Page 1

PATRIOT RSL

USAutomatic

High Quality Low Voltage

Vehicular Slide Gate Operator

Solar or AC Charged

PATRIOT RSL Slide Gate Operator

Installation/Owners Manual

PROUDLY MADE IN THE USA

www.usautomatic.com

Page 2

Page 3

INTRODUCTION

This operator is intended to be installed on vehicular Class I or Class II gates as defined by

UL-325. Maximum gate load not to exceed 600 pounds.

PLEASE READ THIS ENTIRE MANUAL CAREFULLY PRIOR TO INSTALLATION.

In doing so, along with performance of the installation in step-by-step order, you

will achieve optimal results. We strongly recommend that all installation and

service personnel pay particularly close attention to the safety systems section of

this manual and UL-325. In addition to the current sense feature that is provided,

other safety devices are necessary to make each particular installation as safe as

possible to reduce the risk of personal injury and/or property damage. A trained and

authorized service technician or the factory should be consulted for assistance.

Cautions - Very Important

¾ Do not attempt to enter the gate area while the gate is moving. Wait until the gate

comes to a complete stop.

¾ Operate the gate only when it is fully visible, free of persons or obstructions, and properly

adjusted.

¾ Do not allow children to play in the area of the gate. Do not allow anyone to ride on the

gate.

¾ Do not allow children to play with the remote control or any other activation device.

¾ Do not attempt to "beat the gate" while the gate is opening or closing.

This is extremely dangerous.

¾ Test the current sense feature and all safety devices regularly to insure correct

operation.

¾ Study the entire Safety Section, paying particularly close attention to the Entrapment

zones on page 20-22 and be aware of these areas not only during use but also during

any adjustments to the unit.

¾ Modifying the AC charger power cord will void the charger warranty.

Other Safety Standards

¾ All control stations should be located at least 6 feet from any moving part of the gate or

operator.

¾ Do not ever install any control device where a user will be tempted to reach through the

gate or fence to activate a gate.

© USAutomatic, LTD 2005 rev B

All rights reserved. No part of this may be reproduced by any means

without the expressed written consent of the publisher.

1

Page 4

Table Of Contents

Page

Introduction......................................................................................1

Table of Contents.............................................................................2

General Requirements/Gate Qualifications & Applications...........3

Importance of a Properly Designed Gate ........................................4

Mounting Site Review.....................................................................4

Parts Included List...........................................................................5

Operator Illustration/Description.....................................................6

Mounting Operator ..........................................................................7

Mounting Operator /Post Mount Installation ..................................8

Pad Mount Installation.....................................................................9

Mounting Chain Brackets/Connecting Chain.................................10

Installation of Charging Source......................................................11

Control Board Dipswitch Setting Verification...............................11

Current Sense Adjustment / Connecting Control board.................12

Operating the Gate..........................................................................12

Limit Switches................................................................................13

Making Final adjustments .............................................................14

Installing Secondary Entrapment Siren / Installing placards.........14

Installing Cover ..............................................................................14

Circuit Board & Terminal Description...........................................15

Function of Programming Switch Settings ...............................16-17

Emergency Manual Release ...........................................................17

Safety Section............................................................................18-22

Monthly Service / Troubleshooting Introduction...........................23

Troubleshooting Guide..............................................................24-29

Accessory Wiring Diagrams......................................................30-32

Transmitter, Receiver, Keypad Programming..........................33- 36

Magnetic Wire Sensing Loops ..................................................37-38

Notes Page...............................................................................39 - 40

Warranty Statement / Mail in Registration......................Back Cover

2

Page 5

GENERAL REQUIREMENTS

General hand/tools such as wrenches [7/16, 3/4], tape measure, level, clamps, chain

cutter, etc. are required. Your particular installation may require a drill, welder or other

hardware not provided. Concrete pad mounting or post mounting by a qualified installer

is the recommended method of securing the operator.

BATTERY REQUIRED FOR OPERATION (NOT INCLUDED).

We recommend a 12-volt deep cycle gel or AGM battery (33-amp hour minimum). The

cable harness supplied with the operator is designed for bolt type battery post found on

most marine batteries.

IMPORTANT CAUTIONS:

1. Do not test or operate this unit without first ensuring that all hardware is correctly

installed, limit nuts are securely locked in place with the limit locking plate and all

objects are clear of sprockets and chain.

2. Do not perform any welding with the control board or the battery connected. Serious

damage to the control board and/or battery can occur if attempted

3. Loose clothing can get caught in chain and sprockets resulting in bodily harm.

.

GATE QUALIFICATIONS/APPLICATIONS

GATE LENGTH/WEIGHT

This gate operator is rated for vehicular class I or class II slide gates up to 24 feet in

length and up to 600 pounds in weight as defined by UL-325. If your gate exceeds

either one of these limits, please consult a qualified technician or the factory for

alternative solutions.

Note: High quality rollers with bearings will allow your gate to operate with

minimal drag (minimal friction) and will decrease the load on the gate

operator. Many type of slide gate designs exist. Choose a design that will

decrease friction and required torque.

GATE CYCLES PER DAY

Cycles per day will vary depending on the installation. Factors to consider are expected

number of cycles per day accessories that are connected to the operator and length of

gate. The low current receiver which is standard equipment used in conjunction with

solar friendly accessories will maximize the number of cycles per day. Solar charged

systems should not exceed 15 complete open/close cycles per day without additional

solar panels. This gate operator, whether AC or Solar charged, should never be used in

applications, which exceed 100 complete open/close cycles per day. Holding the gate

open can decrease cycles during high cycle time periods. If more cycles are required, a

high traffic gate opener should be used. For help determining number of cycles possible

per day contact the factory for detailed information.

3

Page 6

IMPORTANCE OF A PROPERLY DESIGNED GATE

As a general rule, a gate, which is to be automatically operated, must be stronger and

smoother than one, which will be manually operated. Since the gate is a major

component of the system, great care and concern must be given to the gate design.

A GATE OPERATOR CANNOT OVERCOME A POORLY DESIGNED GATE.

a) Does the gate slide smoothly without binds or excessive resistance? Slide gates should

slide level and plumb if possible to prevent the operator from having to pull the gate

up or down grade when opening or closing. Low quality wheels and rollers usually

create drag, which will cause operator problems.

The use of high quality bearing wheels and rollers are highly recommended.

b) Is the gate frame of substantial strength without excessive weight?

c) Will the frame withstand normal wind load conditions without sway or vibration?

d) Will the gate hit the catch correctly without being hand-guided or pushed into the

catch?

e) Are the bearings / wheels suited for the number of cycles expected per day?

f) Is the track area designed to keep dirt and rocks from obstructing the gate movement?

If any of these problems exist, they must be corrected to achieve a reliable automatic

gate system.

MOUNTING SITE REVIEW

Installers should ask themselves these questions prior to installation and predetermine

the solution to any problems, which may occur.

a) Does sufficient space exist for mounting and future servicing of the operator?

b) *Will the unit open the gate by sliding to the left or the right? See note below.

c) How will the chain brackets attach to the gate?

d) How will the operator be mounted (on a pad or on a post)?

e) How will the charging unit (AC or Solar) be brought to the control box?

f) How and where will the solar panel mount if solar charged, so that optimum sunlight

is received?

g) How will control wiring, if any, be brought to the control box?

h) Have all safety concerns been addressed? (See Safety Section Pgs. 18-22)

NOTE: *Standing on the operator side of the gate, an operator installed to the left of the drive is a left

hand installation, an operator installed to the right is a right hand installation.

4

Page 7

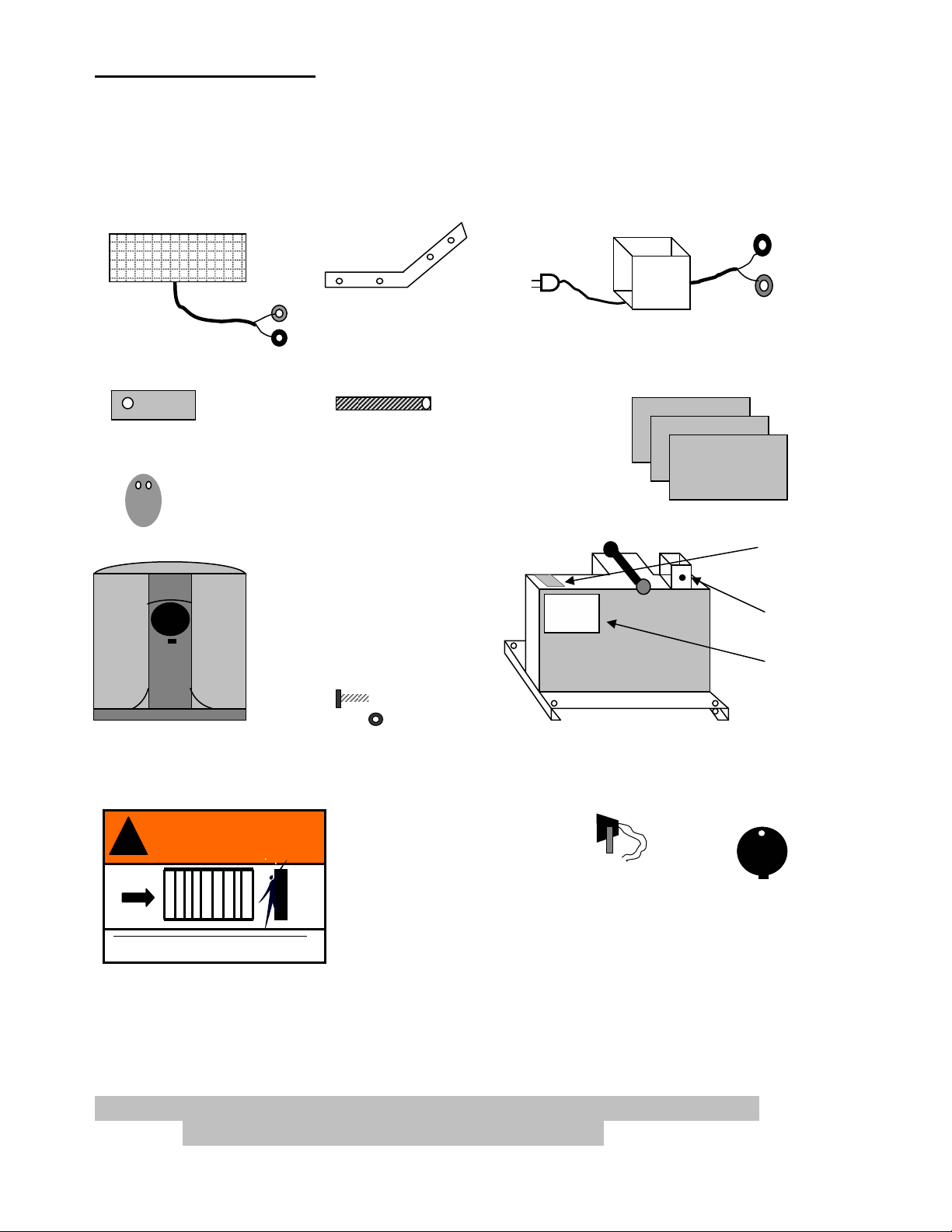

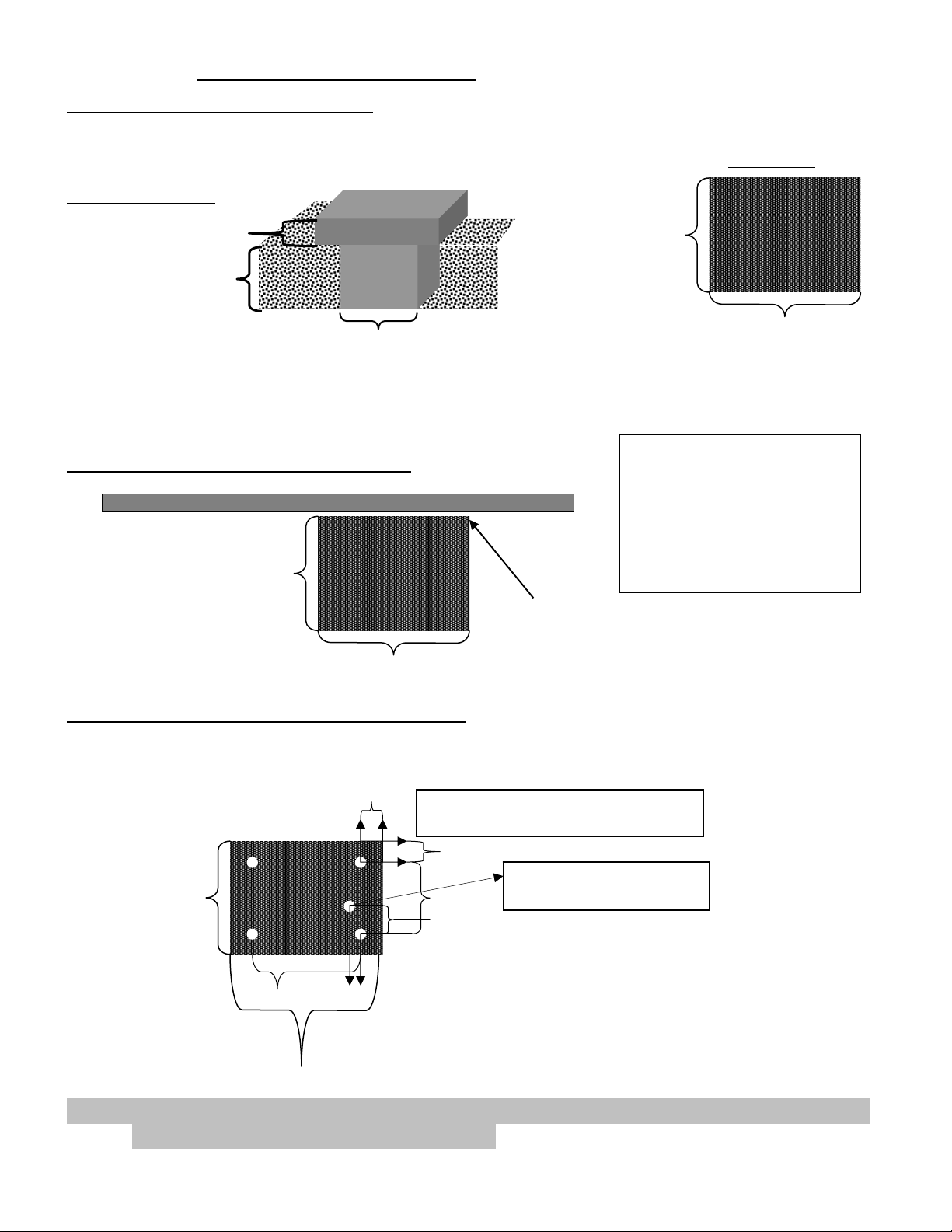

PARTS INCLUDED

p

The Patriot RSL slide gate operator is shipped in two separate boxes. One box contains the operator

chassis, emergency release access cover and the operator cover. The second box contains charging device

(with bracket for solar), secondary entrapment siren, chain brackets, chain, transmitter, chain adjustm ent

bolts, and the installation/user manual with safety placards.

5 watt Solar Panel and

Bracket

OR

Chain Bracket

2 supplied

2”x6” (1/2” hole)

CHAIN #41

3 – 10’ boxes

4 – Master links

1- 2 button

Transmitter

2- ½” x 6” Chain Adjustment

Bolts

4- ½ inch Nuts

UV treated

Polyethylene Cover

4 – ¼” bolts/washers

Operator Chassis

Battery

Charger

Low Current

Receiver

Gear motor

Patriot Control

Board

! WARNING

Secondary

Entrapment

A MOVING GATE HAS THE POTENTIAL OF INFLICTING SERIOUS INJURY OR DEATH

Persons are to keep clear! The gate is able to be moved without prior warning.

Do not let children operate the gate or play in the gate area.

Persons are to operate the gate only when the gate area is in sight and free of people and obstructions.

Safety Placards

2 supplied.

Siren +12vdc

ush in

2

• Placards (Two supplied) should be visible from inside and outside of gate.

NOTE: 12 Volt DC deep cycle battery (33-amp hour minimum) required.

(Not Included) Gel or AGM type recommended

5

Emergency release

access cover

1 – cover, screw and nut

Page 8

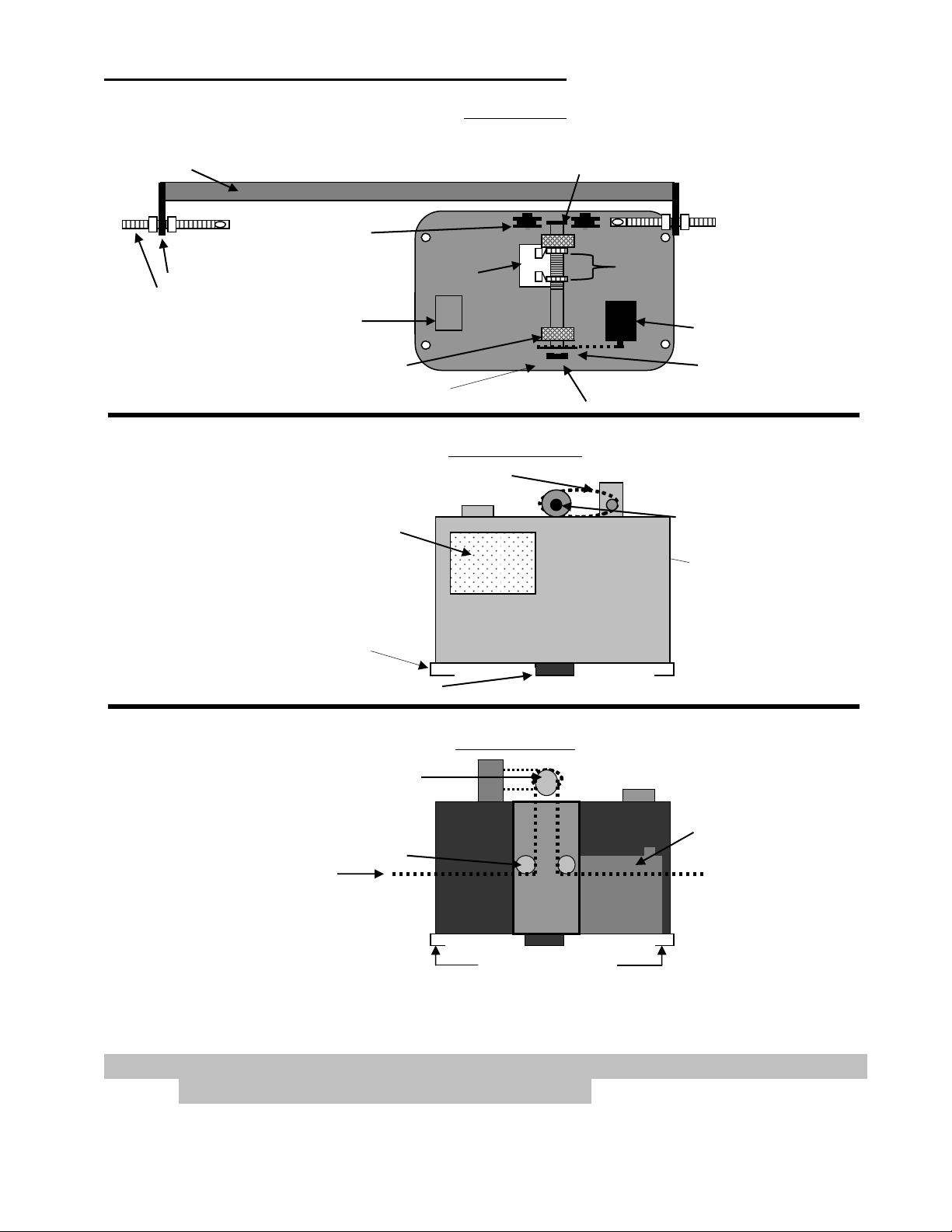

Operator Illustration and Descriptions

Gate Output drive sprocket

Chain rollers

Gate bracket Limit Nut Locking Plate Limit adjustment cams

Chain adjustment bolt

Radio receiver Gear motor

Pillow block bearings Safety disk

Emergency manual release locking bar Emergency release knob

Drive chain/Gear motor

Emergency

Patriot control board release knob

Emergency manual

Release locking bar

Cover boltholes

4 plcs

Post mount sleeve

Output drive sprocket

Compartment

Chain rollers

Chain

Pad mounting holes

TOP VIEW

FRONT VIEW

REAR VIEW

Illustration 1

Illustration 2

Battery

Illustration 3

Note: USAutomatic is not responsible for failure to comply with UL-325 standards,

local building codes or improper installations.

6

Page 9

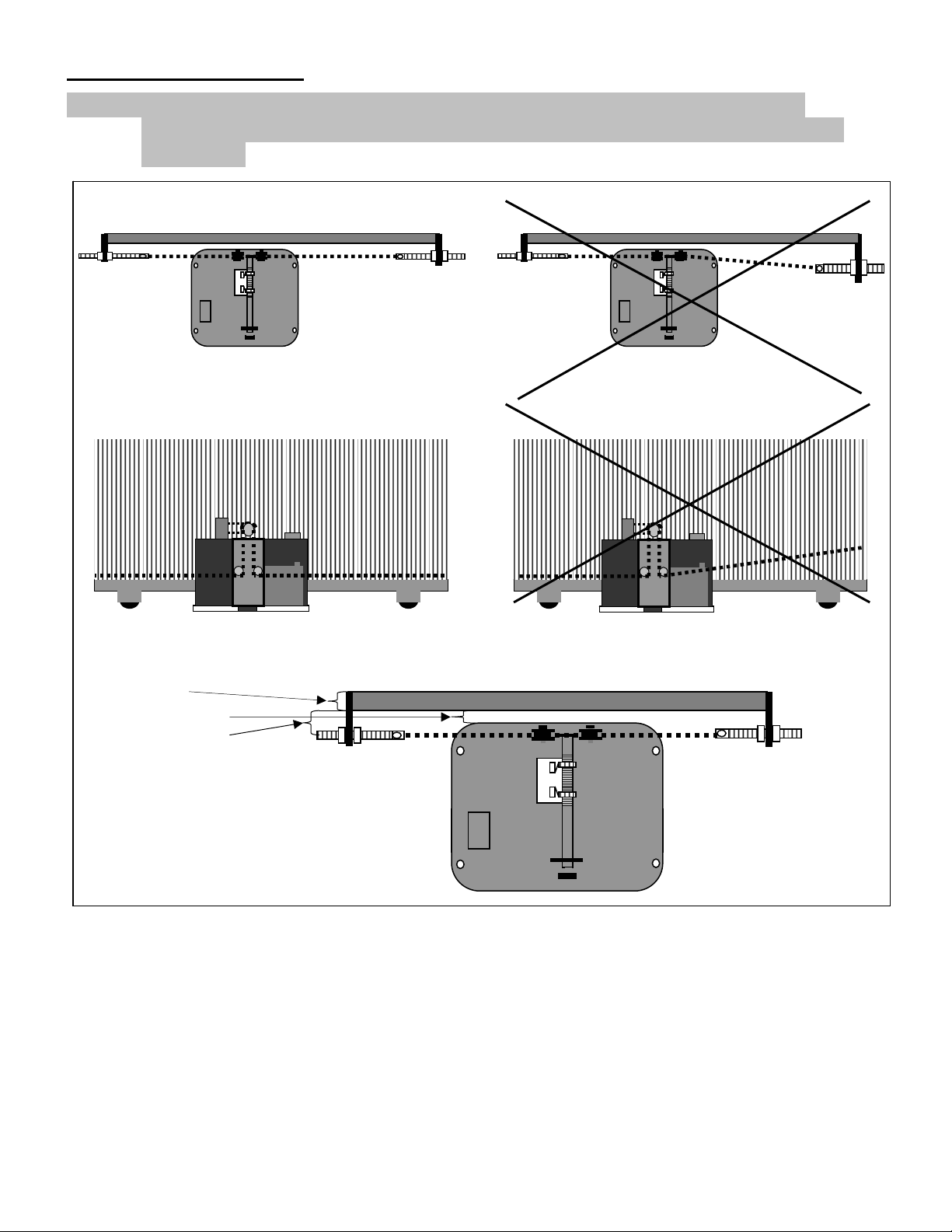

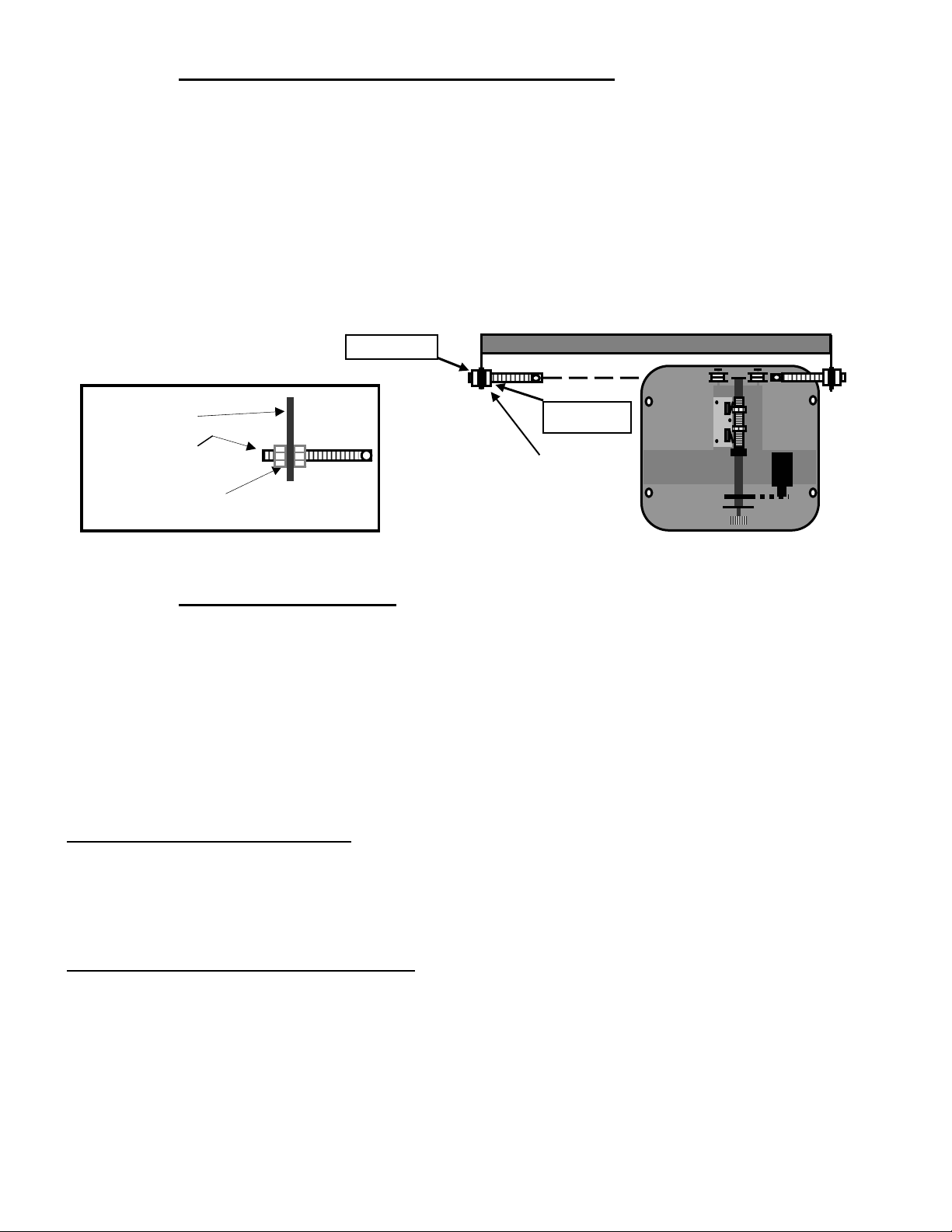

Mounting Operator

NOTE: Do not mount in areas by automatic sprinklers, or flood-prone areas. It is

important that the control board, control devices, and the battery compartment

2.00 inches

1.75 – 2.00 inches

3.25 - 3.50 inches

remain dry.

Correct Installation Incorrect Installation

Illustration 4

Illustration 6

Post or pad mount

Correct dimensions for installed operator.

Illustration 5

Illustration 7

Illustration 8

7

Page 10

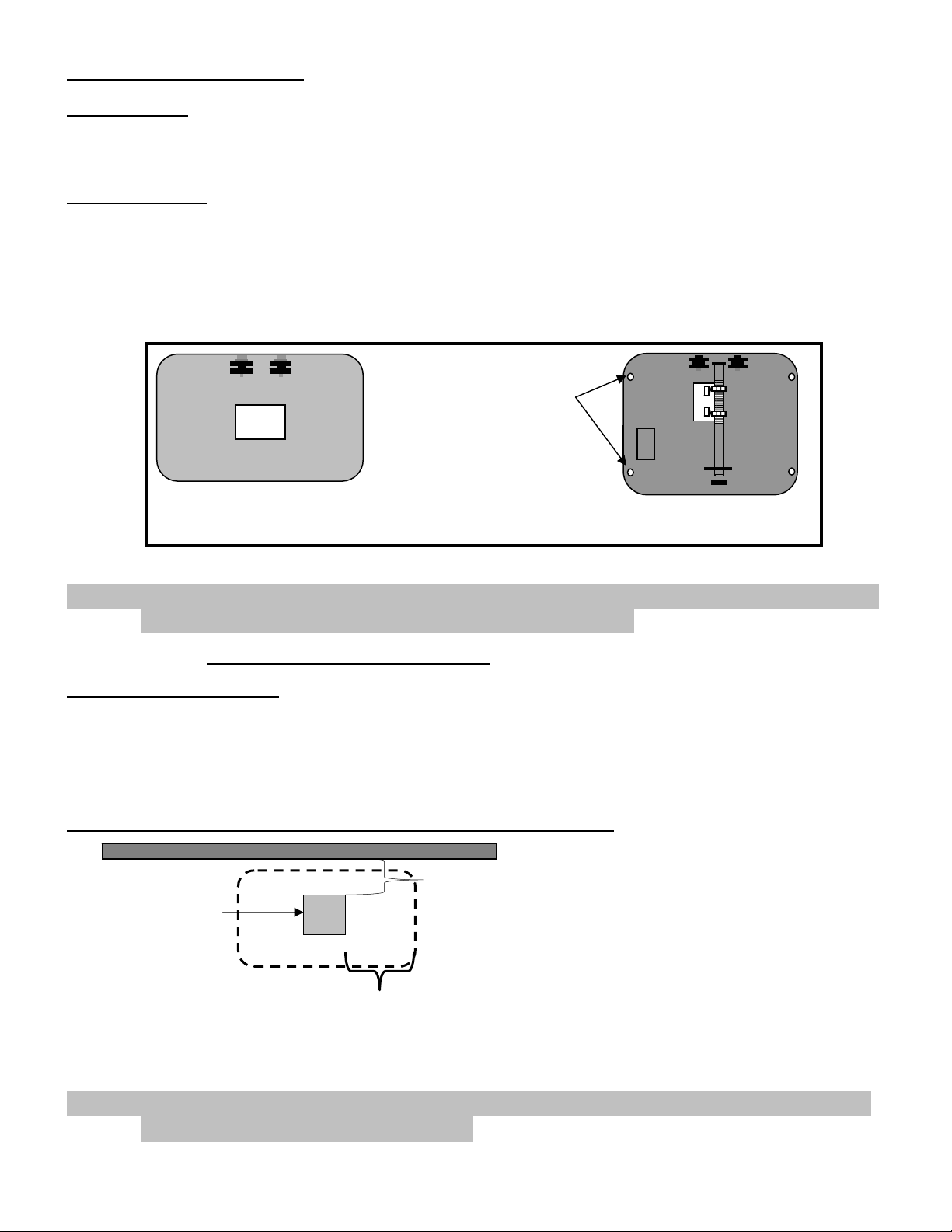

Mounting Operator

b

r

p

)

PAD MOUNT:

The operator base has four predrilled holes and four access holes, which are covered with press in hole plugs. These

holes are sized to accommodate ½ anchor bolts and the plugged hole will accept a standard size ¾ inch socket. Keep

the operator parallel with the gate while securing. See illustrations 9,13 and 14 for dimensions.

POST MOUNT:

The operator base is equipped with a four-inch post receiver located on the botto m of the base. This

receiver will accept a square or round four-inch post. Keep the operator parallel with the gate and level

while securing in place. See illustration 10 for dimensions.

Set the operator in place (pad or post). Ensure that the chain bolts once installed will be properly aligned with the chain

rollers, see illustrations 4 – 8. Once alignment is verified secure operator in place using bolts for pad installation and

welding for post installation. Keep the operator parallel with the gate while securing in place.

Receiver

Post

Receiver post located on

ottom of operato

base.

NOTE: Regardless of mounting method ensure that operator base does not extend into the

driveway area, where damage from traffic could occur.

Anchor bolt

access holes

(4 places).

Use with pad

mount or

post mount

with frame.

Illustration 9

STEP 1 Post Mount Installation

POST SPECIFICATIONS

Steel post is an optional mounting method. The type of post the operator is designed to handle is a 4-inch round or

square thick wall post. The operator can be installed directly onto the post or a steel frame can be constructed on the

top of post. If the method chosen is to construct a frame see dimensions in pad mount section (Illustrations 13,14) for

bolt locations and size. If the direct post mount option is chosen use the dimensions that follow to install, also consider

that additional bracing might be needed.

POST LOCATION TO GATE EDGE AND HOLE PREPARATION

GATE BOTTOM VIEW

4” steel post

(round or square)

8.75 inches

(measured from gate

edge to post edge.)

8.75 inches (measured from

erator edge to post edge

o

Post must be parallel to gate edge. Hole depth should be at least 36 inches and bell shaped to reduce operator

movement to a minimum. The post must be concreted in place.

NOTE: Remember to mount the operator high enough above ground level so that the post

and operator can be welded securely.

When determining post location

ensure that the operator’s outer

edge is a safe distance away from

the drive to avoid damage from

traffic.

See illustration 13 for operator

base overall dimensions.

Illustration 10

8

Page 11

STEP 1 Pad Mount Installation

CONCRETE PAD CONSTRUCTION

The mounting foundation must be very stable and of sufficient strength to prevent any movement. Mounting

site must be clear of flooding.

Cross Section View

4-inch minimum

24-inch minimum

20” MINIMUM

Illustration 11

24-inch minimum

Illustration shown is for dirt surface area. Surface areas of different material may require different pad

dimensions.

CONCRETE PAD LOCATION TO GATE

GATE TOP VIEW

20” MINIMUM

28” MINIMUM

Maximum Distance between

gate edge and pad edge 2.0”

Optimum 1.75”

When determining pad

location ensure that the

operator’s outer edge is a

safe distance away from the

driveway to avoid damage

from traffic.

CONCRETE PAD ANCHOR BOLT LOCATION

Concrete pad top view measures 20” x 28”. This allows for 4” of concrete between the anchor bolts and the

outer edge of the pad. Use the drawing below to locate the four anchor bolts.

20” MINIMUM

TOP VIEW PAD

Gate Side

4 inches

Locate anchor boltholes on gate

side corners using these dimensions.

4 inches

This hole is for ¾ electrical

12 inches

3.3 inches

conduit use dimensions shown.

20 inches

1 inch

28” MINIMUM

Note: USAutomatic is not responsible for failure to comply with UL-325 standards, local

building codes or improper installations.

TOP VIEW PAD

28” MINIMUM

Illustration 12

Illustration 13

Illustration 14

9

Page 12

STEP 2 Mounting of Chain Brackets to Gate

With the operator securely mounted use the following procedure to locate and install gate brackets to gate

ends.

1. Install the chain adjustment bolt into the chain bracket as shown in illustration 15 below.

2. Slide the gate fully open. Using the diagram below locate the correct position for the gate bracket. Clamp

the bracket in place and repeat for gate in the fully closed position. Before welding gate brackets in place

refer to illustrations 4 – 8 to ensure correct installation. Once alignment is correct weld chain brackets in

place.

TOP VIEW (GATE FRAME 2”)

Chain Bracket

Chain Adjustment Bolt

½” Nut (2 plcs)

Illustration 15

Outer nut

Inner nut

Install chain adjustment

bolts as shown to allow

for maximum tension

adjustment.

Illustration 16

STEP 3 Connecting Chain

Using the master links supplied connect one end of chain to one of the chain adjustment bolts. Use additional

master links to connect chain together as needed to route chain through the operator (See Illustration 3,16).

In most installations the chain will have to be cut to the desired length. To determine the desired chain length

loosen the chain adjustment bolts to allow for maximum adjustment (illustration 15). Pull the emergency

release knob to allow the chain to roll freely through the operator. Pull the chain to mate up with the

remaining chain adjustment bolt and mark link that needs to be cut. Once link is cut install master link and

connect to chain adjustment bolt.

CHAIN TENSION ADJUSTMENT

The outer ½” nut on the chain adjustment bolt adjust chain tension, it is important not to over tighten the

chain or premature wear will result. It is also important not to allow the chain to be to loose. Once the chain

tension is correct secure the inner ½ inch nut by tightening it against the chain bracket. The chain will h ave a

few inches of drop across the span of the gate when correct.

GATE POSITION BEFORE OPERATING

After the chain is connected to the gate verify that the gate rolls freely from the fully open position to the

fully closed position. If any friction points exist they must be corrected. Open the gate to the center position

and push the emergency release knob back in place, it might be necessary to roll the gate while pushing the

knob back in place.

NOTE: The gate must be in the center position (half open) at this time.

10

Page 13

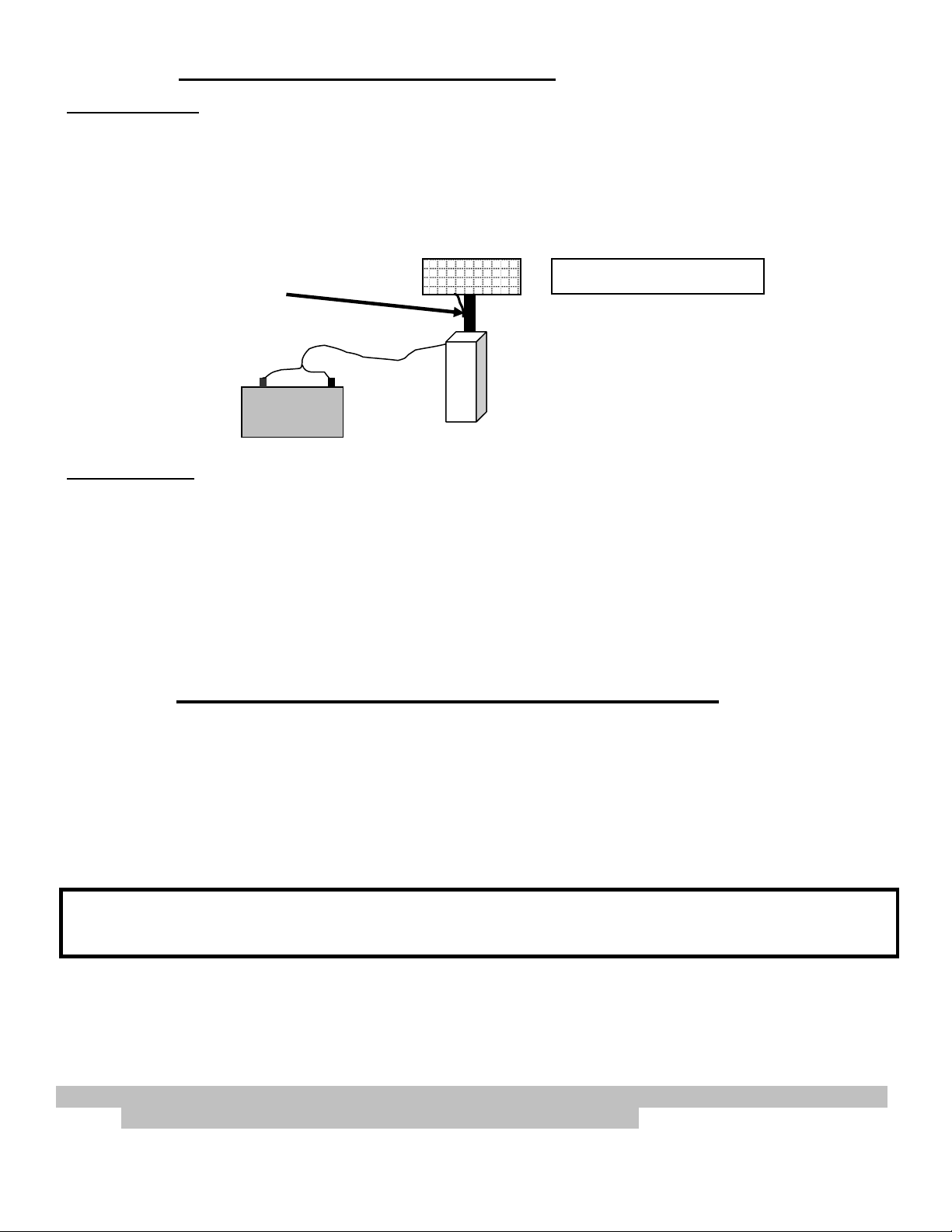

STEP 4 Installation of Charging Source

SOLAR PANEL

Locate and mount the solar panel bracket so that the panel faces southwest and maintains the preformed 45degree angle. The standard cable is 10' in length and must feed in through the bottom of the control box.

Pay attention to the distance when determining your mounting location. Although the cable can be extended

with watertight connectors, charging power is diminished. Sometimes it is necessary to locate the panel

farther away to achieve optimum sunlight, but consider that optimum sunlight might not mean optimum

charging if the distance is too great. Use #16 gauge wire or larger and keep length as short as possible.

Assemble panel(s) to bracket

with supplied hardware.

NOTE: Avoid shaded areas if possible.

AC CHARGER

Red wire +

AGM or Gel

Battery

Locate and install the AC battery charger inside the operator chassis. A hole has been pre-punched for

conduit in the base of the operator (Illustration 14 page 9). The charger requires a receptacle for 110-volt AC

supply; recommended location is above the pre-punched hole. A licensed electrician per local building codes

should install the receptacle.

Modifying the charger power cord will void the charger warranty.

Black wire -

Note: USAutomatic recommends an AC surge protector on all 110-volt AC

installations, especially in lightning prone areas.

Panel facing southwest

Panels should face southwest

for optimum charging. See

explanation above for details.

STEP 5 Control Board Dipswitch Setting Verification

NOTE: This check must be performed before operating the gate for the first time. Failure to do so

Before operating the gate lets make sure the Patriot control board dipswitches are set correctly for your installation.

Locate the dipswitches on the Patriot Control board (see page 16).

Factory default dipswitch settings are 2 and 3 on, right hand installation operator installed on right side of drive viewed

from inside the property.

Identify your installation below and verify dipswitch settings:

Patriot I (Right hand installation)

Dipswitches 2, 3 should be in the on position.

NOTE: Left Hand Installations Only: (Inside property operator on left side of drive)

NOTE: The only thing to remember is that when dipswitch 9 is on, the Limit LED’s below the actuator plug on

may damage the gate operator.

Patriot I (Left hand installation)

Dipswitches 2, 3, 9 should be in the on position.

Left hand installations do not require rewiring the harnesses. The Patriot control board

dipswitch 9 eliminates the need to do this. Failure to turn dipswitch 9 on will cause improper

gate operation. Verify your installation type and verify dipswitch settings.

the control board will show open when closed and closed when open.

11

Page 14

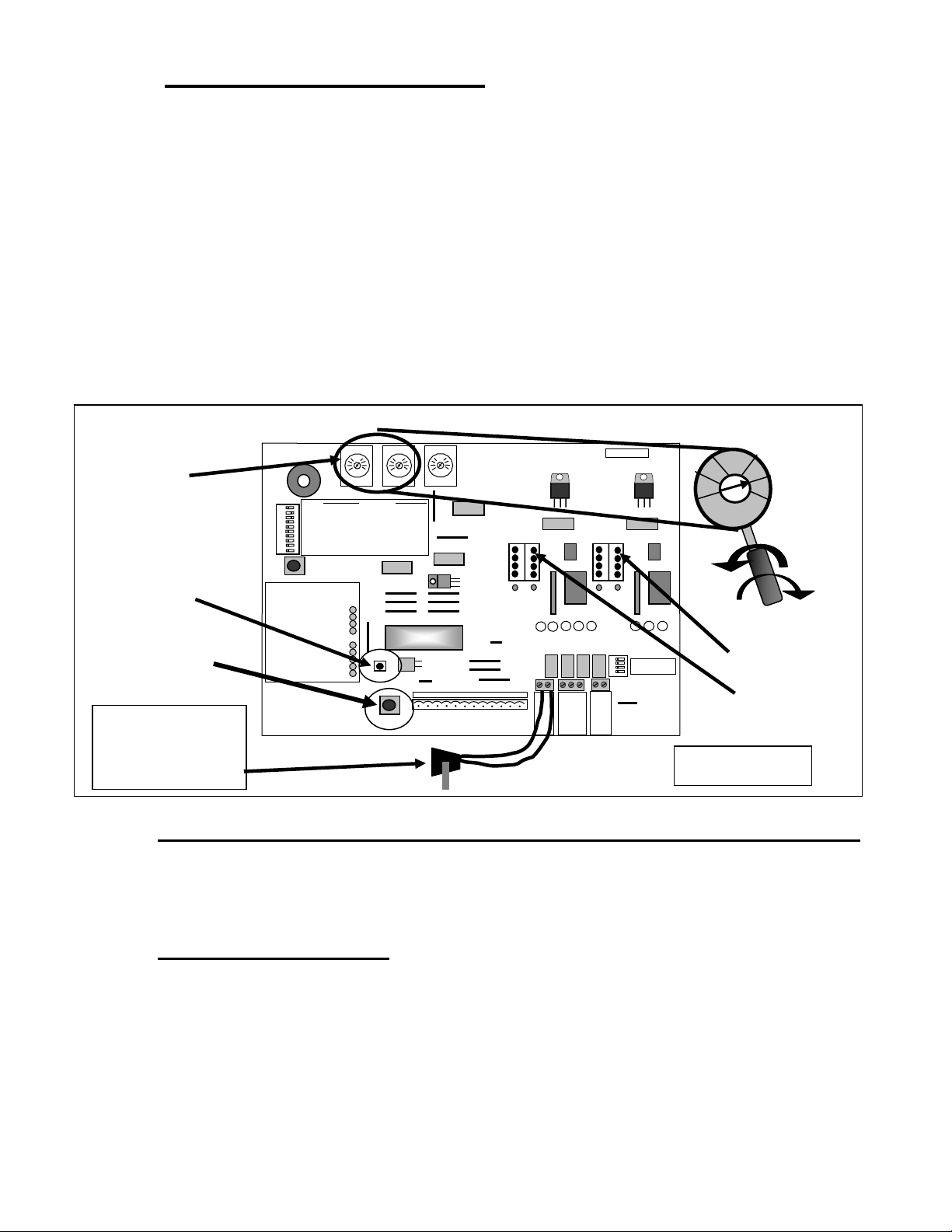

Step 6 Current Sense Adjustment

The control board has two current sense adjustments, MASTER and SLAVE (see illustration 17). Dual gates

will require adjustment of both, adjust sensitivity so that the gate force required to sense an obstruction is at the

desired level.

Remember if the gate reverses direction when operating without contacting an obstruction, then minimizing

sensitivity (increase force) may be required. Do not increase more than necessary.

The adjustment has a maximum rotation of 1 turn, beginning at 0 and ending at 10. The factory setting is around

number 3. Do not force the adjustment past the stop points.

IMPORTANT NOTE:

Locate the current sense adjustments below. Notice that there are two adjustments MASTER and SLAVE.

We intentionally set the sensors at a highly sensitive setting. This may need to be adjusted to achieve gate

movement without tripping the sensitivity circuit and causing the gate to revers e direction. If the gate reverses

direction twice and then stops the control board will need to be reset.

Current sense

adjustments

master and slave

Reset button

Open / Close

Command

Secondary

Entrapment Siren

Red +12 vdc

Black Ground

USAutomatic MADE IN USA

PATRIOT CONTROL BOARD

DS1

1

2

3

4

5

6

7

8

9

10

S2

J2 INDICATORS

1- +12V OUT 1.5 AMP MAX

2- COMMON GROUND

3- PUSH BUTTON INPUT

4- OPEN SAFETY EDGE

5- CLOSE INPUT

6- SECONDARY ENTRAPMENT DEVICE INPUT

7- COMMON GROUND

8- STOP CIRCUIT INPUT N/C

9- FREE EXIT / OPEN INPUT

10- UNDER GATE / CENTER LOOP INPUT

11- SAFETY LOOP / REVERSING ED GE INPUT

12- MOTION DETECTOR INPUT

Vehicular Gate Operator

Class I or Class II per UL325

Gate Weight Max. Load: 650 lbs.

MASTER

SLAVE

Sensitivity

Sensitivity

5

5

10

0

BOTH ON FOR DUAL

OFF

RESET

OPEN/CLOSE

COMMAND

0

CURRENT SENSE

ADJUSTMENT

CURRENT SENSE

ADJUSTMENT

ADJUSTMENT

DS1 SWITCH SETTINGS FACTORY SETTINGS

SW-1 AUTO CLOSE T IMER ENABLE OFF

O

N

SW-2 TIMER TO CLOSE WILL ACTIVATE ON LIMIT ONLY ON

SW-3 MASTER GATE EN ABLE ON

SW-4 SLAVE GATE EN ABLE OFF

SW-5 SOLENOID LO CK OPTION, SEE INSTALLATION MANUAL OFF

SW-6 SOFT STO P RETRACT ENABLE OFF

SW-7 SOFT ST OP EXTEND ENABLE OFF

SW-8 STOP CIRCUIT ENABLE OFF

SW-9 OPERATING DIRECTION REVERSE OFF

SW-10 SOFT START ENABLE FOR SW6 AND SW 7

LED INDICATOR

Timer

5

10

10

0

TIMER TO CLOSE

1 2 3 4 5 6 7 8 9101112

J2

Entrapment

Siren Output

5

10

15

S

M

C

O

C

O

A

O

U

O

L

G

M

T

M

O

L

M

P

M

N

O

O

U

O

O

C

N

T

N

I

K

+

D

G

1

G

L

N

2

N

O

D

V

D

C

K

15

O

SOLONOID LOCK ENABLE

N

MAGNETIC LOCK ENABLE

SECURITY SHUNT ENABLE

MOTION DETECTOR ENABLE

S

S

E

H

C

U

U

N

R

T

I

T

Y

0

Master

actuator

connector.

Slave

Illustration 17

STEP 7 Connecting Control Board / Battery to the Wiring Harness

Verify that the wiring harness is not connected to the control board. Install the battery into the backside of the

operator. Connect the wiring harness Red wire to the positive post of the battery and the black wire to the

negative post of the battery. Connect the wiring harness to the Master connector on the control board.

STEP 8 Operating the Gate (Keep hands away from moving parts)

Verify that the gate is in the half open position and no objects are in the path of the gate.

Locate the “Open / Close Command” pushbutton on the Patriot control board, this will be used to operate the

gate.

Press the “Open / Close Command” pushbutton to operate the gate. Gate should travel in the open direction if

all settings are correct. If gate reverses direction a current sense adjustment must be made (see step 6 above).

Once current sense adjustment is made press the “Open / Close Command” button again.

If gate travels past the desired stop position adjust the limit switches, see page 13.

12

Page 15

LIMIT SWITCHES

The limit switch adjustments are located on the top shelf of the operator. Remove the cover from the operator to

make adjustments. The normal settings from the factory allow for about 15 feet of travel. You will most likely

have to adjust the limits for your installation. To adjust limits press down on the limit plate assembly, this will

release the limit plate from the limit adjustment cams and allow the cams to turn. Turn the limit adjustment

cam, which corresponds to the direction you want to adjust.

NOTE: WHEN THE LIMIT ADJUSTMENT CAM DEPRESSES THE LIMIT SWITCH ACTUATOR

THE GATE WILL STOP.

Top view of the operator

Close Limit Cam Nut

Limit Nut Locking

Limit Switches

NOTE: DO NOT ADJUST THE LIMIT CAM NUTS PAST THE LIMIT SWITCH ACTUATOR

ARM.THIS MAY RESULT IN DAMAGE TO THE LIMIT SWITCH. ENSURE THE LIMIT

PLATE ASSEMBLY SNAPS INTO THE GROOVES ON THE LIMIT CAM NUTS PRIOR

TO OPERATION.

CAUTION: To reduce the risk of injury, USAutomatic strongly recommends the installation of additional

safety devices such as Photo Eye Sensors and Safety Edges. Consult an authorized installing

dealer or the factory for a complete explanation of options and see the Safety Section of this

manual on pages 18 to 22.

Open Limit Cam Nut

Limit switch

actuator

13

Page 16

STEP 9 Making Final Adjustments

Once gate is operating correctly using the “Open / Close Command” pushbutton it is time to setup the radio

controls, transmitter and receiver. If your operator was supplied with the low current receiver see page 33 for

programming instructions. If not see instructions for your specific radio controls.

If you have an understanding of the sensitivity feature, test the sensitivity by manually stopping the gate in mid

travel. The sensitivity setting most likely will be around a 5 or 7 setting on the adjustment.

Operate the gate using the transmitter, the gate should stop in the desired position if not readjus t the limit

switches. If the transmitter is not operating or operating incorrectly reprogram transmitter and receiver.

STEP 10 Installing Secondary Entrapment Siren (UL-325 requirement)

The secondary entrapment siren connects to the control board (Page 12, illustration 17). This siren is very loud

and will be activated when the current sense circuit stops the gate twice prior to reaching a fully open or close

limit. The siren will operate for 5 minutes before shutting off. The “Reset” button on the control board (Page 12,

illustration17) can be pushed to turn off the siren, and reset the control board. The control board must be reset

using the “Reset” button in either case before the gate will operate. The frame has two pre-punched holes below

the control board use these to secure the siren in place using the two snap in plastic fasteners.

STEP 11 Installing Safety Placards (UL-325 requirement)

Mount safety placards on gate. Two signs are provided. Place one sign on each side of the gate where it will be

highly visible to anyone on either side of the gate.

STEP 12 Installing Cover

Locate the emergency release access cover (round cover with USAutomatic logo), the shoulder screw and nut.

Install screw through emergency release access cover and install onto operator cover using the supplied nut.

Tighten nut securely.

Place the cover over the operator with the emergency release knob visible through the access hole. Secure in

place using the 4 – ¼” bolts and flat washers supplied. Slide the locking bar through slot cut below access hole

and secure to emergency manual release access cover, using a lock.

NOTE: USAutomatic strongly recommends the Emergency manual release access cover be securely

locked in place using the locking bar and pad lock (pad lock not supplied)

14

Page 17

Circuit Board & Terminal Description

Patriot Control Board

USAutomatic MADE IN USA

PATRIOT CONTROL BOARD

DS1

1

2

3

4

5

6

7

8

9

10

S2

J2 INDICATORS

1- +12V OUT 1.5 AMP MAX

2- COMMON GROUND

3- PUSH BUTTON INPUT

4- OPEN SAFETY EDGE

5- CLOSE INPUT

6- SECONDARY ENTRAPMENT DEVICE INPUT

7- COMMON GROUND

8- STOP CIRCUIT INPUT N/C

9- FREE EXIT / OPEN INPUT

10- UNDER GATE / CENTER LOOP INPUT

11- SAFETY LOOP / REVERSING ED GE INPUT

12- MOTION DETECTOR INPUT

Vehicular Gate Operator

Class I or Class II per UL325

Gate Weight Max. Load: 650 lbs.

TERMINAL DESCRIPTION

2 Common Ground Input

3 Push Button Input. (normally open contacts)

Push button, radio control, keypad, etc.

(Stops gate while opening)

(Stops a closed gate from opening)(Active on close limit only)

MASTER

SLAVE

Sensitivity

Sensitivity

5

10

0

CURRENT SENSE

CURRENT SENSE

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

DS1 SWITCH SETTINGS FACTORY SETTINGS

SW-1 AUTO CLOSE T IMER ENABLE OFF

O

N

SW-2 TIMER TO CLOSE WILL ACTIVATE ON LIMIT ONLY ON

SW-3 MASTER GATE EN ABLE ON

SW-4 SLAVE GATE EN ABLE OFF

SW-5 SOLENOID LO CK OPTION, SEE INSTALLATION MANUAL OFF

SW-6 SOFT STO P RETRACT ENABLE OFF

SW-7 SOFT ST OP EXTEND ENABLE OFF

SW-8 STOP CIRCUIT ENABLE OFF

SW-9 OPERATING DIRECTION REVERSE OFF

SW-10 SOFT START ENABLE FOR SW6 AND SW 7

LED INDICATOR

BOTH ON FOR DUAL

OFF

RESET

OPEN/CLOSE

COMMAND

Timer

5

5

10

10

0

0

TIMER TO CLOSE

1 2 3 4 5 6 7 8 9 10 11 12

J2

Entrapment

Siren Output

15

S

C

M

O

C

O

O

U

A

O

L

M

T

G

M

O

M

P

L

M

N

O

U

O

O

O

N

T

C

N

I

+

K

D

G

1

G

L

N

2

N

O

D

V

D

C

K

15

O

SOLONOID LOCK ENABLE

N

MAGNETIC LOCK ENABLE

SECURITY SHUNT ENABLE

MOTION DETECTOR ENABLE

S

S

E

H

C

U

U

N

R

T

I

T

Y

1 + 12 volt DC Output.

*Maximum current output 1.5 amp (1500 milliamps)

4 Open Safety Edge (normally open contacts)

5 Close Input (normally open contacts)

6 Secondary Entrapment Input (normally open contacts)

7 Common Ground Input

8 Stop Circuit Input (normally closed contacts)

* DS1 switch #8 must be on for stop circuit function to be enabled.

9 Free Exit/Open Input (normally open contacts)

Loop input or any hold open input such as a 7-day timer, telephone access unit,

or maintain contact switch (normally open contacts). These devices open the

gate and will prevent the gate from closing if the contact is maintained. Once

the contacts have been released, the gate can be closed with a closing signal

device or the automatic close timer feature.

10 Center Loop or Under Gate Loop Input (normally open contacts)

11 Safety Loop/Reversing Edge Input/Photo-Eye (normally open contacts)

12 Motion Detector Input (normally open contacts)

15

Page 18

USAutomatic MADE IN USA

DS1 Programming Switches

PATRIOT CONTROL BOARD

1

2

3

4

5

6

7

8

9

10

S2

J2 INDICATORS

1- +12V OUT 1.5 AMP MAX

2- COMMON GROUND

3- PUSH BUTTON INPUT

4- OPEN SAFETY EDGE

5- CLOSE INPUT

6- SECONDARY ENTRAPMENT DEVICE INPUT

7- COMMON GROUND

8- STOP CIRCUIT INPUT N/C

9- FREE EXIT / OPEN INPUT

10- UNDER GATE / CENTER LOOP INPUT

11- SAFETY LOOP / REVERSING ED GE INPUT

12- MOTION DETECTOR INPUT

Gate Weight Max. Load: 650 lbs.

Factory settings are shown in bold italic type

Sensitivity

5

10

0

CURRENT SENSE

ADJUSTMENT

DS1

O

N

Vehicular Gate Operator

Class I or Class II per UL325

ADJUSTMENT

DS1 SWITCH SETTINGS FACTORY SETTINGS

SW-1 AUTO CLOSE T IMER ENABLE OFF

SW-2 TIMER TO CLOSE WILL ACTIVATE ON LIMIT ONLY ON

SW-3 MASTER GATE EN ABLE ON

SW-4 SLAVE GATE EN ABLE OFF

SW-5 SOLENOID LO CK OPTION, SEE INSTALLATION MANUAL OFF

SW-6 SOFT STO P RETRACT ENABLE OFF

SW-7 SOFT ST OP EXTEND ENABLE OFF

SW-8 STOP CIRCUIT ENABLE OFF

SW-9 OPERATING DIRECTION REVERSE OFF

SW-10 SOFT START ENABLE FOR SW6 AND SW 7

LED INDICATOR

BOTH ON FOR DUAL

OFF

RESET

OPEN/CLOSE

COMMAND

SLAVE

Sensitivity

CURRENT SENSE

ADJUSTMENT

Timer

5

5

10

10

0

0

TIMER TO CLOSE

1 2 3 4 5 6 7 8 9101112

J2

Entrapment

Siren Output

15

S

S

C

M

O

C

U

O

T

M

P

M

U

O

N

T

+

1

G

2

N

V

D

S

O

E

O

A

H

L

C

M

G

U

O

U

M

L

N

N

R

O

O

T

O

I

N

C

I

T

K

D

Y

G

L

N

O

D

C

K

MASTER

1 Automatic close timer enable

ON Timer to close is activated (Safety accessories recommended if turned on)

OFF Timer to close is disabled

2 Timer to close will activate on limit only

ON Timer to close activates only if open limit is activated

OFF Timer to close works from any point the gate is stopped

3 Master Gate Enable

ON Master gate operator enabled to function

OFF Master gate operator disabled

Both must be on for dual gate operation

4 Slave Gate Enabled

ON Slave gate operator enabled to function

OFF Slave gate operator disabled

5 Solenoid lock option

ON In addition to solenoid lock DS2, outputs 12vdc when gate is moving

OFF Disables 12vdc output when gate is moving

6 Soft stop open enable (Right hand installation, if switch 9 is on then close enable)

ON Enables soft stop for open position

OFF Disables soft stop for open position

7 Soft stop close enable (Right hand installation, if switch 9 is on then open enable)

ON Enables soft stop for extend position

OFF Disables soft stop for extend position

8 Stop circuit enable

ON Allows for a stop button input to be utilized

* a normally closed pushbutton is required

OFF Disables the stop button function

9 Operating Direction Reverse

ON Left Hand Slider installation (See note bottom page 11)

OFF Right Hand Slider Installation

10 Not used at this time

ON N/A

OFF N/A

15

O

SOLONOID LOCK ENABLE

N

MAGNETIC LOCK ENABLE

SECURITY SHUNT ENABLE

MOTION DETECTOR ENABLE

16

Page 19

DS2 Programming Switches

USAutomatic MADE IN USA

PATRIOT CONTROL BOARD

DS1

1

2

3

4

5

6

7

8

9

10

S2

J2 INDICATORS

1- +12V OUT 1.5 AMP MAX

2- COMMON GROUND

3- PUSH BUTTON INPUT

4- OPEN SAFETY EDGE

5- CLOSE INPUT

6- SECONDARY ENTRAPMENT DEVICE INPUT

7- COMMON GROUND

8- STOP CIRCUIT INPUT N/C

9- FREE EXIT / OPEN INPUT

10- UNDER GATE / CENTER LOOP INPUT

11- SAFETY LOOP / REVERSING ED GE INPUT

12- MOTION DETECTOR INPUT

Vehicular Gate Operator

Class I or Class II per UL325

Gate Weight Max. Load: 650 lbs.

Factory settings are shown in bold italic type

MASTER

SLAVE

Sensitivity

Sensitivity

5

5

10

0

CURRENT SENSE

ADJUSTMENT

BOTH ON FOR DUAL

OFF

RESET

OPEN/CLOSE

COMMAND

0

CURRENT SENSE

ADJUSTMENT

ADJUSTMENT

DS1 SWITCH SETTINGS FACTORY SETTINGS

SW-1 AUTO CLOSE T IMER ENABLE OFF

O

N

SW-2 TIMER TO CLOSE WILL ACTIVATE ON LIMIT ONLY ON

SW-3 MASTER GATE EN ABLE ON

SW-4 SLAVE GATE EN ABLE OFF

SW-5 SOLENOID LO CK OPTION, SEE INSTALLATION MANUAL OFF

SW-6 SOFT STO P RETRACT ENABLE OFF

SW-7 SOFT ST OP EXTEND ENABLE OFF

SW-8 STOP CIRCUIT ENABLE OFF

SW-9 OPERATING DIRECTION REVERSE OFF

SW-10 SOFT START ENABLE FOR SW6 AND SW 7

LED INDICATOR

Timer

5

10

10

0

TIMER TO CLOSE

1 2 3 4 5 6 7 8 9 10 11 12

J2

Entrapment

Siren Output

15

S

C

O

M

C

O

O

U

A

O

L

M

T

M

G

O

M

P

L

M

N

O

U

O

O

O

N

N

T

C

I

+

K

D

G

1

G

L

N

2

N

O

D

V

D

C

K

15

O

SOLONOID LOCK ENABLE

N

MAGNETIC LOCK ENABLE

SECURITY SHUNT ENABLE

MOTION DETECTOR ENABLE

S

S

E

H

C

U

U

N

R

T

I

T

Y

1 Solenoid lock enable / Gate in operation indicator

ON Solenoid lock output energizes half second before gate begins to move and remains energized

until four seconds after reaching a limit (+12Vdc output 1.5 amp max)

OFF Solenoid lock / gate in operation indicator is inactive

2 Magnetic lock enable

ON Magnetic lock relay is active and will release half second before gate

begins to open (+12 vdc output 1.5 amp max)

OFF Magnetic lock relay is inactive

3 Security Shunt Circuit Enable / Open Gate Indicator

ON Security shunt circuit relay is active (closed circuit)(wire in parallel)

OFF Security shunt circuit relay is inactive (open circuit)

4 Motion Detector Enable

ON Activates motion detector input (if input is activated gate will not open)

OFF Disables motion detector input

Emergency Manual Release

Emergency manual release cover

Remove lock and rotate emergency manual release cover to the up position.

Pull manual release knob out (about ¾ inch)

Once knob has been pulled the gate can then be pushed by hand.

If knob cannot be pulled the gate may need to be agitated left or right.

To reset the knob push in on knob and roll gate until knob snaps in place. It may be

necessary to tap the knob inward to fully lock in place.

WARNING: Only insert hand into access hole as far as needed to grip the

release knob.

Trying to insert hand farther can result in injury.

17

Page 20

SAFETY SECTION

USAutomatic gate operators are certified to UL-325 Vehicular Class I and Class II slide gate standards.

UL325 identifies four different classes of gate operators. These classes are listed below:

Class I: Residential vehicular gate operator- a vehicular gate operator (or system) intended for use in a

Class II: Commercial/General access vehicular gate operator- a vehicular gate operator (or system) intended

Class III: Industrial/Limited access vehicular gate operator- a vehicular gate operator (or system) intended for

Class IV: Restricted Access vehicular gate operator- a vehicular gate operator (or system) intended for use in

The Patriot slide gate operator is designed and intended for use on Class I or Class II vehicular gate installations.

The maximum load of each gate leaf should not exceed 600 pounds with a length not to exceed twenty-four feet.

home of one to four single family dwellings or a garage or parking area associated therewith.

for use in a commercial location or building such as multi-family housing unit (five or more single

family units), hotel garages, retail store, or other buildings servicing the general public.

use in an industrial location or building such as a factory or loading dock area or other locations not

intended to serve the general public.

a guarded industrial location or building such as an airport security area or other restricted access

locations not servicing the general public, in which unauthorized access is prevented via

supervision by security personnel.

SECONDARY ENTRAPMENT DEVICES

USAutomatic has designed all control boards with secondary entrapment device inputs and secondary safety

devices must be installed with all installations. USAutomatic recommends the use of the following devices and

has provided herein instructions for the connection of such devices. UL-325 compliant devices are

recommended. This list does not contain all devices only the ones which have been tested and recommended at

the time of printing.

NOTE: USAutomatic recommends that these devices be CONNECTED after proper gate installation and

operation has been verified. Then connect one device and verify proper operation before installing

the next device. Ensure that power is disconnected from the control board prior to connecting any

wires to the control board.

Contact Safety Devices: Safety Edges (wireless)

Manufacturer - Miller Edge

Non-Contact Safety Device: Photo Eyes

Manufacturer – EMX Industries INC.

Entrapment Alarm Devices: Sirens

Manufacturer – USAutomatic

Model

W12b-3 Piezoelectric siren, 108db +12vdc

NOTE: For information about installation or applications, consult factory

Description

18

Page 21

SAFETY SECTION

INSTALLATION

a) Install the gate operator only when:

1) The operator is appropriate for the construction of the gate and the usage class of the gate,

2) All openings of a horizontal slide gate are guarded or screened from the bottom of the gate to a minimum of

4 feet (1.2m) above the ground to prevent a 2 ¼ inch (57.15mm) diameter sphere from passing through the

openings anywhere in the gate, and in that portion of the adjacent fence that the gate covers in the open

position,

3) All exposed pinch points are eliminated or guarded, and

4) Guarding is supplied for exposed rollers.

b) Only install on vehicular gates, pedestrians must be supplied with a separate access opening.

c) The gate is installed in a location where enough space is supplied between adjacent structures and the gate so

that when opening or closing the chance of entrapment is reduced.

d) The gate must be properly installed and work freely in both directions prior to the installation of the gate

operator. Do not minimize the sensitivity adjustment to compensate for an improper gate installation.

e) Locate all controls at least six feet away from the gate to eliminate the chance of the person operating the gate

from coming in contact with the moving gate. Do not install external buttons, which can be used to operate the

gate within the reach of children.

f) All placards must be installed one on each side of the gate and be visible in the gate area.

g) For gate operators utilizing a non-contact sensor:

1) See instructions on the placement of non-contact sensors for each type of application,

2) Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle, trips the sensor while

the gate is moving, and

3) One or more non-contact sensors shall be located where the risk of entrapment or obstruction exist, such as

the perimeter reachable by a moving gate or barrier.

h) For gate operators utilizing a contact sensor:

1) One or more contact sensors shall be located at the leading edge, trailing edge, and post mounted both inside

and outside of a vehicular horizontal slide gate.

2) A hardwired contact sensor shall be located and it’s wiring arranged so that the communication between the

sensor and the gate operator is not subjected to mechanical damage.

3) A wireless contact sensor such as one that transmits radio frequency (RF) signals to the gate operator for

entrapment protection functions shall be located where the transmission of the signals are not obstructed or

impeded by building structures, natural landscaping or similar obstruction. A wireless contact sensor shall

function under the intended end-use conditions.

WARNING: TO REDUCE THE RISK OF INJURY OR DEATH

1. READ AND FOLLOW ALL INSTRUCTIONS

2. Never let children operate or play with gate controls. Keep remote control away from children.

3. Always keep people and objects away from the gate. NO ONE SHOULD CROSS THE PATH OF A

MOVING GATE.

4. Test gate operator monthly. The gate must stop and reverse directions upon contacting a rigid object

or when the secondary entrapment device is activated.

5. After all adjustments have been made to the limit switches, sensitivity (current sense) circuit, secondary

entrapment devices and all other external devices installed the safety devices must be checked again.

Failure to adjust and retest the gate operator can increase the risk of injury or death.

6. Verify that the emergency release (manual release) knob can be pulled easily. This should only be

checked when power is disconnected from the operator.

7. KEEP GATES PROPERLY MAINTAINED. Read the user manual and have a qualified service

8. THE ENTRANCE IS TO BE USED BY VEHICLES ONLY. Pedestrians must use a separate entrance.

technician make repairs to the gate hardware.

9. SAVE THESE INSTRUCTIONS

19

Page 22

SAFETY SECTION

All safety features required by UL-325 and more are incorporated in the capabilities of all USAutomatic

Control boards and should be utilized, including but not limited to, safety edges, photo electric eyes, reverse

sensing, and motion sensing.

Cautions - Very Important

¾ Do not attempt to enter the gate area while the gate is moving. Wait until the gate comes to a complete stop.

¾ Operate the gate only when it is fully visible, free of persons or obstructions, and properly adjusted.

¾ Do not allow children to play in the area of the gate. Do not allow anyone to ride on the gate.

¾ Do not allow children to play with the remote control or any other activation device.

¾ Do not attempt to "beat the gate" while the gate is opening or closing. This is extremely dangerous.

¾ Test the current sense feature and all safety devices regularly to insure correct operation.

¾ Study this entire Safety Section paying particularly close attention to the entrapment zones shown below

and be aware of these areas not on during use but also during any adjustments to the unit.

ENTRAPMENT ZONES

Zone 1

SIDE VIEW

Zone 3

Zone 1 The leading edge of the gate & fence post.

Zone 2 Between the gate and fence pocket.

Zone 3 The gate track and wheel.

Zone 4 The path the gate travels across the drive. (traffic area)

Zone 5 The path the gate travels when opening (back track gate area)

Zone 4

Zone 2

Zone 5

LEADING EDGE GATE VIEW

Gate Rollers

Fence

Gate Leading Edge

Zone 2

20

Page 23

SAFETY SECTION

Remedies for Safety Concerns

Zone 1 Safety edges and photo electric eyes are the most common types of protection available.

Zone 2 A safety edge may also be utilized here but the best remedy is to eliminate pinch points when

designing the gate. Most injuries at this point result from negligence, such as reaching through the

gate to activate a button, key switch, etc., or riding the gate open.

Contact Safety Edge Photo Eye Beam

Direction of Gate Travel

Gate Rollers

Fence

Gate Leading Edge

LEADING EDGE GATE

Zone 2

Zone 3 This area is best protected with proper gate construction and installation. Care must be taken to

minimize the exposed wheel to track area. A photo-eye or contact edge might also work in this area

depending on your gate construction.

NOTE: All control stations should be located at least 6 feet from any moving part of the gate or operator.

SIDE VIEW

See Safety section page 19 under installation a.)

3 and 4 for more information.

Zone 3

Never install any control device where a user will be tempted to reach through the gate or

fence to activate a gate.

21

Page 24

SAFETY SECTION

Remedies for Safety Concerns

Zone 4 This area is best protected with a photo eye or contact edge wired to the secondary entrapment

input or safety loop input depending on the desired function of the safety device. The beam should

be installed parallel to the gate and extend across the drive area to prevent the gate from closing or

opening on an object in the path of the gate. If the intent of the beam is to prevent the gate from

closing when an object is present. Wire the photo eye to safety loop input on the control board.

Zone 4

Zone 5 Safety edges and photo eyes are the most common types of protection available. The safety device

used should be wired to the secondary entrapment input.

GATE

Entrapment area

see safety section page

19 part a, 1 through 4.

Every installation is unique and it is the installer's responsibility to recognize and remedy all safety concerns.

Please consult a qualified dealer or the factory for a complete explanation of the remedies shown above and

additional tips pertaining to your installation.

O

B

J

E

C

T

22

Page 25

MONTHLY SERVICE

All gate operators require periodic checking and adjustments by a qualified technician of the control

mechanism for force (load), speed and sensitivity. All external accessories and secondary safety

devices must be checked. Secondary safety devices need to be checked at least once a month for

proper operation.

Periodic checking is also advised for the following:

1. Battery cells water level. (use distilled water if needed) Gel batteries are recommended

2. Wheels and gate rollers for wear and grease if necessary.

3. Check bolts and sprocket set screws for correct tightness.

4. Inspect weld points for cracks or other defects.

5. Inspect wiring for cuts, nicks or other defects.

6. Inspect drive chain and sprockets for tension and wear. Adjust or replace as necessary.

7. Time to open or close the gate, this will be first indication of a battery or charging problem.

Troubleshooting Introduction

The USAutomatic control board is equipped with three unique features to assist in

troubleshooting a gate system.

1. The first and most helpful is the series of LED indicating lights. These lights will help to

identify problems with the limit switches and all control circuits. To use the indicators,

press and hold the LED indicator button on the control board. (The lights are not active at

all times to save battery life). Any circuits or limit switches that are activated will be

identified by the illumination of the adjacent LED indicating light.

2. The second feature to assist in troubleshooting is the current sense beeper. The beeper

will sound anytime the current sense circuit is activated. This is useful in detecting a

false reverse due to an improper or too sensitive current reverse setting or a gate that is

requiring excessive force to move.

3. The third feature to assist in troubleshooting is the on board open/close command

pushbutton. This button makes it possible to operate the gate with the twelve terminal

wiring plug removed without having to short across terminal pins.

Current Sense

Beeper

LED indicator

button

LED indicators J2

Open/Close

command push

button

USAutomatic MADE IN USA

PATRIOT CONTROL BOARD

DS1

1

2

3

4

5

6

7

8

9

10

S2

J2 INDICATORS

1- +12V OUT 1.5 AMP MAX

2- COMMON GROUND

3- PUSH BUTTON INPUT

4- OPEN SAFETY EDGE

5- CLOSE INPUT

6- SECONDARY ENTRAPMENT DEVICE INPUT

7- COMMON GROUND

8- STOP CIRCUIT INPUT N/C

9- FREE EXIT / OPEN INPUT

10- UNDER GATE / CENTER LOOP INPUT

11- SAFETY LOOP / REVERSING ED GE INPUT

12- MOTION DETECTOR INPUT

Vehicular Gate Operator

Class I or Class II per UL325

Gate Weight Max. Load: 650 lbs.

MASTER

SLAVE

Sensitivity

Sensitivity

5

5

10

0

CURRENT SENSE

ADJUSTMENT

BOTH ON FOR DUAL

OFF

RESET

OPEN/CLOSE

COMMAND

0

CURRENT SENSE

ADJUSTMENT

ADJUSTMENT

DS1 SWITCH SETTINGS FACTORY SETTINGS

SW-1 AUTO CLOSE T IMER ENABLE OFF

O

N

SW-2 TIMER TO CLOSE WILL ACTIVATE ON LIMIT ONLY ON

SW-3 MASTER GATE EN ABLE ON

SW-4 SLAVE GATE EN ABLE OFF

SW-5 SOLENOID LO CK OPTION, SEE INSTALLATION MANUAL OFF

SW-6 SOFT STO P RETRACT ENABLE OFF

SW-7 SOFT ST OP EXTEND ENABLE OFF

SW-8 STOP CIRCUIT ENABLE OFF

SW-9 OPERATING DIRECTION REVERSE OFF

SW-10 SOFT START ENABLE FOR SW6 AND SW 7

LED INDICATOR

Timer

5

10

10

0

TIMER TO CLOSE

1 2 3 4 5 6 7 8 9101112

J2

Entrapment

Siren Output

23

LED indicators for

15

15

master /Slave limits.

Master Close limit

Master Open limit

O

SOLONOID LOCK ENABLE

N

MAGNETIC LOCK ENABLE

SECURITY SHUNT ENABLE

MOTION DETECTOR ENABLE

S

M

O

C

U

O

T

M

P

M

U

O

T

N

+

1

G

2

N

V

D

S

C

S

O

A

E

O

H

L

G

C

M

U

O

L

U

M

N

N

O

R

O

T

O

C

I

N

I

K

T

D

Y

G

L

N

O

D

C

K

Slave Close limit

Slave Open limit

Page 26

TROUBLESHOOTING SECTION

OUTLINE

1 My slide gate operator will not operate.

2 Emergency release knob cannot be pulled.

3 I can hear gate operator running but my gate is not moving.

4 Gate operates slowly when opening or closing, may stop before cycle is complete.

5 My gate will not automatically close.

6 Gate begins to open or close but stops and reverses after a couple of seconds.

7 Gate opening or closing stops and reverses direction and then stops and will not operate.

8 Gate opens or closes correctly then immediately reverses direction.

9 Gate closes then opens back up in 10 seconds or more, auto close timer is on.

10 Control board 15 amp fuse blows when open/close command is given.

11 Transmitter (Remote control) will not operate the gate.

12 Photo eye, safety loop or other safety accessory will not reverse the gate when closing.

13 Pressing the “RESET” button only, causes the gate to operate.

14 Gate opens using transmitter, but will not close using transmitter (low current receiver only)

15 Gate only operates when the “LED INDICATOR” is pressed.

Terms and Definitions

LED - Light emitting diode, small red lights on control board.

Control board- Located inside the metal box just above the battery.

Receiver - Located inside the metal box in the upper right corner, coax cable connected to it.

Transmitter - Hand held push button, which is used to operate the gate, sends signal to receiver.

Harness - Wire bundle connected to the control board, limit switch plate and motor.

Connector - Control board has two types. Two white 8-pin connectors (X1 and X2) are used to connect actuator

to control board and one green 12-pin connector (J2) (located bottom center of control board) to

connect receiver and accessories to control board. Both are plug type and can be disconnected

(unplugged from control board) without disconnecting wires.

Dip Switches - Small switches, which are located on the control board in two places. The primary set DS1 is

located in the upper left corner and the secondary set DS2 are located in the lower right corner of

the control board with functions listed beside each. See manual (page 16, 17) for more information.

Open position is off or switch not closed.

Push Buttons - Three are located on the control board. “Open/Close command” used to operate the gate, “Led

Indicator” used to activate the leds and the “Reset” used to reset the control board after current

sensing twice before a limit is reached.

Limit Cam Nut Locking Plate – Located on top of the operator, holds the two limit switches and also holds the

limit cam nuts in their adjusted position.

24

Page 27

Limit Cam Nut - Two limit cam nuts are located on the top of the operator; the limit nut locking plate is spring-

loaded and must be depressed before adjusting the limit cam nut. After limit cam nut has been

adjusted make certain that the limit nut locking plate fully engages the limit cam nut to keep it from

rotating.

Gate Chain - This is the long chain connected to the gate and travels through the operator.

Drive Chain - This is the short chain that connects the gear motor to the manual release shaft.

1. Slide gate operator will not operate:

STEP 1 Remove control box cover locate the “Open/Close Command” push button and press it to operate the gate.

STEP 2 Press the “Reset” push button located above the open close command, then push the “Open/Close Command” push

STEP 3 When pressing the “Open/Close Command” push button, listen for a clicking sound, if click is heard then verify: The

STEP 4 Press and hold the “LED Indicator” push button and observe all of the red LED’s (see page 23 for location):

STEP 5 Disconnect the green J2 connector. Once disconnected, press the “Open/Close Command” button. If gate operates go

STEP 6 Verify that DS1 switch 8 is off.

STEP 7 Call the factory for more information if the above steps have not worked.

2. Emergency release knob cannot be pulled:

STEP 1 If the emergency release knob cannot be pulled first verify that it is not already pulled, by trying to roll the gate. If gate

STEP 2 Emergency release knob that is difficult to pull represents something is in a bind. Check the gate wheels and guide

NOTE: DO NOT ATTEMPT TO MODIFY ANY SCREWS ON THE DRIVE SHAFT.

3. I can hear gate operator running but my gate is not moving:

STEP 1 The most likely cause is the emergency manual release knob is pulled ou t. To correct open the emergency release

STEP 2 Other causes could be the gate chain is disconnected, the drive chain on the gear motor is disconnected or one of the

4. Gate operates slowly when opening or closing, may stop before cycle is complete:

NOTE: When the gate is running slow the reason is low battery voltage, two things need to be considered. Battery condition

STEP 1 Determine which situation your operator falls into below:

Solar charged, ensure that you have a deep cycle battery installed and if accessories are connected (keypads, loop

button to operate the gate.

15-amp fuse located on the control board is good if not replace it using the spare located on the control board. Also

check the dipswitches (3 and 4) for correct switch settings based on where the harness is connected to the control

board (Master or Slave). If switches and fuse are good and clicking sound is heard the battery n eeds to be load tested

to determine its condition. Charge or replace depending on results.

a. If the two limit LED’s located below the actuator plug are both on the operator will not operate. Verify that only

one or no limit LED’s are on. If both limit LED’s are on adjust limit cam nuts to the correct location.

b. If any of the LED’s in the lower left corner of the control board are on then this must be corrected. Locate the

accessory, which is activated, and repair or replace. Disconnecting this device will allow the operator to work,

without the disconnected accessory function.

to step 4 b above.

will not move try to pull the emergency release knob while agitating the gate (shake gate in direction of travel).

rollers. Verify the chain is on all the rollers and not twisted or over tight.

cover and push knob in, it may be necessary to roll gate while pushing the knob in. The knob must be pushed in all the

way and it may be necessary to remove the cover to verify. When fully pushed in the space between the plastic safety

disk and the shaft collar should be about ¼”.

sprockets is freewheeling. Identify any of these by removing the cover and inspecting and correct as necessary.

needs to be checked a load test is needed (replace or charge) and determine what caused the battery to become

discharged.

detectors, any device powered by the battery) verify that the current draw needed to power them does not exceed the

25

Page 28

charging power of the solar panel. Verify that solar panel leads are connected to the battery correctly; panel is facing a

southwest direction and is not located in a completely shaded area. Inspect panel surface and wires for damage.

Test solar panel for correct voltage and current output, disconnect panel wires from battery and using a DC voltmeter

measure the dc voltage (should measure about 22 volts) and the dc current (should read about 250 ma) in the peak sun

period. If either, of these readings is incorrect panel maybe defective.

If none of the above check bad then remove battery and have it load tested

at a battery shop. Replace if bad.

AC charged, ensure that you have a deep cycle battery rated at a minimum of 33 amp-hour installed. If accessories are

connected (keypads, loop detectors, any device powered by the battery) verify that the current draw needed to power

them does not exceed the charging power of the charger. Verify that charger leads are connected to the battery

correctly; charger is connected to an approved 110 VAC receptacle. Inspect charger and wires for corrosion or

damage.

NOTE: The USAutomatic multi stage charger does not output any voltage when disconn ected from the battery, you cannot

check charger by disconnecting from battery and measuring voltage output. To check charger output disconnect from

battery, measure battery voltage and note. Reconnect charger and monitor battery voltage it should rise above the

battery voltage noted above.

STEP 2 The charger has lED indicators (lights) on the faceplate, observe the leds that are on or not and refer to the

troubleshooting directions furnished with the charger for defini t i ons of different led indicators.

STEP 3 If none of the above check bad then remove battery and have it load tested at a battery shop. Replace if bad.

5. My gate will not automatically close:

NOTE: If DS1 switch 1 is on and switch 2 is off then the gate should automatically close from any position, but if switch 2 is

also on the gate will only automatically close if the “open limit” LED (both “open limit” LED’s for dual gate) is on.

STEP 1 Locate the “Open/Close Command “ push button; press the button to verify that the gate will close. If gate closes

STEP 2 Verify that DS1 switch 1 is on. If not turn it on and recheck gate operation. If gate remains open continue with step 3.

correctly then proceed to the steps below.

STEP 3 If your installation is a single gate, then only DS1 switch 3 or 4 can be on. If both are on the gate will not

automatically close. Turn off the one that is not being used and recheck gate operation.

STEP 4 Locate the “LED Indicator” push button and depress and hold. While pushing the button inspect the LED indicators

located just below the X1, X2 (master, slave) actuator plugs, note which LED’s are on. Read note below.

NOTE: The two LED’s located below the X1, X2 actuator plug when on represent the closure of the limit switch. If the left

LED is on then the gate should be in the open position, if the LED on the right is on then the gate should be in the

closed position. If DS1 switch 9 (operating direction reverse) is on then this is reversed. If the LED for the open

position is not on when the gate is fully opened then the auto close will not work if DS1 switch 2 is on. The limit

switches need to be adjusted or DS1 switch 2 needs to be turned off. If gate still remains open go to step 5.

STEP 5 Locate the “LED Indicator” push button and depress and hold. While pushing the button inspect the LED indicators

located on the control board (lower left cor n er) an d not e which ones are on. If any LED’s are on disconnect the green

J2 connector from the control board. Press the “Open/Close Command “ push button to close the gate, and then press

the button again to open the gate fully and verify the automatic close is working.

STEP 6 If gate automatically closes correctly then the accessory connected to the J2 connector that is activated (LED is on)

6. Gate begins to open or close but stops and reverses after a couple of seconds.

needs to be repaired.

STEP 1 Remove gate operator cover and locate the Patriot control board . Locate the sensitivity adjustment (see page 12)

potentiometer located on the control board. The white center is adjustable an d needs to be turned in a clockwise

direction.

STEP 2 Normally a setting of 5 will operate most gates; if your gate requires a setting above 6 there is a good chance that your

gate has a problem, which needs to be corrected. Possible causes are incorrect alignment, something is interfering with

the gate, guide rollers are binding, gate not level or the gate chain is too tight. Identify and correct problem.

STEP 3 Other causes could be a safety device connected that is activated. Locate the “LED Indicator” push button and press and

hold operate the gate and note any LED’s that come on. If LED comes on identify the accessory connected to that input

and correct the accessory problem.

STEP 4 Contact the factory for further information.

26

Page 29

7.

Gate opening or closing stops and reverses direction and then stops and will not operate

STEP 1 This is most likely caused by an incorrect sensitivity adjustment. It could also be caused by an obstruction located in the

path of the gate.

STEP 2 Open the emergency manual release cover and pull the release knob. Then roll the gate fully open and closed to verify

that it is rolling freely. If gate is moving freely then the sensitivity adjustment needs to be checked.

STEP 3 Remove the cover and locate the sensitivity ad justment on the control board. The Master and Slave both need to be

8. Gate opens or closes correctly then immediately reverses direction:

checked even if only one is being used. If the setting is above 6 verify again that the gate is moving freely

STEP 1 This is most likely caused by an incorrect limit switch adjustment, which is causing the gate to travel too far and the

operator to current sense. The limit switch adjustments are located on the limit plate. Remove the gate operator cover

and locate the limit plate and limit cam nuts.

STEP 2 Adjust the limit cam nut so that it is closer to the limit switch for the gate position being worked on. This will cause

the limit cam nut to contact the limit switch earlier, which will stop the gate earlier than before. This needs to be done

until the gate stops at the desired position. See note below.

STEP 3 It might be necessary to verify limit switch operation. To do this locate the “LED Indicator” push button and hold in.

Then depress the limit switch lever and observe the limit LED’s located on the control board. The LED should come

on when the limit switch lever is depressed and the “LED Indicator” push button is depressed.

NOTE: If DS1 switch 9 is turned on, then the open and close LED lights are reversed. Open LED represents the closed

STEP 4 If the LED lights will not come on then contact the factory.

9. Gate closes then opens back up in 10 seconds or more, auto close timer is on

position and the close LED represents the open position.

STEP 1 This is most likely caused by an incorrect DS1 switch 9 setting. When standing on the inside of the property and

looking out of the gate which side of the drive is the gate operator installed on? If it is on the right side then DS1

switch 9 should be in the off position. If operator is on the left side of the drive then it should be in the on position.

STEP 2 If this does not correct the problem then the limit wires are connected incorrectly. Locate the limit switches and the

STEP 3 If the gate still operates incorrectly contact the factory.

10. Control board 15 amp fuse blows when open/close command is given.

orange and white wires connected to them. The white wire should be connected to the switch closest to the gate.

STEP 1 Fuses blow primarily for one reason, the gate cannot move. Causes might be something keeping the gate from moving,

the gate is trying to move in the wrong direction due to incorrect limit switch setting or there might be a wiring

STEP 2 See problem number 8 above and verify.

problem.

STEP 3 Press the “LED Indicator” push button and hold it in, observe the LED lights and determine if the open limit or close

limit LED is on. Then determine if the correct LED is on for the gate position.

For example if the left LED is on that is the open limit and the gate should be in the open position. The right LED

represents the closed position.

See note under problem 8 above.

STEP 4 If the open limit LED is on and the gate is closed if a command to operate is given the gate will try to close more,

which can blow a fuse. If the close limit LED is on and the gate is opened a command to operate will try to open the

gate more, which can blow a fuse. In either case the limit switches need to be adjusted and then the cause for them

becoming misadjusted needs to be determ i ned.

STEP 5 Another possible cause is a bad brake on the gear motor. If the brake is on the motor cannot turn and the fuse will

blow. It is possible for low battery voltage to cause this so the battery needs to be checked. If battery load tested good

then contact the factory.

STEP 6 If the gear motor brake is the cause the brake can be disconnected to verify. Please contact factory for further

troubleshooting and return information.

27

Page 30

11. Transmitter will not operate the gate

STEP 1 Verify the battery in the transmitter is good. Also verify that the dipswitches inside the transmitter and receiver are set

to match each other. Remove the receiver cover by squeezing the sides and the switches are located inside. Remove

the transmitter cover and locate the switches.

STEP 2 Remove the gate operator cover and locate the Patriot control board. Locate the “LED Indicator” push button and the

“Push Button Input” LED. Push the “LED indicator” push button and hold, then press the transmitter button and

observe the “Push Button LED”. The led should come on while the transmitter button is depressed.

STEP 3 If the “Push Button LED” did not come on then make sure that the green J2 connector on the control board is securely

connected. Remove the receiver cover by squeezing the sides and the switches are located inside.

STEP 4 If the “Push Button Input” LED in step 1 did come on and the gate did not operate then locate the “Open/Close

Command” button located at the bottom center of the Patriot control board. Press the “Open/Close Command” button

and note gate operation.

STEP 5 If the gate did not operate in step 3 verify that the 15-amp fuse on the Patriot control board adjacent to the actuator

plug being used is not blown, (a fuse can be blown and look good) replacing is the best way to verify fuse is good.

STEP 6 If the gate did not operate in step 3 and the fuse was good in step 4 then most likely a safety accessory connected to the

green J2 connector is active. Verify this by depressing the “LED Indicator” push button and observe the leds located in

the lower left corner of the Patriot control board. If a LED is on identify the accessory connected to the corresponding

J2 connector pin and correct the problem.

STEP 7 Other causes are possible, both the open and close limit LED’s are on at the same time, if so adjust limit switches.

Control board could be defective; battery could be too weak to operate the gate. Please call the factory for help