Page 1

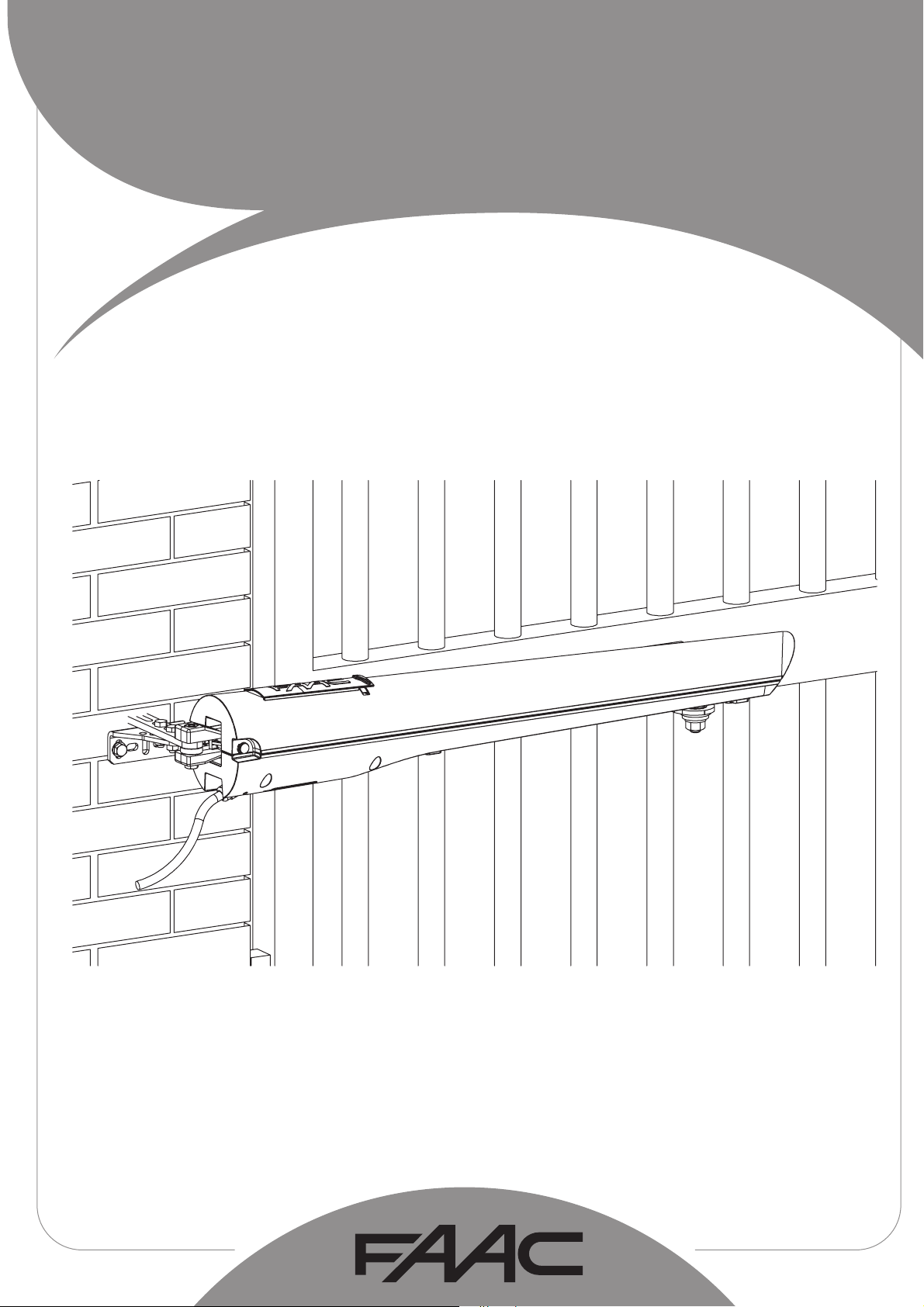

S418

S418

Page 2

CE DECLARATION OF CONFORMITY FOR MACHINES

(DIRECTIVE 98/37/EC)

Manufacturer: FAAC S.p.A.

Address: Via Benini, 1 - 40069 - Zola Predosa - Bologna - ITALY

Declares that: Operator mod. S418

is built to be integrated into a machine or to be assembled with other machinery to create a machine under the provisions of Di-

•

rective 98/37/EC;

conforms to the essential safety requirements of the following EEC directives:

•

2006/95/EC Low Voltage directive.

•

2004/108/EC Electromagnetic Compatibility directive.

•

and also declares that it is prohibited to put into service the machinery until the machine in which it will be integrated or of which it will

become a component has been identified and declared as conforming to the conditions of Directive 89/392/EEC and subsequent

modifications assimilated in Italian National legislation under Presidential decree No.459 of 24 July 1996.

Bologna, 6 March 2009

Managing Director

A. Marcellan

ENGLISH

IMPORTANT NOTICE FOR THE INSTALLER

GENERAL SAFETY REGULATIONS

ATTENTION! To ensure the safety of people, it is important that

you read all the following instructions. Incorrect installation or incorrect use of the product could cause serious

harm to people.

1.

Carefully read the instructions before beginning to install the product.

2.

Do not leave packing materials (plastic, polystyrene, etc.) within reach

of children as such materials are potential sources of danger.

3.

Store these instructions for future reference.

4.

This product was designed and built strictly for the use indicated in this

documentation. Any other use, not expressly indicated here, could

compromise the good condition/operation of the product and/or be

a source of danger.

5.

FAAC declines all liability caused by improper use or use other than that

for which the automated system was intended.

6.

Do not install the equipment in an explosive atmosphere: the presence

of inflammable gas or fumes is a serious danger to safety.

7.

The mechanical parts must conform to the provisions of Standards EN

12604 and EN 12605.

8.

For non-EU countries, to obtain an adequate level of safety, the Standards mentioned above must be observed, in addition to national

legal regulations.

9.

FAAC is not responsible for failure to observe Good Technique in the

construction of the closing elements to be motorised, or for any deformation that may occur during use.

10.

The installation must conform to Standards EN 12453 and EN 12445.

11.

Before attempting any job on the system, cut out electrical power and

disconnect the batteries.

12.

The mains power supply of the automated system must be fitted with an

all-pole switch with contact opening distance of 3mm or greater. Use of

a 6A thermal breaker with all-pole circuit break is recommended.

13.

Make sure that a differential switch with threshold of 0.03 A is fitted

upstream of the system.

14.

Make sure that the earthing system is perfectly constructed, and connect

metal parts of the means of the closure to it.

15.

The automated system is supplied with an intrinsic anti-crushing safety

device consisting of a torque control. Nevertheless, its tripping threshold

must be checked as specified in the Standards indicated at point 10.

The safety devices (EN 12978 standard) protect any danger areas

16.

against mechanical movement Risks, such as crushing, dragging, and

shearing.

Use of at least one indicator-light is recommended for every system, as

17.

well as a warning sign adequately secured to the frame structure, in

addition to the devices mentioned at point “16”.

FAAC declines all liability as concerns safety and efficient operation of

18.

the automated system, if system components not produced by FAAC

are used.

For maintenance, strictly use original parts by FAAC.

19.

Do not in any way modify the components of the automated system.

20.

The installer shall supply all information concerning manual operation

21.

of the system in case of an emergency, and shall hand over to the user

the warnings handbook supplied with the product.

Do not allow children or adults to stay near the product while it is

22.

operating.

The application cannot be used by children, by people with reduced

23.

physical, mental, sensorial capacity, or by people without experience

or the necessary training.

Keep remote controls or other pulse generators away from children, to

24.

prevent the automated system from being activated involuntarily.

Transit through the leaves is allowed only when the gate is fully open.

25.

The User must not in any way attempt to repair or to take direct action

26.

and must solely contact qualified FAAC personnel or FAAC service

centres.

Anything not expressly specified in these instructions is not permitted.

27.

Read this installation manual to the full before you begin installing the product.

Notes on reading the instruction

The symbol indicates notes that are important for the safety of persons and for the good condition of the automated system.

The symbol draws your attention to the notes on the characteristics and operation of the product.

7

Page 3

INDEX

1. DESCRIPTION page.9

1.1. DIMENSIONS page.9

2. TECHNICAL SPECIFICATIONS page.10

3. INSTALLATION page.10

3.1. ELECTRICAL PREPARATIONS (standard system) page.10

3.2. PRELIMINARY CHECKS page.10

3.3. INSTALLATION VALUES page.10

3.4. INSTALLATION OF THE OPERATORS page.11

ENGLISH

3.5. WIRING THE OPERATOR page.12

3.6. MECHANICAL STOPS page.12

4. AUTOMATED SYSTEM TEST page.13

5. MANUAL OPERATION page.13

5.1. RESTORING NORMAL OPERATION page.13

6. SPECIAL APPLICATIONS page.13

7. MAINTENANCE page.13

8. REPAIRS page.13

9. ACCESSORIES page.13

8

Page 4

S418 AUTOMATED SYSTEM

1. DESCRIPTION

The S418 automated system for swing-leaf gates is an electromechanical operator which transmits its movement to the leaf by means

of a Worm-screw system.

The irreversible system guarantees mechanical locking of the leaf when the motor is not operating. An easy-to-use release device

permits movement of the leaf in case of malfunction or a power cut.

The low-voltage operation permits buffer batteries to be connected, thus compensating for temporary power cuts.

The adjustable rear bracket permits the operator to be installed on the most varied types of gates.

Correct operation and the stated features are only obtained using accessories, safety devices and control unit from FAAC.

The lack of a mechanical clutch device requires, in order to guarantee the necessary anti-crushing safety system, the use of a

control unit with adjustable electronic clutch.

The S418 automated system has been designed and constructed to control vehicle access in residential units; any other use must

be avoided.

ENGLISH

1.1. DIMENSIONS

Part Description Part Description

Part Description Part Description

1 Operator 6 Power cable

1 Operator 6 Power cable

2 Release device 7 Front bracket

2 Release device 7 Front bracket

3 Mechanical stop at closing 8 Adjustable rear bracket

3 Mechanical stop at closing 8 Adjustable rear bracket

4 Mechanical stop at opening 9 Rear fitting

4 Mechanical stop at opening 9 Rear fitting

5 Cable cover

5 Cable cover

Fig. 1

Fig. 2

9

Page 5

2. TECHNICAL SPECIFICATIONS

Technical specifications S418

Power supply (Vdc) 24

Nominal power (W) 35

Absorbed current (A) 1.5

Maximum thrust force (daN) 180

Stroke (mm)

350

Speed (cm/sec) 1.8

Maximum size of leaf (m)

2.7

Type and frequency of use at 20°C 80 cycles/day

Consecutive cycles at 20°C 30

Operating ambient temperature (°C) -20 +55

Operator weight (KG) 6

Protection class IP54

Operator dimensions See fig. 2

햲

If you should not wish to use the mechanical stops on opening

and closing, the operator stroke becomes 390 mm.

햳

With leaves of over 2.3 m, an electric lock must be installed to

ensure locking of the leaf.

ENGLISH

3. INSTALLATION

3.1. ELECTRICAL PREPARATIONS (standard system)

no rubbing or sticking along their entire movement.

Hinges must be suitably sturdy and in good condition

•

Mechanical opening and closing stop-points must be present

•

on the ground (not necessary if mechanical operator stops are

used).

It is recommended that any metalwork operations should

be performed prior to installing the automated system.

햲

햳

The structure of the gate directly influences the reliability and

safety of the automated system.

3.3. INSTALLATION VALUES

Determine the assembly position of the operator, referring to

figure 4 and related table. It is a good idea at this stage to choose

whether you want to use the mechanical operator stops or not; this

is because eliminating the mechanical stops increases the working

stroke of the operator and values A and B must be changed.

Fig. 3Fig. 3

Part Description Cables

Part Description Cables

1 Operators Supplied

1 Operators Supplied

3x1.5 mm

2 Control unit

2 Control unit

3 TX photocells

3 TX photocells

4 RX photocells 2x0.5 mm

4 RX photocells 2x0.5 mm

5 Key selector

5 Key selector

6 Flashing lamp 2x1.5 mm

6 Flashing lamp 2x1.5 mm

7 External antenna Coaxial cable

7 External antenna Coaxial cable

8 Mechanical stops

8 Mechanical stops

3x1.5 mm

(power supply)

(power supply)

4x0.5 mm

4x0.5 mm

(2x0.5 mm2 Bus)

(2x0.5 mm2 Bus)

2x0.5 mm

2x0.5 mm

3x0.5 mm

3x0.5 mm

2

2

2

2

2

2

2

2

(1 contact)

(1 contact)

2

2

(2 contacts)

(2 contacts)

2

2

To lay the electrical cables, use adequate rigid and/or

flexible tubes.

To avoid any type of interference, we advise you to always

separate the low-voltage accessories and command

connection cables from the power supply cables, using

separate sheaths.

3.2. PRELIMINARY CHECKS

For correct operation of the automated system, the structure of

the existing gate, or that to be fitted, must have the following

requisites:

The mechanical construction parts must conform to the provisions

•

of Standards EN 12604 and EN 12605.

The length of leaf must conform to what is shown in the technical

•

characteristics of the operator (paragraph 2).

The structure of the leaves must be sturdy and rigid, suitable for

•

an automated system.

There must be regular and uniform movement of the leaves, with

•

햴

햴

L

AB

AB

α

α

165 165 330 90 75 690 105

165 165 330 90 75 690 105

90°

With mechanical

With mechanical

stops

stops

With mechanical

With mechanical

stop

stop

at opening

at opening

With no stops

With no stops

햲

햲

Working stroke of the operator.

Working stroke of the operator.

햳

햳

Maximum value.

Maximum value.

햴

햴

Minimum value.

Minimum value.

90°

175 175 350 90 85 690 105

175 175 350 90 85 690 105

110° 150 150 340 80 70 690 105

110° 150 150 340 80 70 690 105

175 165 340 100 75 708 105

175 165 340 100 75 708 105

90°

90°

180 180 360 100 80 708 105

180 180 360 100 80 708 105

110° 160 160 360 90 70 708 105

110° 160 160 360 90 70 708 105

90° 180 180 360 110 70 708 105

90° 180 180 360 110 70 708 105

110° 170 170 380 100 70 708 105

110° 170 170 380 100 70 708 105

C 햲D 햳Z

C 햲D 햳Z

L

Once the operator has been installed, check that the value of

“X” in figure 5 is greater than 500 mm. If the value of “X” is less

than 500 mm, an impact test must be performed as described

by standard UNI EN 12445, checking that the values found

comply with what is established by standard UNI EN 12453.

If the values found should not correspond to what is

established by the standard, the area MUST be protected

with a protecting device complying with standard

UNI EN 12978.

Fig. 4Fig. 4

E

E

Fig. 5Fig. 5

햴

햴

10

Page 6

If the size of the pilaster or the position of the hinge should not

permit installation of the operator,

a niche will have to be made in

the pilaster in order not to change

value A, as indicated in figure 6.

The size of the niche must be such

as to permit easy installation of

the operator, not limiting its

rotation and allowing activation

of the release device.

Fig. 6Fig. 6

The rear bracket, adjustable to different positions, facilitates the

installation procedure, being adaptable to different types of gate

and limiting any modifications necessary to satisfy installation

values A and B. Figure 7 shows certain positions which the bracket

can take; all positions intermediate to those shown may be

obtained.

Positions must be chosen which permit assembly of the bracket,

using both the securing screws.

Fig. 8Fig. 8

Secure the rear bracket, as indicated in figure 10, so as to

2.

satisfy values A and B determined

previously.

Secure the rear fitting of the operator as indicated in figure

3.

11.

Fig. 9Fig. 9

ENGLISH

Fig. 10Fig. 10

Fig. 7Fig. 7

3.3.1. GENERAL RULES FOR DETERMINATION OF THE INSTALLATION VALUES

To obtain opening of the leaf to 90° : A+B=C.

•

To obtain opening of the leaf more than 90° : A+B<C

•

Lower values of A and B produce higher peripheral leaf

•

speeds.

Limit the difference between value A and value B to within 4 cm,

•

greater differences cause variations in speed during movement

of the gate on opening and closing.

Keep the value Z so that the operator does not strike against

•

the pilaster.

The mechanical stops intervene in the first and final 50 mm of the

•

stroke. Not exploiting the entire operator stroke could limit the

field of regulation or reduce it to zero.

3.4. INSTALLATION OF THE OPERATORS

To correctly install the operators, follow the procedure indicated:

1.

Secure the fixed part of the rear bracket in the position

determined previously, using suitable assembly systems. In the

case of iron pillars, the bracket may be welded directly to the

pilaster, see figures 8 and 9.

During assembly procedures, check that the bracket is

perfectly horizontal using a spirit level.

Check that the front fitting is in the position indicated in figure

4.

12 (with the mechanical stop at closing) or in figure 13 (with

no mechanical stop at closing). If this should not occur, the

operator must be temporarily powered, in order to bring the

fitting into position.

To do this, a 12 V DC battery may be used.

Fig. 12Fig. 12

5.

Secure the front bracket as indicated in figure 14.

Fig. 11Fig. 11

Fig. 13Fig. 13

11

Fig. 14Fig. 14

Page 7

6.

Secure the operator to the rear bracket using the appropriate

bolt supplied, as indicated in figure 15.

7.

Bring the leaf of the gate to the closure position.

8.

Bring the operator, together with the related bracket,

alongside the leaf.

9.

Check that the operator is horizontal using a spirit level, as

indicated in figure 16, and provisionally secure it witch clamps

or two welding points.

ENGLISH

The axis of the securing holes of the front bracket must

be aligned with the axis of the securing holes of the rear

bracket, see figure 17. If the structure of the gate should not

permit reliable securing, the structure of the gate must be

adapted to provide a solid supporting base.

Fig. 15Fig. 15

Fig. 16Fig. 16

Fig. 18Fig. 18

3.5. WIRING THE OPERATOR

The operator is supplied with the cable already wired. If the cable

has to be replaced, a cable for outside mobile laying must be

used ( e.g. H07RN-F).

3.6. MECHANICAL STOPS

The S418 operator is supplied with mechanical stops on opening

and closing as standard. These may be used in place of the

mechanical stop-points for the leaf. For adjustment of the stops,

proceed as follows:

3.6.1. MECHANICAL STOP AT OPENING

Prepare the operator for manual operation, see paragraph

1.

5.

Manually bring the leaf into the opening position.

2.

Loosen the securing screw, figure 19 ref. 햲. The screw does

3.

not need to be completely removed.

Move the mechanical stop until it is close to the front fitting,

4.

as indicated in figure 20.

Tighten the securing screw once again.

5.

The mechanical stop is coupled to a toothed sector, figure 19

ref. 햳. In the case of obstructions during movement, check

that the coupling is free. DO NON USE FORCE.

10.

Prepare the operator for manual operation, see paragraph

5, and move the leaf manually, checking that it completes

the entire opening operation required, stopping at the

mechanical stops.

If, during the test, the operator should strike against the leaf

of the gate, value E may be increased, see figure 4, up to

a maximum of 115 mm, using appropriate spacers placed

between the front bracket and the leaf of the gate.

11.

Perform any corrective measures necessary and repeat the

procedures from point 9.

12.

Definitively secure the front bracket, using a suitable securing

system as indicated in figure 18.

If it is decided to weld the bracket directly onto the leaf, the

operator must be released temporarily. Wait for the bracket

to cool before reassembling the operator.

Fig. 17Fig. 17

Fig. 19Fig. 19

3.6.2. MECHANICAL STOP AT CLOSING

Prepare the operator for manual operation, see paragraph

1.

5.

Manually bring the leaf into the closing position.

2.

Loosen the securing screw, figure 21 ref. 햲. The screw does

3.

not need to be completely removed.

Move the mechanical stop until it is close to the front fitting,

4.

as indicated in figure 22.

Tighten the securing screw once again.

5.

The mechanical stop is coupled to a toothed sector, figure 21

ref. 햳. In the case of obstructions during movement, check

that the coupling is free. DO NON USE FORCE.

Fig. 21Fig. 21

12

Fig. 20Fig. 20

Fig. 22Fig. 22

Page 8

4. AUTOMATED SYSTEM TEST

•

Once all the necessary electrical connections have been made,

power up the system and programme the control unit on the

basis of individual needs (see relevant instructions).

•

Perform the test of the automated system and of all connected

accessories, paying special attention to safety devices.

•

Give the booklet “User guide” to the final user and instruct him/her

on the correct operation and use of the automated system.

5. MANUAL OPERATION

If the automated system should need to be moved manually,

owing to a power cut or operator malfunction, act as follows on

the release device:

1.

Switch off the power supply to the system using the differential

switch located upstream the system.

2.

Slide off the protective cap, figure 23 ref. 햲.

3.

Insert the release key supplied, figure 23 ref. 햳, and turn it

anticlockwise until it stops, figure 23 ref. 햴. The release position

is indicated by an open padlock.

4.

Move the leaf manually.

To keep the operator in manual operation mode, the release

device must categorically be left in its current position and

the system not be powered.

ENGLISH

5.1. RESTORING NORMAL OPERATION

To restore normal operation mode, proceed as follows:

1.

Ensure that the system is not powered.

2.

Turn the release key clockwise until it stops, figure 24 ref. 햲,

and remove the key, figure 24 ref. 햳. The locking position is

indicated by a closed padlock.

3.

Close the protective cap, figure 24 ref. 햴.

4.

Manually move the leaf until you note the engaging of the

device; the leaf locks.

5.

Power the system and perform a few operations to check that

all functions of the automated system have been restored.

During the first cycle, the operator might not slow down

correctly. However, wait for the end of the cycle and then

give the opening command once again.

Fig. 24Fig. 24

6. SPECIAL APPLICATIONS

Applications other than those described in the present manual are

EXPRESSLY FORBIDDEN.

7. MAINTENANCE

In order to ensure correct operation and constant safety over time,

make a general check of the system every six months, paying

special attention to the safety devices. In the booklet “User guide”,

a form has been prepared for the recording of maintenance

operations.

8. REPAIRS

The user must not carry out any repairs or maintenance operations;

these must be effected only and exclusively by qualified FAAC

personnel or FAAC service centres.

9. ACCESSORIES

For the available accessories see the FAAC catalogue.

Fig. 23Fig. 23

13

Page 9

Le descrizioni e le illustrazioni del presente manuale non sono impegnative. La FAAC si riserva il diritto, lasciando inalterate

le caratteristiche essenziali dell’apparecchiatura, di apportare in qualunque momento e senza impegnarsi ad aggiornare la presente pubblicazione, le modifiche che essa ritiene convenienti per miglioramenti tecnici o per qualsiasi altra

esigenza di carattere costruttivo o commerciale.

The descriptions and illustrations contained in the present manual are not binding. FAAC reserves the right, whilst leaving

the main features of the equipments unaltered, to undertake any modifications it holds necessary for either technical or

commercial reasons, at any time and without revising the present publication.

Les descriptions et les illustrations du présent manuel sont fournies à titre indicatif. FAAC se réserve le droit d’apporter à

tout moment les modifications qu’elle jugera utiles sur ce produit tout en conservant les caractéristiques essentielles, sans

devoir pour autant mettre à jour cette publication.

Die Beschreibungen und Abbildungen in vorliegendem Handbuch sind unverbindlich. FAAC behält sich das Recht vor,

ohne die wesentlichen Eigenschaften dieses Gerätes zu verändern und ohne Verbindlichkeiten in Bezug auf die Neufassung der vorliegenden Anleitungen, technisch bzw. konstruktiv/kommerziell bedingte Verbesserungen vorzunehmen.

Las descripciones y las ilustraciones de este manual no comportan compromiso alguno. FAAC se reserva el derecho,

dejando inmutadas las características esenciales de los aparatos, de aportar, en cualquier momento y sin comprometerse

a poner al día la presente publicación, todas las modificaciones que considere oportunas para el perfeccionamiento

técnico o para cualquier otro tipo de exigencia de carácter constructivo o comercial.

De beschrijvingen in deze handleiding zijn niet bindend. FAAC behoudt zich het recht voor op elk willekeurig moment de

veranderingen aan te brengen die het bedrijf nuttig acht met het oog op technische verbeteringen of alle mogelijke

andere productie- of commerciële eisen, waarbij de fundamentele eigenschappen van de apparaat gehandhaafd

blijven, zonder zich daardoor te verplichten deze publicatie bij te werken.

FAAC S.p.A.

Via Benini, 1

40069 Zola Predosa (BO) - ITALIA

Tel. 0039.051.61724 - Fax. 0039.051.758518

www.faac.it

www.faacgroup.com

00058I0806 - Rev. 0

Loading...

Loading...