Page 1

SPX-7200 Series

Operations Manual

Suprex® Reader Extender - Ethernet

SPX-7200

EXP-2000

SPX-7200_MAN_082112

Page 2

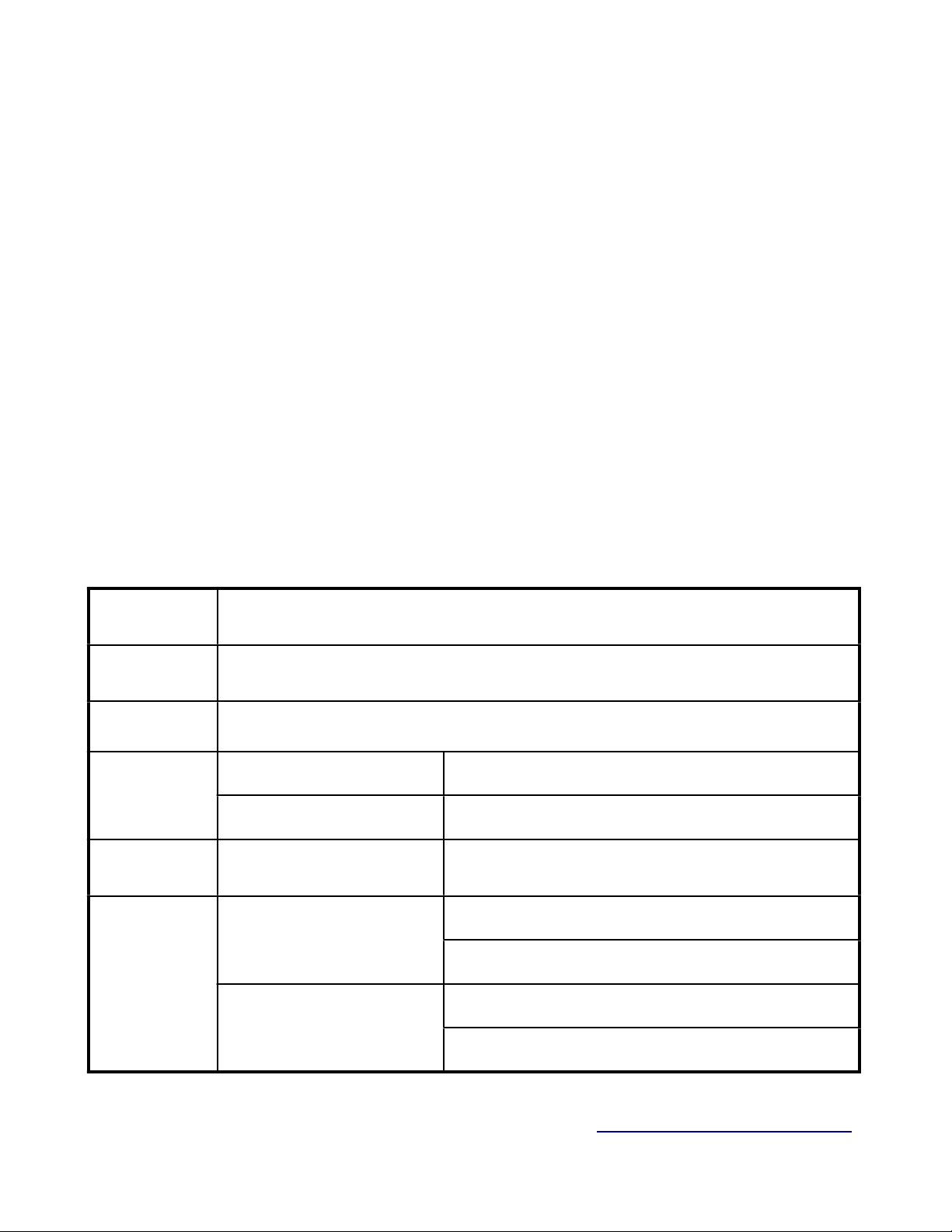

Physical

SPX-7200 ! - Aluminum Enclosure

4.45” x 3.08” x 2.0” ( Each Unit )

Temp

Storage(-55˚C to + 150˚C)

Operating(-40˚C to +80˚C)

Humidity

95% (non-condensing)

Input

Unreg Input 8 to 16 VDC* @ 500mA Max

Power

Output

+5VDC @100mA

Data I/O

Interface

Reader -Wiegand, Strobed (Clock & Data), F/2F

LED - 0 - 30V

(220Vdc 30W (resistive) 1A)

Max Switching

(250Vac 37.5VA 1A)

Relays

(30Vdc 1A (resistive), 1 x 10

5

operations at 20o C

Relays

Running Spec with load

125Vac .3A (resistive), 1 x 10

5

operations at 20o C

Cypress Suprex® SPX-7200 Series Overview

This manual covers the operation and setup of the Cypress Suprex® SPX-7200 Ethernet series units.

Overview:

The SPX-7200 series of Ethernet solutions provides an Ethernet bridge from Card Readers with gates or door hardware

to most access control manufacturers panels. The SPX or Suprex® products include both the remote ( Door/Gate ) unit

and the central ( AC Panel ) unit.

Features:

-- Includes complete solution with remote ( reader/gate/door ) and central ( panel ) interface.

-- Service mode for setup and configuration of Expansion modules.

-- Field configurable reader formats

-- Multifunction indicator for determining operational status of the unit

-- Auxiliary I/O connections available for Door/Gate/Panel status signaling.

-- Multiplexing of Ethernet bridge providing for additional door/gate on a single Ethernet link.

-- Economical expansion capabilities using Suprex® Lynk technology

Electrical and Mechanical Specifications

Cypress Computer Systems, Inc. ⌖ Lapeer, MI 48446 ⌖ www.cypresscomputer.com

© 2012 Cypress Computer Systems Inc.

Page 3

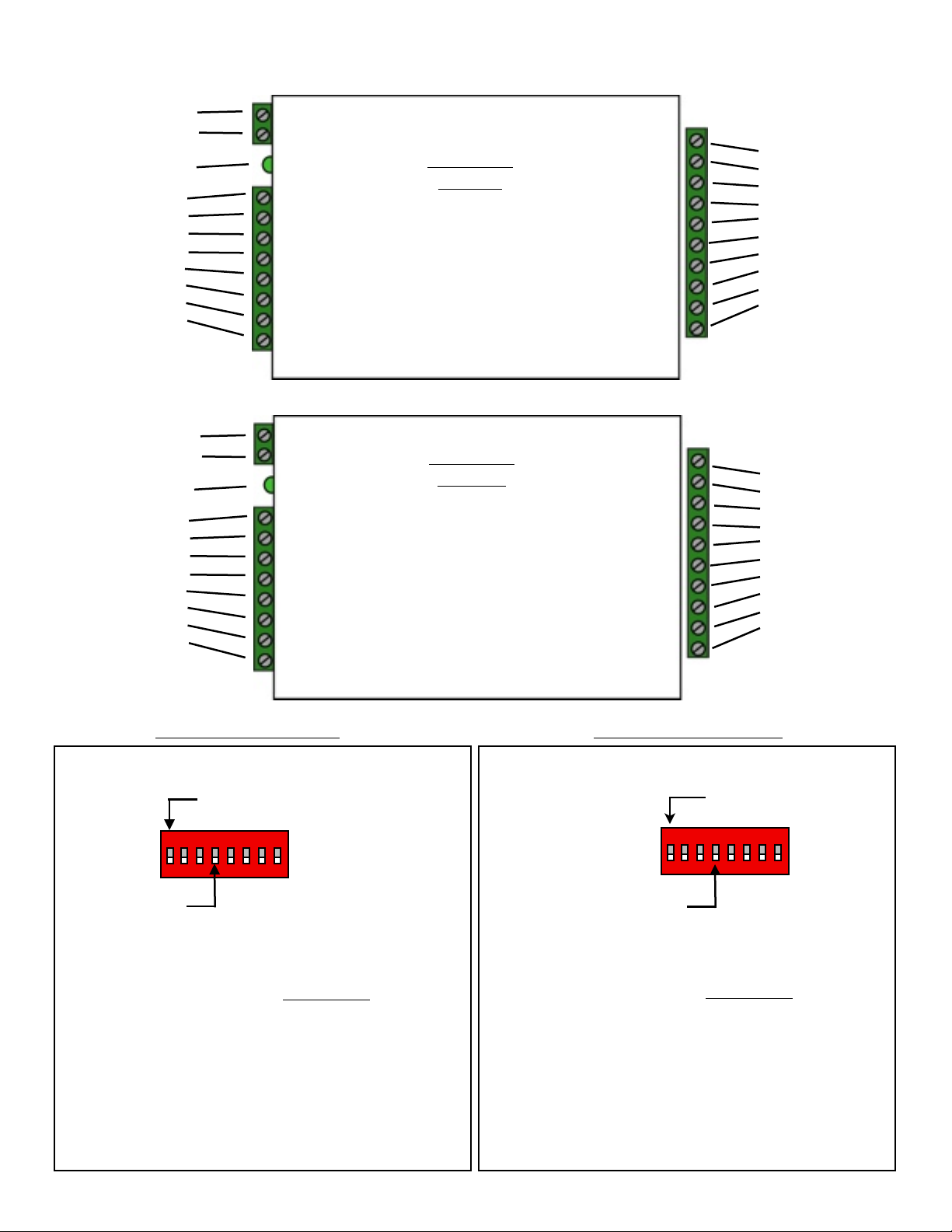

Switch

6 7 8

0

1 x

2 x

3 x x

4 x

5 x x

6 x x

7 x x x

Wiegand

Wiegand / No Filter

Strobed Rising Edge (MR-5)

Strobed Rising Edge (Dorad0 644)

Strobed Rising (Mag-Tek)

Strobed Falling Edge

Reserved

F2F

x = ON

1234567

8

Dip switch #4 is ON

-Disable Pullup resistors

Dip switch #4 is OFF

-Enable Pullup resistors

Switch

6 7 8

0

1 x

2 x

3 x x

4 x

5 x x

6 x x

7 x x x

Wiegand

Wiegand / No Filter

Strobed Rising Edge (MR-5)

Strobed Rising Edge (Dorad0 644)

Strobed Rising (Mag-Tek)

Strobed Falling Edge

Reserved

F2F

x = ON

1234567

8

Dip switch #4 is ON

-Enable Pullup resistors

Dip switch #4 is OFF

-Disable Pullup resistors

1 - 8 to 16 VDC In

2 - Ground

Status LED

1 - exp (+)

2 - exp (-)

3 - +5 VDC out

4 - Prog Res 4

5 - Prog Res 3

6 - LED In

7 - D1/Data out

8 - D0/Clk out

1 - 8 to 16 VDC In

2 - Ground

Status LED

1 - exp (+)

2 - exp (-)

3 - +5 VDC out

4 - R4

5 - R3

6 - LED out

7 - D1/Data In

8 - D0/Clk In

External connections and DIP Switch Settings

SPX-7200

Central

SPX-7200

Remote

1- Relay 4 N.O.

2- Relay 4 Com

3 - Relay 4 N.C.

4 - Relay 3 N.O.

5 - Relay 3 Com

6 - Relay 3 N.C.

7 - Ground

8 - Aux out

9 - R2 in

10 - R1 in

1- Relay 2 N.O.

2- Relay 2 Com

3 - Relay 2 N.C.

4 - Relay 1 N.O.

5 - Relay 1 Com

6 - Relay 1 N.C.

7 - Ground

8 - Aux in

9 - Not used

10 - Not used

Central Unit Settings

DIP Switch #1 ON

-Service Mode

DIP Switch #1 OFF

-Run Mode

Remote Unit Settings

DIP Switch #1 ON

-Service Mode

DIP Switch #1 OFF

-Run Mode

Page 4

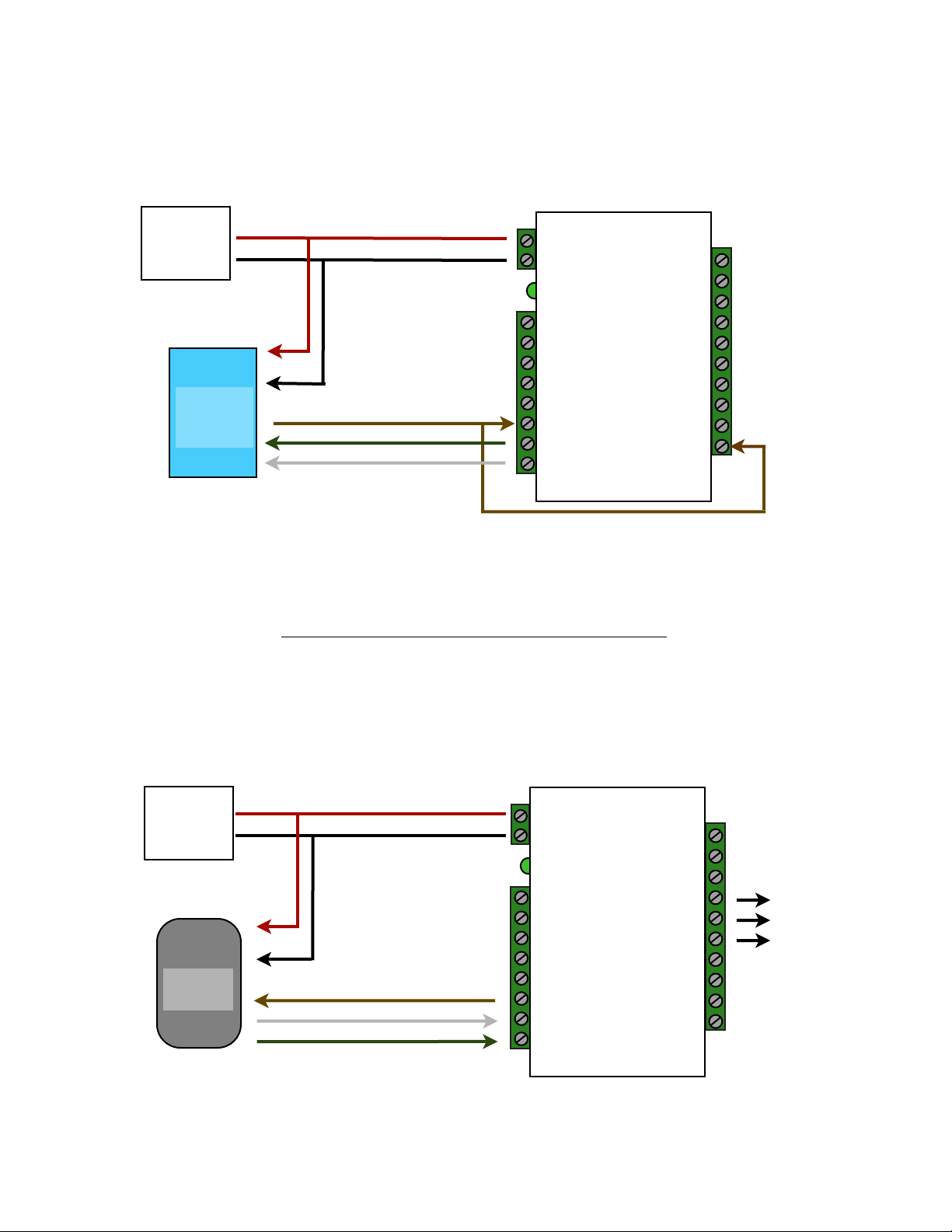

DC

Ground

Ground

Power

Supply

Access

Control

Panel

Quick Reference For Typical Connections

SPX-7200 Series Central

+8 to +16 VDC

Diagnostic LED

LED In

D1/Data Out

D0/Clock Out

R1 Input

Controls

Strike on

Remote

R1 IN

DC

Power

Supply

Card

Reader

See page 14 for other strike control options

SPX-7200 Series Remote

+8 to +16 VDC

Diagnostic LED

R1 N.O.

R1 Com

R1 N.C.

LED Out

D1/Data In

D0/Clock In

Door

Strike

Output

Page 5

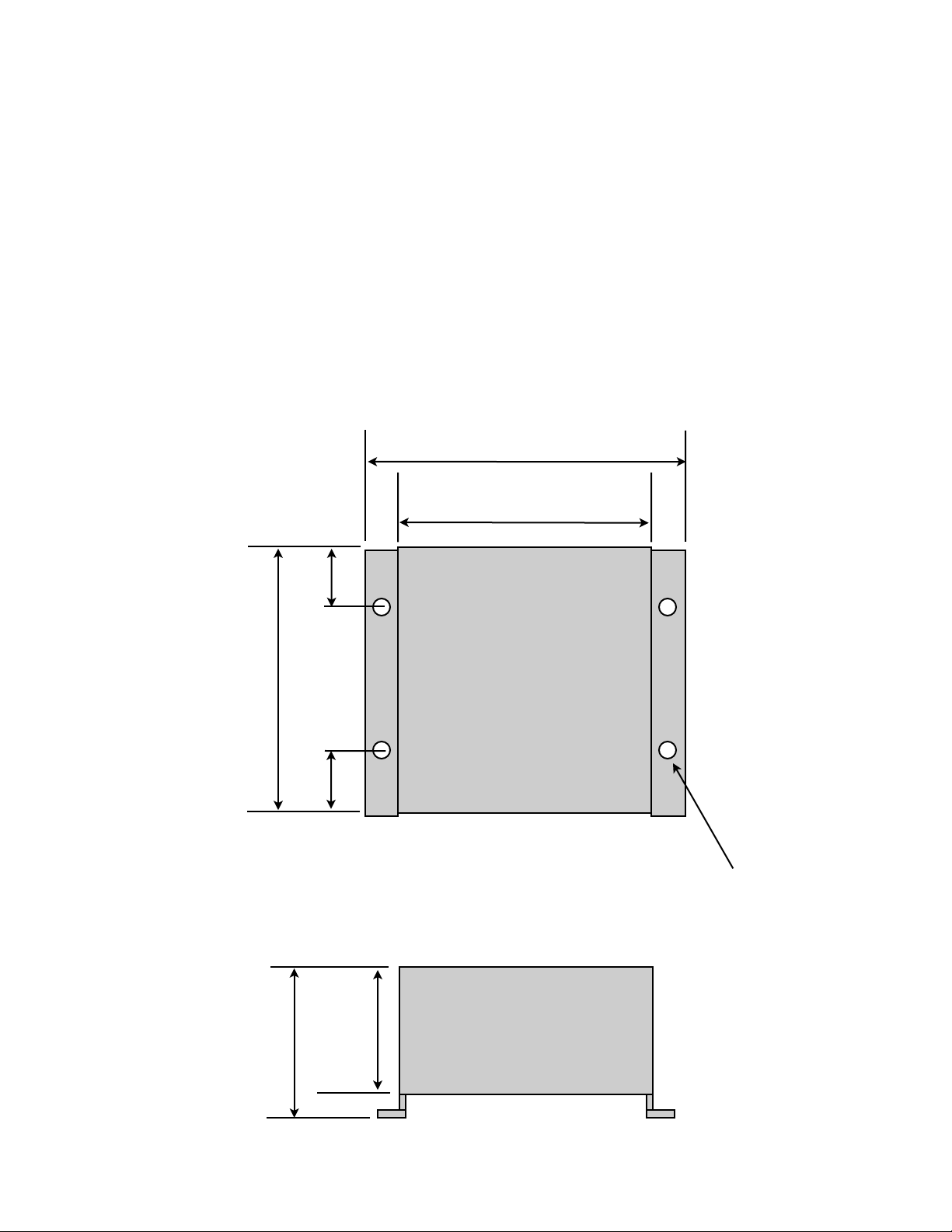

Cypress Suprex® SPX-7200 Enclosure Dimensions

4.45

3.15

3.08

0.80

0.80

ø0.20 X 4

2.00

1.70

Page 6

Cypress Suprex® SPX-7200 Series - Indicators and Operating Modes

LED Diagnostic Indicator:

The LED Diagnostic indicator provides information on the operational status of the unit.

If the units are not communicating, viewing the diagnostic indicator LED’s may help to determine the

nature of the problem.

When the Suprex® units are operating correctly and have a valid communication channel between

the Remote and Central units, the Diagnostic indicators on each unit will flash green rapidly

(2-3 flashed per second) in Service / Config mode and illuminate a steady green in quiet mode.

DIAGNOSTIC LED NOT ILLUMINATED:

If the LED(s) are not illuminated on the unit(s) then the unit is not getting power or there is an electrical problem.

The Diagnostic LED’s will be illuminated Red/Green or flashing whenever power is applied.

CENTRAL UNIT FLASHING BETWEEN RED/GREEN:

With power applied and no communication path between the Remote and Central, the Central unit will flash the

diagnostic indicator alternately between Red and Green.

REMOTE UNIT ILLUMINATED RED:

The Remote unit will diagnostic LED will illuminate solid (not flashing) red if it is not receiving communication from

the Central.

REMOTE AND CENTRAL UNITS FLASHING BETWEEN RED/GREEN:

The Central is not Receiving communication from the Remote.

Operating modes:

By setting DIP switch 1 to the ON position, the unit is placed in Setup / Config mode. When the switch position is

changed, cycle power to the unit to make the switch change take effect.

In "Quiet" mode (DIP switch #1 OFF) the units will remain quiet unless there is a status change, and will slowly

poll each other about every 10 to 15 seconds to check the link integrity.

The Setup / Config mode places the units in a rapid polling sequence to allow troubleshooting and setup of the

communication link.

The Suprex® units use a quiet protocol when operating in Quiet mode. Communication between the Central and

Remote unit only occurs when an event requires data transmission or contact needs to be made to maintain

supervision.

During setup or troubleshooting it may be necessary to observe the communication link between the Central and

Remote units. The rapid polling used in the Setup / Config mode can help indicate whether the units can “See”

each other. Additionally the Central unit Diagnostic LED will indicate Red when communication is lost.

Page 7

Bench Testing:

Before installing the units in the field they should be assembled and tested at a convenient “Bench

top” location. This will make it easier to verify / change settings and check operation when both

units are visible at the same time.

It is also a chance to become familiar with the system if this is the first time using the Suprex®

system. It is much more difficult to setup and test the units when they are several thousand feet

apart.

1. Connect the Remote and Central unit Network ports together using either a crossover cable or

connect both to a common network hub.

2. Connect a suitable power supply to both units. Each unit should be provided with 8 - 16 volts DC

and a minimum of 500mA.

3. Apply power. After about a 5 - 10 second delay both units Diagnostic LED should indicate Green.

4. Touch a jumper wire from the Ground connection the the Relay 1 input on the Central unit. Relay

#1 on the Remote unit should activate with an audible click and the Diagnostic LEDs should flash

green on both the Central and Remote units.

5. Units are shipped from the factory set for the Wiegand data format. If a different format is required

set the DIP switch to the required reader and panel format.

6. If a reader and panel is accessible, connect the reader to the Remote unit and the Central unit to

the panel and verify that card reads are being accepted by the access control system. If any

troubleshooting is necessary, it will be easier to do with both units in close proximity to each other.

7. Once these steps are completed, the units are ready for installation it their permanent locations

and final commissioning as a system.

Network Addressing:

Each Suprex® SPX-7200 pair is preconfigured with a factory default TCP/IP address.

Suprex® Central = 192.168.49.58

Suprex® Remote = 192.168.49.59

It may be necessary to change these settings to be compatible with the network that will be

used in the final installation. The SPX-7200 system requires the use of fixed IP addresses to be

assigned to the units. It may be necessary to coordinate with the System Administrator before

placing the devices on a network.

The Lantronix Xport Direct Device Installer program can be used. The program can be downloaded

from www.lantronix.com under support/downloads/Xport Direct/ Device Installer.

This manual will describe how to change the IP address and net mask for the units using the Xport

Device Installer software. Once the Addresses have been set to be compatible with the network,

final installation can be made.

Page 8

Cypress Suprex® SPX-7200

Changing to UDP -

The Cypress SPX-7200 is factory set to use

TCPIP. To change to UDP use the Lantronix

web interface with the following settings.

Channel 1

Protocol = UDP

Datagram Type = 01

Accept Incoming = Yes

Local Port = 10001

Changing the IP Address

In many cases it may be necessary to change the addressing to be compatible with an existing

network. The address of the Central and Remote both need to be changed using the following

procedure.

It will be necessary to set the host computer to the same subnet as the Suprex® units during this

procedure.

Remote Port = 10001

Remote Host = 0.0.0.0

Use Broadcast = Checked

Device Address Table = All = 0

- Click Ok

- Click Apply Settings.

1. Install the Lantronix “Xport Device Installer” software (Available at the Lantronix web site

(www.lantronix.com).

2. Connect the device(s) to a host computer using the crossover cable or using a Hub and straight

through cables.

3. Apply power to the device(s) being configured.

4. Start the software and follow the procedures indicated in the following pages “Setting IP

Address “.

The Net mask comes set from the factory at : 255.255.255.0

The Net mask setting can be changed using the Xport Device Installer if necessary.

Changing the Net mask

It will be necessary for the Host Computer to be on the same subnet as the device(s) being

configured for this procedure.

1. Start the software and display the Search screen.

2. Select the device from the list.

3. Click on the Telnet button.

4. A Click OK when the Telnet connection window opens.

5. A text based interface should be displayed.

6. Select 0. Server configuration. This selection will allow setting IP Address and Net mask.

Page 9

Setting IP Address - SPX-7200

1. Start the Lantronix XPort Installer software. The startup screen is shown above.

2. Click the “Search” button, after a brief delay, the connected device(s) should

appear in the device list as shown above.

Search

Button

Page 10

3. Select the device to be configured with a mouse click. The device will highlight in

blue as shown above when selected. Verify which device is to be configured by the

MAC address. The MAC address is printed on the Xport module. i.e. make sure you

are configuring the correct Central unit or Remote unit.

4. Click on the “Select IP” button. The dialog box shown above will open. Enter an

IP address for the unit. The IP address should be unique and on the same subnet as

the host computer. Click on the “OK” button after the IP address has been entered.

There will be a delay while the unit reboots. After reboot the unit should reappear in

the device list.

Note: If the unit does not appear in the device list, check power and network

connections. You will not be able to proceed if you are unable to see the unit to be

configured in the device list.

Device in

List

Setting IP Address - SPX-7200

Page 11

Setting IP Address - SPX-7200

5. After the IP addresses have been assigned to both units, select the

CENTRAL unit in the device list.

6: Select the Telnet option and click “OK”

Once both units have had their IP addresses set, it will be necessary to tell the

CENTRAL unit the address of the Remote unit.

Page 12

Setting IP Address - SPX-7200

7. You should now have an open window like this. Press the ENTER key to enter

setup mode.

8. A list of options will be presented, select Option #1 (Channel 1).

Page 13

Setting IP Address - SPX-7200

9. All of the parameters will have been set as factory default, it will be

necessary to set the address of the REMOTE unit in the Channel 1

parameters. In the example above, the parameters for the factory default

settings have been entered. Keep in mind that this is the CENTRAL unit and

we are entering the address of the REMOTE unit.

10. When the address has been entered, click through any remaining

parameters without altering them and the menu should return to the setup

options.

11. Select option 9 (Save and exit) and press enter. The settings will be

written to memory and the Duprex units are now configured to operate in the

new network environment.

Page 14

Cypress Suprex® SPX-7200 Series - Door Strike and LED I/O

Note: The LED and Door Strike operation of the Ethernet Suprex® differs from previous Suprex® versions.

To activate the relay on the Remote unit, connect as shown below. These connections can be used to allow the

Remote relay to operate a DOOR STRIKE, GATE, or other locking hardware. Refer to following pages in this

document for details of each I/O operation and connection.

There are two relays available for accessory outputs at the Remote end. Either relay can be used to provide the

Door Strike or Gate activation function. This example uses Relay 1.

Wiring Example - Door Strike Follows LED

Ground

Suprex RF Central

R1 Input

Access

Control

Panel

Ground

LED Signal

LED In

Controls

Strike on

Remote

R1 IN

Only Relay and LED Connections are shown for clarity, refer to previous diagrams for Power and Data connections.

Wiring Example - Door Strike does not follow LED

Ground

Suprex RF Central

Access

Control

Panel

N.O.

Com

Ground

LED Signal

Strike Signal

Ground

LED In

R1 Input

Controls

Strike on

Remote

Ground

R1 IN

Page 15

Cypress Suprex® SPX-7200 Series - Door Strike and LED I/O

The Cypress Suprex® SPX-7200 Series provides additional data channels to support access control hardware such as door

strikes, tamper alarms, request to exit status, etc. These signals are sent to and from the Remote and Central units without the

need to run additional wiring.

The accessory control I/O use active low inputs. When the inputs are floating (nothing connected) the associated output will be

set to a high level. When the input is set to 0 Volts (Ground) the input will activate its associated output. All Accessory outputs

are Open Collector type and will switch to Ground when activated.

Each input will have an associated output. See the following pages for a diagram of each I/O pair.Inputs can be tested by

making a jumper connection to ground and monitoring the associated output.

Suprex® Central

Ground

Jumper to ground to test

Input

Output

LED In

Red arrow denotes direction of command signal

Suprex® Remote

LED Out

Page 16

Cypress Suprex® SPX-7200 Series - Relay Controls

Suprex® Central

Relay 1 IN

Suprex® Remote

Relay 1 N.O.

Relay 1 Com

Relay 1 N.C.

Suprex® Central

Relay 2 IN

Input Signal

Input Signal

Red arrow denotes direction

of command signal

Relay 2 N.O.

Relay 2 Com

Relay 2 N.C.

Contact

Outputs

Suprex® Remote

Contact

Outputs

Page 17

Cypress Suprex® SPX-7200 Series - Relay Controls

Suprex Central

Relay 3 N.O.

Relay 3 Com

Relay 3 N.C.

Contact

Outputs

Suprex Central

Relay 4 N.O

Relay 4 Com

Relay 4 N.C.

Contact

Outputs

Red arrow denotes direction

of command signal

Input Signal

(5Volts DC

Maximum)

Suprex Remote

Relay 3 IN

Input Signal

(5Volts DC

Maximum)

Suprex Remote

Relay 4 IN

Relay 3 functions as an Alarm relay and monitors the condition of the communication link between

the Central and Remote units. Relay 3 is activated when power is applied and the communication link between the

Central and Remote is functioning. Relay 3 will become deactivated (Alarm condition)

when either the Relay 3 input on the remote is active OR the Remote unit is unable to communicate with the Central

unit. See APP NOTE FOR DETAILS

Page 18

Ground

SPX-XXXX Application Note

R1 in

Diagnostic LED

Using Supervised Contacts with the SPX-series Extenders

Applies to the following products: SPX-5501, SPX-5601, SPX-5521, SPX-5621, SPX-7400,

SPX-7410, SPX-7200, SPX-7500, All RIM series products.

This application note describes the connections necessary to convey supervised contact status over

a Suprex® communication link. The configurations described in this app note should apply to most

panels that utilize supervised contacts. When connected as described, the Suprex® system will

provide a supervised signal to the panel interface by reading the supervised status of the contacts

connected to the Suprex® Remote unit.

Theory of operation: The Access control panel is looking for a certain value of resistance

connected to the supervised contact terminals. The Suprex® Central unit will provide these

resistance values locally at the panel so that the correct supervised status is maintained. At the

same time, the Remote unit must maintain supervision of the wires connected to the relays and

switches that are connected to the remote access point. The contact supervision is provided by the

Remote unit. The Suprex® system does this by comparing the value of programming resistor at the

Central unit with the resistance seen at the Remote interface terminals. When there is a difference

in the two values, the Relay on the Central unit is activated.

There are two different examples. One example is monitoring a normally closed contact at the

Remote unit, and the other example is monitoring a normally open contact at the Remote unit. In

the examples given, a normally closed contact will require a programming resistor of 1K and a

normally open contact will require a programming resistor of 2K. Other resistor values can be used

but 1K resistors are the most common. Other resistance values will require different value(s ) for the

programming resistor(s).

2K

Door

N.C.

Contact

Rex

N.O.

Contact

1K

8 to 16 VDC In

Ground

exp (+)

exp (-)

+5 VDC out

Prog Res 4

Prog Res 3

LED In

D1/Data out

D0/Clk out

1K

1K

Central Unit

1K

1K

Relay 4 N.O.

Relay 4 Com

Relay 4 N.C.

Relay 3 N.O.

Relay 3 Com

Relay 3 N.C.

Ground

Aux out

8 to 16 VDC In

Diagnostic LED

exp (+)

exp (-)

+5 VDC out

R4

R3

LED out

D1/Data In

D0/Clk In

R2 in

Remote Unit

I1-

1K

I1+

I2-

1K

I2+

Relay 2 N.O.

Relay 2 Com

Relay 2 N.C.

Relay 1 N.O.

Relay 1 Com

Relay 1 N.C.

Ground

Aux in

Not used

Not used

Page 19

1234567

8

SPX-7200 Setup - Using Expansion Modules

Before using EXP-2000 Expansion modules with the SPX-7200 system, it will be necessary to perform a short

configuration process. This process determines if the 7200 will utilize expansion modules, and if so, how many will be

used with the system. Each SPX-7200 link can support up to 8 expansion modules.

SPX-7200 units are shipped in the factory default condition. Factory default units will be setup to function as SPX-7200

units without expansion modules. Only communications between the 2 gateway units will be active.

Setup Process:

1. With power off, set the DIP switch on the Central unit according to the table below.

2. Apply power.

The Diagnostic LED should display a steady Green indication.

3. Remove power

Set DIP switch #1 OFF. Any other DIP switches can now be set as required (Reader family/ Pullup resistors).

The Central unit is now configured. No expansion module configuration is required for the Remote unit.

4. The expansion modules will need to be setup and correctly addressed. See EXP-2000 manual for details of

Expansion module setup and configuration. The Expansion units are addressed, and added to the system as pairs.

5. Connect the Expansion modules into the system as indicated in this wiring diagram.

Operation with Expansion Modules:

The SPX-7200 system Remote and Central gateway units will operate as a standard pair Suprex® units, all of the I/O

and data terminals are available for use with readers and access control systems. There are some minor differences in

operation when using the expansion modules. Each pair of

1. The Diagnostic LED on the Gateway units will indicate the status of the main (gateway) communication link only.

2. The Alarm relay on the Central Gateway unit will deactivate (indicate alarm condition) when the communication fails

between the Gateway units or ANY of the the Remote or Central Expansion units.

3. Paired Expansion units will be functionally similar to the standard SPX-1300 Suprex® system.

Central Unit Configuration Mode Settings

" " " Switch

"""1 2 3 4 5 6 7 8

Gateway only - No EXP" 1 0 0 1 0 0 0 0

1 EXP Pair used " " 1 0 0 1 0 0 0 1

2 EXP Pair used" " 1 0 0 1 0 0 1 0

3 EXP Pair used" " 1 0 0 1 0 0 1 1

4 EXP Pair used" " 1 0 0 1 0 1 0 0

1 = ON

0 = OFF

5 EXP Pair used" " 1 0 0 1 0 1 0 1

6 EXP Pair used" " 1 0 0 1 0 1 1 0

7 EXP Pair used" " 1 0 0 1 0 1 1 1

See EXP-2000 Manual for further setup instructions

Page 20

(2)

Cypress Suprex

Ethernet Solution

with Wiegand expansion modules

Door / Parking Gate - Typical

SPX-7200R (1)

EXP-2000R

(2)

ACS

EXP-2000R

(3)

EXP-2000C

(3)

EXP-2000C

SPX-7200C (1)

Card Reader

Wiegand Data

RS-485 Link - Multi-drop

Control and I/O

Page 21

*

DC

Power

Supply

Cypress Suprex® Series - Wiegand Expansion Module

Panel “Central” interface

+8 to +16 VDC

Ground

SPX-XXXX

EXP(+)

EXP(-)

Central

Access

Control

Panel

8 to 16 VDC In

Ground

485(+)

485(-)

+5 VDC Out

Prog Res 4

Prog Res 3

LED Input

D1/Data Out

D0/Clock Out

LED In

D1/Data Out

D0/Clock Out

EXP-2000

Central Unit

R1 IN

RLY4 N.O.

RLY4 Com

RLY4 N.C.

RLY3 N.O.

RLY3 Com

RLY3 N.C.

RS232 Out

Relay2 Input

Relay1 Input

R1 Input

Controls

Strike on

Remote

RS232 In

Ground

Aux Out

Additional

EXP Modules

See EXP-2000 Manual for further setup instructions

Page 22

*

D0/CLK Input

DC

Power

Supply

Cypress Suprex® Series - Wiegand Expansion Module

Reader/Door “Remote” interface

8 to 16 VDC In

Ground

EXP (+)

EXP (-)

SPX-XXXX

Remote

R1 N.O.

R1 Com

R1 N.C.

Door

Strike

Output

Card

Reader

8 to 16 VDC In

Ground

485(+)

485(-)

+5 VDC Out

RLY4 Input (5V)

RLY3 Input (5V)

LED Output

D1/Data Input

LED Out

D1/Data In

D0/Clock In

EXP-2000

Remote Unit

RLY2 N.O.

RLY2 Com

RLY2 N.C.

RLY1 N.O.

RLY1 Com

RLY1 N.C.

RS232 Out

RS232 In

Ground

Aux In

N/C

N/C

Additional

EXP Modules

See EXP-2000 Manual for further setup instructions

Loading...

Loading...