Page 1

Installation Manual

390

Swing Gate System

Leading the way ...

Leading the way ...

Page 2

CE DECLARATION OF MACHINE CONFORMITY

(DIRECTIVE 89/392/EEC, ANNEX II, PART B)

Manufacturer : FAAC S.p.A.

Address: Via Benini, 1 - 40069 Zola Predosa BOLOGNA - ITALY

Declares that: Operator mod. 390

• is manufactured to be incorporated in a machine or for assembly with other machines to constitute a machine

under the provisions of Directive 89/392/EEC, and subsequent amendments 91/368/EEC, 93/44/EEC, 93/68/

EEC;

• conforms to the essential safety requirements of the following further EEC Directives:

73/23/EEC and subsequent amendment 93/68/EEC.

89/336/EEC and subsequent amendment 92/31/EEC and 93/68/EEC

and, furthermore, declares that

putting the machine into service is forbidden until the machine in which it

will be incorporated or of which it will become a part has been identified and it has been declared as

conforming to the conditions of Directive 89/392/EEC and subsequent amendments enacted by the national

implementing legislation.

Bologna, 01 January 2003

The Managing Director

A. Bassi

WARNINGS FOR THE INSTALLER

GENERAL SAFETY OBLIGATIONS

1) ATTENTION! To ensure the safety of people, it is important that you read

all the following instructions. Incorrect installation or incorrect use of the

product could cause serious harm to people.

2) Carefully read the instructions before beginning to install the product.

3) Do not leave packing materials (plastic, polystyrene, etc.) within reach of

children as such materials are potential sources of danger.

4) Store these instructions for future reference.

5) This product was designed and built strictly for the use indicated in this

documentation. Any other use, not expressly indicated here, could

compromise the good condition/operation of the product and/or be a

source of danger.

6) FAAC declines all liability caused by improper use or use other than that for

which the automated system was intended.

7) Do not install the equipment in an explosive atmosphere: the presence of

inflammable gas or fumes is a serious danger to safety.

8) The mechanical parts must conform to the provisions of Standards EN 12604

and EN 12605.

For non-EU countries, to obtain an adequate level of safety, the Standards

mentioned above must be observed, in addition to national legal regulations.

9) FAAC is not responsible for failure to observe Good Technique in the

construction of the closing elements to be motorised, or for any deformation

that may occur during use.

10) The installation must conform to Standards EN 12453 and EN 12445.

For non-EU countries, to obtain an adequate level of safety, the Standards

mentioned above must be observed, in addition to national legal regulations.

11) Before attempting any job on the system, cut out electrical power .

12) The mains power supply of the automated system must be fitted with an allpole switch with contact opening distance of 3mm or greater. Use of a 6A

thermal breaker with all-pole circuit break is recommended.

13) Make sure that a differential switch with threshold of 0.03 A is fitted upstream

of the system.

14) Make sure that the earthing system is perfectly constructed, and connect

metal parts of the means of theclosure to it.

15) The safety devices (EN 12978 standard) protect any danger areas against

mechanical movement Risks, such as crushing, dragging, and shearing.

16) Use of at least one indicator-light (e.g. FAACLIGHT ) is recommended for

every system, as well as a warning sign adequately secured to the frame

structure, in addition to the devices mentioned at point “15”.

17) FAAC declines all liability as concerns safety and efficient operation of

the automated system, if system components not produced by FAAC are

used.

18) For maintenance, strictly use original parts by FAAC.

19) Do not in any way modify the components of the automated system.

20) The installer shall supply all information concerning manual operation of

the system in case of an emergency, and shall hand over to the user the

warnings handbook supplied with the product.

21) Do not allow children or adults to stay near the product while it is operating.

22) Keep remote controls or other pulse generators away from children, to

prevent the automated system from being activated involuntarily.

23) Transit through the leaves is allowed only when the gate is fully open.

24) The user must not attempt any kind of repair or direct action whatever

and contact qualified personnel only.

25) Maintenance: check at least every 6 months the efficiency of the system,

particularly the efficiency of the safety devices (including, where

foreseen, the operator thrust force) and of the release devices.

26) Anything not expressly specified in these instructions is not permitted.

1

Page 3

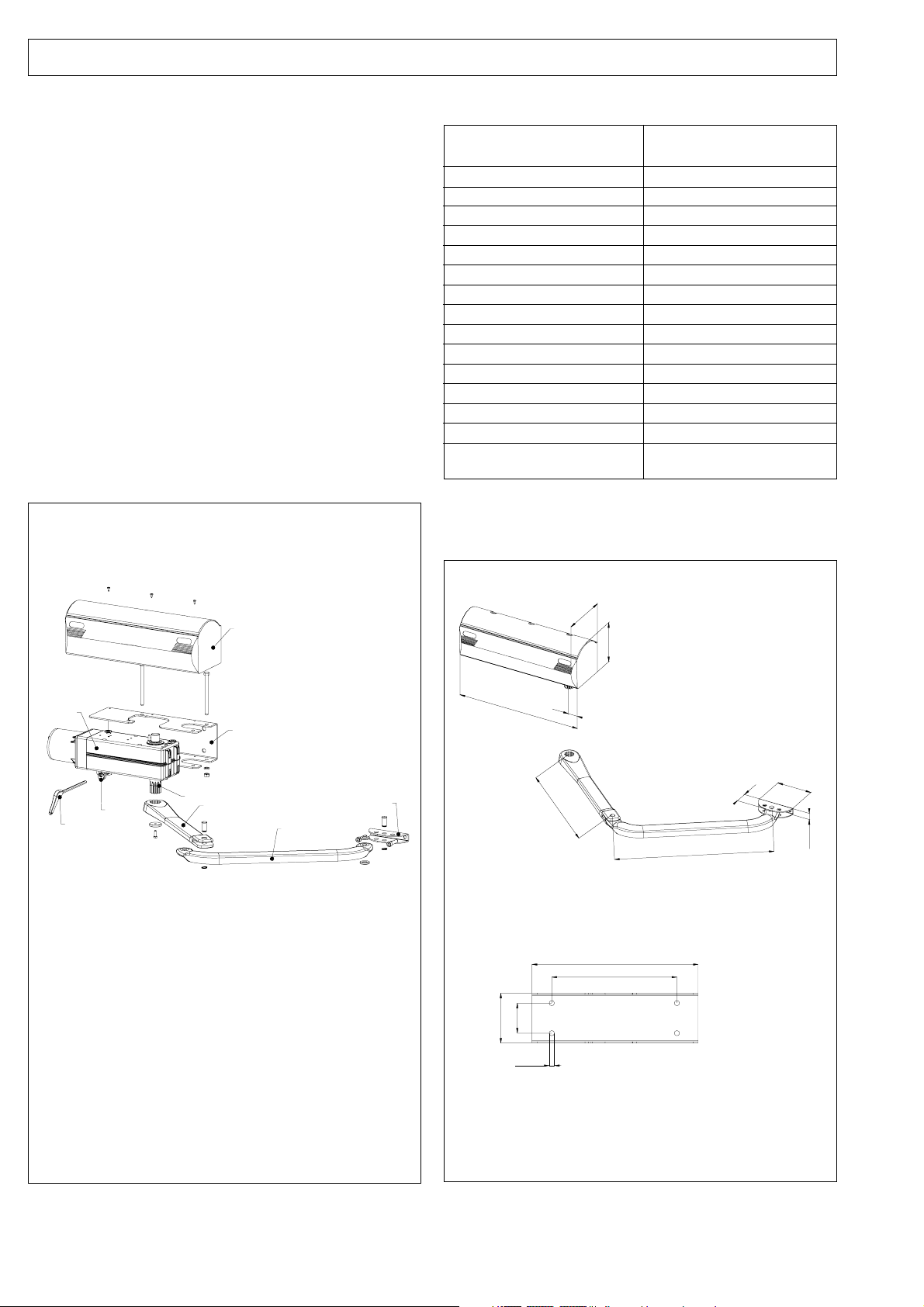

AUTOMATION FAAC 390

These instructions apply to the following model:

FAAC 390

The external automation 390 with articulated arms automates

residential swing-leaf gates with leaves of up to 3m in length, and

is ideal for applications on large pilasters without the need to

provide niches (sometimes required to observe the installation

dimensions of piston driven devices).

It consists of an irreversible electro-mechanical operator with

guard and an articulated-arm activation system to be fitted to

the gate with the appropriate accessories.

The irreversible system ensures the gate is mechanical locked

when the motor is not operating. No lock need be installed for

leaves up to 1,8 m. in length.

A manual release makes it possible to move the gate in the event

of a power-cut or fault.

To obtain anti-crushing protection, you have to use electronic

appliances with a torque control electronic device.

The automation 390 was designed and manufactured to control

access of vehicles. Avoid any other use whatever.

1. DESCRIPTION AND TECHNICAL SPECIFICATIONS

TAB. 1 TECHNICAL SPECIFICATION OF OPERATOR

MODEL

Power supply

Power absorption

Current absorption

Max torque

230V (+6% -10%) 50Hz (60Hz)

FAAC 390

280W

1.2A

250Nm

Starting capacitor

Thermal protection for winding

Reduction ratio

Angular velocity

Ambient temperature

140°C

1:700

8°/sec

-20°C +55°C

Use frequency (cycles / hour)

RPM

Weight of gearmotor

Protection class

Gearmotor overall dimension

Leaf max length

1,8 m (without electric lock)

11.5 kg

IP44

see fig.2

3 m (with electric lock)

2. DIMENSIONS

8μF

15

960

1

5

2

6

4

3

7

1) Guard

2) Operator securing base-plate

3) Release wrench

4) Release

5) Gearmotor

6) Transmission shaft

7) Straight lever of articulated arm

8) Curved lever of articulated arm

9) Front coupling

130

130

410

9

8

100

Fig. 1 Fig. 2

•measurements in mm

60

Ø 1 0

60

390

332

250

480

45

115

21.5

2

Page 4

3. ELECTRICAL EQUIPMENT (standards system)

1) Operators mod. 390

2) Photocells

3) Electronic equipment

4) Key-operated push-button

5) Radio receiver

6) Flashlight

Notes: 1) To lay electrical cables, use adequate rigid and/

or flexible tubes.

2) Always separate low voltage accessories from

those operating at 230V~. To avoid any

interference, always use separate sheaths.

Fig. 3

4. INSTALLATION OF AUTOMATION

4.1. PRELIMINARY CHECKS

To ensure safety and an efficient automation, make sure the

following requirements are met:

• The gate structure must be suitable for automation. In

particular, make sure it is sufficiently sturdy and rigid, and

that its dimensions are in line with those indicated in the

technical specifications.

• Make sure that the leaves move properly and uniformly,

without any irregular friction during their entire travel.

• Check if hinges are in good condition.

• Make sure the travel limit mechanical stops are present.

• We advise you to carry out any metalwork jobs before

installing the automation.

4.2. INSTALLATION DIMENSIONS

Establish the installation position of the operator by consulting Fig.

4-5-6.

4.2.1. RECOMMENDED DIMENSIONS FOR INWARD OPENING

B C

X

A

40 / 60

α°

Notes: As for 120° openings the curved arm must be fixed

to the hole marked with the letter X

αα

α

A B C (max)

αα

60÷110 110÷130 730 90°

110÷160 110÷130 720 90°

160÷210 110÷130 710 90°

210÷260 110÷130 700 90°

260÷310 110÷130 690 90°

310÷360 110÷130 670 90°

60÷110 190÷210 650 120°

110÷160 230÷250 600 120°

160÷210 290÷310 540 120°

210÷260 310÷330 510 120°

•measurements in mm

Fig. 5

4.2.2. RECOMMENDED DIMENSIONS FOR OUTWARD OPENING

α

°

40 / 60

A

~ 41

~ 200

•measurements in mm

Fig. 4

•measurements in mm

3

CB

αα

α

A B C (max)

αα

60÷110 110÷130 430 90°

110÷160 110÷130 380 90°

160÷210 110÷130 330 90°

210÷260 110÷130 280 90°

260÷310 110÷130 240 90°

Fig. 6

Page 5

4.3. INSTALLATION STEPS

The operator 390, base-plate and articulated arm are designed

either for right-hand or left-hand (Fig. 7) installation.

SX

DX

Fig. 7

• Secure the base-plate to the pilaster, using Ø10 screws and

suitable expansion plugs (Fig. 8), and check it is perfectly

horizontal.

• Fit the gearmotor unit on the base-plate and secure it with

the two screws, nuts and flexible washers (Fig.8).

• The transmission shaft must always face downward.

SX

DX

Fig. 8

• Assemble the articulated arm and front coupling as shown

in Fig. 9.

SX

DX

Fig. 11 Fig. 12

• In both cases, provisionally remove the coupling from the arm

in order to secure it.

• Fit the guards on the operator (Fig. 10).

• Re-lock the operator (chapter 6.)

• Make the electrical connections of the selected electronic

appliance, observing the annexed instructions.

4.4. TEST OF THE AUTOMATION

When you have finished installation, carefully check the operating

efficiency of the automation and of all accessories connected

to it, safety devices in particular.

Hand the “User’s Guide” page to the Client, and describe how

the operator should function and be used correctly, stressing the

potentially dangerous areas of the automation.

5. MANUAL OPERATING MODE

If the gate has to be operated manually in the event of a powercut or fault to the automation, use the release device as follows:

• Fit the supplied Allen wrench and turn it by about a half turn

until it stops, in the direction shown in Fig. 13, depending on

type of installation.

6. RESTORING NORMAL OPERATING MODE

To avoid an involuntary pulse from activating the gate during the

manoeuvre, before re-locking the operator , switch off power to

the system.

• Fit the supplied Allen wrench and turn it by about a half turn

until it stops, in the direction shown in Fig. 13, depending on

type of installation.

Fig. 9

• Fit the straight lever of the articulated arm on the gearmotor

shaft and tighten it with the supplied screw and washer (Fig.

10).

• Release the operator (chapter 5.)

• Establish the securing position of the front coupling on the

leaf, observing dimension “C” defined previously (chapter

4.2). Check that arm and coupling are perfectly horizontal.

• The coupling may be welded directly onto the leaf (Fig. 11)

or screwed by using the threaded inserts (Fig. 12).

SX

DX

Fig. 10

DX

SBLOCCA / UNLOCK

DEBLOQUE / ENTRIEGELT

DESBLOQUEAR

BLOQUE / VERRIEGELT

BLOCCA / LOCK

BLOQUE / VERRIEGELT

BLOQUEAR

SX

SBLOCCA / UNLOCK

DEBLOQUE / ENTRIEGELT

DESBLOQUEAR

Fig. 13

7. MAINTENANCE

Do the following jobs at least every six months:

• Check if motor torque is correctly set.

• Check efficiency of the release system.

• Check efficiency of safety devices.

8. REPAIRS

For any repairs, contact our authorised Repair Centres.

BLOCCA / LOCK

BLOQUEAR

8

4

Page 6

End-user guide

AUTOMATION FAAC 390

Read the instructions carefully before using the product, and

keep them for future consultation.

GENERAL SAFETY REGULATIONS

If installed and used correctly, the automation 390 will ensure a

high degree of safety.

Some simple rules regarding behaviour will avoid any accidental

trouble:

- Do not pass through the leaves while they are moving. Before

passing through the leaves, wait until they are fully open.

- Do not, on any account, stand between the leaves.

- Do not stand near the automation and do not allow children

and other people to stand there, especially while it is operating.

- Keep remote controls or any other pulse generator well away

from children to prevent the automation from being activated

involuntarily.

- Do not allow children to play with the automation.

- Do not willingly obstruct movement of the leaves.

- Do not allow branches or shrubs to interfere with leaf movement.

- Keep illuminated signalling systems efficient and clearly visible.

- Do not attempt to activate the leaves manually unless you

have released them first of all.

- In the event of a malfunction, release the leaves to allow access

and wait for qualified personnel to take appropriate action.

- After enabling manual operating mode, switch off the power

supply to the system before restoring normal operating mode.

- Do not make any alterations to the components of the

automation.

- Do not attempt to repair or adjust the system personally, but

contact qualified personnel only.

- Call in qualified personnel at least every 6 months to check the

efficiency of the automation, safety devices and earth

connection.

DESCRIPTION

These instructions apply to the following model:

FAAC 390

FAAC 390 automation for residential swing-leaf gates consists of

an irreversible electro-mechanical operator with guard and an

articulated-arm activation system fitted to the gate with the

appropriate accessories.

The irreversible system ensures the gate is mechanically locked

when the motor is not operating. No lock need be installed for

leaves up to 1,8m in length.

A manual release makes it possible to move the gate in the event

of a power-cut or fault.

The operators are supervised by an electronic control unit,

housed in a container adequately protected against

atmospheric agents.

The leaves are normally in closed position.

When the electronic control unit receives an opening command

by remote control or by any other pulse generator, it activates the

operator to rotate the leaves until they are sufficiently open to

provide access.

If automatic operating mode was set, the leaves close on their

own after the selected pause time has elapsed.

If semi-automatic operating mode was set, a second pulse must

be sent to allow the leaves to close again.

A stop pulse (if supplied) always stops movement.

For detail on operation of the automation under different

operational logics, consult the installation technician.

The automations include safety devices (photocells, sensitive

edges,…) which prevent the leaves from moving when there is an

obstacle in the area they protect.

The automation 390 requires use of electronic appliances with an

electronic torque control device.

The light indicates that leaves are moving.

MANUAL OPERATING MODE

If the gate has to be operated manually in the event of a powercut or automation fault, use the release device as follows:

•Fit the supplied Allen wrench and turn it by about a half turn until

it stops, in the direction shown in Fig. 1-2, depending on type

of installation.

RESTORING NORMAL OPERATING MODE

To avoid an involuntary pulse from activating the gate during the

manoeuvre, before re-locking the operator, switch off power to

the system.

•Fit the supplied Allen wrench in the release device and turn it

by about a half turn until it stops, in the direction shown in Fig.

1-2, depending on type of installation.

•The release device can be activated without removing the

guard.

SX

BLOCCA / LOCK

BLOQUE / VERRIEGELT

DX

SBLOCCA / UNLOCK

DEBLOQUE / ENTRIEGELT

DESBLOQUEAR

BLOCCA / LOCK

BLOQUE / VERRIEGELT

BLOQUEAR

BLOQUEAR

SBLOCCA / UNLOCK

DEBLOQUE / ENTRIEGELT

DESBLOQUEAR

Fig. 1

Fig. 2

9

5

Page 7

QRWHQRWHVQRWHQRWDVDQPHUNXQJRSPHUNLQJHQ

6

Page 8

QRWHQRWHVQRWHQRWDVDQPHUNXQJRSPHUNLQJHQ

7

Page 9

QRWHQRWHVQRWHQRWDVDQPHUNXQJRSPHUNLQJHQ

8

Page 10

The descriptions and illustrations contained in this manual are not

The descriptions and illustrations contained in this manual are not

binding. FAAC reserve the right, whilst leaving the main features of

binding. FAAC reserve the right, whilst leaving the main features of

the main equipment unaltered, to undertake any modifi cations it holds

the main equipment unaltered, to undertake any modifi cations it holds

necessary for either technical or commercial reasons, at any time and

necessary for either technical or commercial reasons, at any time and

without revising the present publication.

without revising the present publication.

FAAC (UK) Limited, 6 Hamilton Close

FAAC (UK) Limited, 6 Hamilton Close

Houndmills Estate, Basingstoke, RG21 6YT

Houndmills Estate, Basingstoke, RG21 6YT

Telephone: 01256 318100

Telephone: 01256 318100

Fax: 01256 318101

Fax: 01256 318101

Email: sales@faac.co.uk

Email: sales@faac.co.uk

Website: www.faac.co.uk

Website: www.faac.co.uk

V3 01/07

V3 01/07

Your authorised FAAC dealer

Your authorised FAAC dealer

Your authorised FAAC dealer

Loading...

Loading...