages supérieurs. Assurez-

vous que les marques sont horizontales les unes par rapport aux autres.

24po = 21 24po = 21 3/83/8popo

J

30po = 27 30po = 27 3/83/8popo

I

H

24po = 21 24po = 21 3/83/8popo

J

30po = 27 30po = 27 3/83/8popo

55

Page 56

´

;

MONTAGE DE LA HOTTE SUR UN MUR

Percez un trou de 3/16po directement dans le mur aux points centraux marqués à

4

l’étape3.

Si les emplacements des xations ne sont pas alignés avec les montants, insérez les

chevilles murales achetées dans les trous.

Dans les trous supérieurs, utilisez deux des vis fournies E pour xer le corps de la

5

hotte au mur.

Vis Pozi (3/16 x 115/16po)

E

Tournevis Pozi

56

Page 57

MONTAGE DE LA HOTTE SUR UN MUR

6

À l’aide de deux vis restantes E, ancrez la hotte dans les trous inférieurs, comme

indiqué.

Vis Pozi (3/16 x 115/16po)

E

Tournevis Pozi

ATTENTION! Pour les installations qui ont un fond encastré, des bandes de bois de

1x2x12pouces (longueur approximative) devront être achetées et installées pour fournir

une zone de montage de niveau. Les vis de montage mural 12C peuvent fonctionner comme

des attaches de xation, sinon 4vis à bois à tête plate doivent être achetées et utilisées pour

ce type d’installation.

57

Page 58

5"1/2

20"

24.2°

1"3/4

20"

12"

12"3/4

1" 5/16

Created by

Denomination

GENERAL ASSEMBLY

Lang EN

Sheet

2

/3

Modif.by

Palazzi, Walter

Approved by

Approval date

Doc. status

7" 1/2

13/16"

13/16"

MONTAGE DE LA HOTTE SOUS UN CABINET DE

CUISINE

Localisez le trou sur la hotte pour le cordon d’alimentation (voir la rubrique

1

«CHOISISSEZ ENTRÉES DÉFONÇABLES VERTICALES OU HORIZONTALES»), puis

faites passer le cordon dans le trou approprié.

Vue de dessus

1" 5/16

7" 11/16 2"

24"-30"-36"

7"

23 15/16" - 29 15/16"

Soulevez la hotte jusqu’à ce qu’elle entre en contact avec le cabinet, puis faites

2

passer le cordon d’alimentation à travers les trous appropriés de la hotte et du

cabinet, jusqu’à la source d’alimentation.

10" 1/2

2" 13/16

Vue arrière

12"

58

Page 59

MONTAGE DE LA HOTTE SOUS UN CABINET DE

CUISINE

Marquez les trous pour xer la hotte au cabinet. Vériez la mesure à l’aide du schéma

3

de la page précédente.

Fixez le corps de la hotte avec les 4vis E du bas fournies avec la hotte.

4

E

Vis Pozi (3/16 x 115/16po)

Tournevis Pozi

59

Page 60

BRANCHEMENTS ÉLECTRIQUES

Connexion à l’alimentation électrique de la maison.

1

Attention! Laissez le courant de la maison coupée jusqu’à ce que l’installation soit

terminée.

• Faites passer le câble d’alimentation à travers l’entrée défonçable.

2

Connexions du boîtier de câblage.

• Raccordez le l blanc du bloc d’alimentation (A) au l blanc de la hotte (D) à

l’aide d’un connecteur de type à visser.

• Raccordez le l noir du bloc d’alimentation (A) au l noir de la hotte (D) à l’aide

d’un connecteur de type à visser.

• Raccordez le l de masse vert ((E) (vert et jaune) sous la vis de mise à la masse.

Câblage

de la

hotte

Remettez en place le couvercle du compartiment de câblage sur

3

place et les ltres à graisse

60

Page 61

UTILISATION DES COMMANDES

POUR DE MEILLEURS RÉSULTATS

Démarrez la hotte plusieurs minutes avant la cuisson, an d’obtenir une bonne circulation

d’air. Laissez la hotte fonctionner pendant plusieurs minutes après la n de la cuisson, an

d’éliminer toute fumée et odeur de cuisine.

Bouton Fonction

Témoin à DEL (L) – Sa couleur indique la vitesse actuelle

Vert – Vitesse1

Orange – Vitesse2

Rouge – Vitesse3

Rouge clignotant – Vitesse élevée

Bouton marche-arrêt

Interrupteur marche-arrêt des lampes.

Appuyez sur le bouton pour allumer la lampe. Appuyez à nouveau pour

l’éteindre.

Bouton marche-arrêt du ventilateur

Interrupteur marche-arrêt du ventilateur.

Appuyez sur le bouton pour mettre le ventilateur en marche à la vitesse1

(indiquée par un témoin vert). Appuyez à nouveau pour éteindre la hotte.

Vitesse2 du ventilateur

Appuyez sur ce bouton pour mettre la hotte sur la vitesse2. (indiquée par

un témoin orange).

Vitesse3/ élevée du ventilateur

Appuyez sur ce bouton pour mettre la hotte sur la vitesse3. (indiquée par

un témoin rouge continu)

Maintenez le bouton de vitesse3 enfoncé pendant 2secondes pour activer

la vitesse élevée.

Le réglage de la vitesse élevée est indiqué par un témoin rouge clignotant.

Cela fait fonctionner la hotte pendant 10minutes à la vitesse la plus élevée,

puis revient à la vitesse précédente.

61

Page 62

ENTRETIEN DES FILTRES

Fitting the Hood canopy

260

13

495 - 675

Fitting the Hood canopy

260

13

495 - 675

NETTOYAGE DES FILTRES À GRAISSE EN MÉTAL

Les ltres à graisse en métal peuvent être nettoyés dans une solution détergente chaude ou lavés au lave-vaisselle.

Ils doivent être nettoyés tous les 2mois, ou plus fréquemment si l’utilisation

de la hotte est particulièrement intense.

Retirez le ltre en poussant le levier vers

11

l’arrière de l’appareil tout en tirant vers le

bas.

2

Lavez le ltre sans le plier. Laissez-le sécher

complètement avant de le réinstaller. Si la

surface du ltre change de couleur au l du

temps, son efcacité n’en sera pas affectée.

3

Pour remettre le ltre en place, poussez le

ltre en position vers le haut tout en tirant

le loquet vers l’avant, puis relâchez le loquet

pour le verrouiller en place

REMARQUES:

• Le nettoyage au lave-vaisselle peut ternir la nition des ltres à graisse en

métal.

• Assurez-vous que les ltres sont complètement secs avant de les remettre en place dans la hotte.

NETTOYAGE DES SURFACES EXTERNES

Veuillez noter que les abrasifs et les agents à récurer peuvent rayer les sur-

faces de nition de la hotte et ne doivent donc pas être utilisés.

Instructions de nettoyage pour les surfaces de nition en acier inoxydable:

Nettoyez les surfaces externes avec un nettoyant pour acier inoxydable du

commerce.

62

Page 63

REMPLACEMENT DU FILTRE À CHARBON ACTIF

Fitting the Hood canopy

260

13

495 - 675

Les ltres à charbon actif ne sont pas lavables et ne peuvent pas être régénérés. Ils doivent être remplacés environ tous les 4mois de fonctionnement,

ou plus fréquemment en cas d’utilisation intensive.

Retirez les ltres à graisse.

1

Retirez l’ancien ltre à

2

charbon actif en dévissant

les deux vis, puis installez le

nouveau ltre en utilisant les

deux mêmes trous de vis.

Remettez en place les ltres

3

à graisse.

63

Page 64

REMPLACEMENT DES LAMPES

Ampoule halogène type GU10 de

1

35W

Retirez l’ampoule (voir l’illustration).

Remplacez l’ampoule par une am-

2

poule neuve du même type, en vous

assurant d’insérer correctement les

deux broches dans les logements du

support de lampe, puis en la tournant pour la verrouiller en place.

Attention: les ampoules peuvent être

chaudes; veuillez attendre quelques

minutes avant de les remplacer.

64

Attention: il est possible de

l’

ampoule halogène GU10 avec ampoule GU10

mettre à niveau

à DEL de 5,5W maximum.

Vériez la référence sur une image.

Ampoules à DEL à

ballast intégré GU10 –

certiées à

la norme UL

1993/nmx-j578/1-ance/

csa c22.2

nº1993

Page 65

DOLCE CORRADO

Created by

Code

BLU

RED

BLK

GRY

12345

6

BLK

V1

MCFV2

ESZ

0-1

MOTOR

Y-G

Y-G

2

SPEED

BLKBLK

F

110-127V ~ 60Hz

WHTWHT

N

3/I

SPEED

0-1

LIGHT

N

LV4L

V3

WHT

12345

6

WHT

ORG

VLT

ORG

BLU

RED

M8-4V

BRW

ORG

Y-G

BLU

GRY

BLU

VLT

SEC.

-+

ELECTRONIC

TRNSFORMER

L N

BRW

GRY (red)

BLK (vlt)

1

2

12

12

GRYGRYGRY

1

LED

BLKBLKBLK

2

1

2

12

GRYGRY

LED

BLKBLK

DRAFT

VLT

LED

RED

VLT

LED

RED

SCHÉMA DE CÂBLAGE

65

Page 66

GARANTIE

FABER CONSUMER WARRANTY & SERVICE

All Faber products are warranted against any defect in materials or workmanship for the original purchaser

for a period of 1 year from the date of original purchase (requires proof of purchase). This warranty covers

labor and replacement parts. Faber, at its option, may repair or replace the product or components

necessary to restore the product to good working condition. To obtain warranty service, contact the dealer

from whom you purchased the range hood, or the local Faber distributor. If you cannot identify a local Faber

distributor, contact us at (508) 358-5353 for the name of a distributor in your area.

The following is not covered by Faber's warranty:

1. Service calls to correct the installation of your range hood, to instruct you how to use your range hood, to

replace or repair house fuses or to correct house wiring or plumbing.

2. Service calls to repair or replace range hood light bulbs, fuses or filters. Those consumable parts are

excluded from warranty coverage.

3. Repairs when your range hood is used for other than normal, single-family household use.

4. Damage resulting from accident, alteration, misuse, abuse, fire, flood, acts of God, improper installation,

installation not in accordance with electrical or plumbing codes or Faber documentation, or use of products

not approved by Faber.

5. Replacement parts or repair labor costs for units operated outside the United States or Canada, including

any non-UL or C-UL approved Faber range hoods.

6. Repairs to the hood resulting from unauthorized modifications made to the range hood.

7. Expenses for travel and transportation for product service in remote locations and pickup and delivery

charges. Faber range hoods should be serviced in the home.

THIS WARRANTY DOES NOT ALLOW RECOVERY OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING, WITHOUT

LIMITATION, DIRECT, INDIRECT, INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES, PERSONAL INJURY/WRONGFUL

DEATH OR LOST PROFITS FABER WARRANTY IS LIMITED TO THE ABOVE CONDITIONS AND TO THE WARRANTY PERIOD

SPECIFIED HEREIN AND IS EXCLUSIVE. EXCEPT AS EXPRESSLY SPECIFIED IN THIS AGREEMENT, FABER DISCLAIMS ALL

EXPRESS OR IMPLIED CONDITIONS, REPRESENTATIONS, AND W ARRANTIES INCLUDING, WITHOUT LIMITATION, ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PAR TICULAR PURPOSE

This warranty gives you specific legal rights that may vary from state to state.

Model#: ______________________________ Serial #: _____________________________

January 4, 2016

.

66

Page 67

CONTENIDO

Sección Página

Instrucciones de seguridad importantes 68

Dimensiones de la campana de cocina 72

Requisitos de altura de la instalación 73

Partes 74

Herramientas necesarias 75

Antes de la instalación retire los materiales de embalaje 76

Solo para el mercado canadiense 77

Elegir el prepunzonado de conexión eléctrica vertical u horizontal 78

Extracción con conducto o sin conducto 80

Opción de recirculación sin conducto 81

Con conducto - salida redonda de 7"

Con conducto - salida rectangular en la parte superior de 3 1/4" x 10"

Con conducto - salida rectangular en la parte trasera de 3 1/4" x 10"

Elegir el método de montaje

Montaje de la campana de cocina en la pared

Montaje de la campana de cocina bajo el mueble

Conexión a la electricidad

Mandos de funcionamiento

Cuidado de los ltros

Sustitución de las lámparas

Diagrama de cableado

Garantía

82

84

85

86

87

91

93

94

95

97

98

99

67

Page 68

INSTRUCCIONES DE SEGURIDAD IMPORTANTES

LEA Y GUARDE ESTAS INSTRUCCIONES ANTES DE COMENZAR A

INSTALAR ESTA CAMPANA EXTRACTORA

ADVERTENCIA: - PARA REDUCIR EL RIESGO DE INCENDIO DE LA CAMPANA POR GRASA:

a) Nunca deje las unidades de supercie desatendidas en ajustes altos. Los derrames por

ebullición pueden causar humos y derrames de grasa que pueden incendiarse. Caliente

los aceites lentamente en ajustes bajos o medios.

b) Siempre encienda la campana cuando cocine a fuego alto o cuando amee alimentos

(por ej. Crepes Suzette, Cherries Jubilee, Peppercorn Beef Flambé).

c) Limpie los ventiladores con frecuencia. No se debe permitir que la grasa se acumule en

el ventilador o en el ltro.

d) Use una olla de tamaño adecuado. Utilice siempre utensilios de cocina apropiados para

el tamaño del elemento de supercie.

ADVERTENCIA: - PARA REDUCIR EL RIESGO DE LESIONES A PERSONAS EN CASO DE

INCENDIO DE GRASA EN LA CAMPANA, TENGA EN CUENTA LO SIGUIENTE*:

a) APAGUE LAS LLAMAS con una tapa ajustada, bandeja para hornear galletas o bandeja

de metal, luego apague el quemador. TENGA CUIDADO PARA EVITAR QUEMADURAS.

Si las llamas no se apagan inmediatamente, EVACÚE Y LLAME AL DEPARTAMENTO DE

BOMBEROS.

b) NUNCA RECOJA UNA OLLA EN LLAMAS - Puede quemarse.

c) NO USE AGUA, incluidos paños de cocina húmedos o toallas; se producirá una violenta

explosión de vapor.

d) Use un extintor SOLAMENTE si:

1. Usted sabe que tiene un extintor Clase ABC y ya sabe cómo operarlo.

2. El incendio es pequeño y está contenido en el área donde comenzó.

3. Se llama al departamento de bomberos.

4. Puede luchar contra el incendio con su espalda hacia una

*

Basado en "Consejos de seguridad contra incendios en la cocina" publicado por NFPA

ADVERTENCIA - PARA REDUCIR EL RIESGO DE DESCARGA ELÉCTRICA O INCENDIO, no

use este ventilador con ningún dispositivo de control de velocidad de estado.

ADVERTENCIA - PARA REDUCIR EL RIESGO DE INCENDIOS, DESCARGAS ELÉCTRICAS

O LESIONES PERSONALES, OBSERVE LO SIGUIENTE:

1. Use esta unidad solo de la manera prevista por el fabricante. Si tiene alguna pregunta,

comuníquese con el fabricante.

2. Antes de reparar o limpiar la unidad, apague el equipo en el panel de servicio y

bloquee los medios de desconexión del servicio para evitar que la energía se encienda

accidentalmente. Cuando los medios de desconexión del servicio no se puedan bloquear,

je de forma segura un dispositivo de advertencia prominente, como una etiqueta, al

panel de servicio.

PRECAUCIÓN: Para uso general de ventilación solamente. No lo use para descargar materiales

y vapores peligrosos o explosivos.

ADVERTENCIA - PARA REDUCIR EL RIESGO DE INCENDIOS, DESCARGAS ELÉCTRICAS

O LESIONES PERSONALES, OBSERVE LO SIGUIENTE:

1. El trabajo de instalación y el cableado eléctrico deben realizarlo las personas calicadas

de acuerdo con todos los códigos y estándares aplicables, incluida la construcción con

clasicación de incendio.

2. Se necesita suciente aire para la combustión adecuada y el escape

68

salida.

de gases a

Page 69

través del tubo de humos (chimenea) del equipo que quema combustible para evitar la

retrogresión. Siga las directrices del fabricante del equipo de calefacción y las normas

de seguridad tales como los publicados por la National Fire Protection Association

(NFPA), la American Society for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE) y las autoridades de los códigos locales.

3. Al cortar o perforar la pared o el techo, no dañe el cableado eléctrico ni otros servicios

ocultos.

4. Los ventiladores con conductos siempre deben tener salida al exterior.

TODAS LAS APERTURAS DE PARED Y PISO DONDE SE INSTALE LA CAMPANA

EXTRACTORA DEBEN SER SELLADAS.

Esta campana extractora requiere al menos 24" de espacio libre entre la parte inferior de la

campana extractora y la supercie de cocción o encimera. Esta campana ha sido aprobada

por UL a esta distancia de la placa.

Esta separación mínima puede ser mayor dependiendo de los códigos de construcción

locales. Para placas de gas y cocinas combinadas, se recomienda y puede ser necesario un

mínimo de 30 ".

Los gabinetes superiores en ambos lados de esta unidad deben estar a un mínimo de 18"

sobre la supercie de cocción o la encimera. Consulte las instrucciones de instalación de la

placa o la campana proporcionadas por el fabricante antes de hacer cualquier corte.

INSTALACIÓN EN VIVIENDAS MÓVILES La instalación de esta campana extractora debe

cumplir con los Estándares de construcción y seguridad de casas prefabricadas, Título 24 CFR,

Parte 3280 (anteriormente Estándar federal para la construcción y seguridad en viviendas

móviles, Título 24, HUD, Parte 280). Vea los requisitos eléctricos"

REQUISITOS DE VENTILACIÓN

Determine qué método de ventilación es mejor para su aplicación. Los conductos pueden

extenderse a través de la pared o el techo.

La longitud de los conductos y la cantidad de codos se deben mantener al mínimo para

proporcionar un rendimiento eciente. El tamaño de los conductos debe ser uniforme. No

instales dos codos juntos. Use cinta adhesiva para sellar todas las juntas en el sistema de

conductos. Utilice calafateo para sellar la pared exterior o la abertura del piso alrededor de

la tapa.

NO se recomiendan conductos exibles. Los conductos exibles crean una contrapresión

y turbulencias de aire que reducen en gran medida el rendimiento.

Asegúrese de que haya espacio libre adecuado dentro de la pared o el piso para el conducto

de escape antes de hacer los cortes. No corte una vigueta o poste a menos que sea

absolutamente necesario. Si se debe cortar una vigueta o poste, entonces se debe construir

un marco de soporte.

ADVERTENCIA - Para reducir el riesgo de incendio, use solamente conductos de metal.

PRECAUCIÓN - Para reducir el riesgo de incendio y para descargar adecuadamente el

aire, asegúrese de sacar el aire - No expulse los humos en espacios dentro de paredes o

techos, áticos, espacios angostos o garajes.

Instalaciones para clima frío

Se debe instalar un registro de tiro adicional para minimizar el ujo de aire frío hacia atrás y se debe

instalar un disyuntor térmico no metálico para minimizar la conducción de las temperaturas exteriores

como parte del sistema de ventilación. El registro debe estar en el lado del aire frío del interruptor

térmico. El interruptor debe estar lo más cerca posible de donde el sistema de ventilación ingrese a la

parte calentada de la casa.

69

Page 70

!

ADVERTENCIA

• El sistema de ventilación DEBE terminar fuera del hogar.

• NO termine el conducto en un espacio ático o en otro espacio cerrado.

• NO use tacos de pared de 4" tipo lavadero.

• NO se recomiendan los conductos de tipo exible.

• NO obstruya el ujo del aire de combustión y ventilación.

• El incumplimiento de los requisitos de ventilación puede provocar un

incendio.

REQUISITOS ELÉCTRICOS

Se requiere un suministro eléctrico de 120 voltios, 60 Hz solo CA en un circuito separado con

fusible de 15 amperios. Se recomienda un fusible de retardo o un cortacircuitos. El fusible

se debe dimensionar según los códigos locales de acuerdo con la clasicación eléctrica de

esta unidad, tal como se especica en la placa de número de serie/clasicación ubicada

dentro de la unidad, cerca del compartimento de cableado de campo.

INSTALACIÓN ELÉCTRICA CON CAJA DE CABLEADO

ESTA UNIDAD DEBE CONECTARSE CON CABLE DE COBRE SOLAMENTE. Los tamaños

de los cables deben cumplir con los requisitos del Código Eléctrico Nacional, ANSI / NFPA

70, última edición, y todos los códigos y ordenanzas locales. El tamaño del cable y las

conexiones deben cumplir con la clasicación del equipo. Se pueden obtener copias de la

norma enumerada anteriormente en:

Batterymarch Park

Quincy, Massachusetts 02269

Este electrodoméstico debe conectarse directamente a la desconexión por fusible (o

disyuntor) a través de un cable exible, blindado o no metálico de cobre enfundado.

Deje algo de tensión en el cable para poder mover el dispositivo si alguna vez lo

necesita. Debe haber un conector de conducto de 1/2 homologado por UL en cada

extremo del cable de suministro de energía (en el equipo y en la caja de conexiones).

Al hacer la conexión eléctrica, corte un agujero de 1 1/4" en la pared. Un agujero

cortado a través de la madera debe lijarse hasta que quede liso. Un agujero a través

del metal debe tener un ojal.

70

National Fire Protection Association

Page 71

ADVERTENCIA

!

• Esta campana extractora requiere conexión eléctrica de tierra.

• Si la tubería de agua fría está interrumpida por juntas de plástico, de

materiales no metálicos u otros materiales, NO la utilice para conexión a

tierra.

• NO conecte a tierra a una tubería de gas.

• NO tenga un fusible en el circuito neutro o de tierra. Un fusible en el circuito

neutro o de tierra podría provocar una descarga eléctrica.

• Consulte con un electricista calicado si tiene dudas acerca de si la campana

extractora está correctamente conectada a tierra.

• El incumplimiento de los requisitos eléctricos puede provocar un incendio.

Advertencia de la Propuesta 65 del Estado de California (solo EE. UU.)

ADVERTENCIA

Este producto contiene productos químicos que el Estado de California reconoce

como causantes de cáncer y defectos de nacimiento u otros daños reproductivos

Para obtener más información, vaya a www.P65Warnings.ca.gov

.

71

Page 72

DIMENSIONES DE LA CAMPANA DE COCINA

7 1/4

3

7

1/4

23 15/16” - 29 15/16” - 35 15/16”

24" 30"

72

24"

30"

Page 73

REQUISITOS DE ALTURA DE LA INSTALACIÓN

MÍN. 24" SOBRE PLACA ELÉCTRICA / MÍN. 30" SOBRE

PLACA DE GAS

Mín. 24" - 30"

73

Page 74

PARTES

PARTES INCLUIDAS

REF. PARTE

Cuerpo de la campana - Incluye controles, iluminación, ltros, extractor 1

A

Válvula antirretorno (3 1/4" x 10") 1

B

Brida redonda de 7" 1

C

Rejilla (Solo para el mercado canadiense) 1

D

REF

PARTE

E

Tornillos Pozi (3/16" x 1 15/16")

F

Tornillos Torx (1/8" x 3/8")

4

4

D

C

A

Accesorios disponibles

Filtro de carbón activado (FILTER5)

Nota: El Filtro de Carbón se ja con dos tornillos

(Ver página 81 y Figura C).

Los Filtros de Carbón deben adquirirse únicamente con

distribuidores Faber autorizados.

B

74

Page 75

PARTES (cont.)

PARTES NECESARIAS

PARTE

Conductos redondos de metal de 7"

Conductos rectangulares de 3 1/4" x 10"

Válvula antirretorno de 7"

Conectores de cable.

Cable de alimentación.

Tacos de yeso u otros sujetadores de pared adecuados

según su instalación.

La tapa de la pared/tapa del techo debe comprarse por

separado

-

HERRAMIENTAS NECESARIAS

HERRAMIENTA

Cinta métrica

Lápiz

Taladro eléctrico con una broca de 5/16"

Destornillador Phillips

Destornillador Torx

Destornillador Pozi

75

Page 76

ANTES DE LA INSTALACIÓN RETIRE LOS

MATERIALES DE EMBALAJE

Retire el embalaje lateral.

1

Precaución:

No levante la

campana usando

la barra de madera

Retire el embalaje de espuma y la barra de madera.

2

76

Lista para la instalación.

3

Page 77

SOLO PARA EL MERCADO CANADIENSE

Solo para instalaciones con conductos:

1

Retire los ltros de uno en uno empujándolos hacia la parte posterior de la campana

y tirando hacia abajo al mismo tiempo.

Retire los tornillos como se muestra en la imagen.

2

Retire dos de los tornillos de la carcasa del ensamblaje del motor como se muestra

en la imagen.

Instale los tornillos como se muestra en la imagen.

3

Instale la rejilla D con los dos tornillos que retiró en el paso 2. Atornille la rejilla

de protección en el lugar que se muestra en la imagen de abajo. (La ubicación

correcta tiene un corte rectangular para acomodar la rejilla.)

Tenga cuidado de atornillar la rejilla completamente nivelada para evitar ruidos no

deseados.

D

Destornillador Phillips

77

Page 78

ELEGIR EL PREPUNZONADO DE CONEXIÓN

ELÉCTRICA VERTICAL U HORIZONTAL

13/16"

13/16"

7" 1/2

Preparación de la campana para el prepunzonado eléctrico

78

Retire los ltros de uno

1

en uno empujándolos

hacia la parte posterior

de la campana y tirando

hacia abajo al mismo

tiempo.

Retire la tapa de la

2

caja de cableado

desenroscando los 2

tornillos.

Destornillador Phillips

Page 79

Oricio trasero (Horizontal)

3

Elija el oricio trasero para la conexión eléctrica y rómpalo con un destornillador u

otra herramienta.

Durante la instalación, pase el cable de alimentación a través de este oricio.