Page 1

SYMPTOMS PROBABLE CAUSES CORRECTIVE ACTIONS

The door will not open and the LED does not light up The sensor is not properly powered a. Check the power supply

b. Check the supplied voltage

The door will not open and the LED lights up The wiring of the relay output is not Check the relay wiring

connected correctly

The door opens when no detection occurs and closes The mode of the relay output is Change the dip-switch #2 position

during a detection not correct

The sensing field does not correspond to your The cut of the masking lens is wrong Cut out a new lens to meet the required

requirements sensing field size

TROUBLESHOOTINGS

42.0006/V1-12.01 732937 - Rev. A

FAAC S.p.A. - Via Benini, 1 40069 Zola Predosa - Italia - tel.+39 051 61724 - fax.+39 051 758518 - www.faacgroup.com

C. SETTING THE SENSING FIELD

•To adjust the sensing field according to your specific needs, use the masking delivered in the sensor box;

The minimum detection area at mounting height of 2.2 m is 0.5 m x 0.5 m

•To tailor the sensing field, cut segments

Remarks :

1) Be careful to cut just entire segments

2) It is necessary to cut at least one segment to get a detection

To insert the masking lens :

•Consider the position of the guide pins when inserting both legs of the masking lens to the front cover

•Gently push both legs of the masking lens

To remove the masking lens :

•Insert the screwdriver between the leg of the masking lens and the leg of the front cover

•Use it as a lever downwards

ASYMMETRICAL SENSING FIELD SHORTER DEPTH

SENSING FIELD

DETECTION AREA DETECTION AREA

±10 cm ±10 cm

door threshold door threshold

TECHNICAL

SPECIFICATIONS

THE MOST ADVANCED TECHNOLOGY IN PASSIVE INFRARED SENSOR RANGE

DESCRIPTION

INSTALLATION

TIPS

The passive infrared

sensor

FSA Accessory

for mounting on the wall

The BFP1 is designed for use in opening of automatic doors with small and medium sized sensing fields

It is not recommended for automatic doors with large sensing fields (BFR1 range is recommended) or automatic doors when shopping

carts or trolleys are used.

Technology Passive infrared and microprocessor

Optical characteristics P.I.R. with 4 elements, 15 Fresnel

lenses with full independent masking

possibilities

Mounting height 3 m max

Maximum Detection area for mounting height of 2.2m

2.5 m (W) x 1.5 m (D)

Minimum Detection area for mounting height of 2.2 m

0.5 m (W) x 0.5 m (D)

Detection mode motion

Detection speed 0.1 to 1.5 m/s

Light indicator 1 red LED

Warm up 10 s

Hold time 0.5 s or 2 s

Response time < 200 ms

Power supply 12 VDC –10% to 24 VDC +30%

12 to 24 V AC ±10%

Mains frequency 50/60 Hz

Power consumption < 1 W

Connection small plug-in 5 contacts connector

Recommended cable

section

< 0.5 mm

2

Length of cable 2.5 m

Temperature range from –30°C to +55°C

Standard output relay (free potential change-over contact)

•Max contact voltage 60 V DC/ 42 V AC

•Max contact current 1A (resistive)

•Max switching power 30W (DC) / 60 VA(AC)

Manual adjustments

•shape of sensing field (masking lens)

•sensitivity (dip switch #1)

•relay configuration (dip switch #2)

•Hold time (dip switch #3)

Immunity electromagnetic compatibility (EMC)

according to 89/336/EEC and its

amendments.

• Color anthracite grey

• Weight 40g

• Dimensions 121mm (W) x 51mm (H) x 40mm (D)

• Degree of protection IP54

BFP1 USER’S GUIDE

•The sensor must be firmly

fastened in order to avoid any

vibrations

NODETECTION

NO DETECTION

Guide pins

Cut-Out footprints

Page 2

DIP SWITCHES ON OFF FACTORY SETTING

1 Sensitivity high Sensitivity low (recommended ON

for mounting height < 2,2 m)

2 Passive mode Active mode OFF

3 Hold time : 2 sec Hold time : 0,5 sec OFF

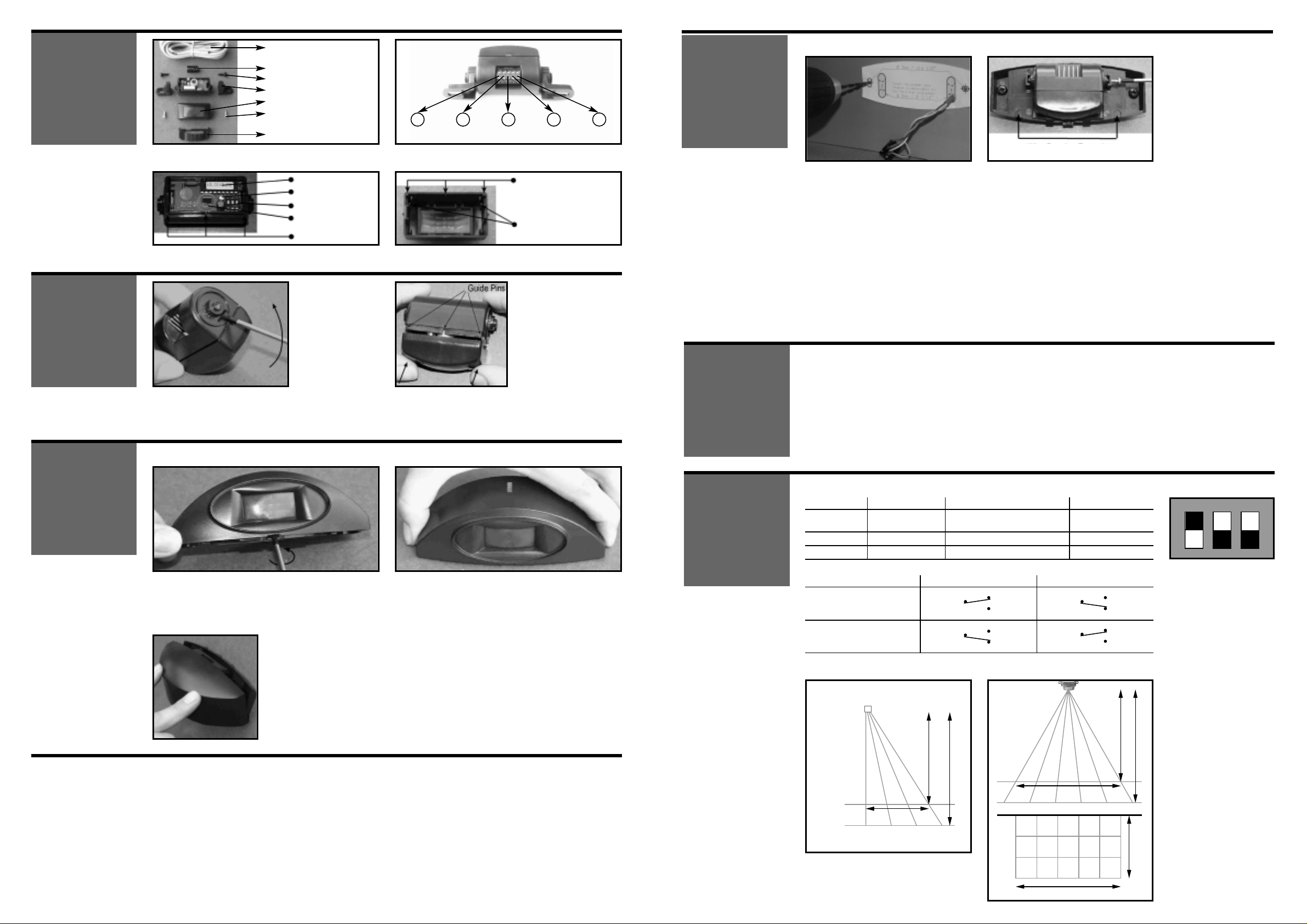

A. MOUNTING THE BFP1

OPENING

AND

CLOSING

THE SENSOR

OPENING

AND

CLOSING

THE FSA

MOUNTING

THE SENSOR

• Use a small screwdriver to open the sensor

• Inser t the screwdriver in the rectangular hole under the bracket cam

• Use it as a lever upwards

• Consider the position of the guide pin when inser ting both legs of the

front cover to the base

• Gently push both sides of the front cover

• Inser t the bottom of the front cover to the bottom clip of the base

• Push on the top of the front cover face

• Either use the screwdriver to open the FSA (left picture)

• Or pinch of f both sides of the front cover (right picture)

• Rotate the front cover upwards

A.DIP SWITCHES SETTINGS AND RELAY CONFIGURATIONS

B.SENSING FIELD POSITION

ON

2

1

3

SETTING

OF

THE SENSOR

ACTIVEMODE PASSIVEMODE

DETECTION

NO DETECTION

DESCRIPTION

OF

THE PRODUCT

AND

THE SENSOR

• Wiring

• Inner view of the sensor front cover

• Description of the product

• Description of the sensor

12-24 V AC/DC

COM NO NC

1 2 3 4 5

OPENING THE FSA ACCESSORY

CLOSING THE FSA ACCESSORY

• The LED flashes for a few seconds when the sensor is switched on

• The LED lights up through the lens when the sensor detects motion

The relay configurations are :

LED

SIGNAL

PROFILE VIEW

FRONT VIEW

FLAT VIEW

• Stick the template on the wall

• Drill the 2 holes to fix the FSA

and the hole for the cable

• Open the FSA (see page 2 :

opening and closing the FSA

Accessory)

• Cut the wire opening footprint

of the base

• Fix the sensor to the FSA base

with the 2 screws

• Connect the sensor to the cable

• Close the FSA (see page 2 :

opening and closing the FSA

Accessory)

Wire Opening Footprints

Main cable

Unplug 5-wire connector

2 screws to fix the BFP1

2 brackets

Lens

2 screws to fix the brackets with

the BFP1

Masking Lens (2 units)

Microprocessor

LED

Dip Switches

PYRO element

Guide Pins of the BFP1 base

Guide pins of the BFP1 base

Guide pins of the masking lens

COM (3)

NO (4)

NC (5)

COM (3)

NO (4)

NC (5)

COM (3)

NO (4)

NC (5)

COM (3)

NO (4)

NC (5)

ACCESSORY

50 cm 50 cm 50 cm

1,5 m depth

2,2 m

3 m

50 cm 50 cm 50 cm 50 cm 50 cm

door

threshold

2,5 m

2,5 m

2,2 m

3 m

1,5 m

height 2,2 m

Loading...

Loading...