Page 1

ENGLISH

BA

C

24 Vdc ELECTRONIC CONTROL UNIT FOR SWING GATES

USE INSTRUCTIONS - INSTALLATION INSTRUCTIONS

This 24 Vdc control unit for swing gates offers high performance and a wide range of adjustments: opening and closing decelerations,

possibility of managing one or two motors, management of opening and closing limit-switches, and the possibility of managing two

GATECODERS.

A sophisticated electronic control constantly monitors the power circuit and disables the control unit in the event of malfunctions that

could impair efficiency of the electronic clutch.

The parameter settings and the operating logics are set and shown on a handy display, which indicates gate status during normal operation.

Operating times are adjusted by self-learning during programming.

The water-tight enclosure is designed to house the control unit, the toroidal transformer and any buffer batteries (optional) having the

characteristics and dimensions indicated in the table below.

2. TECHNICAL SPECIFICATIONS

1. GENERAL CHARACTERISTICS

remrofsnartfoegatlovylppuS .zH06/05-)%01-6+(~V511/032

wopdebrosbA W3

re

daolxamrotoM 2xW07

sesufnoitcetorP 4

scigolnoitcnuF

suaP gnimmargorpgnirudgninrael-fleshguorhT

emite

ecroftsurhT yalpsidnoelbatsujdaslevelruoF

snoitareleceD gnisolc

rotcennocoidaR rotcennocnip-5dipaR

blanimreT

snoisnemiddraoB .mm031x561

ATTENTION: Different output values can be obtained on the 24V~ voltage depending on the mains voltage value. Before start-up, always

check the transformer output voltage. This must not exceed 26V~ for both 230V~ and 115V~ power supply. Voltage must be measured

load free, i.e. with the transformer powered and disconnected from the board.

tinulortnocfoegatlovylppuS .zH06/05-)%01-6+(~V42

daolxamseirosseccA Am005cdV42

emitgnisolc/gninepO gnimmargorpgnirudgninrael-fleshguorhT

stupnidraoblanimreT

stuptuodrao

daol.xamthgilysetruoC/pmalgnihsalF .xamW51cd

erutarepmettneibmagnitarepO C°05+C°02-

deppetS/citamotuA

C

remrofsnartladiorot~V032foscitsiretcarahC AV021/~V22.ces/~V032.mirp

remrofsna

rtladiorot~V511foscitsiretcarahC AV021/~V02.ces/~V511.mirp

seirettablanoitpofoscitsiretcarahC .mm801x07x

erusolcneroodtuofoscitsiretcarahC 55PI-.mm521x522x503

V42

/citamotuaimeS

epytodnoC

dnagninepO

onairtsedeP/gninepolatoT

09.snemid/hA4-V21

hctiws-timilgnisolc-gninepO/potS/

deppetS/citamotuaimeS/citamotuA

redocnE/ylppusyrettaB/~V42ylppusrewoP

cdV42/srotoMcdV42/seirosseccaotylppusrewopcdV42

kcolcirtcelE~/cdV21/pmalgnihsalF-thgilysetruo

3. PRELIMINARY SETTING-UP

ATTENTION: To ensure people’s safety, all warnings and instructions in this booklet must be carefully observed. Incorrect installation or

incorrect use of the product could cause serious harm to people.

Make sure there is an adequate differential switch upstream of the system as specified by current laws, and install an all-pole thermal

breaker on the power supply mains.

To lay electric cables, use adequate rigid and/or flexible pipes.

Always separate the connection cables of low voltage accessories from the 115/230 V~ power cables. To prevent any interference

whatever, use separate sheaths.

Maximum length of power cables between control unit and motors must not exceed 10 m, using cables of 2.5mm2 diameter.

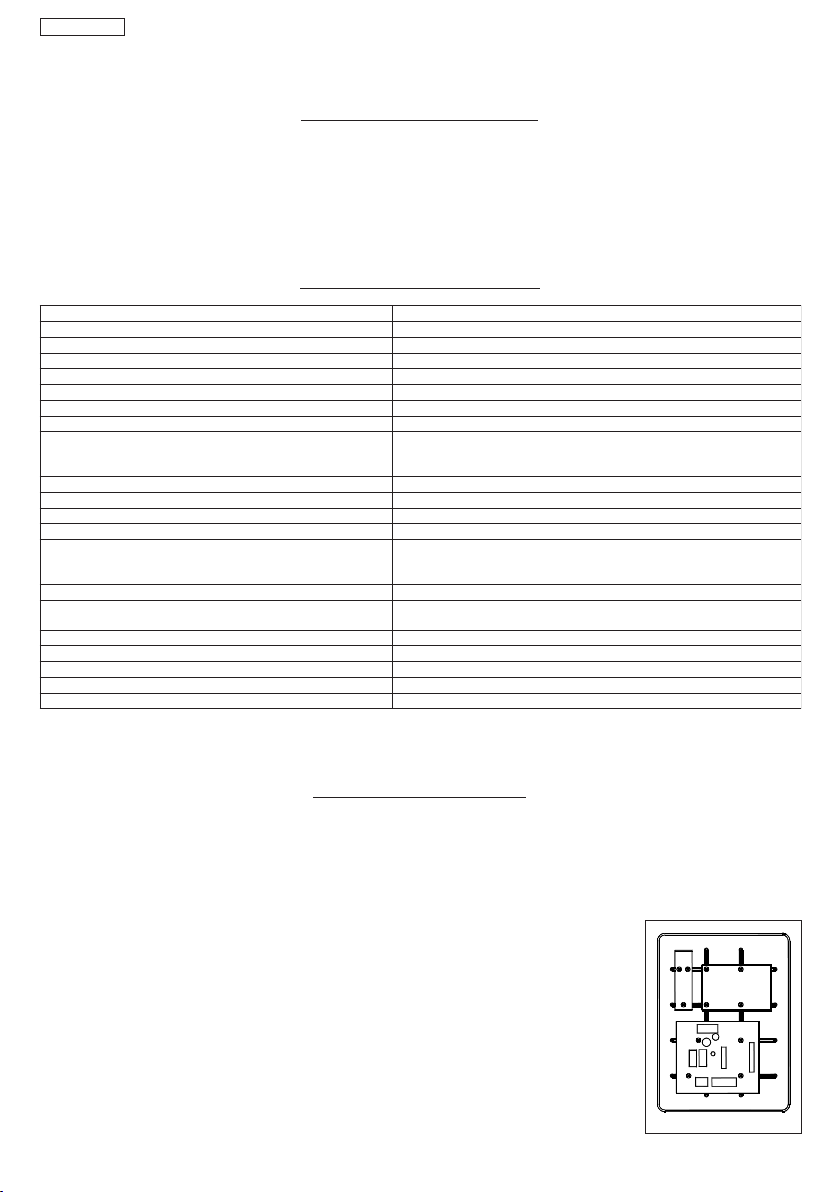

Procedure for securing components inside the water-tight enclosure.

1- Secure the support for the toroidal transformer in position A with 3 Ø4.2x13 self-tapping screws (supplied),

placing the supplied spacers between the transformer support and the guides of the water-tight enclosure.

2- Secure the transformer to the support with 2 clamps (supplied).

3- If using buffer batteries, secure the relevant support in position B with 4 Ø3.5x9.5 self-tapping screws

(supplied), fastening the screws in the crossover holes of the enclosure guides.

N.B.: the support is sized to house 2 batteries (not supplied) with the dimensions specified in the table in

paragraph 2.

4- Position the batteries on the support and secure them with plastic clamps.

5- Secure the control unit in position C with the 4 Ø4.2x13 self-tapping screws (supplied), placing the supplied

spacers between the control unit and the enclosure guides.

secivedytefasgnisolc-gninepO/gninep

10

Fig. 1

Page 2

ENGLISH

4. CONNECTIONS AND OPERATION

4.1. TERMINAL BOARD CN1

4.1.1. Power supply 22V

“VAC -VAC” terminals. The secondar y circuit of the 24V~ 50/60 Hz transformer should be connected to this input. Power supplied by the

transformer is signalled by the lighting of the “ALIM” LED located under the terminal board.

4.1.2. Batteries

“+BAT - -BAT” terminals. Connect the power cables of the buffer batteries (optional) to these terminals. The control unit is designed to

operate with two buffer batteries, with the minimum characteristics shown on the table in paragraph 2. During normal operation, the unit

keeps the batteries charged and these start operating if no power is supplied to the transformer.

N.B.:

• Power supplied by batteries only should be considered an emergency situation. The number of possible manoeuvres is linked to the

quality of the batteries, the structure of the gate to be moved, the time elapsed since power cut occurred, etc, etc.

• Observe the battery power supply polarity.

4.1.3. Accessories

“+24V - -24V” terminals. The accessories power cables should be connected to these terminals.

N.B.:

• The maximum load of the accessories must not exceed 500 mA.

• The output of these terminals is DC - observe the power supply polarity of the accessories.

4.1.4. Earth

“ “ terminal. The control unit earthing cable should be connected to this terminal.

N.B.:

• This connection is absolutely necessary to ensure a correctly operating control unit.

4.2. TERMINAL BOARD CN2

4.2.1. Gearmotor 1

“APM1 - CHM1” terminals. For double leaf applications, connect to these terminals the gearmotor fitted on the leaf which must move

first. For single leaf applications, the gearmotor must be connected to these terminals. The maximum load of the gearmotor must not

exceed 70W.

4.2.2. Gearmotor 2

“APM2 - CHM2” terminals. For double leaf applications, connect to these terminals the gearmotor fitted on the leaf which must move last.

For single-leaf applications, nothing should be connected to these terminals. The maximum load of the gearmotor must not exceed 70W.

4.2.3. Electric lock

“ELS - ELS”terminals. The electric lock, if any, with 12 Vdc/~ power supply, should be connected to these terminals. To facilitate release of

the electric lock, the over-pushing stroke can be input by enabling parameter “F” (see paragraph 9).

N.B.:

• In double-leaf applications, install the electric lock on the leaf where gearmotor 1 is installed.

4.2.4. Flashing lamp / Courtesy light

“LAMP - LAMP” terminals. Both a flashing lamp and a courtesy light can be connected to these terminals, both with 24 Vdc power supply

and maximum 15W. To make this output operational, select parameter “G”, see paragraph 9.

Flashing lamp operation:

During normal operation, the flashing lamp provides a fixed pre-flashing of 1.5 seconds during both opening and closing. When the gate

is open, and the closing safety devices are tripped, the lamp flashes to indicate that a manoeuvre is taking place in the gate movement

area. We advise you to connect the flashing lamp before programming, because it indicates its phases. Use a fixed light flashing lamp;

flashing is controlled by the control unit.

Courtesy light operation:

The courtesy light stays lighted for a fixed time of 90 seconds from the OPEN pulse, after which it goes OFF. Use a lamp with 24 V power

supply and maximum 15W.

4.3. TERMINAL BOARD CN3

4.3.1. Motor 1 closing limit-switch

“COMF - FCC1” terminals. Normally closed contact. This is tripped and stops the closing motion of motor 1. The status of this input is signalled

by LED FCC1.

4.3.2. Motor 1 opening limit-switch

“COMF - FCA1” terminals. Normally closed contact. This is tripped and stops the opening motion of motor 1. The status of this input is

signalled by LED FCA1.

4.3.3. Motor 2 closing limit-switch

“COMF - FCC2” terminals. Normally closed contact. This is tripped and stops the closing motion of motor 2.The status of this input is signalled

by LED FCC2.

4.3.4. Motor 2 opening limit-switch

“COMF - FCA2” terminals. Normally closed contact. This is tripped and stops the opening motion of motor 2. The status of this input is

signalled by LED FCA2.

N.B.:

• If no limit-switch is used, jumper connect the inputs.

• The limit-switches cannot be used as the start of the decelerated section.

4.3.5. Motor 1 encoder

“ENC1” terminal. The signal received from the encoder installed on gearmotor 1 must be connected to this terminal. For operation and

activation of the encoder, see paragraph 6.

N.B.: If no encoder is used, do not, on any account, jumper-connect the inputs.

11

Page 3

ENGLISH

ENCODER

OFF ON

AMPERO

3421

ON

ENCODER

OFF ON

AMPERO

3

421

ON

4.3.6. Motor 2 encoder

“ENC2” terminal. The signal received from the encoder installed on gearmotor 2 must be connected to this terminal. For operation and

activation of the encoder, see paragraph 6.

N.B.: If no encoder is used, do not, on any account, jumper-connect the inputs.

Attention: In two-motor applications, the encoder must be installed on both motors.

4.4. TERMINAL BOARD CN4

4.4.1. Total opening

“COM - OPEN A”terminals. Normally open contact. Connect, to these terminals, any pulse generator (e.g. push-button, key selector, etc.)

which, by closing a contact, generates a gate total opening or closing pulse. The operation of this generator is defined by parameter “D”,

see paragraph 9.

N.B.:

• A total opening pulse always has priority over pedestrian opening.

• To connect several pulse generators, connect the devices in parallel.

4.4.2. Pedestrian opening

“COM - OPEN B” terminals. Normally open contact. Connect, to these terminals, any pulse generator (e.g. push-button, key selector, etc..)

which, by closing a contact, generates a gate partial opening or closing pulse. In double leaf applications, pedestrian opening corresponds

to total opening of leaf 1. In single leaf applications, pedestrian opening corresponds to about 30% of memory-stored total opening.

N.B.:

• A total opening pulse always has priority over pedestrian opening.

• To connect several pulse generators, connect the devices in parallel.

4.4.3. Stop

“COM - STOP” terminals. Normally closed contact. Connect, to these terminals, any safety device (e.g. pressure switch, safety edge, etc.)

which, by opening a contact, immediately stops the gate and disables all automatic functions. The status of this input is signalled by the

“STOP” LED. The gate resumes its memory-stored cycle only by means of another total or partial opening pulse.

N.B.:

• If no STOP devices are connected, jumper connect the input.

• To connect several STOP commands, connect the devices in series.

4.4.4. Closing safety devices

“COM - FSW CL”terminals. Normally closed contact. Connect, to these terminals, any safety device (e.g. photocell, safety edge, pressure

switch etc..) which, by opening a contact, affects the gate's closing motion, reversing it to the mechanical stop, or to the opening limitswitch. The status of this input is signalled by LED “FSW-CL”.

4.4.5. Opening safety devices

“COM - FSW OP”terminals. Normally closed contact. Connect, to these terminals, any safety device (e.g. photocell, safety edge, pressure

switch etc..) which, by opening a contact, affects the gate's opening motion, causing it to stop immediately. When the safety device has

been reset, the gate resumes its memory-stored cycle. The status of this input is signalled by LED “FSW-OP”.

N.B.:

• If no safety devices are connected, jumper connect the inputs.

• To connect several safety devices, connect the devices in series.

The control unit is designed to house a 5-pin radio-receiver module. Installation procedure: turn off power and fit the module in connector

CN5 on the control unit.

ATTENTION: To avoid damaging the receiver and thus irreparably compromising its operation, the receiver must be installed while

observing the fitting direction specified in paragraph 13 (connection lay-out).

This done, observe the radio-receiver instructions to store the radio control in the memory.

6. OPERATION WITH ENCODER OR AMPEROMETRIC OPERATION

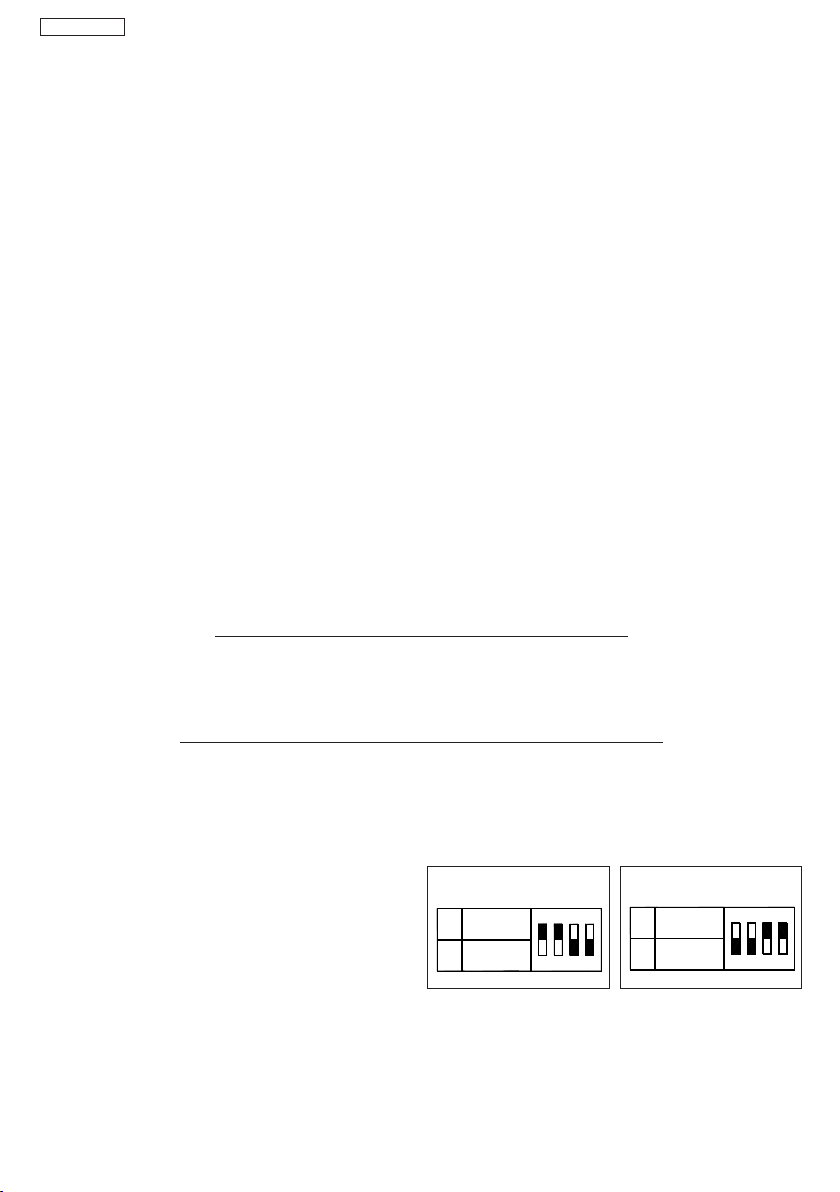

The control unit has 4 DIP SWITCHES, which enable selection of either amperometric operation or operation with Encoder.

Operation with encoder provides greater safety in detecting obstacles and greater repeatability of the deceleration point.

N.B.: Operation with encoder requires mechanical stops, or limit-switches, for both opening and closing.

To select operation with encoder, position DIP-SWITCHES 1 and 2 to ON and DIP-SWITCHES 3 and 4 to OFF (Fig.02).

To select amperometric operation, position DIP-SWITCHES 1 and 2 to OFF and DIP-SWITCHES 3 and 4 to ON (Fig.03).

ATTENTION: For a correct programming procedure of the control unit, carry out this operation before programming the control unit

because it radically modifies its operation.

Operation with Encoder Amperometric operation

Fig. 2

5. INSTALLING THE RADIO CONTROL RECEIVER BOARD

12

Fig. 3

Page 4

ENGLISH

7. CONTROL LEDS

SDELNOFFO

MILAremrofsnartladiorotybylppusrewoP deilppusrewoponroseirettabybdeilppusrewoP

1CCF deppirttonhcti

1ACFdeppirttonhctiws-timilgninepo1rotoM deppirthct

2CCF deppirttonhctiws-timilgnisolc2rotoM deppirthctiws-timilgnisolc2rotoM

2ACFdeppi

POTSdetavitcatondnammocpotS detavitcadnam

LC-WSFdeppirttonecivedytefasgnisolC deppirtecivedytefasgnisolC

PO-WSFdeppirttonecivedytefasgninepO

N.B.:

• Indicated in bold: status of LEDs with gate closed, control unit powered, and both limit-switches installed.

• If the limit-switches are not used, the relevant contacts must be jumper connected and LEDs FCC1 - FCA1 - FCC2 - FCA2 must be

lighted.

• If no STOP devices are connected, jumper connect the input. The STOP LED must be lighted.

ws-timilgnisolc1rotoM deppirthctiws-timilgnisolc1rotoM

iws-timilgninepo1rotoM

rttonhctiws-timilgninepo1rotoM deppirthctiws-timilgninepo2rotoM

mocpotS

deppirtecivedytefasgninepO

The control unit has a handy display for viewing and programming the operating parameters. Furthermore, it constantly shows gate status

during normal operation.

When operating parameters are being displayed and programmed, the display shows the selected

parameter on the left, and its set value on the right. Fig. 04 shows the viewing example of parameter “A”

at value “2”.

During normal operation, the display shows gate status. The displayed values are indicated on the following

table:

EULAVYALPSID SUTATSETAG

tsertaetaG

gninepoetaG

sesuapninepoetaG

gnisolcetaG

)hpargaraptxenees-delbaneerusolc-ercitamotuahtiwylnO(sutat

Fig. 4

9. ADJUSTING THE OPERATING PARAMETERS

N.B.: Before you begin adjusting the operating parameters, select the type of operation for the control unit: with or without encoder (see

paragraph 6).

To access operating parameter adjustment, follow the instructions below:

1- When you have made all the necessary connections, power up the system and check if all the signalling LEDs are in the situation

specified in paragraph 7.

2- The display shows value “ ”.

3- Press and hold down push-button P2 until the display shows the name and value of the first parameter.

4- Press push-button P1 to change the value of the parameter.

5- To move on to the next parameter, press push-button P2.

6- When 60 seconds have elapsed without any key being touched, the control unit exits the adjustment mode. You can manually exit

the adjustment mode by scrolling all the parameters with push-button P2. When the display shows value “ “, you have returned to

normal operation.

8. OPERATION OF DISPLAY

13

Page 5

ENGLISH

The following table summarises all settable parameters and the assignable values.

YALPSID NOITPIRCSED

hctulccinortceleehtfoytivitisnesehtgnitsujdA

ecrofrotommuminiM

ecrofrotomwol-muideM

ec

rofrotomhgih-muideM

ecrofrotomhgiH

:yaled2faeL .sevaelowtehtfoemittesffoehttcelesotuoyselbaneretemarapsi

ht

tesffosdnoces5.1

tesffosdnoces3

tesffosdnoces6

tesffosdnoces01

:erusolceRcitamotuA .erusolceretagcitamot

delbanE

itcnufodnoC .detibihnisidnammoctratseht,denepogniebsietagehtelihwdelbanesinoitcnufsihtfi

:no

E

delban

:ekortsgnihsuprevO gnisolcstistratsdellatsnisikcolcirtceleehthcihwnofaeleht,eslupNEPOyreveta,noitcnuf

delbanE

hsalF/thgilysetruoC gnitceles,slanimretPMAL-PMALehtmorftuptuofoepytehttcelesnacuoy,retemarapsihthtiw

areleceD .seulavtesowtehtmorfgnitceles,noitcesdetarelecedehtfohtgnelehttesotdesusiretemarapsiht

.seulavowt

hgiH

woL

iL .hctiws-timilehttuohtiwrohtiwnoitarepotcelesotuoyselbaneretemarapsiht

:srotomforebmuN sevaelowthtiwrofaelenohtiw:etagfoepytehttcelesotdesusiretemarap

delbasiD

:dnammocANEPOfonoitarepO .nottub-hsup)gninepolatot(ANEPO

.....snepO/sesolC/snepO

delbasiD

sihtelbaneuoyfi

delbasiD

:pmalgni

pmalgnihsalF

:egatnecreptniopnoit

:noitarepohctiws-tim

siht

hgilysetruocdnapmalgnihsalfgnomamorf

:esahpnoitarelecedgniruddeepS ehtmorftignitce

hctiws-timiltuohtiwnoitarepO

hc

tiws-timilhtiwnoitarepO

uaselbasidroselbanenoitcnufsiht

ehtforuoivahebehtsenimretednoitcnufsiht

......snepO/spotS/sesolC/spotS/snepO

.kcolcirtceleehtfoesaelersetatilicafsihT.sdnoceswefaroftnemevom

.t

)sdnoces09rofevitca(thgilysetruoC

gninepo

derots-yromemmumixamfo%04

gninepoderots-yromemmumixamfo%02

detcennocrotomenoylno,etagfael-elgniS

detcennocsrotomowt,etagfael-elbuoD

les,esahpnoitarelecedehtgniruddeepsrotomtesotdesusiretemarapsiht

14

Page 6

ENGLISH

10. PROGRAMMING

N.B.:

• Before you begin programming, select the type of operation for the control unit: with or without encoder (see paragraph 6).

During the programming procedure, the control unit memory-stores the opening, closing mechanical stop points and any pause time

before re-closure.

1- Release the gearmotors, locate the leaves at half open point, and re-lock the operators.

2- Power up the control unit and check if value “ ” is shown on the display.

3- Press and hold down push-button P2 until the display shows the first parameter and relevant value.

4- Give an OPEN A command with any device connected to this input: the display shows value “ ”, and the leaves begin to move.

The first manoeuvre performed by the leaves must be closing. If this does not happen, stop the gate movement with a reset pulse. To

do this, make a bridge between the two “RESET” PINS, using the connector (see Fig.5). Cut

power and put the connector back in its normal position (Fig. 5). Then change over the

wires of the motor/s, which had performed the opening operation. Resume the

programming stage from point 1.

5- When the closing mechanical stop point is reached, the gearmotors pause for about 2

seconds, and then restart with a total opening manoeuvre up to the opening mechanical

stop point or up to the relevant limit-switch.

6- If automatic reclosure was not enabled, this means programming has finished, otherwise

the control unit begins counting pause time.

7- When the required time has elapsed, give another OPEN A pulse, and the gate will begin

to close.

8- When the closing stop has been reached, programming has terminated, and the display

shows value “ ”.

N.B.:

• The display shows value “ ” during the entire programming procedure.

• The flashing lamp stays lighted on a fixed light during the entire programming time.

• Leaf movement is decelerated during the programming procedure.

Fig. 5

This is a very important device for reasons of safety. Its setting stays unchanged long-term, without wear. It is active during both closing and

opening. When it operates, it reverses gate movement without disabling automatic closing if activated.

If the clutch operates several consecutive times during the closing movement, the control unit goes into STOP status, disabling any

automatic command. If the clutch operates several consecutive times, this means that the obstacle remains and it could be dangerous

to perform any manoeuvre. To restore normal operation, the user must give an OPEN A / OPEN B pulse.

12. PROTECTION FUSES

ESUFNOITCETORPESUFNOITCETORPESUFNOITCETORPESUFNOITCETORP

oty

11. OPERATION OF ELECTRONIC CLUTCH

1F A01T=

02x5-V052

ylppusrewoP

~V42

2F A36.0T=

02x5-V052

lppuS

seirossecca

3F A36.0R=

-yrettabdna

regrahc

02x5-V052

pmalgnihsalF

4F A51.3R=

tuptuo

02x5-V052

kcolcirtcelE

uptuo

t

15

Page 7

ENGLISH

13. CONNECTION LAY-OUT

Batteries

Toroidal transformer

230 V~

50 Hz

Power supply for external

+

VAC

VAC

+24V

+BAT

-BAT

F1

Motor 1

Electric lock 12V

accessories

-

-24V

ALIM

CN2

APM1

M1

Motor 2

Earthing

CN1

CHM1

M2

APM2

CHM2

ELS

ELS

F3

LAMP

LAMP

Flashing lamp

Courtesy light

Motor 2 encoder

Motor 1 encoder

COMF

F2

DS1

P1

RST

DS2

G

FD

M

N

2003/4/5

6/7/8/9

A

O

P2

10/11/12

M

S

G

A

L

AMPERO

ON

ENCODER

OFF

ON

3421

JMP1

F4

STOP

FSW-OP

A

ENC2

OPEN

ENC1

+

-

24V dc

-

RX-OP

1

2

3

4

+

5

TX - OP/CL

1

+

2

OPEN

B

DL6

STOP

FSW-CL

DL7

CL

FSW

DL8

CN4

OP

COM

TX-OP

+

TX - OP/CL

+

CN5

1

2

1

2

3

4

5

FCA2

FCA1

FCC1

FCC2

DL5

DL3

DL2

DL4

CN3

FCC2

FCC1

FCA2

FCA1

+

24V dc

-

24V

+

dc

24V

-

+

dc

Receiver

Connector for

5-pin receiver

Closing safety

devices

Opening safety

devices

Opening /closing

safety devices

-

+

24V dc

24V

-

+

dc

24V dc

-

+

RX-CL

1

2

3

4

-

5

+

TX - CL

+

-

1

24V dc

+

2

16

Page 8

ENGLISH

sesolc,desaelernehw

dna,emitesuapskcoL

dnanoitarepospotS

dnanoitarep

esaelernosemuser

esaelernosesr

.ces

5retfa

ospotS

ever

sesolc,desaelernehw

dna,emitesuapskcoL

.ces

5retfa

dnanoitarepospotS

dnanoitarepos

esaelernosemuser

esaelernosesrever

potS

14. FUNCTION LOGICS

,

esaelernO.erusolcspotS

despalesahemitesuap

fi,.ces5retfasesolc

tceffeoN

sdnammocNEPOselbas

dnanoitarepospotS

esaelernosemuser

,

esaelernO.erusolcspotS

despalesahemitesuap

fi,.ces5retfasesolc

tceffeoN

sdnammocNEPOselbas

dnanoitarepospotS

esaelernosemuser

0=E1=d1=Ccigol"PA"citamotuAdeppetS

0=E0=d1=Ccigol"A"citamotuA

iDtceffeoNsdnammocNEPOselbasiD

)delbasidNEPO(

noitarepospotStceffeoN

tceffeoN

sesolc-erdnagninepo

laitrapfaelsetucexE

emitesuapretfa

etagehtsesolC

yletaidemmi

iDtceffeoNsdnammocNEPOselbasiD

)delbasidNEPO(

noitarepospotStceffeoN

tceffeoN

sesolc-erdnagninepo

laitrapfaelsetucexE

emitesuapretfa

etagehtsesolC

yletaidemmi

tceffeoNnoitarepospotStceffeoNnoitomsesreveR

tceffeoNnoitarepospotS

-erdnafaelehtsnepO

emitesuapre

AnepOBnepOpotSsecivedytefasgninepOsecivedytefasgnisolCecivedytefasLC/PO

tfasesolc

sutatsetaG sesluP

esuapnonepO emitesuapsdaoleR

desolC

gnisolC noitometagsesreveRtceffeoNnoitarepospotStceffeoNnoitomsesreveR

17

sutatsetaG sesluP

gninepO noitometagsesreveRtceffeoNnoitarepospotS

-erdnafaelehtsnepO

emitesuapretfasesolc

AnepOBnepOpotSsecivedytefasgninepOsecivedytefasgnisolCecivedytefasLC/PO

desolC

dnanoitometagspotS

dnanoitometagspotS

esluptxennosnepo

esluptxennosesolc

esuapnonepO emitesuapsdaoleR

gninepO

gnisolC

Page 9

ENGLISH

sesolc

dnammocNEPOselbasiD

-er,esaelerno,dna

dnanoitarepospotS

dnan

esaelernosemuser

esaelernosesrever

..ces5retfa

oitarepospotS

sesolc

dnammocNEPOselbasiD

dnanoitarepospotS

dnanoitarepospotS

esaelernosemuser

esaelernosesrever

-er,esaelerno,dna

..ces5retfa

sesolc,desaelernehw

dna,emitesuapskcoL

dnanoitarepospotS

dnanoitarepospotS

esaelernosesr

.ces

5retfa

esae

lernosemuser

ever

sesolc-er,esaelerno,dna

dnammocNEPOselbasiD

..ces5retfa

sdnammocNEPOselbasiDtceffeoNsdnammocNEPOselbasiD

tceffeoN

tceffeoN

dnanoitarepospotS

esaelerno

sesolc-er,esaelerno,dna

dnammocNEPOselbasiD

itometagsesreveR

..ces5retfa

sdnammocNEPOselbasiDtceffeoNsdnammocNEPOselbasiD

tceffeoN

tceffeoN

dnanoitarepospotS

esaelernosemuser

,

esaelernO.erusolcspotS

despalesahemitesuap

fi,.ces5retfasesolc

tceffeoN

sdnammocNEPOselbas

dnanoitarepospotS

esaelernosemuser

0=E1=d0=Ccigol"PE"citamotua-imeSdeppetS

0=E0=d0=Ccigol"E"citamotua-imeS

semuser

1=E0=d1=Ccigol"D"odnoC

)delbasidNEPO(

)delbasidNEPO(

tceffeoN

tceffeo

N

cexE

)delbasidNEPO(

)delbasidNEPO(

tceffeoN

tceffeo

N

tceffeoNnoitarepospotStceffeoNno

tceffeo

NnoitarepospotS

cexE

iDtceffeoNsdnammocNEPOselbasiD

)delbasidNEPO(

noitarepospotStceffeoN

tceffeoN

sesolc-erdnagninepo

laitrapfaelsetucexE

emitesuapretfa

etagehtsesolC

yletaidemmi

dnanoitarepoetagspotS

dnanoitarepoetagspotS

esluptxennosnepo

esluptxennosnepo

AnepOBnepOpotSsecivedytefasgninepOsecivedytefasgnisolCecivedytefasLC/PO

sutatsetaG sesluP

desolC faelehtsnepOgninepolaitrapsetu

nepO sesolCetagehtsesolC

gninepO noitometagsesreveRtceffeoNnoitarepospotS

gnisolC noitometagsesreveRtceffeoNnoitarepospotStceffeoNnoitometagsesreveR

AnepOBnepOpotSsecivedytefasgninepOsecivedytefasgnisolCecivedytefasLC/PO

sutatsetaG sesluP

desolC faelehtsnepOgninepolaitrapsetu

nepO sesolCetagehtsesolC

18

gninepO

gnisolC

-erdnafaelehtsnepO

emitesuapre

AnepOBnepOpotSsecivedytefasgninepOsecivedytefasgnisolCecivedytefasLC/PO

tfasesolc

sutatsetaG sesluP

esuapnonepO emitesuapsdaoleR

gninepO tceffeoNtceffeoNnoitarepospotS

desolC

gnisolC noitometagsesreveRtceffeoNnoitarepospotStceffeoNnoitomsesreveR

Loading...

Loading...