E-Z-GO FLEET GOLF CAR, FREEDOM, FREEDOM LE, PDS FREEDOM, PDS FREEDOM SE Owner's Manual And Service Manual

...

OWNER’S MANUAL

R

AND SERVICE GUIDE

28645-G01-GB

ef Fcv 1

ELECTRIC POWERED

FLEET GOLF CARS & PERSONAL VEHICLES

STARTING MODEL YEAR: 2001

REVISED: 10-10-02

SAFETY

For any questions on material contained in this manual, contact an authorized representative for clarification.

Read and understand all labels located on the vehicle. Always replace any damaged or missing labels.

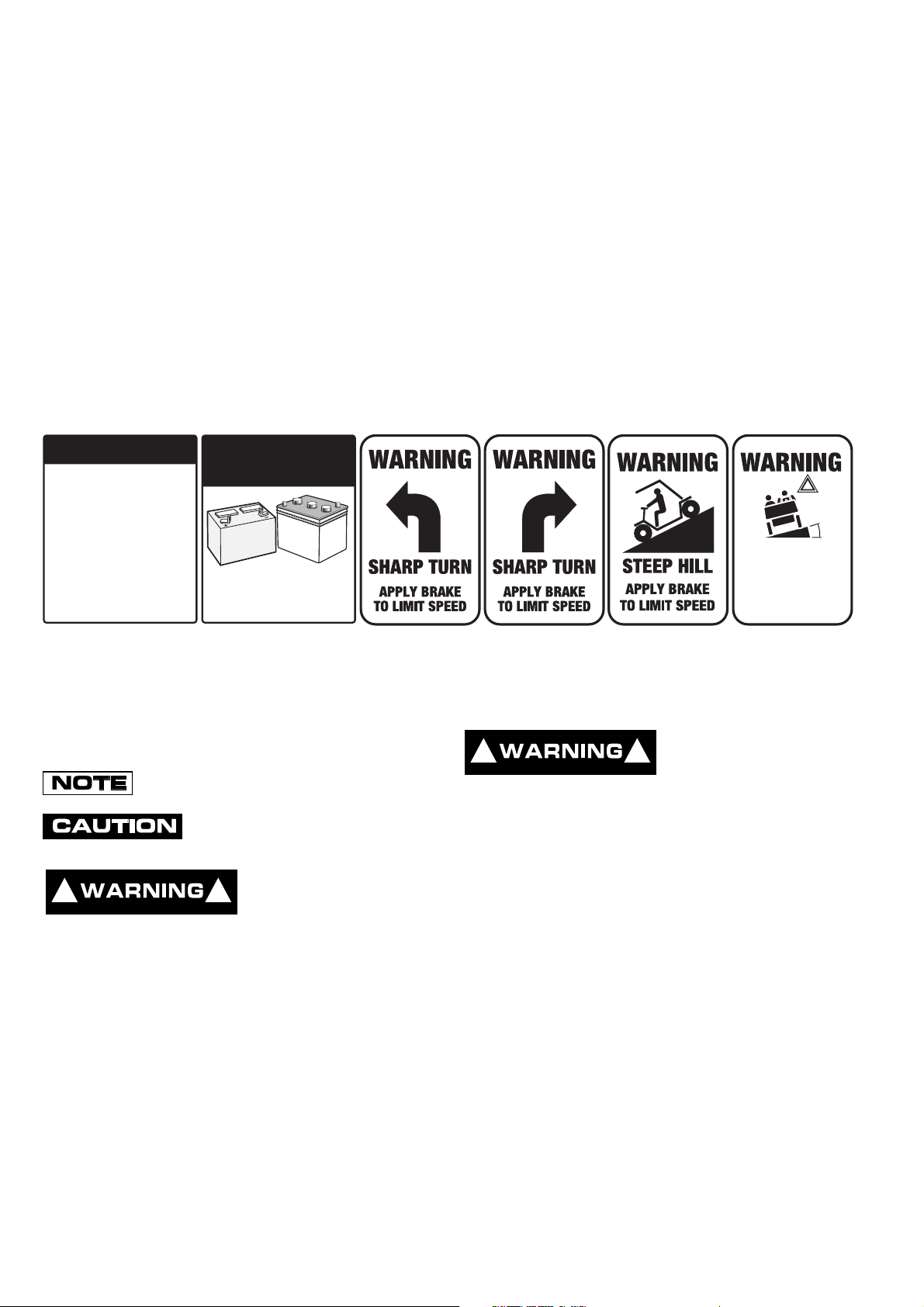

On steep hills it is p ossible for vehi cles to coast at g reater than norm al speeds en countered on a flat surface . To pre-

vent loss of vehicle contr ol and possibl e serious injur y, speeds should be limited to no more than the maxim um speed

on level ground. See GENERAL SPECIFICATIONS. Limit speed by applying the service brake.

Catastrophic damage to the drivetr ain compo nents due to ex cessive speed may result from driving th e vehicle ab ove

specified speed. Da mage caused by excessive speed may cause a loss of ve hicle control, is costly, is considered

abuse and will not be covered under warranty.

Use extra caution when towi ng the v ehicle (s). Do n ot tow a sin gle v ehicle a t speed s in e xcess o f 12 mph (19 kph). D o

not tow more than three vehic les at a time. Do not exceed 5 mph ( 8 kph) while towing multiple v ehicles. Towing the

vehicle at above the rec ommended spee d may result in pe rsonal injury and /or damage to the v ehicle and other property. Vehicles equipped with Prec ision Drive System

located under the passenger seat, in the ‘Tow/Maintenance’ position.

Signs similar to the ones illustrated should be used to warn of situations that could result in an unsafe condition.

™

(PDS) must be towed with the Run-Tow/Maintenance switch ,

BATTERY WARNING

Battery posts,

terminals and related

accessories contain

lead and lead compounds,

chemicals known

to cause cancer and

reproductive harm.

WASH HANDS

AFTER HANDLING!

BATTERIES

AND RELATED PARTS

CONTAIN LEAD

WASH HANDS

AFTER HANDLING!

WARNING: Battery posts, terminals and related

accessories contain lead and lead compounds,

chemicals known to cause cancer and reproductive harm.

Be sure that this manual remains as part of the permanent service record should the vehicle be sold.

NOTES, CAUTIONS AND WARNINGS

Throughout this g uide NOTE, CAUTION and WARNING

will be used.

A NOTE indicates a condition that should be

observed.

A CAUTION indicates a condition that

may result in damage to the vehicle.

A WARNING indi-

! !

cates a hazardous

condition that could

result in severe injury or death.

! !

lead and lead compounds. Wash hands after

handling.

Battery posts, terminals and related

accessories contain

!

<

14

˚

25

%

DO NOT

DRIVE ACROSS

SLOPES IN

EXCESS OF 14˚

Observe these NOTES, CAUTIONS and WARNINGS;

be aware that servicing a vehicle requires mechanical

skill and a reg ard f or c ond iti on s that could be hazardo us .

Improper service or repair may damage the vehicle or

render it uns af e.

(NOTES, CAUTIONS AND WARNINGS CONTINUED ON INSIDE OF BACK COVER)

OWNER’S MANUAL AND

SERVICE GUIDE

ELECTRIC POWERED

FLEET GOLF CARS &

PERSONAL VEHICLES

FLEET GOLF CAR

FLEET PDS GOLF CAR

FREEDOM

™

FREEDOM™ SE

™

FREEDOM

PDS FREEDOM

LE

™

PDS FREEDOM™ SE

™

™

LE

2+2

PDS FREEDOM

SHUTTLE

E-Z-GO Division of Textron reserves the right to make design changes without obligation to make these changes on units previously sold and the information

contained in this manual is subjec t to change without notice.

E-Z-GO Division of Text ron is no t liable f or erro rs in this man ual or f or incide nt al o r c onse quentia l da mage s th at resul t fro m t he use of the materia l in this manual.

CUSTOMER SERVICE DEPARTMENT IN USA PHONE: 1-800-241-5855 FAX: 1-800-448-8124

OUTSIDE USA PHONE: 010-1-706-798-4311 FAX: 010-1-706-771-4609

E-Z-GO DIVISION OF TEXTRON, INC., P.O.BOX 388, AUGUSTA, GEORGIA USA 30903-0388

Owner’s Manual and Service Guide

Page i

GENERAL INFORMATION

This vehicle has been designed and manufactured in the United States of America (USA) as

a ‘World Vehicle’. The Standards and Specifications listed in the following text originate in

the USA unless otherwise indicated.

The use of non Original Equipment Manufacturer (OEM) approved parts may void the

warranty.

Overfilling batteries may void the warranty.

BATTERY PROLONGED STORAGE

All batteries will self discharge over time. The rate of self disc harge varies depending on the

ambient temperature and the age and condition of the batteries.

A fully charged battery will not freeze in winter temperatures unless the temperature falls

below -75° F (-60° C).

For winter storage, the batteries must be clean, fully charged and disconnected from any

source of electrical drain. The battery charger and the controller are both sources of

electrical drain. Unplug the battery charger DC plug from the vehicle receptacle.

On PDS vehicles, disconnect the controller from the battery set by selecting the ‘TOW/

MAINTENANCE’ position on the RUN-TOW/MAINTENANCE SWITCH located under the

passenger seat.

As with all electric vehicle s, the batte ries must be ch ecked and recharged as required or at a

minimum of 30 day intervals.

Page ii

Owner’s Manual and Service Guide

TABLE OF CONTENTS

SAFETY ................................................................................................................. Inside covers

GENERAL INFORMATION ........................................................................................................ ii

SAFETY INFORMATION...... ....... ...... ....... ...... ...... ....... ...... ....... ...... ....... ...... ....... ...... ....... ...........v

BEFORE INITIAL USE .............................................................................................................. 1

Fig. 1 Initial Service Chart ......................................................................................................................1

PORTABLE CHARGER INSTALLATION ............................................................................................................1

Fig. 2 Proper Charger Installation ..........................................................................................................2

Fig. 3 Charger Receptacle Location ......................................................................................................2

CONTROLS AND INDICATORS ...............................................................................................2

KEY/LIGHT SWITCH ....................................... ............. ............. ......................... ............ .....................................2

Fig. 4 Key/Light Switch & State of Charge Meter ..................................................................................2

DIRECTION SELECTOR .....................................................................................................................................3

Fig. 5 Direction Selector Types ..............................................................................................................3

STATE OF CHARGE METER ....................... ............. ............. ............ ......................... ............. ..........................3

ACCELERATOR PEDAL ....................... ............. ............ ............. ......................... ............. ..................................3

Fig. 6 Accelerator and Brake Controls ...................................................................................................3

COMBINATION BRAKE AND PARK BRAKE PEDAL .......... ............. ............. ............ ............. ............ ............. ...3

RUN - TOW/MAINTENANCE SWITCH (PDS VEHICLES ONLY) .......................................................................3

Fig. 7 Run-Tow/Maintenance Switch ..................................................................................................... 4

HORN ..................................................................................................................................................................4

Fig. 8 Horn Button .................................................................................................................................. 4

OPERATING THE VEHICLE ..................................................................................................... 4

PRECISION DRIVE SYSTEM™ .......................................................................................................................... 5

Performance Options..................................................................................................................................... 5

Fig. 9 Performance Options ...................................................................................................................5

Regenerative Braking.....................................................................................................................................6

Pedal-Up Brakng............................................................................................................................................ 6

Walk-Away Feature........................................................................................................................................6

Anti-Roll Back Feature................. ............ ............. ............. ......................... ............ .......................................6

Anti-Stall Feature ........................................................................................................................................... 6

High Pedal Disable Feature .................................................................................... .. ....... .... .. .. ......................6

Diagnostic Mode Feature................................................................... ......... .... .... .... ......... .... ..........................7

STARTING AND DRIVING ................................... ......................... ............ ............. .............................................7

STARTING VEHICLE ON A HILL (Non PDS Vehicl e ) ........................... ......................... ............. ............. ........... 7

COASTING ..........................................................................................................................................................7

LABELS AND PICTOGRAMS ............. ............ ............. ............. ............ ............. ............ .....................................7

SUN TOP AND WINDSHIELD .............................................................................................................................8

VEHICLE CLEANING AND CARE ............................................................................................8

VEHICLE CLEANING ........................ ......................... ............. ......................... ............ .......................................8

VEHICLE CARE PRODUCTS ..................... ......................... ............. ............. ......................... ............................8

REPAIR ................................ .......................................................... ............................................ 9

LIFTING THE VEHICLE ......................................................................................................................................9

Fig. 10 Lifting the Vehicle ......................................................................................................................9

WHEELS AND TIRES .........................................................................................................................................9

Tire Repair .................................................................. .. .. ..... .. .. .. .. .. .. .. .. ..... .. .. .. .. .. .. .. .. .....................................9

Wheel Installation....................................................................... .... .. .... ....... .... .. .... .. ......... ............................10

Fig. 11 Wheel Installati o n ..................... ......................... ............ ............. ............. ................................10

LIGHT BULB REPLACEMENT ..........................................................................................................................10

Fig. 12 Headlight, Turn Signal & Marker Light Bulb Replacement ...................................... .. ......... .. .. .11

Fig. 13 Tail and Brake Light Bulb Replacement .................................................... ............ ..................11

TRANSPORTING VEHICLE ....................................................................................................11

TOWING ............................................................................................................................................................11

HAULING ........................................................................................................................................................... 12

Owner’s Manual and Service Guide

Page iii

TABLE OF CONTENTS

SERVICE AND MAINTENANCE ..............................................................................................12

SERIAL NUMBER PLATE LOCATION ............................................................................................................. 12

Early Production ..........................................................................................................................................12

Fig. 14 Serial Number Plate Location - Early Production .................................................................... 13

Late Production .............................................................................................. ....... .. .... .. .............................. 13

Fig. 15 Serial Number Plate Location - Late Production ..................................................................... 13

PERIODIC SERVICE SCHEDULE .................................................................................................................. 14

Fig. 16 Periodic Service Schedule ...................................................................................................... 14

TIRE INSPECTION ..................... ............. ............ ......................... ............. ............. ............ .............................. 15

BRAKES ........................................................................................................................................................... 15

Periodic Brake Test for Mechanical Brakes................................................................................................. 15

Fig. 17 Typical Brake Performance Test ............................................................................................. 16

REAR AXLE ...................................................................................................................................................... 16

Fig. 18 Add, Check and Drain Axle Lubricant - Early Production ........................................................ 16

Fig. 19 Add, Check and Drain Axle Lubricant - Late Production ......................................................... 16

Checking the Lubricant Level .............................................................................. .. .... .. .... .. .. ..... ................... 17

LUBRICATION ..................................................................................................................................................17

Fig. 20 Lubrication Points - Early Production ...................................................................................... 17

Fig. 21 Lubrication Points - Late Production ....................................................................................... 17

PDS SYSTEM TEST .........................................................................................................................................17

HARDWARE .....................................................................................................................................................17

Fig. 22 Torque Specifications and Bolt Grades ...................................................................................18

CAPACITIES AND REPLACEMENT PARTS ....................... ............. ............ ............. ............ ............. .............18

Fig. 23 Capacities and Replacement Parts .........................................................................................18

BATTERIES AND CHARGING ................................................................................................19

SAFETY ............................................................................................................................................................ 19

BATTERY ......................................................................................................................................................... 19

BATTERY MAINTENANCE ..............................................................................................................................19

At Each Charging Cycle .............................................................................................................................. 19

Monthly........................................................................................................................................................20

Electrolyte Level and Wa te r.......................... ............. ............ ............. ............ ............. ................................ 20

Fig. 24 Correct Electrolyte Level ......................................................................................................... 20

Fig. 25 Water Purity Table ..................................................................................................................20

Fig. 26 Automatic Watering Gun ......................................................................................................... 21

Battery Cleaning..........................................................................................................................................21

Fig. 27 Preparing Acid Neutralizing Solution .......................................................................... .. .... ....... 21

Battery Replacement................................................................................................................................... 21

Fig. 28 Battery Connections ................................................................................................................ 22

Prolonged Storage........................................................... .. .. .. .. .. ....... .. .. .. .. .. .. .. ....... .. .. .. .. .. .. ..........................22

Fig. 29 Freezing Point of Electrolyte ...................................................................................................23

BATTERY CHARGING .....................................................................................................................................22

AC Voltage ............. ......................... ............. ............. ............ ............. ............ ............................................. 23

TROUBLESHOOTING ......................................................................................................................................23

Hydrometer..................................................................................................................................................23

Fig. 30 Hydrometer ............................................................................................................................. 24

Using A Hydrometer.................................................................................................................................... 24

BATTERY CHARGER MAINTENANCE ........................................................................................................... 24

Fig. 31 Hydrometer Temperature Correction .................... ............. ......................... ......................... ...25

Fig. 32 Cleaning Auxiliary Contact in Charger Plug ....................................................................... .....25

GENERAL SPECIFICATIONS..................................................................................................27

TXT ELECTRIC - FLEET...................................................................................................................................28

TXT PDS ELECTRIC - FLEET........................ ............ ............. ............. ............ ............. ............ ........................ 29

TXT ELECTRIC - FREEDOM™......................................................................................................................... 30

TXT ELECTRIC - FREEDOM™ SE................................................................................................................... 31

TXT ELECTRIC - FREEDOM™ LE ................................................................................................................... 32

TXT PDS ELECTRIC - FREEDOM™.................................. ............ ............. ............. ............ ............. ............... 33

TXT PDS ELECTRIC - FREEDOM™ SE.... ............ ............. ............ ............. .................................... ................. 34

TXT PDS ELECTRIC - FREEDOM™ LE............................................ ............ ............. ............ ............. ............. 35

TXT ELECTRIC - SHUTTLE 2+2....................................................................................................................... 36

Page iv

Owner’s Manual and Service Guide

TABLE OF CONTENTS

Fig. 29 Vehicle Dimensions............. ............. ............ .......................... ............ ............. ............ .............. 37

Fig. 30 Vehicle Dimensions, Incline Specifications and Turning Clearance Diameter ..........................38

Fig. 31 PowerWise™ Portable Battery Charger Dimensions.............................................. ..................39

LIMITED WARRANTIES........................................................................................................... 41

DOMESTIC WARRANTY...................................................................................................................................42

INTERNATIONAL WARRANTY (2001)........................................ ......................... ............. ............ ....................43

INTERNATIONAL WARRANTY (2002)........................................ ......................... ............. ............ ....................44

INTERNATIONAL WARRANTY (2003)........................................ ......................... ............. ............ ....................45

DECLARATION OF CONFORMITY (EUROPE ONLY)............................................................ 47

FLEET GOLF CAR (2000)..................................................................................................................................48

FREEDOM™ GOLF CAR (2000) .......................................................................................................................49

FREEDOM™ HP GOLF CAR (2000) ....................................................... .. ....... .. .... .. .. .... ..... .... .. .. .... .. .. ..............50

SHUTTLE 2+2 (2000).........................................................................................................................................51

FLEET AND FREEDOM™ GOLF CAR (2002)...................................................................................................52

SHUTTLE 2+2 (2002).........................................................................................................................................53

LABELS AND PICTOGRAMS.................................................................................. Appendix A

Owner’s Manual and Service Guide

Page v

N

TABLE OF CONTENTS

otes:

Page vi

Owner’s Manual and Service Guide

SAFETY INFORMATION

This manual has been designe d to assist in maintaining t he vehicle in accordanc e with procedur es developed by the

manufacturer. Adherence to these procedures an d troubleshoo ting tips will en sure the be st possible service from the

product. To reduce the chance of personal injury or property damage, the following must be carefully observed:

GENERAL

Many vehicles are used for a variety of tasks beyond the original intended use of the vehicle; therefore, it is impossible

to anticipate and warn aga ins t e ve ry po ss ib le c om bi nati on o f c ircu ms tances tha t may occur. No warnings can take the

place of good common sense and prudent driving practices.

Good common sense an d prudent driving practices do more to prevent accidents and i njury than all of the warnin gs

and instructions combined. The manufactur er strongly suggests that al l users and maintenance personnel read this

entire manual paying particular attention to the CAUTIONS and WARNINGS contained therein.

If you have any questions regarding this vehicle, contact your closest representative or write to the address on the back

cover of this publication, Attention: Product Service Department.

TEXTRON Golf, Turf & Specialty Products reserves the right to make design changes without obligation to make these

changes on units previously sold and the information contained in this manual is subject to change without notice.

TEXTRON Golf, Turf & Specialty Products is not lia ble for err or s in th is ma nual or for i ncide ntal or cons equ ent ial dam ages that result from the use of the material in this manual.

This vehicle conforms to the current applicable standard(s) for safety and performance requirements.

These vehicles are desi gne d and ma nufactured for off-road use. They do not con form to F ede ra l Mo tor Vehicle Safety

Standards of the United States of America (USA) and are not equ ipped fo r operati on on pu blic str eets. Som e comm unities may permit these vehi cles to be operated on their streets on a limit ed basis and in accordance wi th local ordinances.

With electric powe red vehicles, be sure that al l electrical accessories ar e grounded directly to the batte ry (-) post.

Never use the chassis or body as a ground connection.

Refer to GENERAL SPECIFICATIONS for vehicle seating capacity.

Never modify the vehicle in any way that will alte r the weight distributi on of the vehicle, decreas e its stability

or increase the speed beyond the factory specification. Such modifications can cause serious personal injury

or death. Modifications that increase the speed and/or weight of the vehicle will extend the stopping distance and may

reduce the stabilit y of the vehicle. Do not make a ny such modification s or changes. The manufac turer prohibits and

disclaims responsibility for any such modifications or any other alteration which would adversely affect the safety of the

vehicle.

Vehicles that are capable of higher sp eeds must limit th eir speed to no more th an the speed of other ve hicles when

used in a golf course en vironment. Additi onally, speed should be further moderated by the environmental condition s,

terrain and common sense.

GENERAL OPERATI O N

Always:

• Use the vehicle in a responsible manner and maintain the vehicle in safe operating condition.

• Read and observe all warnings and operation instruction labels affixed to the vehicle.

• Follow all safety rules established in the area where the vehicle is being operated.

Owner’s Manual and Service Guide

Page vii

SAFETY INFORMATION

• Reduce speed to compensate for poor terrain or conditions.

• Apply service brake to control speed on steep grades.

• Maintain adequate distance between vehicles.

• Reduce speed in wet areas.

• Use extreme caution when approaching sharp or blind turns.

• Use extreme caution when driving over loose terrain.

• Use extreme caution in areas where pedestrians are present.

MAINTENANCE

Always:

• Maintain the vehicle in accordance with the manufacturer’s periodic service schedule.

• Ensure that repairs are performed by those that are trained and qualified to do so.

• Follow the manufac tu re r’s maintenance p roce dur es fo r t he v eh icle . B e s ur e to disable the vehicle b efore per for ming

any maintenance. Disabling includes removing the key from the key switch and removal of a battery wire.

• Insulate any tools used within the battery area in order to prevent sparks or battery explosion caused by shorting the

battery terminals or associated wiring. Remove the batteries or cover exposed terminals with an insulating material.

• Check the polarity of each battery terminal and be sure to rewire the batteries correctly.

• Use specified replacement parts. Never use replacement parts of lesser quality.

• Use recommended tools.

• Determine that to ols and procedures not specif ically recommended by the man ufacturer will not compromise the

safety of personnel nor jeopardize the safe operation of the vehicle.

• Support the vehi cle using wheel cho cks and jack stands. Never g et under a vehicle t hat is s upported by a jack. Lift

the vehicle in accordance with the manufacturer’s instructions.

• Maintain the vehicle in an area away from exposed flame or persons who are smoking.

• Be aware that a vehicle that is not performing as designed is a potential hazard and must not be operated.

• Test drive the vehicle after any repairs or maintenance. All tests must be conducted in a safe area that is free of both

vehicular and pedestrian traffic.

• Replace damaged or missing warning, caution or information labels.

• Keep complete records of the maintenance history of the vehicle.

The manufacturer cannot anticipate all situations , therefore people attem pting to maintain or repair the vehi cle must

have the skill an d expe rience to rec ogniz e and protect t hem selv es from potenti al si tuation s that could res ult in seve re

personal injury or death and damage to th e vehicle. Use extrem e caution and, if un sure as to the potenti al for injury,

refer the repair or maintenance to a qualified mechanic.

Page viii

Owner’s Manual and Service Guide

SAFETY INFORMATION

VENTILATION

Hydrogen gas is generated in the charging cycle of batteries and is explosive in concentrations as low as 4%. Because

hydrogen gas is lighter than air, it will collect in the ceiling of buildings necessitating proper ventilation. Five air

exchanges per hour is considered the minimum requirement.

Never charge a vehicl e in an area that is sub ject to flame or spark. Pay particul ar attention to natur al gas or propane

water heaters and furnaces.

Always use a dedicated circuit for each battery charger. Do not permit other appliances to be plugged into the receptacle when the charger is in operation.

Chargers must be installe d and operated in accorda nce with charger manufact urers recommendations or app licable

electrical code (whichever is higher).

Owner’s Manual and Service Guide

Page ix

Notes:

SAFETY INFORMATION

Page x

Owner’s Manual and Service Guide

SAFETY INFORMATION

Read all of manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notes, Cautions and Warnings

GENERAL

The following text is prov ide d as r eco mm end ed b y part II

of ASME/ANSI B56.8-1988. E-Z-GO strongly endorses

the contents of this specification.

PART II

FOR THE USER

4 GENERAL SAFETY PRACTICES

4.1 Introduction

4.1.1 Like other ma ch in es, carriers can c aus e in jur y

if improperly used or main tained. Part II contains broad

safety practices applicable to carrier operati ons. Before

operation, the user shall establish such additional specific safety practices as may reasonably be required for

safe operation.

4.2 Stability

4.2.1 Experience has shown that this vehicle, which

complies with this standard, is stable when properly

operated and when operated in acco rdance with speci fic

safety rules and practices established to meet actual

operating terrain and conditions. However, improper

operation, faulty maintenance, or poor housekeeping

may contribute to a co nditio n of instabili ty and defe at th e

purpose of the standard. Som e of the conditions which

may affect stability are failure of the user to follo w safety

practices; also, ground and floor conditions, grade,

speed, loading, the op er ation o f the car rie r wi th i mprop er

loads, battery weight, dy namic and static forces, and the

judgement exercised by the carrier operator.

(a) The user shall train carrier operators to adhere

strictly to the operating instructions stated in this Standard.

(b) The user shall survey specific operating conditions

and environment, and establ ish and train carrier operators to comply with additional, specific safety practices.

4.3 Nameplates, Markings, Capacity, and Modifica-

tions

4.3.1 The user shal l maintain in a legible con dition

all nameplates, warnings, and instructions which are

supplied by the manufacturer.

4.3.2 The user shall no t p erf orm any m odi fic ation or

addition which affects capacity or safe operation, or

make any change not in accordance with the owner’s

manual without the manufact urer’s prior written authorization. Where authorized modifications have been made,

the user shall ensure that capacity, operation, warning,

and maintenance in struction plates, tags, or decals ar e

changed accordingly.

4.3.3 As required under paras. 4.3.1 or 4.3.2, the

manufacturer shall be contacted to secure new nameplates, warnings, or instructions which shall then be

affixed in their proper place on the carrier.

4.4 Fuel Handling and Storage

4.4.1 The user shall supervise the stor age an d h an-

dling of liquid f uels (when us ed) to be ce rtain that it is in

accordance with ap propriate paragraphs of ANSI/NFPA

505 and ANSI/NFPA 30.

4.4.2 Storage and handling of liquefied petroleum

gas fuels shall be in acc ordance with appropriate paragraphs of ANSI/NFPA 505 and ANSI/NFPA 58. If such

storage or handling is not i n com pliance with these standards, the user shall pr event the car rier from bei ng used

until such storage and handling is in compliance with

these standards.

4.5 Changing and Charging Storage Batteries for

Electric Personnel and Burden Carriers

4.5.1 The user shall require battery changing and

charging facilities and procedures to be in accordance

with appropriate paragraphs of ANSI/NFPA 505.

4.5.2 The user shall periodically inspect facilities

and review procedures to be certain that appropriate

paragraphs of ANSI/NFPA 505, are strictly complied with,

and shall familiarize carrier operators with it.

4.6 Hazardous Locations

4.6.1 The user shall determine the hazard classifi-

cation of the particul ar atmosphere or location in whi ch

the carrier is to be used i n accordance with ANSI/NFPA

505.

4.6.2 The user shall permit in haz ardous are as o nly

those carriers approved and of the type required by

ANSI/NFPA 505.

4.7 Lighting for Operating Areas

4.7.1 The user, in accordance with his responsib ility

to survey the environment and operating conditions, shall

determine if the carrier requires lights and, if so, shall

equip the carrier with appropriate lights in accordance

with the manufacturer’s recommendations.

Owner’s Manual and Service Guide

Page xi

SAFETY INFORMATION

Read all of manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notes, Cautions and Warnings

4.8 Control of Noxious Gases and Fumes

4.8.1 When equipment powered by internal com-

bustion engines is used in enclosed areas, the atmosphere shall be maintained within limits specified in the

American Conference of Governmental Industrial

Hygienists publication, “Threshold Limit Values for

Chemical Substances and Phys ical Agents in the Workroom Environment”. Thi s sh all be ac com pl is hed by ven tilation provided b y the user, and/or the installati on, use,

and proper maintenance of em ission control equipment

recommended or provided by the manufacturer of the

equipment.

4.9 Warning Device(s)

4.9.1 The user shall make periodic inspections of

the carrier to be certain that the sound-produ cing and/or

visual device(s) are mai ntained in good operatin g condition.

4.9.2 The user shall determine if operating conditions require the carrier to be equipped with additional

sound-producing a nd/or visual dev ices and be re sponsible for providing and mai ntaining such dev ices, in ac cordance with the manufacturer’s recommendations.

5 OPERATING SAFETY RULES AND

PRACTICES

5.1 Personnel and Burden Carrier Operator

Qualifications

5.1.1 Only persons who are trained in the proper

operation of the carrier shall be authorized to operate the

carrier. Operators shall be qualified as to visual, auditory,

physical, and m ental ability to safely o perate the equipment according to Section 5 and all other applicable

parts of this Standard.

5.2 Personnel and Burden Carrier Operators’

Training

5.2.1 The user shall conduct an operators’ training

program.

5.2.2 Successful completi on of the operators’ training program shall be r equired by the user befor e operation of the carrier. The program shall be presented in its

entirety to all new operators and not condensed for those

claiming previous experience.

5.2.3 The user should include in the operators’ training program the following:

(a) instructional material provided by the manufac-

turer;

(b) emphasis on safety of passeng ers, mater ial l oads,

carrier operator, and other employees;

(c) general safety rules co ntained w ithin th is Standard

and the additional s pecific rules determined by the user

in accordance with this Standard, and why they were fo r mulated;

(d) introduction of equipment, control locations and

functions, and explana tion of how they work when used

properly and when used i mproperly, and surface conditions, grade, and other co nditions of the environment in

which the carrier is to be operated;

(e) operational performance tests and evaluations during, and at completion of, the program.

5.3 Personnel and Burden Carrier Operator

Responsibility

5.3.1 Operators shall abide by the following safety

rules and practices in paras. 5.4, 5.5, 5.6, and 5.7.

5.4 General

5.4.1 Sa feguard th e ped estrian s at all ti mes. Do not

drive carrier in a manner that would endanger anyone.

5.4.2 Riding on the carrier by persons other than the

operator is authorized only on personnel seat(s) provided

by the manufacturer. All parts of the body shall remain

within the plan view outline of the carrier.

5.4.3 Wh en a carrier is to be left unattended, stop

carrier, apply the parking brake, st op the engine or turn

off power, turn off the control or ignition circuit, and

remove the key i f provided. Block the wheels if mac hine

is on an incline.

5.4.4 A carrier is considered unattended when the

operator is 25 ft. (7.6 m) or more fr om the carrier which

remains in his vie w, or whenever the oper ator le aves the

carrier and it is not within his view. When the operator is

dismounted and within 25 ft. (7.6 m) of the c arrier still in

his view, he still must have contr ols neutralized, and the

parking brake(s) set to prevent movement.

5.4.5 Maintain a safe distance from the edge of

ramps and platforms.

5.4.6 Us e only approved carriers in ha za rd ous lo ca tions, as defined in the appropriate safety standards.

5.4.7 Report all accidents involving personnel,

building structures, and equipment.

5.4.8 Oper ators shall not add to, or m odify, the carrier.

Page xii

Owner’s Manual and Service Guide

SAFETY INFORMATION

Read all of manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notes, Cautions and Warnings

5.4.9 Carriers shall not be parked or left unatte nded

such that they block or obstruct fire aisles, access to

stairways, or fire equipment.

5.5 Traveling

5.5.1 Observe all traffic regulations, including autho-

rized speed limits. Under nor mal traffic conditions keep

to the right. Maintain a safe distance , based on sp eed of

travel, from a carrier or v ehicle ahead; and k eep th e carrier under control at all times.

5.5.2 Yield the right of way to pedestrians, ambulances, fire tru cks, or other carrier s or vehicles in e mergency situations.

5.5.3 Do not pass another carrier or vehicle traveling in the same d irection at in tersections, bli nd spots, or

at other dangerous locations.

5.5.4 Keep a clear view of the path of travel,

observe other tra ffic and personn el, and ma intain a saf e

clearance.

5.5.5 Slow down or stop, as conditio ns dictate, and

activate the sound-producing warning device at cross

aisles and when visibility is obstructed at other locations.

5.5.6 Ascend or descend grade s slo wly.

5.5.7 Avoid turning, if possible, and use extreme

caution on grades, ramps, or inclines; normally travel

straight up and down.

5.5.8 Under all travel conditions the c arrier shall b e

operated at a speed that wil l permit it to be brou ght to a

stop in a safe manner.

5.5.9 Make starts, stops, turns, or direction reversals in a smooth manner so as not to shift the load,

endanger passengers, or overturn the carrier.

5.5.10 Do not indulge in dangerous activities, such as

stunt driving or horseplay.

5.5.11 Slow down when approaching, or on, wet or

slippery surfaces.

5.5.12 Do not drive carrier onto any elevator unless

specifically authorized to do so. Approach elevators

slowly, and then enter squarely after the elevator car is

properly leveled. Once on the elevator, neutralize the

controls, shut off power, and set parking brakes. It is

advisable that all other personnel leave the elevator

before a carrier is allowed to enter or exit.

5.5.13 Avoid running over loose objects, potholes,

and bumps.

5.5.14 To negotiate turns, reduce speed to improve

stability, then turn hand steering wheel or tiller in a

smooth, sweeping motion.

5.6 Loading

5.6.1 Handle only stable and safely arrang ed loads.

When handling off-center loads which cannot be centered, operate with extra caution.

5.6.2 Handle only loads within the capacity of the

carrier as specified on the nameplate.

5.6.3 Handle loads exceedin g the dimensions used

to establish carrier capacity with extra caution. Stability

and maneuverability may be adversely affected.

5.7 Operator Care of Personnel and Burden

Carriers

5.7.1 At the beginning of each shift during which the

carrier will be used, th e operator shall check the c arrier

condition and inspect the tires, warning devices, lights,

battery(s), speed and di rection al controll ers, brakes , and

steering mechanis m. If the carrier i s found to be in need

of repair, or in any way unsafe, the matter shall be

reported immediately to the design ated auth ority and the

carrier shall not be operated unti l it has been restor ed to

safe operating condition.

5.7.2 If during operation the carrier becomes unsafe

in any way, the matter shall be repor ted immediately to

the designated authority, and the carrier shall not be

operated until it has been restored to safe operating condition.

5.7.3 Do not make repairs or adjustments unless

specifically authorized to do so.

5.7.4 The engine shall be stopp ed and the operator

shall leave the carrier while refueling.

5.7.5 Spillage of oil or fuel shall be carefully and

completely absorbed or evaporated and fuel tank cap

replaced before starting engine.

5.7.6 Do not operate a c arrier wi th a l eak in the fuel

system or battery(s).

5.7.7 Do not use open flam es for checking electrolyte level in storage battery(s) or liquid level in fuel tanks.

6 MAINTENANCE PRACTICES

6.1 Introduction

6.1.1 Carriers may become hazardous if mainte-

nance is neglected. Therefore, maintenance facilities,

trained personnel, and procedures shall be provided.

Such facilities may be on or off the premises.

Owner’s Manual and Service Guide

Page xiii

SAFETY INFORMATION

Read all of manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notes, Cautions and Warnings

6.2 Maintenance Procedures

6.2.1 Maintenance and inspection of all carriers

shall be performed in conformance with the manufacturer’s recommendations and the following practices.

(a) A scheduled pr eventive maintenance, lub rication,

and inspection system shall be followed.

(b) Only qualifie d and authorized personnel shall be

permitted to maintain, repair, adjust, and inspect carriers.

(c) Before under taking maintenance o r repair, follow

the manufacturer’s recommendations for immobilizing

the carrier.

(d) Block chassis before working underneath it.

(e) Before disco nnecting any part of the engine fuel

system of a gasol in e o r dies el powered carrier with g ra vity feed fuel systems, be sure shutoff valve is closed, and

run engine until fuel system is depleted and engine stops

running.

(f) Before disconnecting any part of the engine fuel

system of LP gas powered carriers, close the LP gas cylinder valve and run th e engine until fu el in the syste m is

depleted and the engine stops running.

(g) Operation to check performance of the carrier shall

be conducted in an authorized area where safe clearance exists.

(h) Before commen cing operation of the carr ie r, follow

the manufacturer’s instructions and recommended procedures.

(i) Avoid fire hazards and have fir e protection equipment present in the work area. Do not use an open flame

to check level o r leakage of fuel, battery electro lyte, or

coolant. Do not use open pans of fuel or flammable

cleaning fluids for cleaning parts.

(j) Properly ventilate the work area.

(k) Handle LP gas cylinders with care. Physical damage, such as dents, scrapes, or gouges, may dangerously weaken the tank and make it unsafe for use.

(l) Brakes, steering mechanisms, speed and directional control mecha nisms, warning devices, ligh ts, governors, guards, and safety devices shall be inspected

regularly and maintained in a safe operating condition.

(m) Special carriers or devices designed and

approved for hazardous area operation shall be

inspected to ensure that maintenance preserves the original approved safe operating features.

(n) Fuel systems shall be checked for leaks and condition of parts. If a leak is found, action shall be taken to

prevent the use of the carrier until the leak has been

eliminated.

(o) The carrier manufacturer’s capacity, operation, and

maintenance instruc tion plates, tags, or decals shall be

maintained in legible con dit ion .

(p) Batteries, motors, speed and directional controllers, limit switch es, protec tive dev ices, ele ctrical cond uctors, and connections shall be inspected and main tained

in conformance with manufacturers recommended procedures.

(q) Carriers shall be kept in a clean conditi on to minimize fire hazards and facilitate detection of loose or

defective parts.

(r) Modifications and additions which affect capacity

and safe machine operation shall not be performed by

the customer or user without ma nufact urer’s prior written

authorization; wher e auth orized modifi cati ons have been

made, the user shall ensure that capacity, operation,

warning, and maintenance instruction plates, tags, or

decals are changed accordingly.

(s) Care shall be taken to ensure t hat all repl acement

parts are interchangeable with the or igina l parts and of a

quality at least equal to that provided in the original

equipment.

END OF ASME/ANSI B56.8-1988 TEXT

Page xiv

Owner’s Manual and Service Guide

SAFETY INFORMATION

Read all of manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notes, Cautions and Warnings

GENERAL

The following text is prov ide d as r eco mm end ed b y part II

of ANSI / NGCMA Z130.1 - 1993. E-Z-G O, as a memb er

of the National Golf Car Manufacturers Association

(NGCMA), strongly endor ses the conten ts of this specification.

PART II

MAINTENANCE AND OPERATIONS

5. GENERAL SAFETY PRACTICES

5.1. Introduction

Like other machines, golf cars can cause injury if improperly used or maintained. This section contains broad

safety practices recommended for safe golf car operations. Before operation, the controlling party should

establish such additional specific safety practices as may

be reasonably required for safe operations.

Experience has shown th at golf cars which comply wit h

the provisions stated i n Part II of this Standard are safe

when properly operated in accordance with the safety

and operation warnings affixed to every golf car. The safe

operation is enhanced w hen the golf cars are operated

within a specific set of operation instructions, safety rules

and practices established to meet actual operating terrain and conditions.

The safety informatio n contained in P art II is intend ed to

provide the controlling party with basic safety information

and to encourage the controlling party to implement a

golf car safety program.

It is suggested and recommended that Part II be

reprinted in the golf car manufacturer’s operation and

service manuals to enc ourage safe opera tions and pr actices at the controlling party’s facility.

5.2.1. Steep Grade

In areas where steep grades exist, golf car operations

should be restricted to the design ated golf car pathways

where possible, and shall be identified with a suitable

warning giving the followin g infor mation : “Warning, steep

grade, descend slowly with one foot on brake.”

5.2.2. Wet Areas

Wet grassy areas ma y cause a golf car to lose traction

and may affect stability. Wet areas shall be chained or

roped off to prevent golf car operations or be identified by

a suitable warning not to ope rate golf cars in this area

due to wet terrain.

5.2.3. Sharp Turns, Blind Corners, Bridge

Approaches

Sharp turns, blind spots, bridge approaches and other

potentially hazardous areas shall be either chained or

roped off to prevent golf car ope rations or identified wit h

a suitable warning to the operator of the nature of the

hazard and stating the proper prec autions t o be taken to

avoid the hazard.

5.2.4. Loose Terrain

Loose terrain ma y cause a golf car to lose traction and

may affect stability. Areas of loose terrain should be

repaired if possible, or chained or roped off to prevent

golf car operation or identified by a suitable warning to

operators not to operate golf cars in this area due to

loose terrain or possible hazardous conditions.

5.2.5. Golf Car/Pedestrian Interfer en ce Area s

5.2. Safety Survey

The controlling party shall perform a safety s urvey periodically, and as conditions warrant to the ir premises, to

identify areas where golf cars should not be operated

and to identify possible hazards.

Owner’s Manual and Service Guide

Areas where pe destrians an d golf car s interfere shall be

avoided whenever poss ible by rer outing the golf car tr affic or the pedestrian traffic to eliminate the interference. If

elimination of th e interf erence is not p ossible o r is high ly

impractical, signs shall be erected warning pedestrians

of the golf car tra ffic and golf c ar oper ators of t he p edestrian traffic and to drive slowly and use extreme caution.

Page xv

SAFETY INFORMATION

Read all of manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notes, Cautions and Warnings

6. MAINTENANCE

6.1. Introduction

6.1.1. Golf cars may become haz ardou s if mai ntenance

is neglected or impr operly performed. T herefore maintenance facilities, trained personnel and procedures in

accordance with the manufacturer’s recommendations

should be provided by the controlling party.

6.2. Preventive Maintenance

A regularly sched uled inspe ction and prev entive mai ntenance program in accordance with the manufacturer’s

recommendations should be established. Such a program will be a valuable tool in providing the golfing

patron with a safe, properly operating golf car and

thereby help to avoid accidents.

6.2.1. Personnel

Only qualified, t rained a nd authoriz ed pers onnel shall be

permitted to inspect, adjust and maintain golf cars.

liters per car per charge. Because of the highly v olatile

nature of hydrogen gas and its propensity to rise and

accumulate at the ceiling in pocke ts, a minimum of 5 air

changes per hour is rec omm end ed. The controllin g part y

shall consult applicable fire and safety codes for the specific ventilation levels required as well as the use of

explosion proof electrical apparatus.

6.2.4. Maintenance Procedures

All maintenance sha ll be performed in accordance with

the manufacturer’s recommended maintenance procedures as outlined in the manufacturer’s operation and

service manuals.

6.2.5. Maintenance Safety Procedures

All maintenance sha ll be performed in accordance with

the manufacturer ’s recommended safety procedur es as

outlined in the manufacturer’s operation and service

manuals. The followin g list of recommended safety pro cedures are general in nature an d in no way supersede

the manufacturer’s specific instructions.

6.2.2. Parts and Materials

Only manufacturer’s recommended replacement parts

and materials shall be used.

6.2.3. Ventilation

Maintenance and st orage areas shall be properly ven tilated to avoid fire haza rds in accor dance with applic able

fire codes and ordinances.

6.2.3.1. Ventilation for gasoline powe red golf cars shall

be provided to remove flammable vapors, fumes and

other flammable mat erials. Consu lt applica ble fire code s

for specific levels of ventilation.

6.2.3.2. Ventilation for electric powered golf cars shall

be provided to remove the accumulation of flammable

hydrogen gas emitted dur ing the charging process. The

amount of hydrogen gas emitted depends upon a number of factors such as the c ondition of the batteries, t he

output rate of the battery ch arger an d the am oun t of tim e

the batteries are on charge. Hydrogen emissions are

generally considered to be in the area of 10 to 20 cubic

6.2.5.1. Follow manufacturer’s instructions for immobilizing golf car before beginning any maintenance.

6.2.5.2. Block chassis before working underneath golf

car.

6.2.5.3. Before disconnecting any part of the fuel system, drain the syste m and turn all shut off valves to the

‘OFF’ position to prevent leakage or accumulation of

flammable fuels in the work area.

6.2.5.4. Avoid fire hazards and have fire protection

equipment available.

6.2.5.5. Before performing any maintenance on an electric golf car, disable the elect rical system in accordance

with the manufacturer’s instructions.

6.2.5.6. Use only properly insulated tool s when working

on electrically powered golf cars or around batteries.

6.2.5.7. Brakes, steering mechanisms, warning devices,

Page xvi

Owner’s Manual and Service Guide

SAFETY INFORMATION

Read all of manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notes, Cautions and Warnings

governors and all other safety devices shall be inspected

and maintained in a safe and proper oper ating condi tion

and shall not be modified as supplied by the manufacturer.

6.2.5.8. After each maintenance or repair the golf car

shall be driven by qualified, trained an d authorized personnel to ensure proper operation and adjustment.

6.2.5.9. Driving golf car to check for proper operation

and adjustment after repair shall be performed in an area

that is free of vehicular and pedestrian traffic.

6.2.5.10. Record all main tenance perfo rmed in a ma intenance record log by date, name of person performing

maintenance and typ e of maintenance. Controlling party

management should periodically inspect maintenance

log to ensure currency and completeness of entries.

7. FUELS HANDLING AND STORAGE/

BATTERY CHARGING

7.1. The con trolling party shall supervise th e storage

and handling of liquid fuels in accordance with applicable

fire and safety requirements.

7.2. Storage an d handling of liquefied petroleum gas

fuels shall be in accordance with American Gas Association recommenda tions and applicab le fire safety requirements.

7.3. The contr olling party shall require bat tery changing and charging fac ilit ies an d pr ocedures to be in accordance with applicable ordinances or regulations (also

see paragraph 6.2.3.2).

7.4. The controlling party shall periodically inspect

facilities and review procedures to be certain that the

procedures in parag raphs 6.2.3.2 and 7.3 are being followed.

6.2.5.11. Provide operator comment cards to assist in

identifying non-periodic maintenance needs for specific

golf cars.

6.2.6. The controlling party shall maintain in a legible

condition all nameplates, warnings and instructions

which are supplied by the manufact urer.

6.2.7. The controlling party shall not perform any modification or addition whic h affects capacity or safe operation, or make any change not in accordance with the

owner’s manual without the manufacturer’s prior written

authorization. Where authorized modifications have been

made, the controlling party shall ensure that capacity,

operation, warning and maintenance instruction plates,

tags or decals are changed accordingly.

6.2.8. As required under paragraphs 6.2.6 and 6.2.7 the

manufacturer shall be contacted to secure new nameplates, warnings or instructions which shall then be

affixed in their proper place on the golf car.

8. OPERATING SAFETY RULES AND

PRACTICES

8.1. Operator Qualifications

8.1.1. Only authorized persons shall be allowed to oper-

ate golf cars. It is recommended that no persons be

allowed to operate golf car s except those persons who

posses a valid motor vehicle driver’s license.

8.1.2. The controlling party shall display the operation

and safety instructio ns as recommended by the golf car

manufacturers and the golf cour se safety r ules in a c onspicuous place near the golf ca r rental area or golf car

pick-up area. It is also recommended, as with all motor

vehicles, that the warning “Do not operate golf cars when

under the influence o f alcohol or drugs.” be pos ted in a

conspicuous location.

Owner’s Manual and Service Guide

Page xvii

N

SAFETY INFORMATION

Read all of manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notes, Cautions and Warnings

otes:

Page xviii

Owner’s Manual and Service Guide

OPERATION AND SERVICE INFORMATION

Read all of manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notes, Cautions and Warnings

Thank you for purchasin g this vehicle. B efore drivi ng the

vehicle, we ask you to spend some time reading this

Owner’s Manual and Servi ce Guide . This guid e contains

the information that will assist you in maintaining this

highly reliable vehicle. Some illustrations may show

items that are optional for your vehicle. This guide covers

the operation of sev eral vehicles; therefo re, some pictorial views may not represent your vehicle. Physical differences in controls will be illustrated.

This vehicle has bee n designed and manufactured as a

‘World Vehicle’. Some countries have in dividual requirements to comply with their specifications; therefore,

some sections may not apply in your country.

Most of the service procedures in this guide can be

accomplished using common automotive hand tools.

Contact your service representative on servicing the

vehicle in accor dance with the Periodic Servi ce Schedule.

Service Parts Manu als and Technician’s Repair and Service Manuals are available from a local Distributor, an

authorized Branch or the Service Parts Department.

When ordering parts or requesting information for your

vehicle, provide ve hicl e model, seri al numbe r and man ufacture date code.

BEFORE INITIAL USE

Read, understand and follow the safety label on the

instrument panel. Be sure you understand how to oper ate the vehicle, its equip ment and how to use it safely.

Maintaining good perfor man ce dep end s t o a lar ge ex ten t

on the operator.

Hydrogen gas is generat-

! !

ing process. A 4% concentration of hydrogen gas is

explosive and could cause severe injury or death.

Charging must take place in an area that is adequately ventilated (minimum of 5 air exchanges per hour).

To reduce the chance of battery explosion

that could result in severe injury or death,

never smoke around or charge batteries in

an area that has open flam e or electrical

equipment that could cause an electrical

arc.

Before a new vehicle is put into operation, the items

shown in the INITIAL SERVICE CHART must be performed (Ref Fig. 1 on page 1).

ed as a natural part of the

lead acid battery charg-

Vehicle batteries must be fully charged before initial use.

Check for correct tire inflation. See GENERA L SPECIFI-

CATIONS.

Determine and record braki ng distance required to stop

vehicle for future brake performance tests.

Remove the protective c lear pla stic, tha t prote ct the seat

bottom and back rest during s hipping, bef ore placing the

vehicle in service.

ITEM SERVICE OPERATION

Batteries Charge batteries

Seats Remove protective plastic covering

Brakes Check operation and adjust if necessary

Establish acceptable stopping distance

Tires Check air pressure (see SPECIFICATIONS)

Portable Remove from vehicle and properly mount

Charger

Ref Isc 1

Fig. 1 Initial Service Chart

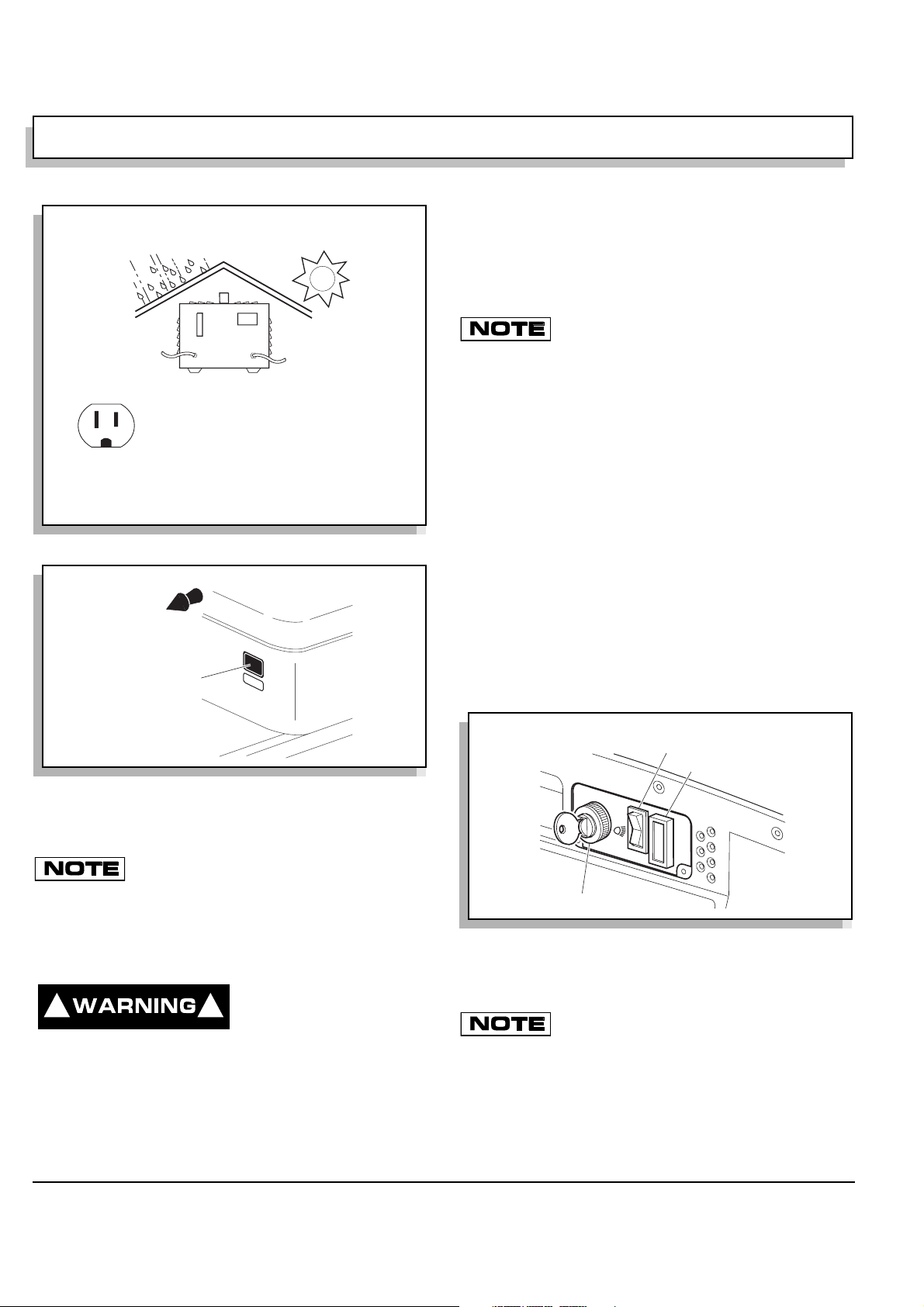

PORTABLE CHARGER INSTALLATION

To prevent overheat-

! !

ing that may cause

serious damage to

the charger and create the potential for fire,

do not block or obstruct the airways. Por t able chargers must be mounted on a platform above the ground or in such a manner

as to permit the maximum air flow underneath and around the charger.

Portable chargers a re shipped with the vehicle. P rior to

vehicle or charger ope ration, char gers must be remo ved

and mounted on a platform or wall above the ground to

permit maximum air flow around and underneath the

charger. If the charger is operated in an outdoor location,

rain and sun protection mu st be provided (Ref Fig. 2 on

page 2). A dedicated circuit is required for the charge r.

Refer to the charger ma nual for appropriate circuit protection. The charger may remain plugged in to the AC

outlet. To charge the vehicle, refer to the instruction

labels on the char ger. Insert the polarized DC plug completely into the vehicle receptacle (Ref Fig. 3 on page 2).

The charger will automat ically start a few seconds after

plug insertion. The ch arger will automatically st op when

Owner’s Manual and Service Guide

Page 1

OPERATION AND SERVICE INFORMATION

R

Read all of manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notes, Cautions and Warnings

The charging (DC) cord is equipped with a polarized con-

Provide Protection From Elements

nector which fits into a matching rece ptacle on the vehi cle.

The power (AC) cord is equipped with a groun ded plug.

Do not attempt to remove, cut or bend the ground post.

the charge r.

If vehicle is to be charged with a non E-Z-GO

charger, refer to the instructions supplied with

Do Not Block Louvered Airways

NEMA 15 - 5R Grounded AC Receptacle

110 - 120 VAC. Dedicated 15 AMP Circuit

Locations outside the US and Canada: Reference

appropriate local electrical code and charger manufacturer recommendations for AC power requirements

Ref Pci 1

Fig. 2 Proper Charger Installation

Front of

Vehicle

Charger

Receptacle

Ref Crl 1

Fig. 3 Charger Receptacle Location

batteries are fully charged and the DC plug can be

removed to permit use of the vehicle.

CONTROLS AND INDICATORS

Vehicle controls and indicators consist of:

• key/light switch

• direction select or

• state of charge meter

• accelerator pedal

• combination service and park brake pedal

• run - tow/maintenance switch (PDS only)

• horn

KEY/LIGHT SWITCH

Located on the d as h panel , thi s switc h e nables the basic

electrical system of the vehicle to be turned on and off by

turning the key. To prevent inadvertent operation of the

vehicle when left unattended, the key should be turned to

the ‘OFF’ position and removed (Ref Fig. 4 on page 2).

Direction Selector (PDS only)

State of Charge Meter

OFF

ON

Looping the DC cord through the steering

wheel when charging, serves as a good

reminder to store the cord out of the way when finished with

charging. The DC plug can be damaged by driving over or

catching the cord on the vehicle when driving away. A charging

interlock feature on the PowerWise™ charger prevents vehicle

operation while the DC plug is inserted in vehicle receptacle.

To prevent a physical

! !

hazard that could result

in an electrical shock or

electrocution, be sure that the charger plug is not

damaged and is inserted into a grounded receptacle.

The power (AC) cord is equipped with a

grounded plug, do not attempt to pull out,

cut or bend the ground post.

Page 2

Owner’s Manual and Service Guide

Key/Light Switch

ef Kes 1

Fig. 4 Key/Light Switch & State of Charge Meter

If the vehicle is equipped with lights, the key switch has a

position to operate them, indica ted by the light ic on.

If the vehicle is equipped with factory installed

custom accessories, some accessories remain

operational with the key switch in the ‘OFF’ position.

OPERATION AND SERVICE INFORMATION

R

R

Read all of manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notes, Cautions and Warnings

DIRECTION SELECTOR

To prevent loss of

! !

tion selector while the vehicle is in motion.

Moving the selector will result in a sudden

slowing of the vehicle and the beeping of a

warning device.

control, do not move

PDS vehicle direc-

Park

Brake

PARK

Service

Brake

To reduce the possibility of component

damage, the vehicle must be complete-

ly stopped before moving the direction selector.

On PDS models, if the direction selector is shifted before the

vehicle comes to a complete stop, a warning beeper will activate.

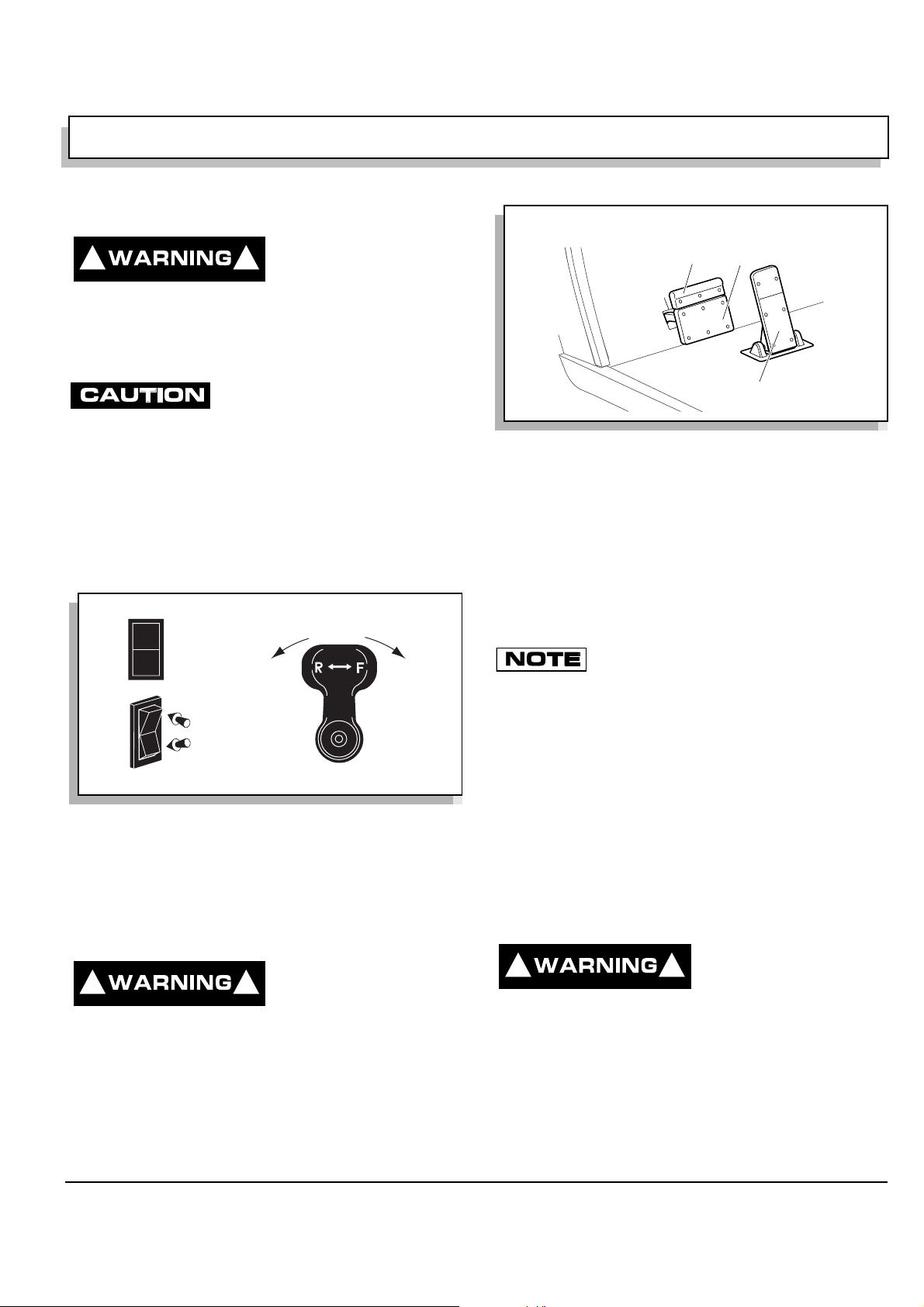

Located on the seat support panel or the dash panel, this

lever or switch permits the selection of either ‘F’ (forward), ‘R’ (reverse) or neutral (the posit ion between forward and reverse). Vehicle should be left in neutral when

unattended (Ref Fig. 5 on page 3).

ef Dsl 1

FWD

REV

FWD

REV

Forward

Reverse

Neutral, as shown

Fig. 5 Direction Selector T ypes

Reverse

Neutral

Forward

STATE OF CHARGE METER

Located in the dash, the state of charge m eter indicates

the amount of usable power in the batter ies (Ref Fig. 4

on page 2).

ACCELERATOR PEDAL

Unintentional move-

! !

ment of the acceler-

ator pedal will

release the park brake and may cause the

vehicle to move which could result in

severe injury or death.

With the key switch ‘ON’, depressing the accelerator

pedal starts the motor. When the pedal is released, th e

motor will stop (Ref Fig. 6 on page 3). To stop the vehicle

more quickly, depress the service brake.

ef Abc 1

Fig. 6 Accelerator and Brake Controls

If key switch is ‘ON’ and park brake is set, depressing the

accelerator inadver tently will releas e the park brake an d

will cause the vehicle to move whic h could c ause sev ere

injury or death.

Depressing the accelerator pedal will release the park

brake if it is engaged. This is a feature to assure the vehicle is not driven with the park brake engag ed. Depressing the accelerat or pedal is not the preferred method of

releasing the park brake.

Depressing the lower section of the brake

pedal is the preferred method of releasing the

park brake to assure the longest service life of brake components.

Accelerator

COMBINATION BRAKE AND PARK BRAKE

PEDAL

The brake pedal incorpo rates a park brake feature (Ref

Fig. 6 on page 3). To engage, push down on the upper

section of the pedal until it locks in place. The park brake

will release when the service brak e pedal is depressed.

Use the lower section of the brake pedal to operat e the

service brake system.

RUN - TOW/MAINTENANCE SWITCH

(PDS VEHICLES ONLY)

To reduce the possi-

! !

bilty of severe inju-

ry or death resulting

from loss of vehicle control, consider the

grade of the terrain the vehicle is on and set

vehicle’s park brake accordingly before

switching the Run - Tow/Maintenance

switch to the ‘Tow/Maintenance’ position.

When in the ‘Tow/Maintenance’ position, the

Anti-Roll Back and Walk-Away safe ty features of the PDS system no longer function.

Owner’s Manual and Service Guide

Page 3

OPERATION AND SERVICE INFORMATION

Read all of manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notes, Cautions and Warnings

Before attempting to tow vehicle, move

the Run-Tow/Maintenance switch to the

‘Tow/Maintenance’ position. Failure to do so will damage the

controller or motor.

Before disconnecting or connecting a battery, or any other wiring, move the Run-Tow/Maintenance switch to the ‘Tow/Maintenance’ position.

After connecting a battery, or any other wiring, wait a minimum

of 30 seconds before moving the Run-Tow/Maintenance switch

to the ‘Run’ position.

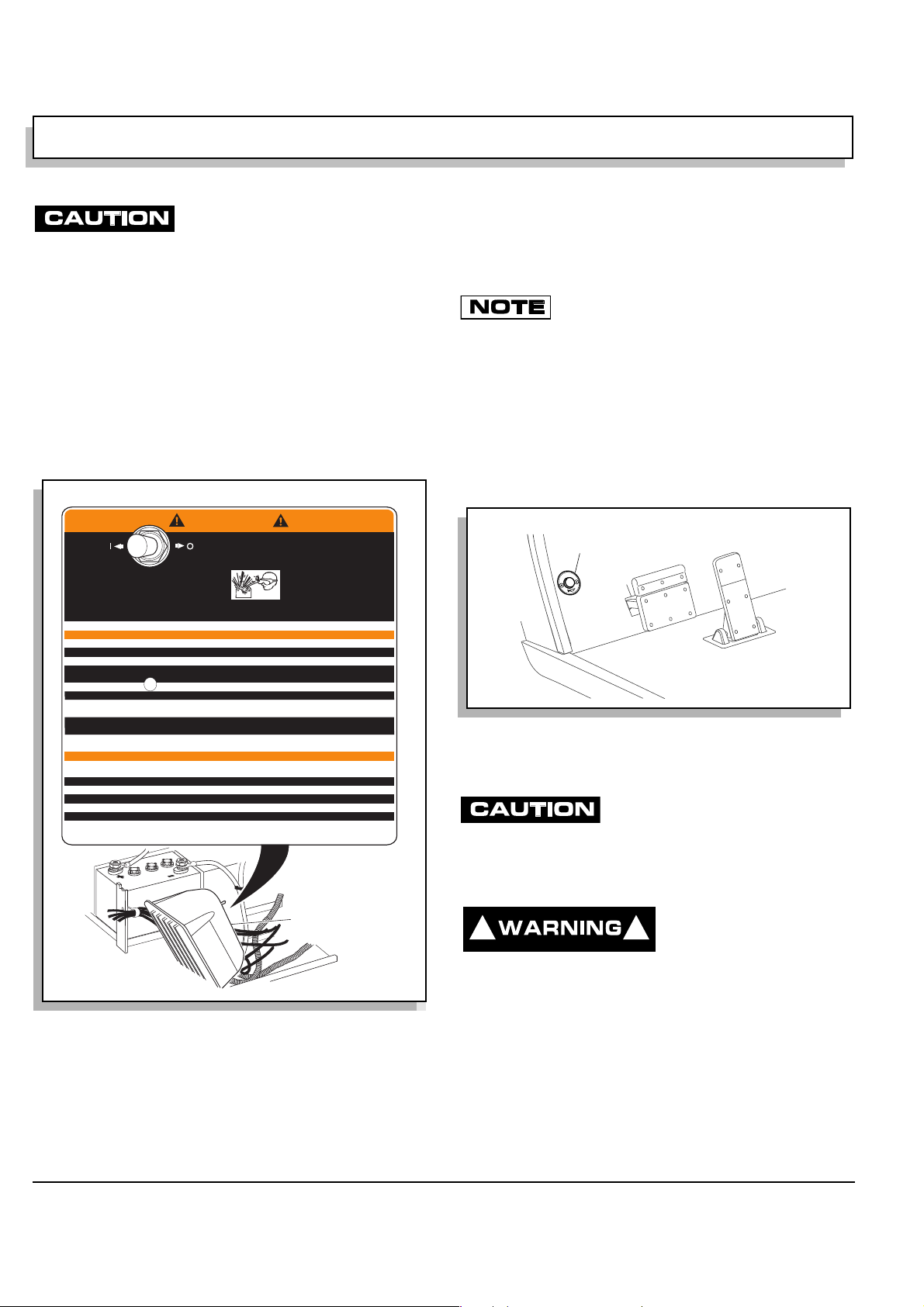

The PDS vehicl e is equipped with a two position sw itch

located under the pass en ger s i de o f th e s ea t on th e c ontroller environmental cover (Ref Fig. 7 on page 4).

WARNING

■ Tampering with or unauthorized modification of this unit

73093-G01

RUN

TOWING

Always select 'TOW/MAINTENANCE'

position before towing

■ To disable electrical system, place switch in 'TOW/ MAINTENANCE' position and remove battery wire

■ After reconnecting batteries, allow a minimum of 30 seconds before selecting 'RUN' position

THE FOLLOWING CODES REQUIRE THAT THE REAR WHEELS BE RAISED BEFORE PERFORMING TESTS

Beep Fault Symptoms Correction Required

1-1 Controller Failure Vehicle will not run Check motor wiring & motor Ω. Replace controller

1-2 Throttle fault Solenoid clicks, will not run Replace/adjust pedal box, harness

1-4 High pedal disable Vehicle will not run Release pedal/check pedal box, linkage & switch

2-4 Solenoid coil failure Vehicle will not run Check coil connections/wiring,

or disconnected replace solenoid if required

3-1 Solenoid driver fail Vehicle will not run Check coil wiring for shorts, replace controller

3-3 Solenoid did not close Vehicle will not run Check all solenoid wiring, replace solenoid if required

3-4 Field winding open Solenoid clicks, will not run Check motor & controller field connections,

replace power harness or motor if required

4-1 Armature open Solenoid clicks, will not run Check motor & controller armature connections,

replace power harness or motor if required

4-3 Solenoid drop out Vehicle stops Check solenoid/wiring, replace if required

THE FOLLOWING CODES REQUIRE THAT THE VEHICLE BE OPERATED UNDER LOAD WHILE PERFORMING TESTS

Beep Fault Symptoms Correction Required

1-3 Speed sensor fault Vehicle runs slowly Check speed sensor connections & magnet/torque,

replace speed sensor if required

2-1 Low battery voltage Vehicle performance reduced Charge batteries/replace bad batteries

2-2 High battery voltage Regen performance reduced Check that battery voltage is less than 48 VDC

2-3 Thermal cutback Vehicle performance reduced Allow controller to cool, check heat sink bolt torque

3-2 Solenoid welded Vehicle runs slowly Check auxiliary power. Replace solenoid

4-2 Motor stalled Vehicle stopped Remove mechanical blockage

To enter diagnostic mode ◆ Turn key switch to 'OFF' ◆ Move 'RUN/TOW MAINTENANCE' switch to 'RUN'. ◆ Move direction

selector switch from neutral position to 'REV' position five (5) times ◆ After a confirming beep(s) sounds, the diagnostic fault

code will sound when a fault is detected. To exit diagnostic mode: Select 'TOW MAINTENANCE' position.

by non E-Z-GO personnel could result in serious personal

TOW

injury, will void the warranty and result in permanent

MAINTENANCE

damage to the vehicle

■ Possibility of electrical arc or battery

explosion. Before removing/connecting

batteries or electrical components, turn

switch to 'TOW MAINTENANCE' position

With the switch in ‘RUN’ position:

• the controller is activated

• the electronic braking system and warning be epe r

features are activated

PDS vehicles operate only in the ’RUN’ position.

The PDS is a low power consumption unit but it will drain

the vehicle batterie s over a period of time. If the vehi cle

is to be stored for a prolonged perio d of time, the PDS

should be disconnected from the batteries. See ‘Prolonged Storage’ on page 22.

HORN

The horn is operated by pushing the horn button located on

the floor to the left of the brake pedal (Ref Fig. 8 on page 4).

Horn

R

N

O

H

Ref Hor 1

PARK

Fig. 8 Horn Button

OPERATING THE VEHICLE

Improper use of the vehicle or the lack

of proper maintenance may result in

damage or decreased performance.

Controller

Environmental

Cover

Ref Rtm 1

Fig. 7 Run-Tow/Maintenance Switch

With the switch in ‘TOW/MAINTENANCE’ position:

• the controller is deactivated

• the electronic braking system is deactivated which

allows the vehicle to be towed or roll freely

• the warning beeper is deactivated

Page 4

Owner’s Manual and Service Guide