Page 1

Version 05/06 - Page 1

Observe all governing codes and ordinances. Proper installation

is your responsibility. Make sure you have everything necessary for

correct installation. It is the responsibility of the installer to comply with

the clearances specified.

To avoid damage to motor bearings and impellers, keep drywall spray,

construction dust, etc. away from the remote blower.

Before installing remote blower, read the installation

instructions for the vent system that will be used in

conjunction with this remote blower.

Important

READ AND SAVE THESE INSTRUCTIONS

The installer must leave these instructions with the

homeowner. The homeowner must keep these

instructions for future reference and for local electrical

inspectors' use.

Care of your remote blower

Disconnect power supply and lock out service panel before cleaning

or

servicing. To clean, remove cover and vacuum blower and housing,

being careful not to damage blower wheel. The motor is permanently

lubricated. Do not oil or disassemble.

Electrical requirements

Important: Observe all governing codes and ordinances.

It is the customer’s responsibility:

• To contact a qualified electrical installer.

• To assure that the electrical installation is adequate and in

conformance with:

National Electrical Code, ANSI/NFPA 70 — latest edition*, or CSA

Standards C22.1-94, Canadian Electrical Code, Part 1 and C22.2

No.0-M91 - latest edition** and all local codes and ordinances.

If codes permit and a separate ground wire is used, it is recommended

that a qualified electrician determine that the ground path is adequate.

Do not ground to a gas pipe. Check with a qualified electrician if you

are not sure remote blower is properly grounded. Do not have a fuse in

the neutral or ground circuit.

A 120-volt, 60-Hz, AC-only supply wired for 15 amp service is

required.

The blower motor must be connected with copper wire only.

The remote blower must be connected to the downdraft vent system

or rangehood wiring as described in the downdraft vent system or

rangehood instructions for connecting the remote blower motor wiring.

Flexible armored or nonmetallic cable must be used. A U.L./CSA-listed

strain relief must be provided at each end of the power supply cable.

Wire sizes must conform to the requirements of the National Electrical

Code ANSI/NFPA 70 — latest edition* or Canadian Electrical Code, C22.1

and C22.2 No. 113-M1984 (or latest edition),** and all local codes and

ordinances. 14 gauge wire (minimum) is recommended.

Remote Blower (1200 CFM)

Installation Instructions

Use & Care Manual

You can be killed or seriously injured if you don’t

follow instructions.

TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

Installation work and electrical wiring must be

done by qualified person(s) in accordance with all

applicable Codes and Standards, including Fire

Rated Construction. Sufficient air is needed for

proper combustion and exhausting of gases through

the flue (chimney) of fuel burning equipment to

prevent back drafting. Follow the heating equipment

manufacturer’s guideline and safety standards such

as those published by the National Fire Protection

Association (NFPA), and the American Society of

Heating Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities. When

cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities. Ducted

fans must always be vented to the outdoors.

Use this unit only in the manner intended by the

manufacturer. If you have any questions, contact

the manufacturer.

Before servicing or cleaning unit, switch power off

at service panel and lock the service disconnecting

means to prevent power from being switched on accidentally. When the service disconnecting means

cannot be locked, securely fasten a prominent warning

device, such as a tag, to the service panel.

WARNING - TO REDUCE THE RISK OF SHOCK: This

fan must be installed with an isolating wall control/

switch.

CAUTION: For General Ventilating Use Only. Do Not

Use To Exhaust Hazardous or Explosive Materials

and Vapors.

To reduce the risk of fire, use only metal ductwork.

This unit must be grounded.

This unit is suitable for use with solid-state speed

controls.

For Residential use ONLY

Copies of standards listed may be obtained from:

* National Fire Protection Association

One Batterymarch Park

Quincy, Massachusetts 02269

** CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

WARNING

!

CAUTION – To reduce risk of fire and to properly

exhaust air, be sure to duct air outside – Do not vent

exhaust air into spaces within walls or ceilings or

into attics, crawl spaces, or garages”

Page 2

Version 05/06 - Page 2

Venting requirements

Maximum length of ductwork

Duct length is given as a general reference only. For a longer

duct run, or smaller duct system, contact a qualified and

trained duct installer. Check with local codes for makeup

air requirements, if any. It is recommended that you use

round duct instead of rectangular duct, especially if elbows are

required. If rectangular duct is required, if should be transitioned

to 10" (25.4 cm) round duct as soon as possible.

For best performance, use no more than three 90° elbows.

If more than one elbow is used, make sure that there is a

minimum of 24 inches of straight duct between any two

elbows. Do not install two elbows together.

55 feet for 10" round ductwork - count 90°

elbows as 5 feet and 45° elbows as 3 feet.

Begin the installation

1. Discard any cardboard packaging from the blower wheel.

2. Remove wiring box cover and screws.

3. Attach an appropriate U.L./CSA-listed strain relief in the

knockout.

Note: For most installations, it is recommended that the strain relief

be installed so that it can be tightened from inside the remote blower

housing.

4. Reattach the wiring box cover loosely. It will be removed again

later.

Follow the instructions on the next

page for your type of installation

Determine which ducting method is best for your application.

Duct system can extend either through the wall or the roof.

Locate the remote blower so that the length of the duct system

and the number of elbows is kept to a minimum to provide

efficient performance. Where possible, remote blower should

be centered between wall studs or roof rafters. The size of the

duct system should be uniform. Do not install two elbows

together.

Use duct tape to seal all joints in the duct system. Use caulking to

seal remote wall or floor opening around the cap. Flexible duct

is not recommended. It creates back pressure/air turbulence

and greatly reduces performance. Make sure there is proper

clearance within the wall or floor for exhaust duct before making

cutouts. Avoid pipes, wires, or other duct systems that may

be running through the wall. Do not cut a joist or stud unless

absolutely necessary. If a joist or stud must be cut, then a

supporting frame must be constructed.

The remote blower carton contains a duct collar plate.

• The duct collar plate attaches to the front of downdraft duct

system plenums so that the 10" (25.4 cm) round duct can be

attached to the downdraft duct system.

Make sure that there is enough space for any vent transitions that

may be needed between the remote blower and the connecting

vent system. For optimum performance, locate any necessary

vent transitions nearest to the rangehood or downdraft that will

be used with this power system. This remote blower requires

a separate U.L./CSA approved wiring cable that

should be installed at the same time the vent system is being

installed.

Install this side of the fan

facing an unoccupied space.

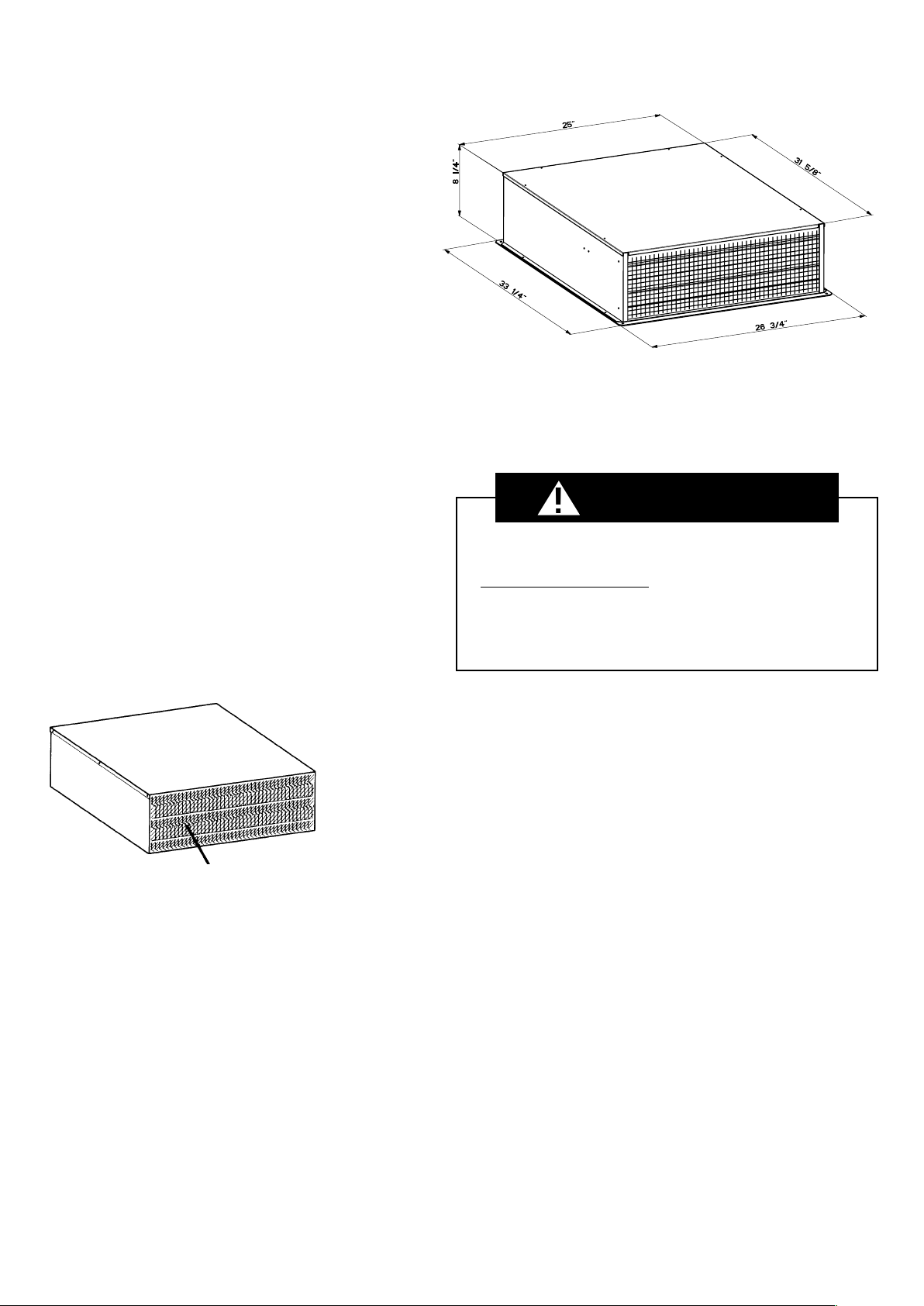

Dimensional diagram

You can be killed or seriously injured if you don’t follow

instructions.

Excessive Weight Hazard

Use two or more people to move and install remote

blower.

Failure to do so can result in back or other injury.

WARNING

MAKE SURE THAT THE DISCHARGE END OF THE REMOTE

BLOWER FACES AWAY FROM THE DIRECTION OF PREVAILING

WINDS.

!

Page 3

Version 05/06 - Page 3

1. Choose a location on an outside wall where no wall studs, wires,

pipes, etc. run through the opening area. A minimum distance

of 24" (61 cm) from remote blower to ground may be required

depending on local code. Make sure to leave room for anticipated

snowfall in your region.

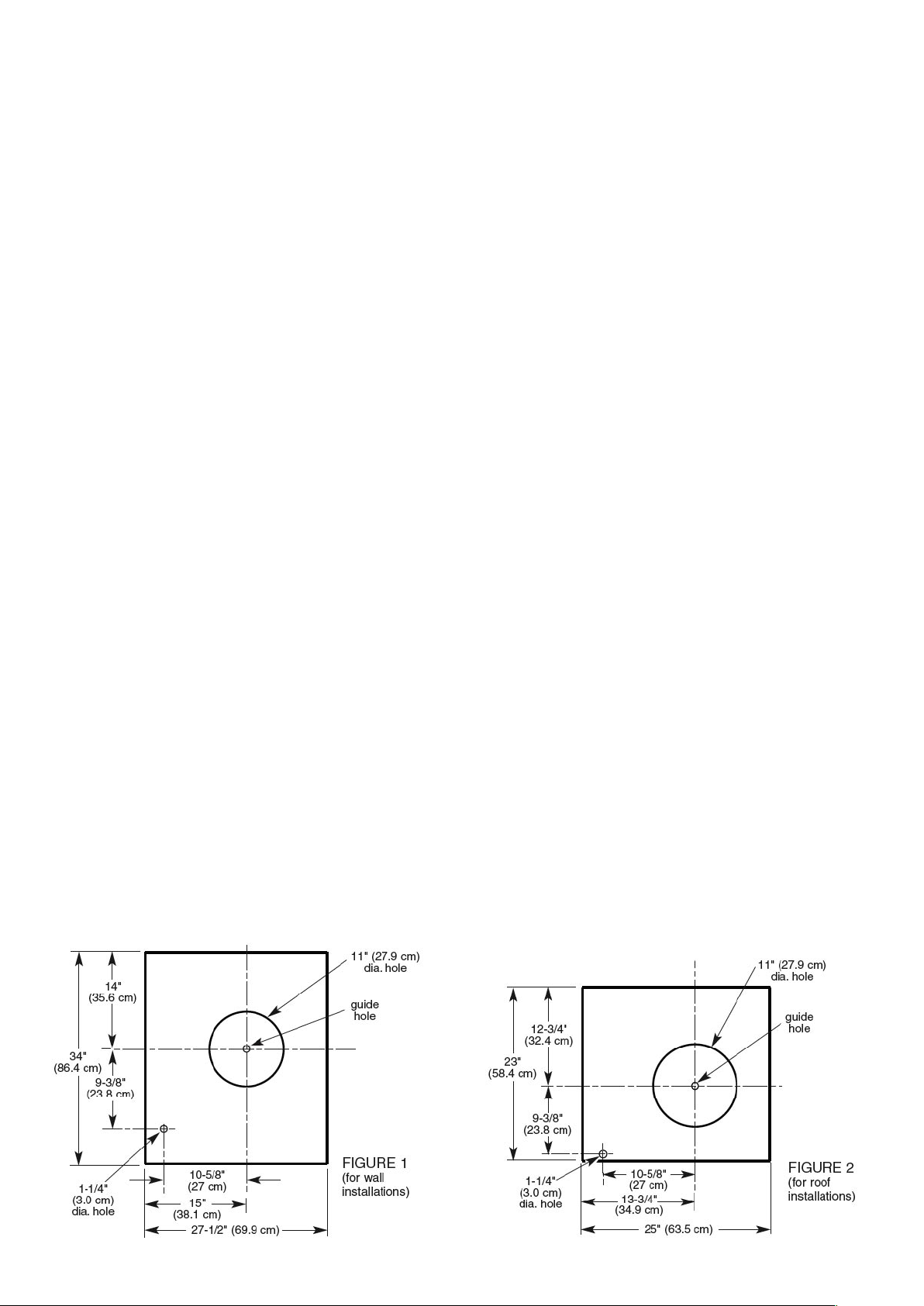

2. Drill the guide hole in the center of the 11" (27.9 cm) diameter

opening area.

3. Mark a 27-1/2" x 34" (69.9 x 86.4 cm) rectangle on wall as

indicated in FIGURE 1.

4. Cut a rectangular hole in the siding only. Do not cut sheathing.

Nail down all siding ends.

5. Mark an 11" (27.9 cm) diameter circle around guide hole as

indicated in FIGURE 1. Mark center of the 1-1/4" (or 3.0 cm)

diameter hole for electrical wiring as indicated in FIGURE 1.

6. Cut 11" (27.9 cm) diameter hole in sheathing. Drill the 1-1/4"

(or 3.0 cm) diameter electrical wiring hole.

7. Run a large bead of caulk on the back side of the housing along

the outer edge.

8. Center the remote blower ring in the 11" (27.9 cm) diameter

hole, making sure that the 1-1/4" (or 3.0 cm) diameter electrical

wiring hole lines up with the hole in the wiring box.

9. Attach the remote blower to wall using screws appropriate for

your installation. All four holes in the back panel must be filled to

prevent moisture that may get inside the remote blower housing

from leaking into the home.

10. Seal all around the mounting screw heads with caulk.

11. Go to “Make the duct & electrical connections”, Page 4.

Wall installations

Roof installations

FOR FLAT ROOF INSTALLATIONS SEE NEXT PAGE

1. Choose location on rear slope of roof that minimizes vent run.

Avoid obstacles such as TV leads, electric lines, etc. If remote

blower top is level with roof peak, it will not be seen from street.

Remember this location as you work from inside the attic.

2. Mark a point half-way between the rafters and drill a guide hole

at this point.

3. From the outside, using the guide hole as a starting point, mark

the rectangular cut-out as indicated in FIGURE 2. Remove ONLY

the shingles in THIS AREA.

4. Mark an 11" (27.9 cm) diameter circle around guide hole as

indicated in FIGURE 2. Mark center of the 1-1/4" (or 3.0 cm) diameter

hole for the electrical wiring as indicated in FIGURE 2.

5. Cut out the roof boards along the 11" (27.9 cm) diameter circle.

Drill the 1-1/4" (or 3.0 cm) diameter electrical wiring hole.

6. Remove roofing nails from the upper two-thirds of the shingles

to allow the back flashing sheet on the remote blower housing to

fit under them.

7. Center the remote blower ring in the 11" (27.9 cm) diameter hole,

making sure that the 1-1/4" (or 3.0 cm) diameter electrical wiring

hole lines up with the hole in the wiring box.

8. Attach the remote blower to roof or frame using screws appropriate

for your installation. All four holes in the back panel must be filled

to prevent moisture that may get inside the remote blower housing

from leaking into the home.

9. Seal all the shingles around the remote blower housing, flashing

sheet, and mounting screw heads or frame with roofing cement.

Top and side flanges of the back plate may be covered with trim. It

is recommended that electrical connection be made and checked

first. Do not block the vent grill opening at the bottom of the trim.

Doing so will decrease blower performance.

Figure 1- Wall installations Figure 2 - Roof installations

Page 4

Version 05/06 - Page 4

1. Remove the cover from the remote blower. Then remove the

wiring box cover.

2. Pull electrical wiring through the hole in the blower base and

secure it according to local codes.

3. Make the electrical connections. Connect the white and black

wires of the power supply cable wire to the white and black wires

in the wiring box with twist-on connector. Connect the green power

supply ground wire to the green ground screw.

4. Replace the wiring box cover and screws taking care not to pinch

the wiring under the wiring box cover.

5. Turn on power (See Installation Instructions that came with your

vent hood system). Check operation of blower and make sure damper

is opening freely.

6. Reinstall remote blower housing.

Flat roof installations

Make the duct & electrical connections

wiring diagram

You can be killed or seriously injured if you don’t follow

instructions.

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

• Disconnect power before making electrical connection.

• Connect the ground wire to green ground screw in wiring box.

Failure to do so can result in death or electrical shock.

WARNING

Figure 3 - Flat roof installations

1. Locate the 11" (27.9 cm) dia. hole between rafters.

2. Build a sloping base that will mount the remote blower at a

minimum pitch of 2-1/2" (6.4 cm).

3. Weatherproof the base as required.

4. Locate the base so that the remote blower’s vent aligns with the

11" (27.9 cm) dia. hole and the blower sits evenly on the base with

no gaps. Note: Make sure that the discharge end of the remote

blower faces away from the direction of prevailing winds.

5. Use dimensions from either FIGURE 1 or 2 to locate the 1-1/4"

(3.0 cm) dia. wiring hole. CONTINUE WITH POINT 6 UNDER

ROOF INSTALLATIONS ON PAGE 3.

Figure 4 - Electrical connections

!

Warranty & Service

All Faber products are warranteed against any defect in materials or workmanship for the original purchaser for a period of 1 year from the date of

original purchase. This warranty covers labor and replacement parts. The

warranty does not cover consumable parts such as filters and light bulbs.

This warranty does not apply if this product has been subjected to faulty

installation, misuse, or neglect. This warranty excludes any consequential

expense or damage resulting from any use or malfunction of the product.

All implied warranties are limited to the duration of this warranty.

To obtain warranty service, contact the dealer from whom you purchased

the rangehood, or the local Faber distributor. If you cannot identify a local

Faber distributor, contact us at (508) 358-5353 for the name of a distributor

in your area.

Page 5

Version 05/06 - Page 5

Observer toutes les dispositions des codes et règlements en vigueur.

C’est au propriétaire de l’appareil qu’incombe la responsabilité d’une installation

correcte. Veiller à disposer de tout le matériel nécessaire pour la réalisation

d’une installation correcte. C’est à l’installateur qu’incombe la responsabilité

de respecter les dégagements de séparation spécifiés.

Pour éviter d’endommager les paliers du moteur et l’hélice ou la turbine, veiller

à protéger le ventilateur d’extraction contre les produits.

Avant d'installer le ventilateur d'extraction, lisez les

instructions d'installation pour la hotte qui sera employé en

même temps que ce ventilateur d'extraction.

Important

IMPORTANT : LIRE ET CONSERVER CES INSTRUCTIONS.

Installateur: Remettre les instructions d’installation au propriétaire de l’appareil.

Propriétaire: Conserver les instructions d’installation pour consultation ultérieure

et à l’intention de l’inspecteur local de installations électriques.

Entretien du ventilateur d’extraction

Avant tout travail de nettoyage ou d’entretien, interrompre l’alimentation

électrique et verrouiller le disjoncteur. Pour le nettoyage, enlever le couvercle

et nettoyer le ventilateur et la caisse l’aspirateur; veiller à ne pas endommager

la turbine. Le moteur est monté sur des paliers lubrifiés à vie. Ne pas lubrifier

ni démonter.

Alimentation électrique

Important : Respecter les prescriptions de tous les codes et règlements en

vigueur. C’est au client qu’incombe la responsabilité de :

• Contacter un électricien qualifié pour l’installation.

• Veiller à ce que l’installation électrique soit réalisée d’une manière

adéquate et en conformité avec les prescriptions de la dernière édition du

Code national de l’électricité

ANSI/NFPA 70*, ou des normes CSA C22.1.94 / Code canadien de

l’électricité (partie 1) et C22.2 N°0- M91 **, et avec les prescriptions

de tous les codes et règlements locaux en vigueur.

Si un conducteur distinct de liaison à la terre est utilisé lorsque le code le

permet, on recommande qu’un électricien qualifié vérifie que la liaison à la

terre est adéquate. Ne pas utiliser une tuyauterie de gaz pour la liaison à la

terre. En cas d’incertitude quant à la qualité de la liaison à la terre de la hotte,

consulter un électricien qualifié. Ne pas installer un fusible en série avec le

conducteur neutre ou le conducteur de liaison à la terre.

L’appareil doit être alimenté par un circuit 120 volts, 60 Hz, CA seulement, 15

A, avec un fusible.

Le ventilateur d’extraction doit être raccordé au réseau électrique uniquement

avec des conducteurs de cuivre.

On doit raccorder le moteur du ventilateur au câblage du système d’aspiration

ou par le bas ou la hotte conformément à la description présentée dans

les instructions qui accompagnent le système d’aspiration par le bas ou la

hotte. Utiliser du câble flexible blindé ou à gaine non métallique. Un serrecâble (homologation UL/CSA) doit être installé à chaque extrémité du câble

d’alimentation. La taille des conducteurs doit satisfaire les prescriptions de la

plus récente édition du Code national de l’électricité ANSI/NFPA 70*, ou des

normes CSA C22.1.94 / Code canadien de l’électricité (C22.1) et C22.2 N°0113- MI984 (ou la plus récente édition)**, et les prescriptions de tous les codes

et règlements locaux en vigueur. On recommande l’emploi de conducteurs de

calibre 14 ou plus gros.

On peut obtenir aux adresses suivantes des exemplaires des

normes mentionnées :

**CSA International

8501 East Pleasant Valley Rd.

Cleveland, Ohio 44131-5575

*National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

Risque possible de décès ou de blessure grave si

vous ne suivez pas le instructions.

AVERTISSEMENT – POUR MINIMISER LES RISQUES

D'INCENDIE, CHOC ÉLECTRIQUE OU DOMMAGES

CORPORELS, OBSERVER LES PRESCRIPTIONS

SUIVANTES :

Le travail d'installation et de câblage électrique

doit être exécuté par des personnes compétentes

et en conformit avec les prescriptions des normes

et codes applicables, ceci incluant les normes de

résistance au feu des éléments de construction.

La disponibilité d'un volume d'air appropri pour

l'alimentation de l'équipement à combustion et

l'évacuation des gaz de combustion par la cheminée

pour qu'il n'ait pas de reflux est nécessaire. Respecter

les directives du fabricant de l’équipement de

chauffage et les prescriptions des normes de

sécurité -comme celles publiées par la National

Fire Protection Association (NFPA) et l’American

Society of Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE) - et les prescriptions des

autorités réglementaires locales. Lors d’opérations

de découpage et de perçage dans un mur ou plafond,

veiller à ne pas endommager les câblages électriques

ou canalisations qui peuvent s’y trouver.

Le conduit d’évacuation associé à un ventilateur doit

toujours décharger l’air à l’extérieur.

Suivez les recommandations du fabricant et entre en

communication avec lui pour toute information.

Fermez le courant avant tout entretien et veillez a

ce qu'il reste fermé. Si on ne peut pas verrouiller le

panneaux du service électrique, affichez un avis de

danger sur la porte.

AVERTISSEMENT – POUR MINIMISER LE RISQUE

DE CHOC ÉLECTRIQUE: Ce ventilateur doit être

installé avec un mur d'isolement iterrupteur de

commande.

AVIS: Pour L'évacuation Générale - Veillez à Ne Pas

Evacuer Des Matériaux Ou Vapeurs Explosif.

Pour réduire le risque d’incendie, utiliser uniquement

des conduits métalliques.

Cet appareil doit être relié à la terre.

Ce ventilateur peut être utilisé avec les commandes

de vitesse à circuits intégrés.

Uniquement pour usage menager. Le système

d'évacuation DOIT sortir à l'extérieur. N'ÉVACUEZ

PAS le conduit soit dans une mansarde soit dans

un espace enfermé.

AVERTISSEMENT

Instructions d’installation et

Guide d’utilisation et d’entretien

pour Ventilateur d'extraction

!

Page 6

Version 05/06 - Page 6

Circuit d’évacuation de l’air

Déterminer la configuration d’évacuation la mieux adaptée à l’application. Le

circuit d’évacuation doit traverser le toit ou un mur. Choisir l’emplacement

d’installation du ventilateur extérieur de manière à minimiser la longueur du

circuit d’évacuation et le nombre de coudes, pour optimiser la performance.

Si c’est possible, centrer le ventilateur entre des poteaux du colombage

ou des solives du toit. La taille du circuit d’évacuation devra être uniforme.

Ne pas installer deux coudes adjacents.

Au niveau de chaque jointure du système, assurer l’étanchéité avec du

ruban adhésif pour conduits. Au point de passage du conduit d’évacuation

à travers le mur ou un plancher, assurer l’étanchéité avec un produit de

calfeutrage. On déconseille l’emploi de conduit d’évacuation flexible,

susceptible de générer une rétropression et des turbulences, ce qui

dégraderait considérablement la performance. Avant de découper les

ouvertures de passage dans le mur ou le plancher, vérifier que les distances

de séparation adéquates seront respectées. Veiller à ne pas endommager

les tuyauteries et câblages ou autres conduits susceptibles de se trouver

dans les cavités murales. Ne couper un poteau ou une solive que si c’est

absolument nécessaire; dans un tel cas, il faudra construire une structure

de support remplaçant l’élément coupé.

L’emballage du ventilateur extérieur contient un raccord de matière plastique

noire et une plaque de raccordement.

• On fixe le raccord de matière plastique noire sur le ventilateur extérieur

avec quatre vis (fournies). Le conduit d’évacuation rond de 25,4 cm (10

po) est ensuite connecté sur ce raccord.

• La plaque de raccordement devra être fixée sur la chambre de

raccordement du système d’aspiration vers le bas pour qu’il soit possible

d’y raccorder le conduit rond de 25,4 cm (10 po).

Veiller à ce qu’il y ait un espace disponible suffisant pour tout raccord de

transition qu’il serait nécessaire d’installer entre le ventilateur extérieur

et le système de raccordement. Pour optimiser la performance, placer

tout raccord de transition nécessaire aussi près que possible de la hotte

ou du système d’aspiration par le bas utilisé(e) en conjonction avec ce

ventilateur. Ce ventilateur extérieur devra être alimenté par un câble

électrique (homologation UL/CSA) indépendant, installé en même temps

que le circuit d’évacuation.

Longueur maximale du circuit d’évacuation

55 pi pour Dia. 10 po conduit d’évacuation circulaire

coude 90° = 5 pi et coude 45° = 3 pi

La longueur du circuit d’évacuation n’est citée que comme référence

générale. Pour un circuit de plus grande longueur ou constitué de

conduits de plus petit diamètre, contacter un installateur qualifié. Le cas

échéant, chercher dans le code local les prescriptions concernant

le renouvellement de l’air. On recommande l’emploi d’un conduit

d’évacuation circulaire plutôt que rectangulaire, particulièrement si l’emploi

de raccords à 90° est nécessaire. Si l’emploi d’une section de conduit

rectangulaire est nécessaire, minimiser sa longueur et raccorder celui-ci

à du conduit circulaire de diamètre 25,4 cm (10 po).

Pour optimiser la performance, ne pas utiliser plus de trois coudes à

90°. S’il est nécessaire d’installer plusieurs coudes, ceux-ci devront

être séparés par une section rectiligne d’au moins 61 cm (24 po). Ne

pas raccorder deux coudes ensemble.

1. Enlever tout débris d’emballage qui pourrait rester dans

le ventilateur.

2. Ôter les vis et le couvercle de la boîte de raccordement

électrique.

3. Installer un serre-câble (homologation UL/CSA) dans

le trou de passage à l’arrière de la boîte de raccordement.

4. Rattachez le couvercle de la boîte de raccordement

électrique lâchement. Elle sera enlevée encore plus tard.

Observer les instruct ions

appropriées correspondant au

type d’installation.

Risque possible de décès ou de blessure grave si

vous ne suivez pas le instructions.

Poids excessif

Deux personnes ou plus doivent intervenir pour

déplacer et installer la hotte.

Le non-respect de cette instruction peut causer une

blessure au dos ou d’autres blessures.

Commencez l'installation

AVERTISSEMENT

Installez ce côté du ventilateur

faisant face à un esp a c e

inoccupé.

Dimensions de ventilateur

VEILLER À CE QUE LE CÔTÉ DÉCHARGE DU VENTILATEUR

NE FASSE PAS FACE À LA DIRECTION DES VENTS

DOMINANTS.

!

Page 7

Version 05/06 - Page 7

Sortie murale

1. Choisir un emplacement sur un mur extérieur où il n’y aura pas

d’interférence entre le conduit d’évacuation et les poteaux du colombage,

les câblages, les tuyauteries, etc. Le code local peut imposer une distance

d’au moins 61 cm (24 po) entre le sol et le ventilateur extérieur; tenir

compte des accumulations de neige potentielles, selon la région.

2. Percer le trou de guidage/centrage au centre de l’ouverture de dia.

27,9 cm (11 po) à réaliser.

3. Tracer sur le mur un rectangle de 69,9 x 86,4 cm (27 1/2 x 34 po)

– voir FIGURE 1.

4. Découper une ouverture rectangulaire dans le parement seulement.

Ne pas couper les planches de doublure. Immobiliser les extrémités

des planches de parement par clouage.

5. Tracer un cercle de diamètre 27,9 cm (11 po) centré sur le trou de

guidage – voir FIGURE 1. Marquer la position du centre d’un trou de 3

cm (1 1/4 po) pour le passage du câble électrique, voir FIGURE 1.

6. Découper l’ouverture de dia. 27,9 cm (11 po) dans les planches de

doublure. Percer le trou de dia. 3 cm (1 1/4 po) pour le passage du

câble électrique.

7. Appliquer une grosse coulée de calfeutrant sur la face arrière de la

caisse, le long du bord externe.

8. Centrer la collerette du ventilateur extérieur sur l’ouverture de dia.

27,9 cm (11 po); veiller à ce que le trou de 3 cm (1 1/4 po) pour le

passage du câble électrique soit aligné avec le trou de passage dans

la boîte de raccordement du câblage.

9. Fixer le ventilateur extérieur sur le mur avec des vis de taille appropriée.

Obturer les quatre trous du panneau arrière pour éviter l’introduction

d’humidité dans la résidence, à travers la caisse du ventilateur.

10. Calfeutrer autour de la tête de chaque vis de fixation.

11. Passer à l’étape "Raccordement du câblage électrique et du

circuit d’évacuation", page 8.

Sortie à travers le toit

POUR INSTALLATIONS DU VENTILATEUR EXTÉRIEUR

SUR UN TOIT PLAT PASSER À L’ÉTAPE PAGE 8

1. Choisir un endroit sur le versant arrière du toit qui minimisera la

longueur du conduit d’évacuation. Éviter tout obstacle comme câble

de télévision, conducteur électrique, etc. Si le sommet du ventilateur

extérieur est au même niveau que le faîte du toit, il ne sera pas visible

depuis la rue; tenir compte de ceci lors des opérations effectuées dans

le grenier.

2. Marquer un point centré entre les solives pour le perçage du trou

de guidage.

3. Depuis l’extérieur, à partir de la position du trou de guidage, tracer

les limites de l’ouverture rectangulaire présentées à la FIGURE 2. DANS

CETTE ZONE, enlever SEULEMENT les bardeaux du toit.

4. Tracer un cercle de diamètre 27,9 cm (11 po) centré sur le trou de

guidage – voir FIGURE 2. Marquer la position du centre d’un trou de

3 cm (11/4 po) pour le passage du câble électrique, voir FIGURE 2.

5. Découper l’ouverture circulaire de dia. 27,9 cm (11 po) dans les

planches du toit. Percer le trou de dia. 3 cm (1 1/4 po) pour le passage

du câble électrique.

6. Enlever les clous de toiture dans la partie supérieure de la zone

(2/3) pour pouvoir insérer sous les bardeau le solin de la caisse du

ventilateur.

7. Centrer la collerette du ventilateur extérieur sur l’ouverture de dia.

27,9 cm (11 po); veiller à ce que le trou de 3 cm (1 1/4 po) pour le

passage du câble électrique soit aligné avec le trou de passage dans

la boîte de raccordement du câblage.

8. Fixer le ventilateur extérieur sur le toit ou sur le cadre de support,

avec des vis de taille appropriée. Obturer les quatre trous du panneau

arrière pour éviter l’introduction d’humidité dans la résidence, à travers

la caisse du ventilateur.

9. Utiliser de l’asphalte à toiture pour assurer l’étanchéité entre les

bardeaux et le ventilateur tout autour de la caisse du ventilateur, au

niveau du solin et sur les têtes de vis au niveau de la structure de

support.

10. Les sections supérieure et latérales du solin peuvent être recouvertes

d’une garniture. On recommande de réaliser d’abord et contrôler le

raccordement électrique. Ne pas obturer l’ouverture de la grille sous

Figure 1 - Sortie murale Figure 2 - Sortie à travers le toit

Page 8

Version 05/06 - Page 8

Raccordement du câblage électrique et

du circuit d’évacuation

1. Enlever le couvercle du ventilateur extérieur. Enlever ensuite le

couvercle de la boîte de raccordement.

2. Introduire le conducteur électrique à travers le trou dans la base

du ventilateur; immobiliser les conducteurs conformément aux

prescriptions du code local.

3. Réaliser les raccordements électriques. Dans la boîte de raccordement,

connecter ensemble les conducteurs noirs et les conducteurs blancs,

avec des connecteurs de fils. Connecter le conducteur vert de liaison

à la terre avec la vis de liaison à la terre.

4. Réinstaller les vis et le couvercle de la boîte de raccordement; veiller

à ne coincer aucun conducteur sous le couvercle.

5. Mettre l’appareil sous tension (voir le Guide d’utilisation et d’entretien

fourni avec l’appareil). Contrôler le bon fonctionnement du ventilateur

et vérifier que le volet de réglage peut manoeuvrer librement.

6. Réinstaller la caisse du ventilateur extérieur.

1. Positionner l’ouverture de dia. 27,9 cm (11 po) entre les solives.

2. Réaliser une base inclinée permettant l’installation du ventilateur

extérieur avec une inclinaison d’au moins 6,4 cm (2 1/2 po) par

pied.

3. Réaliser la finition appropriée pour la protection contre les

intempéries.

4. Positionner la base de telle manière que la décharge du ventilateur soit

alignée avec le trou de dia. 27,9 cm (11 po), et pour que le ventilateur

puisse reposer d’aplomb sur la base sans qu’il y ait d’espacement.

Note : Veiller à ce que le côté décharge du ventilateur ne fasse pas

face à la direction des vents dominants.

5. Respecter les dimensions mentionnées à la FIGURE 1 ou 2 à la

page 3 pour positionner le trou de 3 cm (1 1/4 po) pour le passage

du câblage.

diagramme de câblage

Figure 3 - sur un toit plat

Pour l’installation du ventilateur

extérieur sur un toit plat :

Risque possible de décès ou de blessure grave si vous ne

suivez pas le instructions.

AVERTISSEMENT – POUR MINIMISER LES RISQUES

D'INCENDIE, CHOC ÉLECTRIQUE OU DOMMAGES

CORPOREL S, OBSERVER LE S PRESCRIP TIONS

SUIVANTES :

• Interrompre l’alimentation électrique avant d’effectuer

des raccordements.

• Connecter le conducteur de liaison à la terre avec la vis

verte dans la boîte de connexion.

Le non-respect de ces instructions peut provoquer un choc

électrique ou un accident mortel.

AVERTISSEMENT

Figure 4 - Raccordement du câblage

électrique

!

Garantie et Service

Faber garantit à l’utilisateur-acheteur d’origine que les produits Faber vendus

neufs par nous sont sans vice de matériel et de main-d’oeuvre d’origine

pour une période d’un an à partir de la date d’achat. La garantie couvre la

main-d’oeuvre et les pièces de remplacement. Par contre, elle ne couvre

pas les pièces reliées à l’usure normale de l’appareil (exemple: les filtres et

les ampoules). La garantie ne s’applique pas si le produit a été mal installé,

utilisé d’une manière inadéquate ou négligé. Cette garantie exclue toutes

les dépenses consécutives dûes à des dommages résultant d’un mauvais

fonctionnement du produit. La présente garantie remplace toutes autres

garanties et déclarations expresses.

Afin d’obtenir un service sous garantie, communiquer avec le marchand où

la hotte a été achetée ou le distributeur Faber de la région. Si l’on ne peut

trouver de distributeur Faber, communiquer avec nous au (508) 358-5353 afin

d’obtenir le nom d’un distributeur dans la région.

Loading...

Loading...