Page 1

S800 ENC

Page 2

© Copyright FAAC S.p.A. dal 2016. Tutti i diritti riservati.

Nessuna parte di questo manuale può essere riprodotta, archiviata, distribuita a terzi

né altrimenti copiata, in qualsiasi formato e con qualsiasi mezzo, sia esso elettronico,

meccanico o tramite fotocopia, senza il preventivo consenso scritto di FAAC S.p.A.

Tutti i nomi e i marchi citati sono di proprietà dei rispettivi fabbricanti.

I clienti possono effettuare copie per esclusivo utilizzo proprio.

Questo manuale è stato pubblicato nel 2016.

© Copyright FAAC S.p.A. from 2016. All rights reserved.

No part of this manual may be reproduced, archived, distributed to third parties nor

copied in any other way, in any format and with any means, be it electronic, mechanical

or by photocopying, without prior written authorisation by FAAC S.p.A.

All names and trademarks mentioned are the property of their respective manufacturers.

Customers may make copies exclusively for their own use.

This manual was published in 2016.

© Copyright FAAC S.p.A. depuis 2016. Tous droits réservés.

Aucune partie de ce manuel ne peut être reproduite, archivée ou distribuée à des tiers

ni copiée, sous tout format et avec tout moyen, qu’il soit électronique, mécanique ou

par photocopie, sans le consentement écrit préalable de FAAC S.p.A.

Tous les noms et les marques cités sont la propriété de leurs fabricants respectifs.

Les clients peuvent faire des copies pour leur usage exclusif.

Ce manuel a été publié en 2016.

FAAC S.p.A. Soc. Unipersonale

Via Calari, 10 - 40069 Zola Predosa BOLOGNA - ITALY

Tel. +39 051 61724 - Fax +39 051 758518

www.faac.it - www.faacgroup.com

© Copyright FAAC S.p.A. ab dem 2016. Alle Rechte vorbehalten.

Kein Teil dieses Handbuchs darf reproduziert, gespeichert, an Dritte weitergegeben

oder sonst auf eine beliebige Art in einem beliebigen Format und mit beliebigen

Mitteln kopiert werden, weder mit elektronischen, noch mechanischen oder durch

Fotokopieren, ohne die Genehmigung von FAAC S.p.A.

Alle erwähnten Namen und Marken sind Eigentum der jeweiligen Hersteller.

Die Kunden dürfen nur für den Eigengebrauch Kopien anfertigen.

Dieses Handbuch wurde 2016 veröffentlicht.

© Copyright FAAC S.p.A. del 2016. Todos los derechos están reservados.

No puede reproducirse, archivarse, distribuirse a terceros ni copiarse de ningún modo,

ninguna parte de este manual, con medios mecánicos o mediante fotocopia, sin el

permiso previo por escrito de FAAC S.p.A.

Todos los nombre y las marcas citadas son de propiedad de los respectivos fabricantes.

Los clientes pueden realizar copias para su uso exclusivo.

Este manual se ha publicado en 2016.

© Copyright FAAC S.p.A. van 2016. Alle rechten voorbehouden.

Niets uit deze handleiding mag gereproduceerd, gearchiveerd, aan derden openbaar

gemaakt of op andere wijze gekopieerd worden, in om het even welke vorm en met geen

enkel middel, noch elektronisch, mechanisch of via fotokopiëren, zonder schrfitelijke

toestemming vooraf van FAAC S.p.A.

Alle vermelde namen en merken zijn eigendom van de respectievelijke fabrikanten.

De klanten mogen kopieën maken die enkel voor eigen gebruik bestemd zijn.

Dez handleiding werd in 2016 gepubliceerd.

S800 ENC 2 532116 - Rev.A

Page 3

CONTENTS

EC Declaration of conformity ................................... 1

Declaration of incorporation of partly completed machinery 1

1. INTRODUCTION TO THE INSTRUCTION MANUAL ........... 2

1.1 Meaning of the symbols ......................................... 2

2. SAFETY RECOMMENDATIONS .................................. 3

2.1 Installer safety .................................................... 3

2.2 Transport and storage ............................................ 4

2.3 Unpacking and handling ........................................ 4

2.4 Product waste disposal .......................................... 4

3. S800 ENC ............................................................ 5

3.1 Intended use ...................................................... 5

3.2 Limits of use ....................................................... 5

3.3 Unauthorised use ................................................. 5

3.4 Use in an emergency ............................................. 5

3.5 Product identification ............................................ 5

3.6 Technical specifications .......................................... 6

3.7 Identification of components ................................... 7

Installation accessories (supplied separately) ................ 7

4. INSTALLATION REQUIREMENTS ................................ 8

4.1 Mechanical requirements ........................................ 8

4.2 Electric system .................................................... 9

4.3 Typical system ..................................................... 9

5. INSTALLATION ................................................... 10

5.1 Required tools ...................................................10

5.2 Remove the leaf and lower hinge ..............................10

5.3 Put in the foundation box ......................................10

5.4 Set up the guide bracket ........................................ 11

5.5 Installing the leaf ................................................11

5.6 Installing the actuator...........................................12

5.7 Adjusting the positive stops ....................................13

TABLES

1 Symbols: notes and warnings on the instructions .................... 2

2 Symbols: safety recommendations (EN ISO 7010) .................... 2

3 Symbols: Personal Protective Equipment ............................ 3

4 Symbols: signs on the packaging. ................................... 4

5 Technical data ..................................................... 6

6 Symbols: work equipment (type and size) ......................... 10

7 Guide to solving malfunctions .................................... 15

8 Routine maintenance ............................................ 16

EC DECLARATION OF CONFORMITY

The Manufacturer

Company name: FAAC S.p.A. Soc. Unipersonale

Address: Via Calari, 10 - 40069 Zola Predosa BOLOGNA - ITALY

hereby declares that the following products:

Description: Underground actuator for swing gates

Model: S800 ENC 100° CBAC 230V; S800 ENC 180° CBAC 230V;

S800 ENC 100° SBW 230V; S800 ENC 180° SBW 230V

comply with the following applicable EU legislations:

Directive EMC 2004/108/EC

Directive ROHS 2 2011/65/EU

Furthermore, the following harmonised standards have been applied:

EN 61000-6-2:2005

EN 61000-6-3:2007

Bologna, 01-01-2016

CEO

DECLARATION OF INCORPORATION OF PARTLY

COMPLETED MACHINERY

(2006/42/EC ANN.II P.1, LETT. B)

Manufacturer and person authorised to prepare the relevant technical documentation

ENGLISH

Translation of the original instructions

6. START-UP.......................................................... 14

6.1 Force adjustment (By-Pass) .....................................14

Closure of the box ..............................................14

6.2 Final operations ..................................................14

7. MAINTENANCE ................................................... 15

7.1 Routine maintenance ...........................................15

7.2 Operating problems .............................................15

Bleeding .........................................................15

Topping-up the oil level........................................15

8. INSTRUCTIONS FOR USE ....................................... 17

8.1 Safety Recommendations ......................................17

8.2 Use in an emergency ............................................ 17

8.3 Manual operation................................................17

Release manoeuvre.............................................17

Restoring automatic operation ...............................17

ANNEX

1 The limits of use of S800 ENC in relation to the wind ............... 18

2 Limits of use of the positive stops ................................. 18

3 Foundation for leaf of MAX weight and width ..................... 19

Company name: FAAC S.p.A. Soc. Unipersonale

Address: Via Calari, 10 - 40069 Zola Predosa BOLOGNA - ITALY

hereby declares that for the partly completed machinery:

Description: Underground actuator for swing gates

Model: S800 ENC 100° CBAC 230V; S800 ENC 180° CBAC 230V;

S800 ENC 100° SBW 230V; S800 ENC 180° SBW 230V

the following essential requirements of the Machinery Directive 2006/42/EC

(including all applicable amendments) have been applied and met:

EHSR 1.1.2, 1.1.4, 1.1.5, 1.1.6, 1.1.7, 1.2.3.4, 1.3.1,

1.3.2, 1.3.3, 1.3.7, 1.3.8.1, 1.3.8.2, 1.3.10, 1.3.11.1,

1.3.11.2, 1.4.1, 1.4.5, 1.4.6, 1.4.8, 1.4.9, 1.4.15, 1.5.3,

1.5.4, 1.5.15, 1.6.1, 1.6.1.1

and that the relevant technical documentation has been compiled in compliance

with part B of Annex VII.

Furthermore, the following harmonised standards have been applied:

EN 12453:2000

EN12100:2010

EN13849-1:2008

EN13849-2:2008

It is also declared that the partly completed machinery identified above may not be commissioned until the final machine - into which it will be incorporated - has been declared

complaint with the provisions of the above mentioned Machine Directive 2006/42/EC.

Bologna, 01-01-2016 CEO

S800 ENC 1 532116 - Rev.A

Page 4

1. INTRODUCTION TO THE INSTRUCTION MANUAL

This manual provides the correct procedures and requirements for

installation and keeping of S800 ENC in safe conditions.

The results of the risk assessment conducted by FAAC S.p.A. on the

entire life cycle of the product has been considered when drafting

the manual in order to implement effective risk reduction.

The following stages of the life cycle of the product have been considered:

- delivery/handling of the supply

- assembly and installation

- setting up and commissioning

- operation

- maintenance/resolving any faults

- disposal at the end of the product’s life

Risks arising from installation and using the product have been

considered:

- risks for the installer/maintenance technician (technical person-

ENGLISH

Translation of the original instructions

nel)

- risks for the automation user

- risks for product integrity (damage)

In Europe, the automation of a door/gate falls under the Machinery

Directive 2006/42/EC and the relevant harmonised standards. Whoever automates a door/gate (new or existing) is referred to as the

Manufacturer of the Machine. By law, it is therefore required, among

other things, to carry out a risk analysis of the machine (automatic

door/gate, as a whole) and take protective measures to fulfil the essential safety requirements specified in Attachment I of the Machinery

Directive.

This manual also contains general information and guidelines in

a purely illustrative and not exhaustive manner, so as to facilitate

the activities carried out by the Manufacturer of the Machine, in all

respects, in relation to the risk analysis and drafting instructions for

use and maintenance of the machine. It is specifically understood

that FAAC S.p.A. does not accept any liability with regard to the reliability and/or completeness of the above instructions. Therefore, the

manufacturer of the machine must carry out all the activities required

by the Machinery Directive and the relevant harmonised standards,

according to the actual condition of the locations and structures

where the product S800 ENC will be installed, prior to commissioning the machine. These activities include the analysis of all the risks

associated with the machine and subsequent implementation of all

safety measures intended to fulfil the essential safety requirements.

This manual contains references to European standards. The automation of a door/gate must fully comply with laws, standards and

regulations applicable in the country where installation will take place.

§

For manual lifting, arrange for 1 person every 20 kg being lifted.

PAGE E.g.: 6 see Page 6.

FIGURE E.g.: 1-3 see Figure 1 -detail 3.

TABLE E.g.: 1 see Table 1.

CHAPTER/PARAGRAPH E.g.: §1.1 see Paragraph 1.1.

ANNEX E.g: 1 refer to Annex 1.

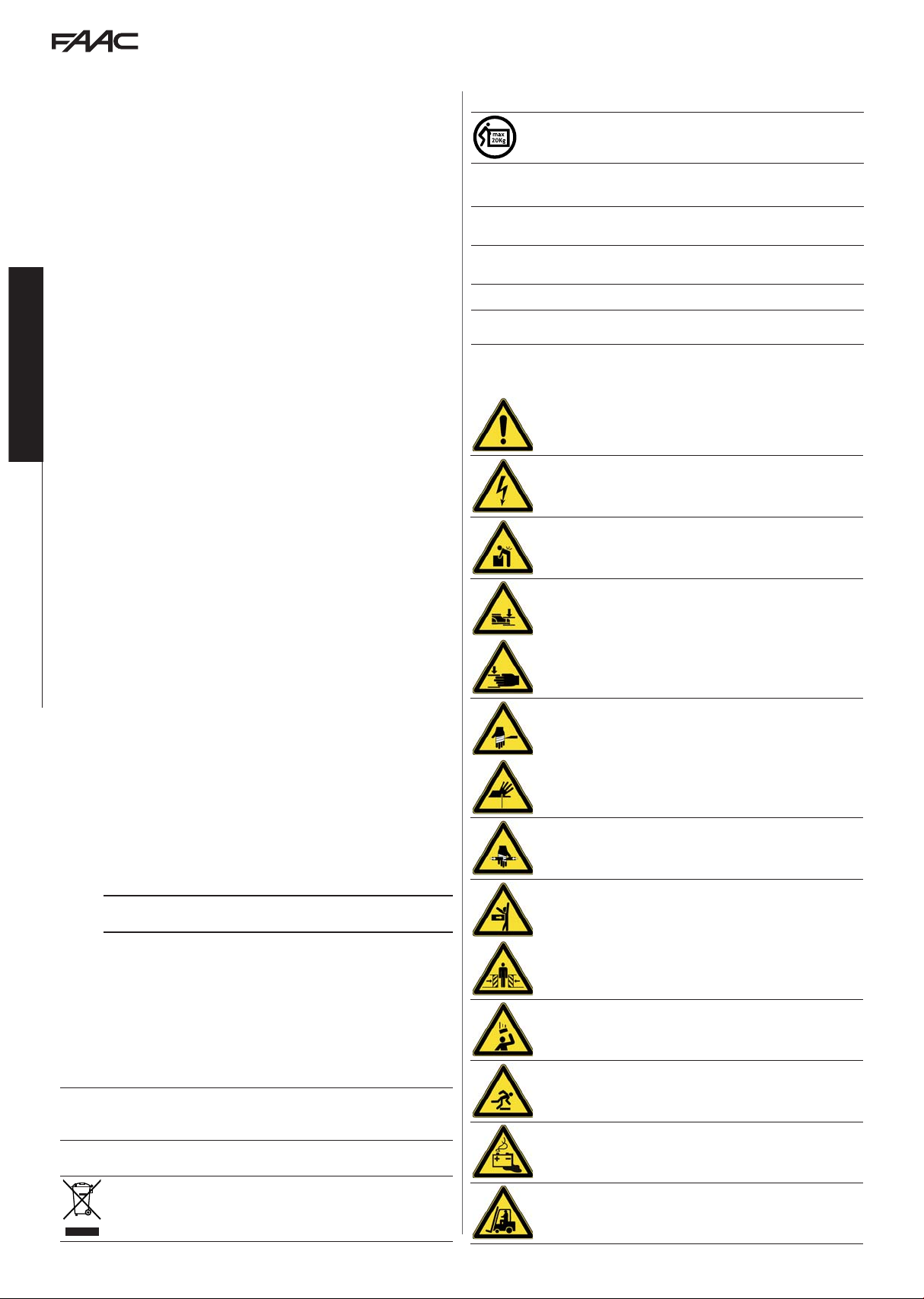

2 Symbols: safety recommendations (EN ISO 7010)

GENERIC HAZARD

Risk of personal injury or damage to parts.

ELECTROCUTION HAZARD

Risk of electrocution due to the presence of live parts.

RISK OF CRUSHING, MUSCOLOSKELETAL DISORDERS

Risk of musculoskeletal crushing - Risk of personal injury in case of lifting

heavy loads manually.

CRUSHING HAZARD

Risk of crushing hands/feet due to the presence of heavy parts.

CUTTING/AMPUTATION/PIERCING HAZARD

Risk of cutting due to the presence of sharp parts or the use of pointed

tools (drill).

SHEARING HAZARD

Risk of shearing due to moving parts.

Unless otherwise specified, the measurements provided in the instruc-

tions are in mm.

RISK OF IMPACT/CRUSHING

Risk of impact or crushing due to moving parts.

1.1 MEANING OF THE SYMBOLS

1 Symbols: notes and warnings on the instructions

ATTENTION ELECTROCUTION HAZARD - The operation or step described

F

!

S800 ENC 2 532116 - Rev.A

must be performed in compliance with the provided instructions and

safety regulations.

WARNING: RISK OF PERSONAL INJURY OR DAMAGE TO THE PARTS - The

operation or step described must be performed in compliance with the

provided instructions and safety regulations.

WARNING - Details and specifications to be followed in order to ensure

correct operation of the system.

RECYCLING and DISPOSAL - The constructive components and materials,

batteries and electronic components must not be disposed of with household

waste but delivered to authorised disposal and recycling facilities.

FALLING OBJECTS HAZARD

Risk of impact due to falling objects.

TRIPPING HAZARD

Risk of tripping due to the presence of thresholds higher than 5 mm.

SPENT BATTERIES HAZARD

Risk for the environment and health arising from spent batteries due to

possible leakage of the liquid content.

COLLISION WITH FORKLIFT TRUCKS HAZARD

Risk of collision/impact with forklift trucks.

Page 5

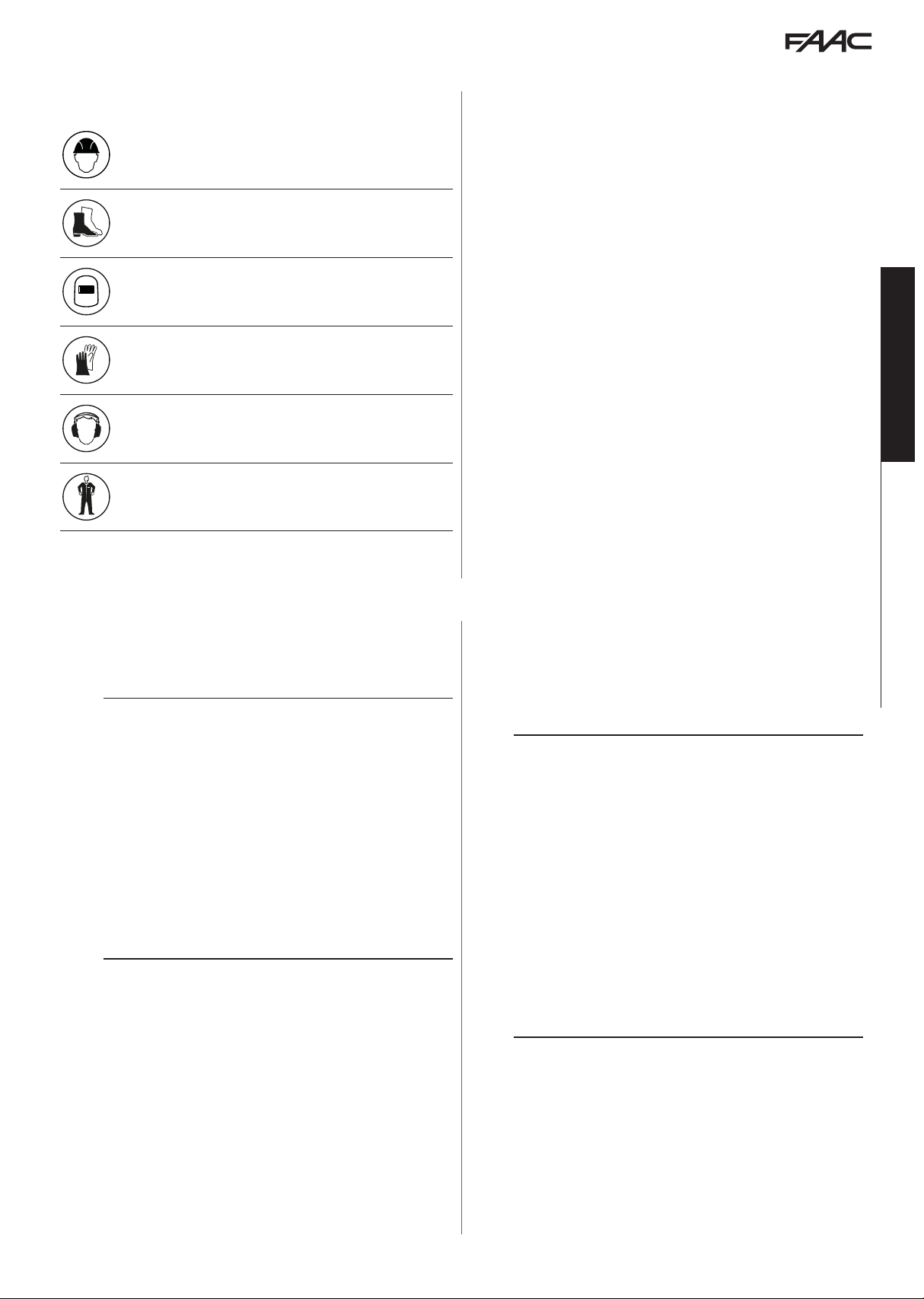

3 Symbols: Personal Protective Equipment

Personal protective equipment must be worn for protection from any risks (e.g. crushing, cutting, shearing...):

Obligation to wear head protection helmet.

Obligation to wear safety footwear.

Obligation to wear mask/goggles to protect the eyes from the risk of fragments due to the use of drill or welder.

Obligation to wear work gloves.

Obligation to wear ear protectors.

Obligation to wear work clothes without any parts that may get caught

in moving parts..

ENGLISH

2. SAFETY RECOMMENDATIONS

This product is placed onto the market as “partly completed machinery”, therefore it cannot be commissioned until the machine in which

it will be incorporated has been identified and declared to conform

to the Machinery Directive 2006/42/EC by the actual Manufacturer.

Incorrect installation and/or incorrect use of the product might cause

!

serious harm to people. Read and comply with all the instructions

before starting any activity on the product. Keep these instructions

for future reference.

Perform installation and other activities adhering to the sequences

provided in the instructions manual.

Always comply with all the requirements contained in the instructions

and warning tables at the beginning of the paragraphs. Always

comply with the safety recommendations.

Only the installer and/or maintenance technician is authorised to

work on the automation components. Do not modify the original

components in any way.

Close off the work site (even temporarily) and prevent access/transit. EC countries must comply with the legislation that transposes

the European Construction Site Directive 92/57/EC.

The installer is responsible for the installation/testing of the automation and for completing the Register of the system.

The installer must prove or declare to possess technical and professional proficiency to perform installation, testing and maintenance

activities according to the requirements in these instructions.

2.1 INSTALLER SAFETY

Installation activities require special work conditions to reduce to the

minimum the risks of accidents and serious damage. Furthermore,

the suitable precautions must be taken to prevent risks of injury to

persons or damage.

The installer must be in good physical and mental condition, aware

!

of and responsible for the hazards that may be generated when using

the product.

The work area must be kept tidy and must not be left unattended.

Do not wear clothes or accessories (scarves, bracelets, etc.) that may

get caught in moving parts.

Always wear the personal protective equipment recommended for the

type of activity to be carried out.

The required level of workplace lighting must be equal to at least

200 lux.

Operate CE marked machinery and equipment in compliance with

the manufacturer's instructions. Use work instruments in good

conditions.

Use the transport and lifting equipment recommended in the instructions manual.

Use safety-compliant portable ladders of adequate size, fitted with

anti-slip devices at the top and bottom, equipped with retainer hooks.

Translation of the original instructions

S800 ENC 3 532116 - Rev.A

Page 6

2.2 TRANSPORT AND STORAGE 2.3 UNPACKING AND HANDLING

4 Symbols: signs on the packaging.

Read the instructions.

Handle with care. Presence of fragile parts.

RISKS

PERSONAL PROTECTIVE EQUIPMENT

Upward direction. Do NOT turn over.

Store away from water and humidity.

PROHIBITION to stack the pallets.

5

ENGLISH

PALLETISED SUPPLY

RISKS

PERSONAL PROTECTIVE EQUIPMENT

Translation of the original instructions

Maximum number of stackable packages.

CE marking.

Follow the instructions on the package

!

while handling it.

Use the forklift truck or pallet truck in

observance of the safety rules to avoid

risks of collision/impact.

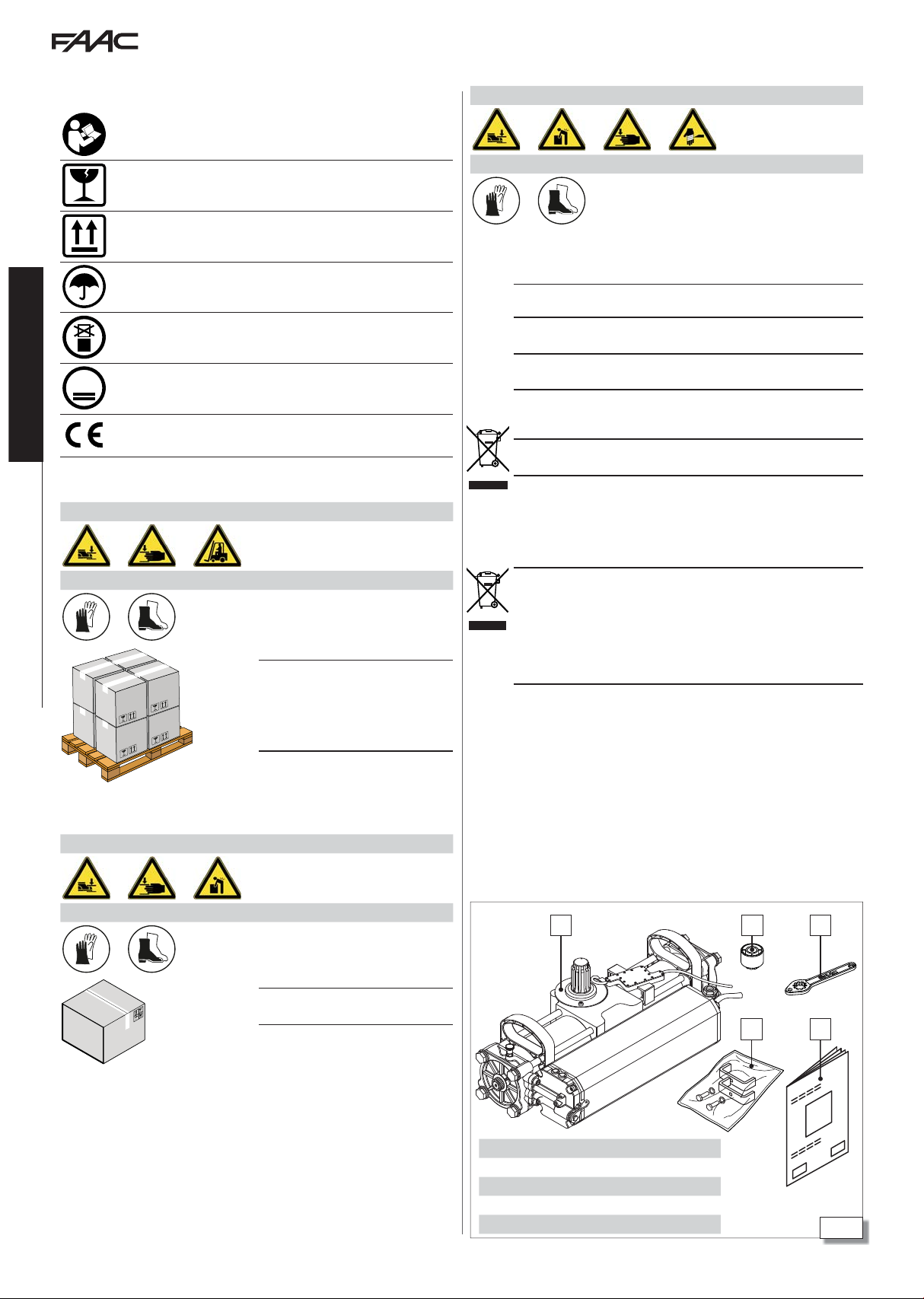

1. Open the package.

2. Remove all the components.

Lift the actuator by the handles.

!

Make sure all of the components in the supply are present and intact

1.

3. Dispose of the packaging material.

The packaging materials (plastic, polystyrene, etc.) must not be left

!

within the reach of children as they are potential sources of danger.

Discard the packaging after use in the appropriate containers in compliance with waste disposal regulations.

2.4 PRODUCT WASTE DISPOSAL

After dismantling the product, dispose of it in compliance with

Standards in force.

The constructive components and materials, batteries and electronic

components must not be disposed of with household waste but delivered to authorised disposal and recycling facilities. The oil must

be collected in a sealed container and handed over to an authorised

disposal and recycling facility. Do not mix with other substances

such as anti-freeze or transmission fluids. Keep the used oil away

from heat sources and out of reach of children.

SINGLE PACKAGE

RISKS

PERSONAL PROTECTIVE EQUIPMENT

Follow the instructions on the package

!

while handling it.

STORAGE

Store the product in its original packaging, in closed and dry premises,

protected from the sun and free from dust and aggressive substances.

Protect from mechanical stress. If stored for more than 3 months,

regularly check the condition of the components and the packaging.

- Storage temperature: 5°C to 30°C.

- Percentage of humidity: 30% to 70%.

S800 ENC 4 532116 - Rev.A

1 S800 ENC

2 Installation support

3Key

4 Positive stop fastenings

5 Instruction manual

1 2 3

54

1

Page 7

3. S800 ENC

3.1 INTENDED USE

Underground actuators of the FAAC S800 ENC series are designed

to activate horizontally moving swing gates for residential/condominium use.

One underground actuator must be installed for each leaf.

The systems set up with S800 ENC must only be intended for vehicle

transit.

See the instructions in § 8.3 to move the gate by hand.

Any other use, not specifically described, is prohibited and might affect

!

the integrity of the product and/or be a source of danger.

3.2 LIMITS OF USE

The leaf must comply with the dimensional and weight limits specified in the technical data.

Comply with the frequency of use limits indicated in the technical

data.

Environmental phenomena, even occasional, such as ice, snow and

strong wind may hinder correct operation of the automation and

affect component integrity and may become a potential source of

danger (see § Use in an emergency).

The limits of use in relation to the wind are described in detail in

Limits of use of S800 ENC in relation to the wind.

In the presence of a pedestrian door integrated in the leaf of the gate,

motorised movement must be prevented when the pedestrian door

is not closed.

S800 ENC is not designed as a protective system against intrusion.

S800 ENC must be connected to an electronic board FAAC for 230 V

motor control of swing gates, fitted with a BUS connection and slowdown control at the limit switch.

The automation set-up requires necessary safety devices to be installed, which are identified by the installer after having carried out

a proper risk assessment of the installation site.

- Do not use the automation when its range of action is not clear

of people, animals or objects.

- Do not pass and/or stop within the automation's range of action

while it is moving.

- Do not obstruct the movement of the automation.

- Do not climb onto, hold onto or be pulled by the leaf.

- Do not allow children to come close or play near the automation's

range of action.

- Do not allow the control devices to be used by persons who are

not specifically authorised and trained.

- Do not allow the control devices to be used by children or persons

with reduced mental-physical abilities, unless under the supervision of an adult responsible for their safety.

When moving it manually, slowly guide the leaf for its entire stroke,

!

do not push the leaf so it moves freely.

3.4 USE IN AN EMERGENCY

In any malfunction, emergency or fault, disconnect the power supply of the automation. If the conditions allow the leaf to be safely

moved manually, use the MANUAL OPERATION; otherwise, keep the

automation out of service until it is restored/repaired.

In case of a fault, the automation must be restored/repaired must

only be carried out by the INSTALLER/MAINTENANCE TECHNICIAN.

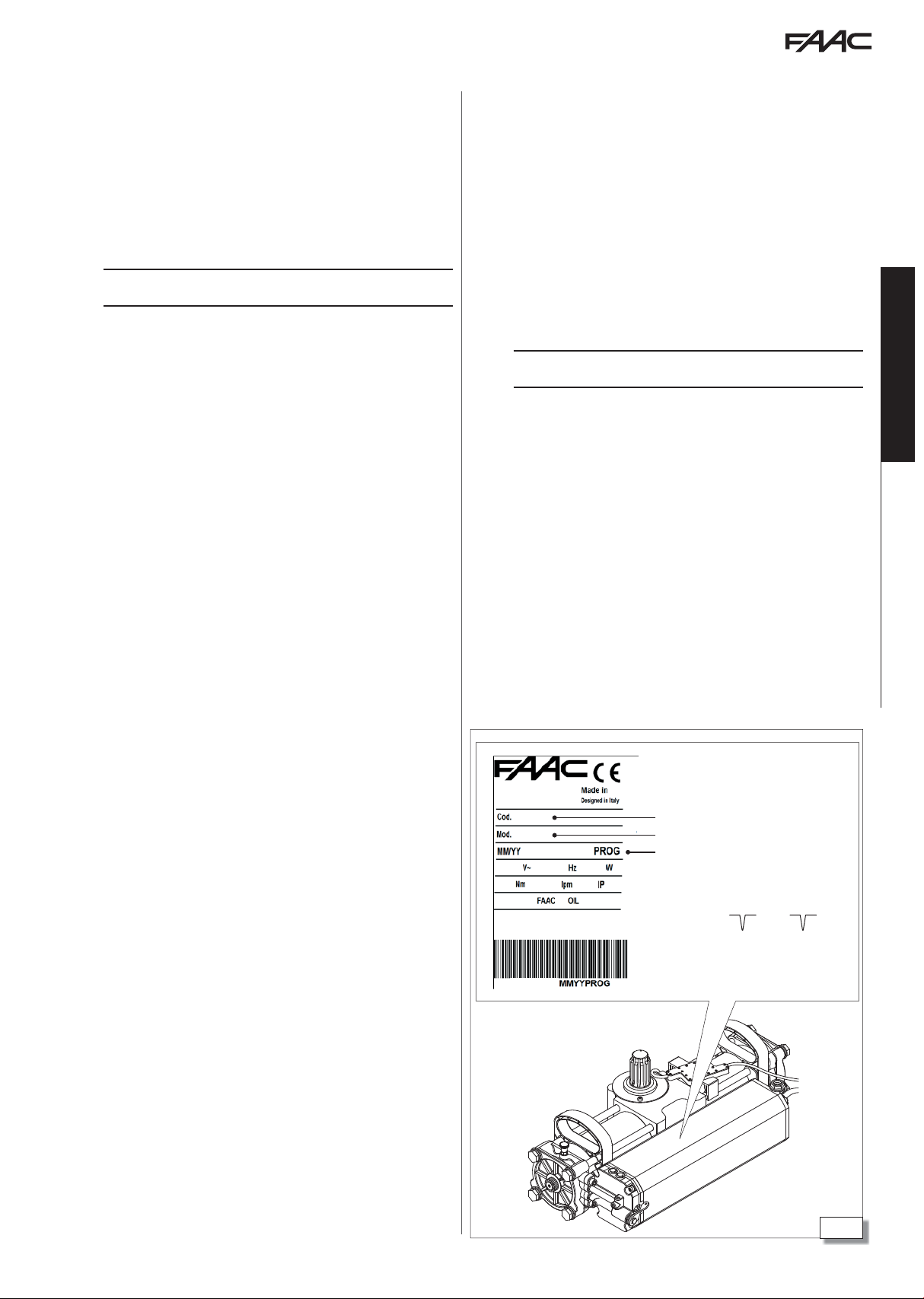

3.5 PRODUCT IDENTIFICATION

The product is identified by the plate (see 2).

ENGLISH

Translation of the original instructions

3.3 UNAUTHORISED USE

- Any use other than the intended use is prohibited.

- It is prohibited to install the automation outside of the limits set

forth in the Technical data and the Installation requirements.

- It is prohibited to install the automation along escape routes.

- It is prohibited to install the automation to implement smoke

and/or fire protection doors (fire doors).

- It is prohibited to install the automation in areas that are at risk of

explosion and/or fire: the presence of flammable gases or fumes

poses a severe danger for safety (the product is not certified

pursuant to directive 94/9/EC ATEX).

- It is prohibited to power the system with energy sources other

than those set forth.

- It is prohibited to integrate unrelated commercial systems and/

or equipment, or employ them for uses that are not allowed by

the respective manufacturers.

- It is prohibited to use and/or install accessories that are not

specifically approved by FAAC S.p.A..

- It is prohibited to use the automation before having commis-

sioned the system.

- It is prohibited to use the automation with faults/tampering

which could jeopardise safety.

- It is prohibited to use the automation with movable and/or fixed

guards that have been tampered with or removed.

- Do not expose the actuator to direct jets of water of any type

and amount.

- Do not expose the actuator to chemical or aggressive environ-

mental agents.

FAAC S.p.A. Soc. Unipersonale

Via Calari, 10 - 40069 Zola Predosa BOLOGNA

Italy

tttttt

S800 ENC

tttttt

tttt

tttttt

tttttt

tttttt

Sales code

Product name

IDENTIFICATION NUMBER

tttttt

tttttttt

ttt

Month/Year of manufacture + Progressive

number in production month.

Example: 0115 0001

made in January 2015 S/N 1

2

S800 ENC 5 532116 - Rev.A

Page 8

3.6 TECHNICAL SPECIFICATIONS

The hydraulic actuator S800 ENC is available in different versions

for 100° or 180° leaf opening options and for the CBAC or SBW type of

motor block.

- CBAC (With Opening and Closing Block): when the motor is not

running, resistance to movement is high. The hydraulic RELEASE device is required for manual operation. Electric locks

are not required to hold the opening/closing positions.

- SBW (Without Windy Block) suitable for windy areas: when the

motor is not running, resistance to movement is low (the limits of

use in relation to the wind are described in detail in 1). The

Hydraulic Release device is recommended for manual operation. Electric locks are required to hold the opening/closing

positions.

Control system

- S800 ENC must be connected to a FAAC electronic board for the

control of 230 V for swing gates, fitted with a BUS connection

and slowdown control at the limit switch.

Standard equipment (on all versions)

ENGLISH

- BUS magnetic absolute encoder to detect slowdown and stroke

end positions and to recognise obstacles to movement (anticrushing electronic function).

- By-pass screws to adjust the maximum crushing force during

opening and closing.

- Service release lever: for manual operation during installation/

maintenance.

- Integrated mechanical opening and closing stops (positive stop):

used to define the leaf stop points. No external mechanical

stops are required when using the positive stops. Using positive

stops will also reduce the maximum stroke (maximum reduction: 30° for opening and 30° for closing). The limits of use of the

positive stops in relation to the length and weight of the leaf are

described in detail in 2.

FAAC Components required for installation:

- foundation box

- grooved joint kit

Optional FAAC accessories:

- hydraulic release device with coded key accessible from inside as

well as outside the gate (required on CBAC versions)

- lock with customised key for hydraulic release

Translation of the original instructions

5 Technical data

Model

Version

Mains power supply voltage 230 V~ 50 Hz 230 V~ 50 Hz 230 V~ 50 Hz 230 V~ 50 Hz

Electrical motor Asynchronous single-phase Asynchronous single-phase Asynchronous single-phase Asynchronous single-phase

Thrust capacitor 8 F 8 F 8 F 8 F

Thermal protection 120 °C 120 °C 120 °C 120 °C

Max power 280 W 280 W 280 W 280 W

Max torque 550 Nm 550 Nm 550 Nm 550 Nm

Max. leaf width 2 m 2 m 4 m 4 m

Max. leaf weight 800 kg 800 kg 800 kg 800 kg

Max angular speed 7.8 °/s 7.8 °/s 7.8 °/s 7.8 °/s

Max leaf opening angle 113 ° 187 ° 113 ° 187 °

Operating ambient temperature -20 °C +55 °C -20 °C +55 °C -20 °C +55 °C -20 °C +55 °C

Type of use Residential-Condominium Residential-Condominium Residential-Condominium Residential-Condominium

Continuous operating time (ROT) 133' at 23 °C 133' at 23 °C 133' at 23 °C 133' at 23 °C

Protection rating IP67 IP67 IP67 IP67

Type of oil FAAC HP OIL FAAC HP OIL FAAC HP OIL FAAC HP OIL

Dimensions (W x D x H)

(Foundation box)

Weight

(Foundation box)

S800 ENC

100° CBAC 230V

380 x 220 x 160 mm

(507 x 283 x 200 mm)

16 kg

18.3 kg)

(

S800 ENC

180° CBAC 230V

450 x 220 x 160 mm

(507 x 283 x 200 mm)

16.5 kg

(18.3 kg)

S800 ENC

100° SBW 230V

380 x 220 x 160 mm

(507 x 283 x 200 mm)

16 kg

(18.3 kg)

S800 ENC

180° SBW 230V

450 x 220 x 160 mm

(507 x 283 x 200 mm)

16.5 kg

(18.3 kg)

S800 ENC 6 532116 - Rev.A

Page 9

3.7 IDENTIFICATION OF COMPONENTS

INSTALLATION ACCESSORIES (SUPPLIED SEPARATELY)

Hydraulic actuator S800 ENC

1 2 43

5 4 3

Foundation box

12

13

5

6

ENGLISH

14

78

9

10

11

15

1 Pinion

2 Absolute encoder

3 Lifting handles

4 Bleed screws

5 Stroke end mechanical stop adjustment screws (positive stop)

6 Oil filler cap

7 By-pass screws (force adjustment)

8 Service release lever

9 Positive stop fastenings

10 Installation support

11 Key

3

Grooved joint kit Hydraulic release (optional)

16

Foundation box

12 Cover

13 Removable plate (not used when the hydraulic release is installed)

14 Foundation box

15 Cover fastening screws

17

18

19

20

Translation of the original instructions

Grooved joint kit Grooved joint kit with guide bracket

16 Screws with grower to fasten

the actuator

17 Grooved joint 18 Bush

18 Bush 19 Guide bracket with grooved joint

Optional accessories

20 Hydraulic release (required on CBAC versions)

S800 ENC 7 532116 - Rev.A

16 Screws with grower to fasten the

actuator

4

Page 10

4. INSTALLATION REQUIREMENTS

4.1 MECHANICAL REQUIREMENTS

The mechanical construction elements must comply with the provisions of Standards EN 12604

Before installing the automation, suitability of the mechanical requirements must be verified and any required procedures must be

implemented for this purpose.

The necessary mechanical requirements are:

Solid ground to support the weight of the actuator and the leaf.

!

Flat and horizontal flooring in the leaf movement area.

Set-up of an adequate rainwater draining system from the founda-

tion box.

Perfectly vertical leaf in all positions along the stroke with smooth and

even movement, without friction.

A solid, stable structure (columns, hinges, leaves) and without the risk

ENGLISH

Translation of the original instructions

of detachment or sagging considering the weight of the leaf, the forces

developed by the actuator and the action of the wind. Perform the

structural calculation if necessary.

Adequate fall protection devices for the leaf.

No signs of corrosion or cracks in the structure.

Hinges in good condition, lubricated, with no play or friction.

External mechanical opening and closing stops to limit the leaf

stroke. The stops must be adequately sized and firmly secured to

withstand the impact of the leaf. The external mechanical stops are not

required when using positive stops. The limits of use of the positive

stops in relation to the length and weight of the leaf are described in

detail in Limits of use of the positive stops.

The thresholds and elements extending out from the floor must be adequately shaped or marked to eliminate the risk of tripping or slipping.

Safety clearance between the wall (or other fixed element) and the

most prominent part of the open leaf, adequate to protect against

the risk of crushing/trapping people. Alternatively, check that the

opening force is within the limits allowed by the current regulation.

Safety clearances between the fixed and mobile parts, adequate to

protect against the risk of crushing hands. Alternatively, apply

protections that prevent inserting one’s fingers.

Safety clearance between the floor and the bottom edge of the leaf

along its entire stroke, suitable to protect against the risk of dragging

a person’s feet. Alternatively, apply protections that prevent inserting one’s foot.

No sharp edges and protruding parts, to avoid the risk of cutting and

hooking. Alternatively, eliminate or adequately protect the sharp

edges and protruding parts.

Installing S800 ENC only requires the presence of the upper hinge of

the leaf since the lower rotation fulcrum is provided by the foundation

box. If an existing gate is automated, it must be dismantled and the

lower hinge removed before installing the actuator.

Refer to the EN 349 standard for the definition of the minimum spaces,

to prevent crushing body parts.

Refer to standard EN ISO 13857 for the definition of the safety distances

to prevent the danger zones from being reached.

The dimensions and positioning of the foundation box are indicated

in 5.

and EN 12605.

POSITIONING THE ACTUATOR

Actuator installed perpendicular to the closed leaf

AA

90° 90°

Left leaf

Actuator installed parallel to the closed leaf

AA

180°

!

OVERALL DIMENSIONS

60 (A)

90°

Left leaf

A distance A equal to or greater than 60 mm is required between

the vertical axis of the upper hinge and the pillar.

283

Right leaf

Right leaf

=

507

=

90°90°

90°

180°

220

200

50

273

283

S800 ENC 8 532116 - Rev.A

5

Page 11

4.2 ELECTRIC SYSTEM

Before performing any operation, disconnect the mains power sup-

F

ply. If the disconnecting switch is not visible, put up a ''ATTENTION

- Maintenance in progress'' sign.

The electrical system must comply with the regulations in force in the

!

country of installation.

Use CE-marked components and materials that comply with the Low

Voltage Directive 2006/95/EC and the EMC Directive 2004/108.

The mains power supply of the automation must be fitted with a 6 A

omnipolar circuit breaker with a contact opening distance equal to

or greater than 3 mm, for disconnection purposes in accordance with

current regulations.

The mains power supply of the automation must be equipped with a

differential switch with a threshold of 0.03 A.

The metal masses of the structure must be earthed.

Check that the earthing system is set up in compliance with the regula-

tions in force in the country of installation.

The electrical cables of the automation system must be sized and have

an insulation rating in accordance with regulations in force, placed in

adequate rigid or flexible pipes that are exposed or concealed.

Use separate pipes for power cables and for connection cables of 12-24

V control devices/accessories.

Consult the concealed cable plan to ensure there are no electrical

cables near excavations and drilling areas so as to avoid the risk of

electrocution.

Ensure there are no pipes near the excavations and drilling areas.

The electronic board must be housed in an enclosure which guarantees

minimum IP 44 protection.

The board enclosure must be placed in a non-hazardous area, which is

accessible even with open leaf, at least 30 cm from the ground.

The board enclosure must be fitted with a lock or other device that

prevents access to unauthorised persons. The cable outputs must be

directed downwards. The pipe fittings to the enclosure must prevent

humidity, insects and small animals from entering.

Protect the extension joints of the motor cable and encoder cable, by

using junction boxes with a protection rating of IP 67 or higher.

The total length of the BUS cables must not exceed 100 m.

It is recommended to install a flashing light in a visible position to

indicate gate movement.

The control accessories must be positioned in areas that are not

hazardous to the user and are also accessible with open leaf.

It is recommended to place the control accessories within the automation's visual range. This is mandatory with "dead man" control.

If an emergency stop button is installed, it must comply with EN13850.

Comply with the following heights from the ground:

- control accessories = minimum 150 cm

- emergency buttons = maximum 120 cm

ENGLISH

4.3 TYPICAL SYSTEM

6 indicates the installation layout of a typical system.

7

65

7

8

Translation of the original instructions

1

2

3

4

Typical system Minimum section of cables

1 Power supply 230 V~ 50 Hz 3G 1.5 mm²

2 Board enclosure and circuit breaker

3 Actuator S800 ENC

4 BUS encoder 2 x 0.5 mm² (length MAX 50 m)

5 Junction box

6 Key button

3 4

S800 ENC 9 532116 - Rev.A

7 Pair of BUS 2easy photocells

8 Flashing light

4G 1.5 mm²

6

Page 12

5. INSTALLATION

Installation must be carried out in compliance with Standards EN 12453

!

and EN 12445.

Close off the work site and prevent access/transit.

5.1 REQUIRED TOOLS

5.3 PUT IN THE FOUNDATION BOX

RISKS

PERSONAL PROTECTIVE EQUIPMENT

6 Symbols: work equipment (type and size)

HEX WRENCH of the specified size (7, 8, 12)

7-8-12

CROSS-HEAD SCREWDRIVER of the specified size (6, 8...)

5

ENGLISH

LEVEL

WELDER

INSTRUMENT with TORQUE ADJUSTMENT - if required for safety, a tool is

indicated with torque adjustment and the TIGHTENING TORQUE value. E.g.:

HEX WRENCH 6 set at 2.5 Nm

x.x Nm

2.5 Nm

6

5.2 REMOVE THE LEAF AND LOWER HINGE

If you automate an existing gate, the leaf must be dismantled and the

lower hinge removed before installing the actuator.

Translation of the original instructions

RISKS

The layout 21 of 3provides approximate features of the founda-

!

tion for the leaf having maximum weight and length specified in the

Technical data. It is the responsibility of the installer to assess the

dimensions and materials of the foundation according to the features

of the ground, the gate and the installation environment. Perform

the structural calculation if necessary.

1. Perform excavations and set up separate pipes for the electrical cables

and drains (7).

2. Place the box with the hole aligned with the vertical axis of the upper

hinge (7).

3. Connect the pipes for the electrical cables and the drain.

4. Use a spirit level to ensure the box is horizontal.

5. Cement the box and wait for it to harden.

PERSONAL PROTECTIVE EQUIPMENT

Anchor the leaf to the lifting device with a rope or a suitable chain.

!

After removing the leaf, place it on the ground or anchor it with a rope

or chain to prevent it from tipping over.

Ø MAX 35 mm

Ø MAX 50 mm

7

S800 ENC 10 532116 - Rev.A

Page 13

5.4 SET UP THE GUIDE BRACKET

RISKS

PERSONAL PROTECTIVE EQUIPMENT

The guide bracket is an important component for installation safety,

!

to guarantee the stability and control of the leaf during movement.

The guide bracket in the FAAC catalogue is designed for applications

with leaves up to the maximum weight and length indicated in the

Technical data.

When FAAC guide brackets are not used, the installer is responsible

for designing the bracket suitable for the applied loads, defining the

construction materials, thicknesses, sizes and surface anti-corrosion

treatments. Play between the leaf and bracket must be MAX 2 mm.

The welds made must be certified.

1. Set up the guide bracket (8-1).

2. Position the grooved joint (8-2).

The notch on the joint must be centred with the centreline of the bracket

and directed as shown in the figure.

When the bracket is placed on the box the joint must be centred on the

vertical rotation axis of the leaf (8- 3).

2

41

=

=

3

ENGLISH

8

3. Weld the entire circumference of the joint on the guide bracket

(8-4).

5.5 INSTALLING THE LEAF

RISKS

PERSONAL PROTECTIVE EQUIPMENT

1. Assemble the bush (9-1) in the foundation box, inserted in the

reference pin (9-2).

2. Assemble the guide bracket (9-3).

3. Assemble the leaf on the guide bracket (10) and anchor the

leaf to the upper hinge.

Play between the leaf and bracket must be MAX 2 mm.

!

DO NOT weld the guide bracket to the leaf.

4. Check that:

- the leaf resting on the bracket is perfectly horizontal (use the

spirit level)

- movement is smooth and with no friction along the entire stroke,

all the way to the external opening/closing stops (if present)

3

1

Translation of the original instructions

2

9

When moving it manually, slowly guide the leaf for its entire stroke,

!

do not push the leaf so it moves freely.

10

S800 ENC 11 532116 - Rev.A

Page 14

5.6 INSTALLING THE ACTUATOR

RISKS

PERSONAL PROTECTIVE EQUIPMENT

Lift the actuator by the handles.

!

1. Unscrew and remove both caps of the positive stops (11-1).

- The actuator is provided with positive stops set for maximum leaf

stroke (tightened screws). Ensure both screws are fully tightened

(11-2).

Do not force tightening of the positive stop screws.

!

2. Assemble a fastening on each positive stop (11-3).

ENGLISH

- For this stage, insert the fastening screw without tightening

it. The fastening screw must be tightened after adjusting the

positive stops (§ relative paragraph).

- Only if positive stops are NOT being used, tighten the fastening

screw in this step.

3. Release the actuator by turning the service lever one full turn anti-

clockwise (12-1).

Perform steps 1 2 3 for both the positive stops

positive stop

1

positive stop

3

2

8

11

Do not unscrew the service lever by more than one turn so as to prevent

!

oil from leaking.

4. Inser t the spanner in the pinion (12-2) and rotate the pinion until

it stops, in the closing direction of the leaf. Then move it back,

approximately to angle “α” indicated based on the type of installation or actuator version (13 or 14).

- If the pinion is already turned completely, only move it back.

5. It must now be possible to insert the spanner into the pinion in a

parallel position to the closed leaf. Perform a further minimum

Translation of the original instructions

adjustment if necessary.

Actuator installed perpendicular to the closed leaf Actuator installed parallel to the closed leaf

2

Left leafLeft leaf Right leafRight leaf

- for LEFT leaf, turn the pinion

completely anticlockwise

- for RIGHT leaf, turn the pinion

completely clockwise

Release as follows:

turn by 1 turn

1

12

opened/closed pinion

α

S800 ENC 100° versions α ~3°

S800 ENC 180° versions α ~3°

S800 ENC 12 532116 - Rev.A

α

opened/closed pinion

α α

S800 ENC 100° versions α ~20°

S800 ENC 180° versions α ~10°

13 14

Page 15

6. Lubricate the pinion (15-1).

7. Insert the actuator in the box.

- The actuator with the pinion must be tilted downwards (15-

2), then place it back in a vertical position and aligned with the

grooved joint (15-3). If necessary, temporarily open the leaf

to aid the operation.

- Be careful not to damage the electrical cables.

8. Lift the actuator and insert the pinion into the joint.

The leaf must be closed during this step.

9. Place the support inserted into the key at the bottom of the box

and rest the actuator on it (15-4).

10. Tighten the tie-rods with the grover in the 2 holes of the box and

hooked into the holes of the actuator plate to lift the actuator

(15-5).

Proceed with partial tightening movements, first one tie-rod and then

the other, until they stop. A torque wrench must be used to achieve the

required tightening torque (15-6).

11. Open and close the leaf manually to ensure it can be fully opened

and closed manually. If not, ensure that all of the installation

steps have been carried out correctly. Lastly, remove the key

with the support.

When moving it manually, slowly guide the leaf for its entire stroke,

!

do not push the leaf so it moves freely.

1

2

3

ENGLISH

4

5.7 ADJUSTING THE POSITIVE STOPS

On closing

1. With the actuator released and the leaf closed, loosen the screw

of the closing positive stop (16-1 A or B).

2. Stop unscrewing as soon as you feel resistance.

On opening

1. With the actuator released and the leaf open, loosen the screw of

the opening positive stop (16-1 A or B).

2. Stop unscrewing as soon as you feel resistance.

Check

1. Manually move the leaf to check the stop positions. If necessar y,

correct the adjustments.

Slowly guide the leaf as it moves so as to avoid impact on the positive

!

stops.

2. Block the positive stops by tightening the fastening screws

(16-2).

3. Restore the actuator by turning the service lever clockwise until

it stops (16-3).

5

M12

Translation of the original instructions

6

100 Nm

12

15

Left leaf Right leaf

B

1

A

closing opening

left leaf BA

right leaf AB

S800 ENC 13 532116 - Rev.A

1

8

2

2

7

Restore actuator:

turn completely

3

16

Page 16

6. START-UP

RISKS

PERSONAL PROTECTIVE EQUIPMENT

Before setting up electrical connections, disconnect the power supply

F

of the automation. If the disconnecting switch is not visible, put up

a ''ATTENTION - Maintenance in progress'' sign.

1. Set up the electrical connections according to the instructions of

the electronic control board and the installed accessories.

Electric motor cable

ENGLISH

yellow-green earth

blue neutral

brown phase 1

black phase 2

2. Turn the mains power supply back on.

3. Switch the electronic board on according to the specific instructions. If the motor rotates the wrong way, disconnect the power

and swap the wires of phases 1 and 2.

in a visible position.

5. Put up the CE marking on the gate.

6. Complete the EC Declaration of Conformity of the machine and

the system Logbook.

7. Provide the owner/operator of the automation with the EC Declaration, the system Logbook with the maintenance schedule and

the user instructions of the automation.

SCREW

A adjusts the force of clockwise leaf movement (a)

B adjusts the force of anticlockwise leaf movement (b)

ADJUSTMENT

tighten to increase the force

+

–

loosen to decrease the force

b

a

6.1 FORCE ADJUSTMENT (BY-PASS)

RISKS

PERSONAL PROTECTIVE EQUIPMENT

Translation of the original instructions

Adjust the by-passes in accordance with the applicable standards

!

(EN 12445

1. Remove the protective caps (17-1).

2. Adjust the opening and closing force by actuating the automation

electrically and using the by-pass screw corresponding to the

manoeuvre in progress (17 A or B):

screw A = adjusts the force of clockwise leaf movement

screw B = adjusts the force of anticlockwise leaf movement

tighten to increase the force +

loosen to decrease the force –

3. Set the protective caps back in place (17-1).

CLOSURE OF THE BOX

Close the cover of the box with the supplied screws (18).

).

a

b

1

A

B

17

6.2 FINAL OPERATIONS

1. Ensure that the forces generated by the leaf are within the limits

allowed by the standard. Use an impact curve gauge in accordance with standards EN 12453 and EN 12445. For countries

outside the EU, when there is no specific local standard, the force

must be less than 150 N static.

2. Ensure that the maximum manual moving force of the leaf is less

than 220 N.

3. Use appropriate signs to highlight the areas where residual risks

remain despite having implemented all safety measures.

4. Put up the ''DANGER: AUTOMATIC MOVEMENT'' sign on the gate

S800 ENC 14 532116 - Rev.A

8

18

Page 17

7. MAINTENANCE

RISKS

PERSONAL PROTECTIVE EQUIPMENT

REQUIRED TOOLS

Before performing any maintenance, disconnect the mains power

F

supply. If the disconnecting switch is not visible, apply a "ATTENTION - Maintenance in progress" sign. Restore the power supply once

maintenance is complete and after tidying up the area.

Maintenance must be performed by the installer/maintenance techni-

!

cian.

Comply with all the safety instructions and recommendations provided

in this manual.

Close off the work site and prevent access/transit. Do not leave the

work site unattended.

The work area must be kept tidy and clear upon completing mainte-

nance.

Before starting activities, wait for the components subject to heating

to cool down.

Do not modify the original components in any way.

FAAC S.p.A. disclaims any liability for damage caused by components

that are modified or tampered with.

The warranty shall be forfeited in the event of tampering with com-

ponents.

For replacements, use only original spare parts FAAC.

7.1 ROUTINE MAINTENANCE

The table Routine maintenance ( 16) lists a rough guide of

routine operations, which are guidelines and are in no way exhaustive,

to maintain the automation efficient and safe. It is the responsibility of the machine installer/manufacturer to define the maintenance

schedule of the automation, integrating the list or changing the

service intervals based on the features of the machine.

7.2 OPERATING PROBLEMS

7 Guide to solving malfunctions

CONDITION SOLUTION

The gate does not perform the

SETUP

The gate does NOT OPEN

The gate CLOSES instead of OPENING and vice versa

The gate performs movements at

very low speed

The gate only moves for short

stretches

Irregular movement (jerks) check for air in the hydraulic circuit. Bleed

Excessively noisy automation

BLEEDING

1. Remove the protective caps (19-1).

2. Command the gate to open. During the stroke of the leaf, loosen

the screw (19-2A or B): oil emulsified with air leaks out.

3. Tighten the screw before the leaf completes the stroke.

4. Command the gate to close. During the stroke of the leaf, loosen

the screw (19-2A or B): oil emulsified with air leaks out.

5. Tighten the screw before the leaf completes the stroke.

Repeat the procedure until non-emulsified oil comes out.

6. Set the protective caps back in place (19-1).

TOPPING-UP THE OIL LEVEL

1. Remove the cap (19-3). Check the oil level: it should be just

below the cap.

2. Top-up, if necessary. Set the cap in place again.

Only use FAAC oil.

!

Perform bleeding after topping up the oil level.

ensure the actuator is not blocked

check the presence of the power supply

check motor and encoder connection

check for faults/errors in the actuator or encoder

invert the motor connection phases and perform

a SETUP

check the set force

check the set slowdown spaces

check the encoder connection

check for errors in the encoder

there is air in the hydraulic circuit. Bleed

check the verticality of the leaves

ENGLISH

Translation of the original instructions

1

Left leaf Right leaf

B

Left leaf AB

A

S800 ENC 15 532116 - Rev.A

Right leaf BA

bleed on

opening

bleed on

closing

1

2

2

19

3

Page 18

8 Routine maintenance

If the checks listed below reveal conditions other than those foreseen,

they must be restored.

Operations Frequency

Structures

Check the structure that the gate, plinth and building/fencing parts adjacent to

the automation are fastened to: absence of damage, cracks, fractures, failures.

Check the movement area of the gate: absence of obstacles, absence of objects/

deposits which reduce safety clearances.

Check the absence of hooking points or dangerous prongs. 12

Gate

Check the gate and its fastenings: integrity, no deformations or rust, etc.

Check the correct tightening of screws and bolts.

Check the concentricity between the upper hinge of the leaf and the lower rota-

tion fulcrum provided by the foundation box.

Check hinges and bearings: integrity, perfectly positioned and fastened in place,

no deformation, rust, etc.

Lubricate hinges and/or bearings if necessary. 12

ENGLISH

Check the mechanical stops: fastening and solidity. Both sides must be checked,

simulating the impact that they could undergo during use.

Check the guide bracket of the leaf: integrity, absence of deformation and rust,

proper fastening, etc.

Check the absence of wear/collapsing which could jeopardise the condition that

all the weight of the leaf bears on the lower rotation fulcrum.

Check the anti-falling device: fastening and integrity. 12

General cleaning of the gate operating area. 12

Actuator

Check the integrity and correct fastening. 12

Check the sturdiness of the connections of the actuator to the leaf to avoid

uncontrolled movements of the leaf should it break.

Check the welding of the joint on the guide bracket.

Check reversibility and irreversibility. 12

Check that there is no oil leakage. 12

Top up the oil level, if necessary. Only use FAAC oil. 12

Translation of the original instructions

Bleed the oil, if necessary. 12

Clean the actuator and the foundation box

Check drainage efficiency.

Check the integrity of the actuator cables, of the cable glands and of the junc-

tion boxes.

Electronic equipment

Check the integrity of the electronic board enclosure. 12

Check the integrity of the power and connection cables and of the cable glands.

Check the integrity of the connectors and of the wiring.

Check that there are no signs of overheating, burns, etc. on electronic components. 12

Check the integrity and proper operation of the limit switches, if used. 12

Check the integrity of the earthing connections. 12

Check proper operation of the circuit breaker and residual current device. 12

Control devices

Check the integrity and proper operation of the installed devices and of the

remote controls.

Sensitive edges

Check: integrity, fastening and proper operation. 6

Deformable edges

Check: integrity and fastening. 12

Photocells

Check: integrity, fastening and proper operation. 6

Check the columns: integrity, fastening, no deformation, etc. 6

Flashing light

Check: integrity, fastening and proper operation. 12

Electric locks

Check: integrity, fastening and proper operation.

Clean the insertion seats.

Access control

Check that the gate opens correctly only with authorised user recognition. 12

Complete automation

Check that the automation works properly, according to the programmed logic,

using the various control devices.

Check that the gate moves correctly, smoothly and regularly without any strange

12

noise.

Check its correct opening and closing speed and that it follows the intended

12

slowdowns.

Check proper operation of the manual release: when the release is activated, the

gate should only be able to be moved manually.

Check the presence of lock caps.

12

Ensure that the maximum manual moving force of the leaf is less than 220 N. 6

Check the proper operation of the safety edges for obstacle detection. 6

12

Check the proper operation of the encoder for obstacle detection. 6

Check the proper operation of each pair of photocells. 6

12

Check that there is no optical/luminous interference between the pairs of

photocells.

Check the limitation curve of the forces (standards EN 12453 and EN 12445). For

12

countries outside the EU, when there is no specific local standard, the force must

be less than 150 N static.

Check the presence, integrity and legibility of all the necessary signs: residual

12

risks, exclusive use, etc.

Check the presence, integrity and legibility of the CE marking of the gate and of

the DANGER AUTOMATIC MOVEMENT warning sign.

12

12

12

12

12

12

12

12

6

6

6

12

12

S800 ENC 16 532116 - Rev.A

Page 19

8. INSTRUCTIONS FOR USE

It is the responsibility of the machine installer/manufacturer to draft

the user instructions of the automation in accordance with the Machinery Directive, including all the required information and instructions based on the characteristics of the automation.

The guidelines below, which are purely indicative and in no way

exhaustive, help the installer draft the user instructions.

The installer must provide the owner/operator of the automation with

!

the EC Declaration, the system Logbook with the maintenance schedule

and the user instructions of the automation.

The installer must inform the owner/operator of any residual risks and

the intended use and ways in which the machine should not be used.

The owner is responsible for operating the automation and must:

- comply with all User instructions provided by the installer/maintenance technician and the Safety recommendations

- keep the user instructions

- have the maintenance schedule implemented

- keep the system Logbook, which must be completed by the maintenance technician at the end of all servicing

8.1 SAFETY RECOMMENDATIONS

Systems set up with FAAC S800 ENC series underground actuators are

intended for vehicle transit.

The user must be in good physical and mental condition, aware of

and responsible for the hazards that may be generated when using

the product.

- Do not pass and/or stop within the automation's range of action

!

while it is moving.

- Do not use the automation when its range of action is not clear of

people, animals or objects.

- Do not allow children to come close or play near the automation's

range of action.

- Do not obstruct the movement of the automation.

- Do not climb onto, hold onto or be pulled by the leaf.

- Do not allow the control devices to be used by persons who are not

specifically authorised and trained.

- Do not allow the control devices to be used by children or persons

with reduced mental-physical abilities, unless under the supervision

of an adult responsible for their safety.

- Do not use the automation with movable and/or fixed guards that

have been tampered with or removed.

- Do not use the automation with faults/tampering which could

jeopardise safety.

- Do not expose the automation to aggressive chemical or environmental agents; do not expose the actuator to direct water jets of any

type or amount.

- Do not expose the automation to flammable gases or fumes.

- Do not perform any operation on the automation components.

8.2 USE IN AN EMERGENCY

Environmental phenomena, even occasional, such as ice, snow and

strong wind may hinder correct operation of the automation and

affect component integrity and may become a potential source of

danger.

In any malfunction, emergency or fault, disconnect the power supply of the automation. If the conditions allow the leaf to be safely

moved manually, use the MANUAL OPERATION; otherwise, keep the

automation out of service until it is restored/repaired.

In case of a fault, the automation must be restored/repaired must

only be carried out by the INSTALLER/MAINTENANCE TECHNICIAN.

8.3 MANUAL OPERATION

Before performing the Release manoeuvre, disconnect the power

!

supply of the automation.

With manual movement, slowly guide the leaf along its entire stroke.

Do not push the leaf so it runs freely.

Do not leave the gate unlocked: after performing manual movement,

restore automatic operation.

RELEASE MANOEUVRE

1. Open the cap of the lock (20-1).

2. Insert the key and turn it one anti-clockwise turn until it stops

(20 -2), then move the gate manually.

RESTORING AUTOMATIC OPERATION

1. Turn the key by one clockwise turn until it stops (20-3).

2. Ensure manual movement is prevented, then remove the key and

close the cap (20-1).

2 3

Release

Restore

ENGLISH

Translation of the original instructions

1

20

S800 ENC 17 532116 - Rev.A

Page 20

1 The limits of use of S800 ENC in relation to the wind

The table shows the maximum wind allowed for S800 ENC based on the leaf surface exposed to the wind.

Winds that exceed those allowed may affect the integrity of the mechanical transmission components of S800 ENC.

It is the responsibility of the installer to assess the impact of the wind on all the elements of the structure (columns, hinges, leaves) in order

to define the maximum wind allowed for the automation.

Leaf length (m)

Exposed area (m²)

1 12 11

2 11 10 9

3 10

4

5

6 9

7

8

9 8

10

ENGLISH

Strength and name of the wind

(Beaufort scale)

0 Calm ≤ 1

1 Light air > 1…6

2 Light breeze > 6…11

3 Gentle breeze > 11…19

4 Moderate breeze > 19…29

5 Fresh breeze > 29…39

6 Strong breeze > 39…50

7 Near gale > 50…62

8 Gale > 62…75

Translation of the original instructions

9 Severe gale > 75…87

10 Storm > 87…102

11 Violent storm > 102…117

12 Hurricane > 117

11

12

13 7

14 6

15 5

16 4

1 1.25 1.5 1.75 2 2.25 2.5 2.75 3 3.25 3.5 3.75 4

Wind speed (km/h)

2 Limits of use of the positive stops

The limits of use of the positive stops in relation to the length and weight of the leaf are indicated in the table below.

Using positive stops beyond the allowed limits is not advisable.

If using the integrated mechanical stops beyond the admissible limits is unavoidable, the minimum positive stop speed must be obtained

by setting at least 30° at slowdown speed.

Leaf length (m)

Leaf weight (kg)

50

100

150

200

250

300

350

400

450

500

550

600

650

700

750

800

= Use of positive stops ALLOWED

= Use of positive stops NOT RECOMMENDED

S800 ENC 18 532116 - Rev.A

1 1.25 1.5 1.75 2 2.25 2.5 2.75 3 3.25 3.5 3.75 4

Page 21

3 Foundation for leaf of MAX weight and width

64

POS 2-5Ø8

14

21

FIXTURES

POS 8 POS 9 POS 9

POS 4

POS 6

POS 12

POS 12

POS 11 POS 11

POS 5

POS 1-5Ø8

64

POS 7

POS 3-5Ø8

64

82

POS 6-5Ø10

40

14

61

POS 4-6Ø10

40

14

40

POS 7-5Ø10

40

POS 5-6Ø10

82

61

10

61

61

POS 12-1Ø10

10

10

61

B

POS 9-2Ø10

10

POS 1

10

10

10

POS 3

82

A

A

82

POS 8-2Ø10

82

POS 11-1Ø10

82

POS 11-1Ø10

10

B

POS 2

10

10

10

61

POS 9-2Ø10

10

10

61

61

POS 12-1Ø10

10

ENGLISH

Translation of the original instructions

FLOORING

STRUCTURAL WORK

LEAF UPRIGHT

SEC A-A SEC B-B SEC A-A SEC B-B

FOUNDATION BOX

FOUNDATION BOX

20 48 20

20 27 20

FLOORING

>10

>10

80

80

60

60

88

67

FOUNDATION BOX

B

PLAN PLAN

LEAF UPRIGHT

A

204820

88

A

20 27 20

67

RESISTANCE CLASS EXPOSURE CLASS

C 28/35 XF4

MATERIALS

B

CONCRETE

REINFORCED CONCRETE STEEL B 450C

S800 ENC 19 532116 - Rev.A

Page 22

S800 ENC 20 532116 - Rev.A

Page 23

S800 ENC 21 532116 - Rev.A

Page 24

FAAC S.p.A. Soc. Unipersonale

Via Calari, 10 - 40069 Zola Predosa BOLOGNA - ITALY

Tel. +39 051 61724 - Fax +39 051 758518

www.faac.it - www.faacgroup.com

S800 ENC 22 532116 - Rev.A

Loading...

Loading...