Page 1

Slide Gate Operators

Installation and

Maintenance Manual

D

Gate Openers

orene

DR 3020

DR 3020HX

DRT 3520

Page 2

TABLE OF CONTENTS

General Safety Instructions ............................3

Important Installation Instructions

DS4020/DS 4020H/DS & 4020HX (only) Gate operation ....6

Pad and Operator Location ............................6

Important Installation Instructions for the DST 4520 0nly ....8

Gate operation ...................................... 8

Pad and Operator Location ............................8

Concrete Pad Construction and Layout . . . . . . . . . . . . . . . . . . 9

Operator Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Universal gate arm Installation Guidelines ...............10

Arm Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Initial Limit Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pipe Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Dorene DGC2000 Controller . . . . . . . . . . . . . . . . . . . . . . . . . 12

Power Connection / Electrical Hookup115

Volt Single Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Mag-Lock installation .............................. 13

JS10 .............................................18

Jp3 .............................................. 18

Jp4 .............................................. 18

Shadow loop Installation .............................18

Synchronous Open/Close Operation DGC 2000 . . . . . . . . . . 19

Double Swing gate loop placement . . . . . . . . . . . . . . . . . . . . 21

Final Check .......................................22

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Safety Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Installation ........................................22

Testing ........................................... 22

Warning .......................................... 22

Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

The left LED’S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

The Right LED’s ...................................23

Gate will not open or operate . . . . . . . . . . . . . . . . . . . . . . . . . 23

Final Limit Adjustment ..............................14

DGC – 2000 Controller Settings .......................14

Hand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Close Timer .......................................14

Reverse Delay .....................................14

Close Delay ....................................... 15

Motor Run Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Sensitivity Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Warning Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

To Hold Gate Open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

JP-3 ............................................. 16

Led enable switch .................................. 16

Final Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Blue Box (DGC 2000 ) format All Commands are dry contact,

except JS4 & JS8 .............................. 17

JS1 ..............................................17

JS2 ..............................................17

LIMITED WARRANTY SUMMARY

(For Normal Wear and Tear)

DoreneL.L.C warrants all gate openers to be free of defects in

material & workmanship for a period of 4 years for commercial

use and 6 years for residential use, i.e. single residence, from date

of purchase. Any mechanical part or parts found defective within

this period, at the manufacturer’s option, shall be repaired or

replaced free of charge.

FOB our factory.

The above warranty is in lieu of all other warranties expressed

or implied and shall be void in cases of acts of God, vandalism,

improper installation or improper maintenance.

The electronics are warranted for a period of 2 years under the

same requirements.

JS3 ..............................................17

JS4 ..............................................17

JS5 ..............................................17

JS6 ..............................................17

JS7 ..............................................17

JS8 ..............................................18

JS9 ..............................................18

2

Page 3

GENERAL SAFETY INFORMATION

READ THROUGH THE INSTALLATION INSTRUCTIONS COMPLETELY BEFORE

BEGINNING INSTALLATION, AND THEN PERFORM THEM IN THE ORDER GIVEN

IMPORTANT SAFETY INSTRUCTIONS

Warning: To reduce the risk of injury or death

Read and follow all instruction carefully.1.

Never let children operate or play with gate controls. Keep the remote control away from children.2.

Always keep people and objects away from the gate. No one should cross the path of a moving gate.3.

Test the gate operator monthly. e gate MUST reverse on contact with a rigid object or stop when an 4.

object activates the non-contact sensors. Aer adjusting the force or the limit of travel, retest the gate

operator. Failure to adjust and retest the gate operator properly can increase the risk of injury or death.

Use the emergency release only when the gate is not moving.5.

Keep gate properly maintained. Read the owner’s manual. Have a qualied service person make 6.

repairs to gate hardware.

e entrance is for vehicles only. Pedestrians must use separate entrance.7.

Save these instructions.8.

FOR GATE OPERATORS UTILIZING A NON-CONTACT SENSOR

See Manufacturers instructions on the placement of non-contact sensors for each type of application.1.

Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle, trips the sensor 2.

while the gate is still moving.

One or more non-contact sensors shall be located where the risk of entrapment or obstruction exists, 3.

such as the perimeter reachable by a moving gate or barrier.

FOR GATE OPERATORS UTILIZING A CONTACT SENSOR

One or more contact sensors shall be located at the leading edge, trailing edge, and post mounted both 1.

inside and outside of a vehicular horizontal slide gate.

A hard wired contact sensor shall be located, and it’s wiring arranged, so that the communication between 2.

the sensor and the gate operator is not subjected to mechanical damage.

A wireless contact sensor such as one that transmits radio frequency (RF) signals to the gate operator for 3.

entrapment protection functions shall be located where the transmission of the signals are not obstructed or

impeded by building structures, natural landscaping or similar obstruction. A wireless contact sensor shall

function under the intended end-use conditions.

3

Page 4

INSTALL THE GATE OPERATOR ONLY WHEN:

e operator is appropriate for the construction of the gate and the usage class of the gate.1.

All openings of a horizontal slide gate are guarded or screened from the bottom of the gate to a2.

Minimum of 4’ (1.2m) above the ground to prevent a 2.25” (57.15mm) diameter sphere from passing 3.

through the openings anywhere in the gate, and in that portion of the adjacent fence that the gate

covers in the open position.

All exposed pinch points are eliminated or guarded4.

Guarding is supplied for exposed rollers 5.

e operator is intended for installation only on gates used for vehicles. Pedestrians must be supplied

with a separate access opening.

e gate must be installed in a location so that enough clearance is supplied between the gate and

adjacent structures when opening and closing to reduce the risk of entrapment. Swinging gates shall

not open into public access areas.

e gate must be properly installed and work freely in both directions prior to the installation of the gate

operator. Do not over-tighten the operator clutch or pressure relief valve to compensate for a damaged gate

For gate operator utilizing type D protection 6.

e gate operator controls must be placed so that the user has full view of the gate area when the gate 7.

is moving. e placard as required by 52a.1.6 shall be placed adjacent to the controls

An automatic closing device (such as a timer, loop sensor, or similar device) shall not be employed. 8.

No other activation device shall be connected.

Controls must be far enough from the gate so that the user is prevented from coming in contact with the 9.

gate while operating the controls. Controls intended to be used to reset an operator aer two sequential

activations of the entrapment protection device or devices must be located in the line-of-sight of the gate.

All warning signs and placards must be installed where visible in the area of the gate.

4

Page 5

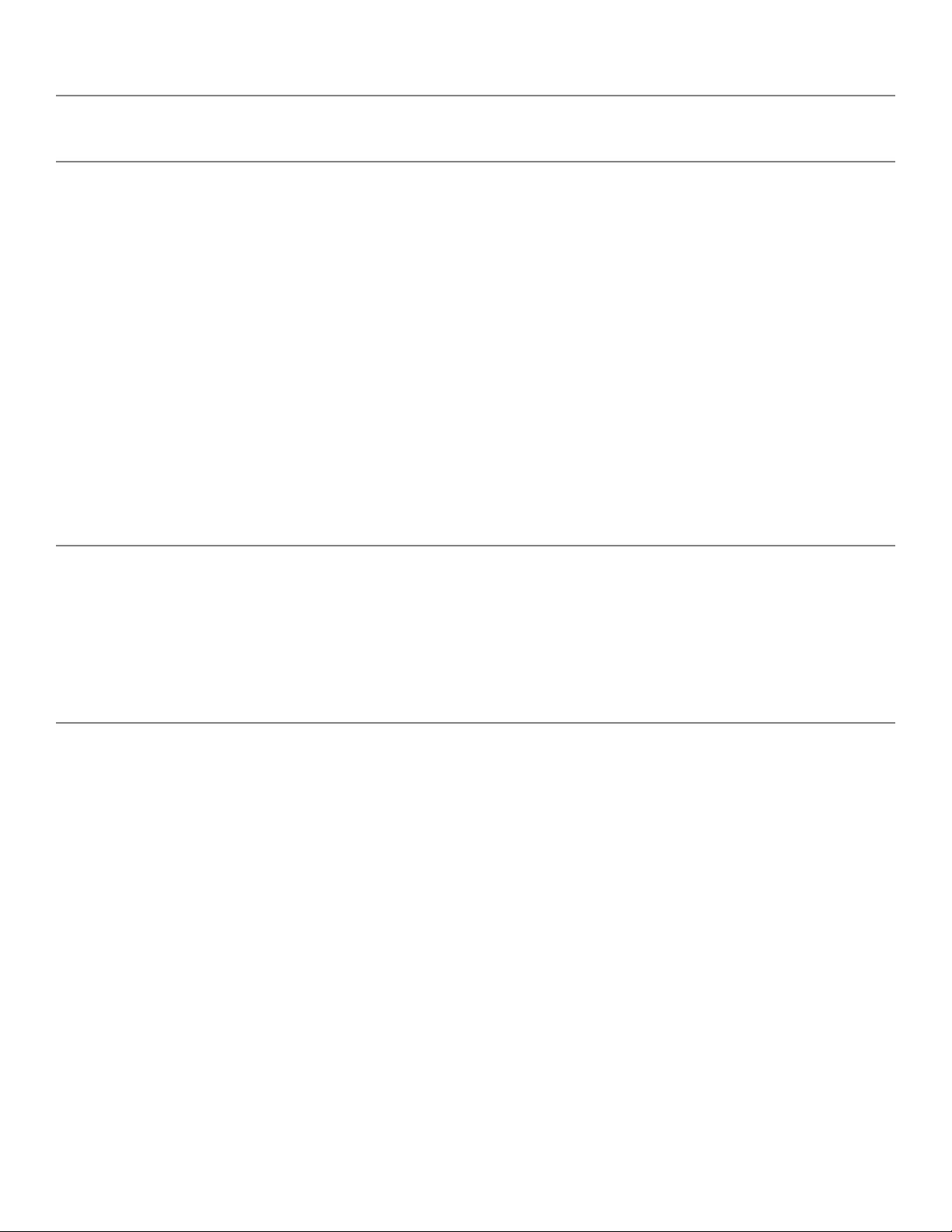

GATE OPERATOR

Usage Class Horizontal Slide Swing

Vehicular I and II

Vehicular III

Vehicular IV

Note: e same type of device shall not be utilized for both the primary and the secondary entrapment

protection means. Use of a single device to cover both the opening and closing directions is in

accordance with the requirement; however, a single device is not required to cover both directions.

A combination of one type B1 for one direction and one type B2 for the other direction is the

equivalent of one device for the purpose of complying with the requirements of either the primary

or secondary entrapment protections means.

A

A, B1, or B2

A, B1, B2, or D

B1, B2, or D

A, B1, B2, D or E

A, B1, B2, D or E

A or C

A, B1 or C

A, B1, C or D

A, B1, C or D

A, B1, C, D or E

A, B1, C, D or E

ENTRAPMENT PROTECTION TYPES:

Type A Inherent entrapment sensing system.

Type B1 Provision for connection of, or supplied with, a non-contact sensor (photoelectric

sensor or the equivalent).

Type B2 Provision for connection of, or supplied with, a contact sensor (edge device or

the equivalent).

Type C Inherent adjustable clutch or pressure relief device.

Type D Provision for connection of, or supplied with, an actuating device requiring continuous

pressure to maintain opening or closing motion of the gate.

Type E An inherent audio alarm.

5

Page 6

IMPORTANT INSTALLATION INSTRUCTIONS

Gate Closed Position

4”

1”

Concrete Pad

DR 3020 / DR 3020HX / DRT3520

Gate Open Position

18” Min.

Electrical Stub Ups

Y

DR 3020/DR 3020HX/DRT 3520

GATE OPERATION

e gate must roll freely with no binding of the wheel, guides, and/or gate hardware before any operator is

connected to the gate.

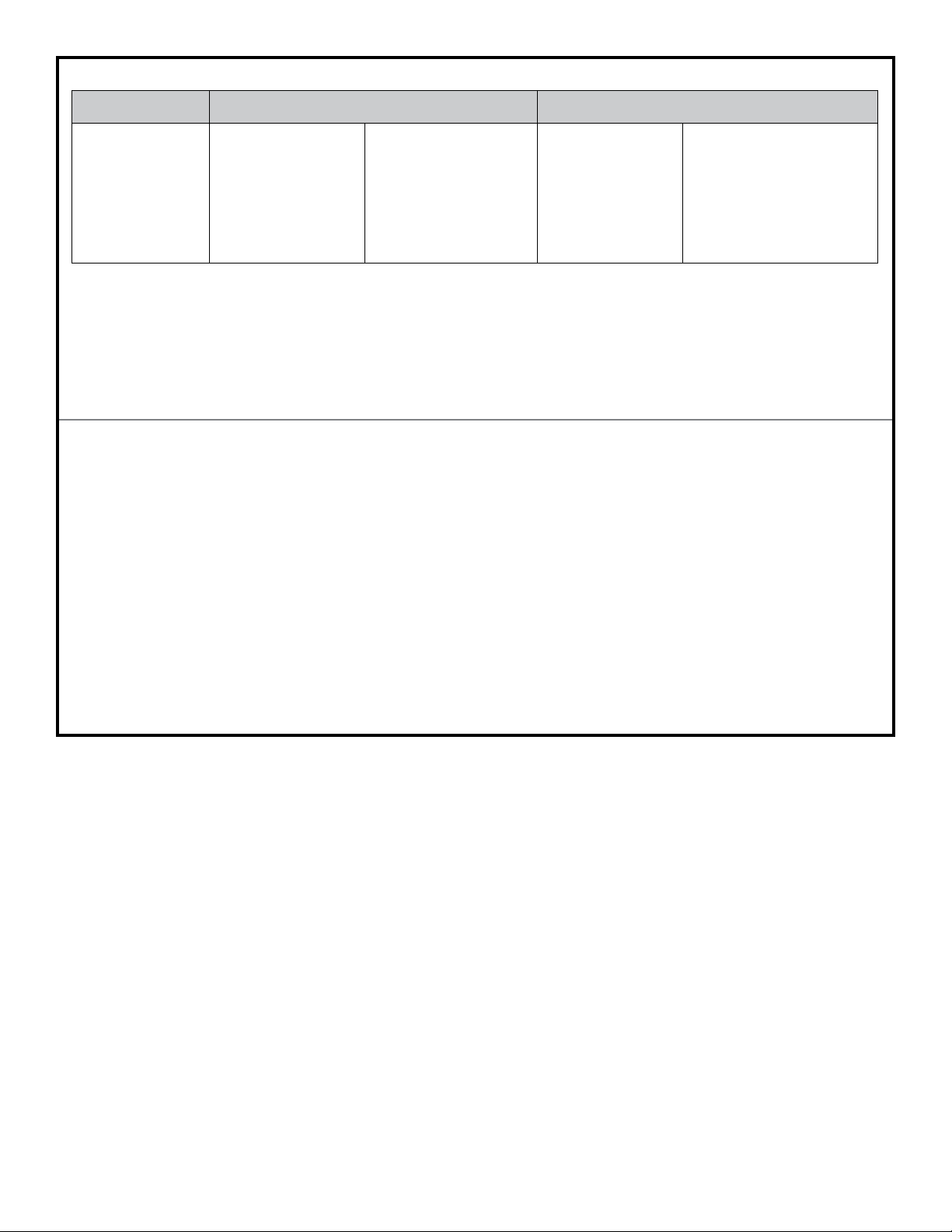

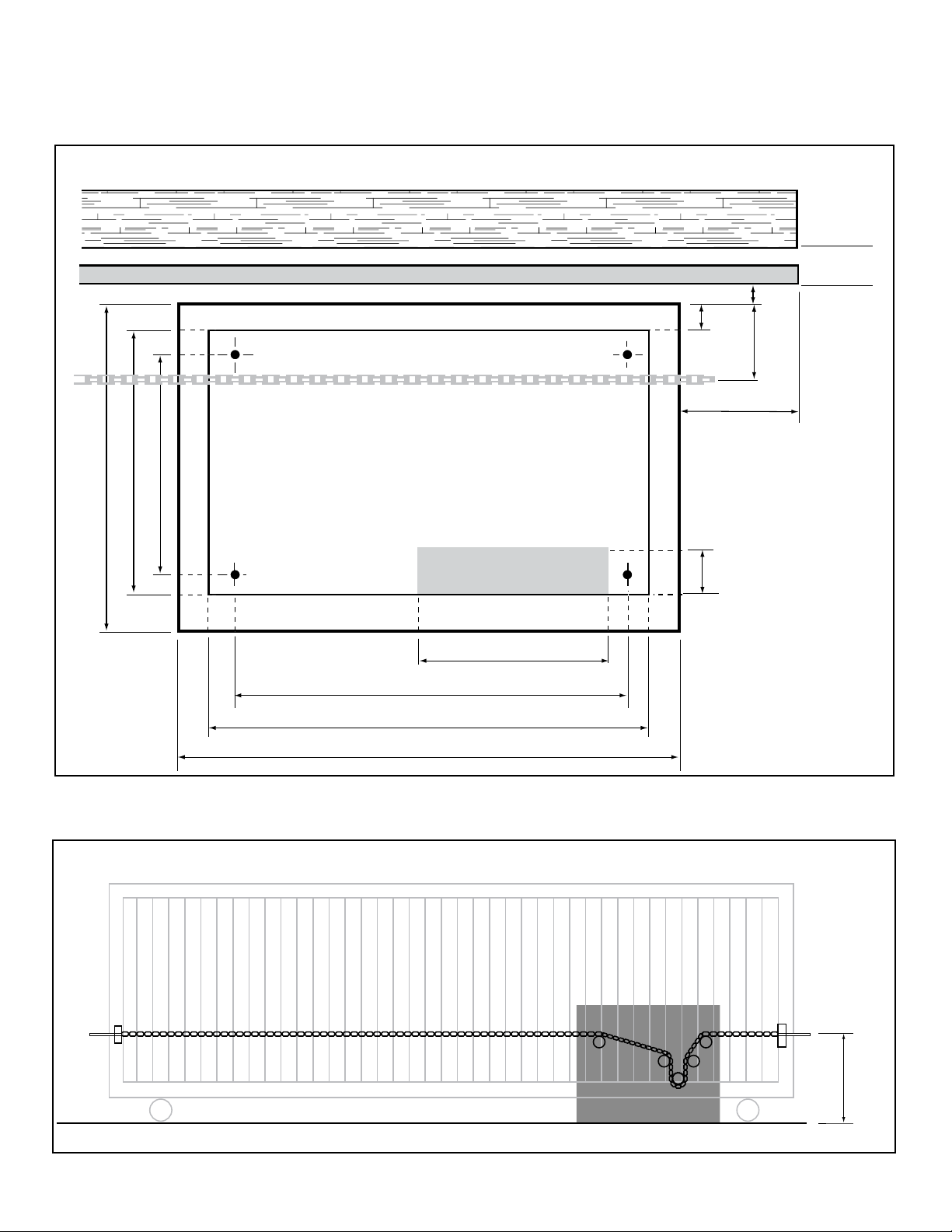

PAD AND OPERATOR LOCATION

Position the pad as indicated in Figure #1. Failure to do so may cause erratic operation resulting in reduced

operator life.

Important: If the gate is not at least twenty-eight inches longer than the opening, an extension should be added

to the rear portion of the gate r the mounting of the rear chain bolt bracket. See Fig #2 e

extension must be rigid and long enough to allow the gate to fully close without the rear chain bolt

bracket hitting the operator.

Note: If there is already concrete where the operator is to be mounted, a pad is not necessary, if the existing

concrete is level.

Y dimension in Figure 2 must be high enough so that water will not stand under the operator in a worst case

scenario.

Soil conditions may vary but in sandy or loose soil the pad should be at least 18”-24” inches deep.

6

Figure 1 (Front Mount)

Concrete Pad Construction and Layout

Figure 2 (Side View)

Page 7

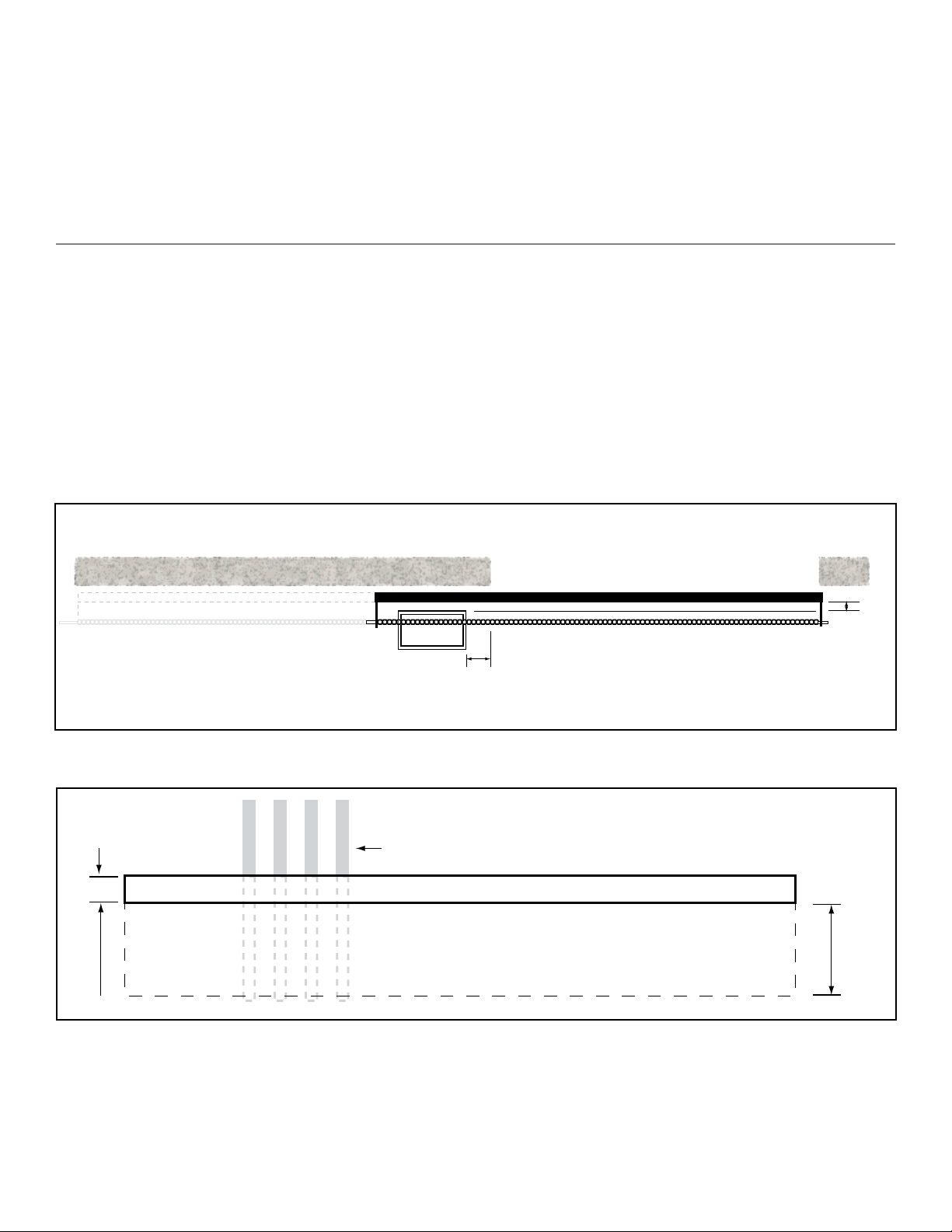

CONCRETE PAD CONSTRUCTION AND LAYOUT

DR3020/DR3020HX

20” - Mounting Holes

10”

4”

4”

2

1

/2”

1

1

/2”

1˝

26” Pad Size Minimum

18”

Electrical Stub Up Area

Chain

Gate

Wall

22” - Cover Size

12

1

/2”

10

1

/2”

13”

Operator

DR 3020 / DR 3020HX

e gate must roll freely with no binding of the wheel, guides, and/or gate hardware before any operator is

connected to the gate.

Figure 3 (Top View)

Figure 4 (Front Mount)

7

Page 8

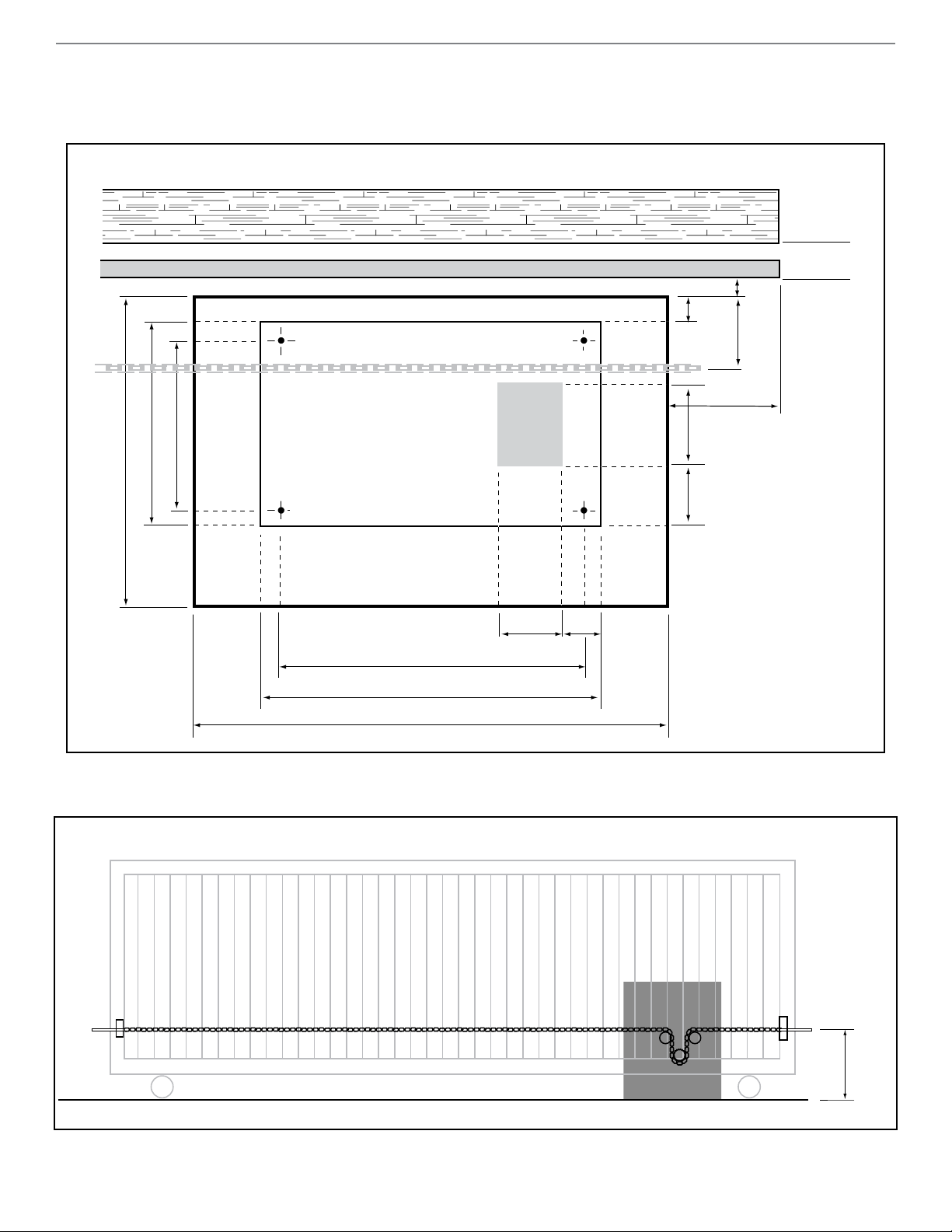

CONCRETE PAD CONSTRUCTION AND LAYOUT

DRT3520

123/4” - Mounting Holes

4

1

/2”

2

1

/2”

1

1

/2”

23/4”

4”

1˝

6

1

/4”

4˝

24” Pad Size Minimum

20”

Electrical Stub

Up Area

Chain

Gate

Wall

16” - Cover Size

14”

11

1

/2”

10”

Operator

DRT 3520

e gate must roll freely with no binding of the wheel, guides, and/or gate hardware before any operator is

connected to the gate.

Figure 5 (Top View)

8

Figure 6 (Front Mount)

Page 9

MECHANICAL HOOK UP (FRONT MOUNT)

Operator

DR 3020 / DR 3020HX / DRT3520

Position the pad as indicated in Figure #1. Failure to do so may cause erratic operation resulting in reduced

operator life.

Clamp both chain bolt brackets to the gate as in Figure 2, with the hole in each of the brackets lining up with 1.

the operator idler sprocket, vertically and horizontally. Weld in place

Important: Failure to line up brackets properly will result in premature idler and guide wear and may cause the

chain to jump o the sprocket.

Connect the longer chain bolt to the chain and the rear chain bolt bracket, with room for adjustment.2.

Route the chain through the operator so that the drive sprocket has maximum tooth contact. See Figure #23.

Fasten the shorter chain to the front chain bolt and tighten the nuts so that the end of the chain bolt is away 4.

from the chain ush with the nut.

Hold the gate and extend the chain to the front of the chain bolt.5.

Cut the chain to the proper length and fasten to the front of chain bolt with the master link supplied.6.

Adjust the chain by tightening the rear chain bolt until slack is about two or three inches for every ten feet of 7.

chain.

Tighten the rear chain bolt nuts.8.

Note: Excessive tightening of the chain will reduce bearing life.

Note: Hand of operator is the same for rear mount if driving the gate o the bottom of the drive sprocket/

is is, however reverse if the driving the gate o the top of the drive sprocket.

OPERATOR MOUNTING

Locate the operator on the concrete pad per gure #4 and fasten to the pad using 3/8˝ x 1-7/8˝ or longer concrete

anchors.

Figure 7 (Rear Mount)

9

Page 10

INITIAL LIMIT ADJUSTMENT

Remove limit nut keeper1.

Move the gate to the fully open position, minus one foot2.

Adjust the open limit nut until the open limit switch just activates.3.

Replace the limit nut keeper.4.

Important: Do not let the close limit nut go past the close limit switch when performing step #5.

Move the gate to the fully closed position, minus one foot5.

Adjust the close limit nut until the close limit switch just activates.6.

Figure 8 (Top View) Figure 9 (Side View)

Note: e hand of the operator is easily identied aer the operator is hooked up electrically by activating on of

the limit switches, which will illuminate the open or close limit switch LED. Hand is very easily altered by the hand

change switch. See Fig #7 for location of the switch.

10

Page 11

DORENE DGC2000 CONTROLLER

11

Page 12

POWER CONNECTION / ELECTRICAL HOOKUP

1

Dead

Dead

Dead

L-1 (hot) (117 VAC) input only

High

Voltage

In

Mag Lock

Wires

Motor

Wires

Neutral (117 VAC) input only

Ground (117 VAC) input only

Neutral

Lock

White - Motor Wire

Red - Motor Wire

Yellow - Motor Wire

Dead

2

3

4

5

6

7

8

9

10

11

12

Dead

Dead

Important: Turn power OFF at the breaker before making any connections or adjustments.

Note: Port 1, 2, 11 and 12 are not to used. ey are empty ports.

e operator should be on a separate line with a 15 AMP breaker. Supply voltage must be within

10% of the operator rating under load conditions. Connect power in accordance with local codes

All operations must be properly grounded with a supply grounding conductor

Note: Master Slave installations must have the same phase power when separate breakers are used

115 VOLT SINGLE PHASE

See gure 11

#12 OR #14 gauge shielded, standard wire is recommended for the high voltage hoop-ups.

Secure the 115 volt single phase HOT line to port #101.

Secure ground supply line to port #92.

Secure neutral supply line to port #83.

Important: Turn power OFF before making any connections or adjustments.

MAG-LOCK INSTALLATION

If a 115 volt lock is used, connect the neutral wire from the lock to port #7 and the power wire from the

lock to port #6

12

Figure 11 (Power Connection)

Page 13

CLUTCH ADJUSTMENT

Important: Always turn power o before making any adjustment.

Remove the two set screws in the clutch adjuster nut.1.

Using a 1 ¼” Open-end wrench (available at the factory) tighten the clutch adjuster nut until proper tension 2.

is achieved. (See Note below) Try just a ¼ turn at a time and then test. DO NOT USE A PIPE WRENCH OR

CHANNEL LOCKS TO ADJUST THE CLUTCH!.

Important: Do not over tighten the clutch! Gear damage may result voiding the warranty!

Note: e clutch must be suciently tight so that it does not slip in normal operation and so that the motor

and the current sensor “feel” a load when the gate is obstructed.

Aer the clutch is properly adjusted, with power OFF, tighten the two set screws in the clutch adjuster nut.3.

FINAL LIMIT ADJUSTMENT

It is possible that a nal adjustment may be required for the arm to stop exactly as desired. In the open position,

the swing arms and the pipe arm should be doubled on the top of each other. On CLOSE the motor should

turn o before the arm hits the stop so that it coasts to the stop. If the operation is not as described, adjust the

position of the limit collar to correct the error.

DGC – 2000 CONTROLLER SETTINGS HAND

is switch changes the direction the motor runs to open the gate, le or right

CLOSE TIMER

is switch is used to activate (on) or deactivate (o) the automatic close timer. e gate will

close aer a specied time as set under Close Delay if this switch is ON unless the gate is

being held open by an accessory.

Brake Delay (for slide gates only)

is set of switches determines the length of time between the motor turning o and the

electronic brake coming on. All switches should be ON except for a gate on an incline.

REVERSE DELAY

is set of switches is to prevent instant reversal of the motor to reduce operator/gate stress

and to prevent operator malfunction. Note: Never put all of these switches in the OFF position as

operator damage may result.

13

Page 14

CLOSE DELAY

32

ON

OFF

16 8 4 2 1

If the close time is switched into the circuit, this set of switches adjusts

the length of time the gate stays open before closing automatically. For example,

if you want 45 second you would turn on 32+8+4+1=45 as illustrated below in gure 12.

Figure 12

MOTOR RUN TIMER

is timer should be set at least 10 seconds or longer than the normal operating time, and

will stop the gate if for some reason the motor runs longer than the switch setting. If this

happens the stop LED will ash 3 times then pause, 3 times then pause, it will continue to

ash until power has been turned o.

SENSITIVITY ADJUSTMENT

is is used to adjust the current level at which the gate will respond to an

obstruction. Turn clock-wise for more sensitive and counter clock-wise for less

sensitive.

Caution: e current sense feature is designed only to protect the operator and

reduce vehicle damage. It is not intended for pedestrian trac!

Note: e setting must always be sensitive enough to respond to an

obstruction, but not so sensitive that it responds without obstruction.

WARNING ALARM

One to three seconds prior to gate movement.

14

Page 15

TO HOLD GATE OPEN

Wire switch to stop prior to full open to close reverse switch and press transmitter to restart.

JP-3

Anti-tailgate feature. See Figure #6 on page 11

LED ENABLE SWITCH

e two rows of LED’s, located in the upper le hand corner of the

DGC 3000, Functions for thirty minutes from power-up and turns o

automatically to save power. To verify the LED’s are enabled, activate a limit

switch momentarily. If the corresponding LED does not light, press the

LED enable button, located below the 2 rows of LED’s, to turn on the LED’s

for another 30 minutes.

Safety is for secondary entrapment – devices connected to this terminal will cause the gate to stop and

reverse 3”. e gate must be activated by a person to move aer this has occurred.

Pulse Open/Pulse Close terminal is used to both open and close the gate from a single button. Activation of the

button will open the gate unless the gate is fully open in which case it will close the gate.

24V Power terminal is one leg of 24 VAC power (COMMON is the other side of 24 VAC power, and is

grounded), which can be used to power a radio receiver, digital keypad or other accessory with 24 VAC voltage

requirements.

Important: This terminal must not be grounded at any time even through any controls which will be used to

activate the gate!

FINAL ASSEMBLY

Operate the gate to the middle of its operation and turn power OFF at the breaker (this prevents activation of 1.

the operator during nal assembly). If preferred, you may turn power OFF and back ON at the operator, the

operator will not move until activated.

Remove the arm by removing the stainless steel bolt.2.

Install the operator cover (make sure the grommet remains properly seated), and re-install the arm as 3.

described under ARM INSTALLATION.

Tighten the stainless steel bolt to 44./lbs.4.

e gate operator installation is not complete unless the warning signs are installed on the gate.5.

15

Page 16

BLUE BOX FORMAT

All Commands are dry contact, except JS4 & JS8

JS1

Open / Common / Closed. — Dry Contact Command: For Open & Closed gate function, Telephone Entry,

Digital Key Pad, Postal Box, etc...

JS2

Limit Switches — Pre-wired, normally a closed circuit

JS3

Stop / Common / Pulse, Stop / Common — Normally a closed circuit, for a stop button on 3 button switch

(remove jumper wire on JS7 if JS3 is used) Pulse/Common for use when “close timer is o to open & close gate

with transmitter. Must also change JP10 jumper to Common/Pulse

JS4

24V / Common / 24V / 1Amp 24VAC, for use with accessories

JS5

Stop / Common / Close — Same as JS1, good to use for exit loop

JS6

Gate Edge / Common / Gate Edge — 2 wire safety edge input-Gate will stop back 3” & stop has started with a

constant transmitter or open command. Also to be used with rear photo eye only.

JS7

Same as JS3 — Jumper wire must be used between Stop / Common in order to work. Pulse / Common for

use when “close Timer” is o to Open / Close gate with transmitter. Must also change jumper wire on JP10 to

common / pulse.

16

Page 17

JS8

L

I

M

I

T

S

W

I

T

C

H

LOOP DETECTOR

JS9

VEHICLE LOOP/PHOTO EYE

COMMON

VEHICLE LOOP/PHOTO EYE

NORMALLY OPEN

COMMON

C

NO

+Alarm / –Alarm / Spare — For external alarm prior to gate moving either open or closing.

JS9

Loop Detector-Photo Eye / Common / Loop Detector-Photo Eye — Normally open circuit to connect safety loop

and/or photo eyes to operator.

JS10

Open / Common / Pulse — Jumper wire must be used on open / common, it is ready for ready for transmitter /

receiver with automatic timing closing. Common / Pulse for use with transmitter open a transmitter closing. No

automatic closing

JP3

Jumper across the two pins is for a special brake delay call factory for further details

JP4

Anti tailgate — Jumper on the two pins will stop the gate closing if the safety loop is crossed. e gate will hold

in this position until the gate to the full closed position.

SHADOW LOOP INSTALLATION

Install a micro switch on top of the open limit switch.1.

Connect the normally open (no) wire from the shadow (center) loop detector to the terminal on the new 2.

micro switch.

Connect the common wire from the shadow loop detector to the common terminal on JS9 of the DCG2000 3.

Controller box..

Add an additional wire from the vehicle loop / photo eye terminal on the DCG2000 Controller4.

Figure 13

17

Page 18

SYNCHRONOUS OPEN/CLOSE OPERATION DGC 2000

OPEN

COMMON

CLOSE

JS1

STOP

COMMON

PULSE

JS3

GATE EDGE

COMMON

GATE EDGE

JS6

VEHICLE LOOP/PHOTO EYE

COMMON

VEHICLE LOOP/PHOTO EYE

JS9

OPEN

COMMON

CLOSE

JS1

STOP

COMMON

PULSE

JS3

GATE EDGE

COMMON

GATE EDGE

JS6

VEHICLE LOOP/PHOTO EYE

COMMON

VEHICLE LOOP/PHOTO EYE

JS9

LEFT RIGHT

only if needed

Controllers must be operated from same 110v line.1.

Synchronous* Open/Close operation ins obtained by installing two twisted pair cables between the JS1 2.

Open/Common and Close/Common connectors of two DGC 2000 controllers.

Connection required only with the Gate Edge or other Safety Device.3.

*Formerly referred to as Master-Slave Operation

Twisted pair cable - Belden P/N 9501

18

Page 19

SYNCHRONOUS OPEN/CLOSE OPERATION DGC 2000

STOP

COMMON

PULSE

RED

BLACK

RED

BLACK

JS7

STOP

COMMON

PULSE

JS7

LEFT RIGHT

RED STOP WIRES

BLACK COMMON WIRESN.C. SWITCH

Controllers must be operated from same 110v line.1.

Synchronous* Open/Close operation ins obtained by installing two twisted pair cables between the JS1 2.

Open/Common and Close/Common connectors of two DGC 2000 controllers.

Connection required only with the Gate Edge or other Safety Device.3.

*Formerly referred to as Master-Slave Operation

Twisted pair cable - Belden P/N 9501

19

Page 20

DOUBLE SWING GATE LOOP PLACEMENT

VEHICLE

SAFETY LOOP

SAFETY LOOP

SHADOW/CENTER

LOOP

FREE EXIT LOOP

4 ft. min.

shortest leg

2 ft.

4 ft.

4 ft.

4 ft. min.

4 Foot General Rule

- Shortest leg on loop is minimum

of 4 ft.

- 4 ft. space between loops

- 4ft. away from edge of gate

INSIDE

OUTSIDE

20

Figure 15

Page 21

FINAL CHECK

Turn power ON at breaker and recheck all functions, including all safety functions.1.

If any adjustments are necessary, make those adjustments and re-test for proper operation.2.

Gate is now ready for normal operation.3.

Important: The gate operator installation is not complete unless the warning signs are installed on the gate.

MAINTENANCE

Severe or excessive usage requires more frequent checks.1.

All safety functions should be veried at least once every three months.2.

e chains should be adjusted and lubed as required at least once every six months.3.

e gearbox level should be checked and lled as required every twelve months.4.

Note: The proper level is to the bottom of the middle drain hole.

e grease ttings should be lubed every twelve months.5.

SAFETY ACCESSORIES

is unit has a current sending feature to reduce vehicle and operator damage. It is not intended for pedestrians

and should not be relied upon as a safety device for pedestrians. Other external devices such as electric eyes and

gate edges should be used to reduce the possibility of injury to pedestrians. Such devices are available at Dorene,

LLC.

INSTALLATION

Dorene, LLC recommends fastening perforated metal to both the gate and related fencing so as to reduce the

possibility of injury to persons interfering with the gate operation. It is also recommended to add fencing to

prevent persons from entering the gate and operator operating areas. Never install any accessory in any location,

which if accessed from the opposite side from that intended might increase the risk of personal injury.

TESTING

All safety devices should be checked at least once a month and at least once every three months by a unqualied

service technician. Never leave a gate operating if any safety device is not functioning properly. Please call

Dorene, LLC if you have any questions about this operator, its functioning or proper safety devices.

WARNING

To reduce the risk of injury to persons, use this operator only with rolling gates.

CAUTION

To reduce the risk of injury to person, operate gate only when fully visible, properly adjusted and free of

obstructions. Do not permit children to play in the area of the gate.

21

Page 22

TROUBLESHOOTING

To trouble shoot the gate operator it is important to understand how the LED’s function work.

Note: The power LED functions all the time that power get to the DGC 2000 Controller box. The LED’s

function for thirty minutes from power-up and go off automatically to save power. To verify that the

LED’s are enabled, activate a limit switch momentarily. If the corresponding LED does not light,

press the LED enable switch, located below the LED’s to enable them for another thirty minutes.

Troubleshooting Assumes the following: (which are not necessarily true):

There is 115v AC power to L-1 and neutral at the high voltage terminal.

The LED’s have been enabled (press the LED enable switch if necessary)

All external controls are connected.

There are no loose or “bad” connections.

IfanLEDisindicatingapossiblecausetothemalfunction,thatproblemisdealtwithrst.

THE LEFT LED’S

OPEN, CLOSE, STOP, PULSE O/C, SAFETY indicate what external inputs are being activated. If the gate is

stuck open or closed, rst verify that one of those LED’s is not on, indicating that an accessory is holding it in

that position.

Note: TheSTOPLEDwillcontinuouslyashthreetimesandpauseafterthemotorhasrunlongertheset-

ting on the motor run timer. The operator will not function again until power has been removed and

re-applied. It is important to determine the cause of this and correct the problem before putting the

unit back into operation.

THE RIGHT LED’S

OPEN LIMIT, CLOSE LIMIT, CLOSE TIMER, OPEN MODE, and CLOSE Mode indicate what operator

functions are taking place. e OVER CURRENT LED lights when the current sensor activates and stays on

until another input of action takes place. is LED can also light if no current is sensed for 15 seconds while the

motor is “being told” to run. Also if, for example, the OPEN LIMIT LED is lit while the open limit switch is not

activated, check for a defective switch. Flashing OVER CURRENT LED indicated low voltage situation.

GATE WILL NOT OPEN

OR OPERATE

No LED’s are on

Cause Solution

No power between L1 and

Neutral with power switch on

No power between L-1 and

Neutral with power switch o

Check connection from power supply

Check wiring from high voltage terminal to power plug. Replace as necessary

If problem can’t be corrected, you may need to replace the controller

Check connection from high voltage plug to controller

Check wiring from high voltage terminal to power plug. Replace as necessary.

22

Page 23

23

Page 24

24

www.gateopeners.com

Loading...

Loading...